Direct measuring device and direct measuring method for loading capacity of grinder equipment

A measuring method and measuring device technology, which is applied in mechanical equipment, measuring devices, optical devices, etc., can solve the problem of no load measuring device and achieve the effect of preventing the mill from bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] There are many different types of ball mills, such as wet ball mills (there are two kinds of overflow type and grid type according to the ore discharge method), which are generally used for metal ore dressing; dry ball mills are generally used for coal grinding in power plants and powder grinding in dry process cement plants. . This embodiment is described as follows by taking the wet ball mill as an example.

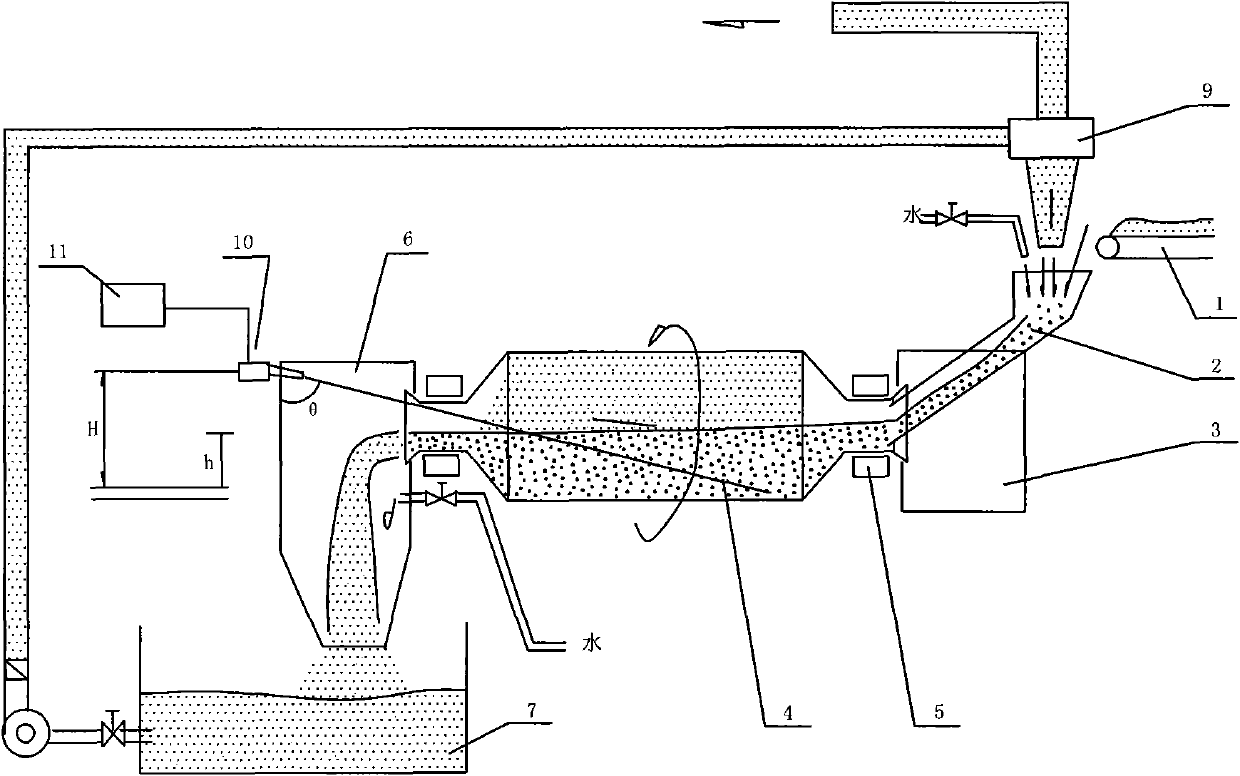

[0035] The process equipment of the mill system installed with the direct measurement device of the loading capacity described in this embodiment is as follows: figure 1 , including the ore feeding belt 1, the feeding hopper 2, the feeding box 3, the mill 4 (water is added to the inlet and outlet), the discharging box 6 and the pulp tank 7 located below the discharging tank, which are installed in sequence, and the pulp tank is provided with The inlet of the pipeline is connected to the hydrocyclone 9 through the mortar pump 8, and the bottom flow outlet is dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com