Quasi morphological filtering method for extracting two-dimensional contour in contact measuring head measurement

A two-dimensional contour and quasi-morphological technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as the increase in the maximum value of the probe radius compensation error, the inability to confirm the correctness of the normal direction, and the inability to guarantee the validity of the compensation results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

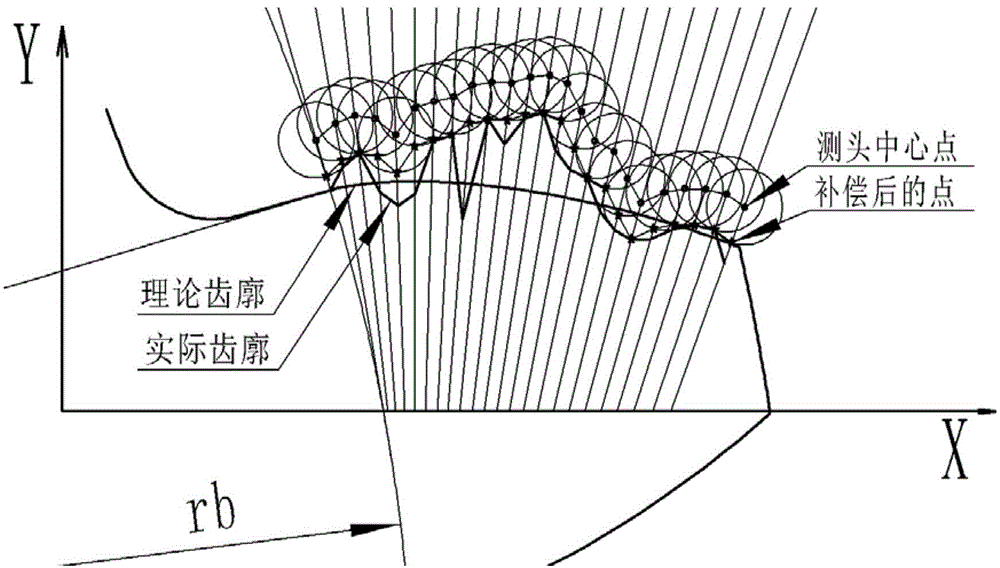

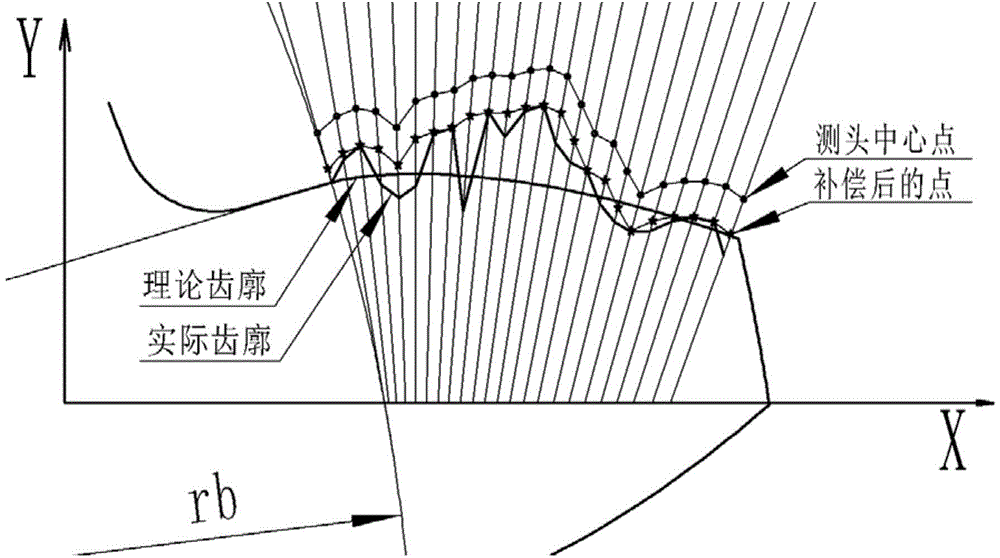

[0033] The specific embodiment of the present invention will be further described below by taking the non-involute modified tooth profile measurement of spur gears as an example in conjunction with the accompanying drawings.

[0034] First, as a comparison, the general method of extracting the measured two-dimensional profile from the measurement data using the traditional probe radius compensation method is given as follows:

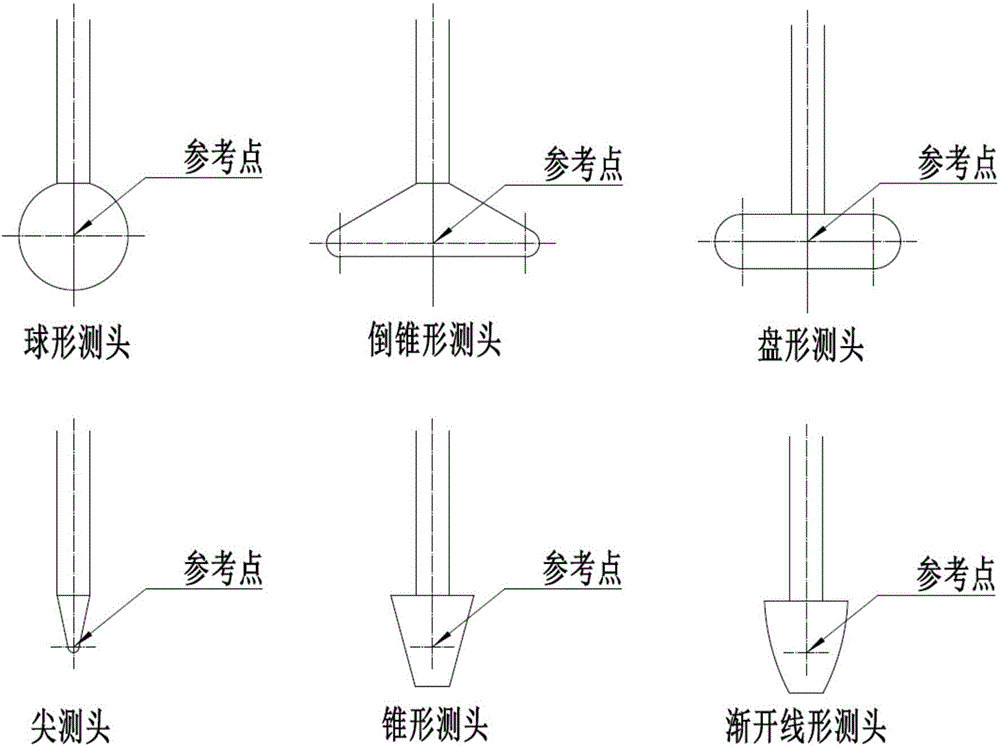

[0035] When using a trigger probe to measure the tooth profile on the measuring machine, in order to reduce the probe radius compensation error, it must be measured from the normal direction of each measured point on the measured tooth profile, that is, the normal direction of each measured point as the detection direction. However, before the actual tooth profile measurement, the actual normal direction of each measured point cannot be known. The processing method at this time is to calculate the theoretical method corresponding to each measured point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com