Waste rubber powder mixed model steel fiber reinforced lightweight aggregate concrete and preparation method thereof

A technology of lightweight aggregate concrete and waste rubber powder, which is applied in the field of plastic-steel fiber reinforced lightweight aggregate concrete mixed with waste rubber powder and its preparation, can solve the problems of low strength, easy brittle failure, poor impact resistance, etc., and achieve improved performance , reduced mining, good viscoelastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

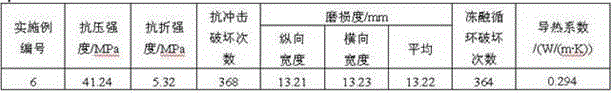

Examples

Embodiment 1

[0040] Taking the preparation of one cubic meter of plastic-steel fiber-reinforced lightweight aggregate concrete mixed with waste rubber powder as an example, the raw materials and mass ratios used are:

[0041] Cement 420kg

[0042] Plastic steel fiber 8kg

[0043] Rubber powder 10.2kg

[0044] Fine sand 626.2kg

[0045] Fly ash ceramsite 686kg

[0046] Net water consumption 185kg

[0047] Water reducer 0.35kg

[0048] The above cement is P·O42.5R grade ordinary Portland cement, produced by Baotou Mengxi Cement Co., Ltd.; the fiber is special-shaped plastic steel fiber, the fiber length is 25-39mm, and there are wavy embossments on the surface along the fiber length direction , the fiber cross-section is pentagonal, produced by Zhejiang Ningbo Dacheng New Material Co., Ltd.; the rubber powder is processed from waste tires, using 80-mesh rubber powder produced by Baotou Huancheng Rubber Recycling Co., Ltd.; the shape of fly ash ceramsite It is spherical, with a particle...

Embodiment 2

[0056] Taking the preparation of one cubic meter of plastic-steel fiber-reinforced lightweight aggregate concrete mixed with waste rubber powder as an example, the raw materials and mass ratios used are:

[0057] Cement 420kg

[0058] Plastic steel fiber 7kg

[0059] Rubber powder 5.1kg

[0060] Fine sand 653.5kg

[0061] Fly ash ceramsite 686kg

[0062] Net water consumption 185kg

[0063] Water reducer 0.20kg

[0064] The rubber powder in the above-mentioned embodiment 1 is replaced with 60 meshes. Other raw materials and consumption are identical with corresponding embodiment.

[0065] The preparation method is the same as that of Example 1, and plastic-steel fiber-reinforced lightweight aggregate concrete mixed with waste rubber powder is prepared and placed in a standard curing room for curing.

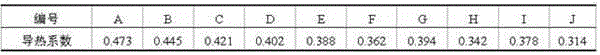

[0066] Its performance test method is identical with embodiment 1, and each performance test result is shown in Table 2.

[0067] Table 2

[0068]

Embodiment 3

[0070] Taking the preparation of one cubic meter of plastic-steel fiber-reinforced lightweight aggregate concrete mixed with waste rubber powder as an example, the raw materials and mass ratios used are:

[0071] Cement 420kg

[0072] Plastic steel fiber 7kg

[0073] Rubber powder 10.2kg

[0074] Fine sand 626.2kg

[0075] Fly ash ceramsite 686kg

[0076] Net water consumption 185kg

[0077] Water reducer 0.30kg

[0078] The rubber powder in the above-mentioned embodiment 1 is replaced with 80 meshes. Other raw materials and consumption are identical with corresponding embodiment.

[0079] The preparation method is the same as that of Example 1, and plastic-steel fiber-reinforced lightweight aggregate concrete mixed with waste rubber powder is prepared and placed in a standard curing room for curing.

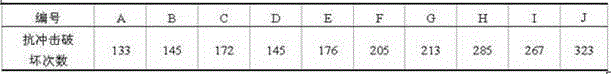

[0080] Its performance test method is identical with embodiment 1, and each performance test result is shown in Table 3.

[0081] table 3

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com