Method and device for determining material solid/liquid interfacial energy by experiment

A liquid interface, experimental technology, applied in the direction of surface tension analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

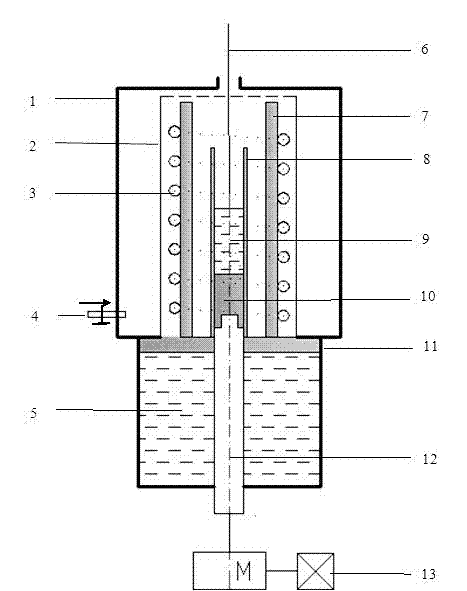

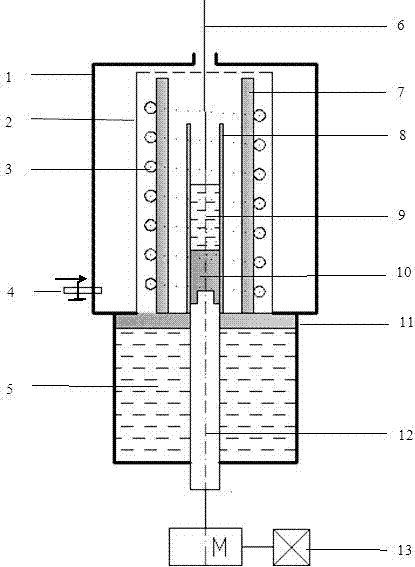

[0027] Cut the aluminum ingots into Φ16×100mm cylindrical rods with a wire cutting machine, clean them and dry them with a hair dryer, put them into corundum tubes 8 with an inner diameter of Φ16mm, and fix them on the tie rods. Assemble the pull rod 12 with the sample, the cooling pool 5 with the liquid metal Ga-In-Sn and the servo motor 13, and adjust the position of the sample in the heating system through the pull rod 12. First pass the argon gas protection, start the heating system after about 20 minutes, set the parameters of the temperature control system 6: the target temperature is (660+10) ℃, the heating time is 40 minutes, and the holding time is 20 minutes to ensure the heat flow in the furnace is stable. Place the prepared Φ4mm spherical solid aluminum on the surface of the aluminum melt from above the device, wait for the solid surface and the melt to infiltrate each other, then turn on the servo motor 13, and pull the sample into the cooling pool at a speed of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com