Patents

Literature

246results about How to "Controllable clotting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Geopolymer gel material for rush repairs and rush constructions

ActiveCN101628791AGood mechanical propertiesEasy constructionSolid waste managementCement productionSlagMetakaolin

The invention provides a geopolymer gel material for rush repairs and rush constructions, which is prepared by adding water to 13-17 percent by weight of exciting agent and 82-87 percent by weight of slag containing aluminosilicate. The slag comprises one or the combination of more of blast furnace slag, steel slag, coal ash and coal gangue, and the exciting agent comprises the following components in percentage by weight: 35-75 percent of SiO2, 0-55 percent of Na2O, 0-65 percent of K2O, 0-1 percent of CaO and 0-1 percent of SO3. The geopolymer gel material which has the characteristic of quick setting and hardening is prepared by using the industrial waste slag as a main raw material and matching the exciting agent, and the geopolymer gel material has excellent mechanical property and controllable setting time and can replace gel materials such as fast setting and hardening cement, and the like in the processes of rush repairs and rush constructions. The industrial solid wastes such as the blast furnace slag, the steel slag, the coal ash, the coal gangue, and the like containing the aluminosilicate series are used as main raw materials, metakaolin is not added and the raw materials do not need to be calcined, thus the invention has low energy consumption, less pollution, simple process, low cost, environmental protection and energy saving.

Owner:深圳市航天新材科技有限公司

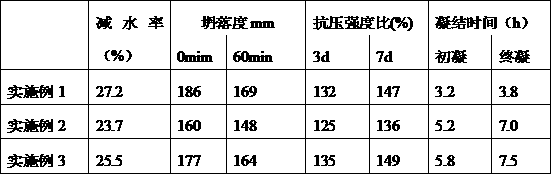

Alkali-activated high-performance water reducer and preparation method thereof

ActiveCN103011662AHigh water reduction rateEnhancement effect is goodBlack liquorProcess engineering

The invention discloses an alkali-activated high-performance water reducer and a preparation method thereof. The alkali-activated high-performance water reducer comprises a composite alkali-activator, a composite water reducer, black liquor of a paper mill, a composite retarder, a composite air entraining agent, a composite thickener, a composite regulator and the balance of water. The preparation method for the alkali-activated high-performance water reducer comprises the following steps of: adding the components and water to a reaction kettle in sequence; and mixing and carrying out a reaction on the components and the water under the room-temperature environment to obtain the finished product. The alkali-activated high-performance water reducer disclosed by the invention can activate the cementitious activity of the mixed materials such as slag, coal ash, gangue and the like, has excellent adaptability to different cements and highly doped concrete, and can greatly reduce the adding amount of cement clinker. The alkali-activated high-performance water reducer has the characteristics of a high water-reducing agent, good peaceability, a remarkable reinforcing effect, a good collapse preventing effect, adjustable setting time and the like. Moreover, the external additive has a simple production process, no pollution, low energy consumption and low cost, can solve an environmental pollution problem of the black liquor of the paper mill, and has good practicability.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

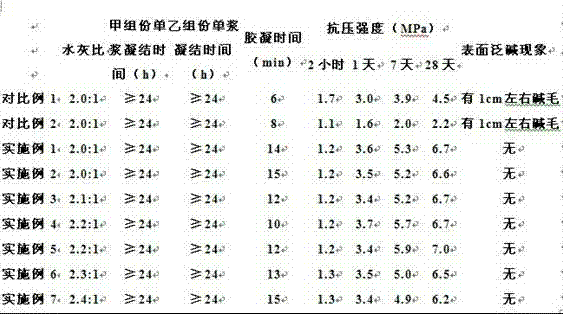

High-moisture filling material and preparation method thereof

The invention discloses a high-moisture filling material and a preparation method thereof. The high-moisture filling material comprises a composition A and a composition B, wherein the composition A comprises 52.4 to 95 by weight percent of sulfo-aluminate cement clinkers, 2.7 to 39 by weight percent of aluminate cement clinkers, 0.3 to 2 by weight percent of setting retarder, and 1.5 to 8 by weight percent of suspending agent; the composition B comprises the following ingredients: 40 to 80 by weight percent of anhydrite, 10 to 30 by weight percent of lime, and 10 to 36 by weight percent of compound additives. The high-moisture filling material has the advantages of easily-available raw materials, low price, good stability, high long-term strength and no risk of surface efforescence.

Owner:CCTEG CHINA COAL RES INST

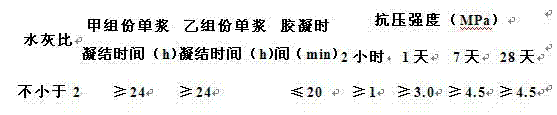

Polymer cement mortar for slab ballastless track of high-speed railway

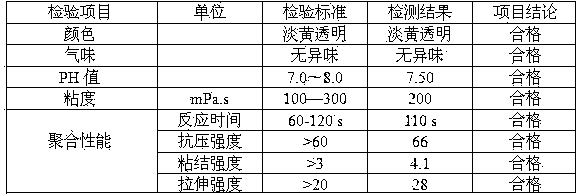

The invention discloses polymer cement mortar for a slab ballastless track of a high-speed railway. The polymer cement mortar a comprises a dry raw material and a liquid raw material, wherein the dry raw material comprises a binding material component, an elastic adjusting component, an expanding component, an internal curing component, an aggregate component and a coagulation adjusting component; the liquid raw material comprises a polymer emulsion, a water reducing agent, a defoaming agent, an air entraining agent and water; and the weight ratio of the dry raw material to the liquid raw material is 100:(15-25), and the dry raw material and the liquid raw material are uniformly mixed in a proportion to prepare the polymer cement mortar. The polymer cement mortar has the advantages of controllable coagulation time, high adhering strength, adjustable elastic modulus, good elasticity and toughness, high durability and the like, and is capable of replacing cement emulsified asphalt mortar to be applied to a packing material of the slab ballastless track or can be used as a quick repairing material of a filling layer of cement emulsified asphalt mortar.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +1

Phosphogypsum based plastering gypsum

The invention discloses a phosphogypsum based plastering gypsum, and relates to a plastering material for a building wall. The phosphogypsum based plastering gypsum mainly comprises 75 to 95 percent of phosphogypsum based building gypsum, 1 to 3 percent of sierozem powder, 0.1 to 0.5 percent of retarder, 1.1 to 5.5 percent of composite water retention agent, 0.3 to 1 percent of ethylene-vinyl acetate copolymerized latex powder, and 0 to 20 percent of stuffing. The phosphogypsum based plastering gypsum effectively improves water retention property and lowers cost by adopting the combination of cellulose ether water retention agent and bentonite, effectively adjusts settling time and prolongs operable time by adopting the retarder, improves construction property, cohesive property and cracking resistance by doping the stuffing and the latex powder, and reduces adverse effects of impurities on the strength of plastering gypsum by adding the sierozem powder. The phosphogypsum based plastering gypsum has the advantages of good workability and construction property, long operable time, high breaking resistance, compression resistance and adhesion strength, good volume stability, good cracking resistance and lower cost, and can be used for a plastering layer of the building wall.

Owner:CHONGQING UNIV

Phosphate base cementing agent

The invention discloses phosphate base cementing agent which is formed by uniformly mixing phosphate cementing mixture and water. The phosphate cementing mixture comprises the following component according to mass percent: 65 to 80 percent of phosphate cementing mixture and 20 to 35 percent of water; the phosphate cementing mixture comprises the following components according to mass percent: 20 to 60 percent of dihydric phosphate, 20 to 40 percent of magnesite, and 0 to 40 percent of inorganic mineral filler, wherein the mass of retarder occupies 5 to 15 percent of that of the magnesite; and the mass of sand occupies 0 to 30 percent of that of the phosphate cementing mixture. Phosphate gelling slurry can be served as structural adhesive to prepare fibrous composite material for concrete reinforcement, to improve the compatibility between the phosphate gelling slurry and concrete, and can also be served as gelling material to prepare artificial composite board material, self-leveling slurry, protective paint and the like.

Owner:SHENZHEN UNIV

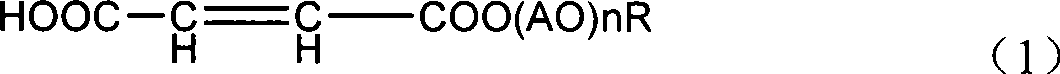

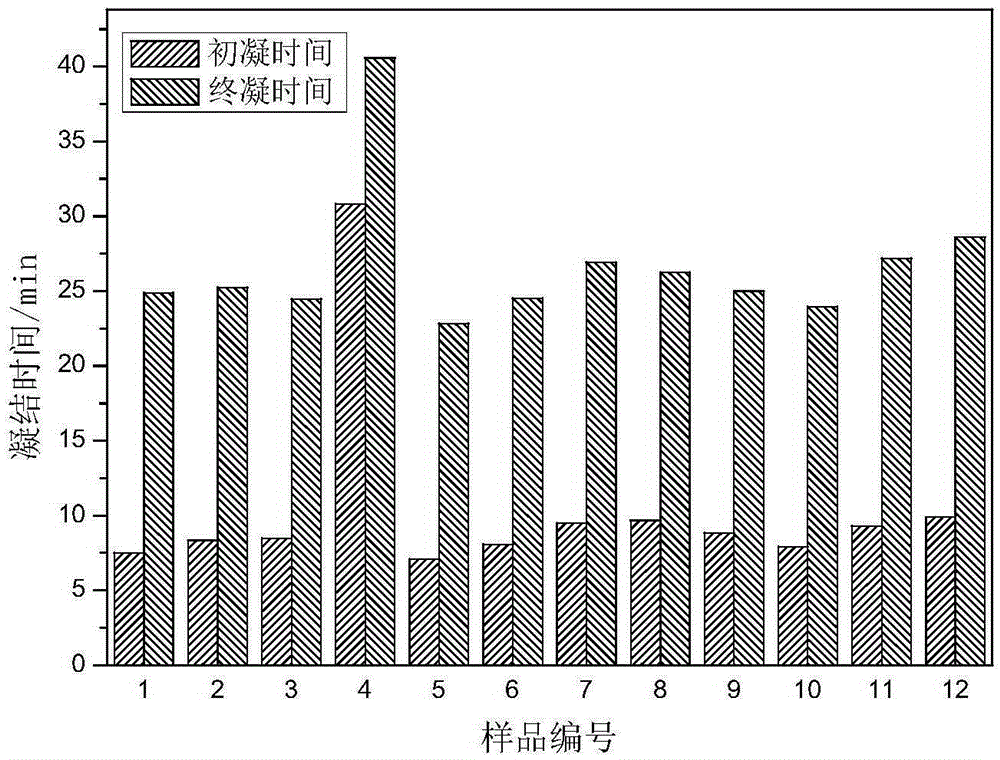

Design and preparation of coagulation time controllable high performance polycarboxylic acid water reducing agent

The invention relates to the design and synthesis of a poly carboxylic acid water reducing agent, the coagulating time of which can be controlled. The poly carboxylic acid water reducing agent is prepared by co-polymerize the following three monomers in water: the monomer a occupying 30 to 70 percent and indicated by a general expression 1, the monomer b occupying 10 to 50 percent and indicated by the general expression 2, and the monomer c occupying 10 to 40 percent and indicated by the general expression 3. The coagulating time is controlled by the monomer a which is made by condensing maleic anhydride and polyoxyethylene monoalkyl ether. The length of a polyoxyethylene monoalkyl ether chain controls the change of the coagulating time: the longer the chain, the shorter the coagulating time is; and the shorter the chain is, the longer the coagulating time is. The monomer a does not contain inhibitive substances in the process of synthesis, therefore, the water reducing agent is easy to be controlled in the coagulating process. The poly carboxylic acid water reducing agent is suitable for the construction of concrete under different temperature conditions: under higher temperature, the water reducing agent with longer coagulating time can be adopted, and under lower temperature, the water reducing agent with shorter coagulating time can be adopted. The poly carboxylic acid water reducing agent has good adaptability to cement and admixtures and has the advantages of low mixing quantity, good slump constant hold facility and water segregation resistance, and the like.

Owner:武汉格瑞林建材科技股份有限公司

High-early-strength magnesium phosphate concrete and preparation method thereof

InactiveCN101386518AQuickly restore functionalityFast setting and hardeningSolid waste managementMagnesium phosphateHazardous substance

The invention discloses a quick-hardening early strength magnesium phosphate concrete, which is mainly prepared from the following components in weight percentage: 12.7 to 30 percent of magnesia, 8.7 to 20 percent of phosphate, 1.2 to 15 percent of retarder, 10 to 25 percent of fine aggregate, 10 to 50 percent of water and the balance being water. The concrete material has the characteristics of quick coagulation and hardening, high early strength, good erosion resistance and the like, and can be widely applied to the quick repairing in projects or structures such as railways, airfields, bridges, harbors and docks and the quick solidification and closing of toxic and harmful substances, and can also be applied to the civil engineering and building construction under the sever conditions of sulfate erosion, marine corrosion, low temperature and the like. The invention has the advantages of simple preparation method, process and necessary equipment, low cost, no pungent ammonia gas generation in the construction and convenient popularization and application.

Owner:汪宏涛

Method for producing architectural gypsum powder by using phosphogypsum

This invention relates to a method for producing construction gypsum powder from ardealite. The method comprises: (1) prehomogenizing ardealite waste residue, placing in a continuous high-efficiency calcining kiln, and calcining; (2) taking out and aging naturally for 7-15 d; (3) milling into 100-200 mesh powder. This invention uses a unique calcination technique to produce high performance construction gypsum from ardealite waste residue, and has such advantages as no secondary pollution and saved water resource.

Owner:宁夏建筑材料研究院(有限公司)

Multifunctional quick repair material for cement concrete pavements and preparation method thereof

The invention relates to pavement repair, particularly a multifunctional quick repair material for cement concrete pavements, which is prepared by mixing the following raw materials in percentage by weight: 20-30% of magnesium oxide, 14-26% of ammonium monoacid phosphate, 9-14% of boric acid, 5-20% of aluminate cement, 2-10% of fly ash, 2-10% of rubber powder, 0.5-1.5% of polypropylene fiber, 0.5-1.5% of redispersible latex powder, silica sol and water; the silica sol accounts for 20-60% of the water. The preparation method of the multifunctional quick repair material for cement concrete pavements is implemented by proportionally mixing the raw materials. The material is convenient for construction, has enduring effect after curing, and has quick and enduring repair capacities for most damage forms of cement concrete pavements.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

Injectable hollow hydroxyapatite microsphere/chitosan composite drug carrier material and preparation method thereof

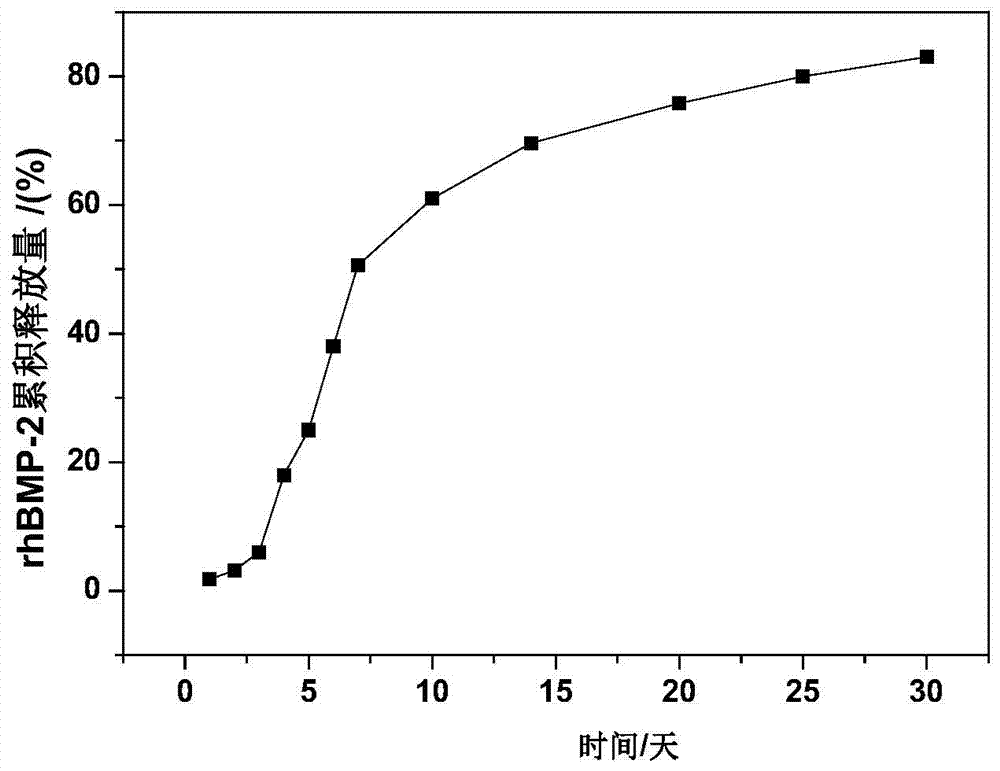

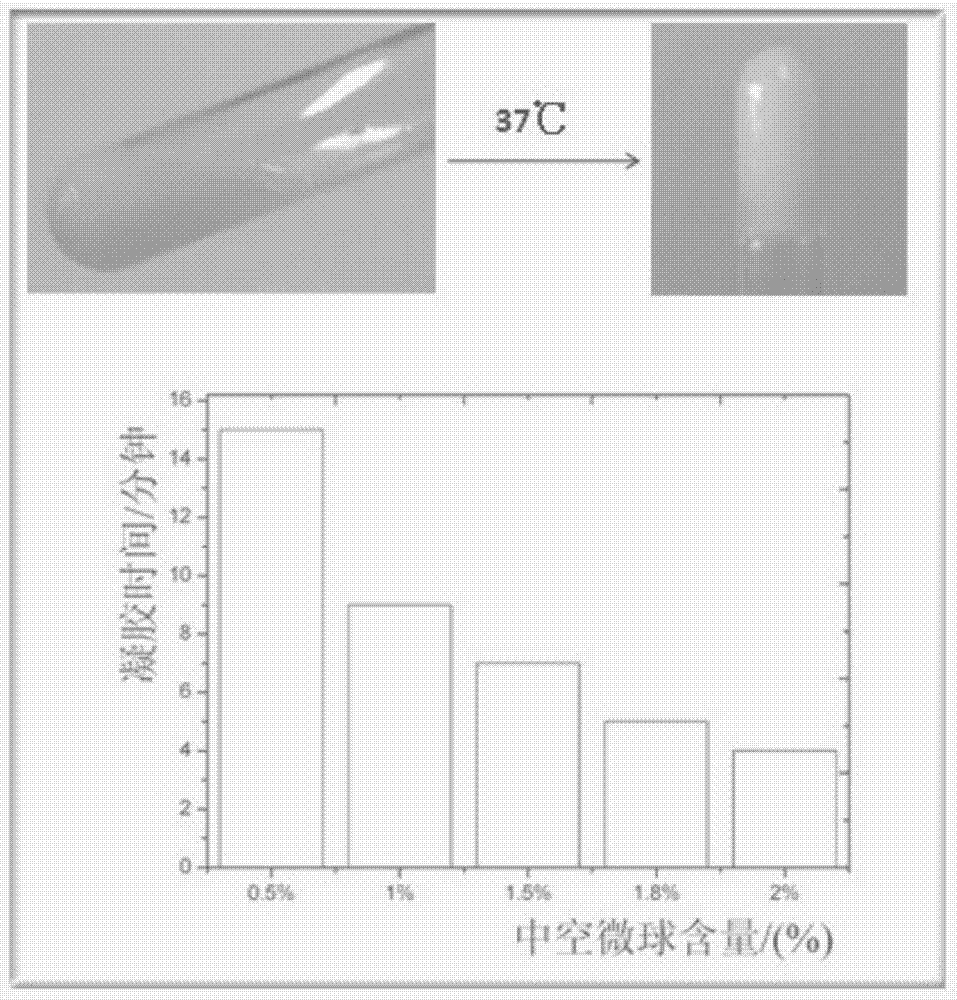

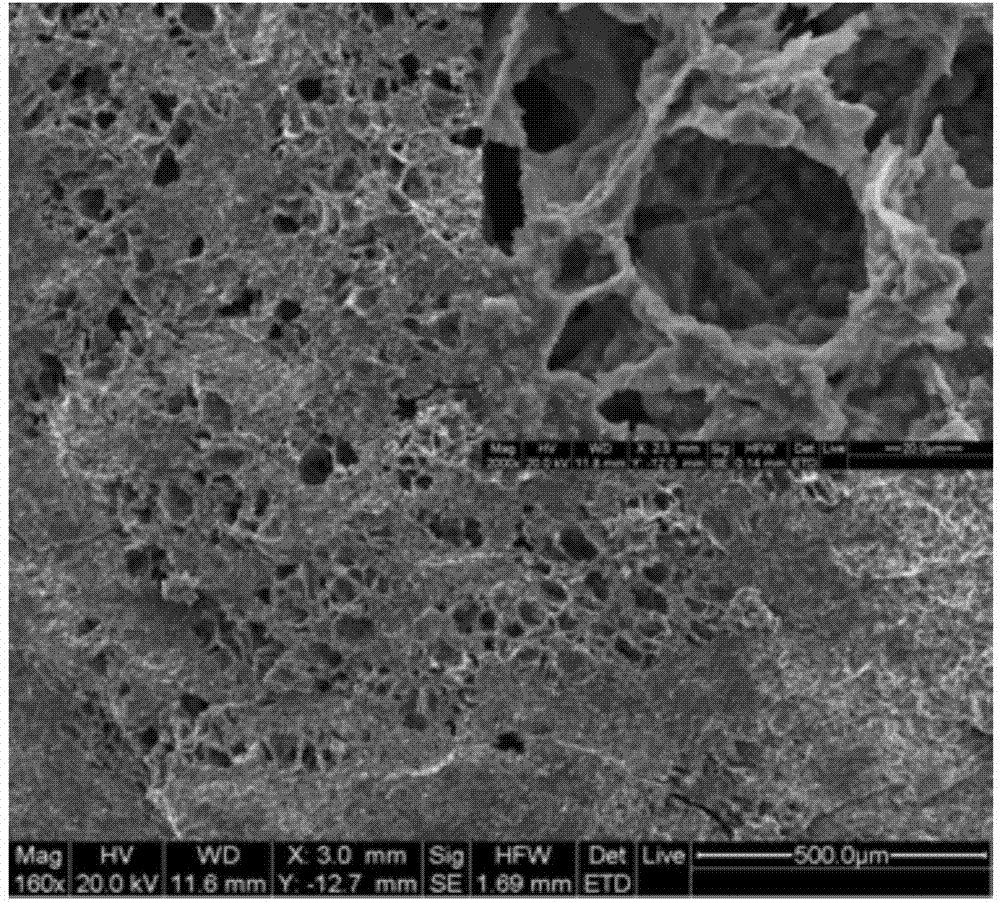

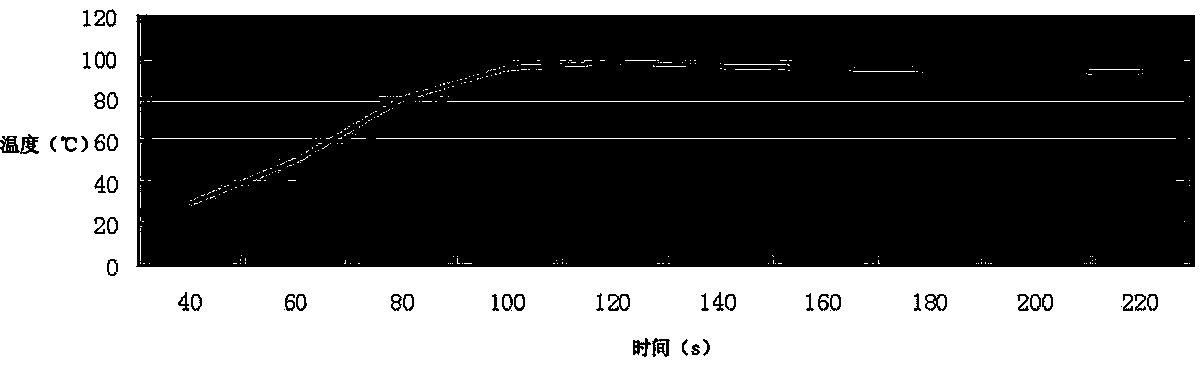

InactiveCN103690959ADrug sustained release effect is goodControllable degradation rateSkeletal disorderPharmaceutical non-active ingredientsControlled releaseMicrosphere

The invention discloses an injectable hollow hydroxyapatite microsphere / chitosan composite drug carrier material. The material comprises the following components in percentage by weight: 0.5-2wt% of hollow hydroxyapatite, 2wt% of chitosan, 5.6wt% of beta-sodium glycerophosphate and 90.4-91.9 wt% of water. The preparation method comprises the following steps: first, loading drug in the hollow sodium hydroxyapatite microsphere; then, preparing chitosan thermo-sensitive hydrogel; finally, mixing the drug-loaded hollow hydroxyapatite microsphere and the chitosan thermo-sensitive hydrogel in a solid-liquid ratio of (0.05-0.2)g / 10ml, and stirring to obtain the injectable hollow hydroxyapatite microsphere / chitosan composite drug carrier material. The material can realize slow and controlled release of drug, gives the material injectable molding property, and realizse minimally invasive therapy to bone defect or fracture.

Owner:TONGJI UNIV

High polymer chemistry coal and rock mass reinforcer for coal mines

InactiveCN103408721ALow viscosityHigh hydroxyl valueDrilling compositionDiamineDibutyl tin dilaurate

The invention provides a high polymer chemistry coal and rock mass reinforcer for coal mines and solves the problems of the existing polyurethane reinforcing material, such as high price, inflammable and toxic properties, poor performance stability and the like. The high polymer chemistry coal and rock mass reinforcer for coal mines provided by the invention comprises components A and B which are the same in volume, wherein the component A consists of polyether polyol, catalyst and fire retardant, and the component B is polyaryl polymethylene isocyanate; the polyether polyol has more than 3 functional groups, hydroxyl value of 450-550 and molecular weight of 300-500; the catalyst is composed of dibutyltin dilaurate and triethylene diamine; and the fire retardant is composed of methyl methylphosphonate, tri(1,3-dichloro-2-propyl) phosphate and sodium silicate. The high polymer chemistry coal and rock mass reinforcer for coal mines provided by the invention belongs to polyurethane grouting agents and silicate modified polyurethane grouting agents, and is an environment-friendly material with resin content of 100% and no volatile organic compounds, and all indexes of the reinforcer completely accord with AQ1089-2011 quality standard of high polymer material for reinforcing coal and rock mass in coal mines.

Owner:DATONG COAL MINE GRP

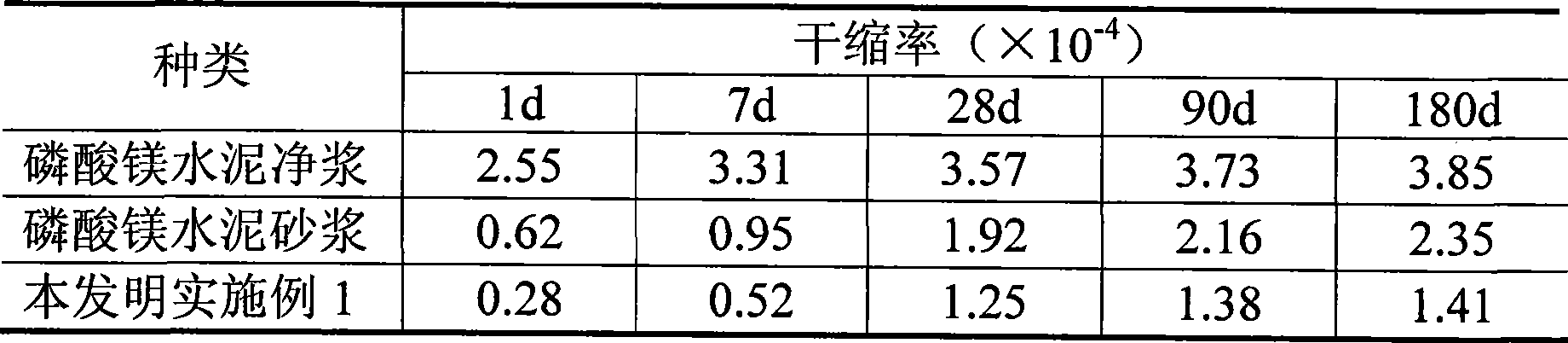

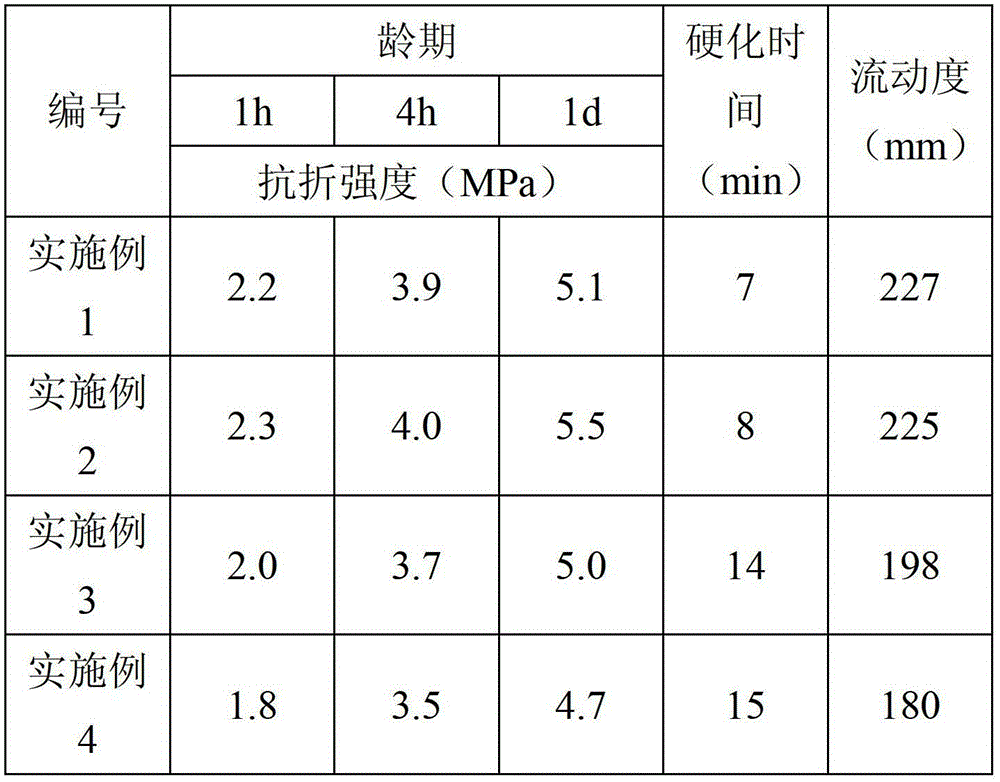

Rapid repair material based on building broken stones and preparation method thereof

The invention relates to building stone repairing. A rapid repair material based on building broken stones comprises a gelation mixture which quickly solidifies with water, wherein the gelation mixture comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. A preparation method of the materials comprises the following steps of: 1, preparing the magnesium phosphate cement; 2, mixing the magnesium phosphate cement, the sand and the silica sol so as to form the gelation mixture which comprises the following components in parts by weight: 40-55 parts of magnesium phosphate cement, 40-50 parts of sand and 10-15 parts of silica sol. The gelation mixture can be quickly solidified with the water to repair the stones. In addition, the gelation mixture is gelatineous before being solidified and facilitates construction; after the solidification, the small solidification shrinkage rate and a durable effect are obtained; and the repair material has high hardness and good water resistance after the solidification.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

Method for preparing non-sintered ceramsite by adding dredged sludge

The invention relates to a method for preparing non-sintered ceramsite by adding dredged sludge. The method comprises the following steps: (1) pre-treatment of the dredged sludge; (2) material preparation: mixing and stirring smashed dredged sludge, cement, quick lime, gypsum and coal ash to prepare a dry mixture; the mass portions of the smashed dredged sludge, cement, quick lime, gypsum and coal ash are as follows: 60 to 80 parts of the dredged sludge, 1 to 6 parts of the cement, 1 to 6 parts of the quick lime, 1 to 6 parts of the gypsum and 3 to 15 parts of the coal ash; then uniformly mixing water glass with water to obtain a mixed solution of the water glass and the water, wherein the mass ratio of the adding amount of the water glass to the dredged sludge is 3 to 15: 60 to 80, and the adding amount of the water accounts for 40 to 60 percent of the total mass of the dry mixture and the water glass; (3) disc granulation; (4) primary curing of a product; (5) waterproofing work; (6) ultimate curing of the product, namely obtaining a finish product of the non-sintered ceramsite. According to the method provided by the invention, a large amount of dredged sludge can be added, the purpose of utilizing waste materials is realized, the requirements of a dredging Industry are met, the production energy consumption is low, and the produced non-sintered ceramsite can meet the demands of construction market.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Composite mineral admixture for concrete

The invention discloses a composite mineral admixture for concrete. The admixture is prepared by mixing and grinding the following raw materials in percentage by weight: 40 to 60% of lithium slag, 10 to 30% of mineral slag, 5 to 20% of nickel slag, 5 to 10% of aerated concrete waste, 5 to 10% of sulfoaluminate cement clinker, and 0.1 to 0.5% of super plasticizer powder. The industrial wastes are fully utilized, the concrete production cost is reduced, and the admixture has a high activity, barely influences the early and late strength of concrete, has a shrinkage-compensating function and good anti-permeability property, and can improve the service life of concrete.

Owner:SOUTHEAST UNIV

Bone cement containing calcium citrate and preparation method of bone cement

ActiveCN105396175AImproved ability to resist collapseStrong plasticityTissue regenerationProsthesisSolid phasesOrthopedic department

The invention belongs to the field of bone damage repair medicinal materials and particularly relates to a preparation method and application of bone cement containing calcium citrate. The bone cement containing calcium citrate is composed of a solid phase part and a liquid phase part, the solid phase part is formed by compounding the calcium citrate and calcium phosphate salt, and the mass ratio of the calcium citrate to the calcium phosphate salt is (2-5):1; the liquid-solid ratio is (0.5-1.5):1. The bone cement containing the calcium citrate has comprehensive biomedical properties such as good plasticity, bone guidance, bone induction activity, cell activity and good degradation rate and is applicable to the orthopedics department, the thoracic surgery department and shaping and restoration of skull and jaw surfaces.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

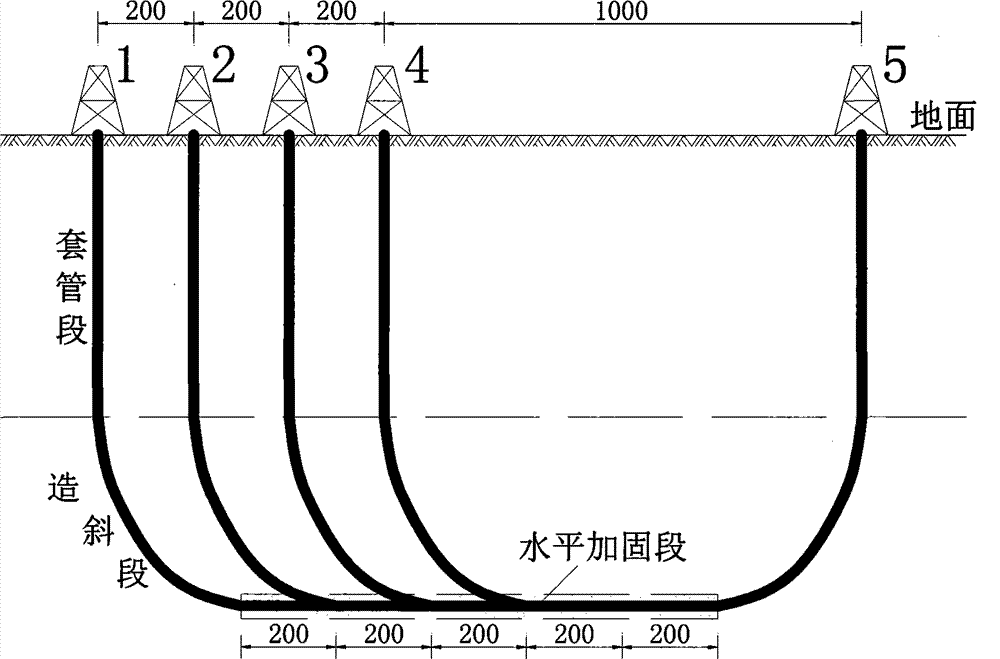

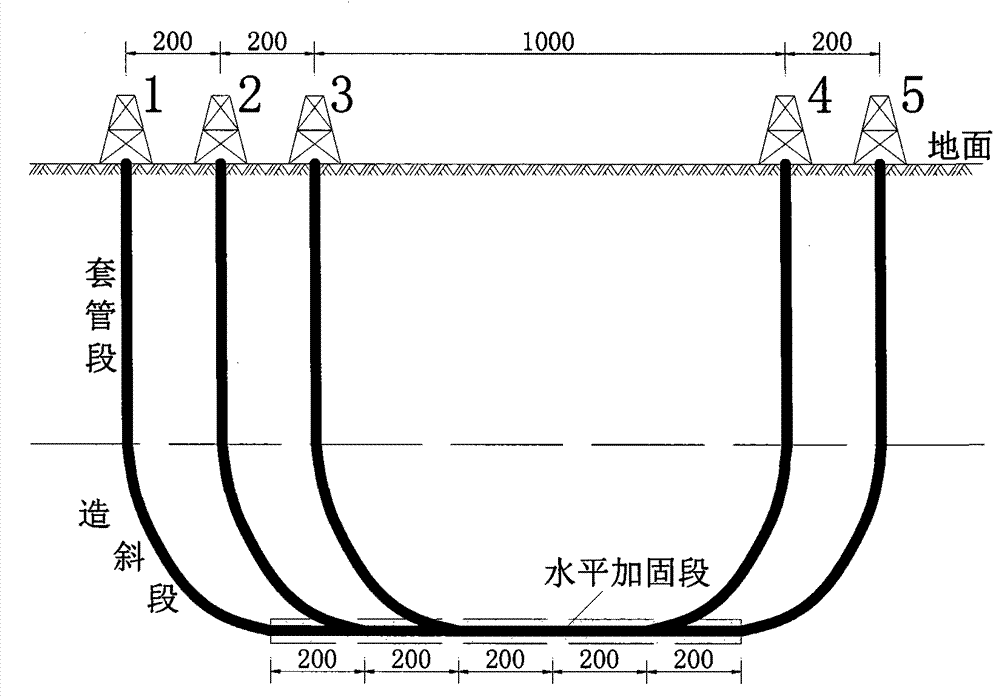

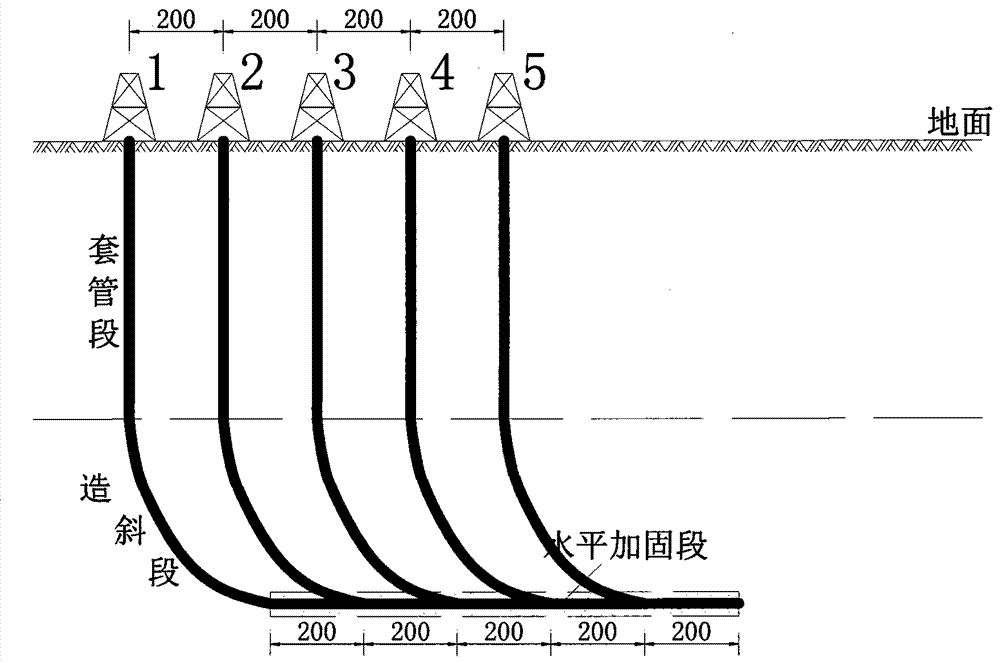

Ground pre-grouting strengthening technology for deep long-distance roadway surrounding rock

ActiveCN103835729AImprove liquidityControllable clotting timeUnderground chambersTunnel liningSlurryLarge range

The invention discloses a ground pre-grouting construction technology suitable for strengthening deep long-distance roadway surrounding rock, and particularly relates to a ground pre-grouting strengthening technology for deep long-distance roadway surrounding rock. The ground pre-grouting strengthening technology for the deep long-distance roadway surrounding rock includes the following steps that firstly, a ground grouting drill hole is formed in the ground through a drilling machine, the ground grouting drill hole comprises a casing pipe segment, a deflecting segment and a horizontal strengthening segment, a casing pipe segment drill hole is internally provided with a casing pipe, the deflecting segment and the horizontal strengthening segment are provided with rock open holes, and ground inlets of the ground grouting drill hole are formed in the walking direction of a roadway; secondly, grout is injected into a stratum rock body where the horizontal strengthening segment exists through a grouting pump located on the ground, and beforehand strengthening government of the roadway surrounding rock is achieved. According to the ground pre-grouting construction technology for strengthening the deep long-distance roadway surrounding rock, strengthening and grouting of the whole roadway surrounding rock can be achieved, and the ground pre-grouting construction technology is suitable for active strengthening of the coal mine large-range roadway surrounding rock and is high in safety and adaptability.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

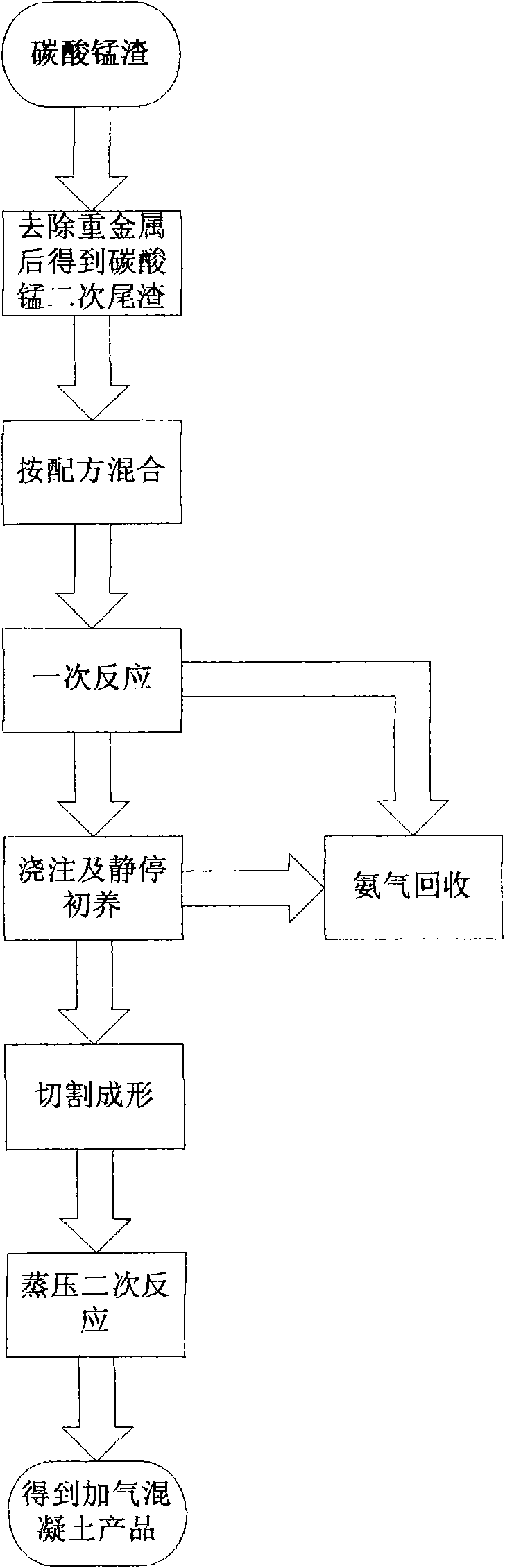

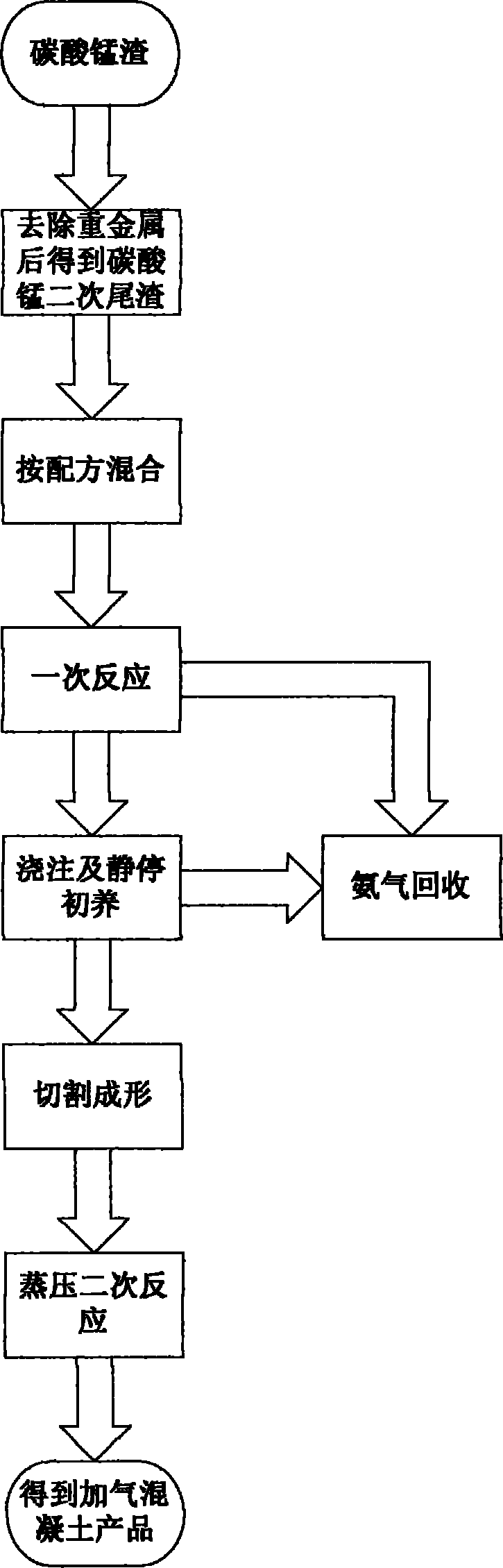

Aerated concrete building block produced by heavy metal-removed manganese carbonate tailing and manufacturing method thereof

ActiveCN101864823ASave mineral resourcesSolve pollutionSolid waste managementBuilding componentsMineral SourcesSlag

The invention discloses an aerated concrete building block produced by heavy metal-removed manganese carbonate tailing and a manufacturing method thereof. The aerated concrete building block comprises the following components in percentage by weight: 10-70% of heavy metal-removed manganese carbonate tailing, 0-70% of sand, 5-25% of lime, 4-20% of cement and 0.005-0.1% of aluminum powder. The invention has the advantages that according to the formula and the method of the invention, manganese carbonate concentrate which can reach mine entering grade in the manganese carbonate slag can be obtained, thus saving mineral product resources; meanwhile, the aerated concrete building block produced by heavy metal removed secondary manganese carbonate tailing conforms to the national standard (GB11968) and can reach the standard of qualified products of each grade or high-class products in the standard.

Owner:HUBEI SHENGRONG ENVIRONMENTAL PROTECTION ENERGY SAVING SCI & TECH LTD

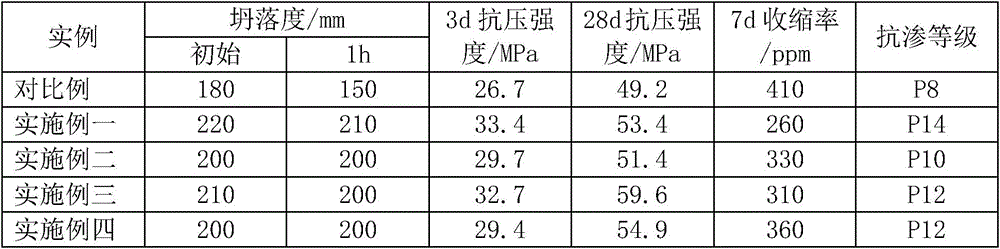

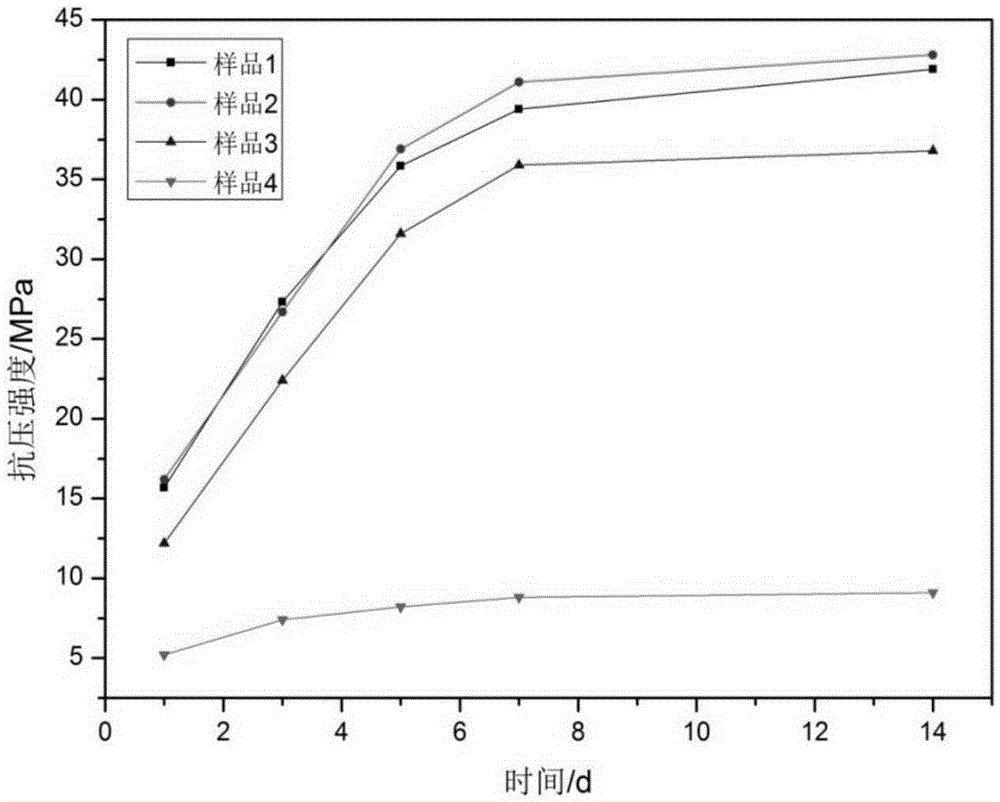

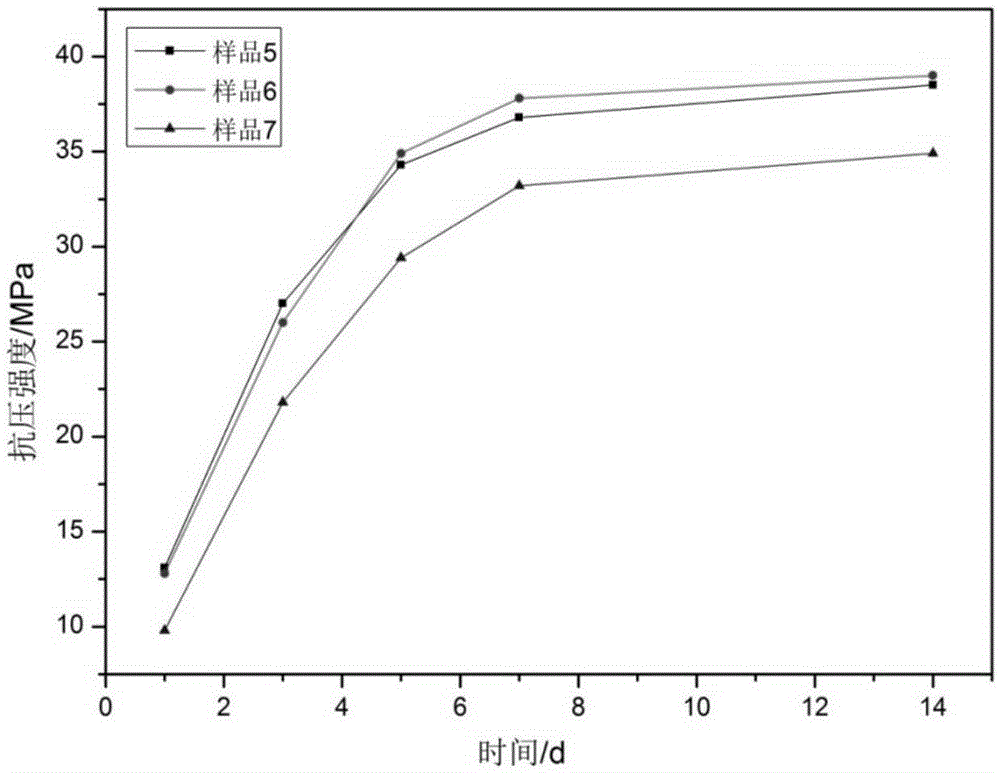

Cement-based composite material suitable for 3D printing rapid-forming process

ActiveCN106830843AControllable clotting time3D printing is goodAdditive manufacturing apparatusPortland cementUltimate tensile strength

The invention relates to a cement-based composite material suitable for making a building structure and components through a 3D printing rapid-forming process. The cement-based composite material is characterized in that an extrudable property is good, a stacking property is good, printing time is controllable, and mechanical properties and durability are excellent. Regarding detailed properties, the material has good thixotropy, controllable condensing and hardening time and good adhesion, hour strength development is rapid, and strength growth is stable at the later stage, requirements for the 3D printing process and rapid construction can be met, and actual application of the 3D printing technology in the building industry is promoted easily. The cement-based composite material includes 100 parts of ordinary Portland cement, 100-300 parts of fine aggregate, 5-20 parts of strength-promoting shrinkage reducing agent, 30-60 parts of mixing water, 0.1-2.0 parts of water reducing agent, 0.5-15 parts of interface reinforcing agent, 0.05-0.2 part of thixotropic agent and 0.5-3.5 parts of liquid coagulating components.

Owner:BEIJING UNIV OF TECH

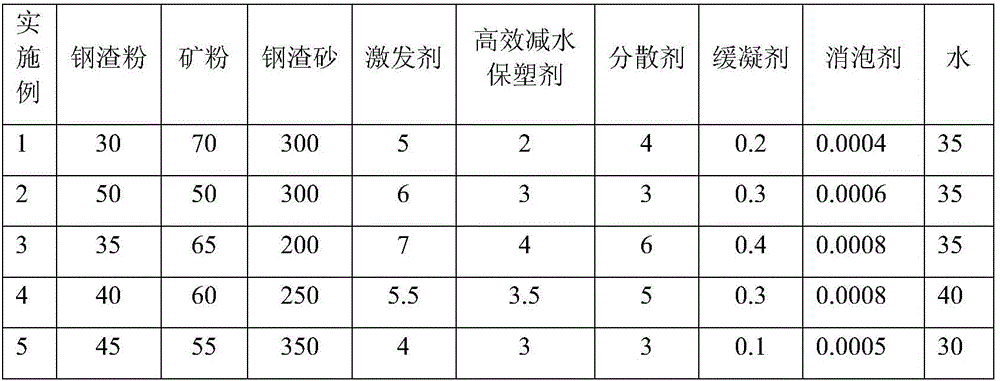

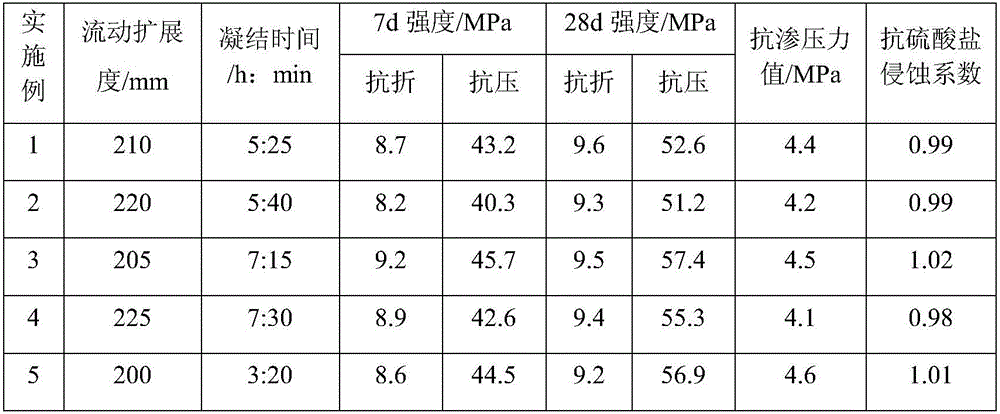

Non-cement green mortar by using steel slag as cementing material and fine aggregate and preparation method thereof

ActiveCN105859229AImprove overall utilizationImprove work performanceLeveling effectBreaking strength

The invention belongs to the field of building materials and particularly relates to a non-cement green mortar by using the steel slag as the cementing material and the fine aggregate and a preparation method thereof. The non-cement green mortar comprises the following components in weight part: 30-50 parts of steel slag powders, 50-70 parts of mineral powders, 200-350 parts of steel slag sands, 4-7 parts of activator, 1-4 parts of a water reducing agent, 3-6 parts of a dispersing agent, 0-0.4 parts of a retarder, 0.0002-0.001 part of a defoamer, and 30-40 parts of water. The non-cement green mortar is good in working performance, automatic in leveling effect, adjustable in setting time with the range of 0.5-8 hours, high in early-late strength, and excellent in impermeability and resistance to sulfate attack. The 7d breaking strength of the non-cement green mortar is larger than 8 MPa, and the compression strength thereof is larger than 40 MPa. The 28d breaking strength of the non-cement green mortar is larger than 9 MPa, and the compression strength thereof is larger than 50 MPa. Therefore, the non-cement green mortar can be widely applied to the engineering practice.

Owner:WUHAN UNIV OF TECH

Synchronous grouting method for recycling large-diameter waste slurry generated during slurry shield

The invention provides a synchronous grouting method for recycling large-diameter waste slurry generated during slurry shield. The product per cubic meter is prepared from the following raw materials by weight: 100-180kg of cement, 50-120kg of slaked lime, 120-350kg of fly ash, 1300-1500kg of sand, 500-800kg of waste slurry, 0.5-2kg of water-retaining thickener, 0.5-2kg of water reducer, 0.5-2kg of retarder and 0.5-2kg of air entraining agent. The method has the advantages that expensive bentonite is unnecessary to be added, and about 100kg of bentonite is saved by mortar per cubic meter, thus effectively reducing the cost; the method has the advantages of good pumpability, water-retaining property, lubricating property, flowability, filling property and the like, and is used for fully utilizing the waste slurry.

Owner:CHINA RAILWAY 14TH BUREAU GRP LARGE SHIELD ENG CO LTD

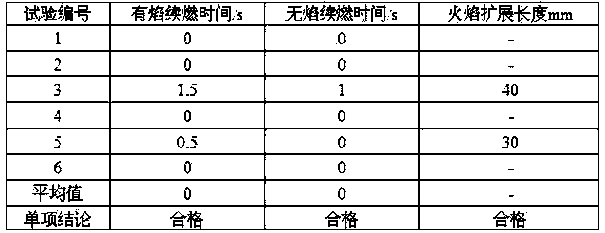

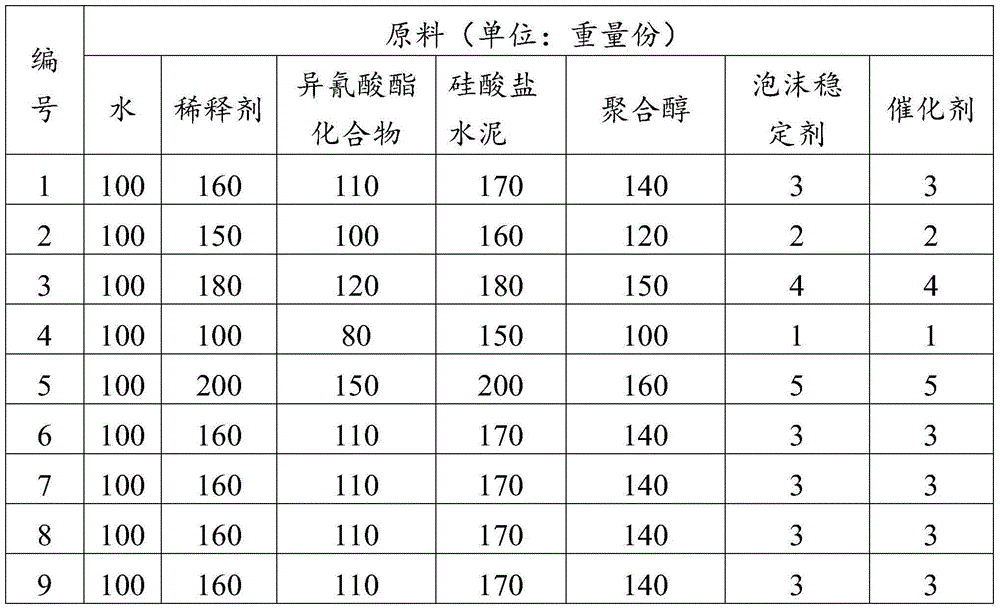

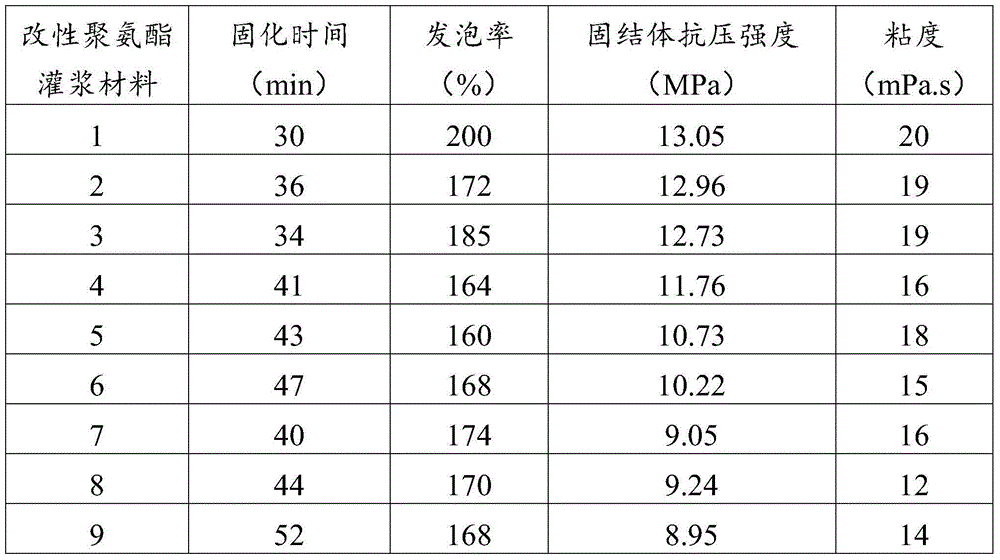

Modified polyurethane grouting material and preparation method and application thereof

ActiveCN104140667ALow costAdjustable setting timeOther chemical processesChemistryEnvironmentally friendly

The invention discloses a preparation method and application of a modified polyurethane grouting material. The preparation method comprises the following steps that firstly, diluents, isocyanate compounds, water and Portland cement make contact and are evenly mixed to obtain a component A, and polymeric alcohol, foam stabilizers and catalysts make contact and are evenly mixed to obtain a component B; secondly, the component A and the component B make contact and are evenly mixed. The preparation method and application of the modified polyurethane grouting material solve the problems of an existing pure polyurethane grouting material that the cost is high, induration strength is low, and an inorganic grouting material is long in setting time and slow in strength development, and the obtained material is low in cost, adjustable in setting time, high in foaming induration strength, good in permeability and environmentally friendly.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Leaking stoppage reinforcing agent

InactiveCN103740348APrevent precipitationGood for condensationDrilling compositionSulfite saltSlurry

The invention discloses a leaking stoppage reinforcing agent comprising the following components in parts by weight: 20-30 parts of sodium silicate, 20-30 parts of phenolic resin, 30-50 parts of calcium carbonate, 1-5 parts of potassium silicate, 1-5 parts of sodium sulfite, 0.5-3 parts of polyacrylamide (PAM), 0.5-3 parts of sodium carboxymethylcellulose CMC-LV and 0.5-3 parts of hydroxyethyl cellulose (HEC). According to a conventional preparation method, the materials are added into a kneading machine in sequence in parts by weight at normal temperature and under normal pressure and then are uniformly mixed and stirred, and then the mixture is crushed into granular products, of which the particle size is 0.01mm-0.3mm, after being dried. The leaking stoppage reinforcing agent disclosed by the invention has the characteristics of easily available raw materials, scientific and simple process, safe construction, capability of reinforcing the wall of a leakage stratum well, capability of being added into different types of leaking stoppage slurry when being used together with other materials for reinforcement, capability of improving the reinforcing performance of leaking stoppage slurry and the like, and is widely applied to petroleum and geological drilling engineering.

Owner:DONGYING TAIER GASOLINE TECH

Flue gas desulphuration gypsum-alkaline residue soil stabilizer

InactiveCN102899048AAlleviate the pressure of resource shortageReduce waste burdenBuilding constructionsOrganic fertilisersEcological environmentSlag

The invention discloses a FGD (flue gas desulphuration) gypsum-alkaline residue soil stabilizer, comprising the following ingredients: 12-30wt% of FGD gypsum, 20-50wt% of alkaline residue, 0-30wt% of slag, 0-5wt% of additive, and 0-20wt% of fly ash; wherein the summation in weight percentage of the ingredients is 100%. The soil stabilizer disclosed herein has the advantages of alleviating the environmental protection pressure of alkaline and power enterprises and resource shortage pressure of building material enterprises, reducing waste discharge burden of enterprises, increasing income, and improving ecological environment.

Owner:中诚正丰环保科技有限公司

Alkali-activated-carbonate/slag compound gel material and preparation method thereof

InactiveCN1699252AHigh strengthWork performance can be adjustedSolid waste managementAlkali activatedSilicon oxide

The invention relates to an alkali-activated-carbonate / slag compound gel material and preparation method which comprises, calculated by mass portions, diluting 0.5-2 parts of additive with 10-25 parts of water, charging 30-50 parts of slag powder into the prepared additive solution, agitating homogeneously, then charging 30-65 parts of natron sodium oxide having a modulus of 1.4-1.8 and exciting agent with the sum of mass concentration 45-55% with the silicon oxide, charging 50-70 parts of marginal carbonate powdered ore, agitating homogeneously, thus obtaining the end product.

Owner:SOUTH CHINA UNIV OF TECH

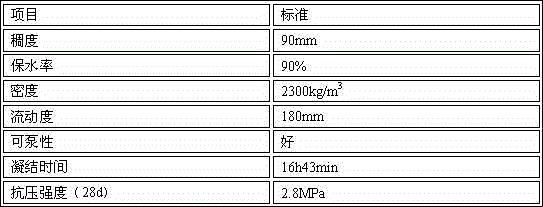

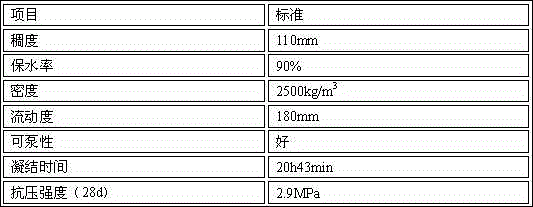

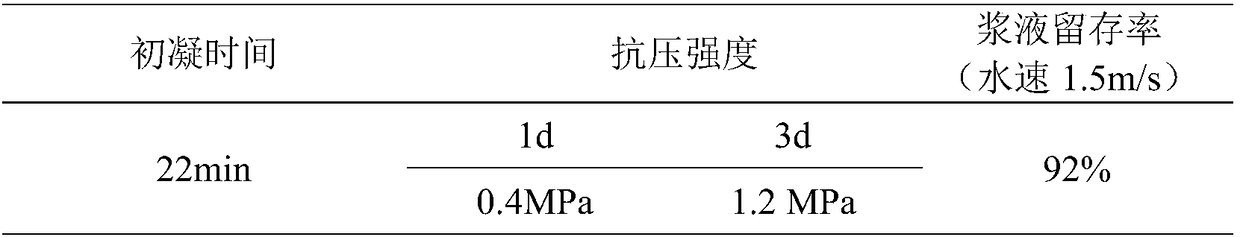

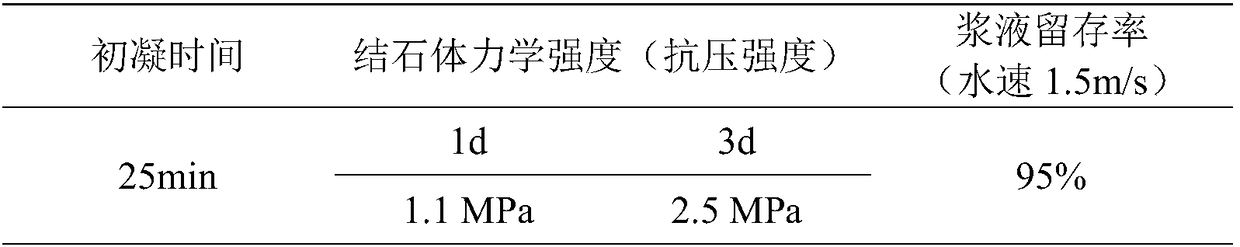

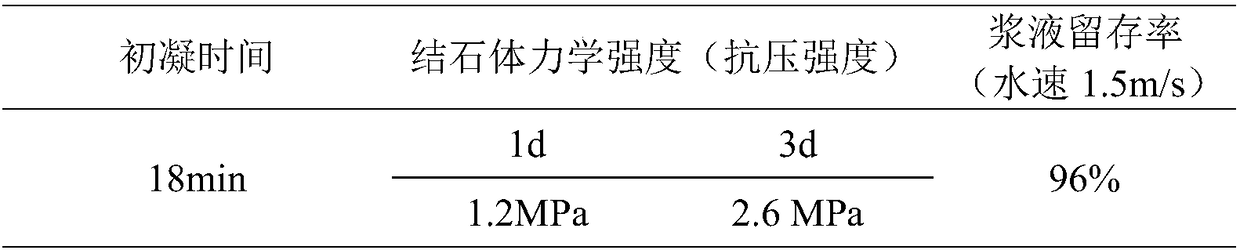

Flowing water dispersion resistant blocking material and preparation method thereof

ActiveCN108484058AControllable clotting timeEfficient governanceProtective foundationMarine site engineeringPolyolWater soluble

The invention discloses a flowing water dispersion resistant blocking material and belongs to the technical field of preparation of injecting paste materials. The blocking material is composed of components A and B, wherein the component A comprises a hydraulic cementing material and water, and a water-binder ratio is 0.6-1 to 1; the component B comprises the following components in percentage byweight: 0.3-1.2% of water-soluble vegetable glue, 0.2-1% of polymer polyol, 0.2-1.5% of alcohol polysaccharide, 10-44% of sodium silicate and 52.3-86.3% of water. The blocking material disclosed by the invention has the advantages of being low in cost, adjustable in setting time, high in dispersion resistance, high in slurry retention rate and excellent in consolidating mechanical property, beingsafe and non-toxic, and the like. Due to tests, the slurry retention rate reaches 90% or higher within 30 minutes at water velocity of 1.5m / s, the highest slurry retention rate can reach 97%, and excellent effects are achieved.

Owner:SHANDONG UNIV

Composite sulphoaluminate cement-based self-leveling material and preparation method thereof

The invention provides a composite sulphoaluminate cement-based self-leveling material which comprises the following components by weight percent: 20-50% of dihydrate gypsum, 10-32% of active admixture, 20-50% of early strength agent, 2-10% of alkaline exciting agent, 0.6-1.2% of coagulant, 0.5-1.0% of water reducing agent, 0.02-0.1% of water-retaining agent and 0-0.1% of defoamer. The composite sulphoaluminate cement-based self-leveling material has the advantages of high early strength, good water tolerance, adjustable coagulation time, low energy consumption and low production cost, can beused as a leveling construction material for various grounds and is convenient for construction.

Owner:长沙归一新材料科技股份有限公司

Casing method of dredging sediment non-sintered ceramsites

The invention relates to a casing method of dredging sediment non-sintered ceramsites, comprising following steps: (1) crushing cement, quicklime, glass fibre powder, and fly ash by using a crusher; (2) mixing the pretreated cement, quicklime, glass fibre powder, and fly ash to make dry mixed casing material, weighing dredging sediment non-sintered ceramsites, wherein the mass ratio is : 10-20 parts of cement, 1-10 parts of quicklime, 1-10 parts of glass fiber powder, 1-10 parts of fly ash, and 50-70 parts of dredging sediment non-sintered ceramsites; (3) adopting a disc shot blasting machine for polishing casing; (4) maintaining for prepared non-sintered casing ceramsites. The casing method can consume a large amount of dredging sediment and meets the requirement for resource utilization of dredging industry, and largely promotes intensity of the dredging sediment non-sintered ceramsites, furthermore the production energy consumption is low, the non-sintered casing ceramsites have a wide application range and meet the requirements of construction markets.

Owner:TIANJIN UNIV OF SCI & TECH

Retarding type high-fluidity high-strength underwater concrete additive and preparation method thereof

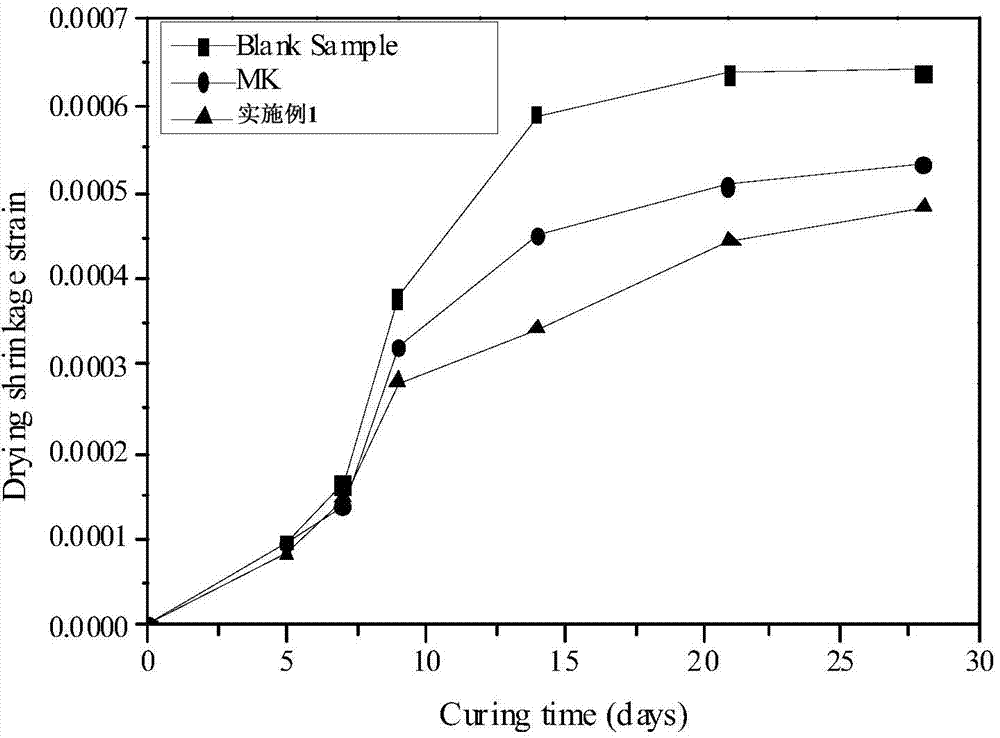

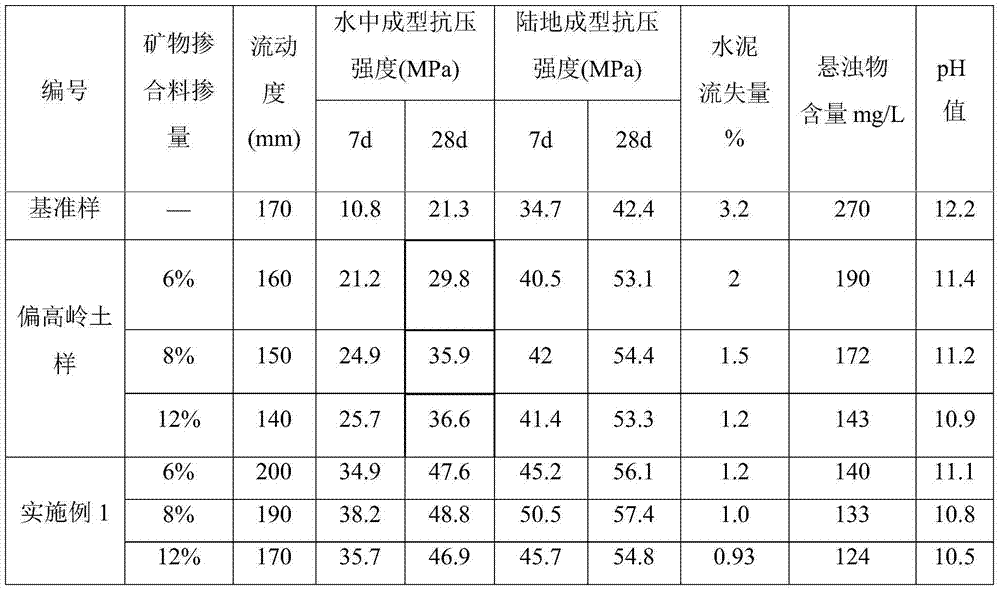

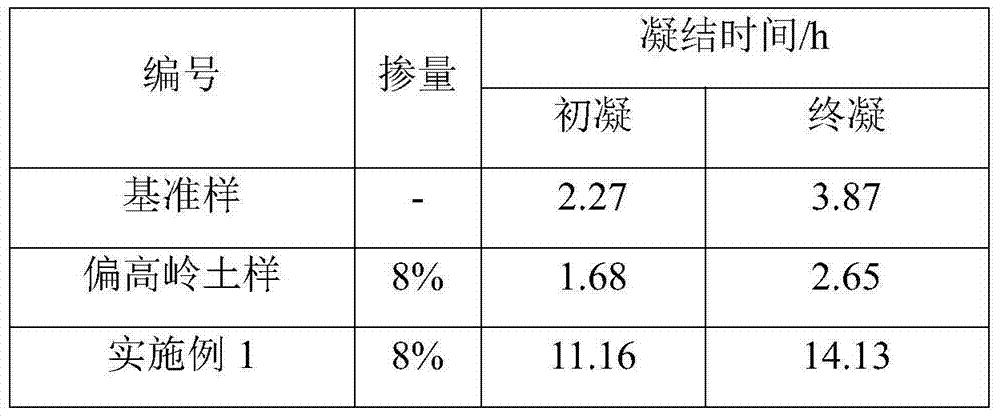

The invention belongs to the technical field of building materials, and particularly relates to a retarding type high-fluidity high-strength underwater concrete additive. The additive can effectively improve the strength and dispersion resistance of concrete and has the advantages of simple preparation process, low production cost and the like. The additive is characterized by comprising metakaolin and a composite modifier. The mass ratio of the metakaolin to the composite modifier is (50:1)-(15:1); the composite modifier is prepared by mixing 70-85% of polyacrylamide, 10-20% of superplasticizer and 5-15% of organic water-soluble polysaccharide substances all by mass based on a total of 100%. As an additive for underwater concrete, the additive can improve the working performance and dispersion resistance of underwater concrete and delay the setting time; and the strength at each age, particularly the early age strength of underwater concrete is remarkably improved. Meanwhile, the volume stability of underwater concrete can be effectively improved.

Owner:WUHAN UNIV OF TECH +1

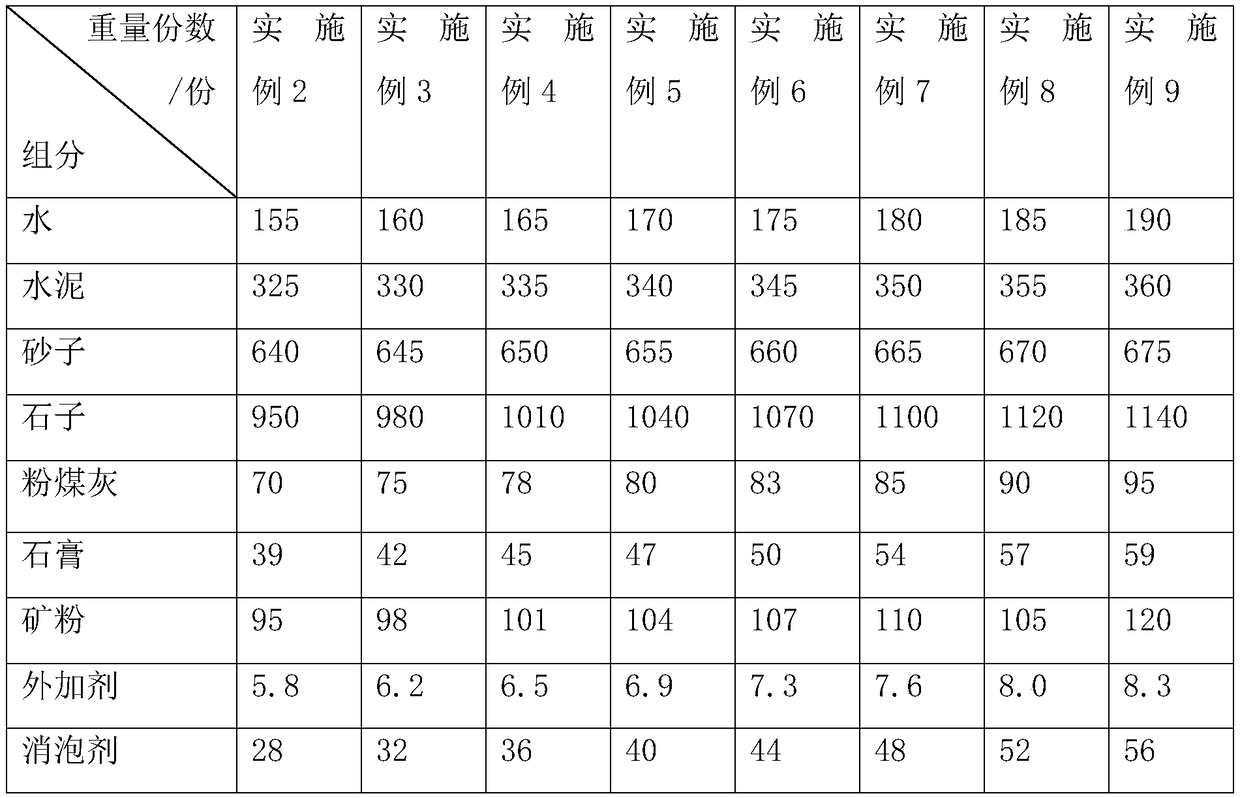

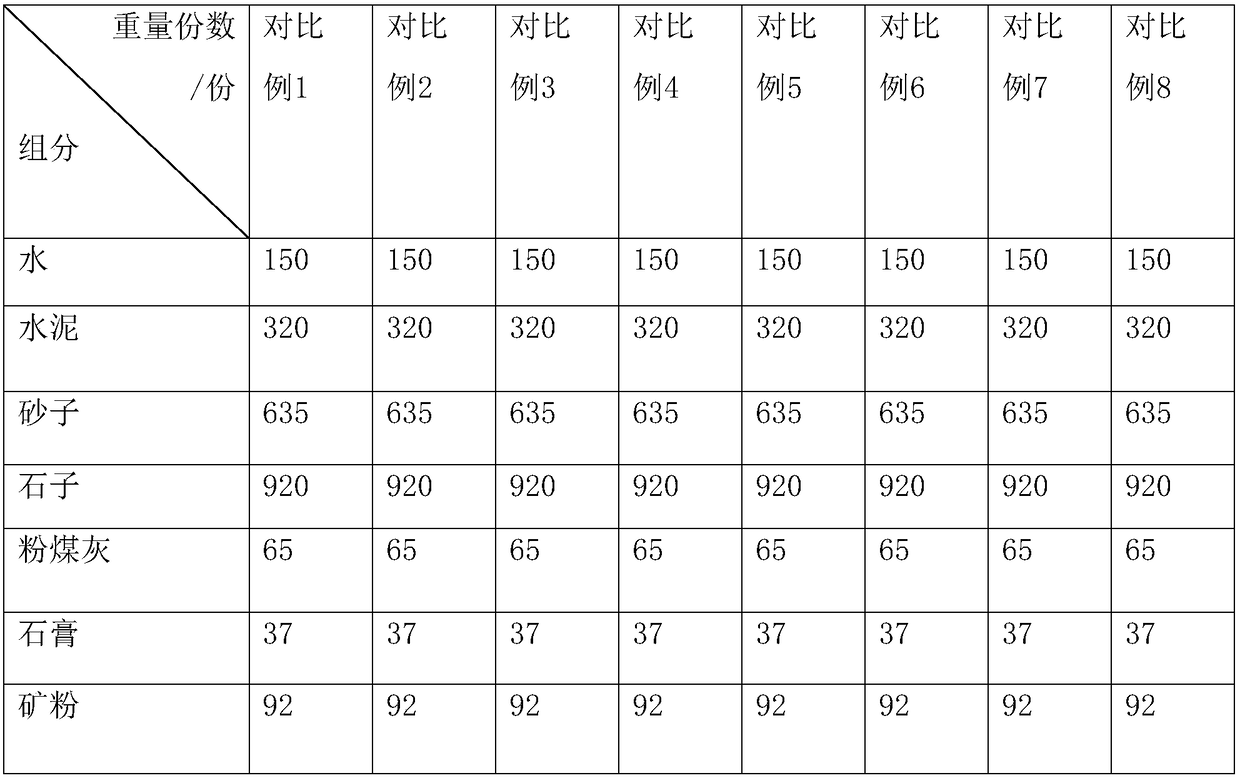

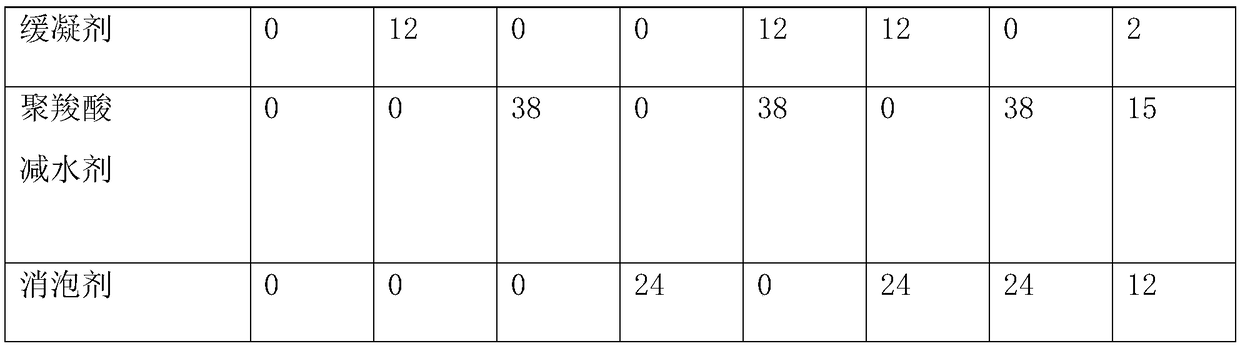

Super-retarding concrete and preparation method thereof

The invention discloses super-retarding concrete and relates to the technical field of building materials. According to the key pint of the technical scheme, the super-retarding concrete comprises thefollowing ingredients (by weight): 150-190 parts of water, 320-360 parts of cement, 635-675 parts of sand, 920-1140 parts of cobblestone, 65-95 parts of an admixture A, 92-120 parts of an admixture B, 37-59 parts of gypsum, and 5.5-8.3 parts of an additive. The additive comprises the following ingredients (by weight): 12-16 parts of a retarder and 38-52 parts of a polycarboxylate superplasticizer. The admixture A comprises fly ash, and the admixture B comprises mineral powder. The retarder is composed of sodium thiosulfate, glycerol and sodium tripolyphosphate according to the mass ratio of 1-3: 2.4-3.5: 2.3-3.2. The problem that concrete's short setting time and low long-term strength are hard to meet the requirement of prolonging the setting time of concrete and guaranteeing long-term strength is solved. By using the retarder and the polycarboxylate superplasticizer cooperatively, the setting time of concrete can be prolonged, and the concrete can have high long-term strength.

Owner:上海石化安东混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com