Patents

Literature

97 results about "Direct measure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct Measures. Direct measures are those that measure student learning by evaluating examples of student work, such as oral presentations, writing assignments, theses or dissertations and exams. Examples include: Course embedded assessments. Score and pass rates on tests and appropriate licensure exams.

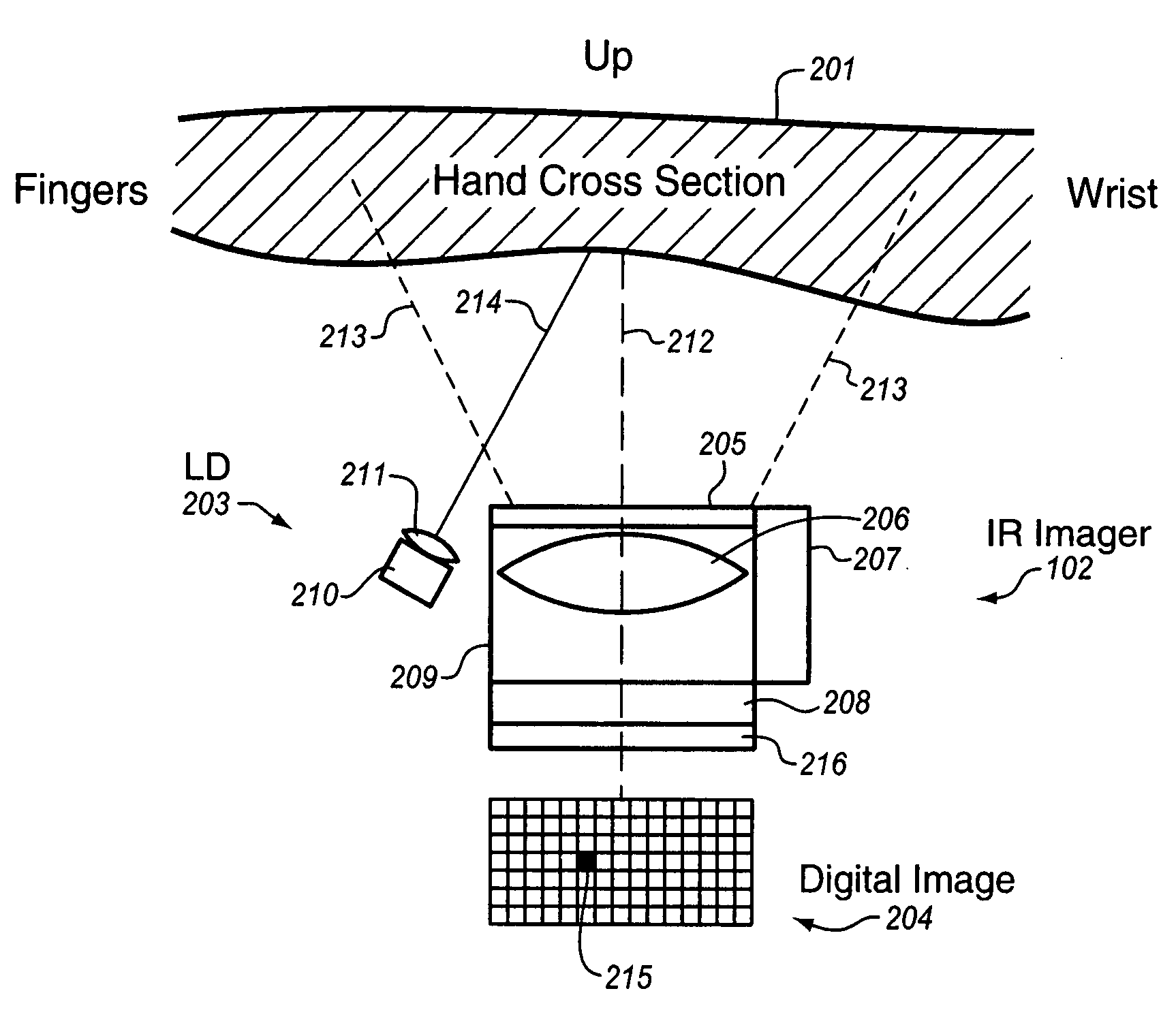

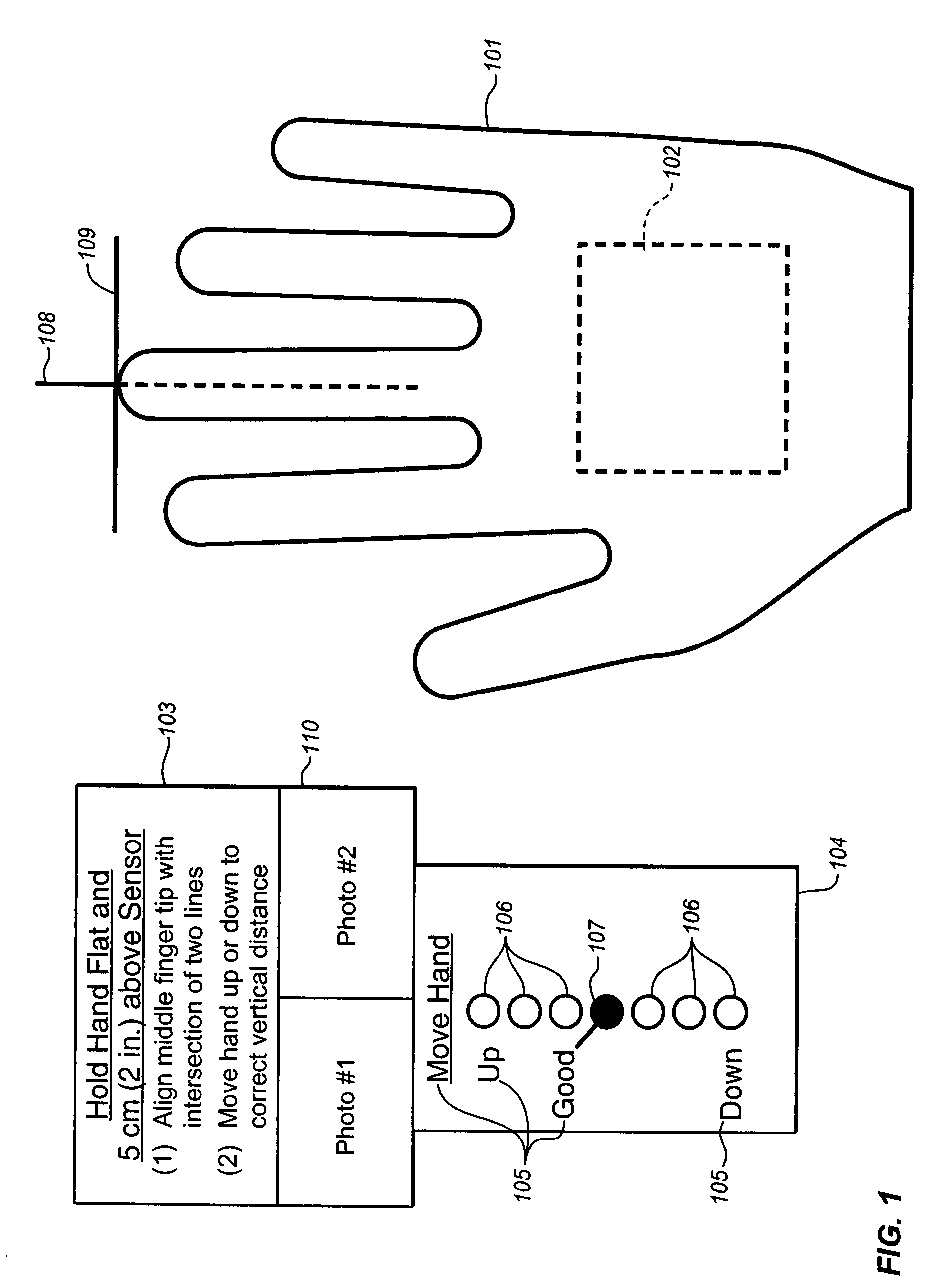

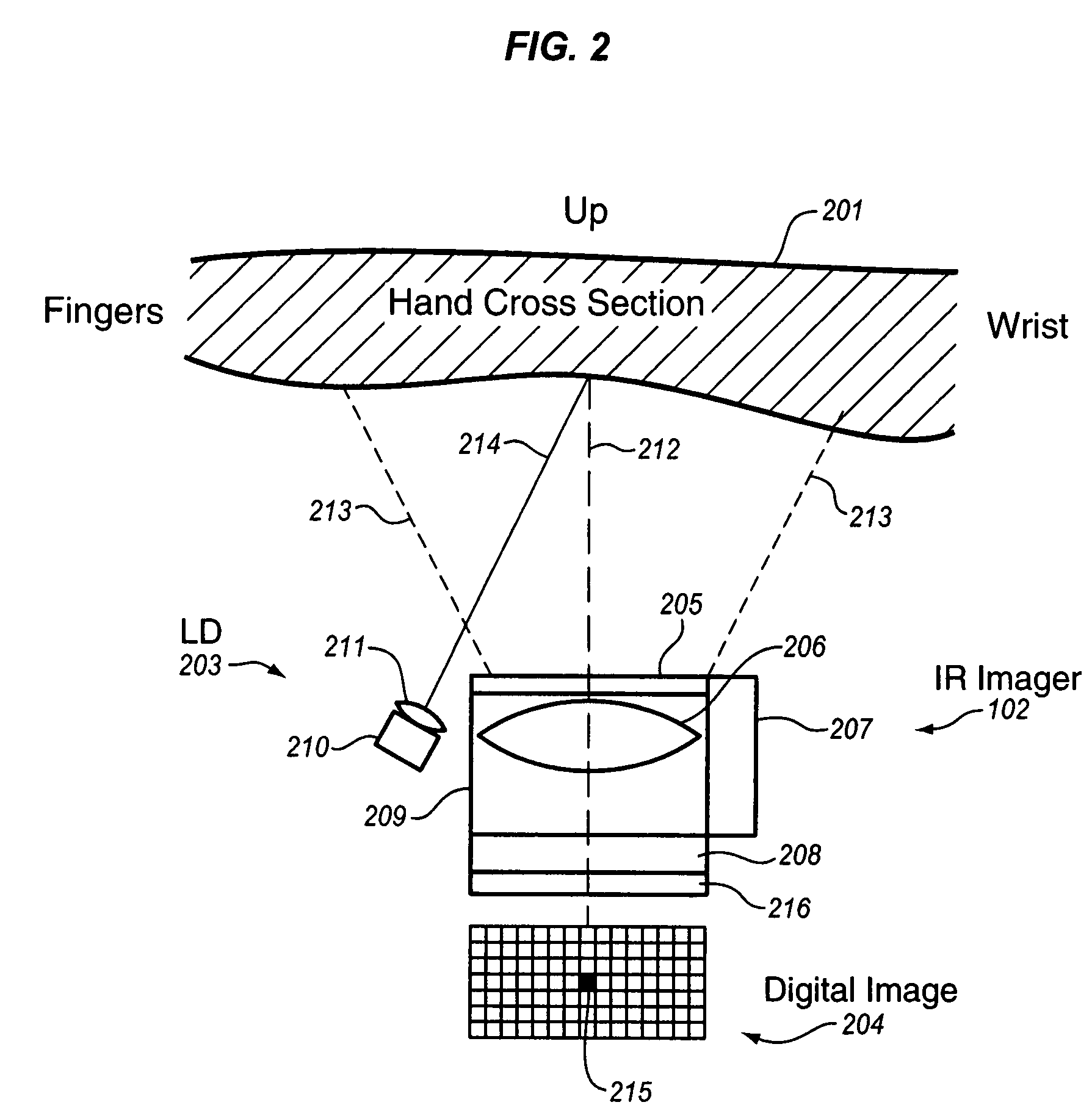

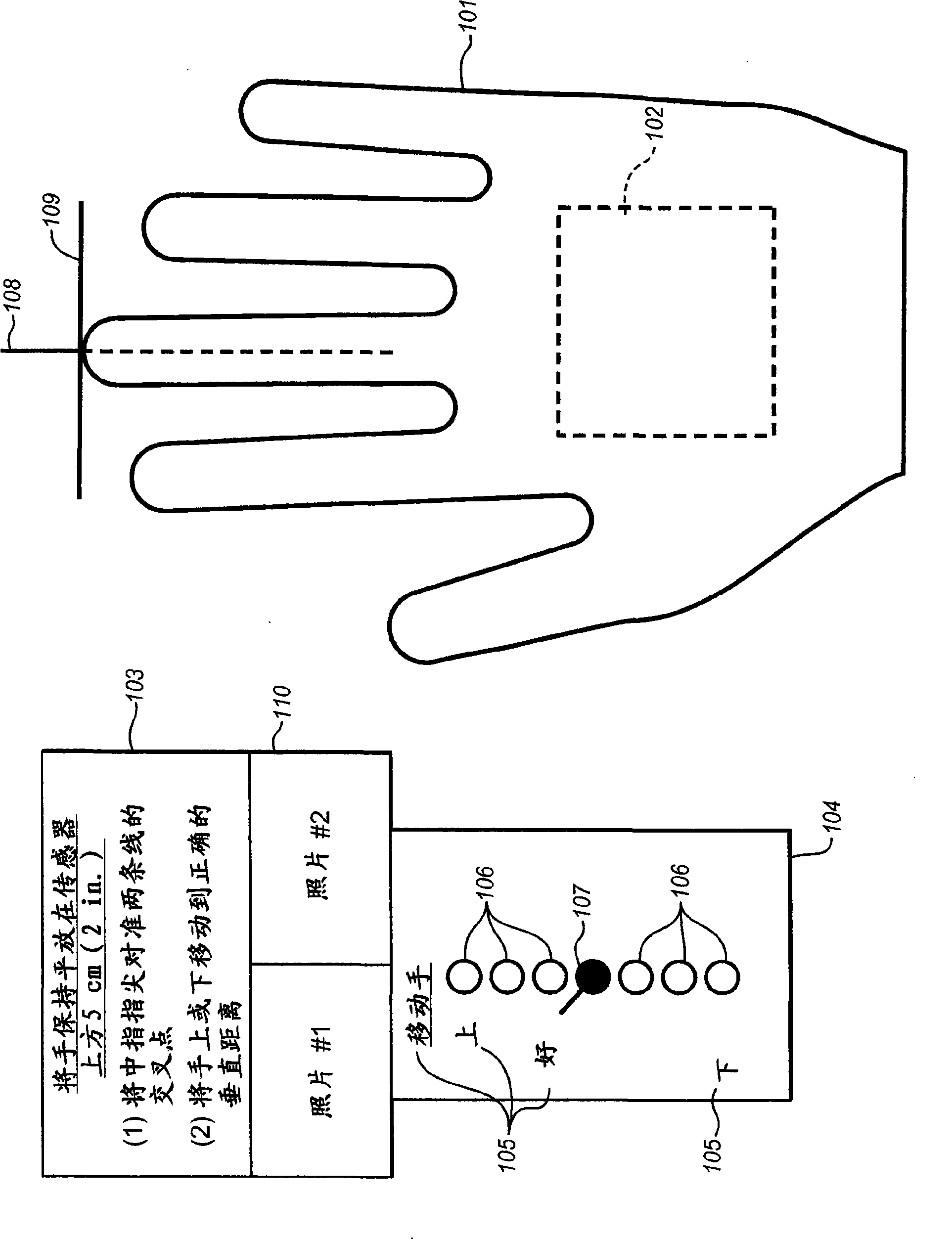

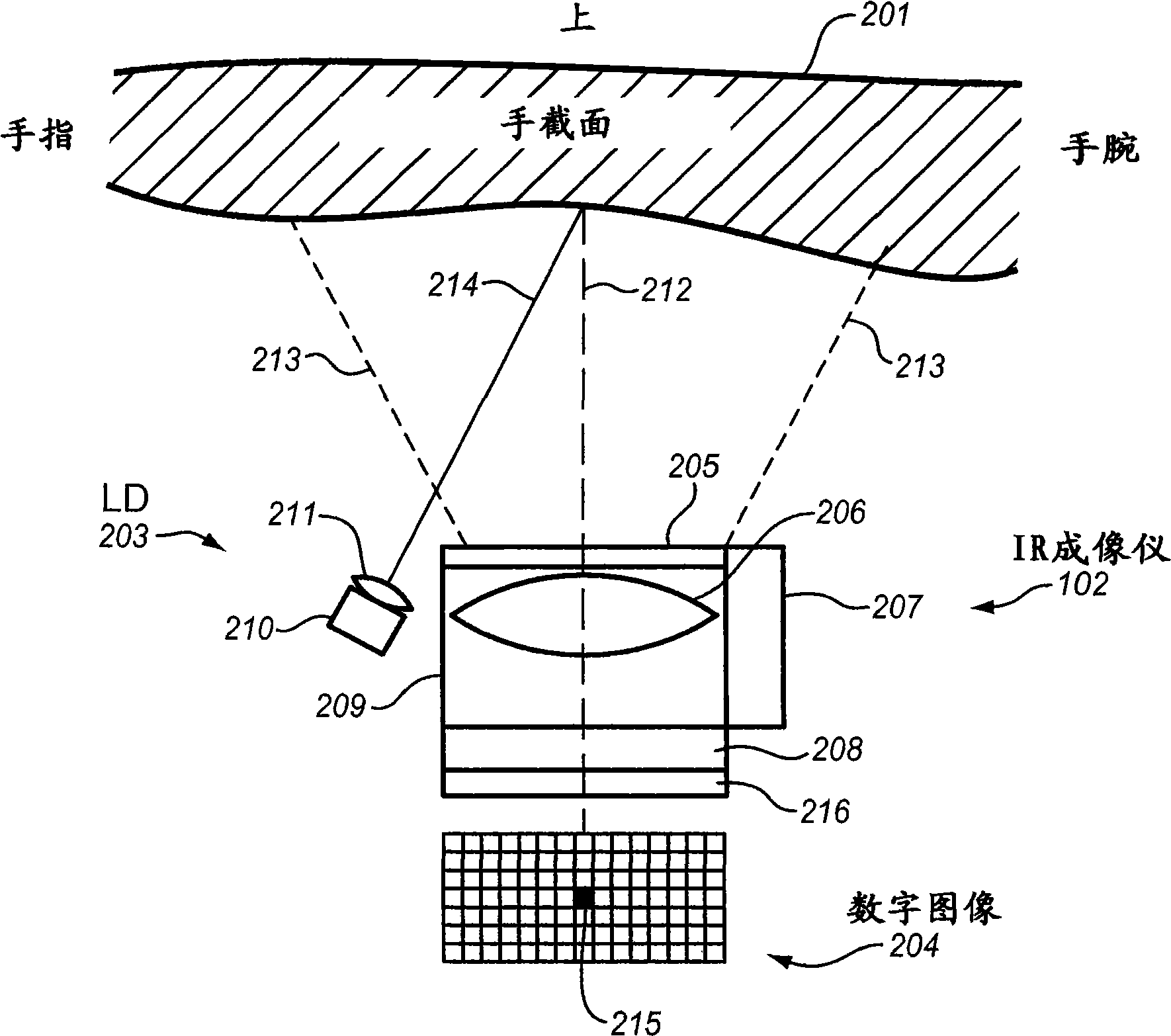

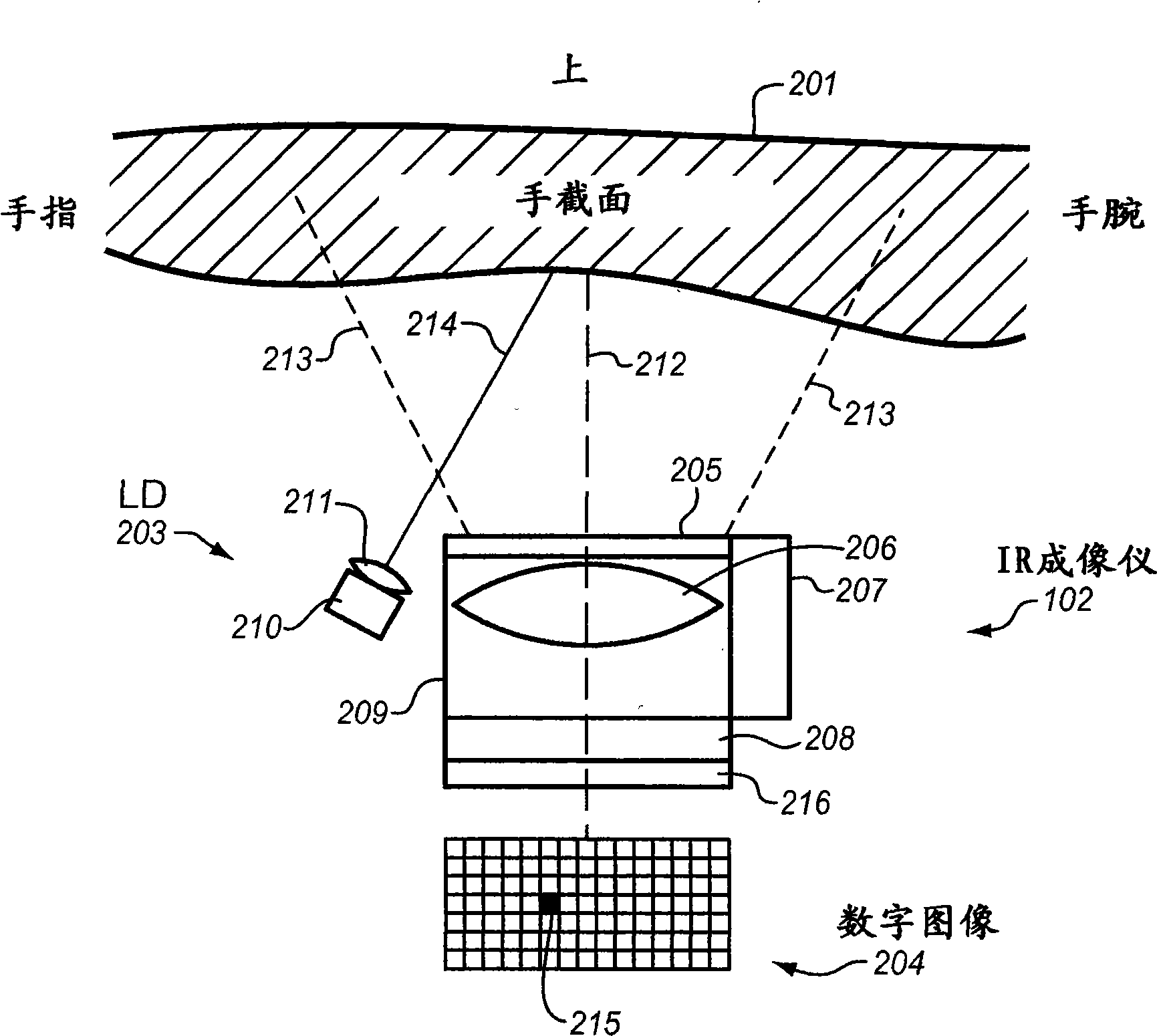

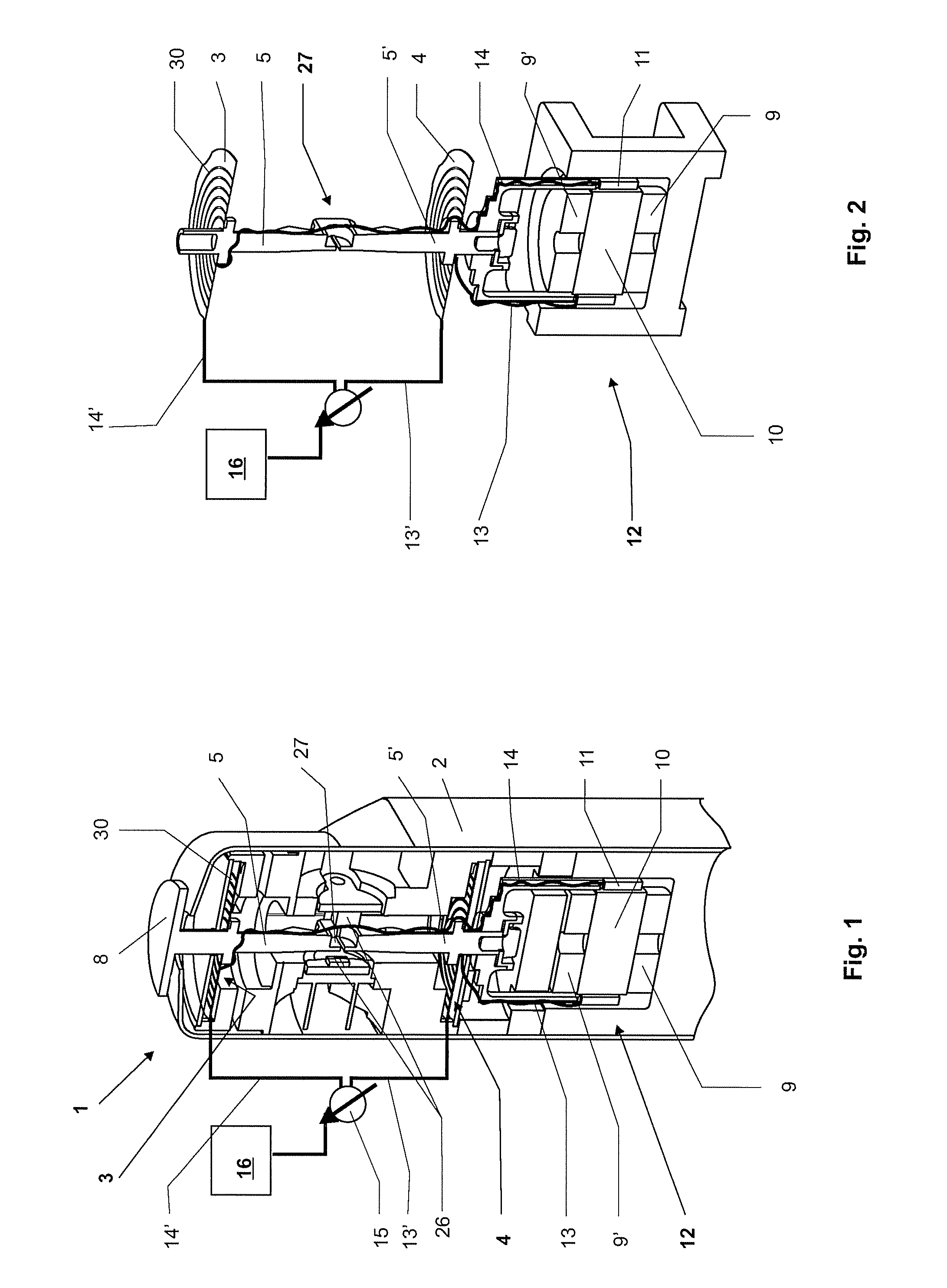

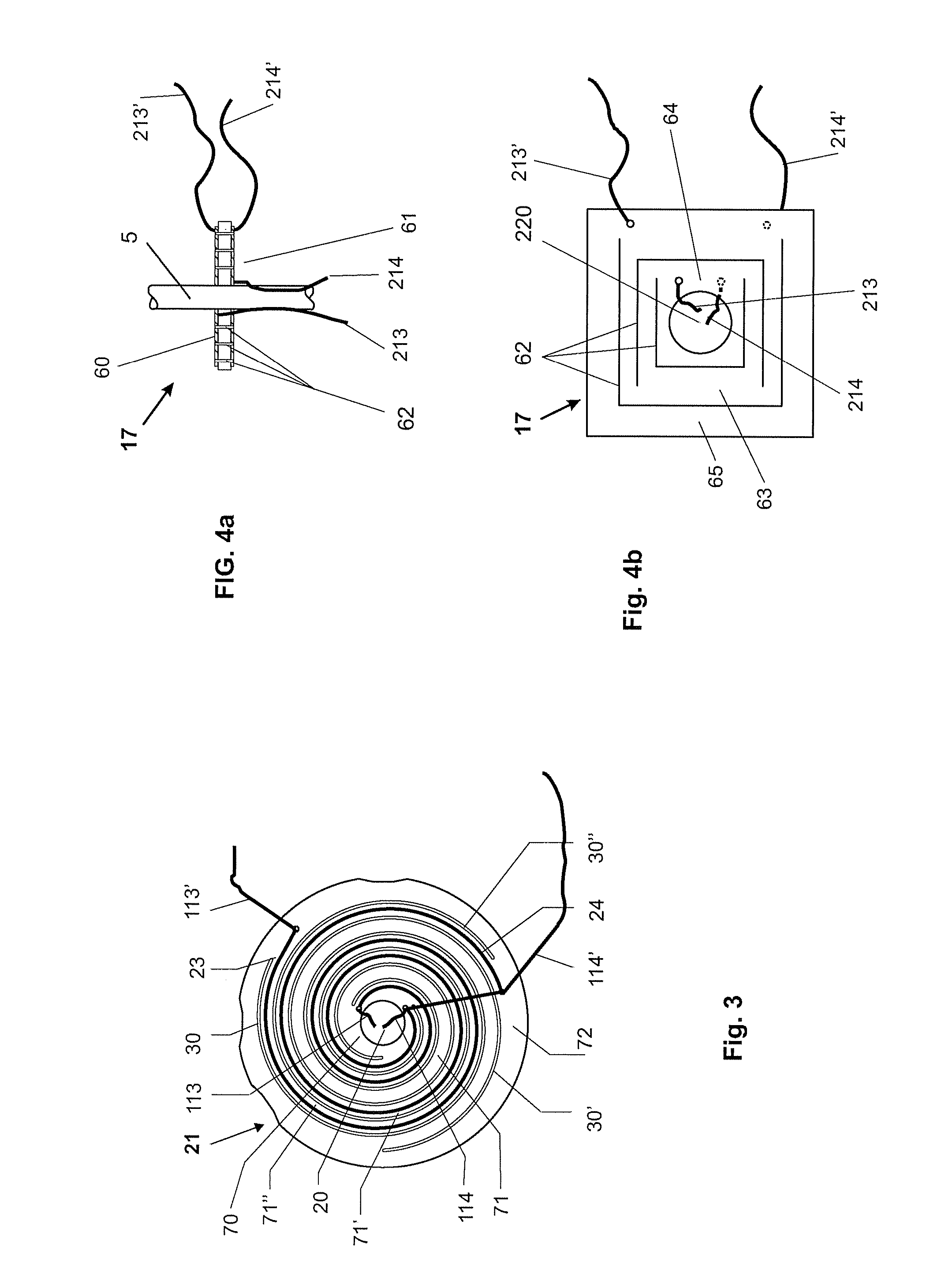

Method and apparatus for biometric identification

InactiveUS20080107309A1Reduce false reject rateReduce false acceptance ratioSubcutaneous biometric featuresBlood vessel patternsVeinVisual perception

The invention describes the first practical, cost effective, truly non-contact implementation of a subcutaneous vein pattern biometric sensor. A laser diode (LD) illuminates the hand in such a way that the pattern of reflected radiation, when viewed by a conventional vein pattern infrared imager, provides a direct measure of target range. Said target range measurement is used to create a visual or audio signal that instructs the individual being scanned to place the hand at precisely the optimum range, such that the vein pattern is in focus. Furthermore, a system and apparatus are described to direct the individual being scanned to move the hand to an optimal horizontal registration or position with respect to the infrared imager.

Owner:CERNI CONSULTING

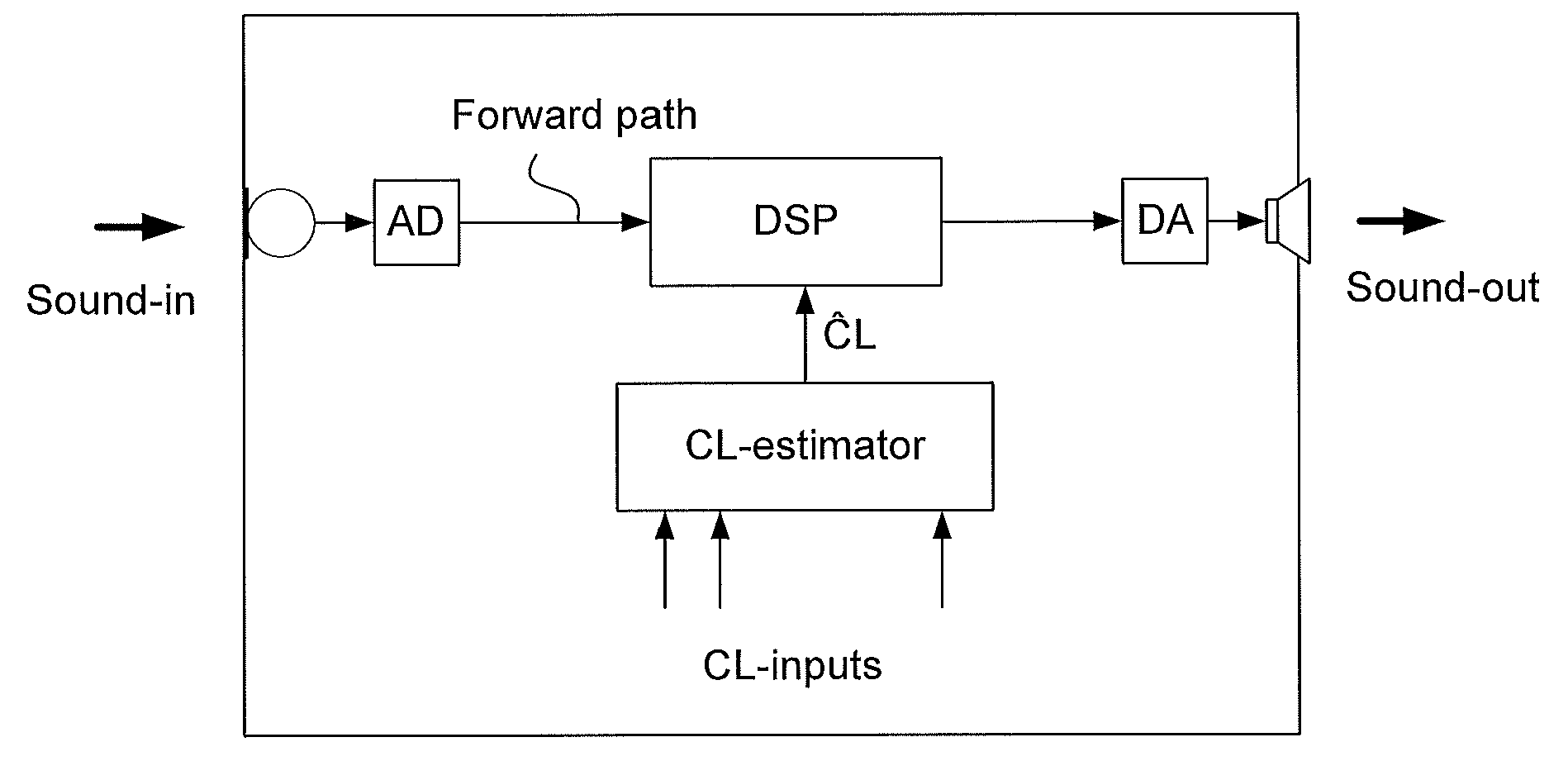

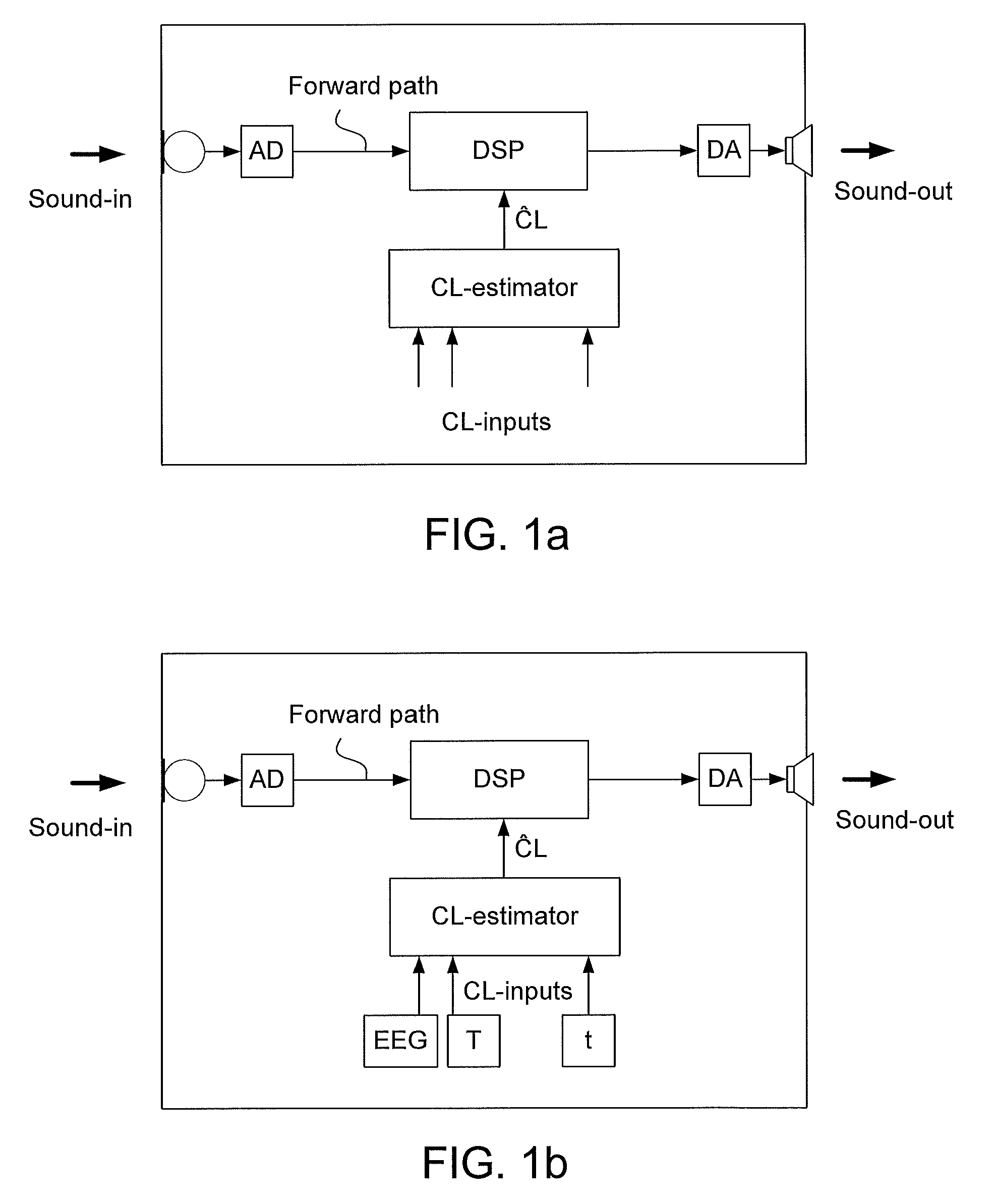

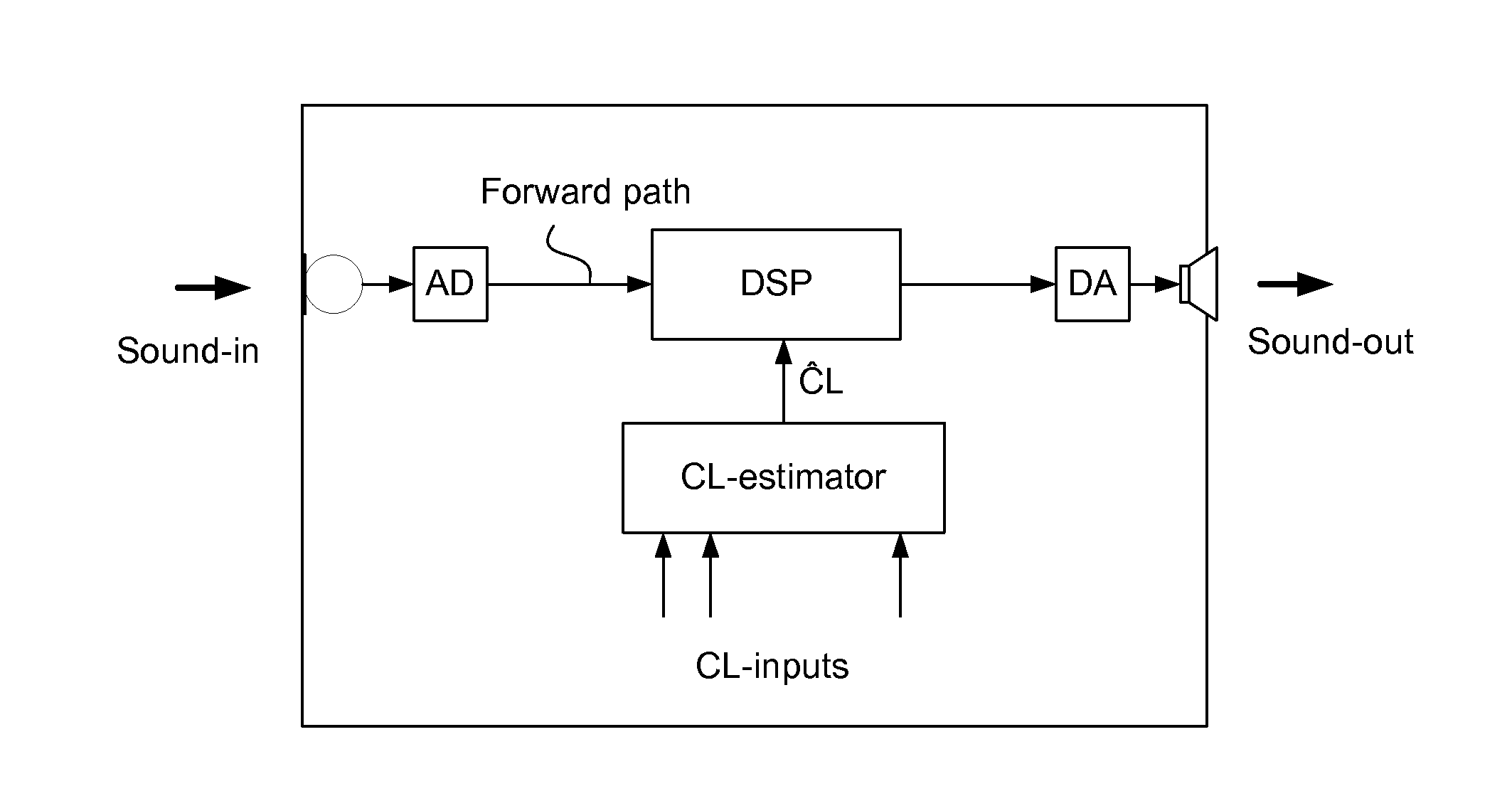

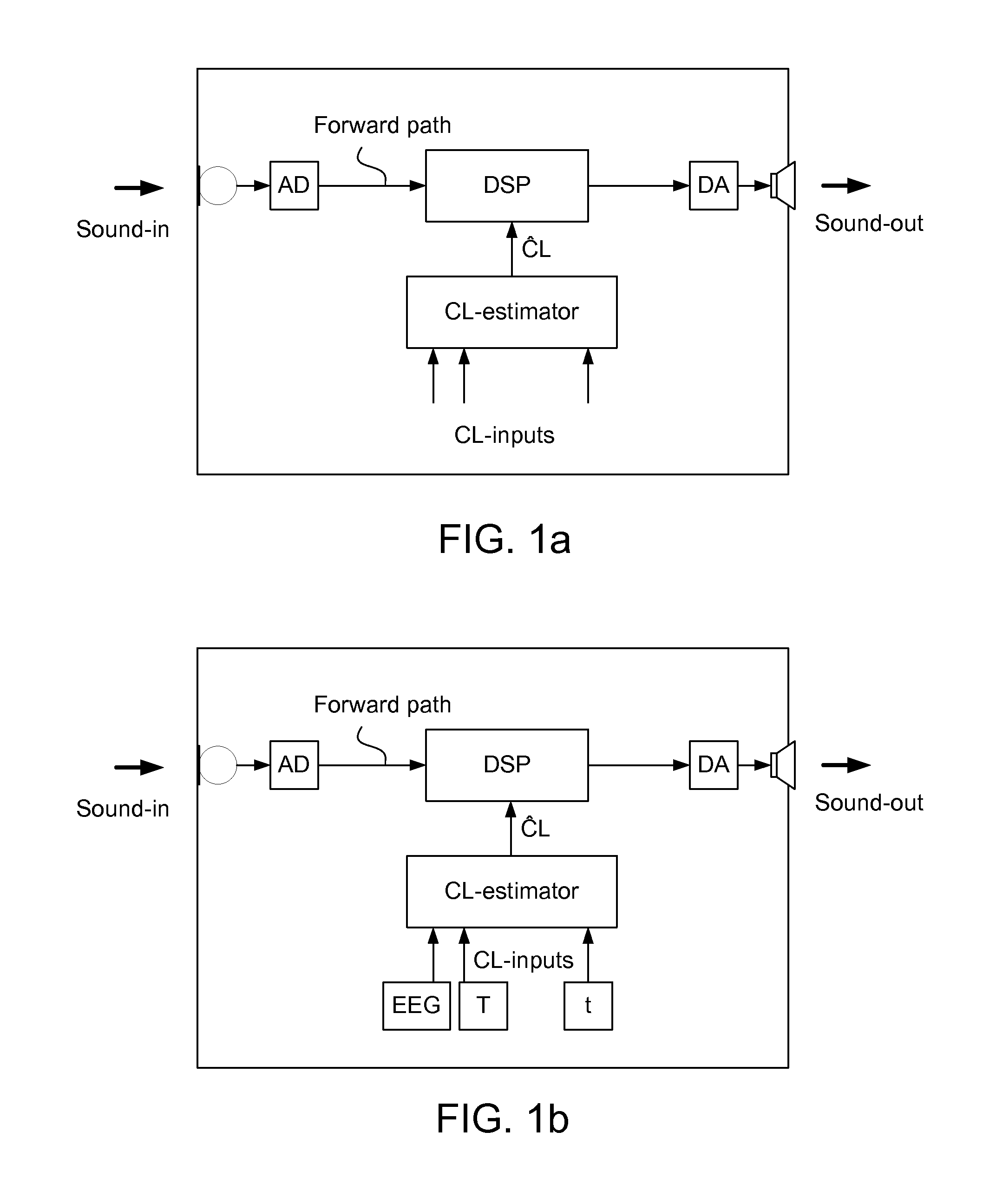

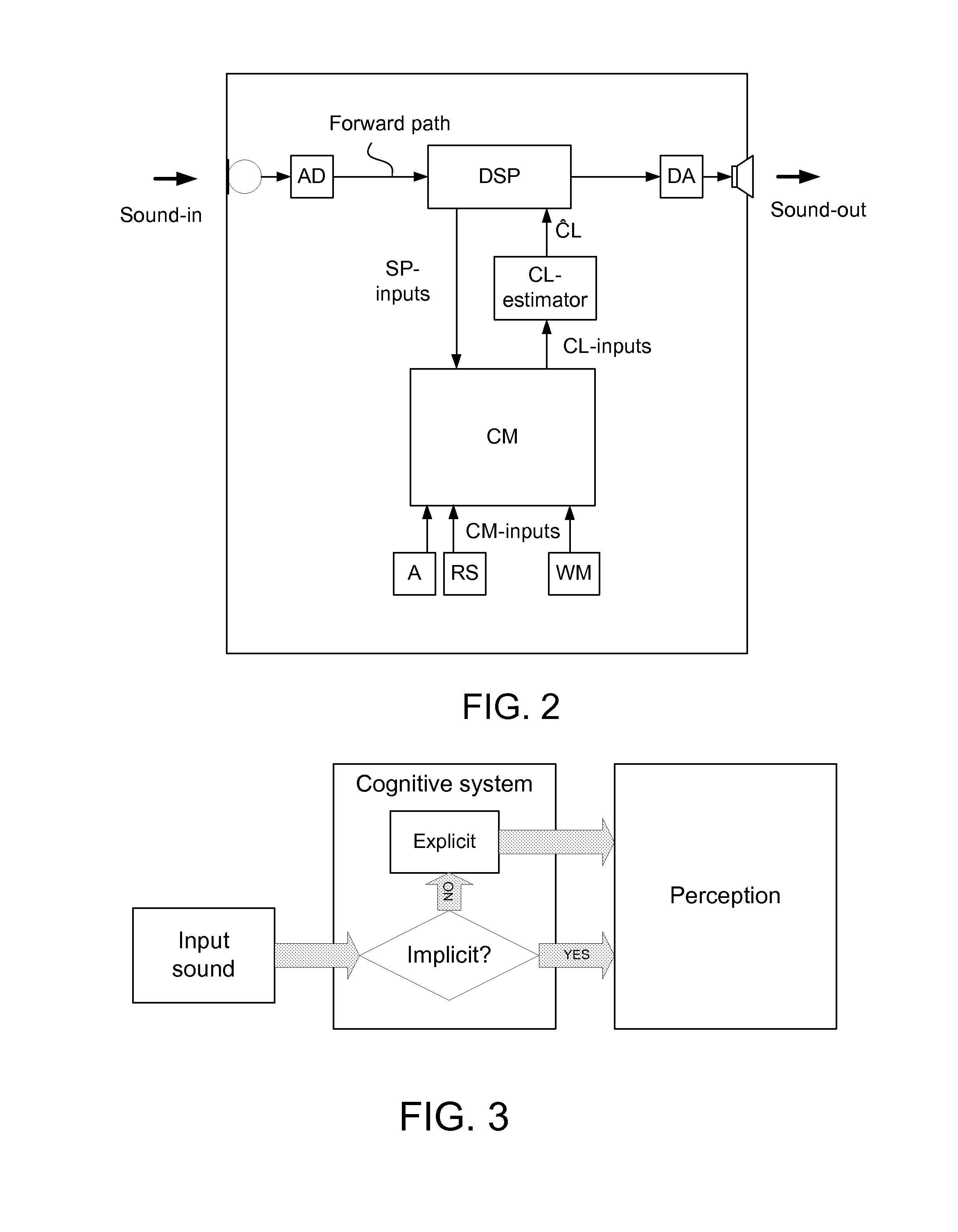

Method of operating a hearing instrument based on an estimation of present cognitive load of a user and a hearing aid system

ActiveUS20100196861A1Easy to customizeImprove comfortElectronic input selection/mixingTeaching apparatusData processing systemHearing aid

A method of operating a hearing instrument for processing an input sound and to provide an output stimulus according to a user's particular needs, and related system, computer readable medium and data processing system. An object is to provide an improved customization of a hearing instrument. The method includes the steps a) providing an estimate of the present cognitive load of the user; b) providing processing of an input signal originating from the input sound according to a user's particular needs; and c) adapting the processing in dependence of the estimate the present cognitive load of the user. The estimate of the present cognitive load of a user is produced by in-situ direct measures of cognitive load (e.g. based on EEG-measurements, body temperature, etc.) or by an on-line cognitive model in the hearing aid system whose parameters have been preferably adjusted to fit to the individual user.

Owner:OTICON

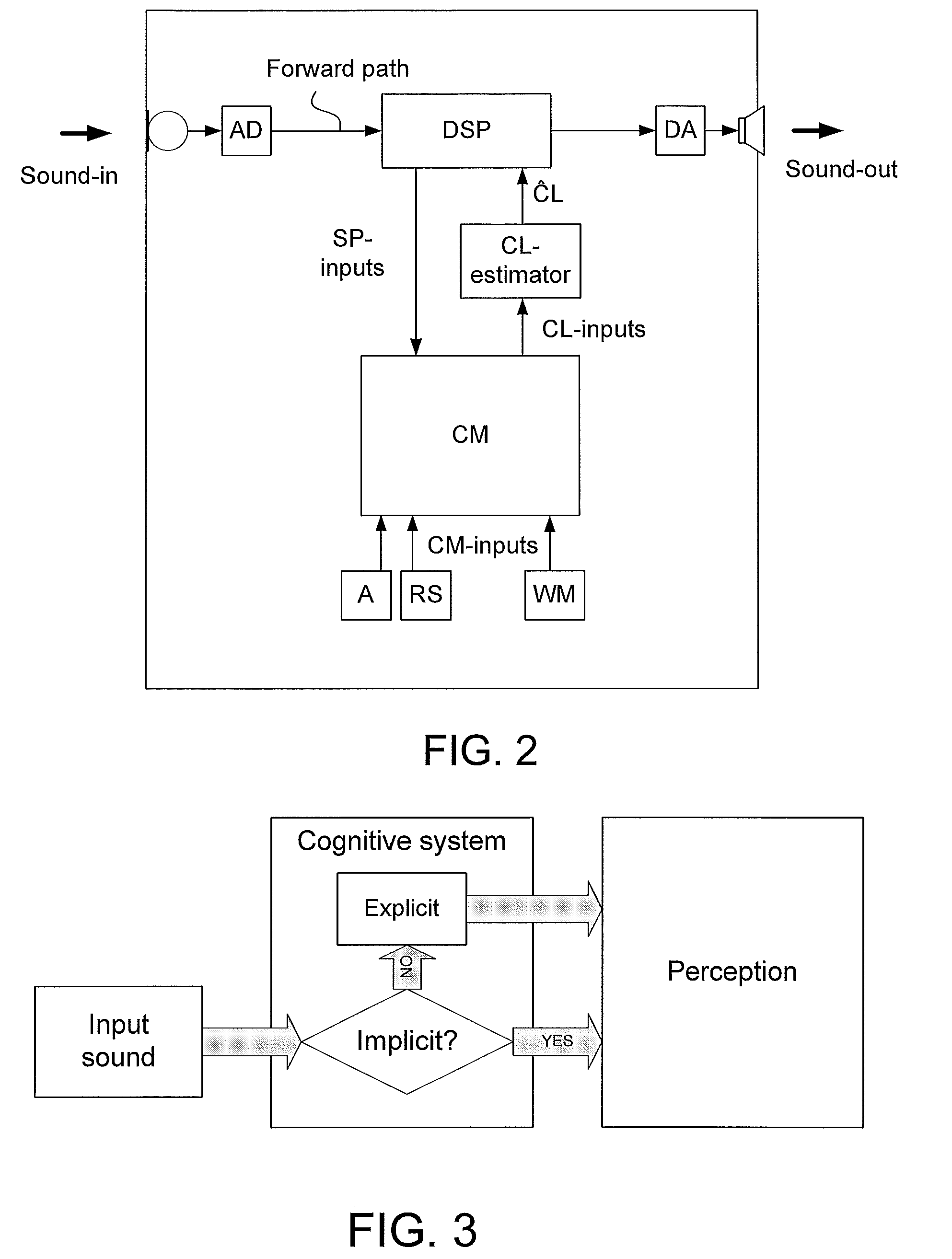

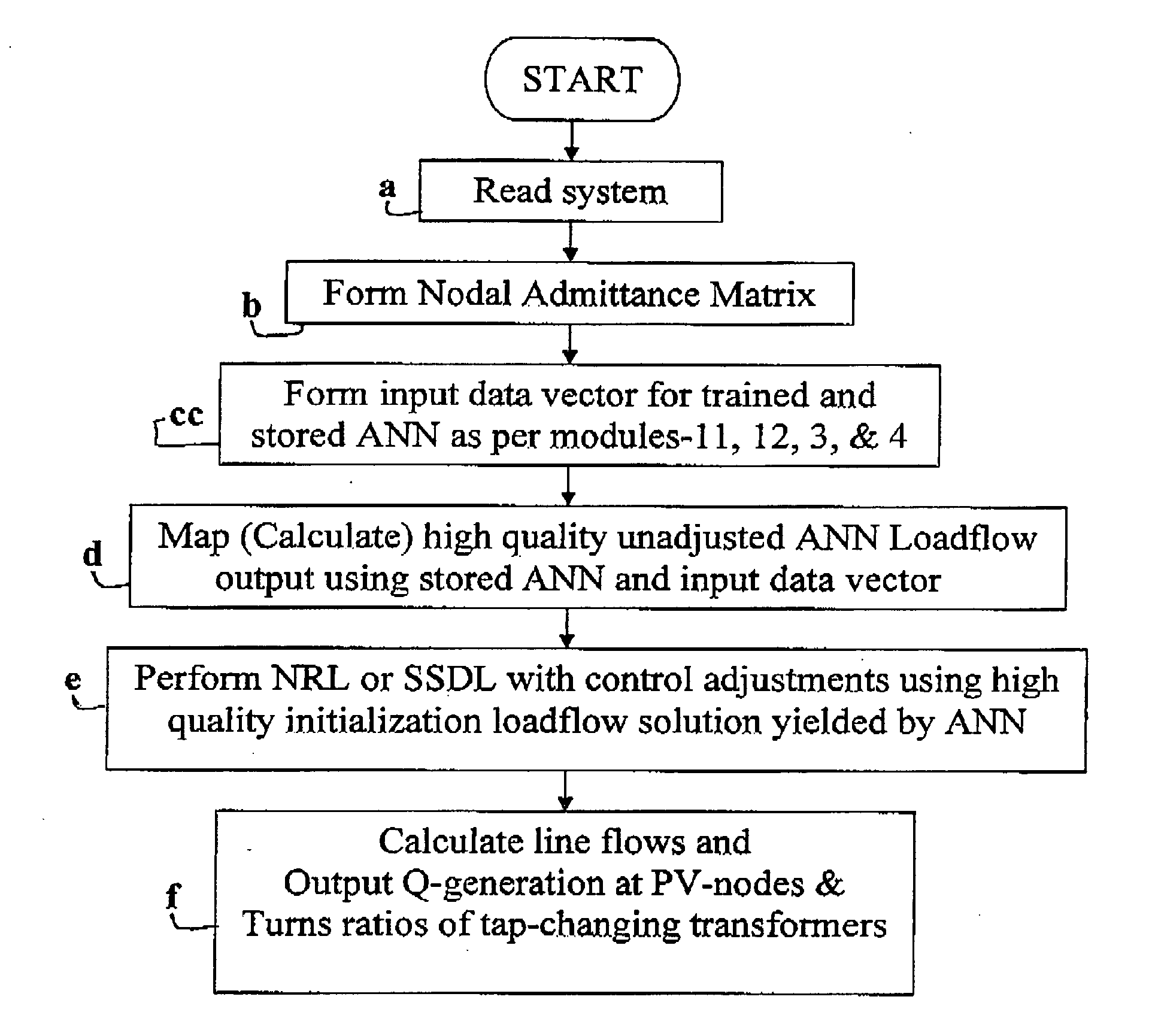

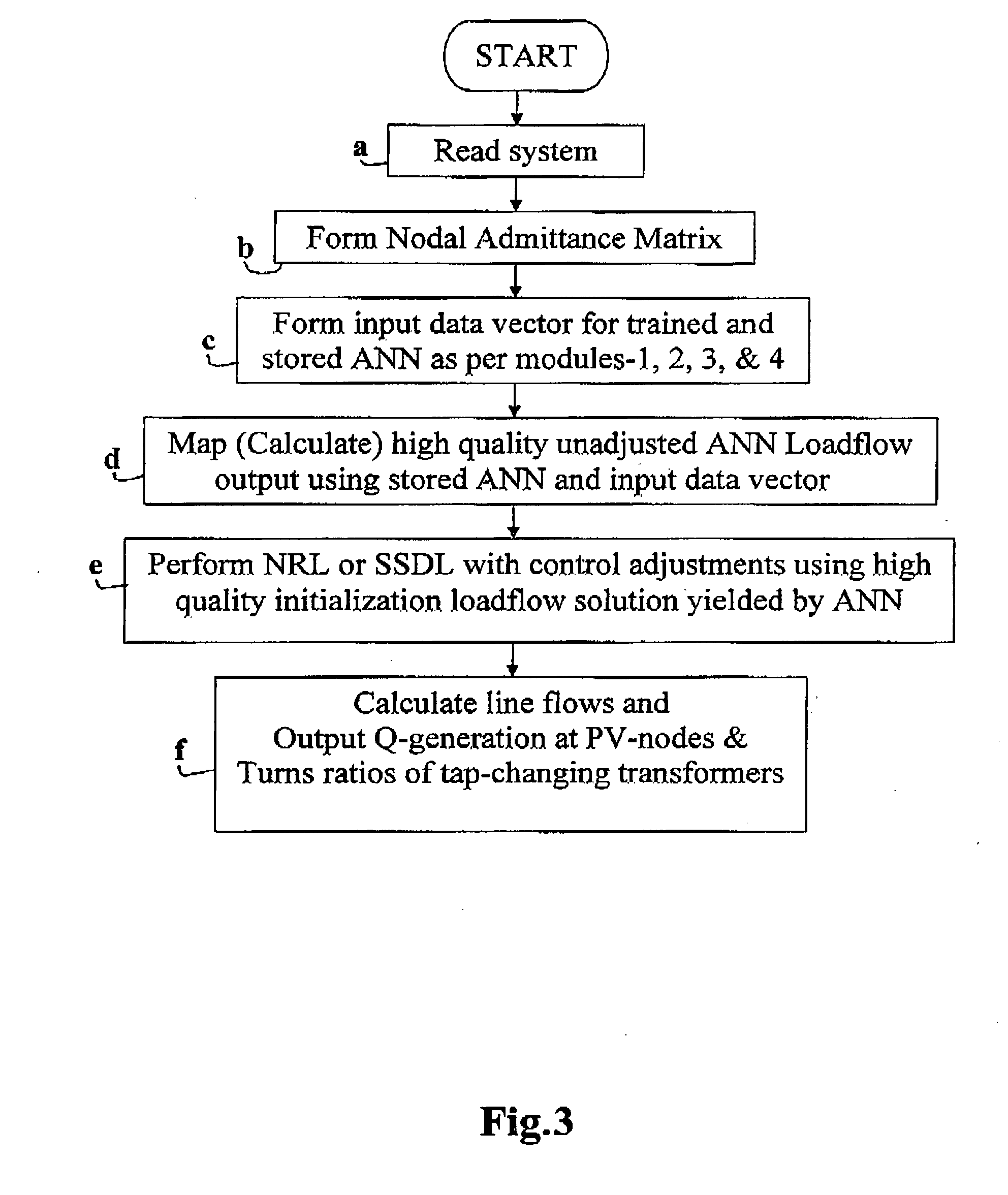

Method of Artificial Nueral Network Loadflow computation for electrical power system

ActiveUS20120078436A1Improve solution efficiencyFast outputMechanical power/torque controlLevel controlNODALData set

Neural Network Loadflow (NNL) computation method is invented involving input vector composed of net nodal injection of real and reactive powers and diagonal elements of conductance and susceptance matrices multiplied by the squared voltage magnitude components of the flat-start normally used as initial solution estimate guess for loadflow solution by conventional NRL or SSDL methods. Training, and testing / validating input-output data sets are generated by applying uniform and non-uniform scaling factors applied to base case loads at PQ-nodes, resistance and reactance of transmission line branches. These scale factors are increased until loadflow solution by conventional methods such as Newton-Raphson Loadflow and Super Super Decoupled Loadflow methods diverge. Divergence of loadflow methods are due to node voltage, node angle, and numerical instabilities. Voltage magnitude and phase angle values in the solution before divergence are respective stability limits and voltage magnitude and phase angle values in loadflow solution provide direct measure to the respective stability margins. Also Suresh's diakoptiks based feature selection technique is presented for ANNs calculating one node variable with one neuron each in their output layers.

Owner:PATEL SURESHCHANDRA B

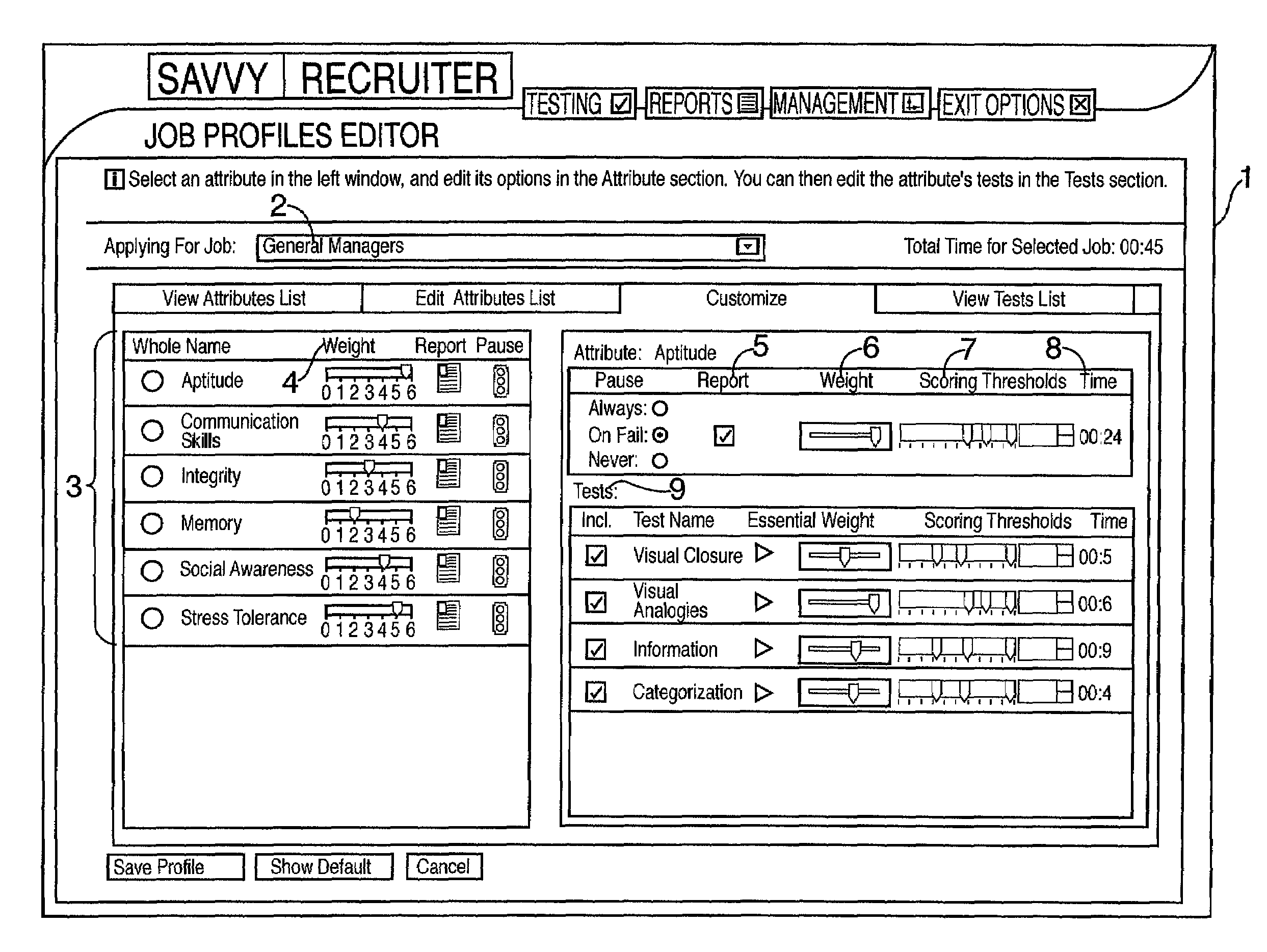

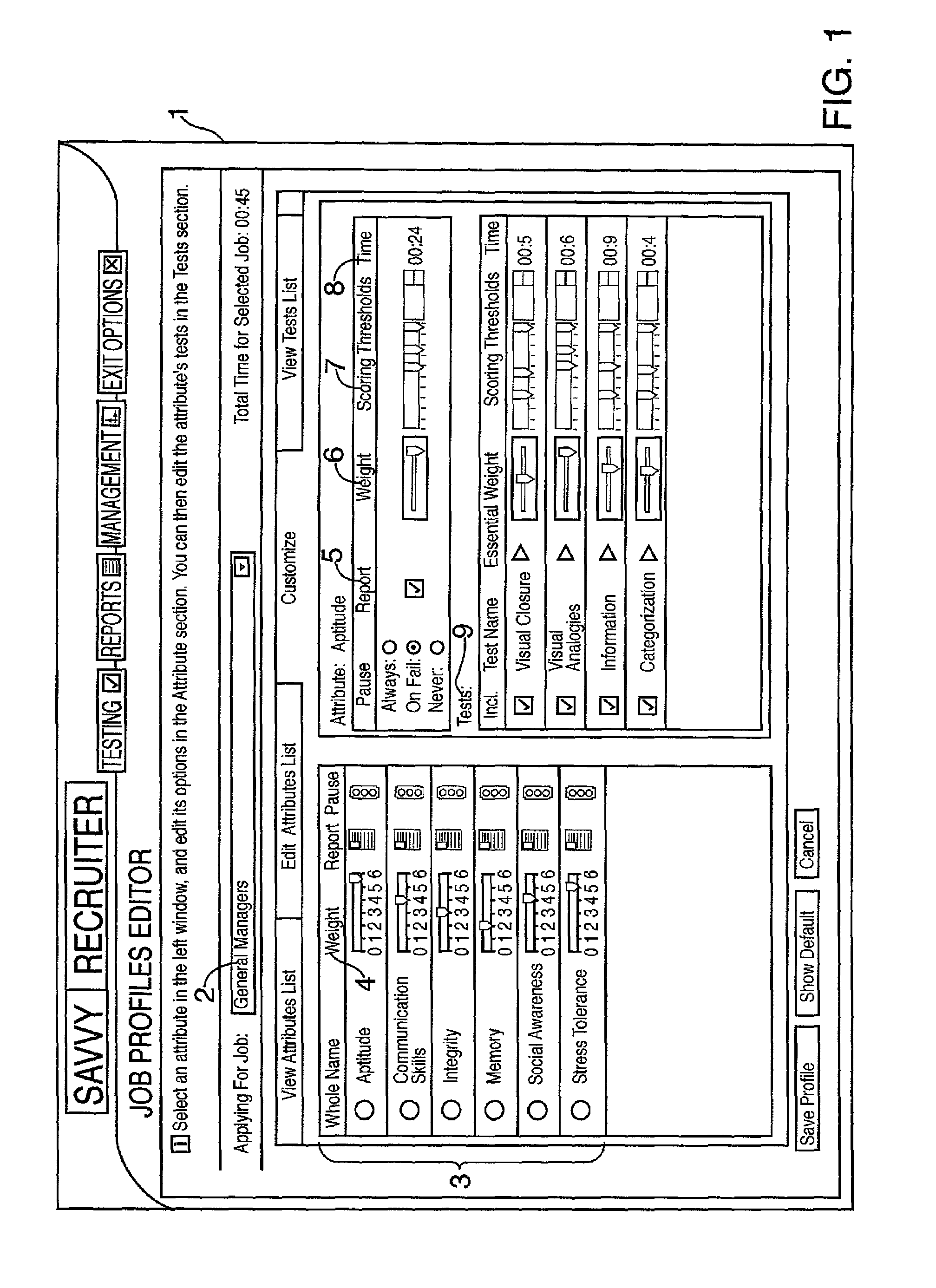

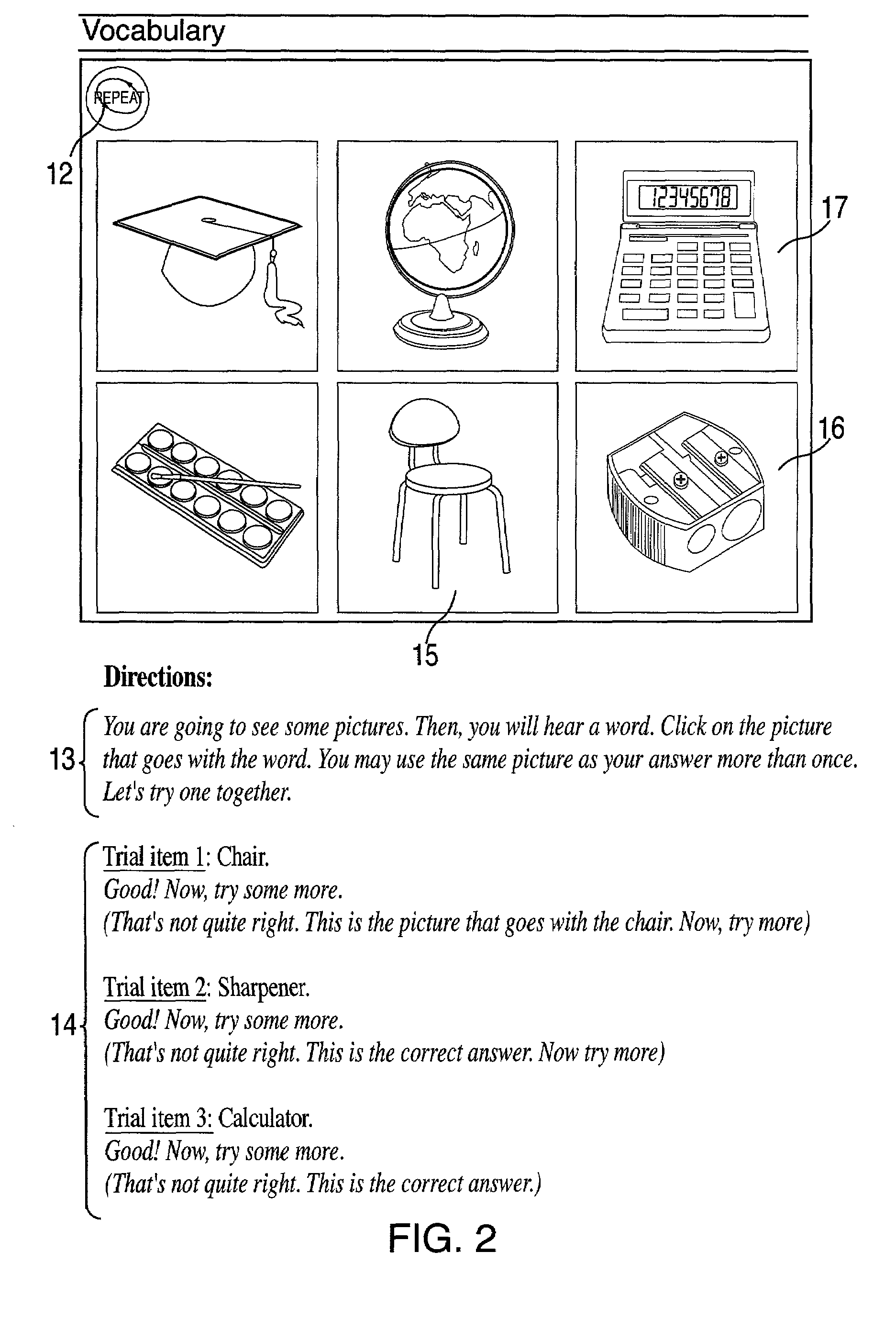

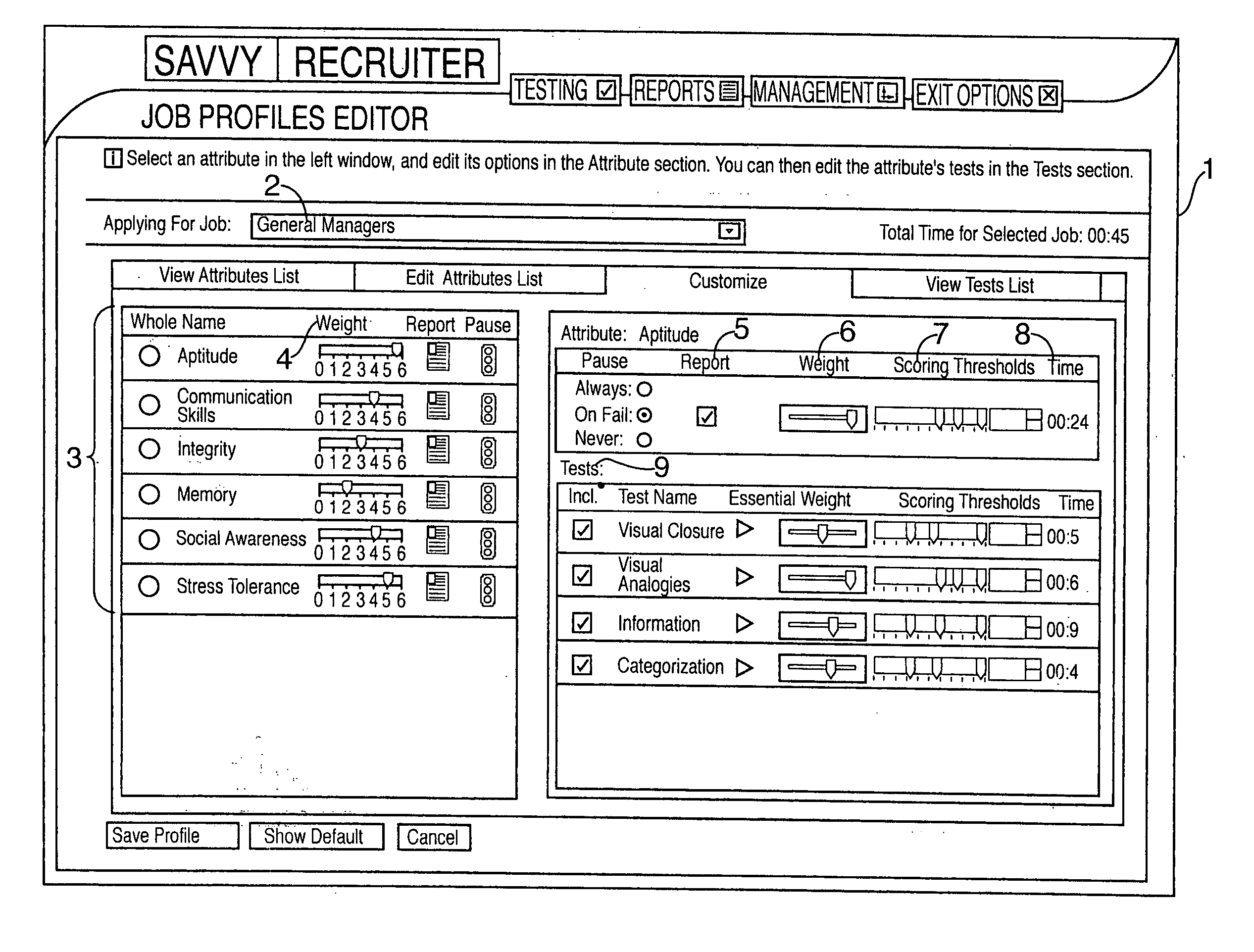

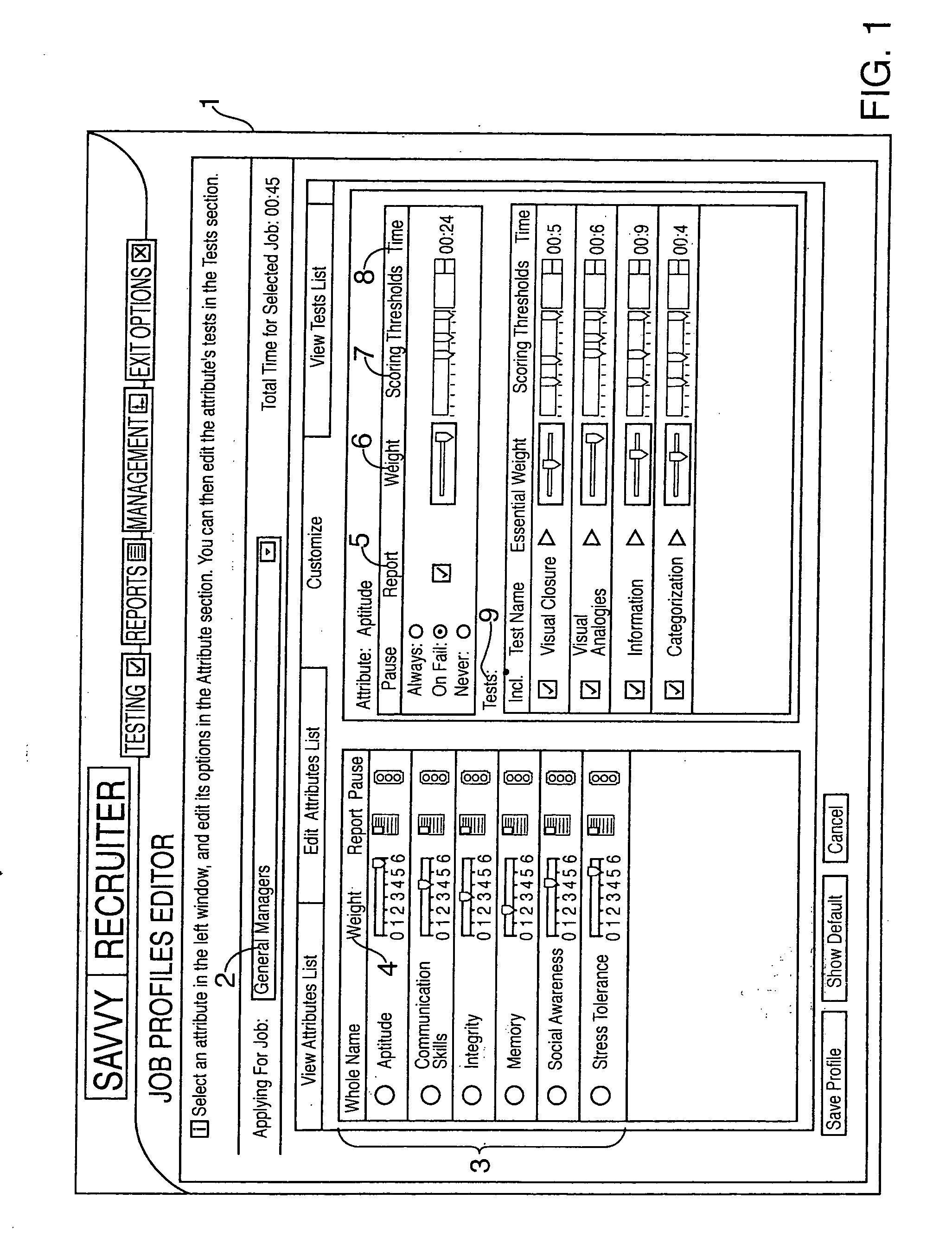

Application of multi-media technology to computer administered vocational personnel assessment

InactiveUS7207804B2Inhibition biasRapid and precise indicationSensorsPsychotechnic devicesVirtual workVisual perception

A multi-media method and system performs psychological assessment of an individual for suitability for particular jobs, whereby the individual is shown and provided with discrete visual and auditory stimuli on a multi-media computer screen, so that the individual's responses can be monitored in conjunction with physiological responses received by biofeedback sensors. The computer tallies the test subject's recorded responses. Virtual work environments are optionally displayed, to enable the tested individual to simulate a real work environment. Unlike other job evaluation systems, the system evaluates a job candidate's ability to maintain task focus under pressure. It directly measures performance under pressure, rather than only inferring potential performance based upon selective input from a job candidate.

Owner:HERSH MICHAEL

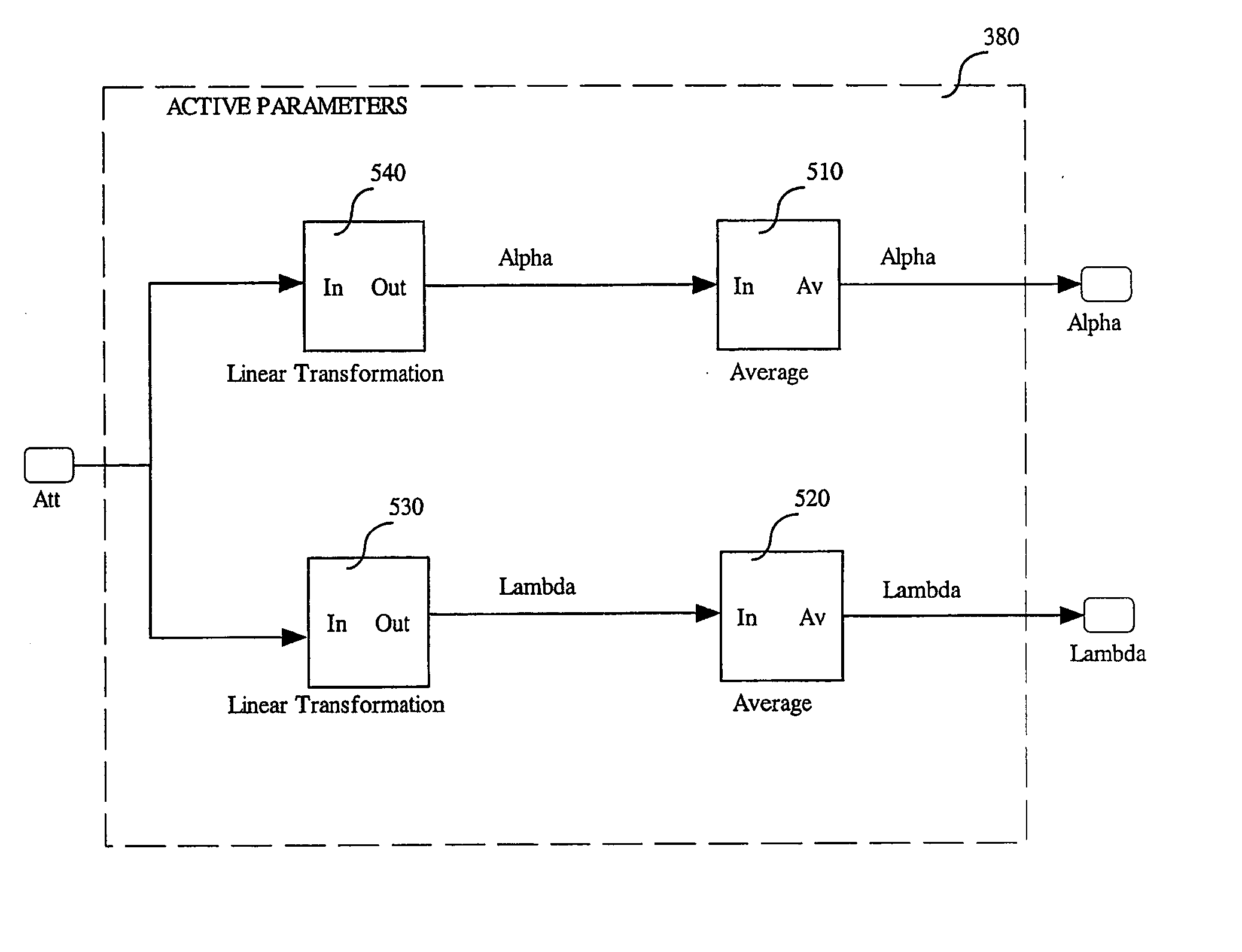

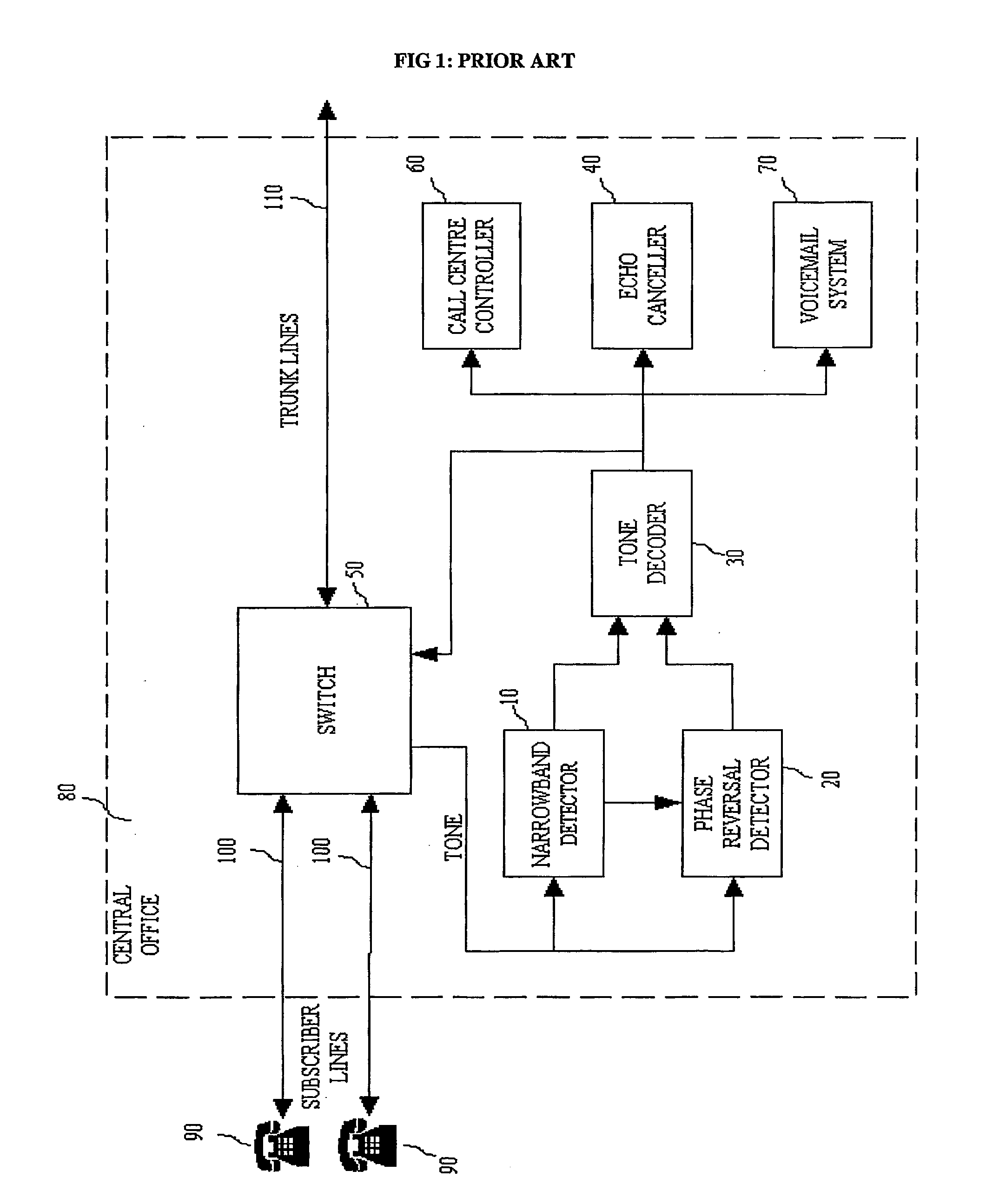

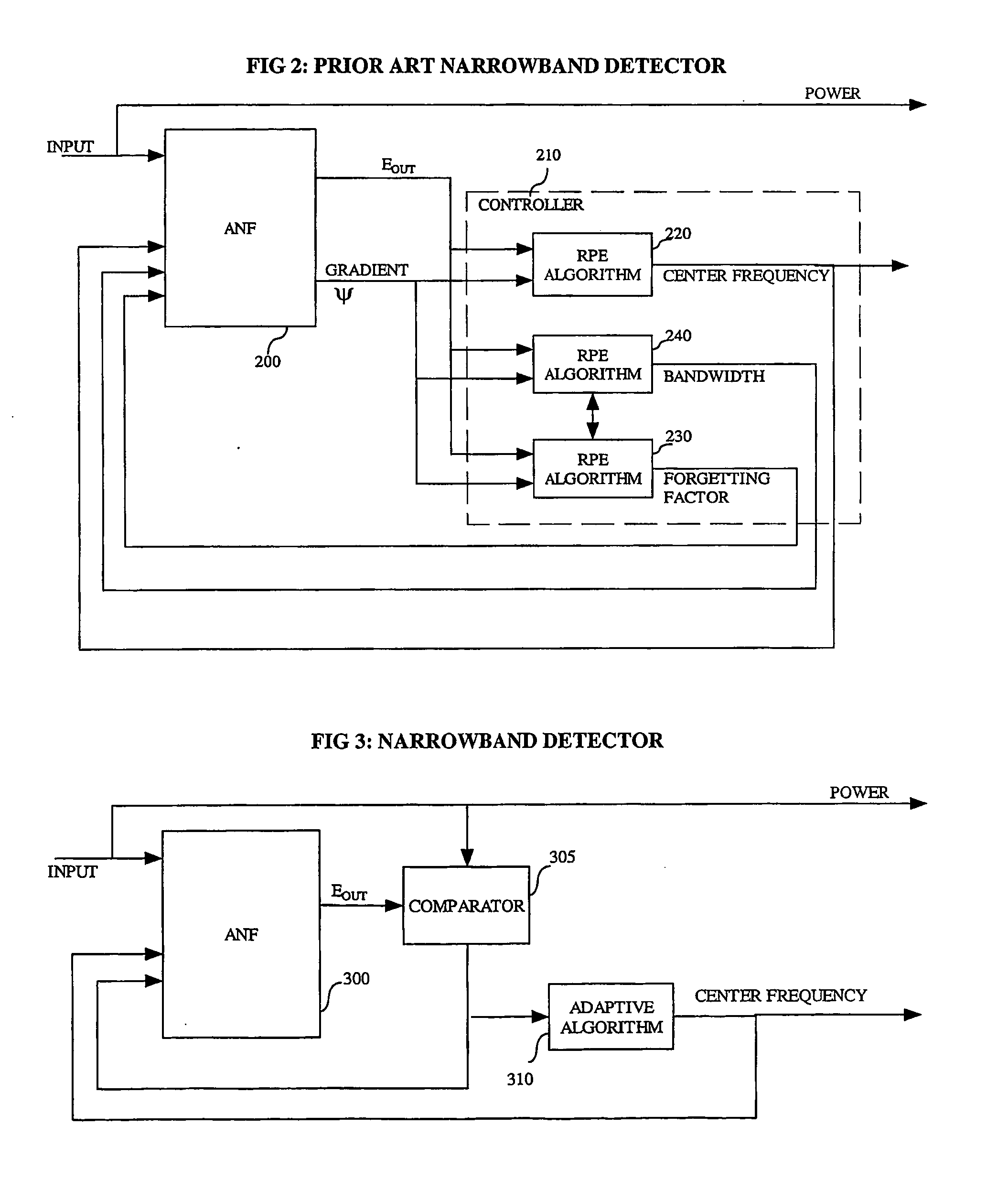

Narrowband detector

InactiveUS20060161428A1Reduce jitterImprove balanceAdaptive networkSpeech analysisAdaptive filterSignal detector

A narrowband signal detector has an adaptable filter and controller for controlling the centre frequency and the bandwidth of the filter, to track the narrowband signal. Better control of the filter can be achieved by basing the filter control on a comparison of output and input to the filter. The comparison gives a more direct measure of how well the filter is tracking the narrowband signal. In the case of a notch filter, if there is poor tracking. The control should be biased rapidly towards improved tracking speed. Otherwise, for good tracking, the control should be biased towards accuracy of tracking. This enables speed and accuracy of detection requirements to be met with less computational load. Applications include telecommunications signalling or data tone detection. Multiple narrowband signals can be detected by a cascade of filters.

Owner:TECTEON

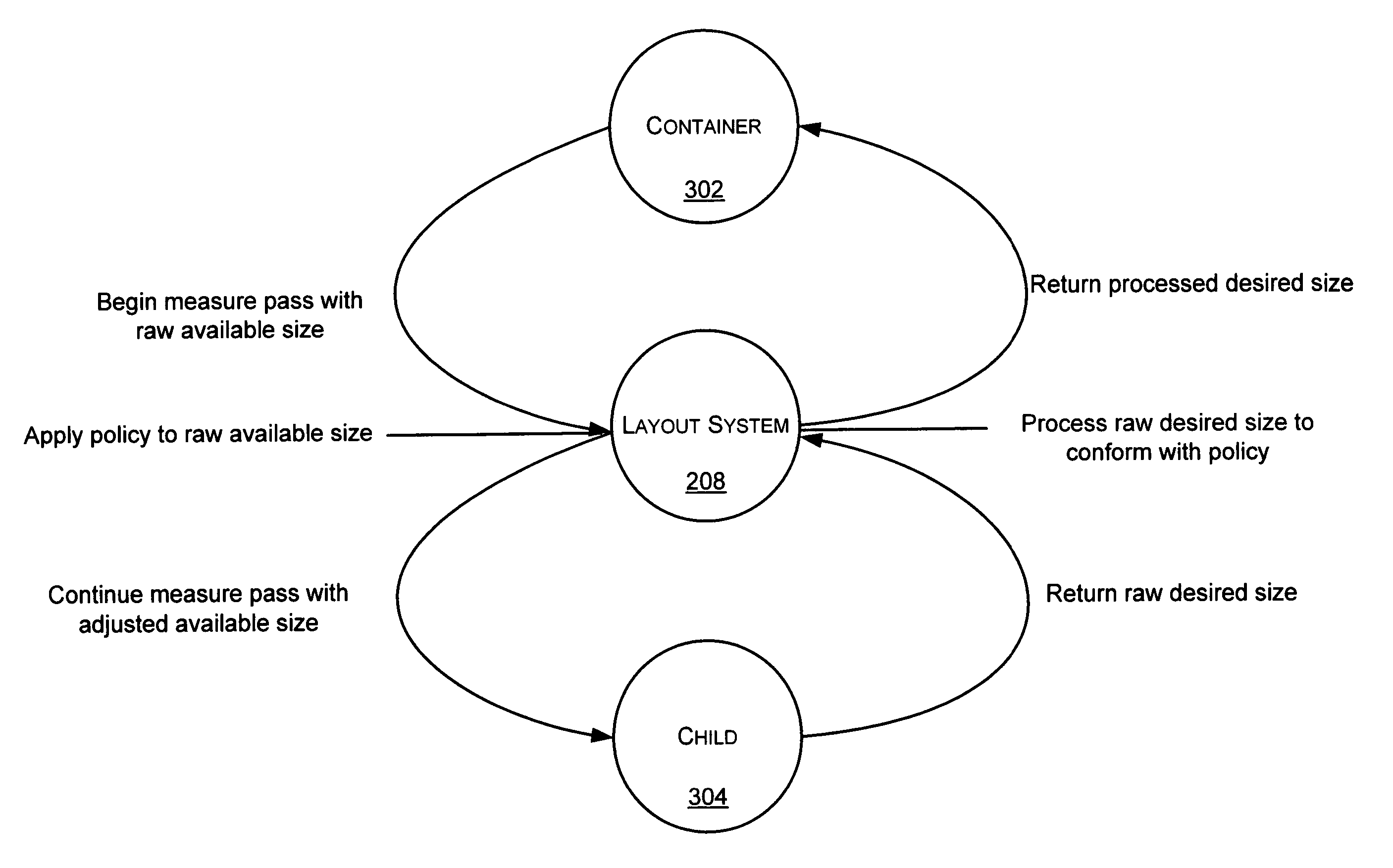

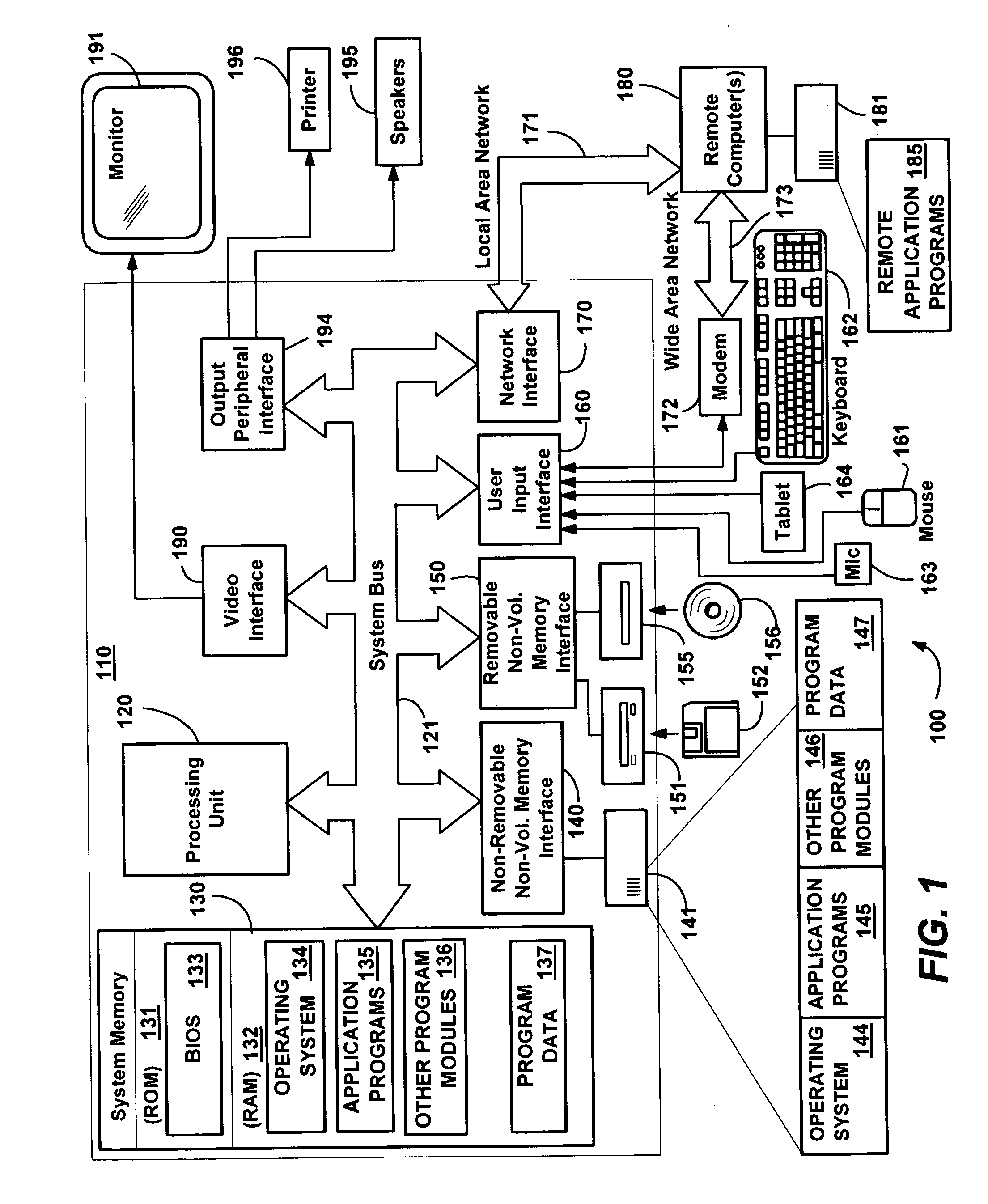

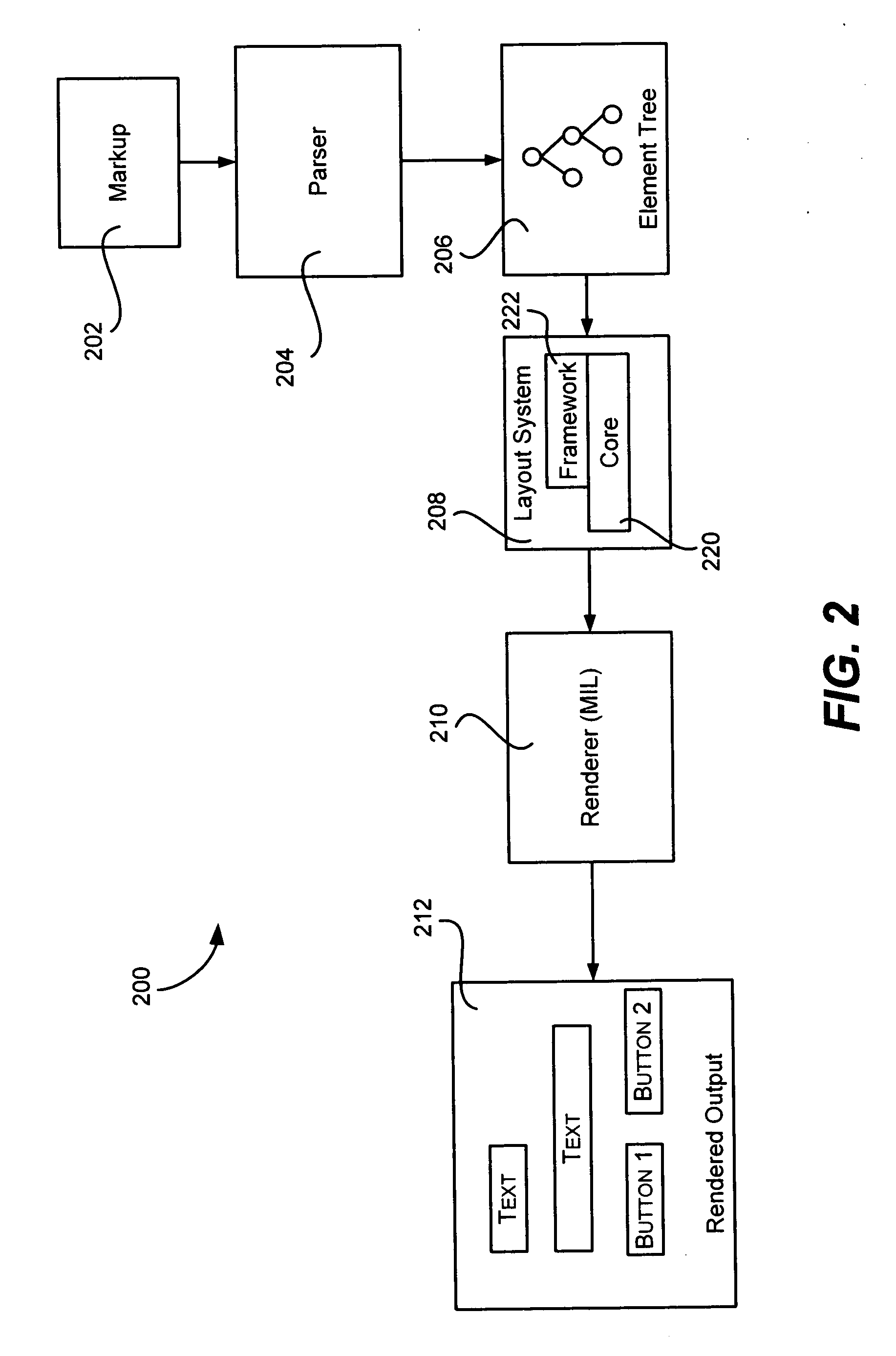

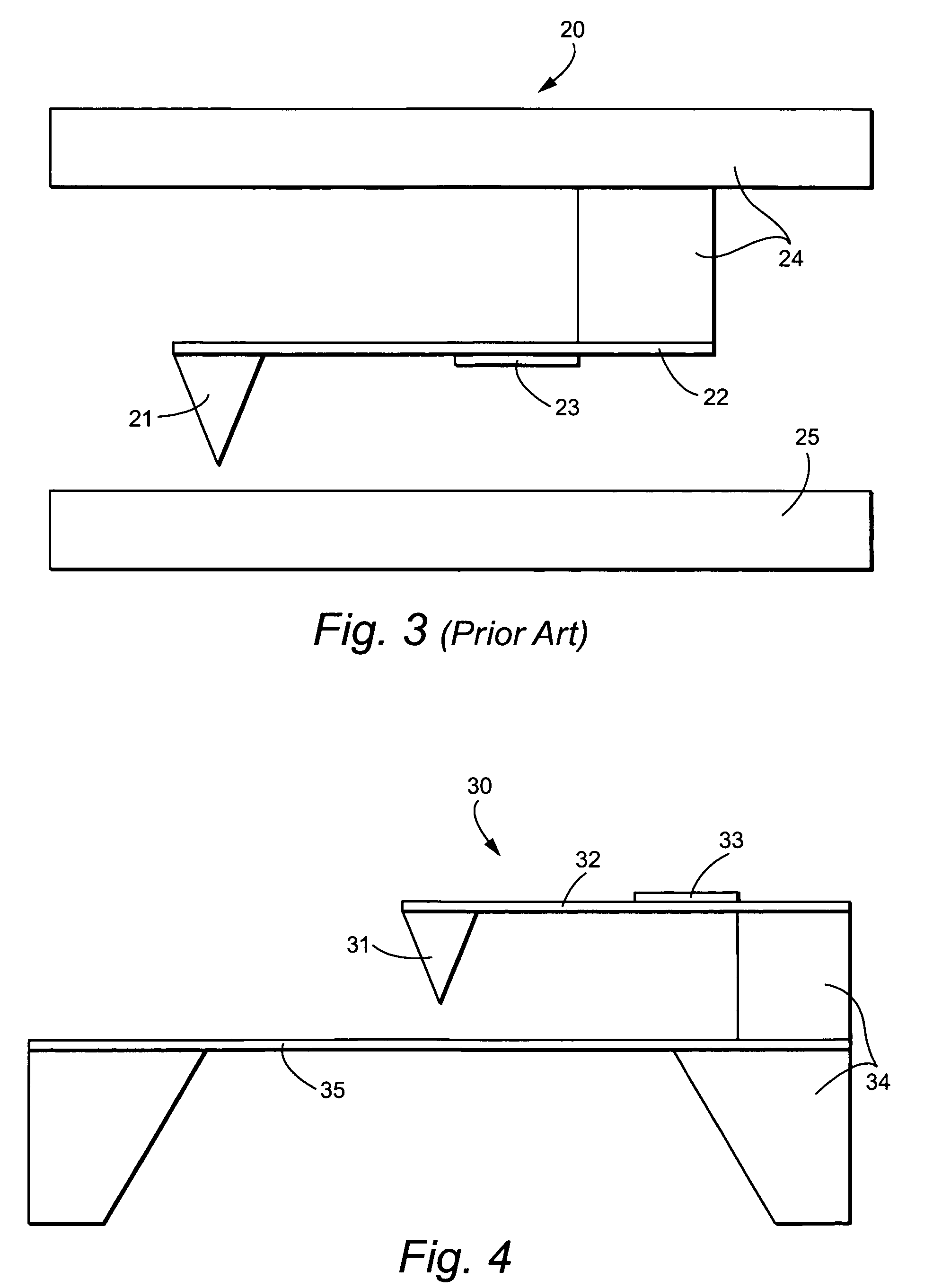

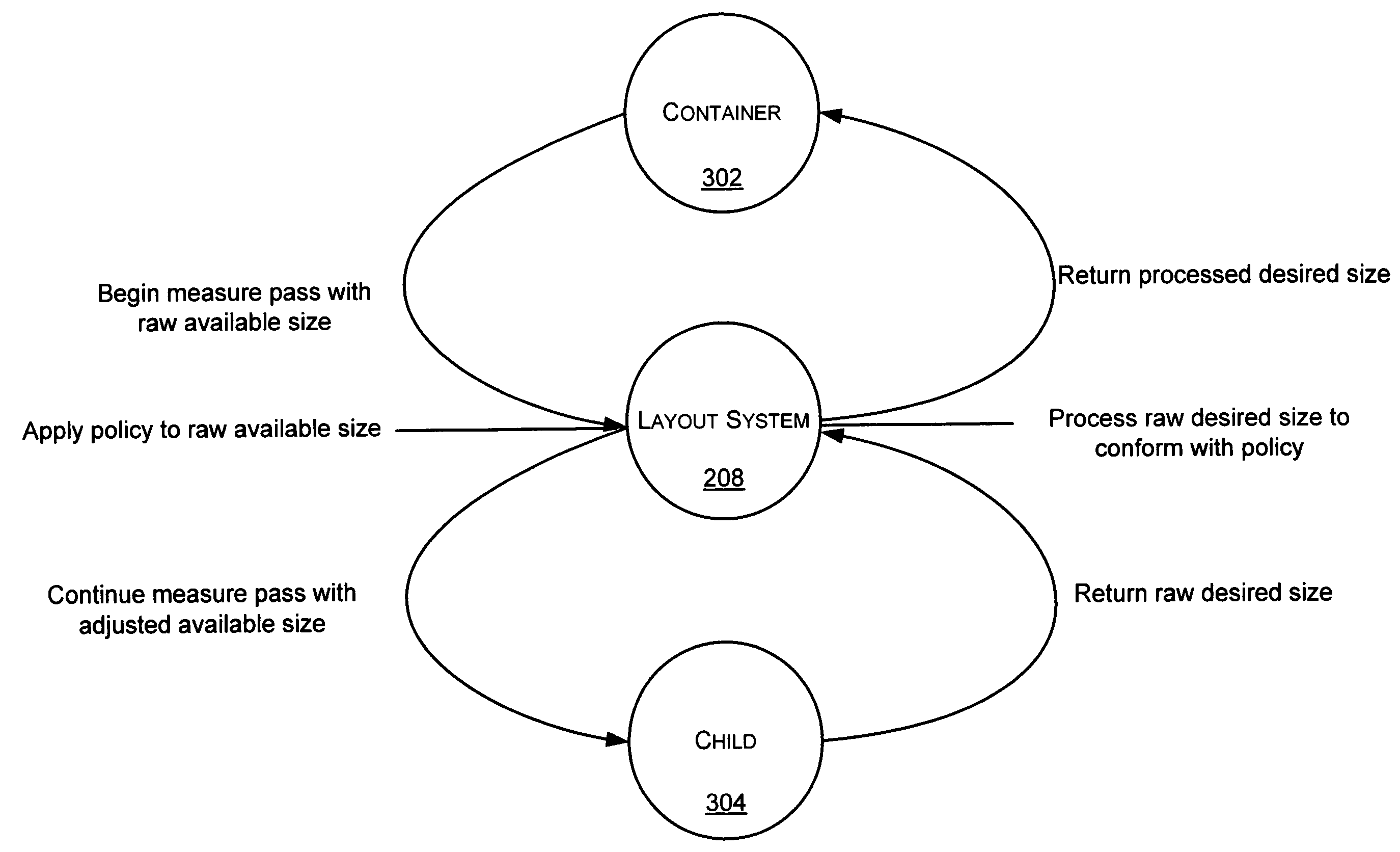

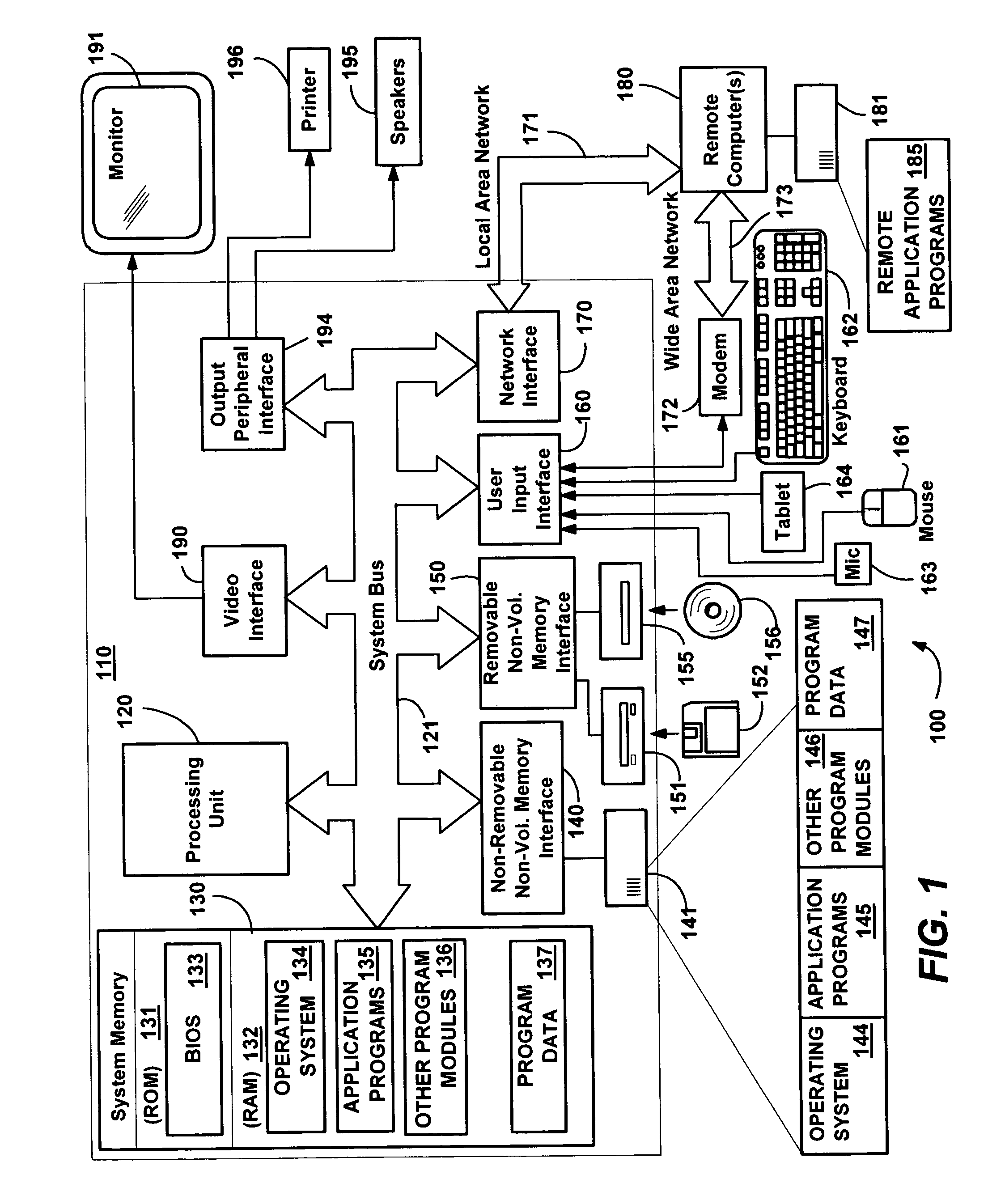

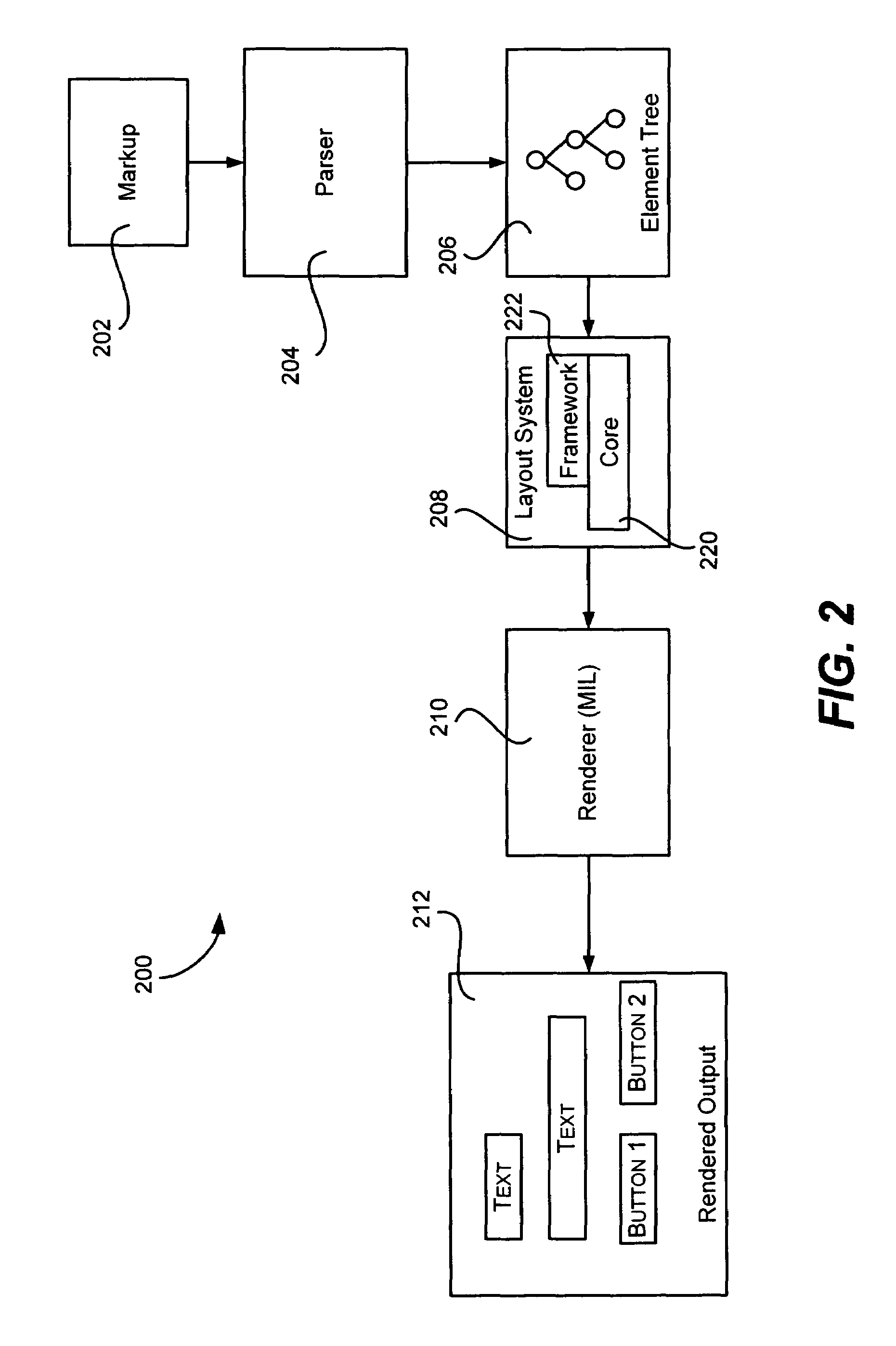

Layout system for consistent user interface results

InactiveUS20060218489A1Suitable displayExecution for user interfacesSpecial data processing applicationsParallel computingMaximum size

Described is a layout system and process for user interface elements of computer programs. The layout system generally refers to a protocol and associated API that enables sizes and positions to be allotted, in which user interface elements are rendered. The layout system may be split between a core layout system and a framework layout system. The core provides minimal policy / rules that are imposed to allow flexibility for a given framework implementation. The framework adds support for user-specified sizing, positioning, margins, minimum sizes, maximum sizes and specific layout elements. Parent elements (e.g., containers) direct measure calls and arrange calls to child elements. The layout system essentially intercepts those calls and depending on policy may manipulate the properties of those calls for sizing, positioning, alignment and the like to ensure uniform and consistent layout results.

Owner:MICROSOFT TECH LICENSING LLC

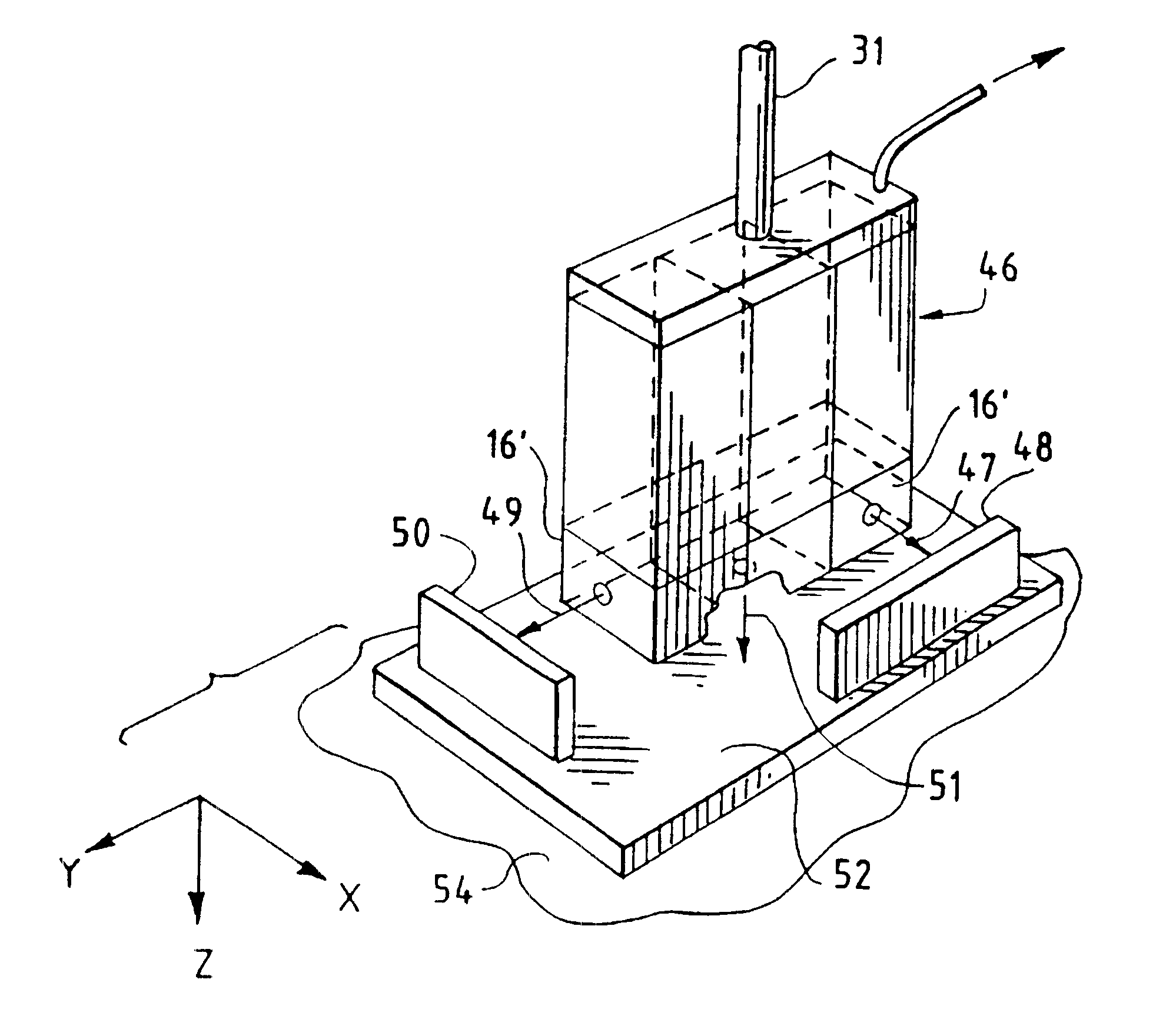

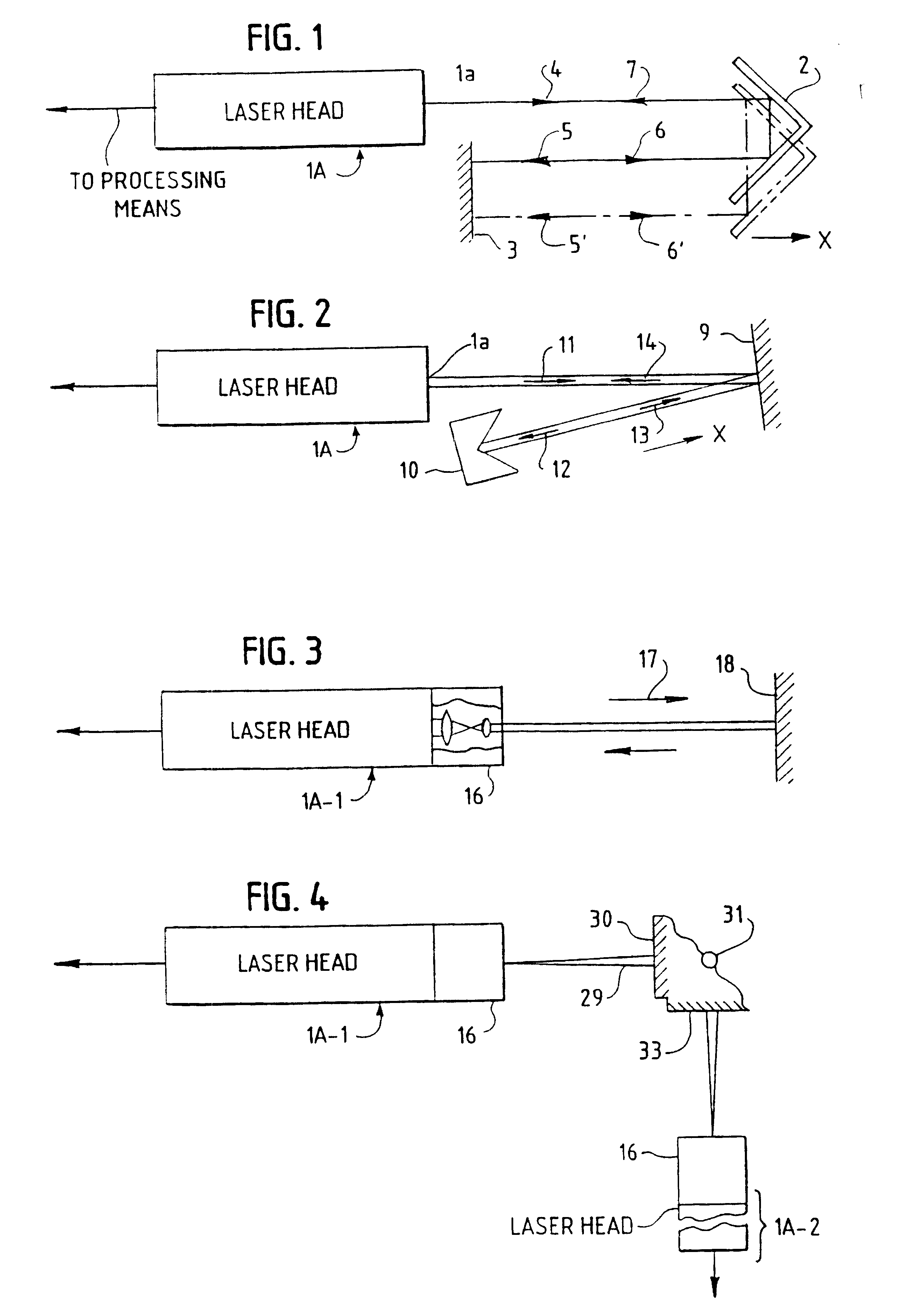

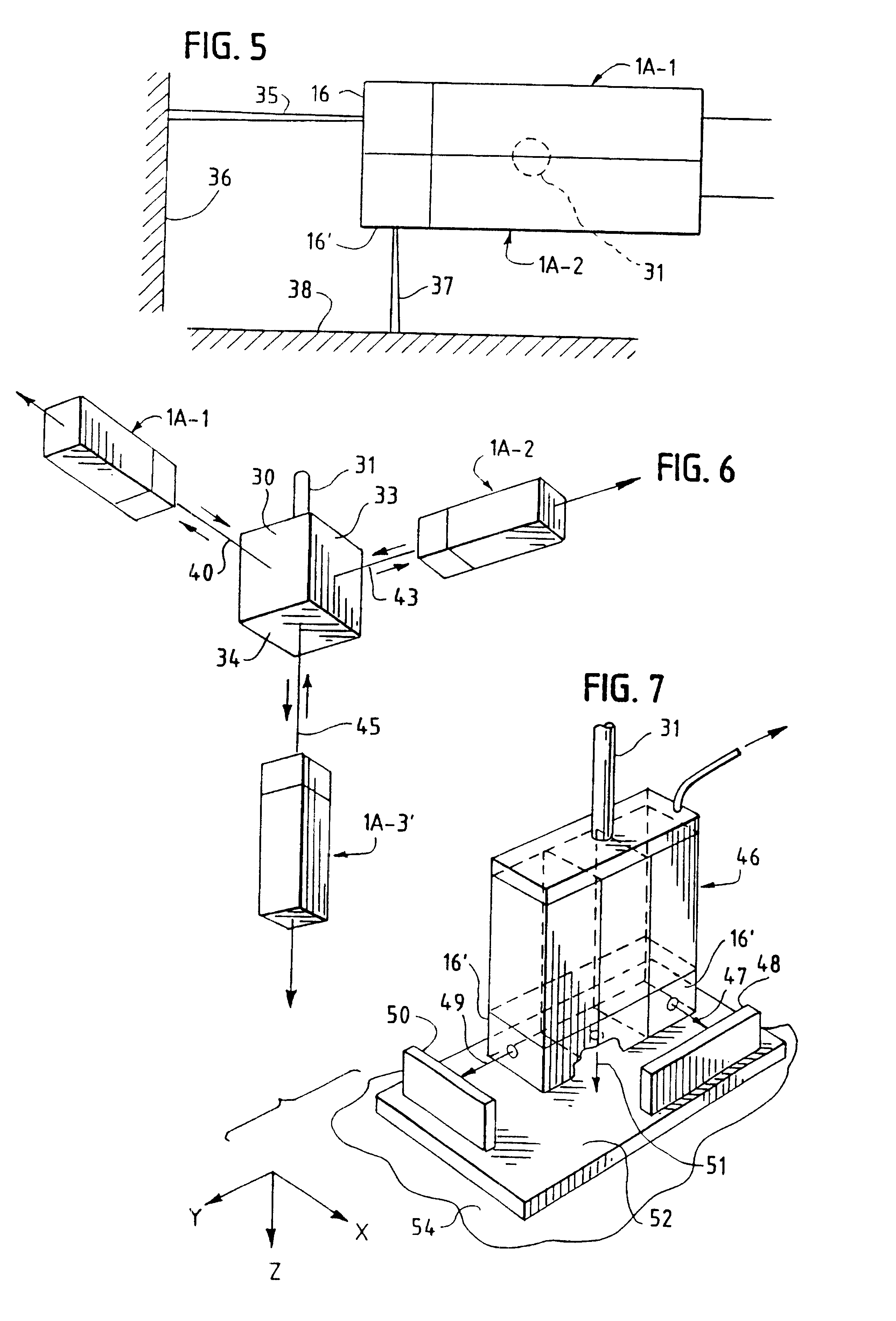

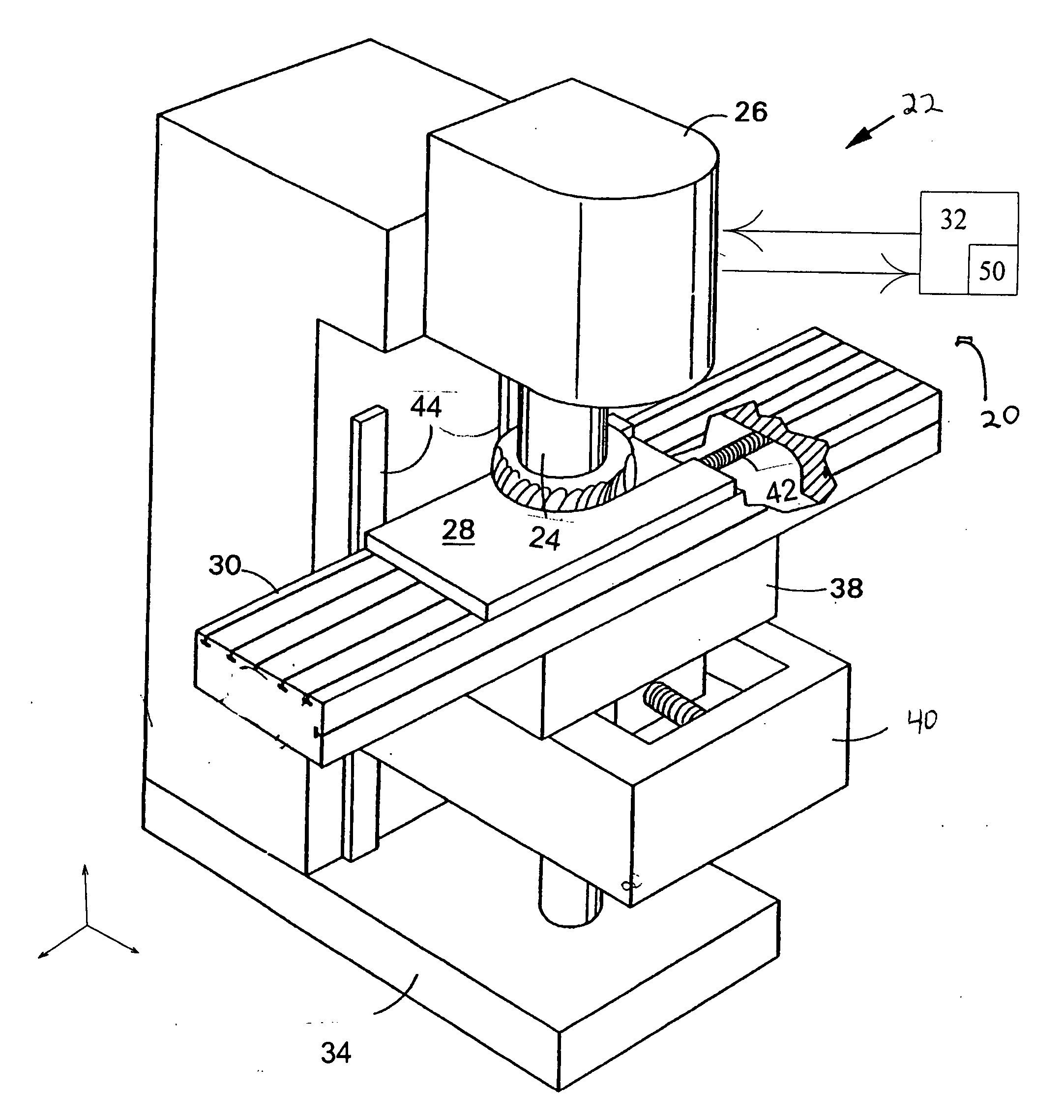

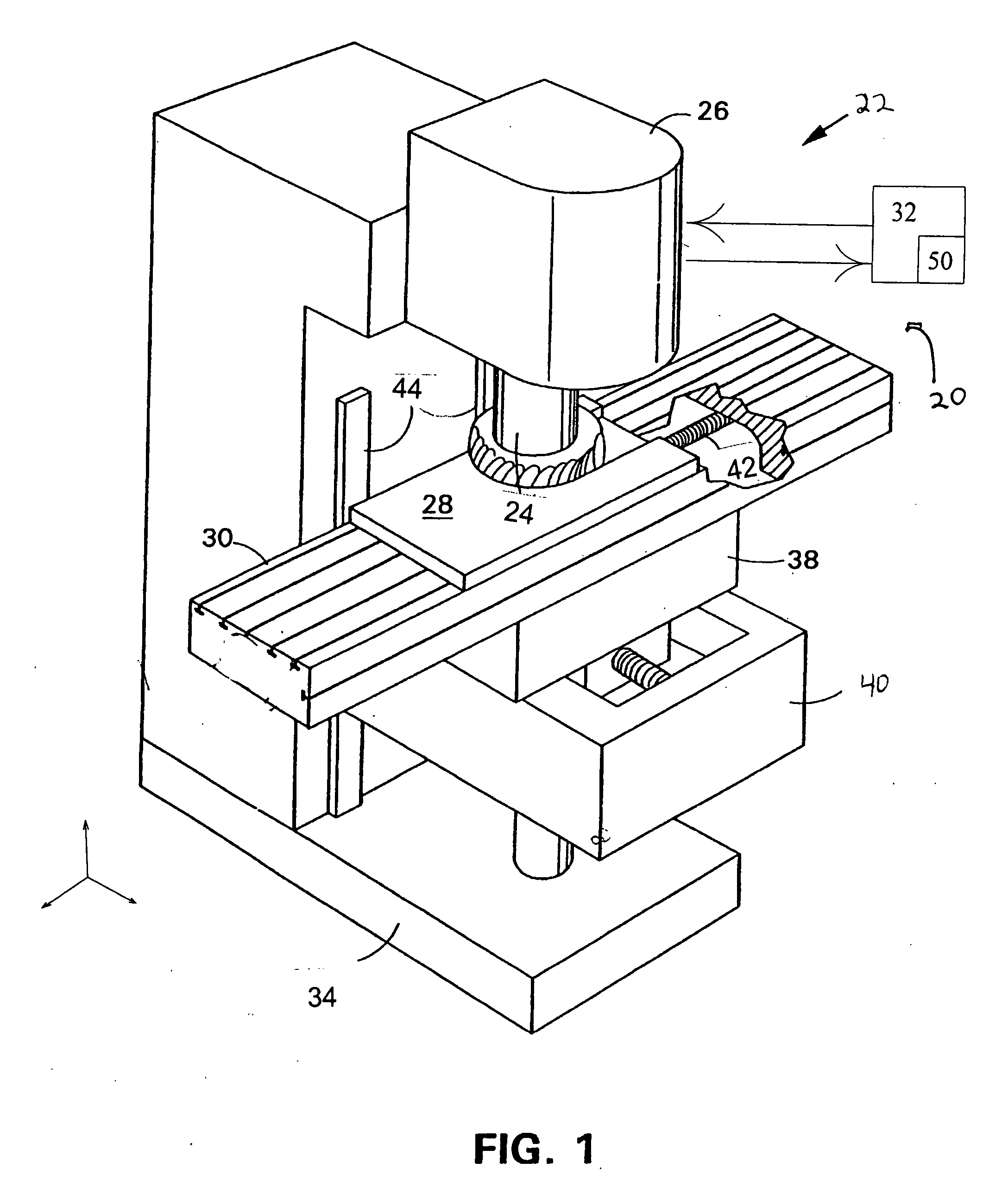

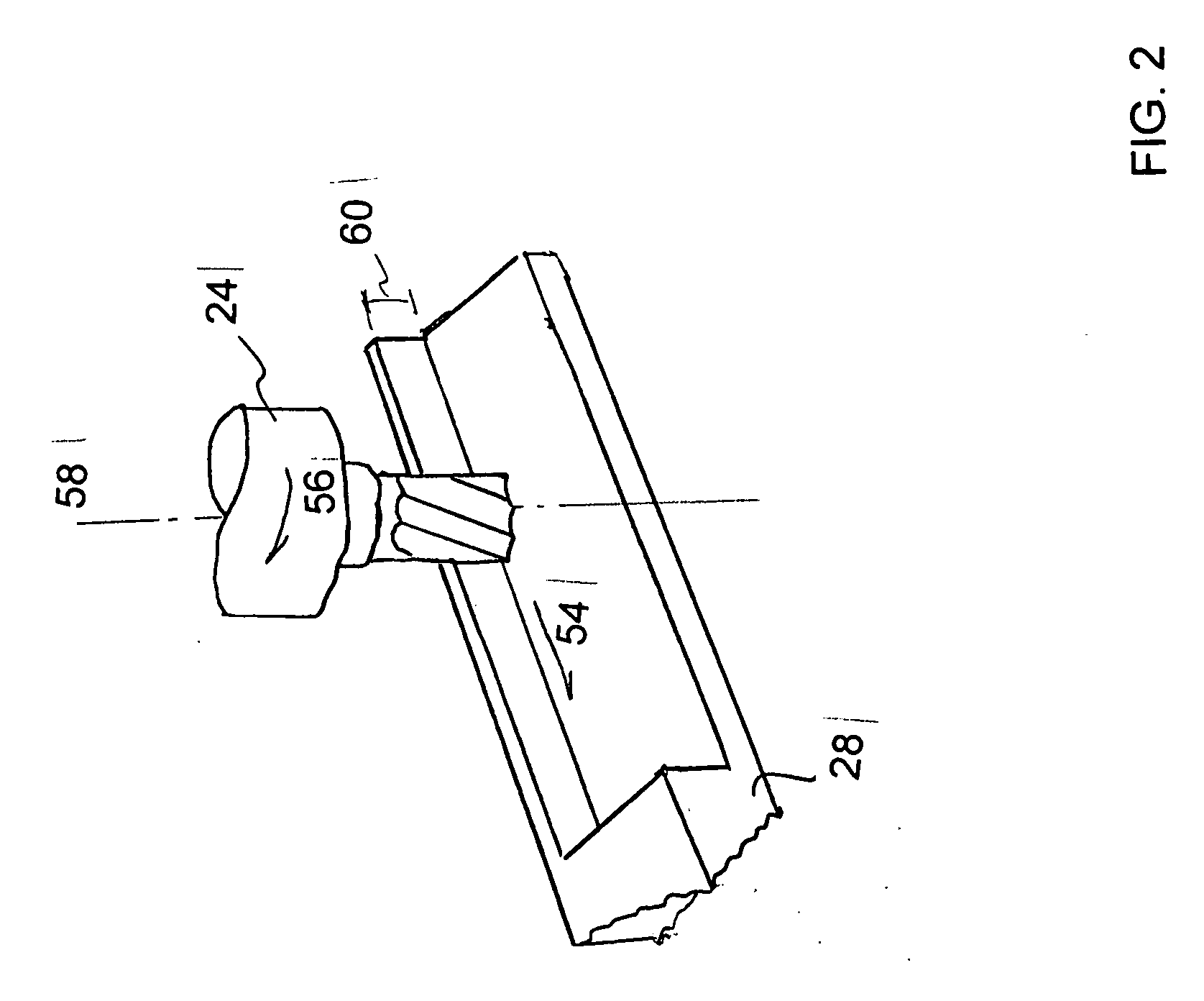

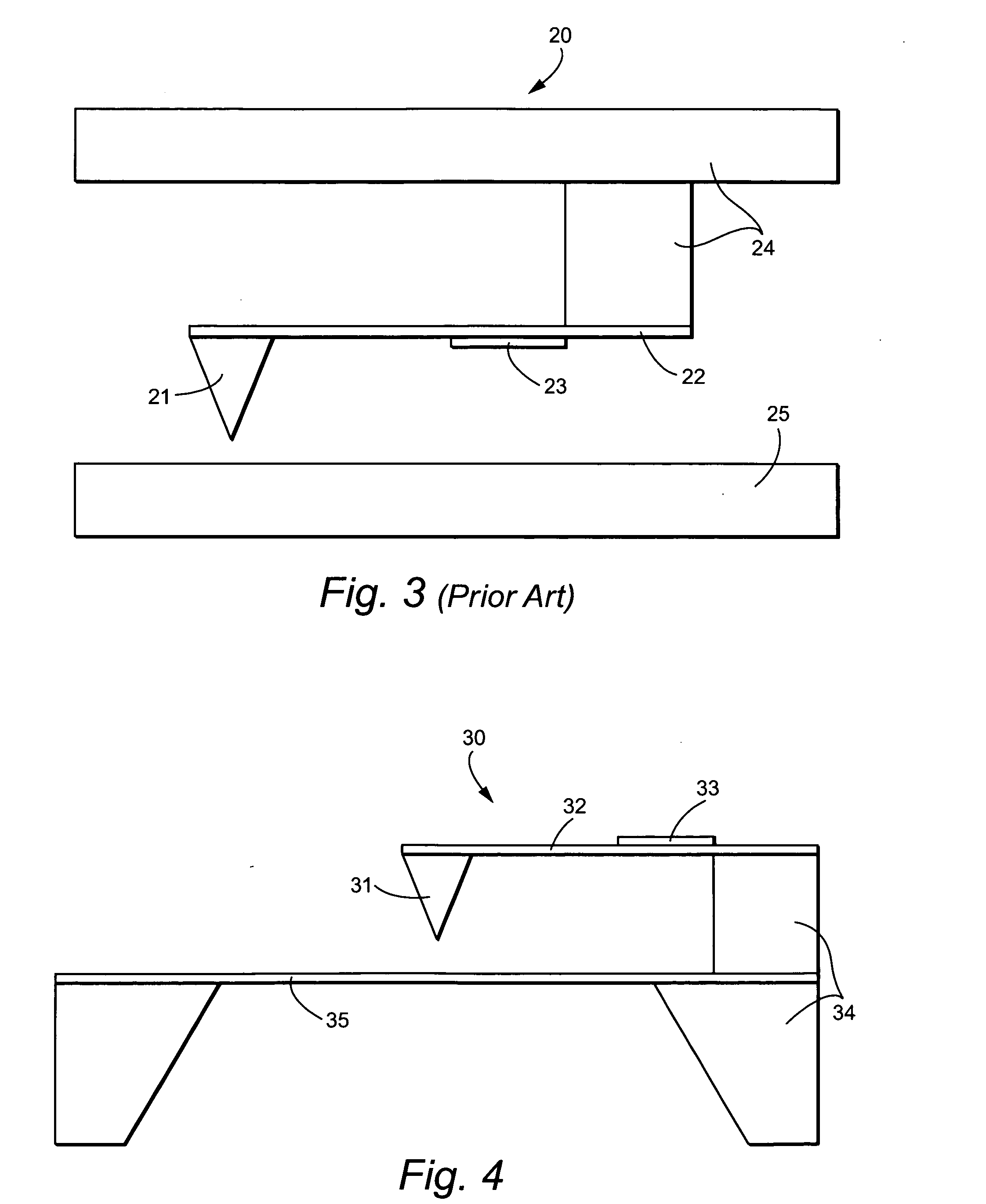

Tool path measurement

InactiveUS6498653B1Small toleranceLarge lateral displacementComputer controlSimulator controlThree-dimensional spaceClassical mechanics

The degree of accuracy a machine tool or the like is moved along a given path is determined by a unique preferably laser beam directing measuring system directing simultaneously or in sequence a laser beam parallel to the orthogonal axes of the two or three dimensional space in which the spindle or other object is to be moved in a path which can diverge appreciably in directions other than the directions of these axes. The beam directing means includes means which provides a measure of the actual positions the object has at various sampling times relative to the axis along which the beam is directed. This actual path position data is compared to the desired path position data used to program the object moving machine to determine the path position error at the sampling times involved.

Owner:OPTODYNE

Method to measure tool wear from process model parameters

InactiveUS20080161959A1Easy accessSimple and direct measureProgramme controlSpecial data processing applicationsPhysics basedEngineering

A system and method for monitoring tool wear in CNC machining operations by monitoring spindle power and extracting instantaneous cutting geometry. The method is based on a physics-based two parameter process model and measuring at two different cutting conditions. The process model parameters are measured with easily accessible spindle power. In contrast to spindle power alone which is influenced by many factors, most especially by variable cutting conditions and by the tool condition, the process model parameters are independent of the geometrically variable cutting conditions and provide a simple and direct measure of tool wear. The two process model parameters change differently depending on the mechanism of the tool wear, specifically flank wear versus cutting edge degradation. This provides a diagnostic for tool wear.

Owner:UNIVERSITY OF NEW HAMPSHIRE

Application of multi-media technology to computer administered vocational personnel assessment

InactiveUS20070105080A1Minimize the differenceReliably and accurately predict real world successSensorsPsychotechnic devicesVirtual workVisual perception

A multi-media method and system performs psychological assessment of an individual for suitability for particular jobs, whereby the individual is shown and provided with discrete visual and auditory stimuli on a multi-media computer screen, so that the individual's responses can be monitored in conjunction with physiological responses received by biofeedback sensors. The computer tallies the test subject's recorded responses. Virtual work environments are optionally displayed, to enable the tested individual to simulate a real work environment. Unlike other job evaluation systems, the system evaluates a job candidate's ability to maintain task focus under pressure. It directly measures performance under pressure, rather than only inferring potential performance based upon selective input from a job candidate.

Owner:HERSH MICHAEL

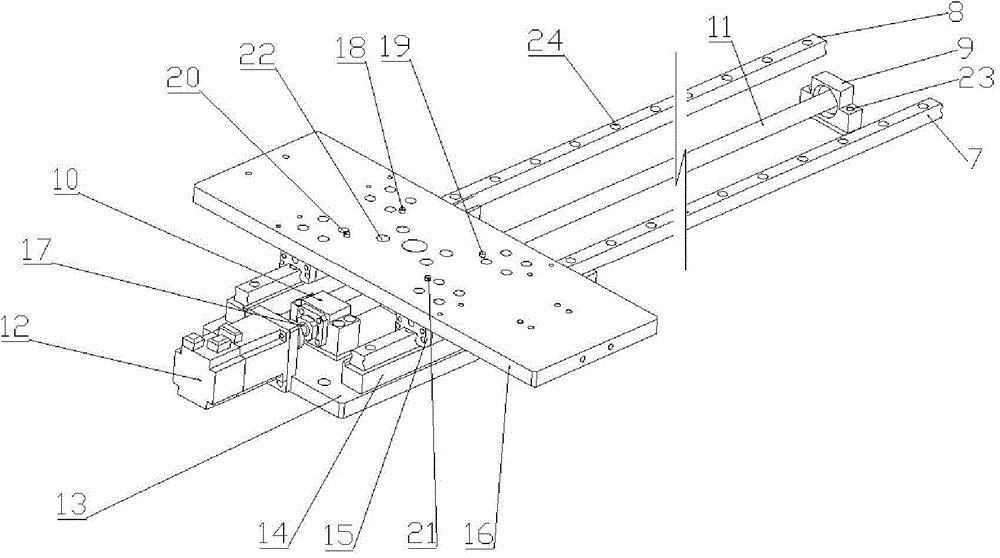

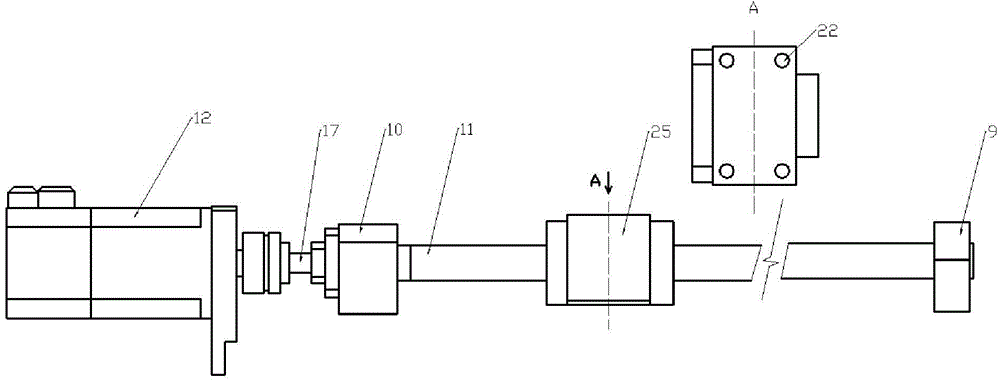

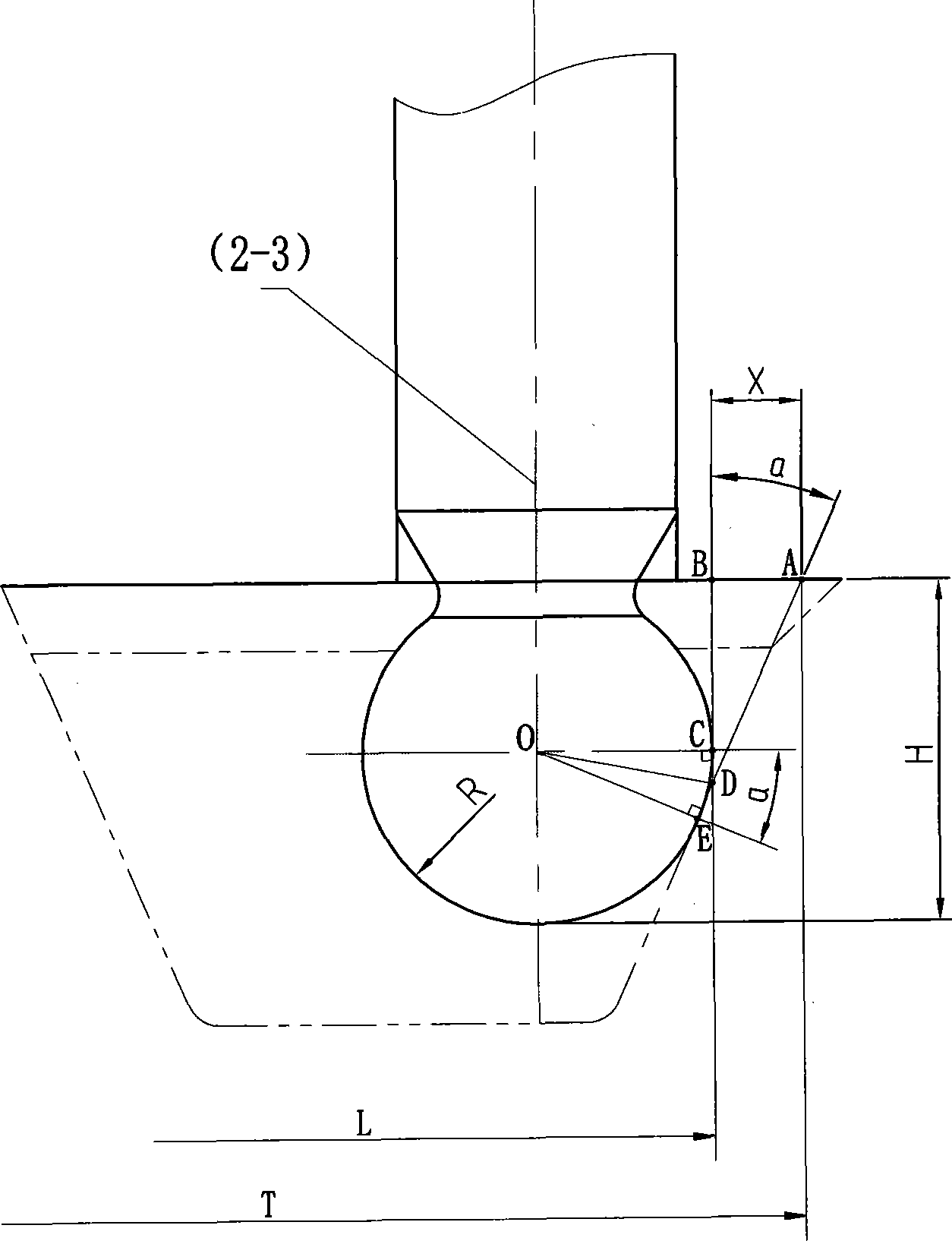

Measuring device for automobile basic parameters and measuring method of measuring device

The invention provides a measuring device for automobile basic parameters and a measuring method of the measuring device. A laser distance measuring sensor which serves as a direct measuring tool is installed on a bracket provided with a lifting mechanism and a rotary mechanism, and the bracket is driven by a linear driving device to move along the length direction of a base, so that the laser distance measuring sensor is moved to a needed position to be measured. The measuring device provided by the invention further comprises a wheel center positioning device for positioning the center of a found wheel, a wheel track measuring assistant device for measuring the distance between left and right wheels in an assistant manner, and an angle measuring assistant device for measuring the approach angle and departure angle of the automobile in an assistant manner. The measuring device provided by the invention can be used for solving the problems that the conventional manual measuring method is relatively great in measuring error, inconvenient to operate and the like and can be used for precisely measuring length, width, height, distance between front and back wheels, a wheel base, the approach angle and the departure angle.

Owner:JILIN UNIV

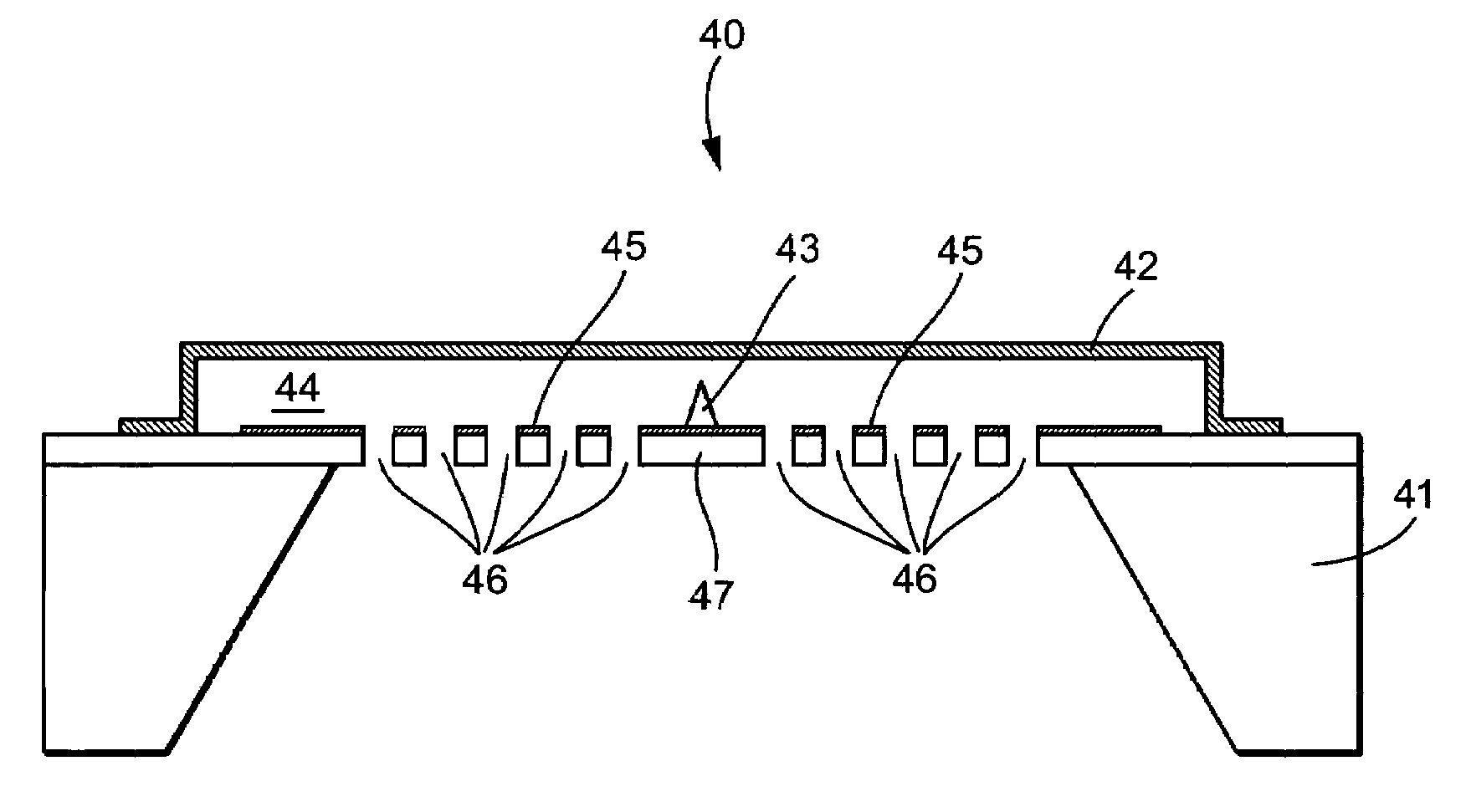

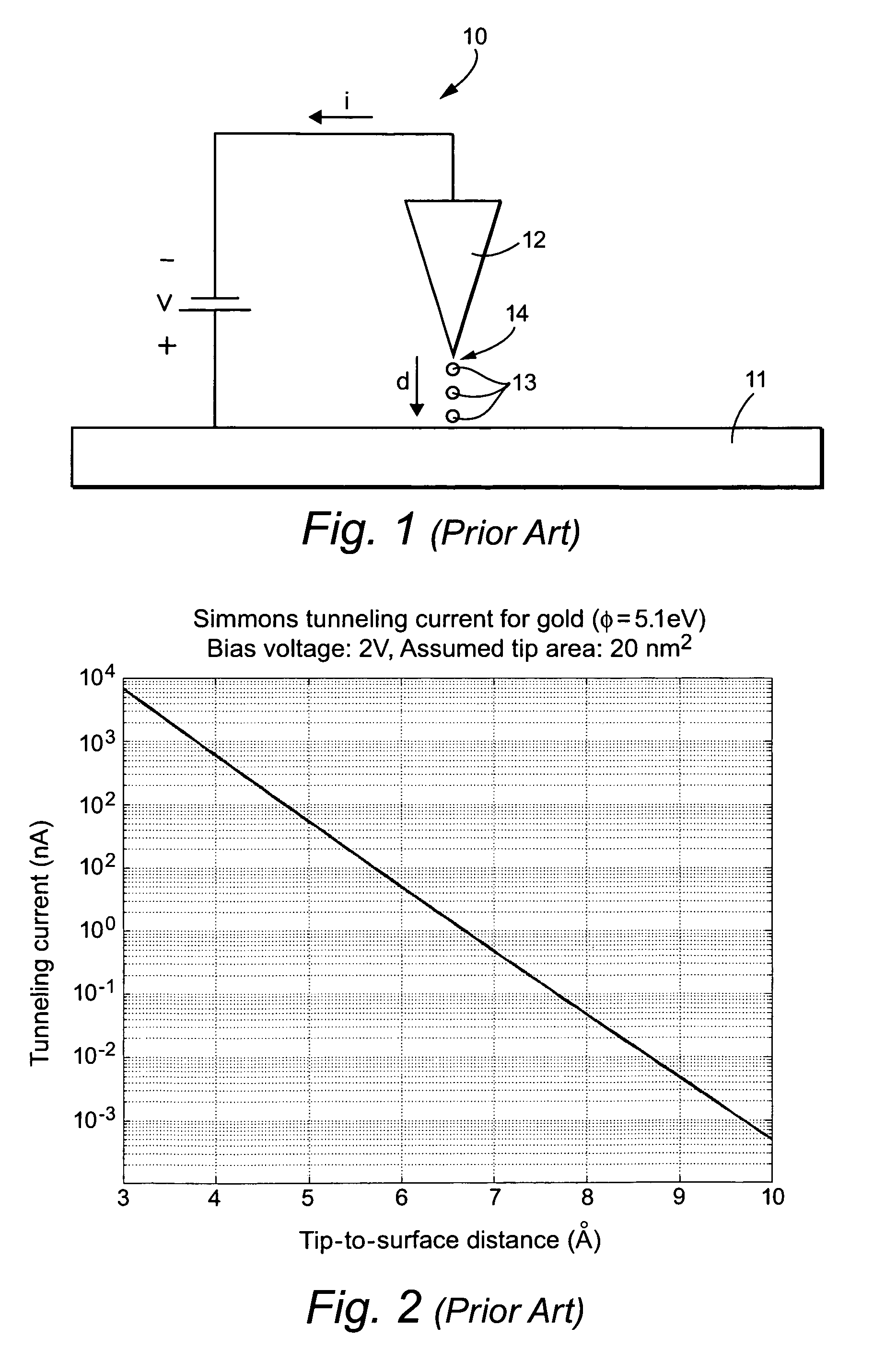

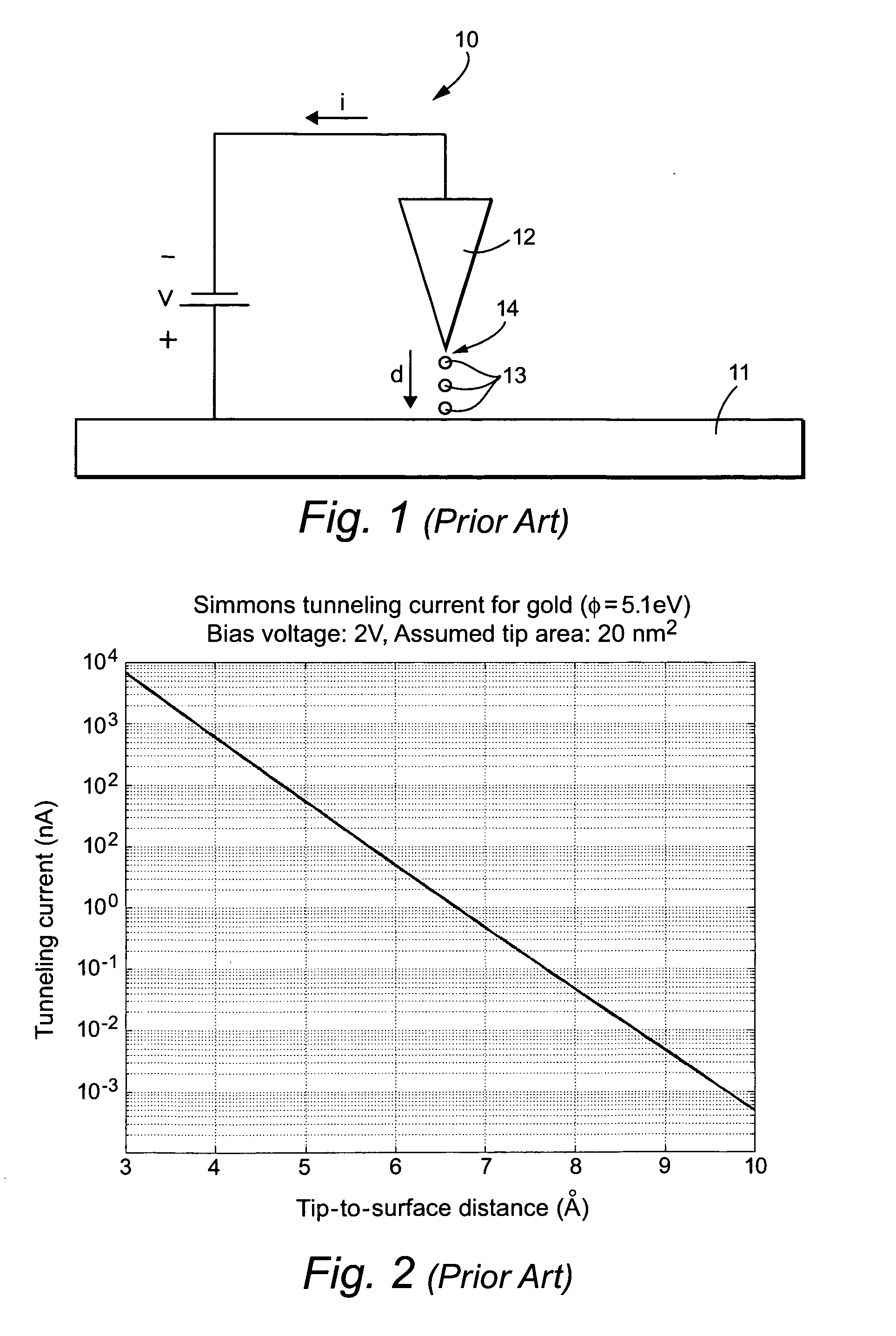

Miniature acoustic detector based on electron surface tunneling

ActiveUS7280436B2Reduce viscous damping and associated noiseReduce vibration sensitivitySemiconductor electrostatic transducersSeismic signal receiversEngineeringSound pressure

Owner:FOR NAT RES INITIATIVES

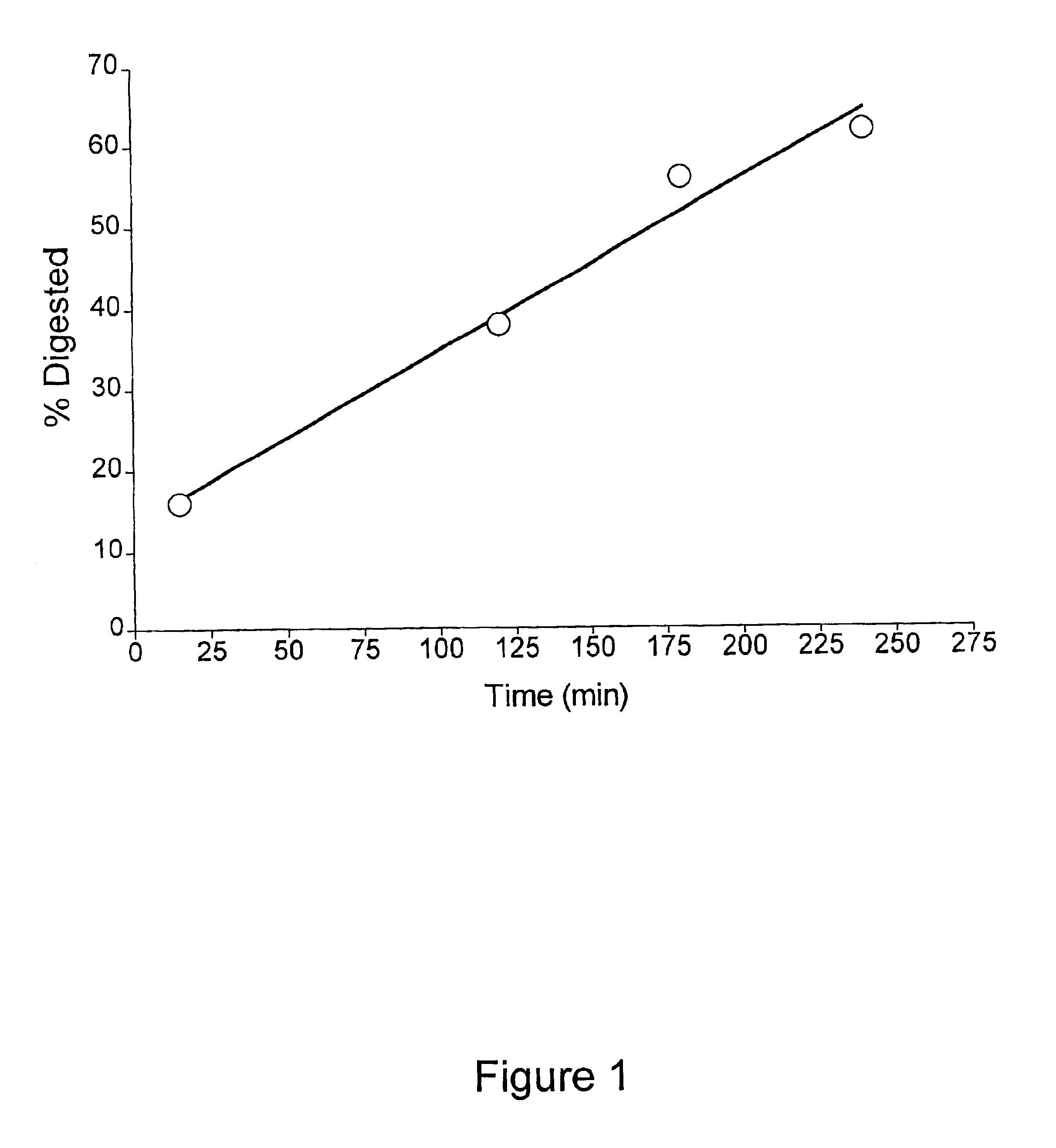

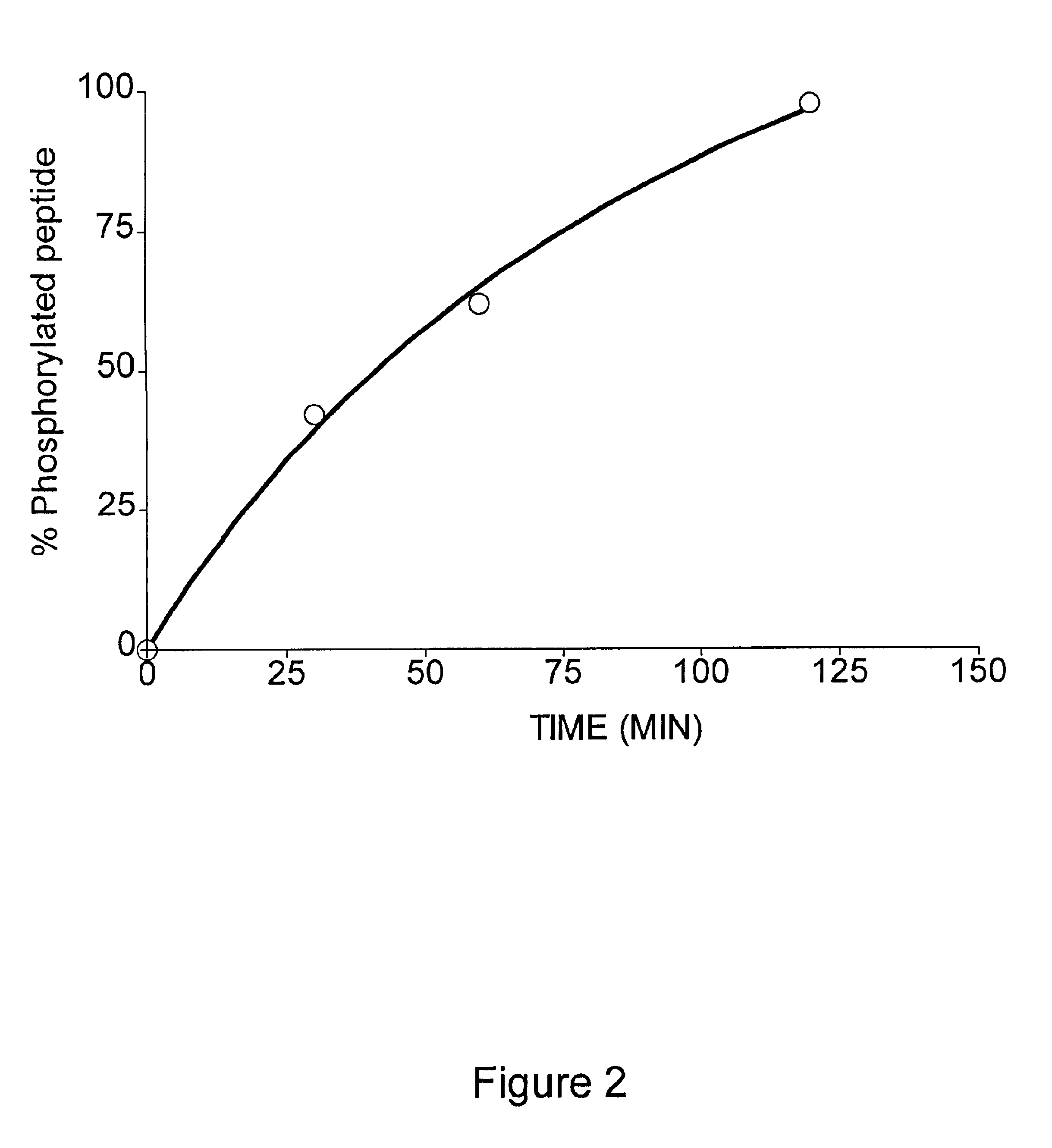

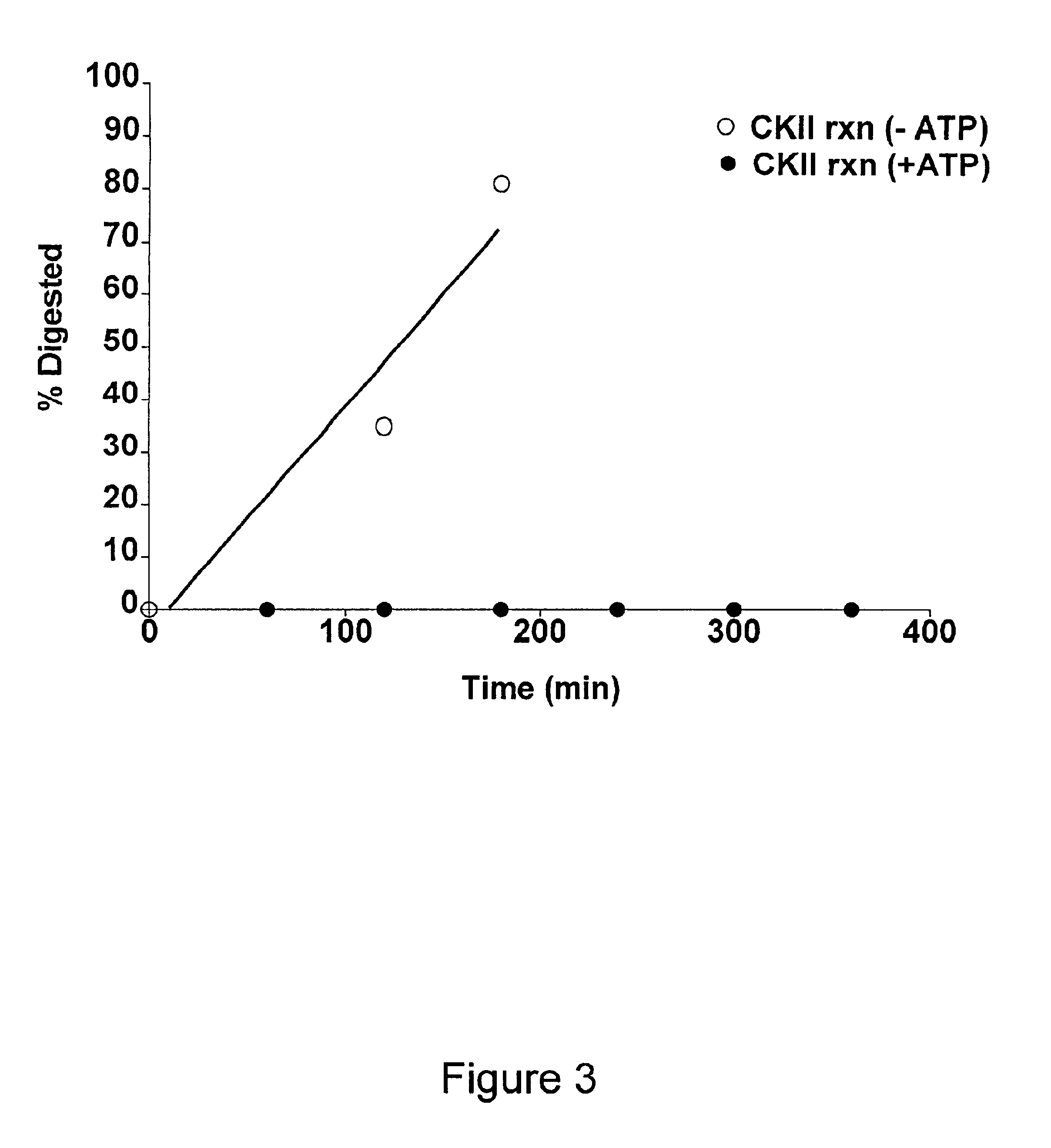

Methods for measuring kinase activity

InactiveUS6942987B2Compound screeningApoptosis detectionKinase activityHigh-Throughput Screening Methods

A method for determining the level of kinase activity or phosphatase activity in a sample without the use of antibodies or radioactive labels is disclosed. The method employs a fluorescently-labeled phosphorylatable reporter peptide that is capable of being cleaved by a protease only when the peptide is in an unphosphorylated state. A change in fluorescence characteristics is an indication that the peptide is cleaved and, therefore, in an unphosphorylated state. Thus, the level of protease cleavage, as measured by the fluorescence change, provides a direct measure of phosphatase activity whereas the level of kinase activity is inversely proportion to the level of protease cleavage. The method is particularly well suited to high throughput screening, for example, for screening compounds which modulate kinase or phosphatase activity.

Owner:PHARMACOPEIA DRUG DISCOVERY INC

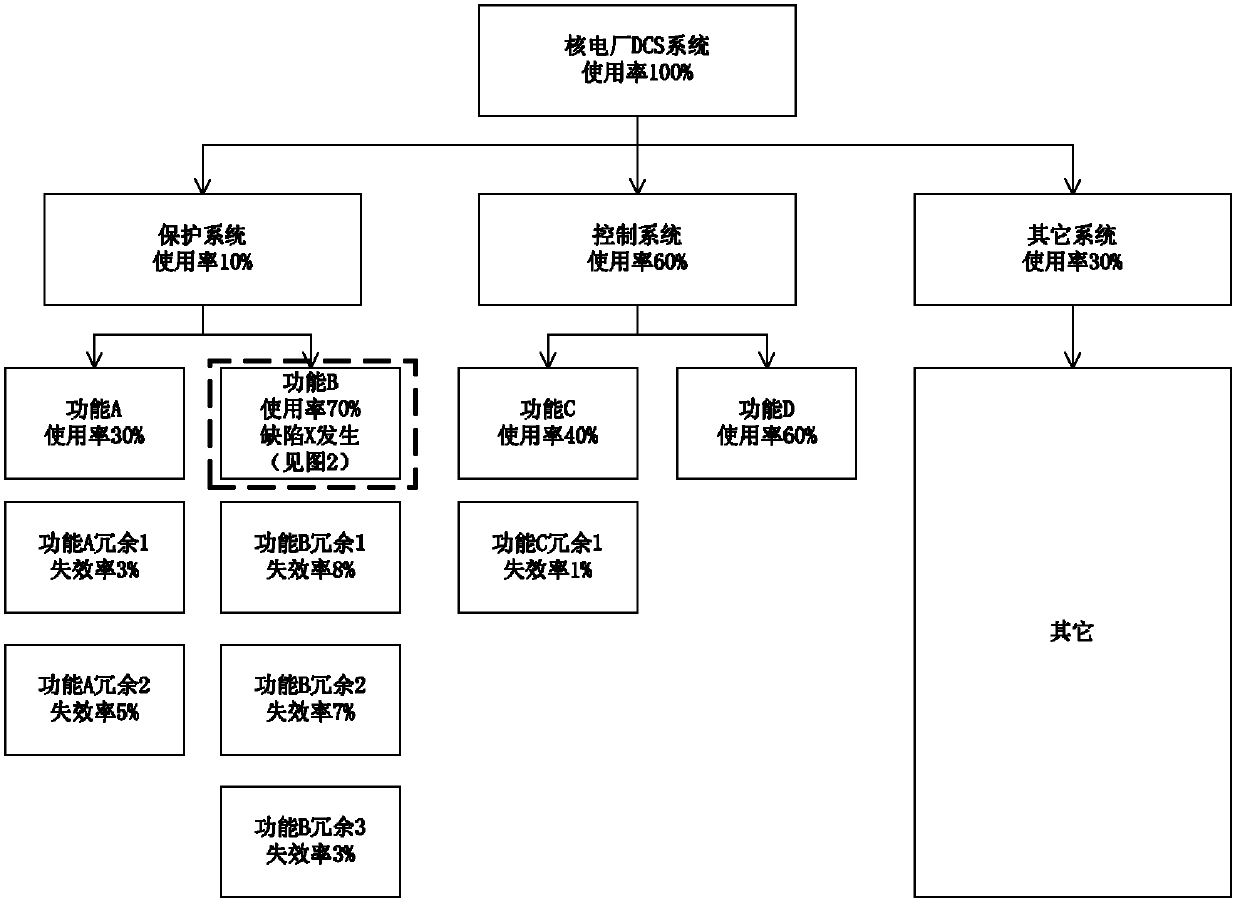

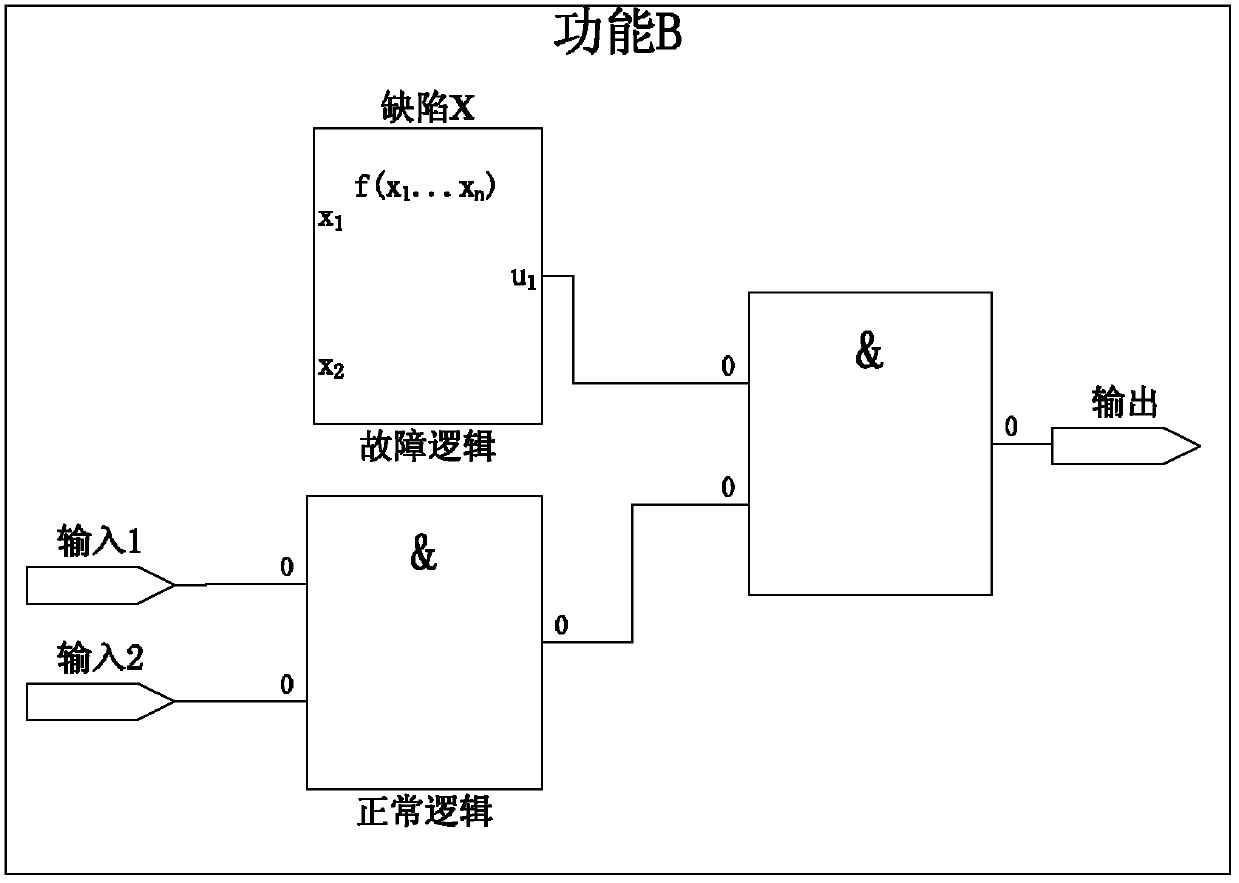

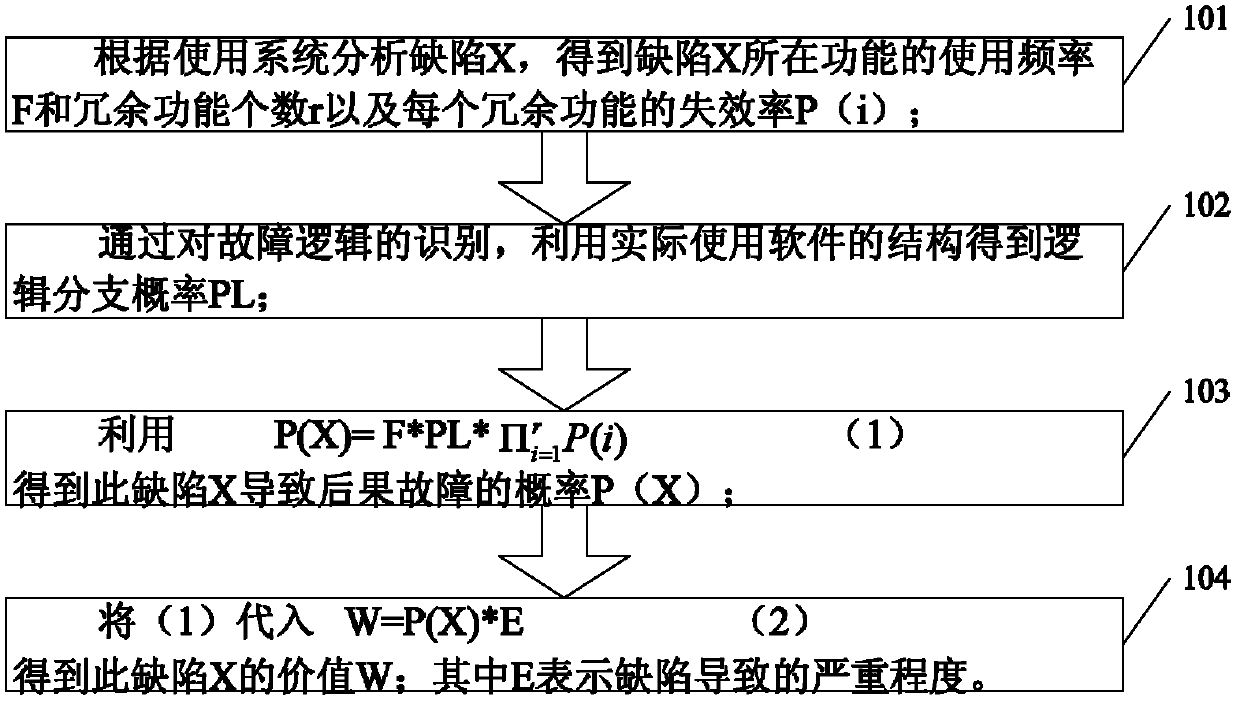

Method for quantitatively evaluating value of security level DCS (Data Communication System) application software defect for nuclear power plant

The invention discloses a method for quantitatively evaluating a value of a security level DCS (Data Communication System) application software defect for a nuclear power plant, which comprises the following steps of: 1, analyzing a defect X according to a used system, and obtaining a use frequency F and a number r of redundancy functions of a function on which the defect X is located and the failure rate P(i) of each redundancy function; 2, utilizing a structure of actually used software to obtain logical branch probability PL through recognition of fault logic; 3, utilizing P(X)=F*PL*Pi<i=1><r> (1) to obtain probability P(X) of fault caused by the defect X; and 4, taking the step (1) into W=P(X)*E(2) to obtain a value W of the defect X. The method disclosed by the invention provides a significant reference for directly judging the contribution of nuclear power plant security level DCS application software V&V (Verification & Validation) personnel or software testers to a project, design quality of designers and the like.

Owner:CHINA TECHENERGY +1

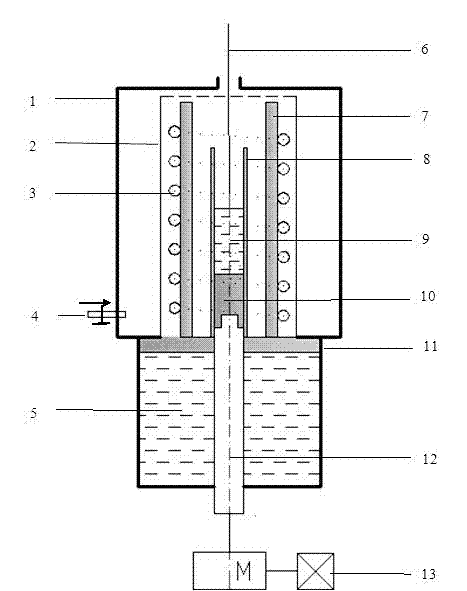

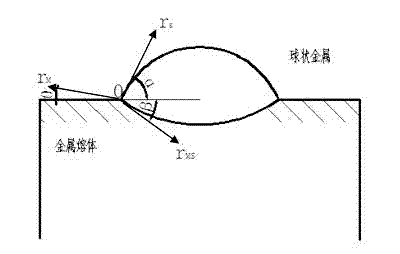

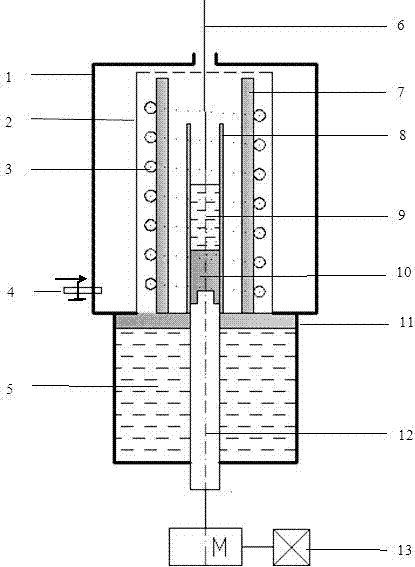

Method and device for determining material solid/liquid interfacial energy by experiment

The invention relates to a method and a device for determining material solid / liquid interfacial energy by experiment, and belongs to the field of solidification technology in material preparation. The invention is characterized by comprising the following steps that: A, a metal ingot is cut into a cylindrical bar with a proper size through a wire cutting machine; the cylindrical bar is cleaned up and dried by a blow drier; the dried cylindrical bar is placed into a suited alundum tube and is fixed on a draw bar; the draw bar with the dried cylindrical bar as a sample, a cooling tank and a servo motor are assembled well; and a position of the sample in a heating system is adjusted by the draw bar and it is ensured that a part of the sample bar is melted well; B, argon as protective gas isfed into the heating system; after 20 minutes, the heating system is started, when a temperature in a furnace of the heating system rises to an objective temperature, the temperature in the furnace is kept for a period of time to ensure the stabilization of heat flow in the furnace; C, a metal globular solid which is congener with the sample is placed on the surface of the molten sample from the upper portion of the device; when the surface of the metal globular solid is infiltrated with the molten sample, a servo drawing system is started; the sample is pulled down fast and enters into the cooling tank to be quenched and thus a feature of a solid / liquid interface is maintained; and a contact angle value is obtained by a direct measure and is substituted into an interfacial tension balance formula and interfacial energy is calculated out by the formula. The present device realizes a core idea that a feature of a solid / liquid interface of a sample at a high temperature is maintained byfast quenching.

Owner:SHANGHAI UNIV

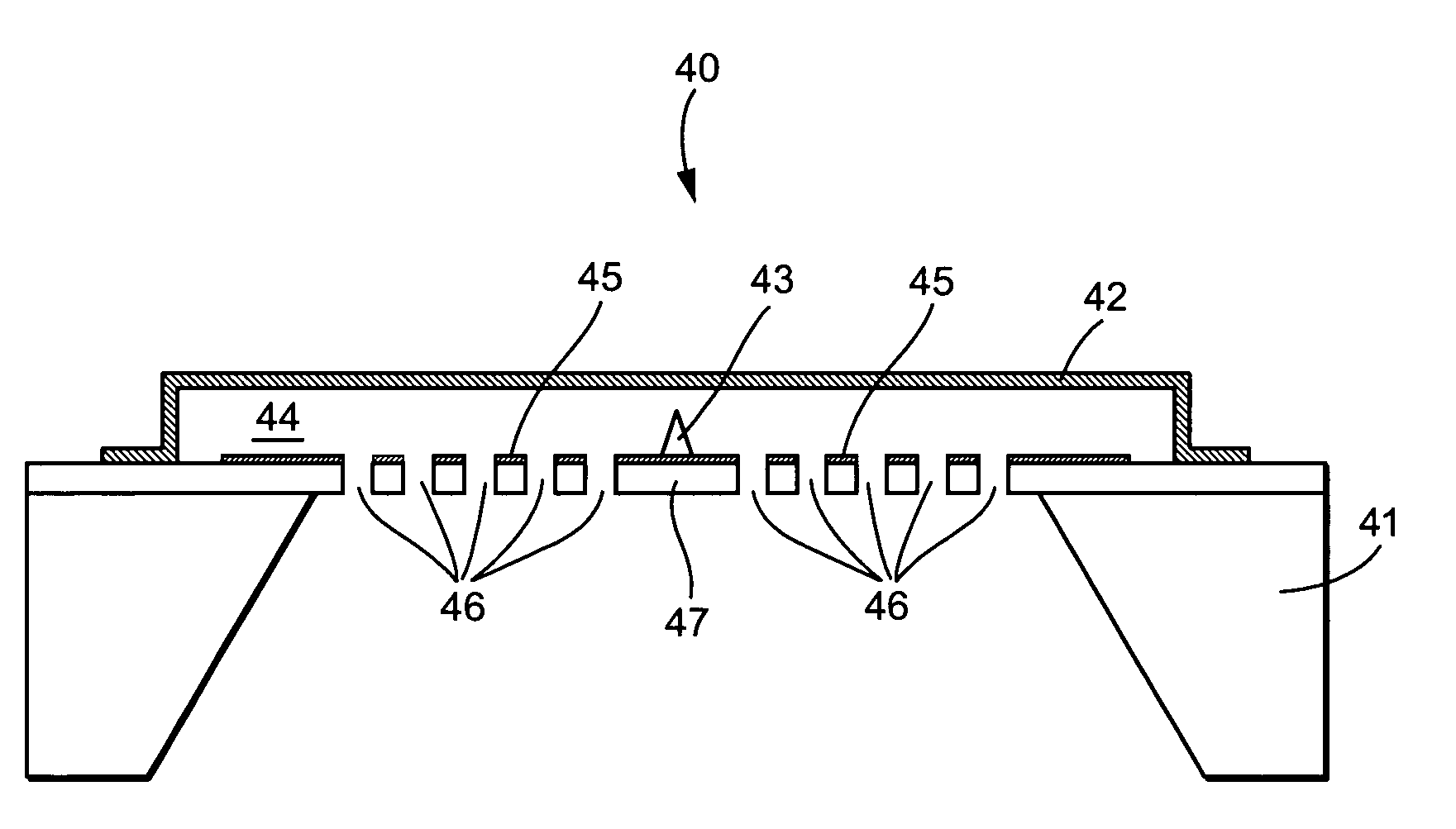

Miniature acoustic detector based on electron surface tunneling

ActiveUS20050249041A1Reduce vibration sensitivityReduce noiseSemiconductor electrostatic transducersSeismic signal receiversEngineeringSound pressure

An electronic surface tunneling acoustic detector or microphone with very high sensitivity is disclosed. A tunneling tip is mounted on a rigid perforated suspension plate, along with control electrodes, which are used to move a conductive membrane suspended above the suspension plate into closer or farther proximity with the tunneling tip. An electrical potential between the control electrodes and membrane, causing the membrane to bend towards the electrodes, and hence the tip, due to electrostatic attraction. As the membrane is pulled toward the tunneling tip, at some point a tunneling current begins to flow in the tunneling tip. The control voltage is subsequently adjusted to achieve a steady-state tunneling current in the tip. As the membrane responds to differential acoustic pressure variations, it moves and therefore upsets the steady state tunneling current. In a feedback loop instantly and constantly adjusts the control voltage to return the membrane to the steady-state condition. As a result, the adjustment of the control voltage is a direct measure of any sound pressure incident upon the membrane.

Owner:FOR NAT RES INITIATIVES

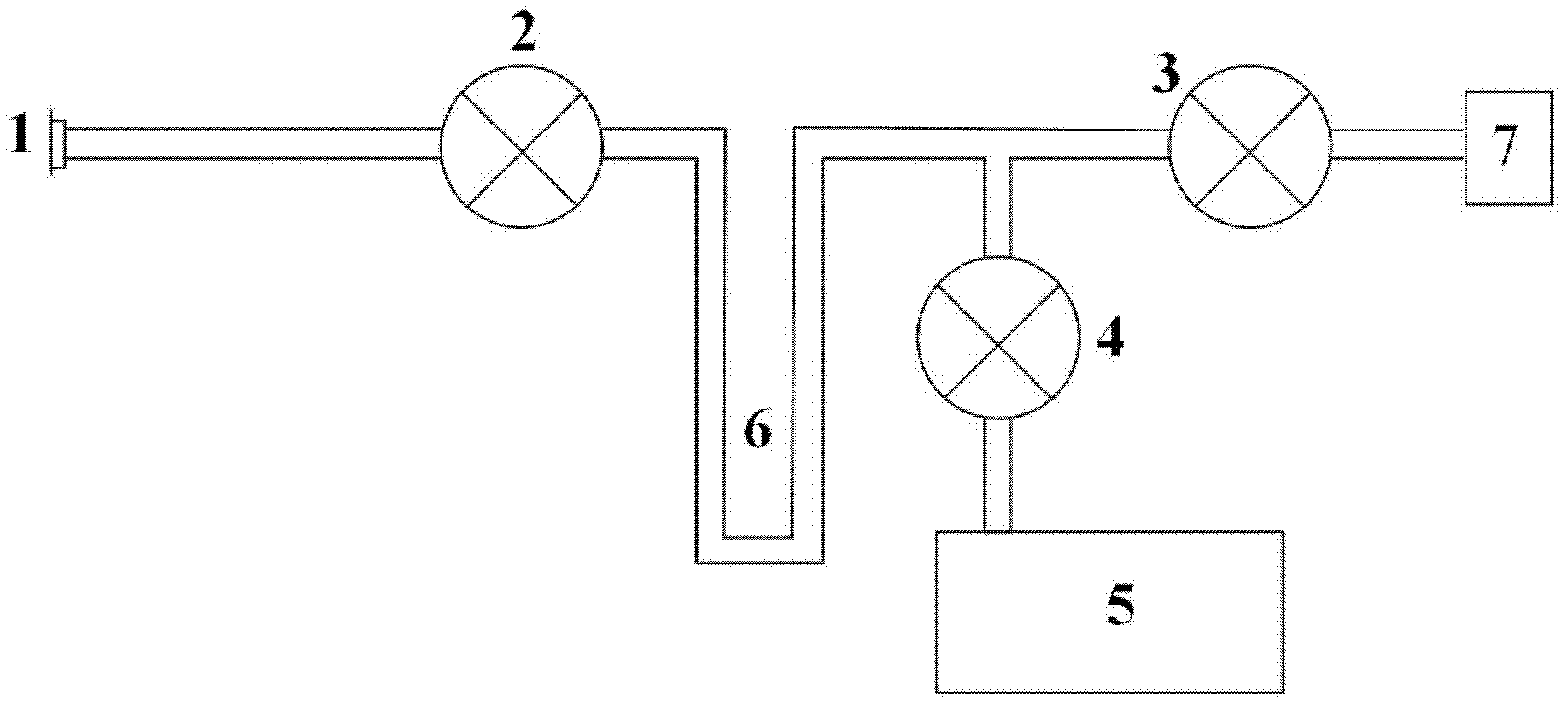

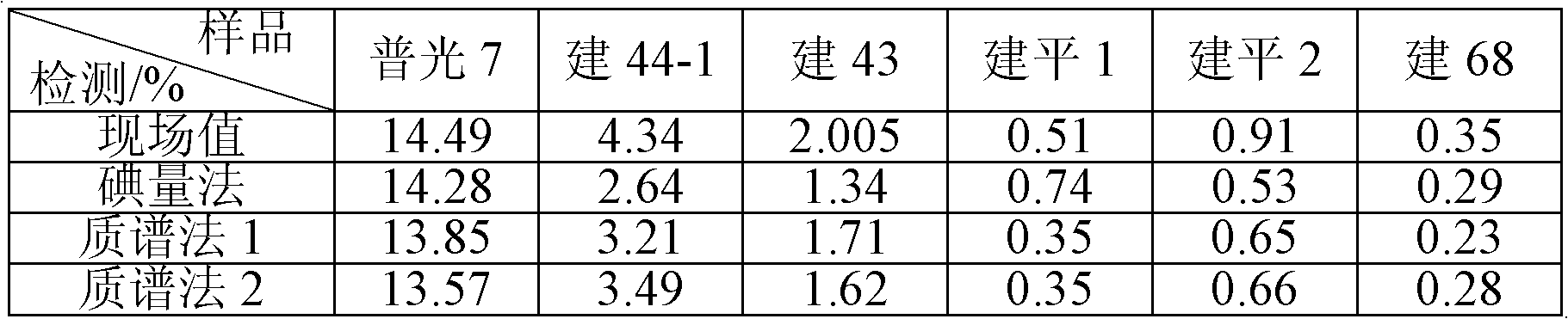

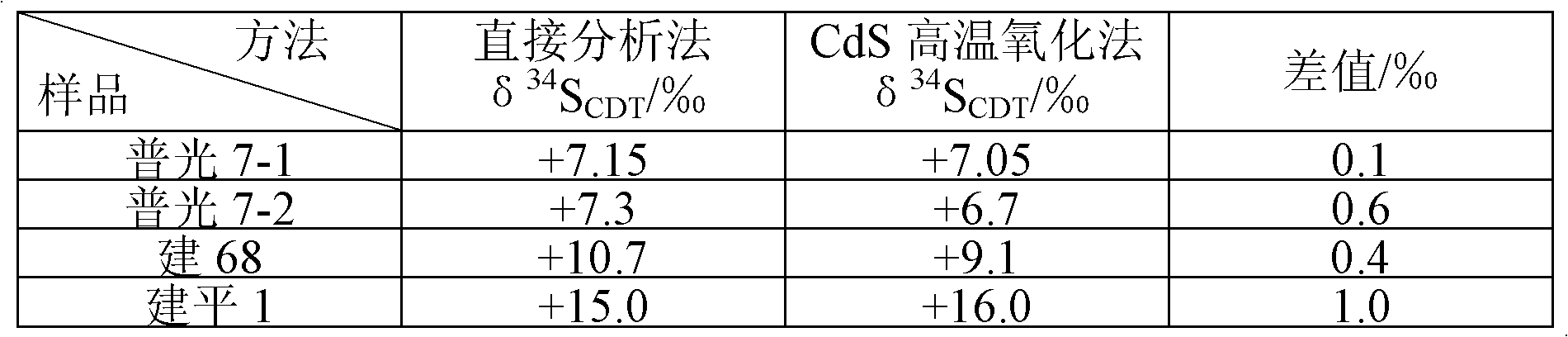

Direct measuring apparatus and measuring method for hydrogen sulfide content and sulfur isotope in natural gas

The invention discloses a direct measuring apparatus and a measuring method for hydrogen sulfide content and sulfur isotope in a natural gas. The measuring apparatus comprises an injection port, a U-shaped cold trap and a mass spectrometer, wherein one end of the U-shaped cold trap is connected with the injection port; the other end of the U-shaped cold trap is connected with the mass spectrometer; a vacuum valve A is disposed on a pipeline between the injection port and the U-shaped cold trap; a vacuum valve B is disposed on a pipeline between the U-shaped cold trap and the mass spectrometer, a vacuum pump is communicated with the pipeline between the U-shaped cold trap and the vacuum valve B through the pipeline; a vacuum valve C is disposed on the vacuum pump; and the apparatus is a sealed apparatus. The measuring method comprises that the natural gas is directly introduced to a mass spectrometer for measuring the hydrogen sulfide content and sulfur isotope after being enriched by the U-shaped cold trap. The apparatus and the method can be used for measuring by the mass spectrometer, and have the characteristics of accurate data, simple operations, little sample, rapid analysis speed, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and apparatus for biometric identification

InactiveCN101548496AEliminate measurement errorsReduce false reject rateSecret communicationVisual perceptionComputer science

The invention describes the first practical, cost effective, truly non-contact implementation of a subcutaneous vein pattern biometric sensor. A laser diode (LD) illuminates the hand in such a way that the pattern of reflected radiation, when viewed by a conventional vein pattern infrared imager, provides a direct measure of target range. Said target range measurement is used to create a visual or audio signal that instructs the individual being scanned to place the hand at precisely the optimum range, such that the vein pattern is in focus. Furthermore, a system and apparatus are described to direct the individual being scanned to move the hand to an optimal horizontal registration or position with respect to the infrared imager.

Owner:CERNI CONSULTING

Layout system for consistent user interface results

InactiveUS7516400B2Suitable displayBiological modelsExecution for user interfacesParallel computingMaximum size

Owner:MICROSOFT TECH LICENSING LLC

Method of operating a hearing instrument based on an estimation of present cognitive load of a user and a hearing aid system

InactiveUS20160080876A1Easy to customizeImprove comfortPsychotechnic devicesElectronic input selection/mixingData processing systemHearing aid

A method of operating a hearing instrument for processing an input sound and to provide an output stimulus according to a user's particular needs, and related system, computer readable medium and data processing system. An object is to provide an improved customization of a hearing instrument. The method includes the steps a) providing an estimate of the present cognitive load of the user; b) providing processing of an input signal originating from the input sound according to a user's particular needs; and c) adapting the processing in dependence of the estimate the present cognitive load of the user. The estimate of the present cognitive load of a user is produced by in-situ direct measures of cognitive load (e.g. based on EEG-measurements, body temperature, etc.) or by an on-line cognitive model in the hearing aid system whose parameters have been preferably adjusted to fit to the individual user.

Owner:OTICON

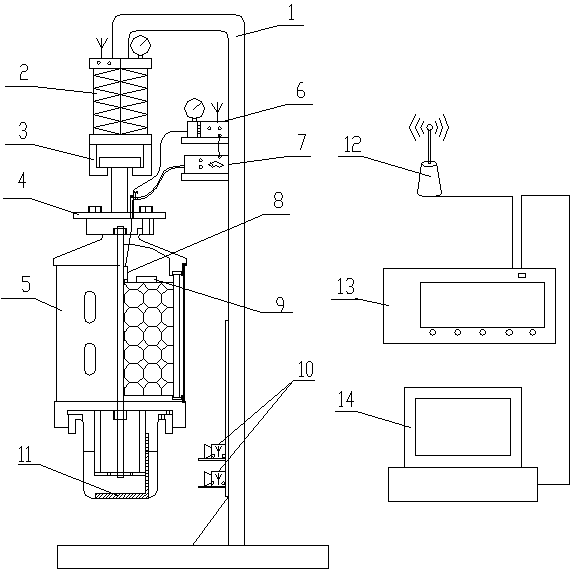

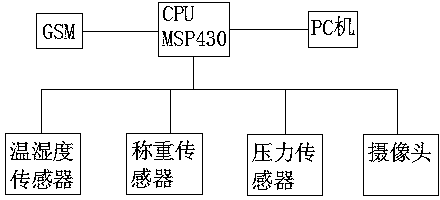

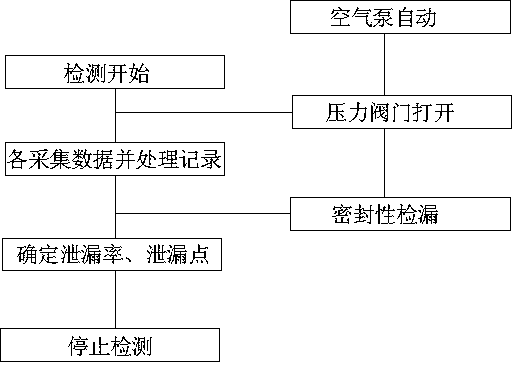

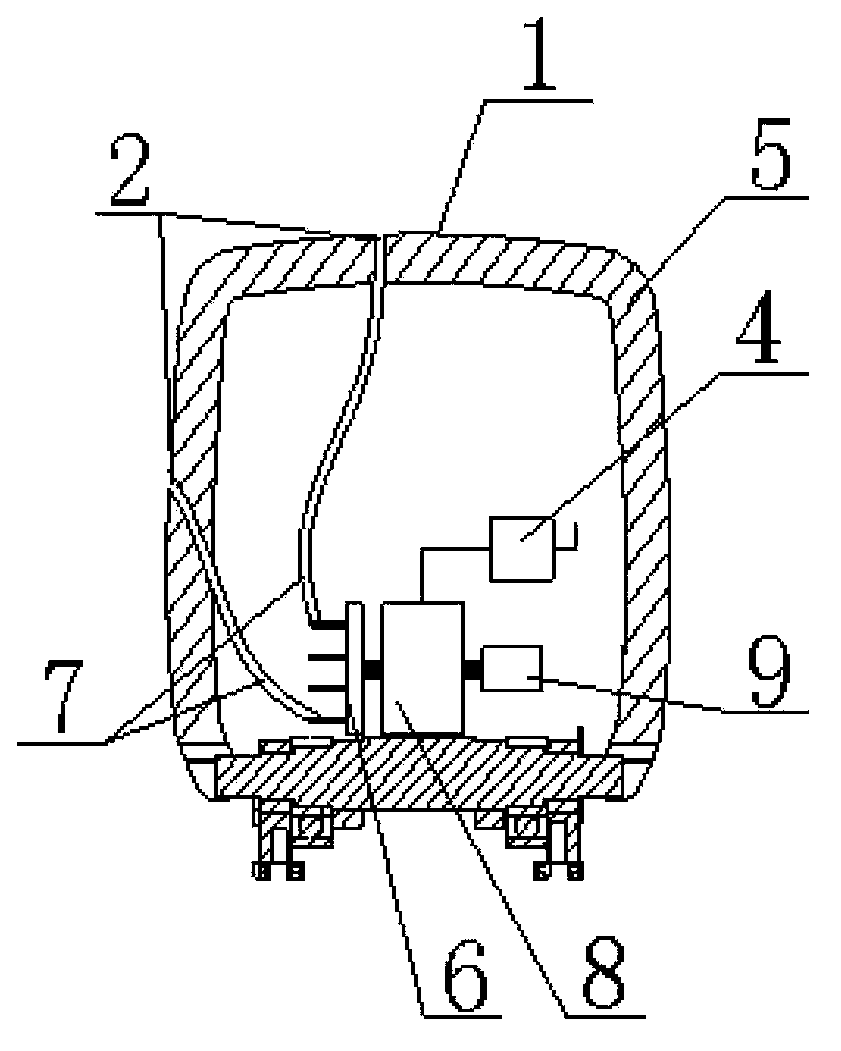

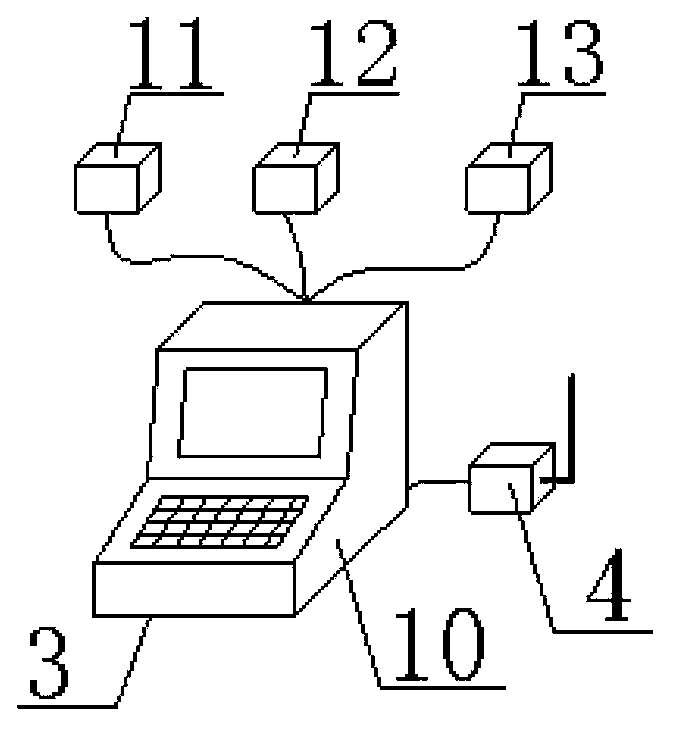

Device and method for detecting airtightness of transformer respirator

InactiveCN104280193ASolve the leak detection problemTo achieve the purpose of detection simulationMeasurement of fluid loss/gain rateRespiratorTransformer

The invention discloses a device and method for detecting the airtightness of a transformer respirator. The device comprises a supporting unit, a measuring unit and a processing unit which are adaptive to a respirator body. The supporting unit comprises a main supporting frame and an auxiliary connecting device. The measuring unit comprises a direct measuring unit and an indirect measuring unit which are distributed on the main supporting frame and the respirator body. The processing unit comprises a receiving unit and a processor and is in wireless connection with the measuring unit. The auxiliary connecting device comprises a measuring connecting frame and a measuring flange plate which are both connected with the respirator body. According to the device, the airtightness detecting fixed value of the respirator is set, under fixed pressure, the parameter information such as the temperature, the humidity, the pressure, the weight and the liquid level of the respirator is measured, airtightness detection is conducted through comparison and judgment, the real breathing normal working state of the respirator can also be simulated, a detection simulation purpose is achieved, and the airtightness detection problem before connecting power equipment is put into operation and in the maintenance process is completely solved.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

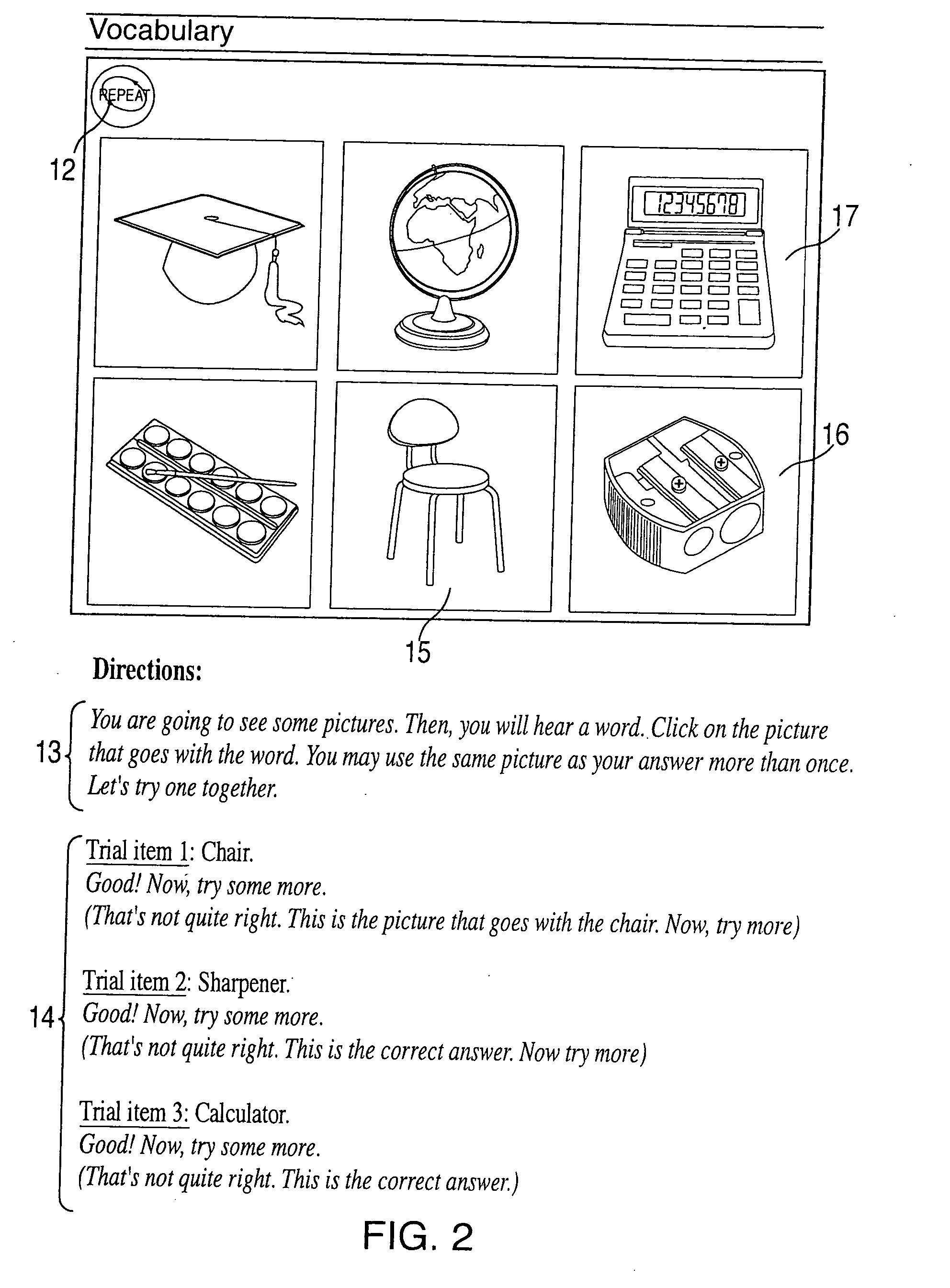

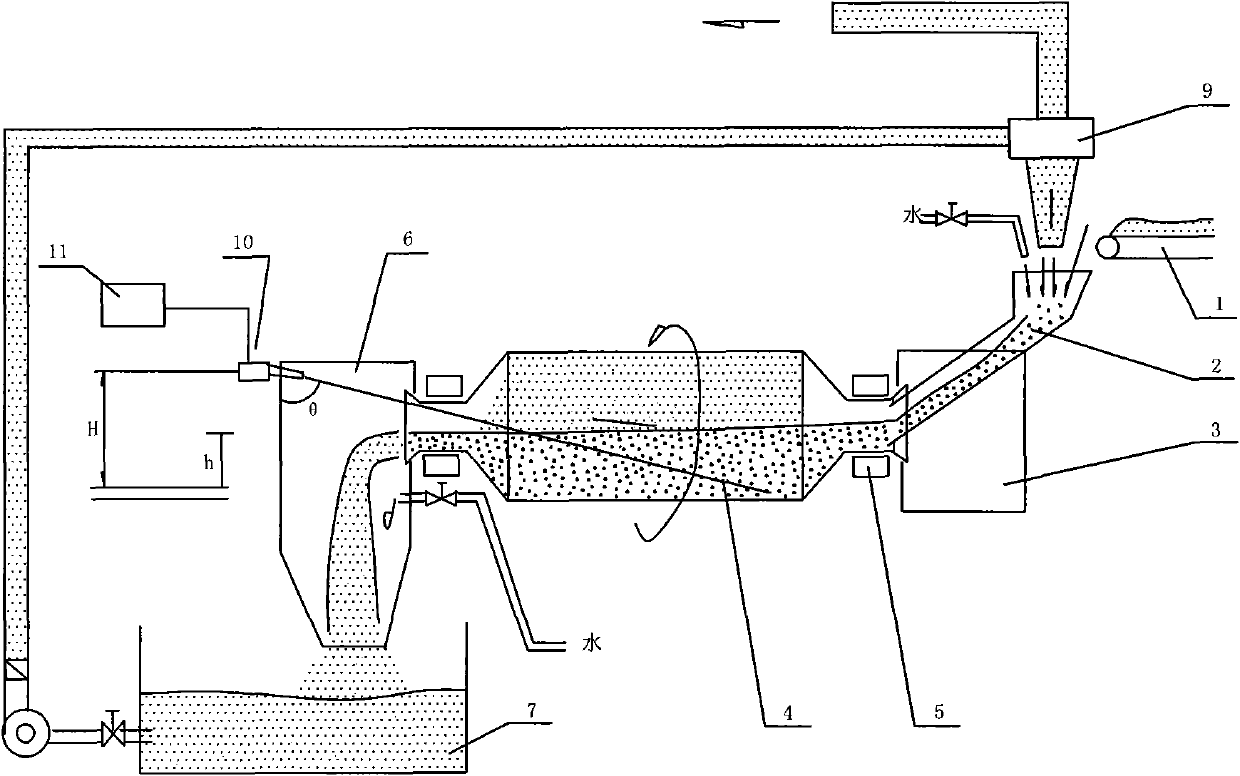

System and method for testing aerodynamic characteristics of movable train on basis of wind pressure integral

ActiveCN103389216ADiscriminant securityPossibility to implement dynamic testingAerodynamic testingRailway vehicle testingExperimental researchSimulation

A system for testing aerodynamic characteristics of a movable train on the basis of a wind pressure integral comprises a simulator (1), a wind pressure measuring point (2) and a testing device (3), wherein the simulator (1) is used for simulating the movable train; the wind pressure measuring point (2) is arranged on the simulator (1); the testing device (3) is used for acquiring aerodynamic characteristic information from the simulator (1); and the simulator (1) and the testing device (3) are mutually connected through wireless transmitting and receiving modules (4) arranged inside the simulator (1) and the testing device (3) respectively. The air pressure can be directed measured by the aid of the testing system, so that interference of the external force to an aerodynamic test result can be effectively avoided, the accuracy of the test result is guaranteed, and an technical assurance can be provided for experimental researches on the aerodynamic performance of a high-speed railway 'wind-train-bridge' system.

Owner:CENT SOUTH UNIV +1

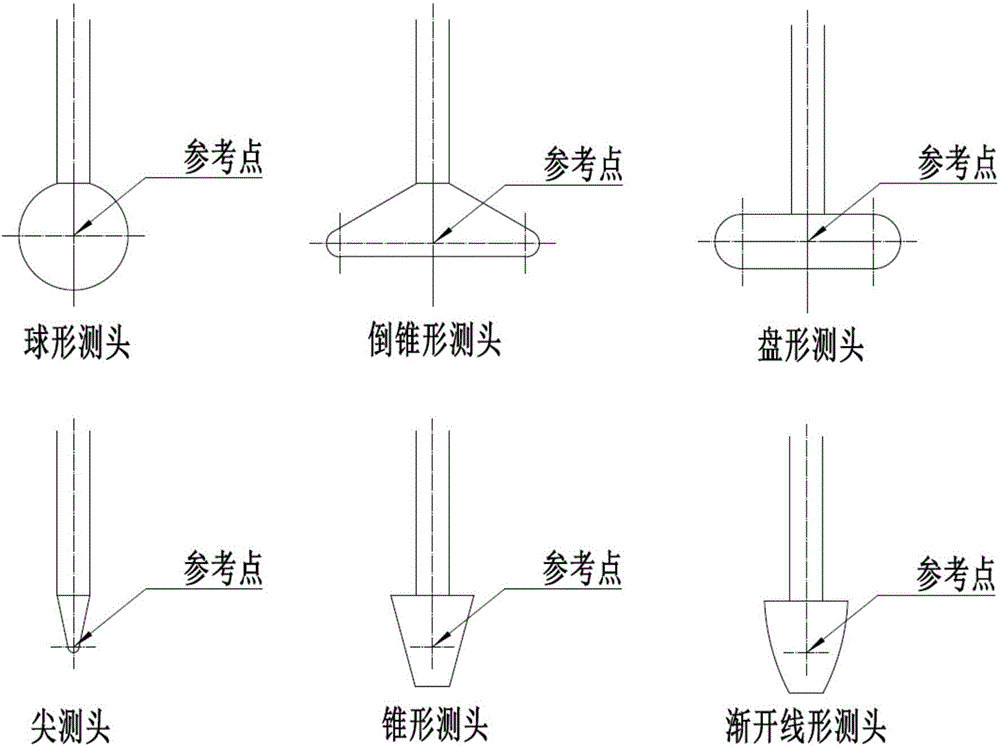

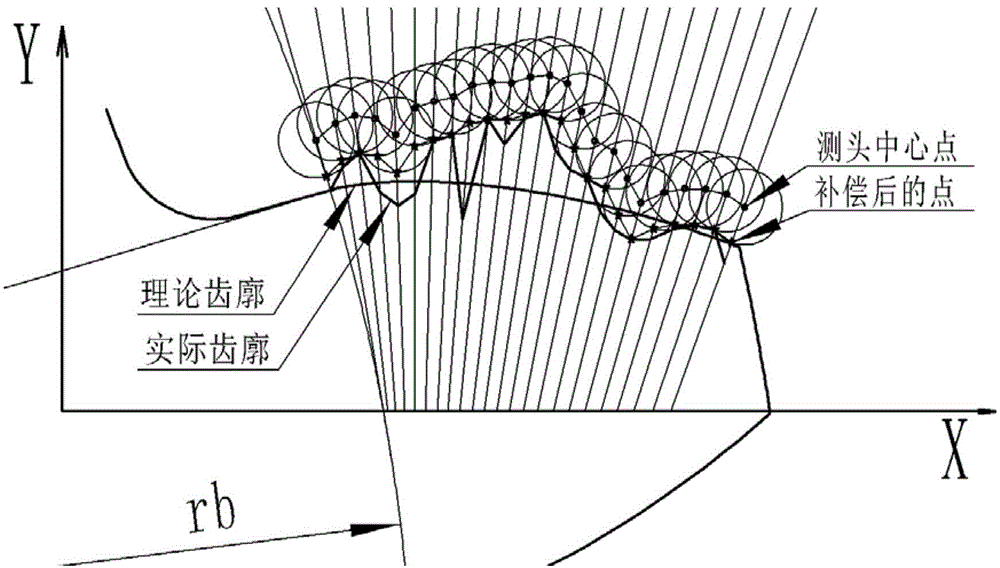

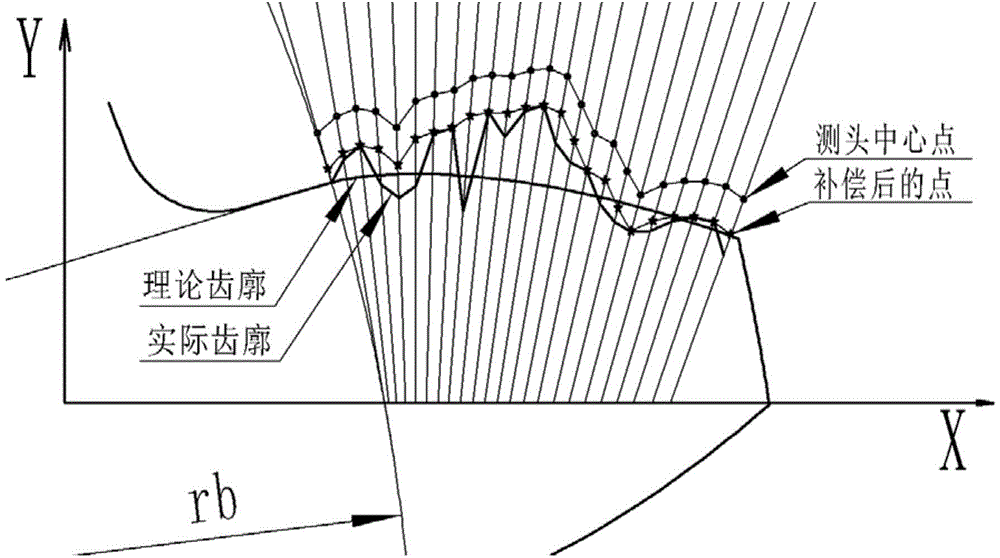

Quasi morphological filtering method for extracting two-dimensional contour in contact measuring head measurement

ActiveCN104089599A2D profile approximationMeasurement devicesMorphological filteringHead measurements

The invention discloses a quasi morphological filtering method for extracting a two-dimensional contour in contact measuring head measurement and belongs to the field of precision measurement technology and instrument technology. According to the quasi morphological filtering method for extracting the two-dimensional contour in contact measuring head measurement, the envelope lines of measuring head contour lines of the positions corresponding to all direct measured data points serve as a final two-dimensional contour measurement result. According to the method, in the two-dimensional contour extracting process, the normal direction in the contact point position does not need to be estimated, and therefore the method is particularly applicable to the situation that in precise measurement, the curvature change of a measured contour is large and even the measured contour is unsmooth.

Owner:BEIJING UNIV OF TECH

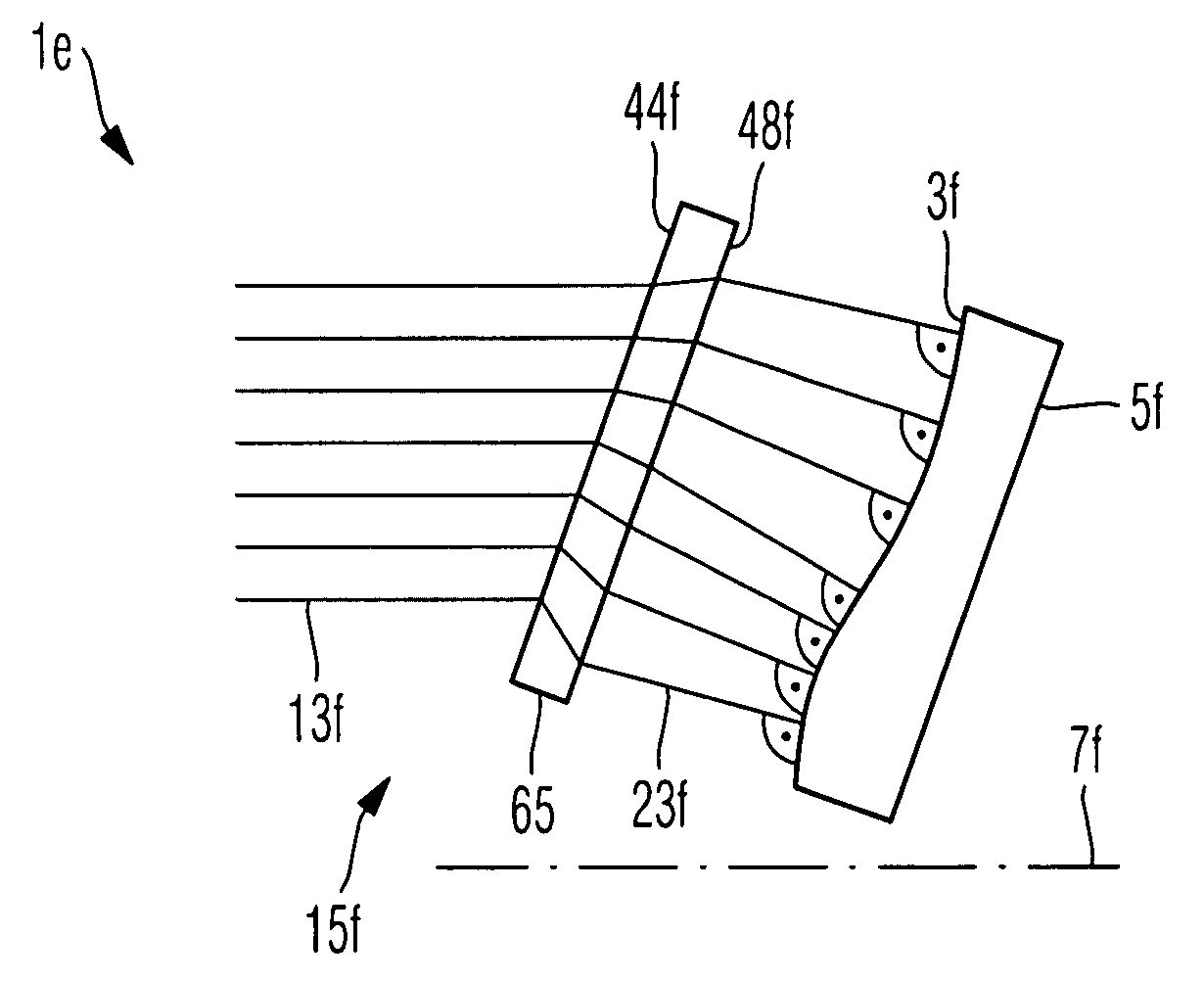

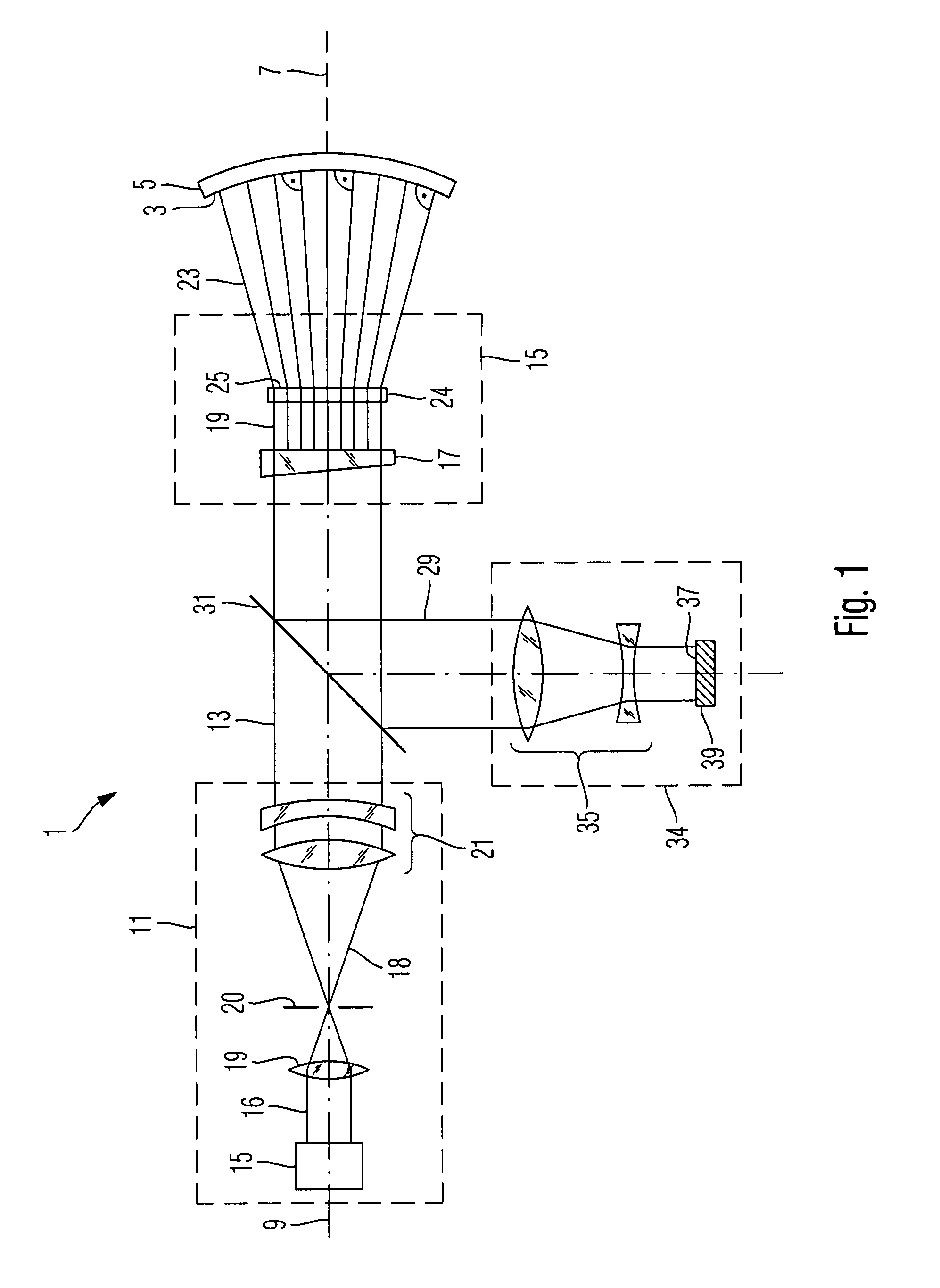

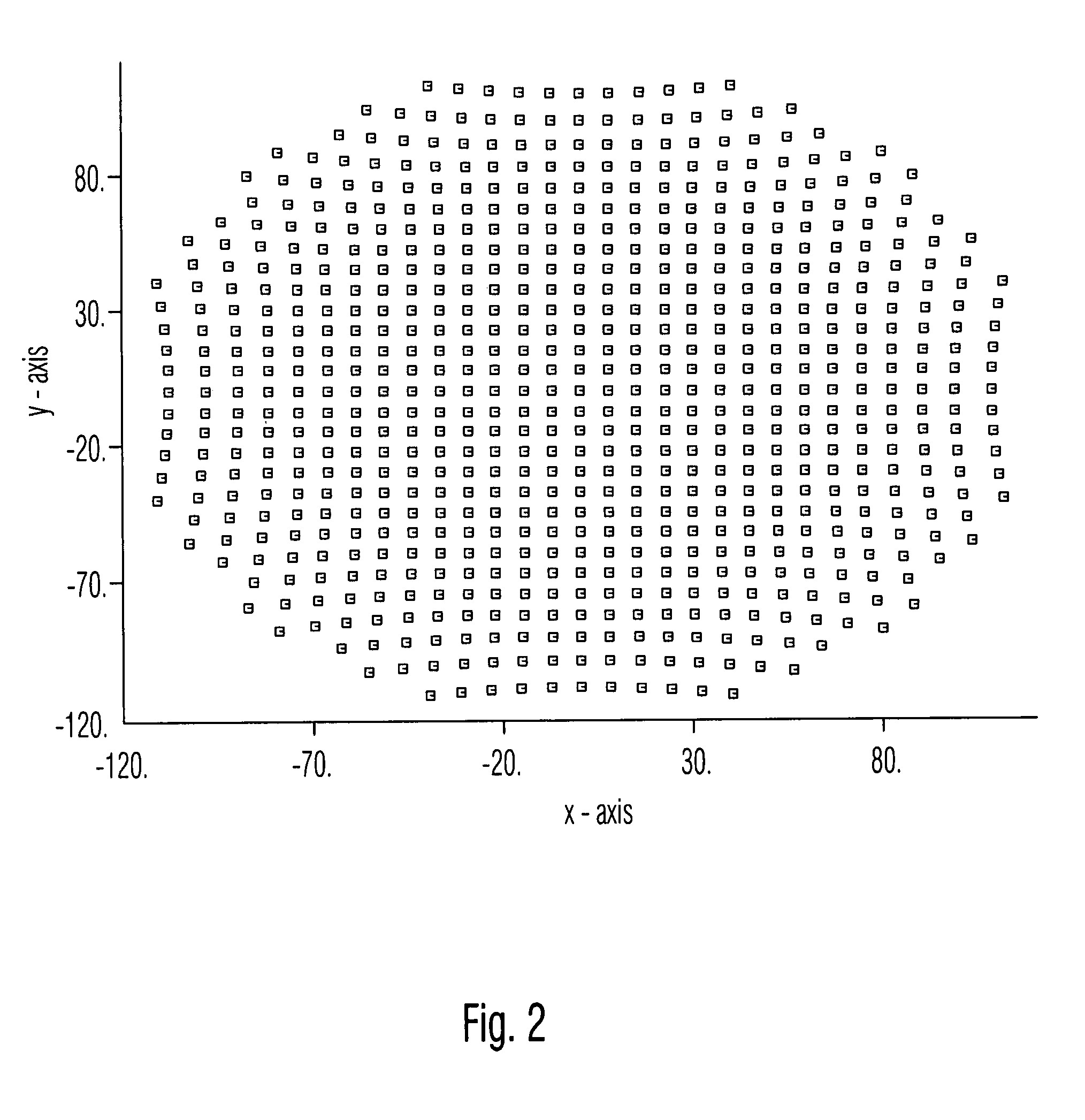

Hologram and method of manufacturing an optical element using a hologram

InactiveUS7848031B2Improve accuracyQuality improvementUsing optical meansLensOptical surfaceDirect measure

A method of manufacturing an optical element (5) comprises testing an optical surface (3) of the optical element, using an interferometer 1a directing measuring light (23a) onto the optical surface wherein the measuring light traverses two successive holograms (44, 48) disposed in the beam path of the measuring light upstream of the optical surface.

Owner:CARL ZEISS SMT GMBH

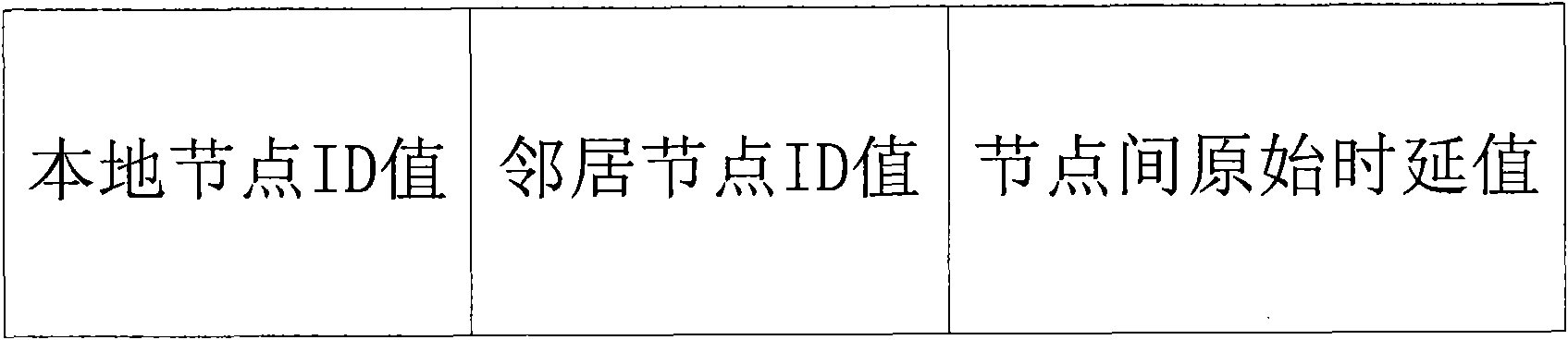

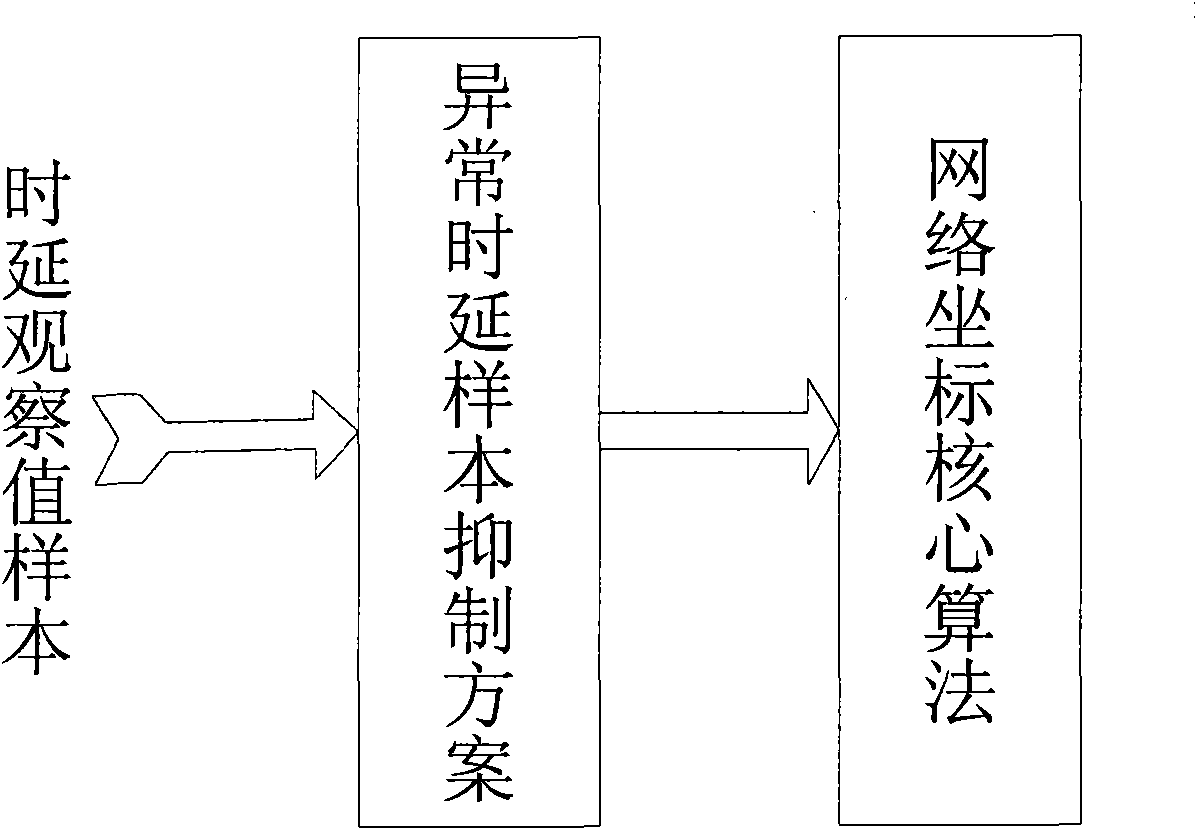

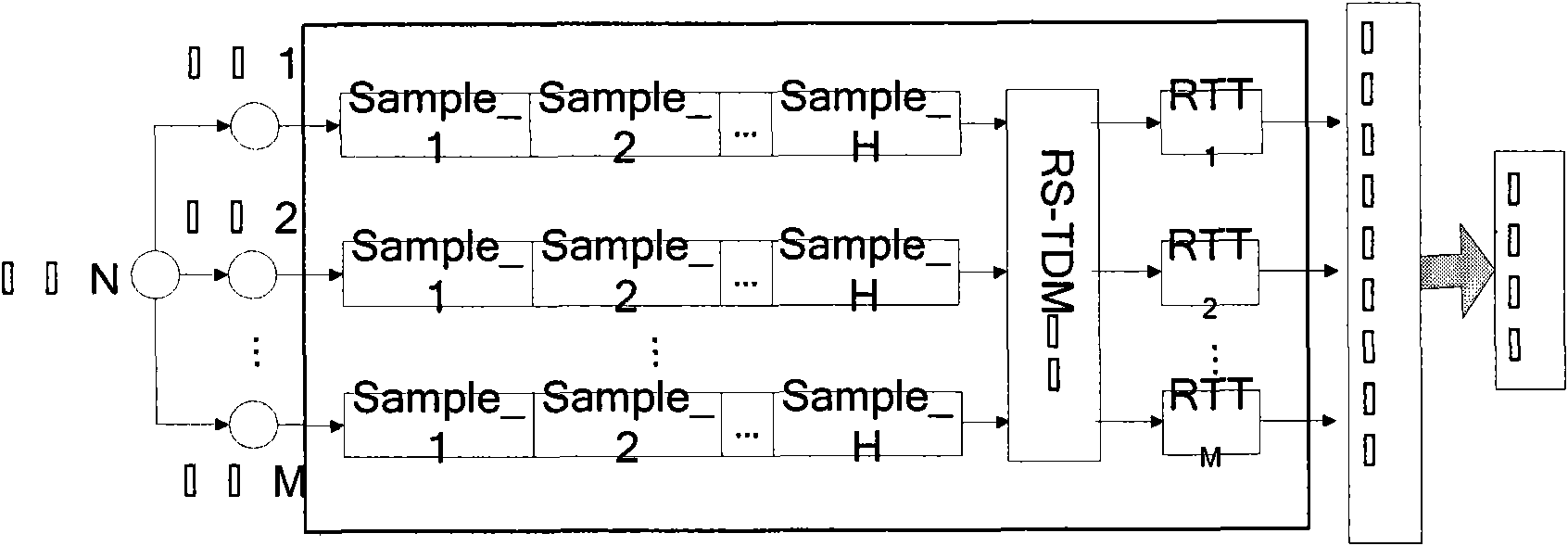

Network coordinate system input delay pre-treatment method based on t detection model

The invention discloses a network coordinate system input delay pre-treatment method based on t detection model. The method is characterized in that: each network node records nearest H direct measuring delay values between the network node and partial neighbour nodes; under the t detection model, according to the delay observed value of the delay queue, confidence interval of observed value at the next moment of the node is estimated, so as to detect and inhibit abnormal delay observed value and obtain delay result smoothly output by the node. The algorithm is based on probability theory t detection model, history record delay sample information between nodes is utilized, and the abnormal delay observed value of the node at the next moment is detected and inhibited, so as to obtain delay result smoothly output by the node, the delay result is used for carrying out network distance semi measure space embedding, thus ensuring the accuracy of the node to establish network coordinate system delay system predication and convergent cycle thereof.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

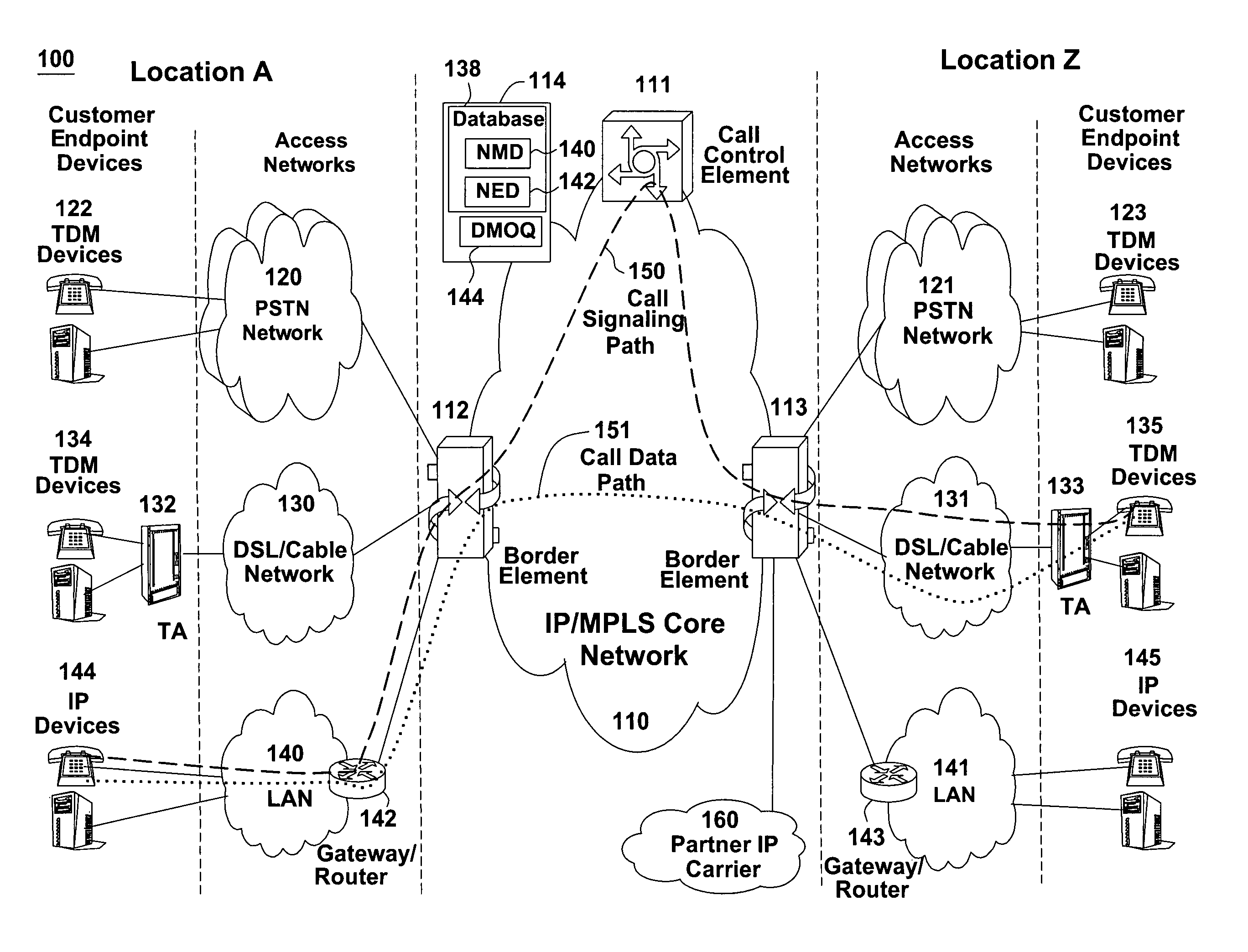

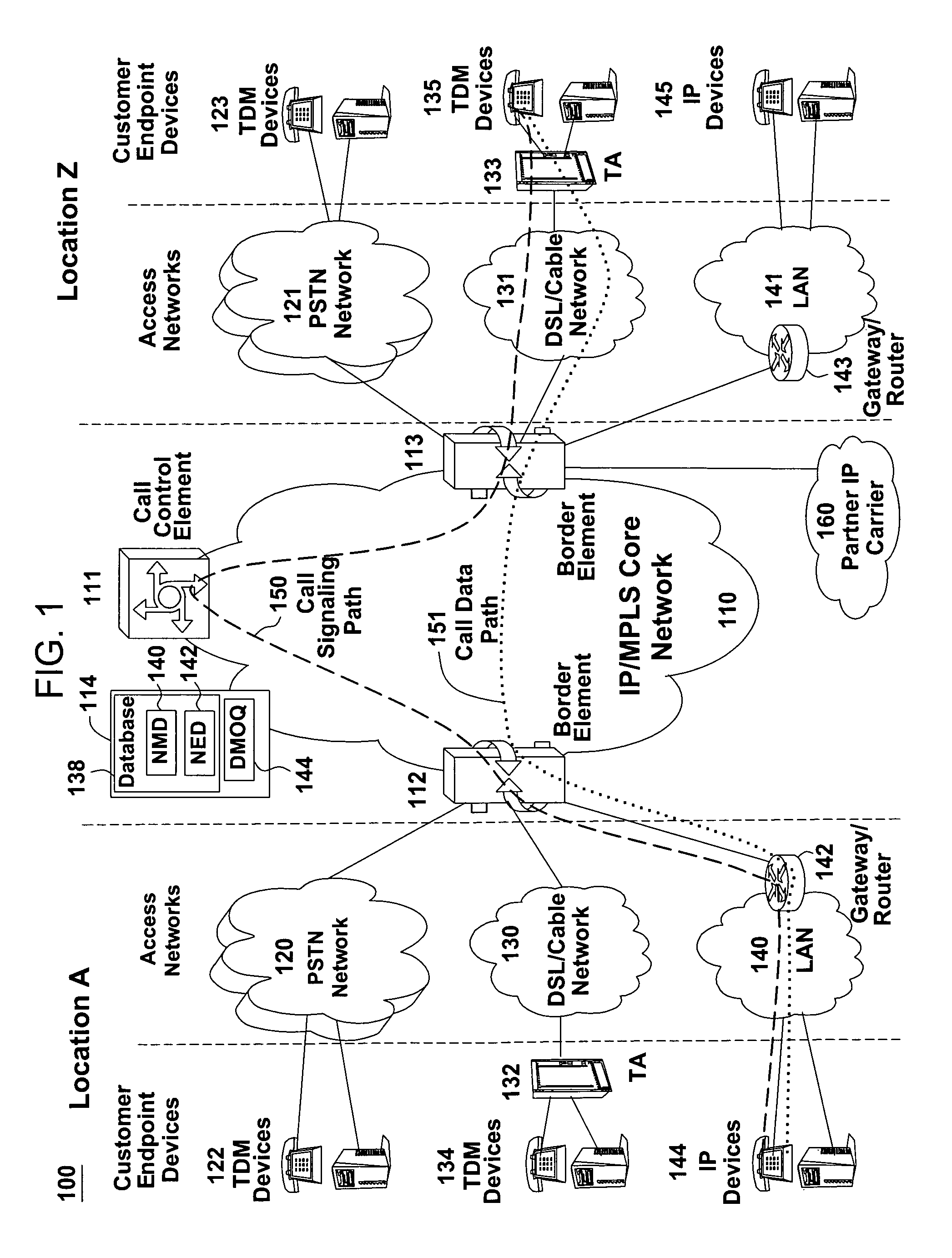

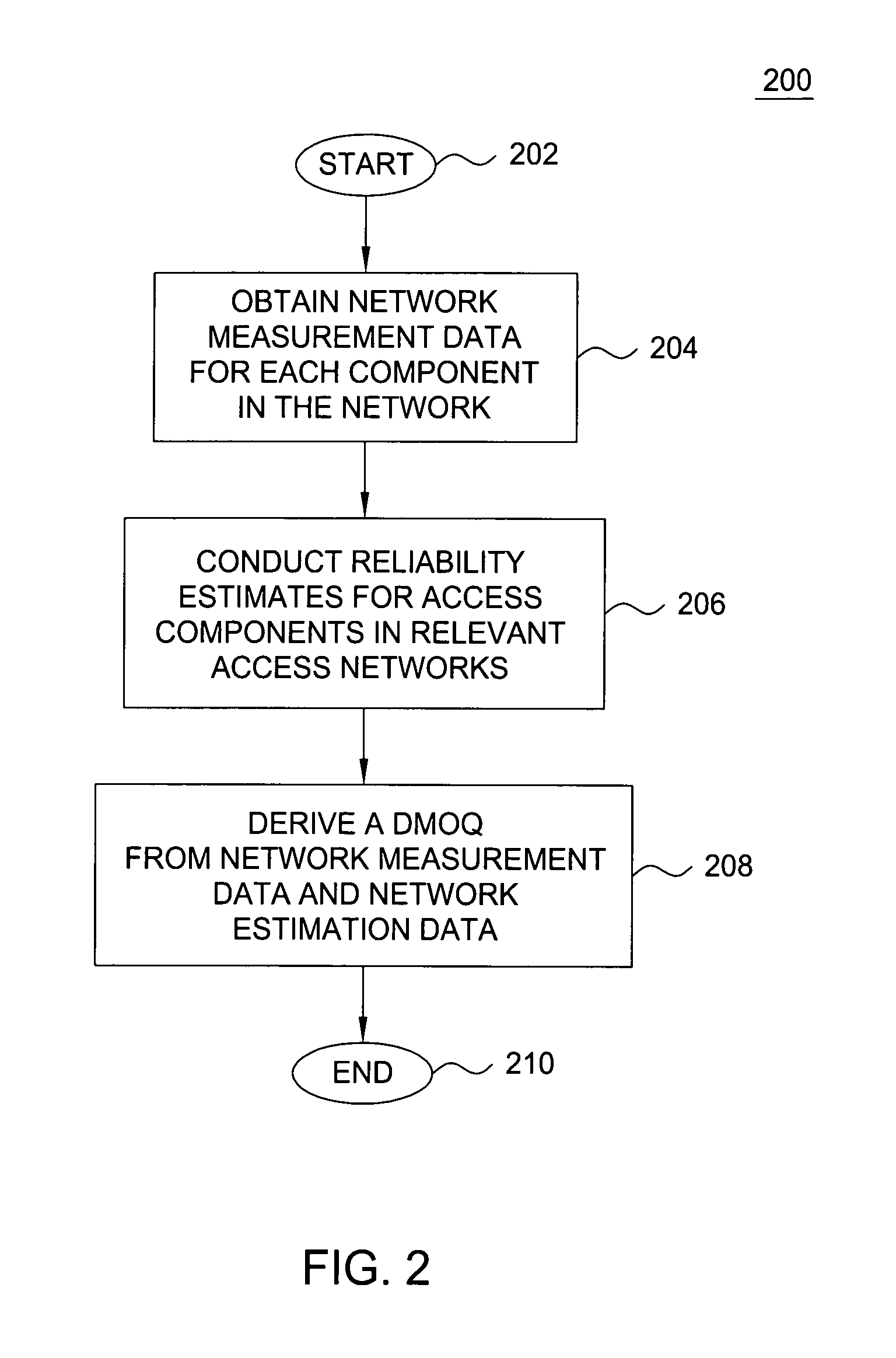

Method and apparatus for determining a direct measure of quality in a packet-switched network

A method and system for analyzing deficiencies in a packet-switched network is described. In one example, network measurement data pertaining to components within a packet-switched network are obtained. Reliability estimates of access networks and associated access links coupled to the packet-switch network are conducted. Lastly, an end-to-end direct measure of quality (DMOQ) is calculated from the network measurement data and network estimation data derived from the reliability estimates.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

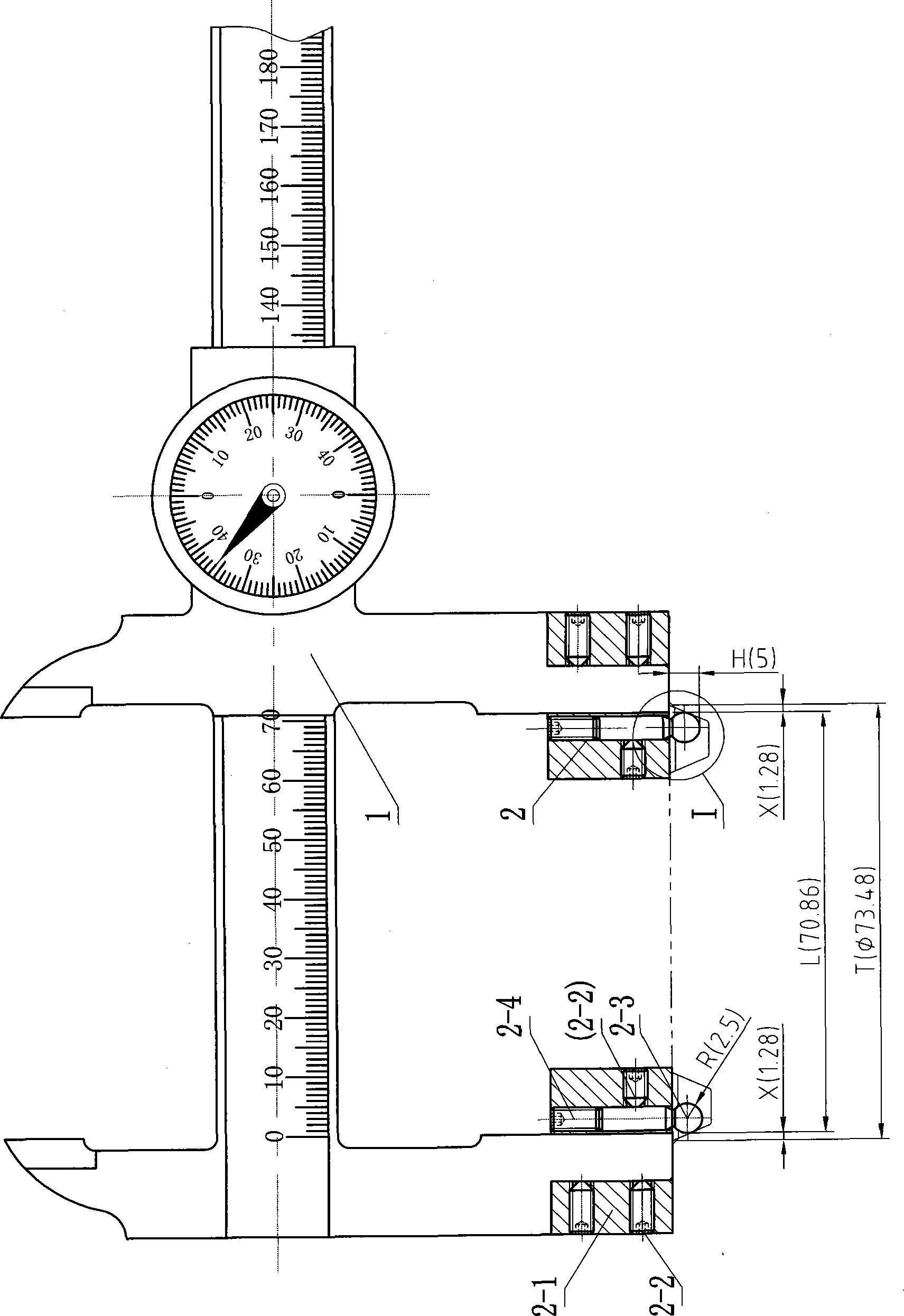

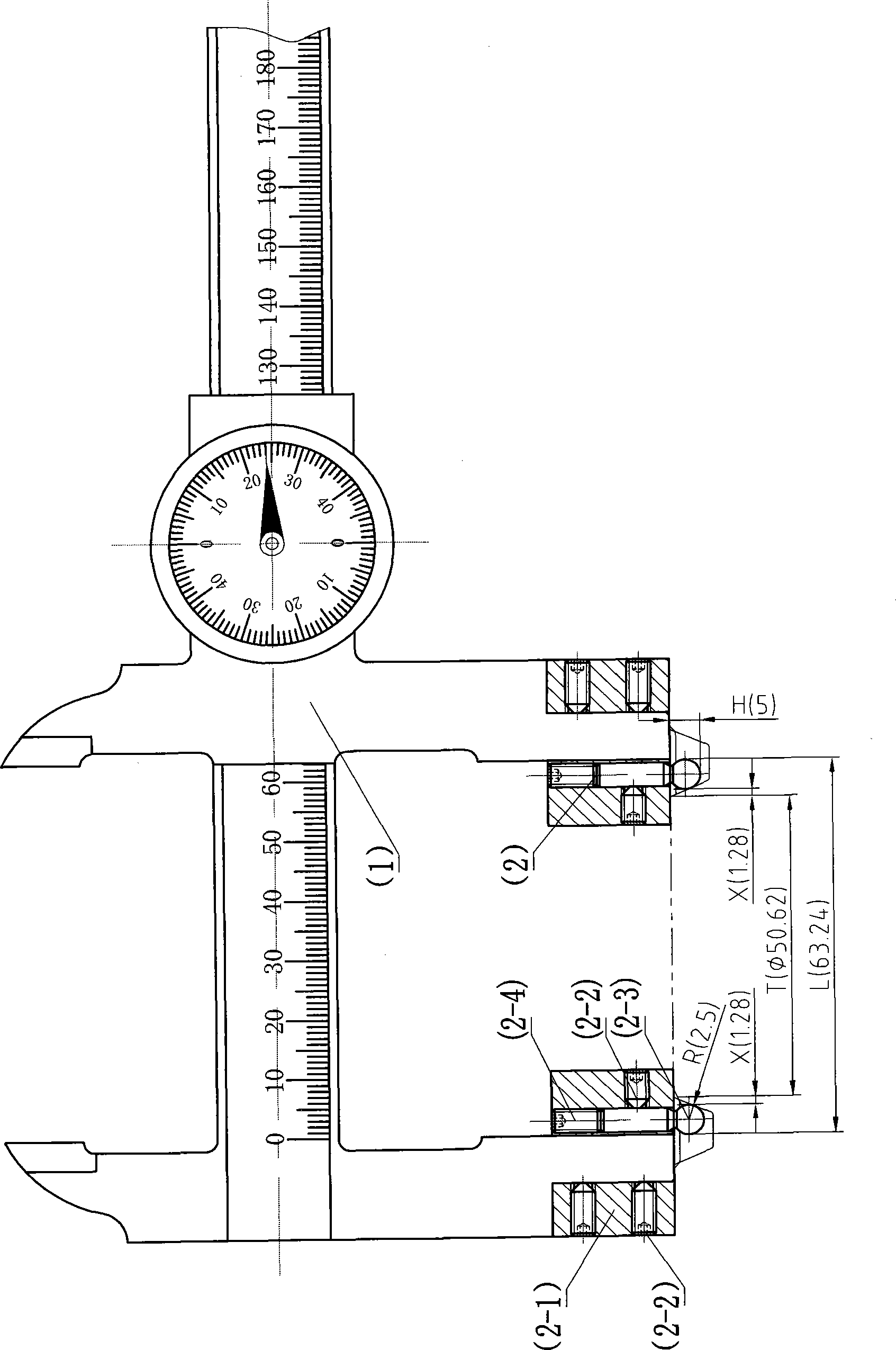

Universal measuring tool and measuring method of diameter of trapezoid packing ring groove

InactiveCN103278071AShorten inspection timeReduce contact surfaceMechanical diameter measurementsVernier scaleCalipers

The invention provides a universal measuring tool and a measuring method of the diameter of a trapezoid packing ring groove. The measuring tool is composed of a vernier caliper with a watch and measuring auxiliary pieces. Two measuring auxiliary pieces are symmetrically arranged on a measuring claw under the frequently-used vernier caliper with the watch, and two protruding spherical measuring heads are symmetrically arranged under standard connection blocks of the measuring auxiliary pieces. In the measuring process, the lower faces of the two standard connection blocks are attached to the flat planes of flanges to be used as measuring standards. The side faces of ball heads of the two spherical measuring heads are respectively in contact with inclined planes of two corresponding sides of the trapezoid packing ring groove. A direct measuring value of the vernier caliper with the watch is read, a relevant correcting value is added or subtracted, so that the value of the diameter of an outer circle or the diameter of an inner circle of the measured trapezoid packing ring groove is obtained. The measuring tool has the advantages of being simple in structure, visual in value reading, strong in universality, and convenient to use. The detection time of the trapezoid packing ring groove can be shortened, and the measuring accuracy of the trapezoid packing ring groove is improved.

Owner:JIANGSU HONGTAI PETROCHEM MACHINERY

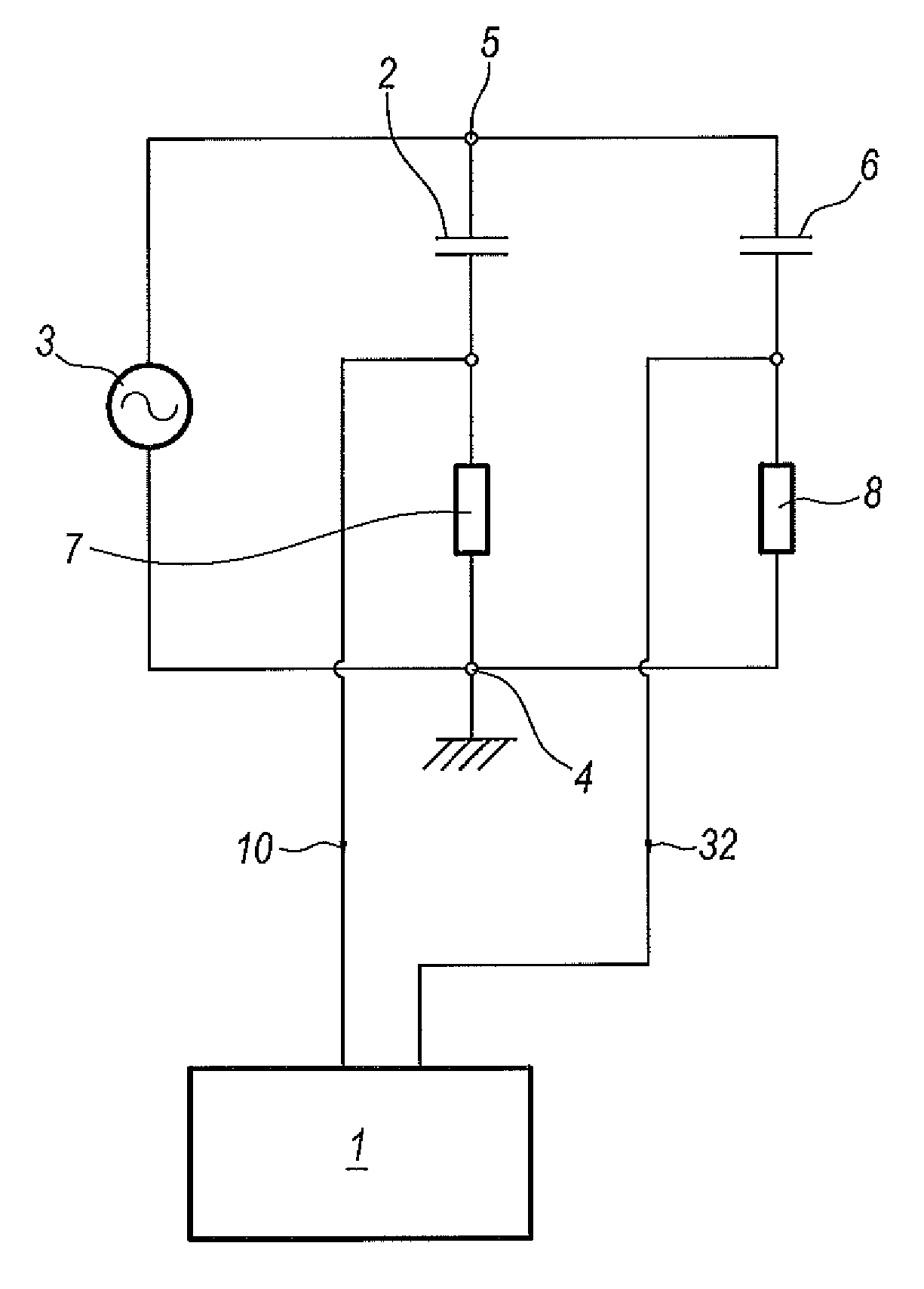

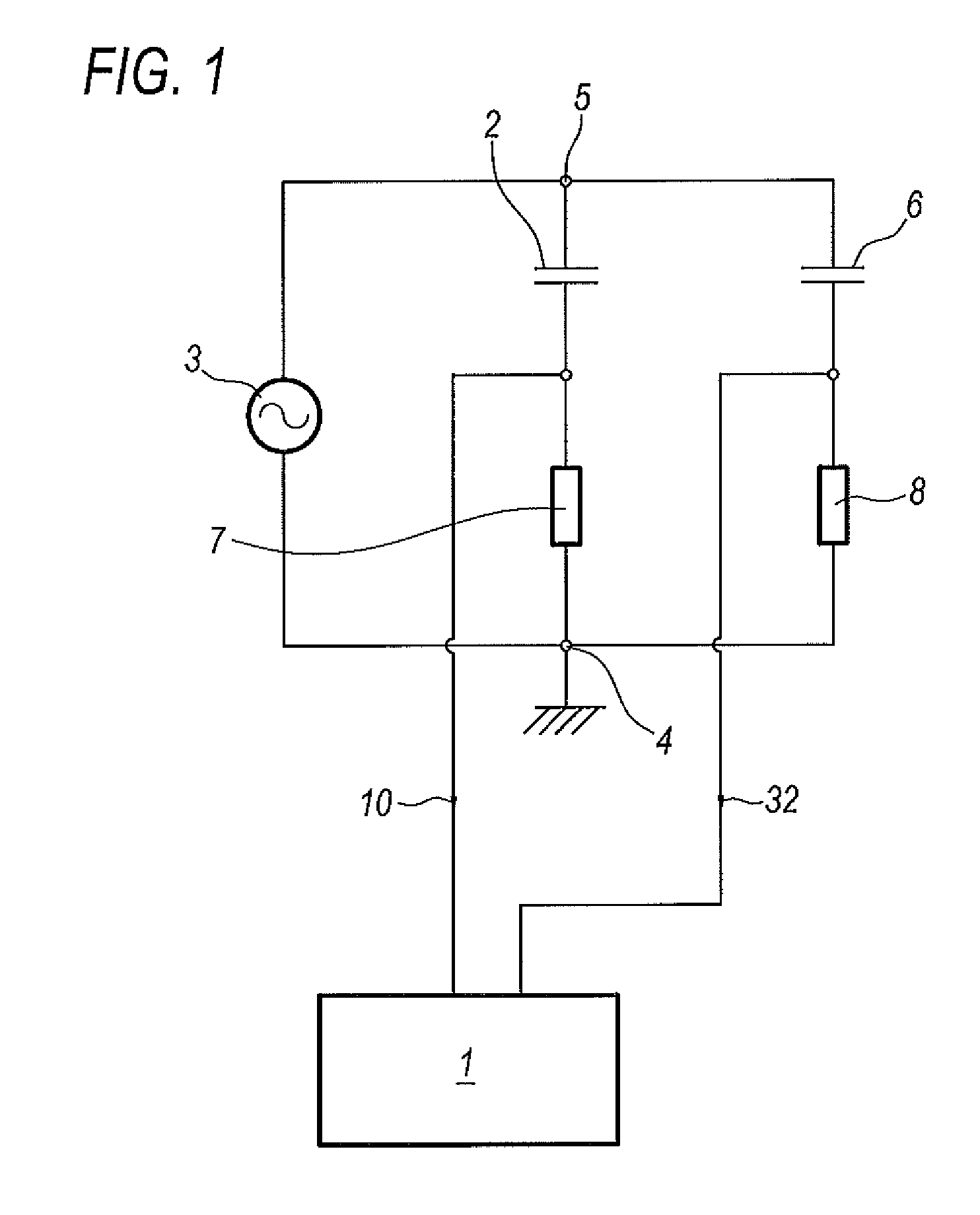

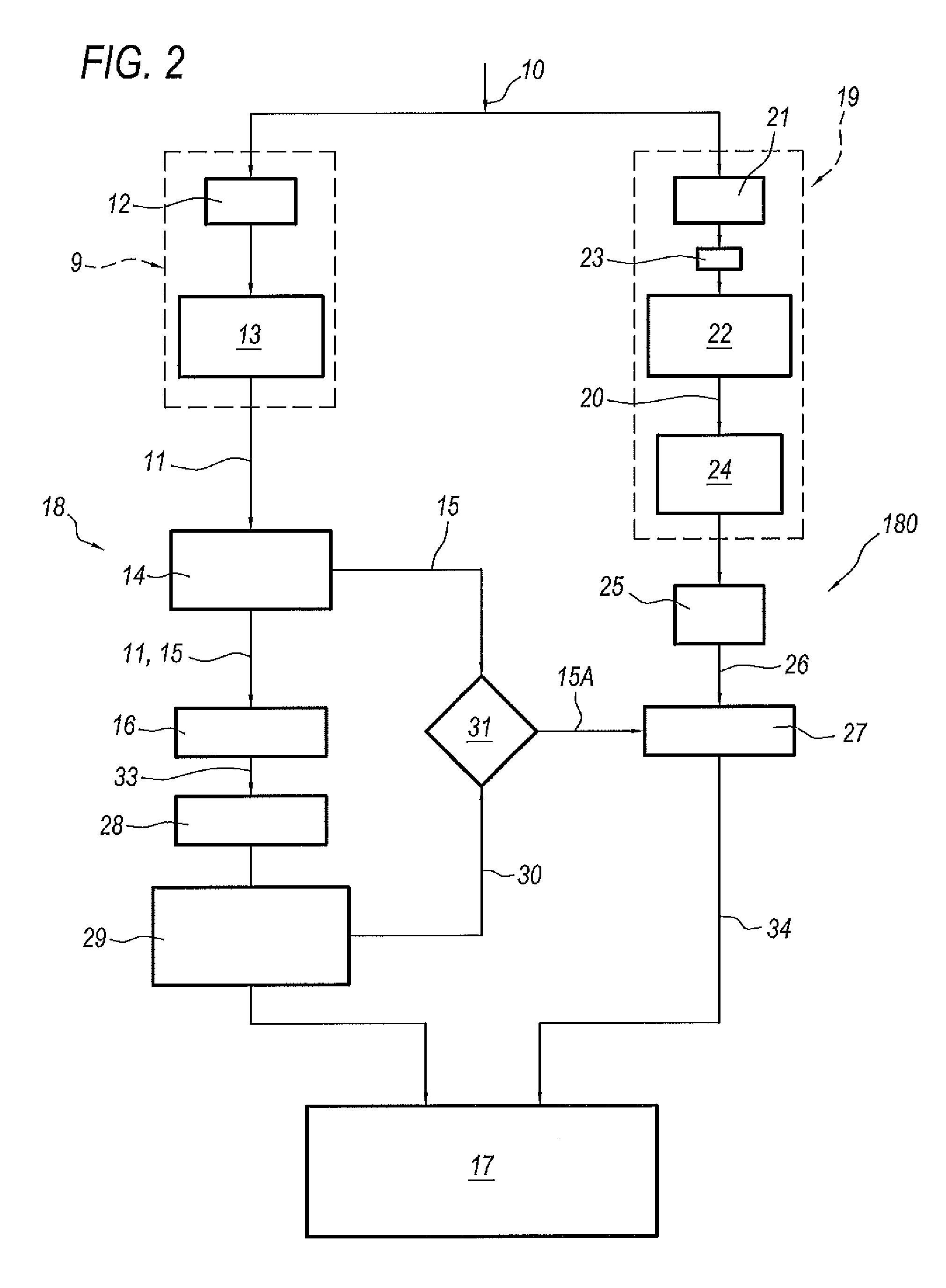

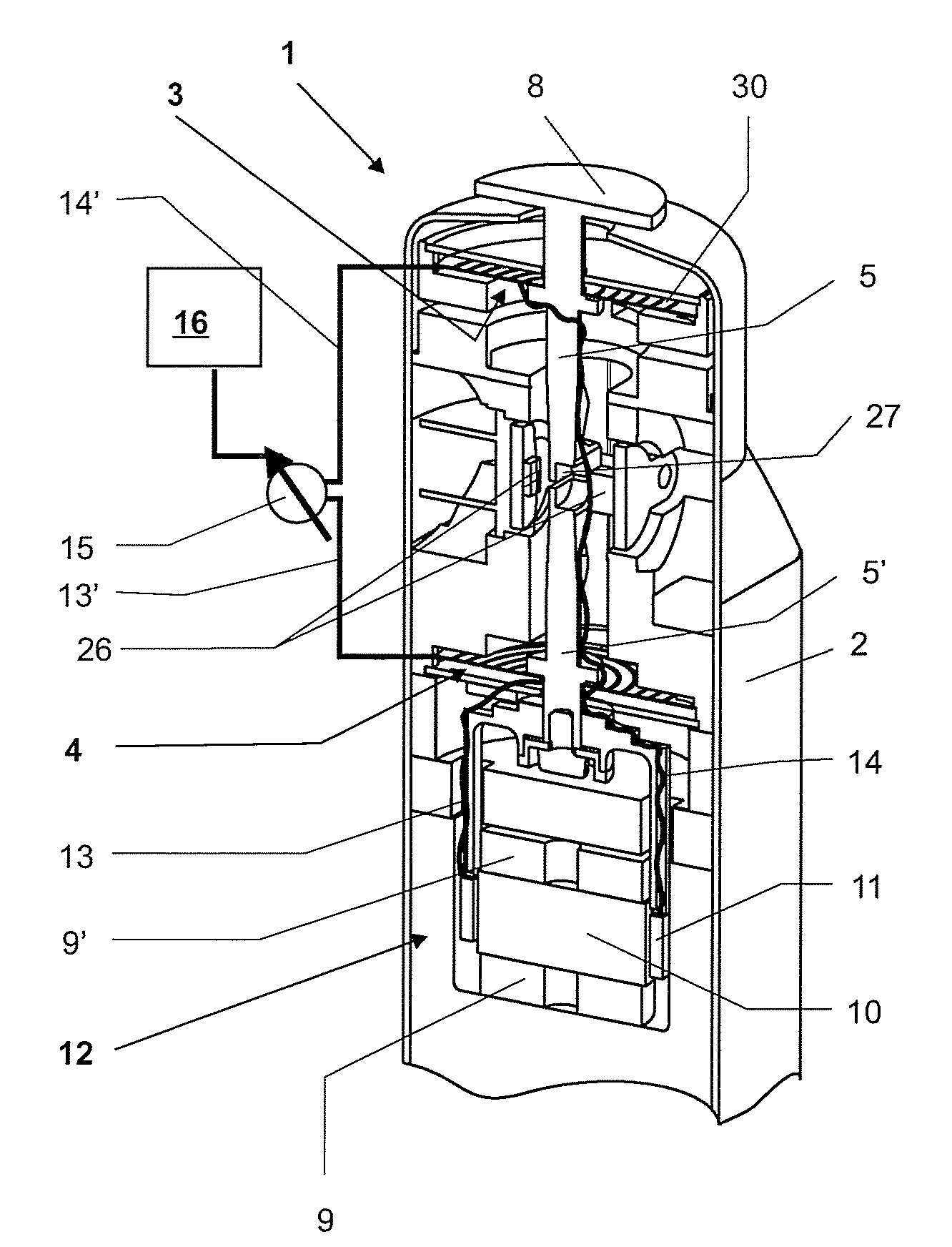

Instrument and method for detecting partial electrical discharges

ActiveUS20120319703A1Maximum freedom of processingHigh sensitivityTesting dielectric strengthResistance/reactance/impedenceEngineeringBroadband

An instrument (1) and a method for detecting partial electric discharges involve acquiring a discharge signal (10), for example picked up by a direct-measuring impedance device (7) through a broadband HF acquisition channel (18), and acquiring the discharge signal (10) in a narrowband LF acquisition channel (180) complying with regulations, using on the LF acquisition channel (180) a trigger controlled in slave mode by a trigger of the broad-band HF acquisition channel (18); they also involve acquiring another discharge signal (32) picked up by an indirect-measuring impedance device (8) through a second narrowband LF acquisition channel (180A) and comparing digital signals (34, 34A) generated in the first and second LF acquisition channels (180, 180A), in order to generate a balanced digital signal (36) without components represenative of common mode electrical signals present in the measuring circuit.

Owner:I S A ALTANOVA GRP SRL

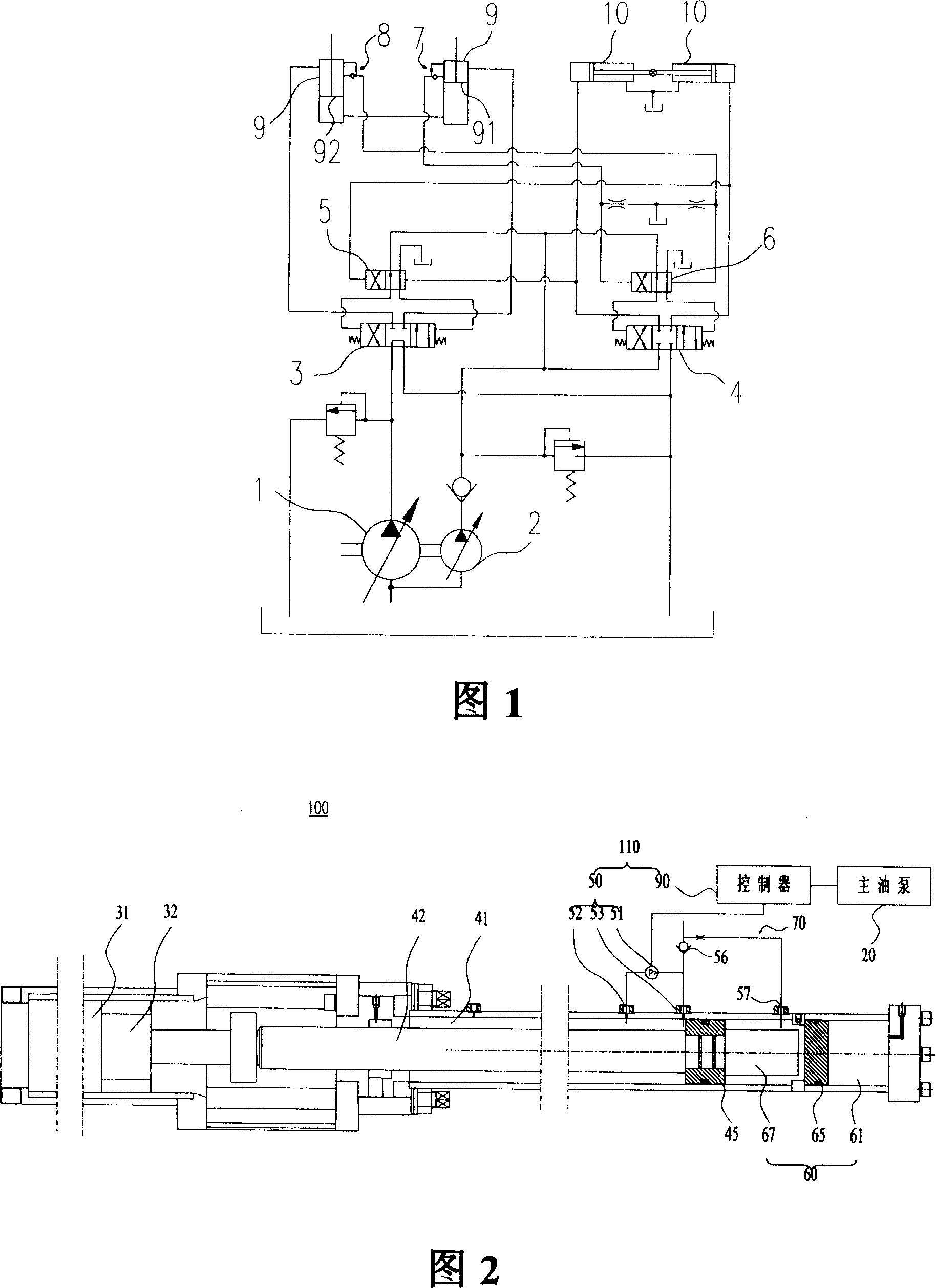

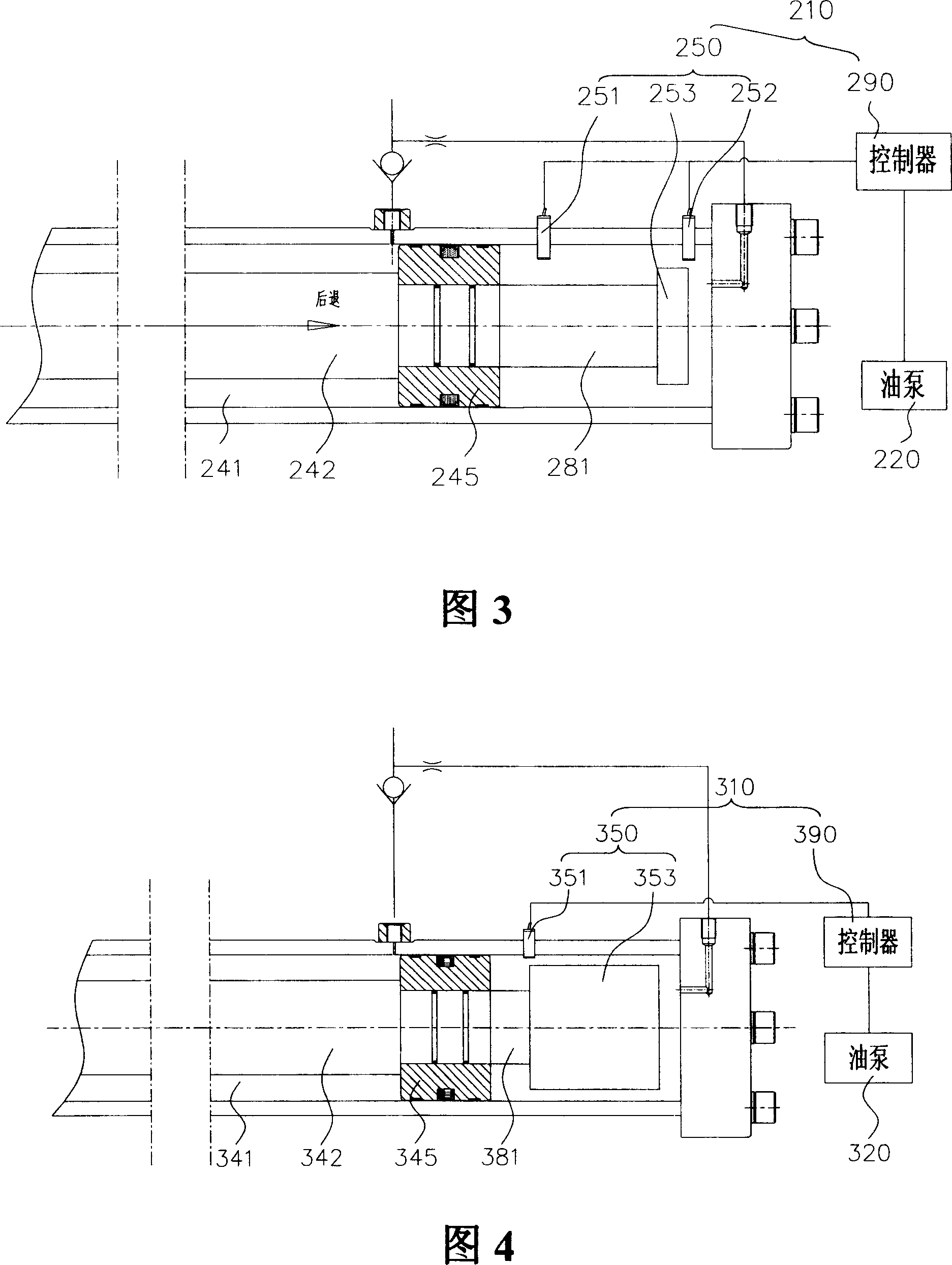

Liquid controlled reversing buffering mechanism and method

InactiveCN101082350AImprove position detection accuracyImprove stabilityPump controlBuilding material handlingControl theoryDirect measure

The invention discloses a liquid control reversing buffer device and method. The device includes position detection device which used in detecting piston moving location of liquid control reversing system and produce position signal. Controller is used in receiving position signal and accord to the signal to regulate oil pump displacement of liquid control reversing system, and then realize the buffer to piston reversing. The device can direct measure position of piston, then improve signal detection precision and dynamic responsiveness, and make liquid control reversing system stable.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

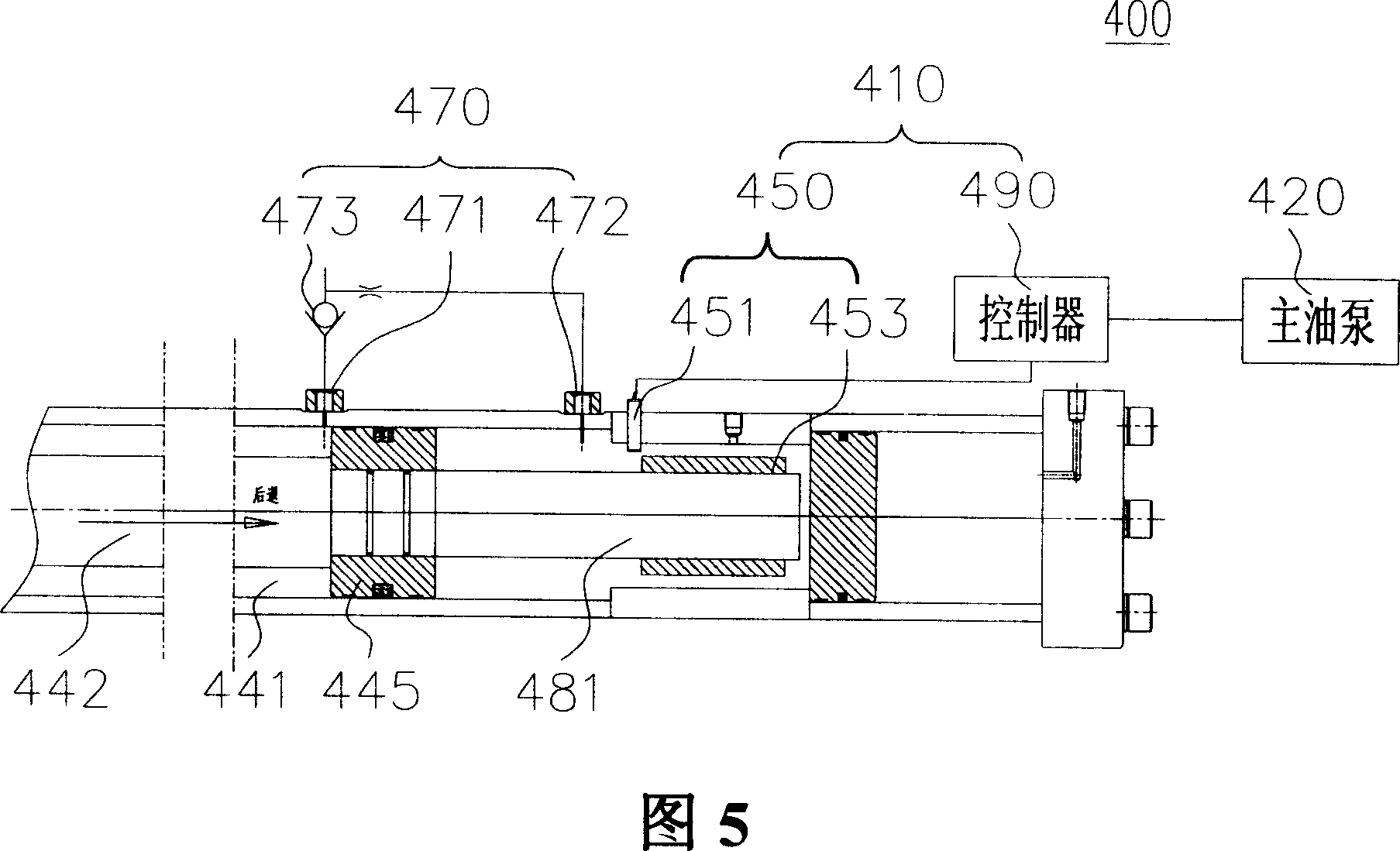

Weighing cell

ActiveUS20080121048A1Small possible amountWeighing apparatus using counterbalanceForce measurementElectricityAs Directed

An electromagnetic force-compensation direct-measuring system is disclosed. Referred to as direct-measuring system, it comprises a parallel-guiding mechanism; and a load receiver connected with the parallel-guiding mechanism and connected to a force-compensation device by a force-transmitting rod. The force-compensation device can include at least one permanent magnet and a coil that is electrically connected to a control circuit. At least one component of the parallel-guiding mechanism is configured to transmit electric signals.

Owner:METTLER TOLEDO GMBH

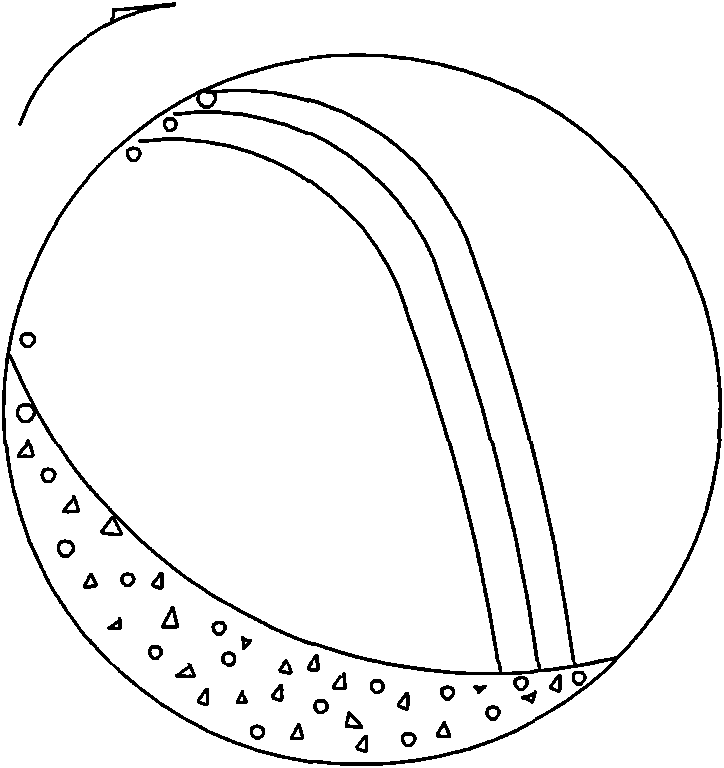

Direct measuring device and direct measuring method for loading capacity of grinder equipment

InactiveCN102023044AAvoid bloatingStable jobMachines/enginesUsing optical meansLaser rangingRs 232 interface

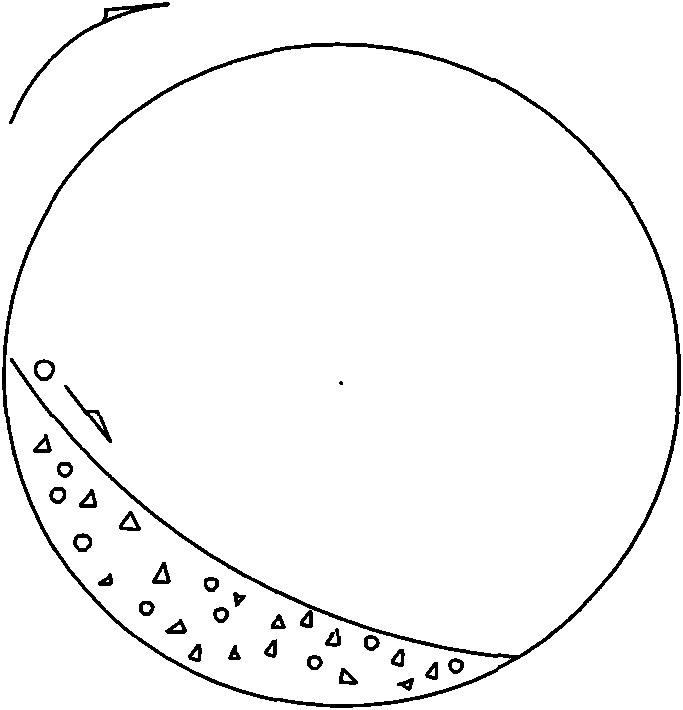

The invention discloses a direct measuring device for the loading capacity of grinder equipment. The device comprises a laser ranging device with an angle ruler, and a controller, wherein a signal output end of the laser ranging device is connected to a signal input end of the controller through an RS232 interface; an transmission end of the laser ranging device is aligned with the interior of the grinder along the vertical face of the axis of the grinder; and the transmission end is higher than the highest loading position in the grinder. Accordingly, the invention also provides a direct measuring method for the loading capacity. The fixed point height of a backing material in the grinder is directly measured by the laser ranging device so as to measure the loading capacity in the ball grinder and effectively and intuitively prevent the grinder from being expanded; and under the condition of stable feeding, the problem of grinding efficiency reflected by high and low material change can be discovered so as to provide a good foundation for the stable work of the grinder.

Owner:戈文燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com