Method of utilizing polluted soil and industrial sludge to prepare ceramsite and ceramsite prepared thereby

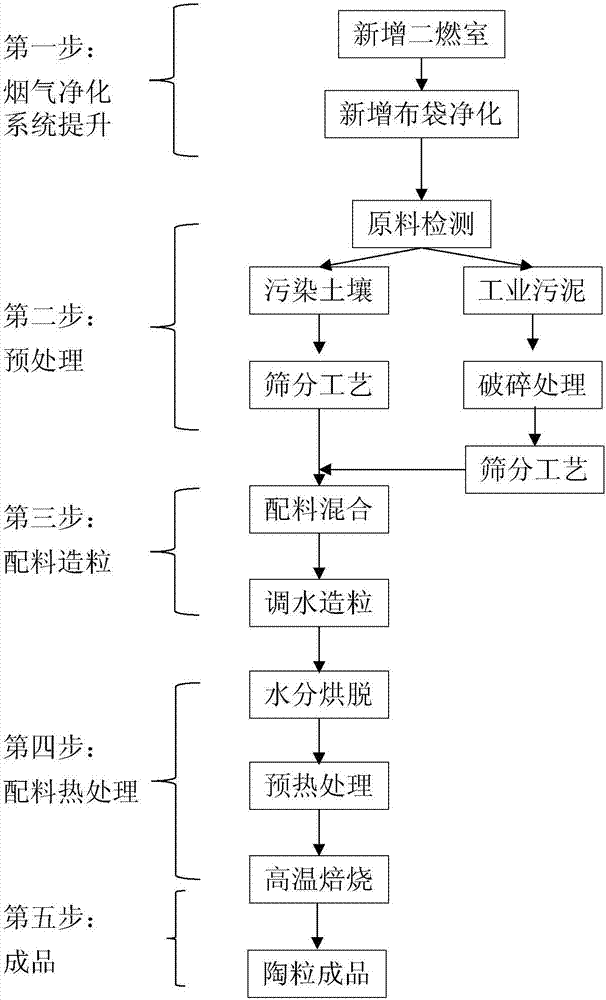

A technology for polluted soil and industrial sludge, applied in clay products, applications, household appliances, etc., can solve problems such as insufficient treatment capacity of heavy metal polluted soil, achieve low environmental release risk of heavy metals, low heavy metal residue rate, and improve environmental safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

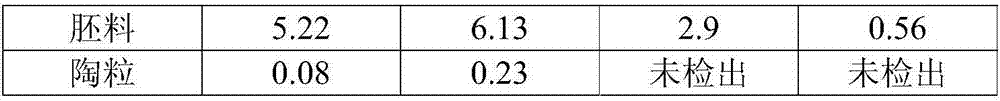

[0050] The decommissioned soil of an electroplating plant was taken, and its heavy metal copper content was 8321mg / kg, zinc content was 4390mg / kg, chromium 2561mg / kg and nickel 331mg / kg, and the two indicators of arsenic and mercury were not detected. Take the printing and dyeing sludge, the heavy metal copper content is 300mg / kg, and the zinc content is 131mg / kg. Sieve the soil and printing and dyeing sludge according to the particle size standard of 2mm. After sieving, the two are fully mixed according to the mass ratio of 8:2 (soil: mud). Subsequently, a small amount of water is added to the mixture to increase the viscosity (moisture content is adjusted to 35%), and then the mixture is conveyed to the roller granulator for granulation by belt. Place the granulated billets at the tail of the rotary kiln (about 450°C) and keep heating for 40 minutes; then transfer the billets to the main body of the rotary kiln to ensure that the pellets are heated at 600°C for 60 minutes. ...

Embodiment 2

[0057] The decommissioned soil of an electroplating plant was taken, and its heavy metal copper content was 8321mg / kg, zinc content was 4390mg / kg, chromium 2561mg / kg and nickel 331mg / kg, and the two indicators of arsenic and mercury were not detected. Take the printing and dyeing sludge, the heavy metal copper content is 300mg / kg, and the zinc content is 131mg / kg. Sieve the soil and printing and dyeing sludge according to the particle size standard of 2mm. After sieving, fully mix the two according to the mass ratio of 7:3 (soil: mud). Subsequently, a small amount of water was added to the mixture to increase the viscosity (the water content was adjusted to 35%), and then the mixture was conveyed to a double-roll granulator by belt for granulation. Place the granulated billets at the tail of the rotary kiln (600°C) and keep heating for 40 minutes; then transfer the billets to the main body of the rotary kiln to ensure that the pellets are heated at 700°C for 90 minutes. Afte...

Embodiment 3

[0064] The decommissioned soil of an electroplating plant was taken, and its heavy metal copper content was 8321mg / kg, zinc content was 4390mg / kg, chromium 2561mg / kg and nickel 331mg / kg, and the two indicators of arsenic and mercury were not detected. Take the printing and dyeing sludge, the heavy metal copper content is 300mg / kg, and the zinc content is 131mg / kg. Sieve the soil and printing and dyeing sludge according to the particle size standard of 2mm. After sieving, fully mix the two according to the mass ratio of 7:3 (soil: mud). Subsequently, a small amount of water was added to the mixture to increase the viscosity (the water content was adjusted to 40%), and then the mixture was conveyed to a double-roll granulator by belt for granulation. Place the granulated billets at the tail of the rotary kiln (600°C) and keep heating for 40 minutes; then transfer the billets to the main body of the rotary kiln to ensure that the pellets are heated at 800°C for 90 minutes. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com