Universal measuring tool and measuring method of diameter of trapezoid packing ring groove

A measurement method, a technology of diameter measurement, which is applied in the direction of mechanical diameter measurement, etc., can solve the problems of unfavorable gasket ring groove processing size adjustment and quality improvement, difficulty in measuring the diameter of the outer circle, and failure to give measurement data, etc., so as to shorten the inspection time , strong versatility and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

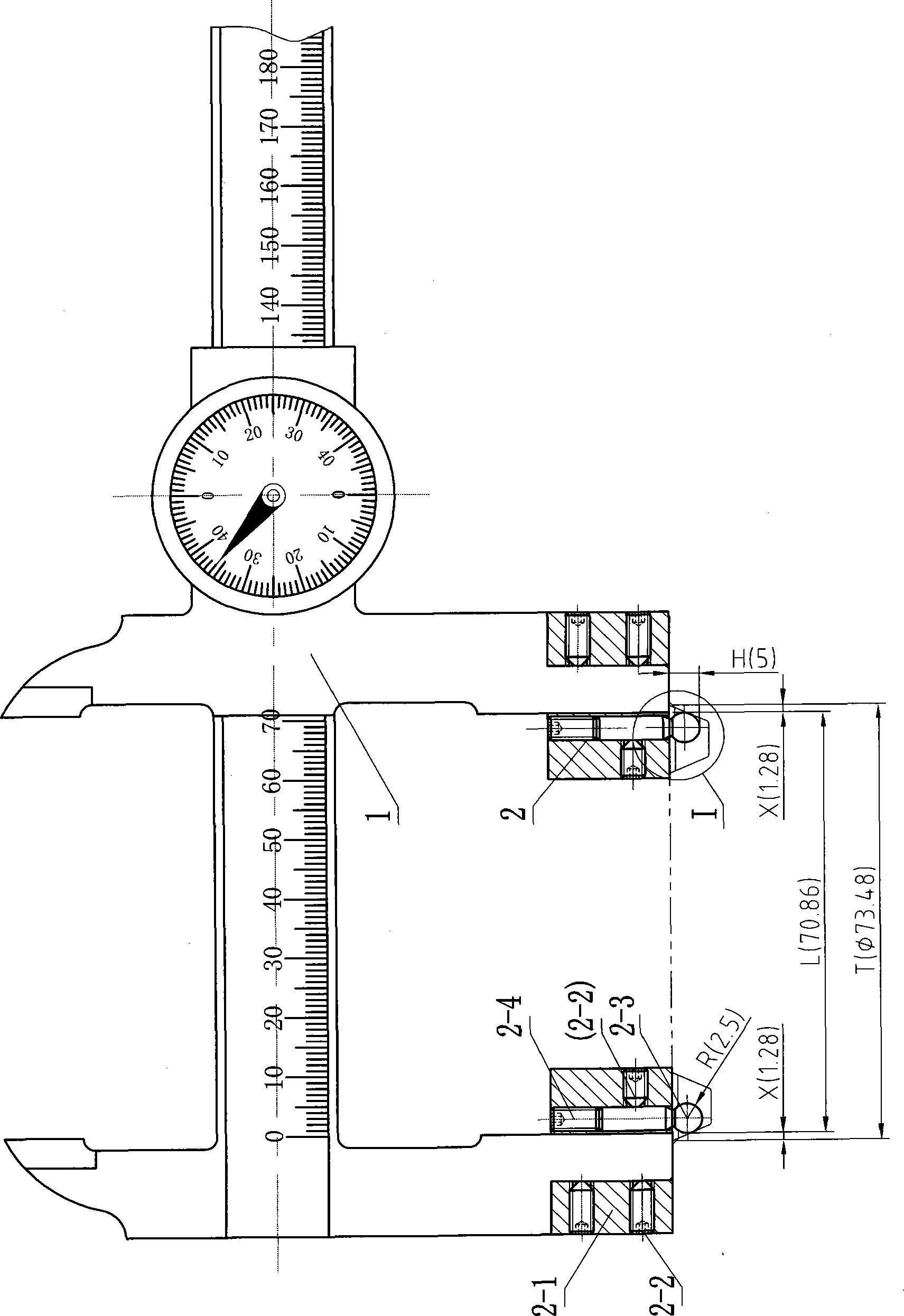

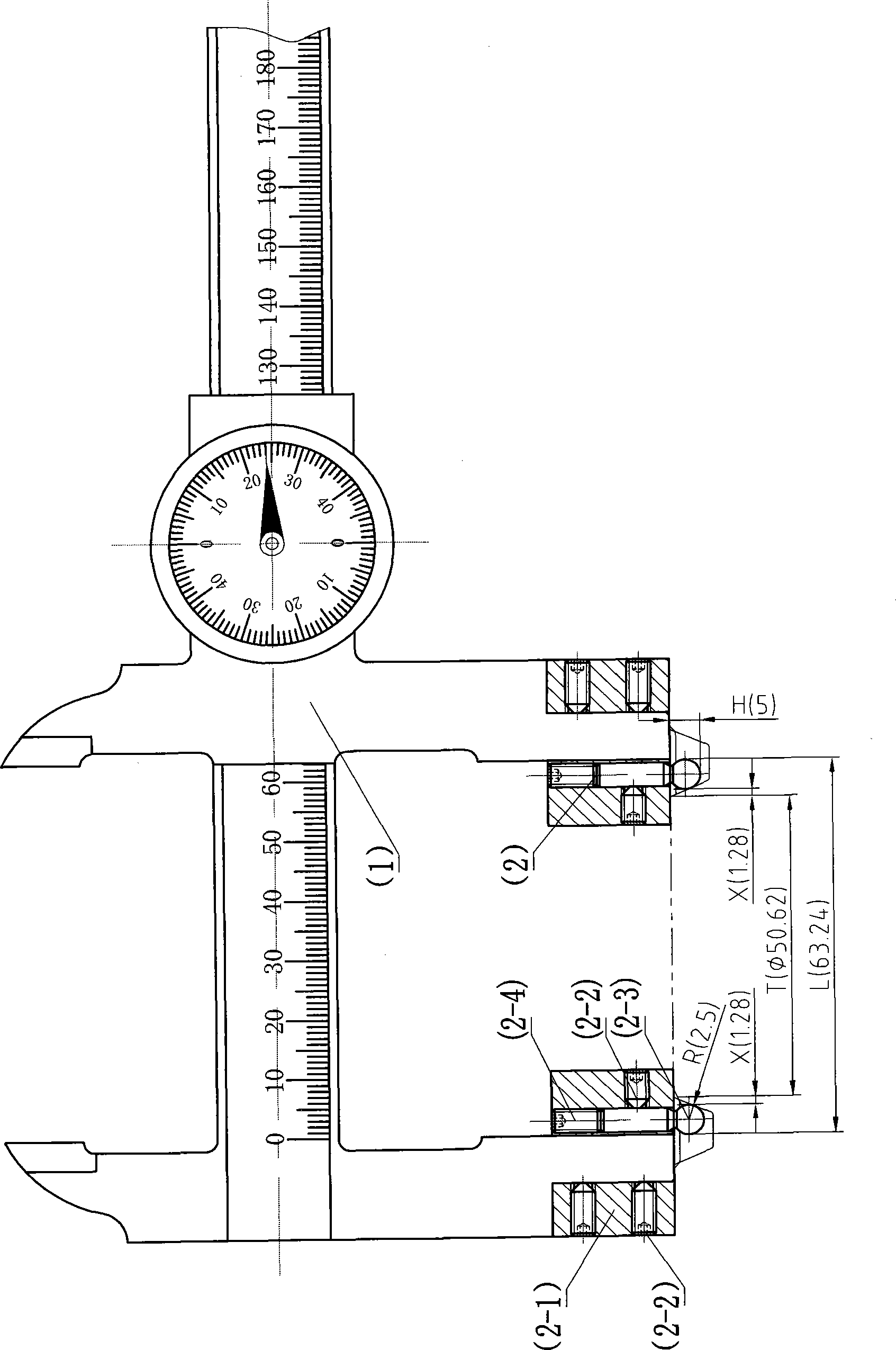

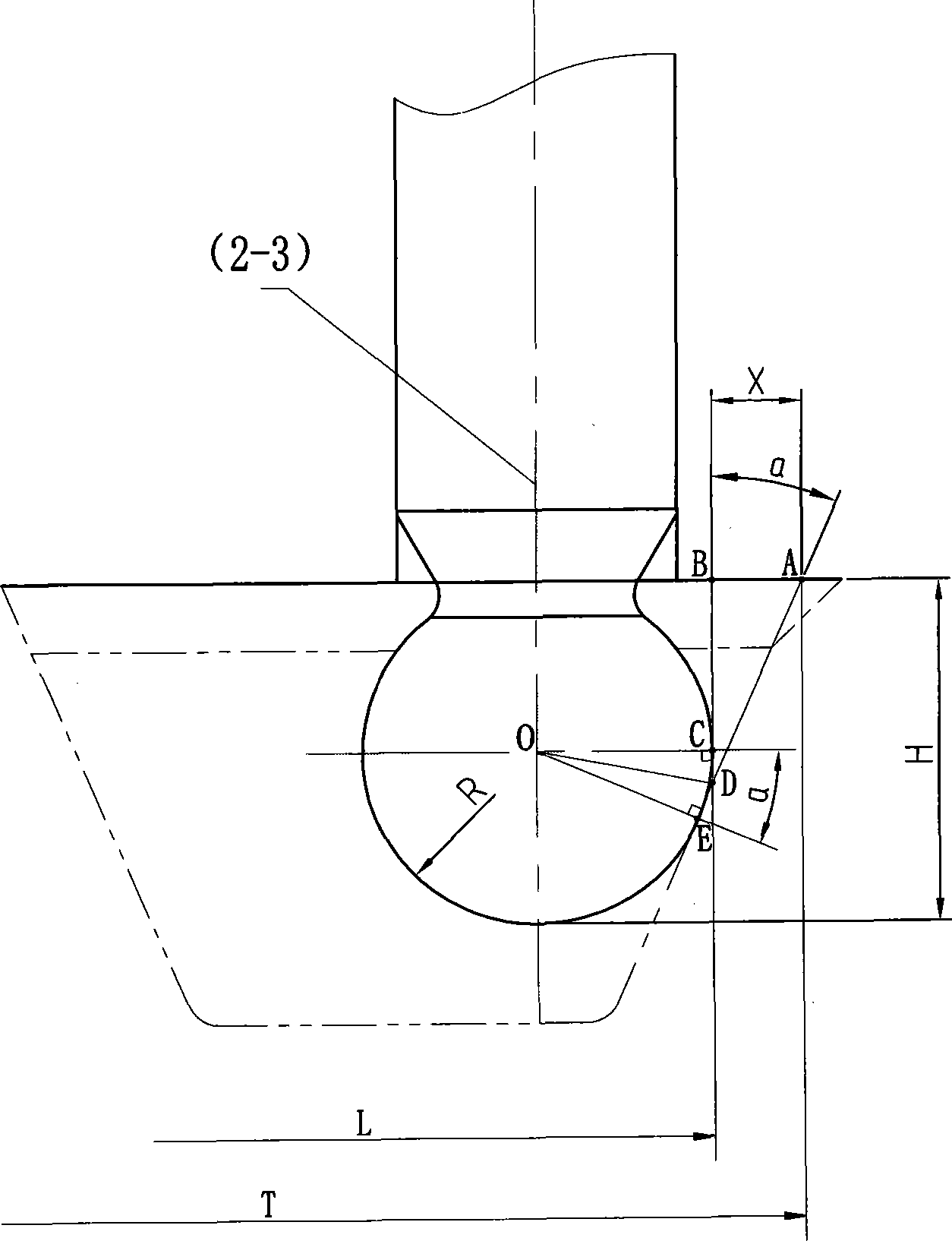

[0024] Example: It is known that the spherical head radius of the spherical measuring head (2-3) is R=2.5mm, and the extension length H=5mm; the trapezoidal backing groove slope angle specified in the drawing is α=23°, and the diameter of the outer circular edge is Φ73. 48mm, the diameter of the inner circle is Φ50.62mm; on the vernier caliper (1): the direct measurement of the diameter of the outer circle is L=70.86mm, and the direct measurement of the diameter of the inner circle is L=63.24mm; find the angle correction value X, and calculate Do the outer diameter and inner diameter T meet the specified requirements?

[0025] Solution: ∵BC=extended length H-ball head radius R=5-2.5=2.5(mm);

[0026] ∵CD=ball head radius R×tanα / 2=2.5×tan(23° / 2)=0.586(mm);

[0027] ∴Angle correction value X=(BC+CD)×tanα

[0028] =(2.5+0.586)×tan23°

[0029] = 1.31 (mm).

[0030] Then: the diameter of the outer circle of the backing ring groove T = direct measurement value L + (2 × angle cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com