Non-cement green mortar by using steel slag as cementing material and fine aggregate and preparation method thereof

A technology of cementitious material and fine aggregate, which is applied in the field of cement-free green mortar and its preparation, can solve the problems of limiting the application of high added value of steel slag, poor volume stability, low activity of steel slag, etc., and achieves sulfate corrosion resistance. Excellent, save natural resources and energy, easy to prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

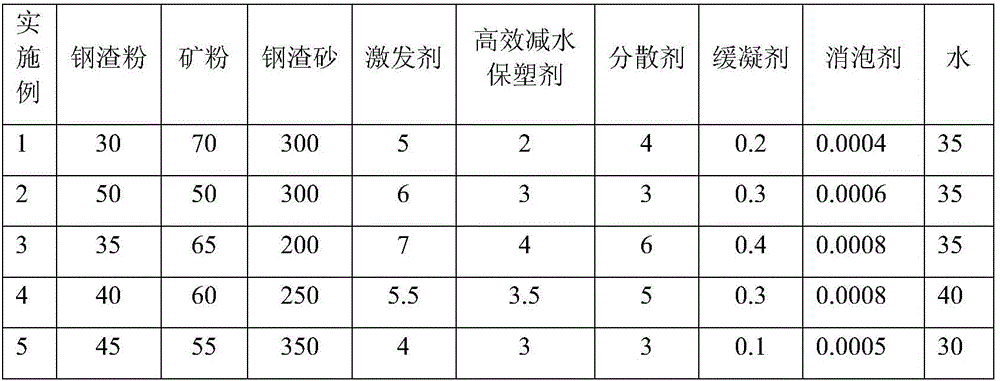

Embodiment 1

[0038] A cement-free green mortar with steel slag as cementitious material and fine aggregate, consisting of the following components in parts by weight: 30 parts of steel slag powder, 70 parts of mineral powder, 300 parts of steel slag sand, 5 parts of activator, water reducing 2 parts of agent, 4 parts of dispersant, 0.2 part of retarder, 0.0004 part of defoamer, 35 parts of water.

[0039] The steel slag powder is prepared by aging, crushing, screening, magnetic separation and grinding process from the waste slag discharged from the steelmaking plant, and the Blaine specific surface area of the steel slag powder is greater than 400m 2 / kg; the ore powder is blast furnace slag, S95 grade, and its Blaine specific surface area is greater than 350m 2 / kg; the steel slag sand is prepared by crushing, sieving and magnetic separation processes after the waste slag discharged from the steelmaking plant is aged for 2 years, gray black, and the fineness modulus of the steel slag sa...

Embodiment 2

[0043] A cement-free green mortar with steel slag as cementitious material and fine aggregate, consisting of the following components in parts by weight: 50 parts of steel slag powder, 50 parts of mineral powder, 300 parts of steel slag sand, 6 parts of activator, water reducing 3 parts of agent, 3 parts of dispersant, 0.3 parts of retarder, 0.0006 parts of defoamer, 35 parts of water.

[0044] The steel slag powder is prepared by aging, crushing, screening, magnetic separation and grinding process from the waste slag discharged from the steelmaking plant, and the Blaine specific surface area of the steel slag powder is greater than 400m 2 / kg; the ore powder is blast furnace slag, S95 grade, and its Blaine specific surface area is greater than 350m 2 / kg; the steel slag sand is prepared by crushing, sieving and magnetic separation processes after the waste slag discharged from the steelmaking plant is aged for 2 years, gray black, and the fineness modulus of the steel slag ...

Embodiment 3

[0048] A cement-free green mortar with steel slag as cementitious material and fine aggregate, which consists of the following components in parts by weight: 35 parts of steel slag powder, 65 parts of mineral powder, 200 parts of steel slag sand, 7 parts of activator, water reducing 4 parts of agent, 6 parts of dispersant, 0.4 part of retarder, 0.0008 part of defoamer, 35 parts of water.

[0049] The steel slag powder is prepared by aging, crushing, screening, magnetic separation and grinding process from the waste slag discharged from the steelmaking plant, and the Blaine specific surface area of the steel slag powder is greater than 400m 2 / kg; the ore powder is blast furnace slag, S95 grade, and its Blaine specific surface area is greater than 350m 2 / kg; the steel slag sand is prepared by crushing, sieving and magnetic separation processes after the waste slag discharged from the steelmaking plant is aged for 2 years, gray black, and the fineness modulus of the steel sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com