Patents

Literature

189results about How to "Erosion effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

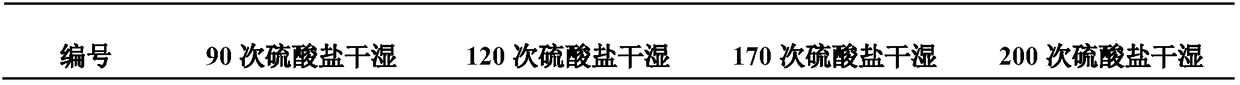

Preparation method of high-performance anti-corrosion repairing mortar

A preparation method of high-performance anti-corrosion repairing mortar including following components, by weight: 150-250 parts of cement, 280-725 parts of quartz sand, 50-200 parts of mineral powder, 50-150 parts of fly ash, 0-50 parts of silicon ash, 5-10 parts of barium nitrate, 0.1-1 part of an early strength agent, 1-4 parts of PP fibers, 0.5-20 parts of latex powder, 0.5-5 parts of cellulose ether, 0.5-2 parts of a water repellent agent, 0.001-0.1 parts of an air entraining agent, 0.1-2 parts of a water reducing agent, 0-1 part of a defoaming agent, and 100-250 parts of water. The invention, aiming to the characteristic of sulphate attack and the performance requirement of repairing mortar, discloses the repairing mortar which can repair the surface of damaged concrete with a protective film formed thereon to prevent the concrete form being corroded again. The repairing mortar is good in construction performance, can be used for coating the surface of the damaged concrete or filling damaged positions of the concrete. The repairing mortar is high in bonding strength and strength, is good in anti-permeability and flexibility, is simple in preparation process, is especially suitable for repairing the concrete subjected to sulphate attack, is great in market prospect and is good in practicability.

Owner:潍坊德霖建材科技有限公司

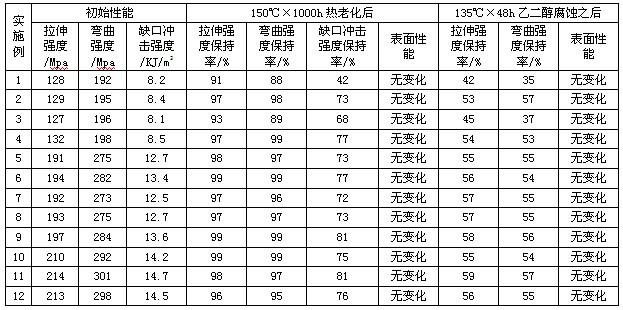

Hydrolysis-resistant alcoholysis-resistant nylon 66 composite material and preparation method thereof

The invention provides a hydrolysis-resistant alcoholysis-resistant nylon 66 composite material and a preparation method thereof. The hydrolysis-resistant alcoholysis-resistant nylon 66 composite material is characterized by comprising the following ingredients in parts by weight: 51.8 to 84.5 parts of nylon resin, 15 to 40 parts of short-cut glass fibers, 0.1 to 0.6 parts of nucleating agent, 0.1 to 0.6 parts of thermal stabilizer, 0.1 to 1.0 part of alcoholysis-resistant auxiliary agent, 0.1 to 5 parts of barrier material and 0.1 to 1.0 part of lubricant. The manufacturing method comprises the following steps that: the nylon 66 resin, antioxidant, hydrolysis-resistant agent, the barrier material, the nucleating agent and the lubricant, which are previously dried, are uniformly mixed at a high speed; and the mixture and the glass fiber are fed into a double-screw extruder to be extruded and pelleted. The hydrolysis-resistant alcoholysis-resistant nylon 66 composite material not only has good high temperature resistance and high thermal oxidation aging resistance, but also has excellent property for resisting the corrosion of glycol and solution thereof, and can completely satisfy the requirements on manufacturing components such as car heat radiator cooling water tanks, thermostats and charge air coolers.

Owner:SHANGHAI KINGFA SCI & TECH +1

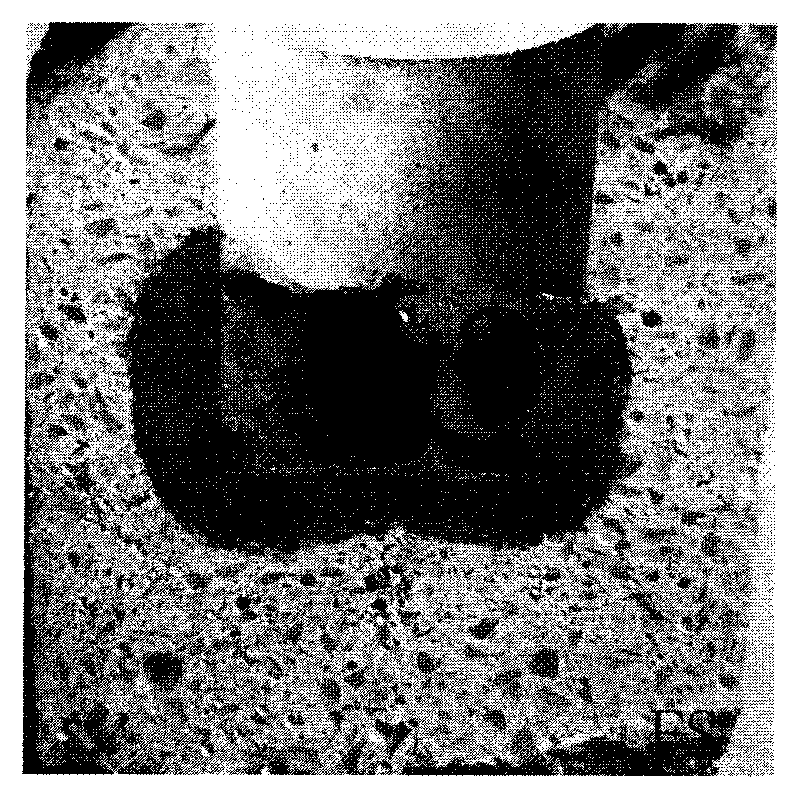

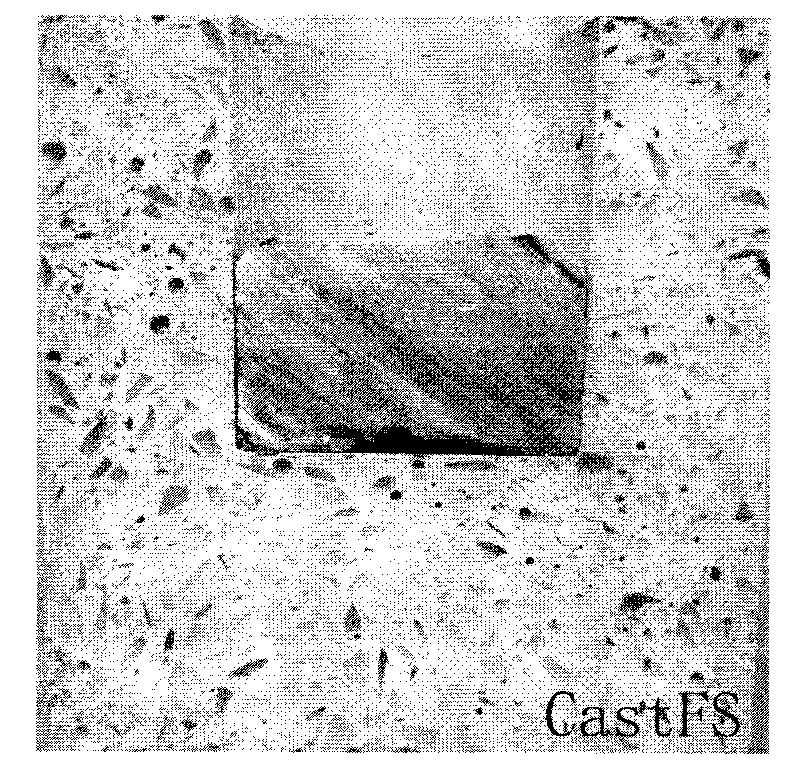

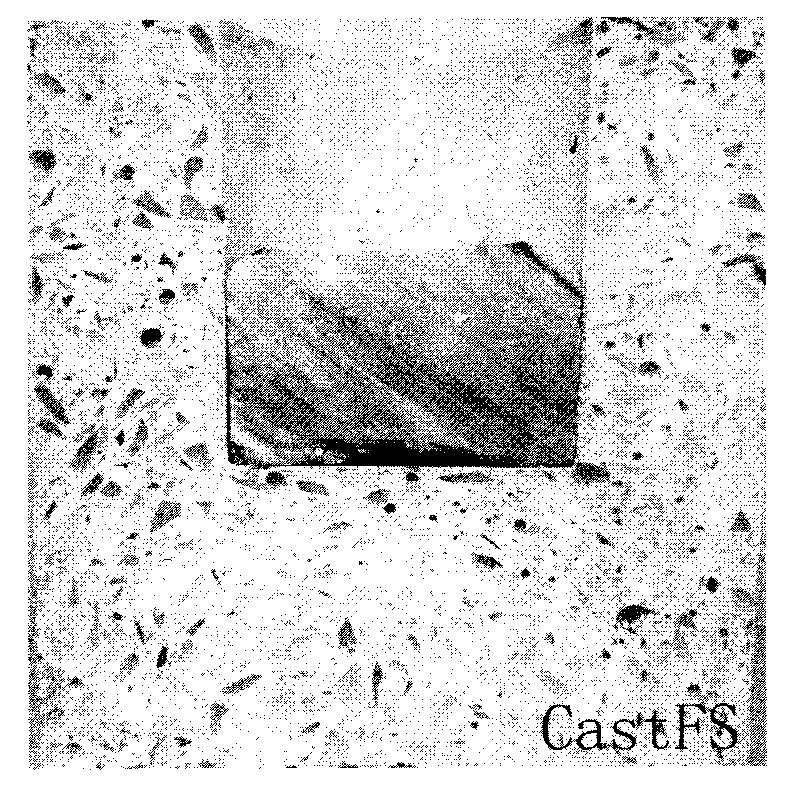

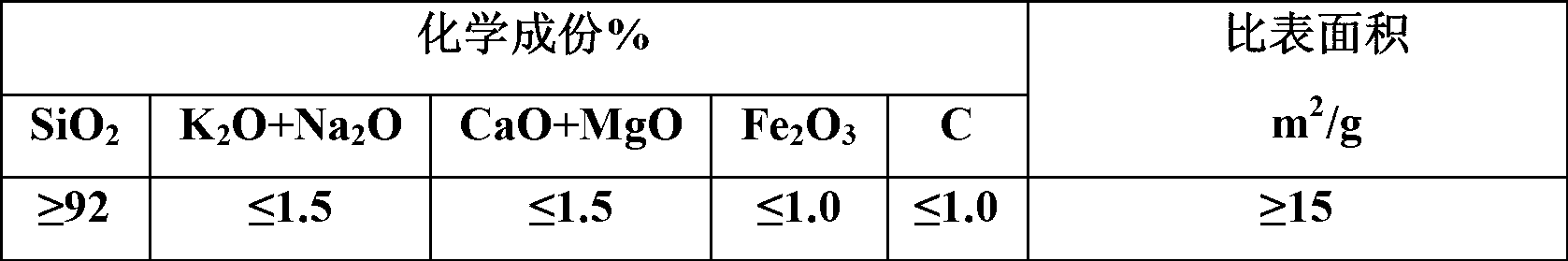

Preparation method of fused silica refractory casting material unwetted by aluminum liquid

The invention belongs to the field of refractory materials and discloses a preparation method of a fused silica refractory casting material unwetted by an aluminum liquid, which comprises the following step of: enhancing a ground substance by adopting 10-20wt% of white alundum powder, 4-8wt% of calcium aluminate cement, 3-5wt% of hydrated alumina compound binding agent, 4-10wt% of silicon oxide micropowder and 3-6wt% of alumina micropowder, wherein 60-70wt% of fused silica is used as a main material, BaSO4 and Na3AlF6 is adopted as a compound aluminum liquid anti-wetting agent with the addition of 1-6wt%, and additional 0.12wt% of trimeric sodium phosphate and additional 0.03wt% of sodium hexametahposphate are adopted as dispensing agents. The casting material prepared by using the method has high strength, is unwetted by the aluminum liquid, has the highest use temperature of 1000 DEG C and can be used as the refractory materials, such as an aluminum flowing groove of an aluminum smelting furnace and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

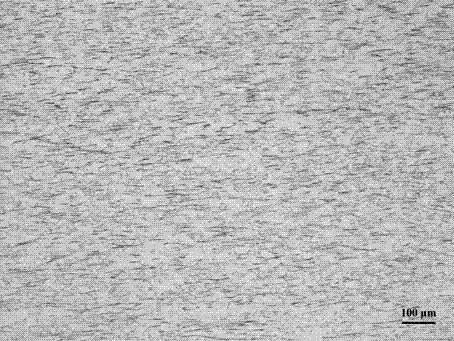

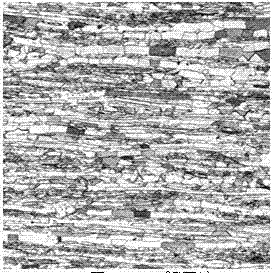

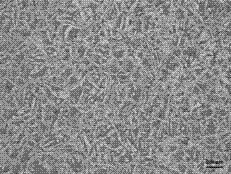

Austenitic stainless steel metallographic etchant, preparing method and use thereof

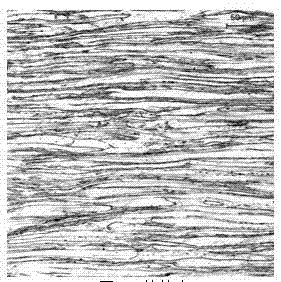

InactiveCN101353794ADisplay clearErosion effect is goodPreparing sample for investigationHydrofluoric acidAlcohol

The invention discloses a metallographic-phase aggressive agent of an austenitic stainless steel, a preparation method thereof and application thereof. The metallographic-phase aggressive agent comprises the mixed solution of hydrofluoric acid and nitric acid, calculated by volume ratio, the proportion of each component of the agent is that hydrofluoric acid : nitric acid : water is equal to 2 : 1 : 7. The preparation method thereof is carried out according to the following steps of: taking 70ml of water first, then taking 10ml of analytically pure nitric acid and finally taking 20ml of analytically pure hydrofluoric acid, which are then evenly mixed. The application method thereof comprises the following steps of: putting a simple of the austenitic stainless steel in the metallographic-phase aggressive agent of the austenitic stainless steel and observing the color change of the surface of the sample by time, taking out the sample of the austenitic stainless steel when metallographic-phase surface of the sample is corroded to darker silver gray, washing the sample with water which is then neutralized with alkaline solution and finally washing with water and absolute ethyl alcohol. The technical effects thereof are represented by good corrosion effect, clear austenite grain boundary, slow corrosion speed, easy control, no pollution and other aspects.

Owner:董加坤

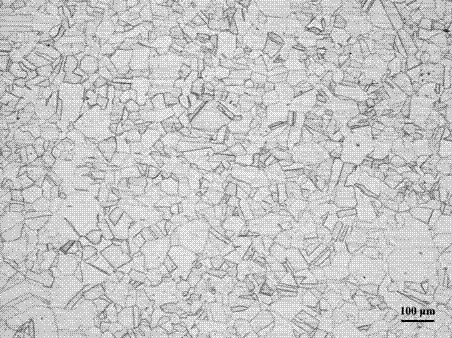

Metallographic etchant and erosion method of austenitic stainless steel

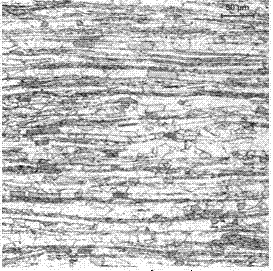

ActiveCN102517585AClear grain boundariesErosion is slowPreparing sample for investigationSS - Stainless steelAustenite

The invention relates to a metallographic etchant and an erosion method of austenitic stainless steel, which are especially suitable for metallographic erosion of 316 / 316L / 316H / 317 / 317L austenitic stainless steels. The metallographic etchant of the invention is composed of the following ingredients in percentage by volume: 30-35% of hydrochloric acid with mass percent concentration of 40%, 15-20%of nitric acid with mass percent concentration of 68%, 30-35% of propanetriol, and 15-20% of hydrogen peroxide solution with mass percent concentration of 30%. The metallographic etchant of the invention has the advantages of reasonable design, good erosion effect, good tissue display effect of eroded sample, non-pollution and slow and stable erosion reaction.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Wet paved/pre-paved polymer self-adhesive waterproofing rolled material and preparation method thereof

InactiveCN102454226AExtended service lifeWeather resistantUnderground chambersRoof covering using flexible materialsPolymer resinCompound (substance)

The invention provides a wet paved / pre-paved polymer self-adhesive waterproofing rolled material which comprises a modified asphalt self-adhesive layer. The modified bitumen self-adhesive layer contains petroleum asphalt, modifier, softener, tackifier and filler. The wet paved / pre-paved polymer self-adhesive waterproofing rolled material which is prepared from the by taking a polymer resin layer as a base has a long use life, stable chemical properties and excellent waterproof effect, wherein the modified asphalt self-adhesive layer is prepared through single side or double side adhering.

Owner:沈阳蓝光科技发展有限公司

Aluminium-magnesia carbon brick and preparation method thereof

The invention provides an aluminium-magnesia carbon brick and a preparation method thereof, belonging to the field of refractory materials. The raw materials of the aluminium-magnesia carbon brick include 30-80 parts of waste aluminium-magnesia carbon brick grains, 3-40 parts of special grade bauxite chamotte, 3-10 parts of magnesia, 3-10 parts of magnesia-alumina spinel, 5-8 parts of graphite, 3-15 parts of micro powder additives and 2.2-3.5 parts of organic bonds by weight. The preparation method is characterized by sorting, hydrating, drying and grinding the waste aluminium-magnesia carbonbricks from the steel mills and then mulling the waste aluminium-magnesia carbon brick grains with other raw materials, forming and carrying out heat treatment to prepare the aluminium-magnesia carbon brick. The energy-saving and environment-friendly aluminium-magnesia carbon brick prepared by the invention has high compression strength, low porosity, good resistance to molten steel corrosion andservice life reaching or exceeding the service lives of the traditional aluminium-magnesia carbon bricks. In the invention, the waste aluminium-magnesia carbon bricks are rationally utilized and consumption of the mineral resources is reduced.

Owner:ZHENGZHOU DONGFANG SANLI REFRACTORY MATERIALS

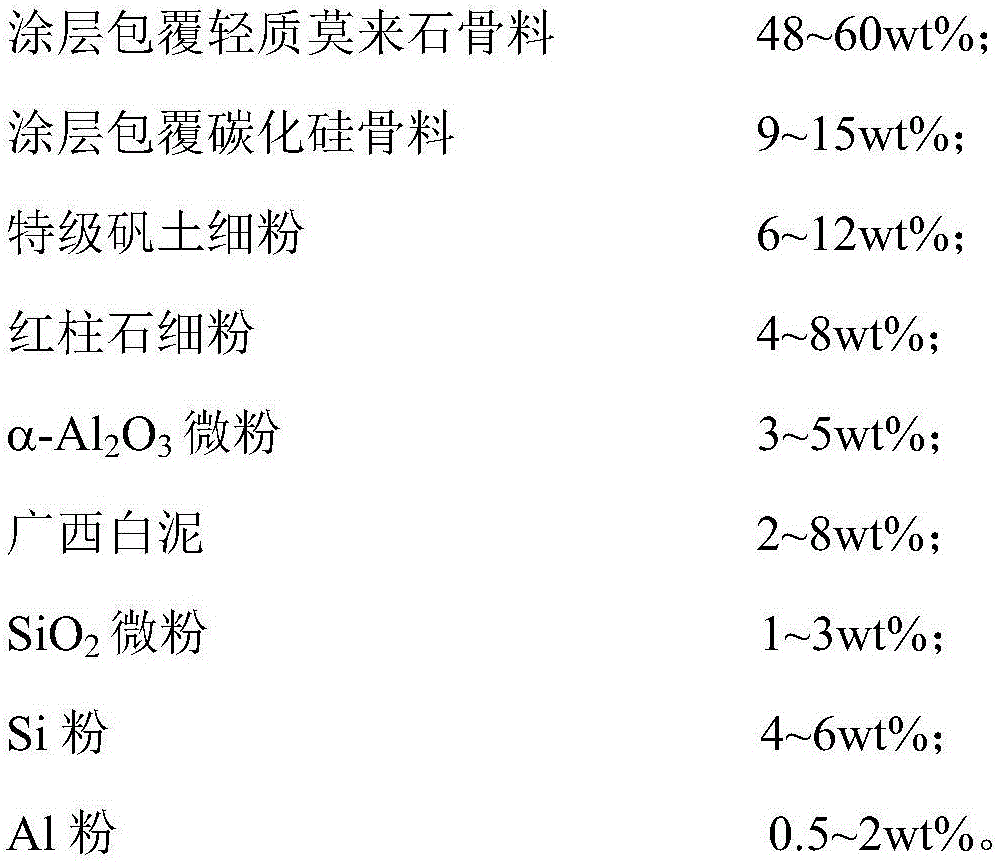

Mullite silicon carbide complex-phase fireproof material and preparation method thereof

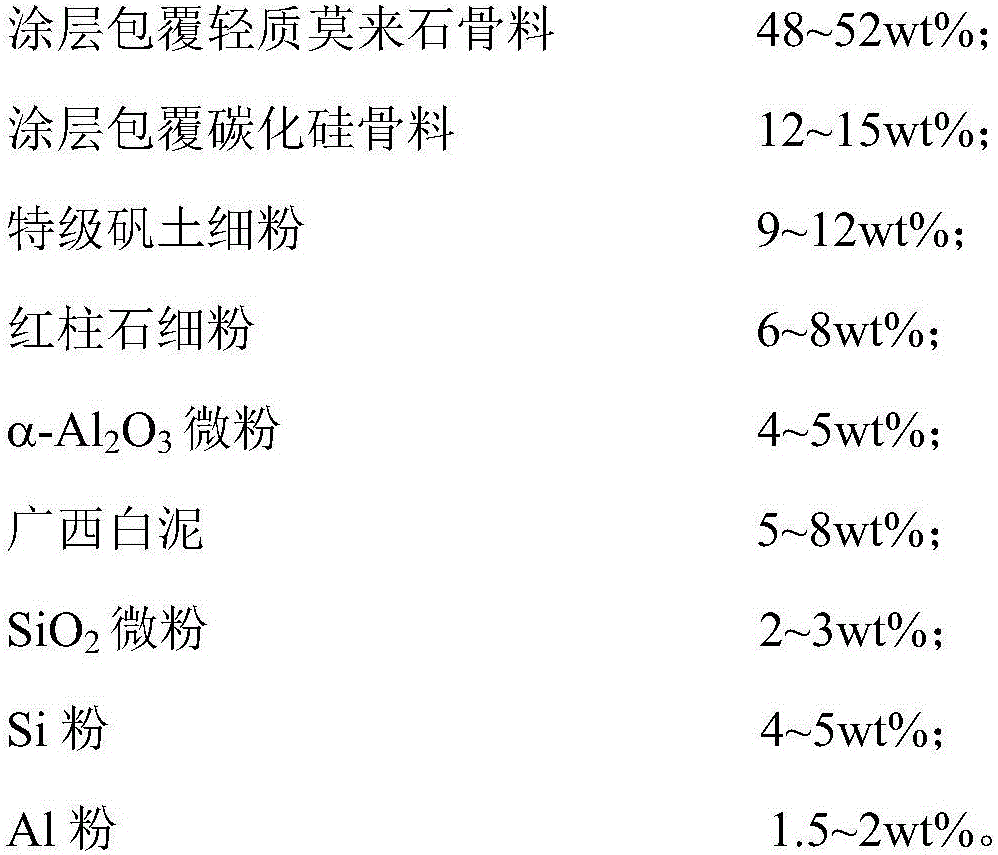

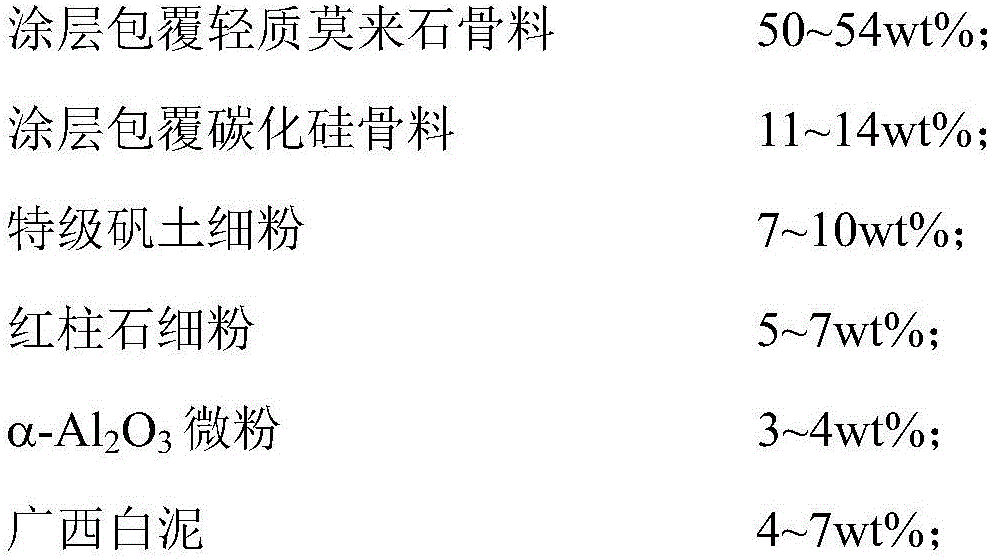

The invention relates to a mullite silicon carbide complex-phase fireproof material and a preparation method thereof. The mullite silicon carbide complex-phase fireproof material is characterized in that 48-60wt% of coating cladding mullite light aggregate, 9-15wt% of coating cladding silicon carbide aggregate, 6-12wt% of top-grade bauxite fine powder, 4-8wt% of andalusite fine powder, 3-5wt% of alpha-Al2O3 micro powder, 4-8wt% of Guangxi white clay, 1-3wt% of SiO2 micro powder, 4-6wt% of Si powder and 0.5-2wt% of Al powder are used as raw materials. The preparation method comprises the following steps of firstly mixing two kinds of the aggregate in the raw materials, adding a bonding agent, then performing mixed refining on the mixed aggregate, the bonding agent and other raw materials, performing material trapping, performing compression moulding, performing drying, and performing baking under the condition of 1250-1400 DEG C so as to obtain the mullite silicon carbide complex-phase fireproof material. The mullite silicon carbide complex-phase fireproof material prepared by the preparation method disclosed by the invention has the excellent characteristics of being low in heat conduction coefficients, good in erosion resistance, and high in intensity.

Owner:WUHAN UNIV OF SCI & TECH

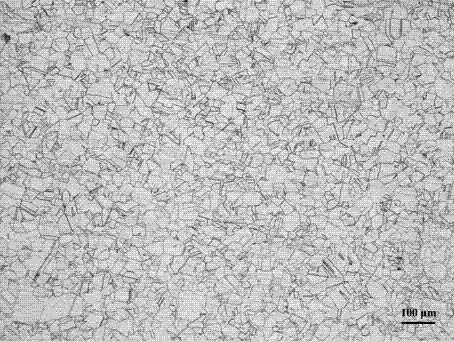

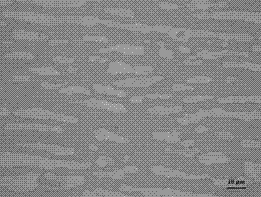

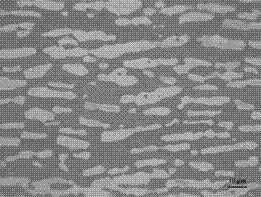

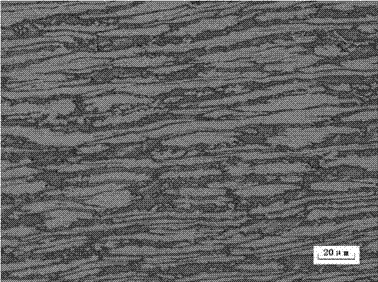

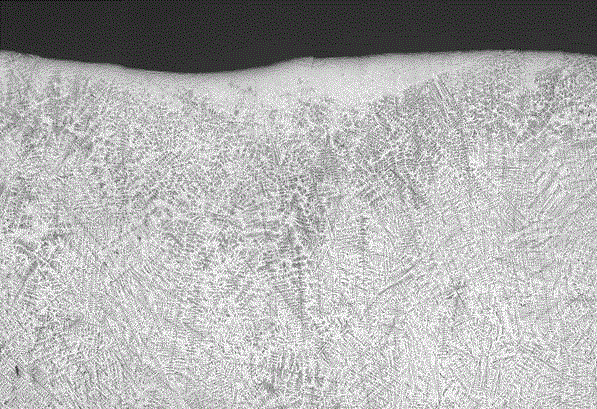

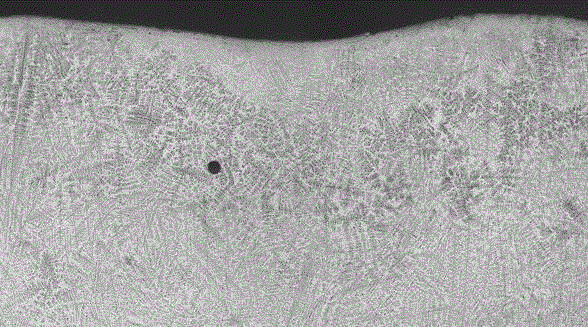

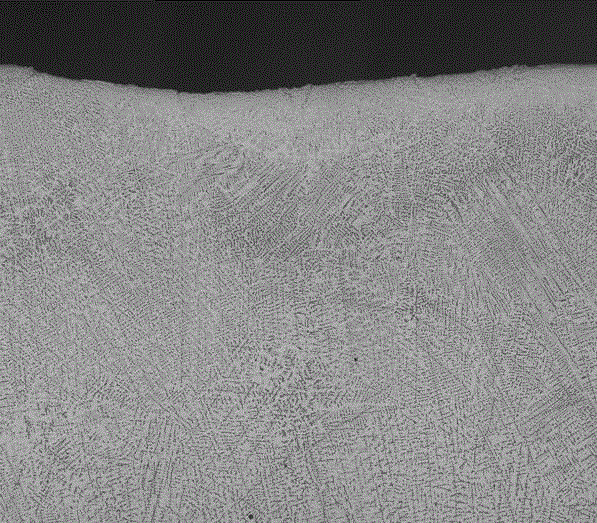

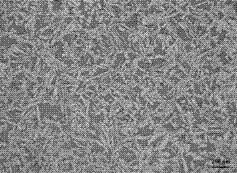

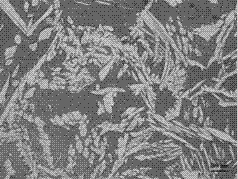

Method for displaying two-phase grain boundary of duplex stainless steel

ActiveCN103792128AGood technical effectErosion effect is goodPreparing sample for investigationAlcoholCopper sulfate

The invention relates to a method for displaying two-phase grain boundary of duplex stainless steel. The method comprises the following steps: I, preparation of a metallographic sample, namely, (1) cutting the metallographic sample by adopting a machining saw; (2) roughly grinding the observation surface of the sample; (3) mechanically polishing the observation surface of the sample by adopting a metallographic polishing machine; (4) finely polishing the observation surface by the metallographic polishing machine; (5) cleaning the observation surface of the sample with ethyl alcohol; II, preparation of a corrosive agent, namely, preparing a mixed solution from 10-15g of copper sulfate, 50 mm <3> of nitric acid with the volume percentage being 65-68% and 100-150 mm <3> of hydrochloric acid with the volume percentage being 36-38%; III, corrosion of the metallographic sample, namely, putting the metallographic sample into a metallographic corrosive agent, taking out the duplex stainless steel when the metallographic observation surface is corroded to be deep silver gray, cleaning the sample with water, and wiping the observation surface of the metallographic sample by degreasing cotton dipped with absolute ethyl alcohol. The method for displaying two-phase grain boundary of duplex stainless steel can be used for quickly, simply and conveniently displaying the two-phase grain boundary of the duplex stainless steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

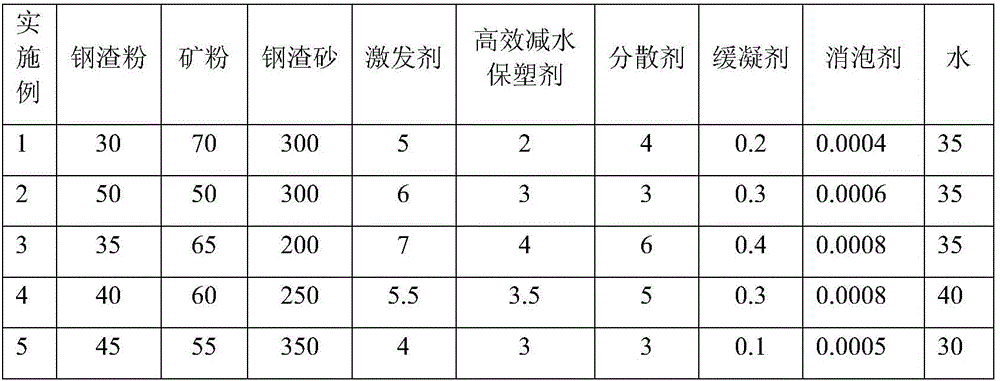

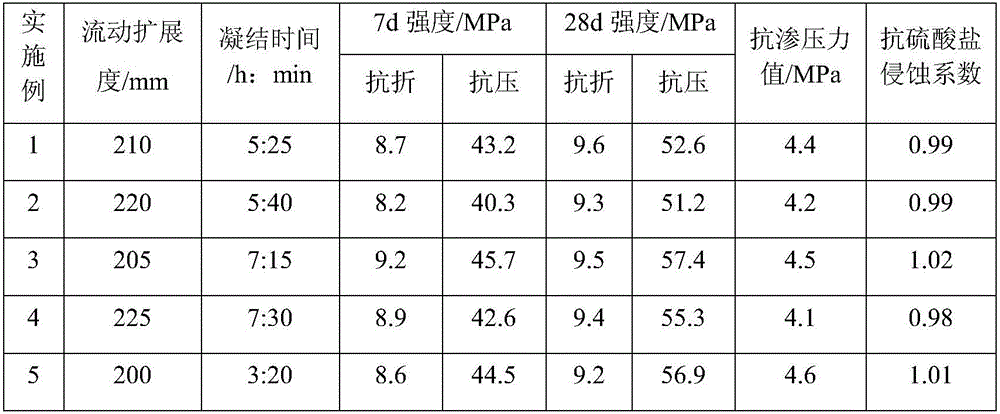

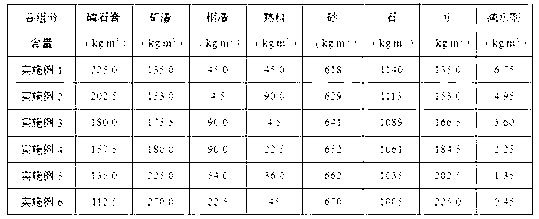

Non-cement green mortar by using steel slag as cementing material and fine aggregate and preparation method thereof

ActiveCN105859229AImprove overall utilizationImprove work performanceLeveling effectBreaking strength

The invention belongs to the field of building materials and particularly relates to a non-cement green mortar by using the steel slag as the cementing material and the fine aggregate and a preparation method thereof. The non-cement green mortar comprises the following components in weight part: 30-50 parts of steel slag powders, 50-70 parts of mineral powders, 200-350 parts of steel slag sands, 4-7 parts of activator, 1-4 parts of a water reducing agent, 3-6 parts of a dispersing agent, 0-0.4 parts of a retarder, 0.0002-0.001 part of a defoamer, and 30-40 parts of water. The non-cement green mortar is good in working performance, automatic in leveling effect, adjustable in setting time with the range of 0.5-8 hours, high in early-late strength, and excellent in impermeability and resistance to sulfate attack. The 7d breaking strength of the non-cement green mortar is larger than 8 MPa, and the compression strength thereof is larger than 40 MPa. The 28d breaking strength of the non-cement green mortar is larger than 9 MPa, and the compression strength thereof is larger than 50 MPa. Therefore, the non-cement green mortar can be widely applied to the engineering practice.

Owner:WUHAN UNIV OF TECH

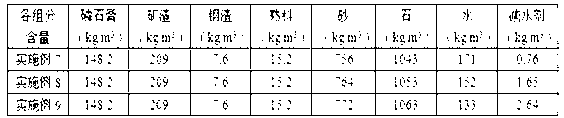

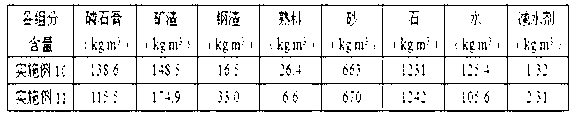

Cement concrete preventing corrosion of chlorine salt and preparation method thereof

The invention belongs to the technical field of building materials, and discloses cement concrete preventing corrosion of chlorine salt and a preparation method thereof. The concrete comprises a concrete gel material, yellow sands, stones, water and a water reducer, wherein the gel material comprises the following components in percentage by weight: 20-50% of ardealite, 30-60% of slag, 1-20% of steel slag and 1-20% of clinker. C30 mobile cement concrete, C40 mobile cement concrete and C40 hard concrete can be prepared by the method provided by the invention. The chlorine salt corrosion preventing performance of the cement concrete is remarkably superior to that of common silicate cement concrete or slag silicate cement concrete. The preparation method provided by the invention is simple. Various solid wastes can be effectively and reasonably utilized, and the condition that the cost and consumption of the existing cement concrete are high is reduced. Meanwhile, the cement concrete prepared by the invention further has excellent chlorine salt corrosion preventing performance.

Owner:广东武理湾区科技发展有限公司

Double-phase stainless steel microstructure and sigma mesophase chromatic corrosive and corrosion method

InactiveCN102766869AResponse is smooth and safeEasy to operatePreparing sample for investigationCorrosion reactionHydrofluoric acid

The present invention relates to a double-phase stainless steel microstructure and sigma mesophase chromatic corrosive and a corrosion method, and is suitable for the detection of double-phase stainless steel. The corrosive comprises components of: 0.1-2g of potassium metabisulfite, 5-25ml of hydrochloric acid with mass percent concentration of 40%, 5-15ml of nitric acid with mass percent concentration of 68%, 5-15ml of hydrofluoric acid with mass percent concentration of 40% and 150-300 ml of deionized water. The invention has advantages of good corrosion effect, good display effect of structure of a corroded specimen, no pollution, stable corrosion reaction, and easy configuration.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

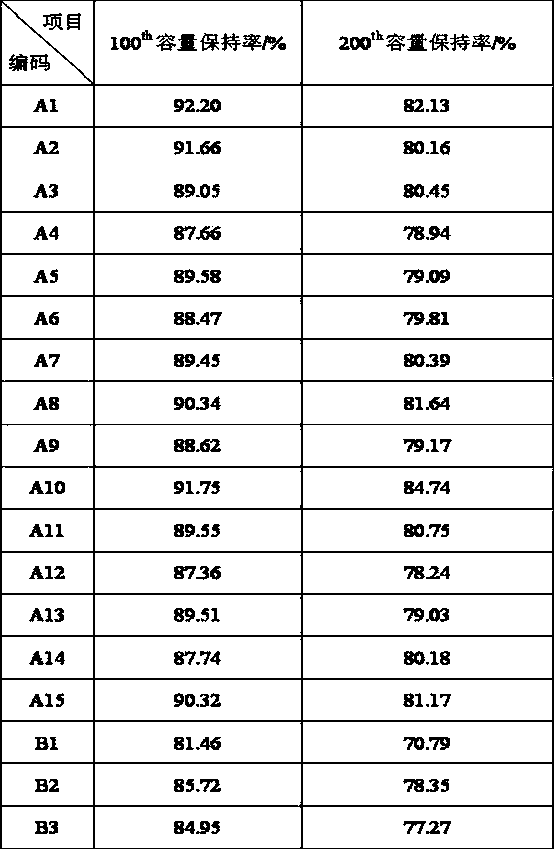

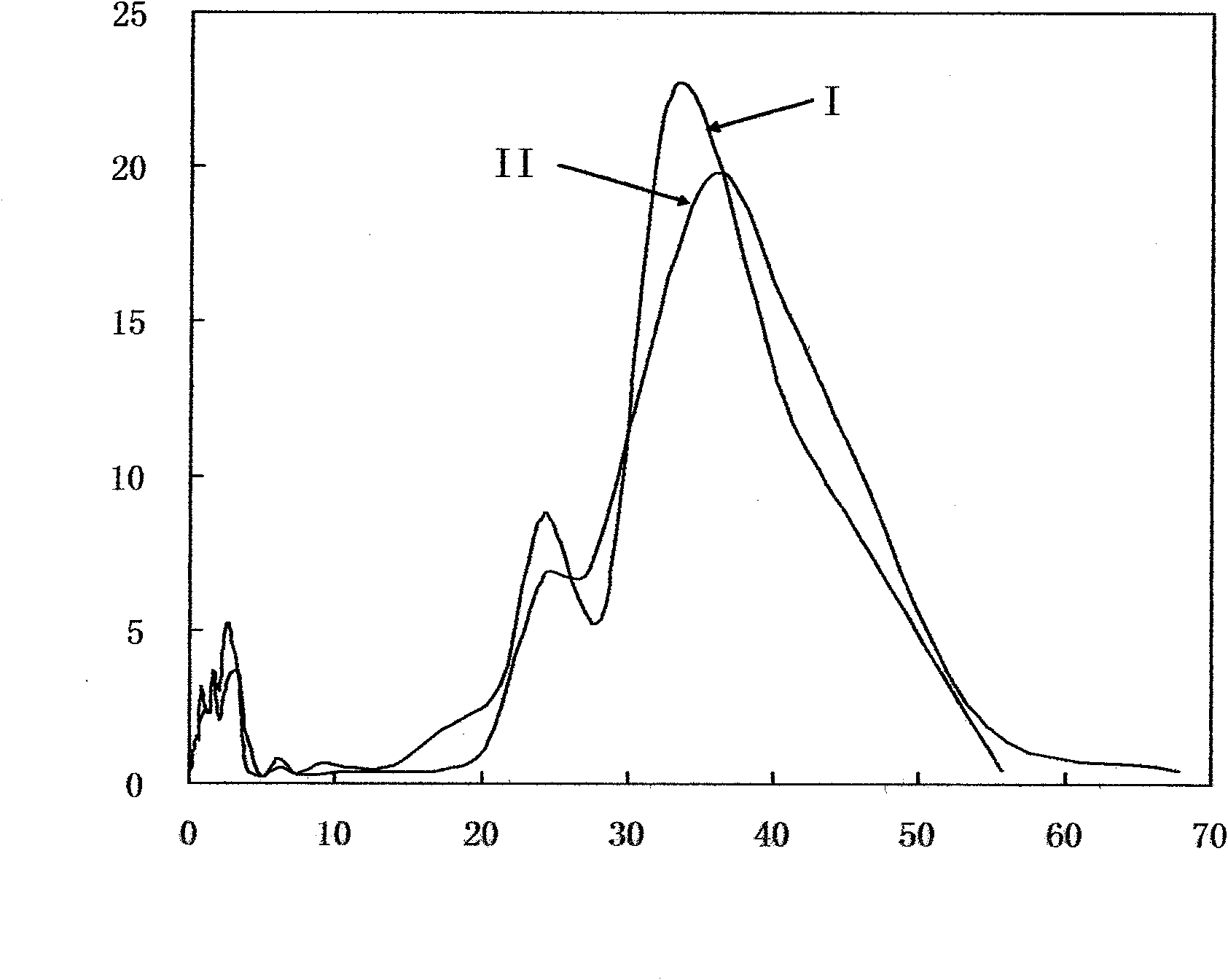

Lithium ion battery positive pole piece as well as preparation method and lithium ion battery comprising pole piece

InactiveCN103855401AImprove adhesionGood electrical contactCell electrodesSecondary cellsRare earthPole piece

The invention provides a lithium ion battery positive pole piece. The positive pole piece comprises a current collector, positive active membrane layers which are arranged on the front surface and the back surface of the current collector and conductive membrane layers which are arranged between the current collector and each positive active membrane layer, wherein each positive active membrane layer comprises first binder, a positive conducting agent, a rare-earth oxidant and a positive active substance. The invention also discloses a preparation method of the positive pole piece and a lithium ion battery comprising the positive pole piece. The lithium ion battery is good in conducting performance, good in structural stability and high in capacity retention ratio.

Owner:SHANGHAI BYD

Dispersive air brick

InactiveCN101607832AGood resistance to molten steel erosionStable erosion performanceCeramicwareInorganic saltsBrick

The invention relates to an air brick, in particular to a dispersive air brick manufactured by a cast molding technology. The materials comprise main raw materials, micro-powder, an expanding agent, a bonding agent, a dispersing agent, a microvesicle air entraining agent and a foam stabilizing agent, wherein the microvesicle air entraining agent adopts rosin ester air entraining agent, the foam stabilizing agent adopts nonionic type acid amide foam stabilizing agent, and the dispersing agent adopts organic nonionic type water reducing agent. Inorganic salt ionic type water reducing agent and acidic and weak acidic retarder are not recommended to use in the materials. A blank molded by the materials needs to be immediately maintained at high temperature so as to accelerate blank hardening. The dispersive air brick adopts the cast molding technology and has simple technology process, less equipment investment and high production efficiency, and not only the dispersive air brick with a regular shape can be manufactured, but also a large special-shape dispersive air brick can be manufactured; and the manufactured product has even air hole distribution, stable venting performance, molten steel scouring resistance, high erosion ability and good stripping resistance.

Owner:LUOYANG LIER REFRACTORY MATERIAL +2

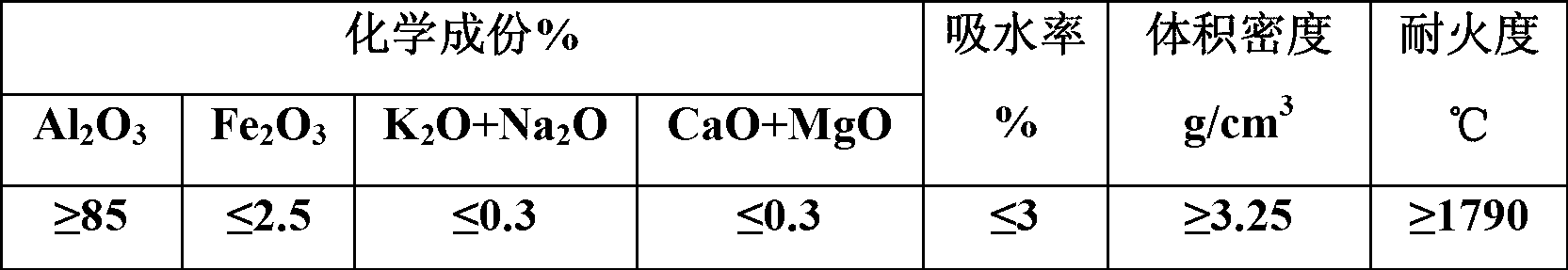

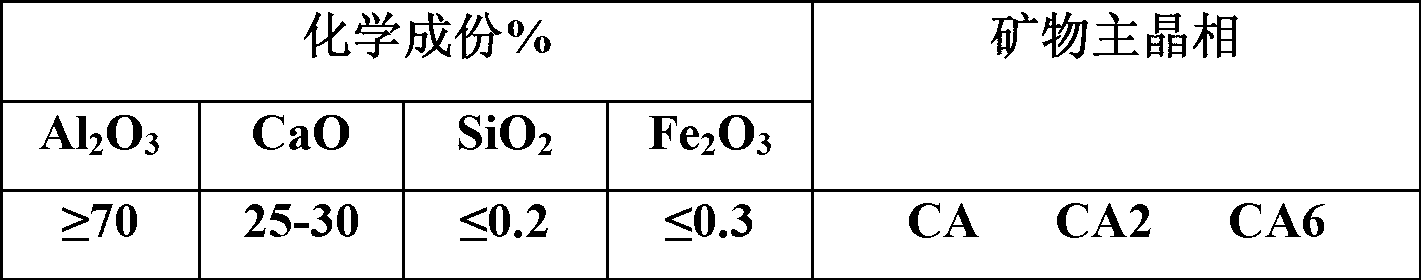

Corundum pouring material for kilneye of cement kiln and using method thereof

InactiveCN102659420ASmall coefficient of linear expansionHigh thermal conductivityAl powderMetallurgy

The invention relates to a corundum pouring material for a kilneye of a cement kiln and a using method thereof. The material of the pouring material comprises 69-72% by mass of sintered-plate-shaped corundum, 12-16% by mass of Si3N4 fine powder, 1-3% by mass of alpha-Al2O3 micropowder, 8-12% by mass of pure calcium aluminate cement, 2-4% by mass of elementary substance Si powder, 0.3-0.6% by mass of Al powder, 1-2% by mass of stainless steel fiber, 0.03-0.1% by mass of explosion-proof fiber, and 0.1-0.2% by mass of water reducer. The using method of the corundum pouring material for the kilneye of the cement kiln comprises the following steps: adding water whose mass is equivalent to 5.5-6.8% mass of the pouring material, stirring uniformly, moulding, curing for 2-3 days, demoulding, and roasting. The corundum pouring material for the kilneye of the cement kiln in the invention has the advantages of good thermal shock stability, excellent performance of resistance of corrosion, long service life and friendly environment. The corundum pouring material can meet the producing requirements of a large-scale cement kiln.

Owner:WUHAN UNIV OF SCI & TECH

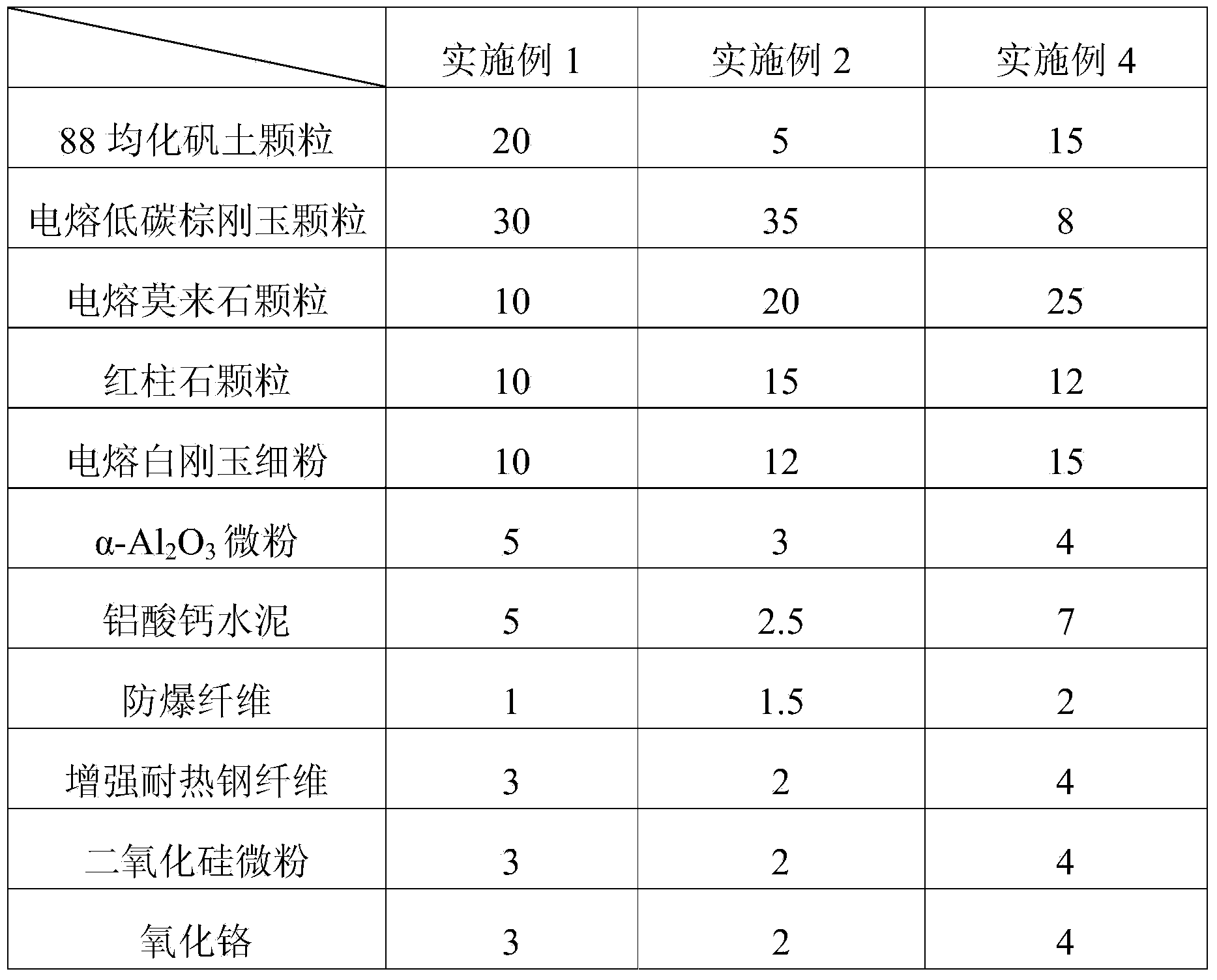

Alumina electric furnace cover and preparation method thereof

The invention aims to provide an alumina electric furnace cover, which is high in thermal shock resistance, density and iron slag erosion resistance and long in service life. The alumina electric furnace cover comprises the following components in percentage by weight: 5 to 20 percent of 88 homogenized alumina particles, 8 to 35 percent of electrofused low-carbon brown aluminum oxide particles, 10 to 25 percent of electrofused mullite particles, 10 to 15 percent of andalusite particles, 10 to 15 percent of electrofused white corundum fine powder, 3 to 5 percent of alpha-Al2O3 micro powder, 2.5 to 7 percent of calcium aluminate cement, 1 to 2 percent of explosion-proof fibers, 2 to 4 percent of reinforced heat-resistant steel fibers, 2 to 4 percent of silicon dioxide micro powder and 2 to 5 percent of chromium oxide. A preparation method comprises the following steps of uniformly mixing the electrofused white corundum fine powder, the alpha-Al2O3 micro powder, the silicon dioxide micro powder and the explosion-proof fibers; adding the electrofused mullite particles and the andalusite particles, stirring the mixture for at least 3min, adding the other raw materials, and stirring the mixture for at least 8min; adding water and a water reducing agent, performing stirring and casting molding, and performing natural curing, de-molding and drying.

Owner:北京利尔高温材料股份有限公司

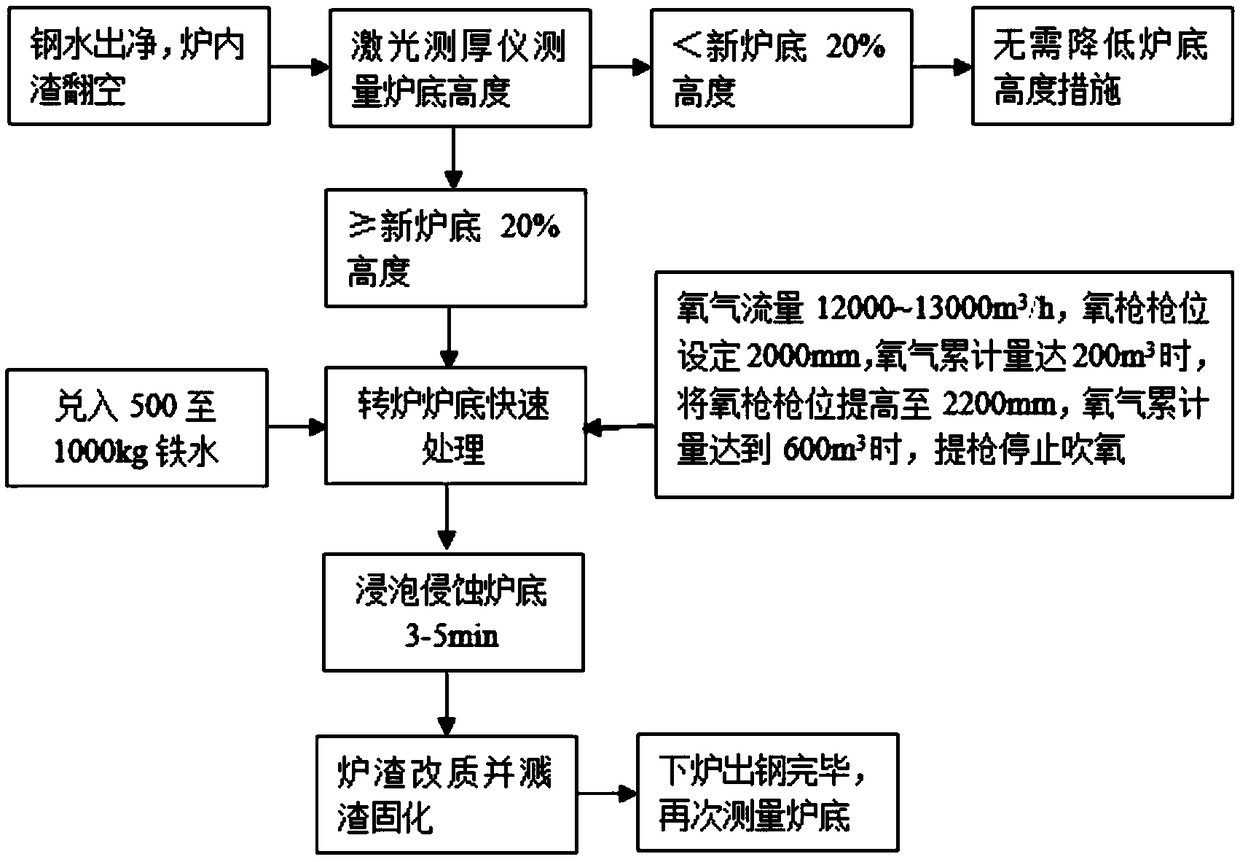

Method for quickly reducing height of converter bottom

ActiveCN108950126AErosion effect is goodHeating up fastManufacturing convertersSlagHigh pressure oxygen

The invention discloses a method for quickly reducing the height of a converter bottom. By utilizing the technological characteristics that the temperature rises quickly and a furnace clinker with thehigh FeO content is produced after reaction through the reaction of molten iron and oxygen, the thermodynamic conditions of high temperature and high FeO content required by eroding furnace bottom steel slags are met. Meanwhile, high-pressure oxygen is blown into a furnace through an oxygen lance, so that furnace bottom residual steel slags are favorably eroded and peeled off with the help of a favorable dynamic condition that an oxygen stream washes and stirs the furnace bottom steel residues. According to the method, on the premise of ensuring the safe, stable and efficient production of aconverter, the height of the converter bottom can be effectively reduced. Meanwhile, the method has the characteristics of high efficiency, low cost, safety and reliability.

Owner:MAANSHAN IRON AND STEEL COMPANY

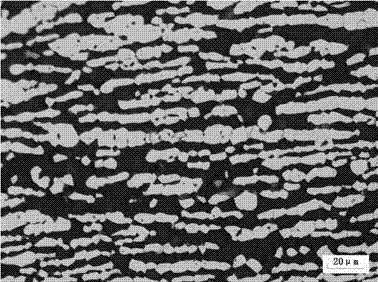

Metallographical corrosive liquid and preparation method thereof and 2205 duplex stainless steel metallographical display method

InactiveCN103924246AResponse is smooth and safeEasy to operatePreparing sample for investigationMicroscopic observationDistilled water

The invention discloses a metallographical corrosive liquid and a preparation method thereof and a 2205 duplex stainless steel metallographical display method. The metallographical corrosive liquid is composed of potassium metabisulfite, hydrochloric acid and distilled water. The preparation method comprises the following steps: dissolving potassium metabisulfite with distilled water at the temperature of 50-60 DEG C, then adding hydrochloric acid and uniformly stirring, so that the metallographical corrosive liquid is prepared. The 2205 duplex stainless steel metallographical display method comprises the following steps: polishing, cleaning and drying a 2205 duplex stainless steel sample, so that a sample to be detected is obtained; corroding for 10-20 minutes by adopting the metallographical corrosive liquid until the metallographical surface of the sample turns black, so that a sample for observation is obtained, and observing by adopting a metallographical microscope. Compared with the prior art, the invention has the advantages and characteristics that the corrosive liquid is simple to prepare and pollution-free; the preparation method is simple and rapid, and black ferrite crystal particles and white austenite crystal particle tissue can be observed more obviously.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

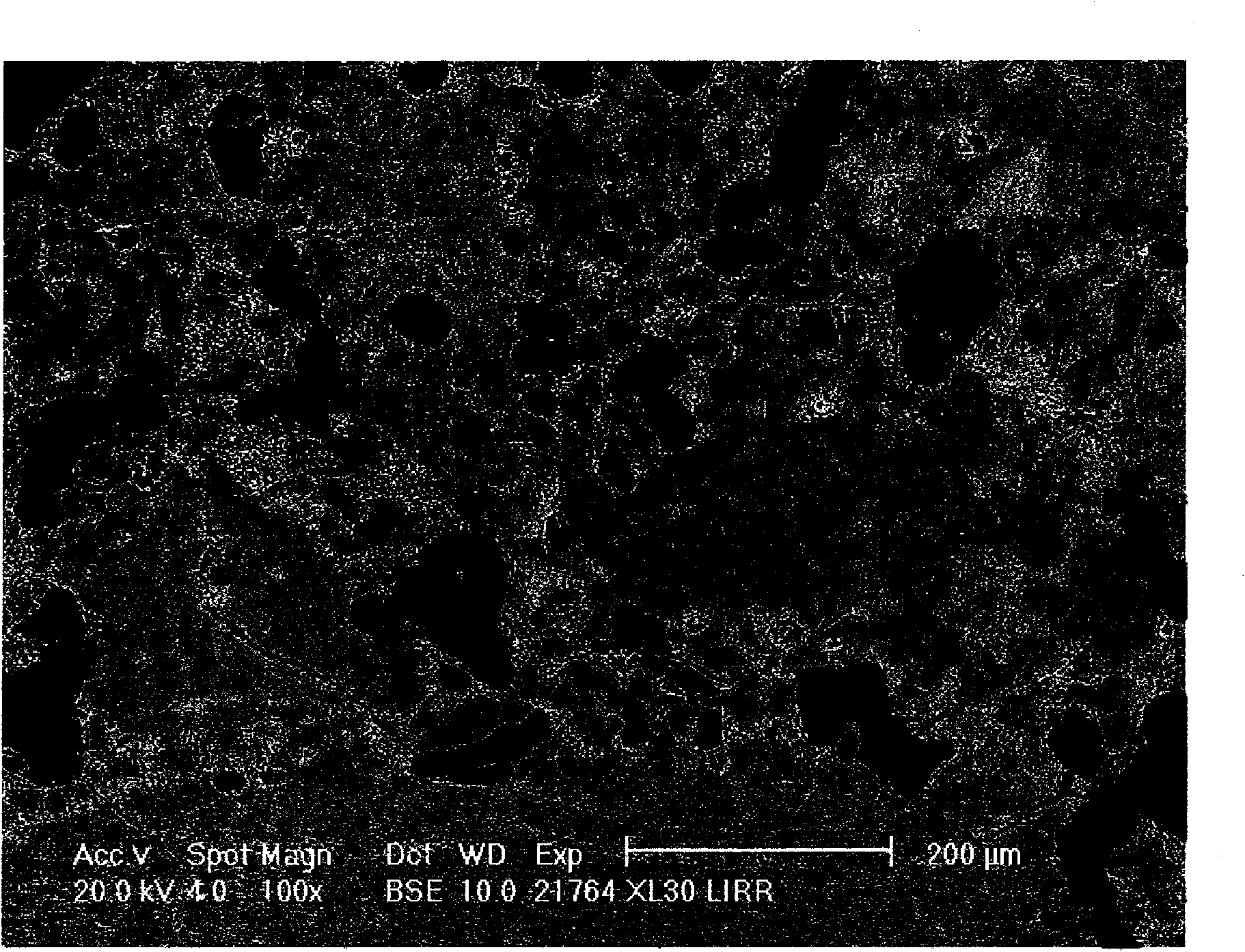

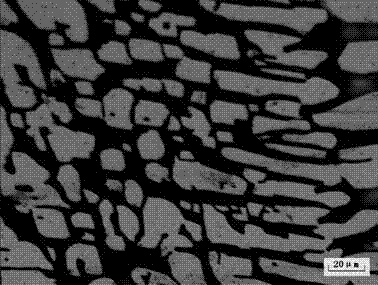

Austenitic stainless steel continuous cast billet oscillation mark zone solidification structure and dendrite structure corrosion liquid and corrosion method thereof

InactiveCN104532243ASolve the problem that the solidification structure in the vibration mark area of the continuous casting slab cannot be clearly displayedImprove the display effectPreparing sample for investigationAlcoholIron chloride

The invention provides an austenitic stainless steel continuous cast billet oscillation mark zone solidification structure and dendrite structure corrosion liquid with a good erosion effect, and a corrosion method thereof. The corrosion liquid is prepared by mixing 1.32-2.60mass% of iron chloride with 13.03-19.67mass% of hydrochloric acid, 30.49-32.89mass% of anhydrous ethanol, and the balance of water, wherein the mass concentration of hydrochloric acid is 36-38%. The corrosion method comprises the following steps: washing scales of a sample through a routine technology, carrying out coarse grinding, carrying out fine grinding, polishing, cleaning, and carrying out blow drying; fully immersing the prepared sample in the prepared corrosion liquid, continuously shaking in the corrosion process, and corroding for 1-2.5min until the oscillation mark zone of the sample is eroded to be silvery to obtain a corroded sample; and flushing the corroded sample below a tap, cleaning by using alcohol, and carrying out blow drying.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

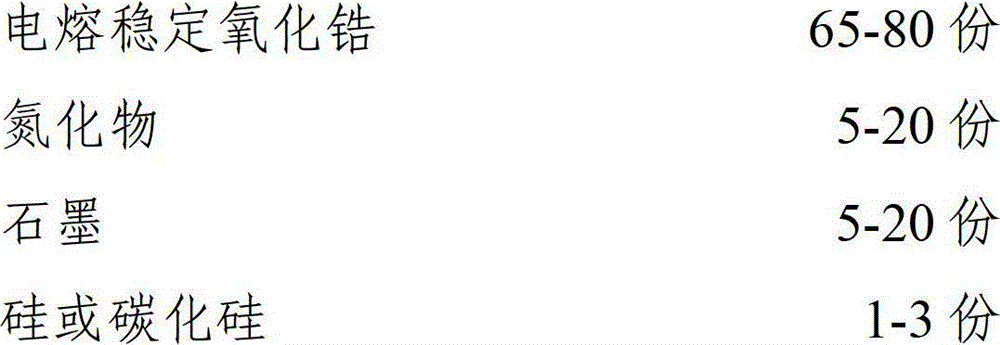

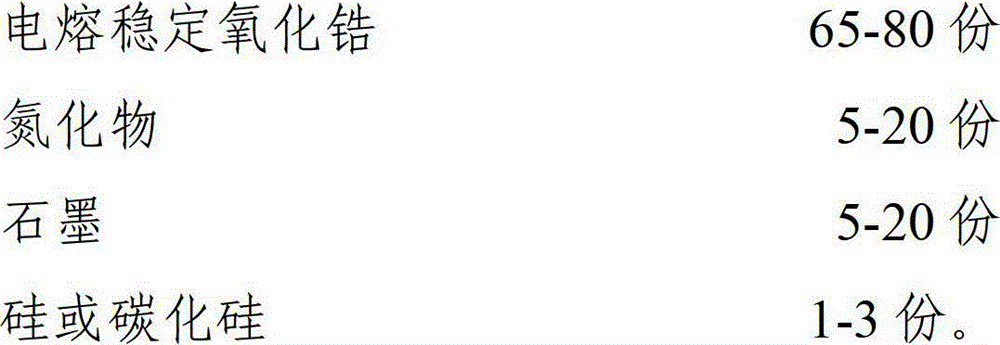

Composite material containing nitride and submerged nozzle applying composite material

InactiveCN102910904AImprove corrosion resistanceImprove stabilityMelt-holding vesselsThermal dilatationBoron nitride

The invention provides a composite material containing a nitride, which comprises the following components: electrofusion-stabilized zirconia, the nitride, graphite, silicon or silicon carbide. The invention further provides a submerged nozzle fabricated by adopting the composite material. The composite submerged nozzle prepared by taking the electrofusion-stabilized zirconia and graphite as well as one or more of the nitrides such as sialon, alon, MgAlON, silicon nitride, silicon nitride iron and boron nitride as major raw materials, and taking resin as a binding agent has excellent erosion resistance and thermal shock resistance. The electrofusion-stabilized zirconia has excellent casting powder erosion resistance, nitrogen compounds are introduced, and as the nitrogen compounds have the good characteristics that the nitrogen compounds are low in thermal expansion coefficient, high in thermal conductivity and high in strength and cannot moisten molten steel or casting powder, the erosion resistance and thermal shock resistance of the submerged nozzle are improved greatly.

Owner:北京利尔高温材料股份有限公司

Flexible composite spinel tin refractory material for pyrometallurgical noble metal smelting and preparation method of flexible composite spinel tin refractory material

The invention discloses a flexible composite spinel tin refractory material for pyrometallurgical noble metal smelting and a preparation method of the flexible composite spinel tin refractory material. According to the flexible composite spinel tin refractory material for the pyrometallurgical noble metal smelting and the preparation method of the flexible composite spinel tin refractory material, eutectic aluminum chromium, magnesium chromium spinel and magnesium aluminum spinel are used as a main crystal phase; electric-melting zirconium oxide is introduced into a substrate part; the thermal shock resistance of a product is improved by producing micro-cracks by converting a crystal form of the zirconium oxide during a firing process, and meanwhile, the crystal lattice structure is changed by forming magnesium tin spinel by introducing tin oxide, so that the flexibility and the performance of resisting noble metal smelting slag erosion of a product are improved. The flexible composite spinel tin refractory material for the pyrometallurgical noble metal smelting and the preparation method of the flexible composite spinel tin refractory material have great significance on solving the problems about thermal spalling and structural spalling damage of a noble metal smelting furnace refractory lining material during a using process, and the overall service life of the noble metal smelting furnace refractory lining material is prolonged.

Owner:郑州汇特耐火材料有限公司

Microporous high-penetration-resistance high-aluminum casting material, and preparation method and application method thereof

The invention discloses a microporous high-penetration-resistance high-aluminum casting material, and a preparation method and an application method thereof. The casting material is prepared from the following components in parts by weight: 51-95 parts of aggregate, 23.5-41.5 parts of powder, 3-6 parts of composite dewetting agent and 0.02-0.4 part of composite water reducing agent, wherein the aggregate is superfine bauxite chamotte; and the powder contains 180-mesh superfine bauxite fine powder, 800-mesh superfine bauxite fine powder, CA-70 cement, alpha-Al2O3 micro powder and SiO2 micro powder. A lining cast by the microporous high-penetration-resistance high-aluminum casting material provided by the invention is low in porosity, small in pore size of air pores and high in resistance to aluminum alloy liquid-state or vapor-state element penetration and corrosion; the aluminum alloy melt penetration resistance is improved; the mechanical strength is high, the high-temperature volume is stable, and the thermal shock resistance is favorable; and nodulation and bulge phenomena at the three-phase juncture can be effectively avoided.

Owner:贵阳联合高温材料有限公司

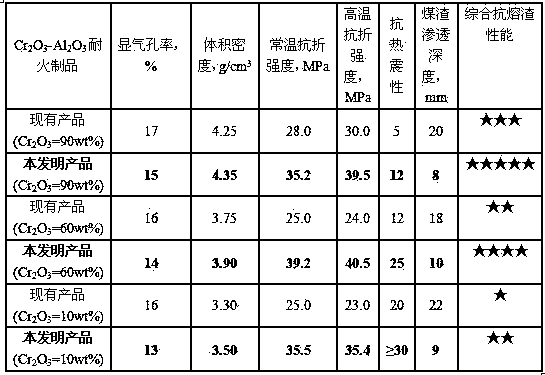

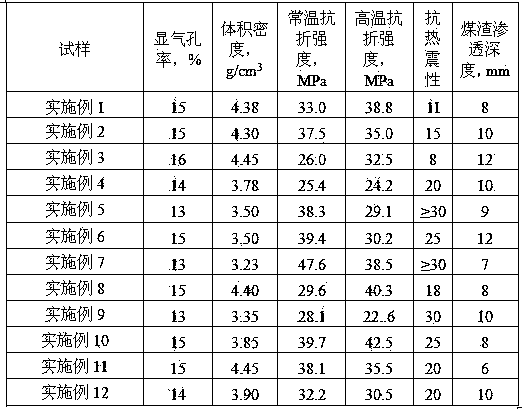

Al2O3-Cr2O3 refractory product and preparation method thereof

The invention belongs to the field of refractory materials, and mainly relates to a Al2O3-Cr2O3 refractory product and a preparation method thereof. The total mass percent of Al2O3 and Cr2O3 in the product is at least 90%, wherein the mass percent of Cr2O3 in the product is 5-95%. The product is prepared by mixing Al2O3-containing and Cr2O3-containing refractory raw particles and fine powders with a binder into a billet and firing the billet at high temperature. The invention is characterized in that the Al2O3-Cr2O3 refractory product contains P2O5 which accounts for 0.8-5 wt% of the product. In the Al2O3-Cr2O3 refractory product, the P element is added in the form of a raw material in the billet manufacturing process; and the P element is simple substance phosphorus. The simple substance phosphorus is powdery red phosphorus of which the purity is not lower than 99.0%. The Al2O3-Cr2O3 refractory product is fired under normal pressure in an oxidizing atmosphere.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Corrosive agent and corrosion method for carbon steel and austenitic stainless steel composite material microscopic structure

InactiveCN108179420ANo pollution in the processNo action requiredPreparing sample for investigationCorrosion reactionOperability

The invention provides a corrosive agent and a corrosion method for a carbon steel and austenitic stainless steel composite material microscopic structure. According to the corrosive agent and the corrosion method, the safety is achieved, the operability is good, the erosion effect is good, the corroded sample tissue is good in display effect, the pollution is little, and the corrosion reaction isstable. The method comprises the steps that firstly, a first corrosive agent or a second corrosive agent is prepared, wherein the content of all components of the first corrosive agent comprises 0.1-0.2g of copper sulfate, 5-25 ml of nitric acid, 5-20 ml of absolute ethyl alcohol and 150-200 ml of deionized water, and the content of all components of the second corrosive agent comprises 0.2-0.5gof copper sulfate, 5-25ml of hydrochloric acid, 5-15 ml of hydrogen peroxide and 150-200 ml of deionized water; the sample is prepared into a sample to be tested; the sample to be tested is fully immersed in the first corrosive agent or the second corrosive agent to be corroded for 15-120 seconds to obtain a roughly corroded sample; the roughly corroded sample is washed, is cleaned with alcohol after being washed, and then is blown to be dried by cold air, and metallographic corrosion is completed.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

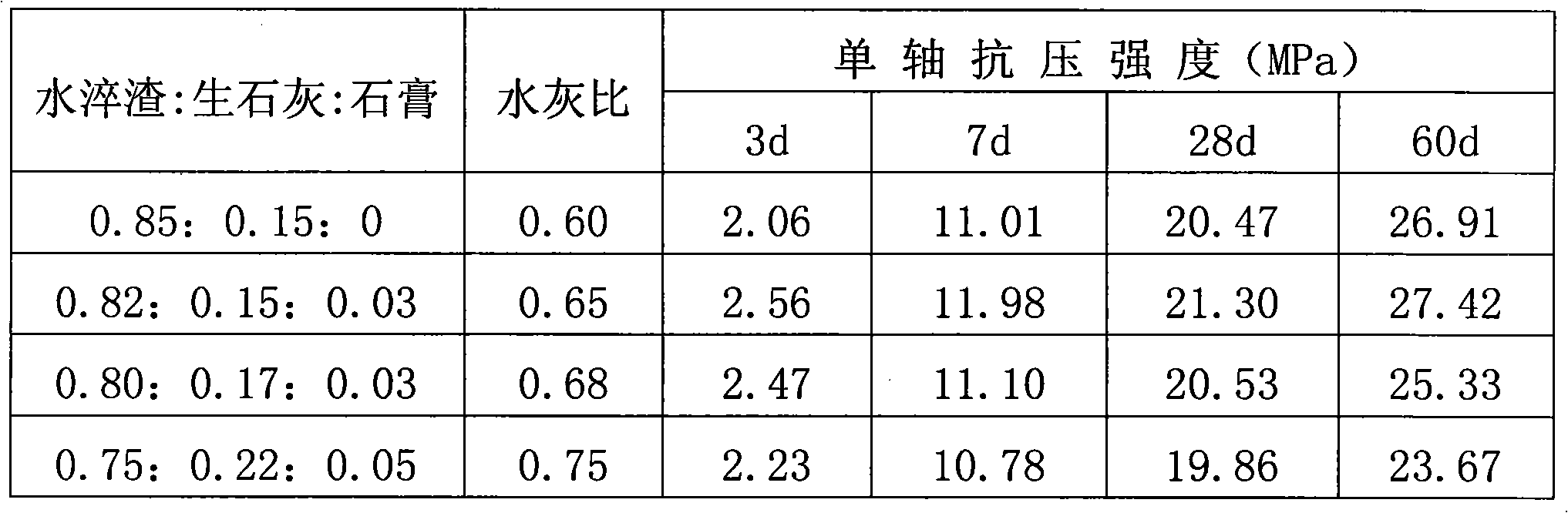

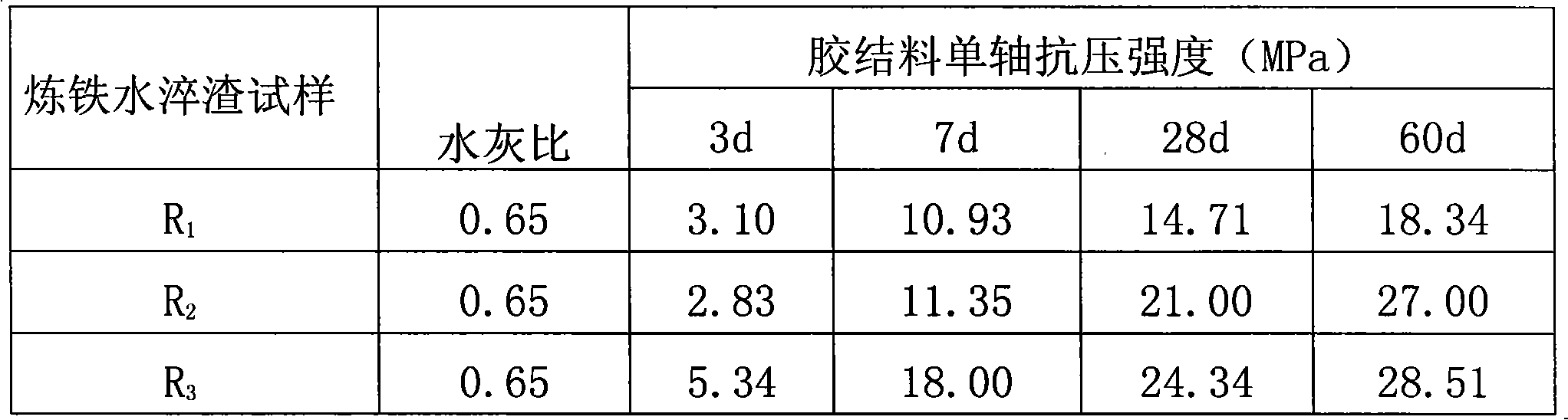

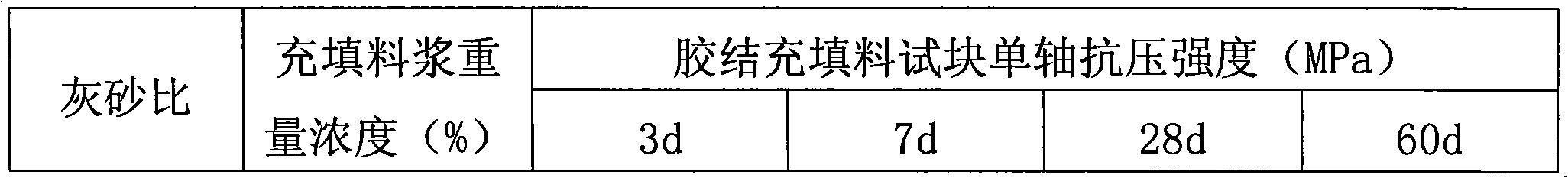

Mine-filling cementing material and preparation method thereof

The invention relates to a mine-filling cementing material and preparation method thereof. The cementing material is prepared from the following raw materials in weight percentage: 75 to 85 percent of iron-making water-granulated slag which is quenched by water, 15 to 22 percent of activating agent and 0 to 5 percent of intensifier, wherein the activating agent comprises quicklime or hydrated lime and the CaO content of the activating agent is 70 to 80 percent based on the dry weight; the intensifier comprises plaster; and the grinded granularity of the raw materials is + 0.071 millimeters and the content of the grinded raw materials is not more than 12 percent. The preparation method comprises the steps of: drying the raw materials, mixing the raw materials in a ratio, dryly grinding the raw materials to prepare dry a mine filling cementing material; or drying the raw materials, dryly grinding the raw materials respectively and then mixing the raw materials to prepare a dry material in a ratio; or mixing the raw materials in a dry weight ratio, adding water into the mixture and wetly grinding the mixture to obtain the mine-filling cementing material slurry. The mine-filling cementing material and the preparation method thereof can save cost and realize the high-efficiency waste resource recycling; tail cementing filling material prepared by adopting the cementing material of the invention has the advantages of relatively high mechanical strength, high water absorption capability and high sulphate resistance, so the min- filling cementing material is a cementing material better than cement in the aspect of mine cemented filling.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

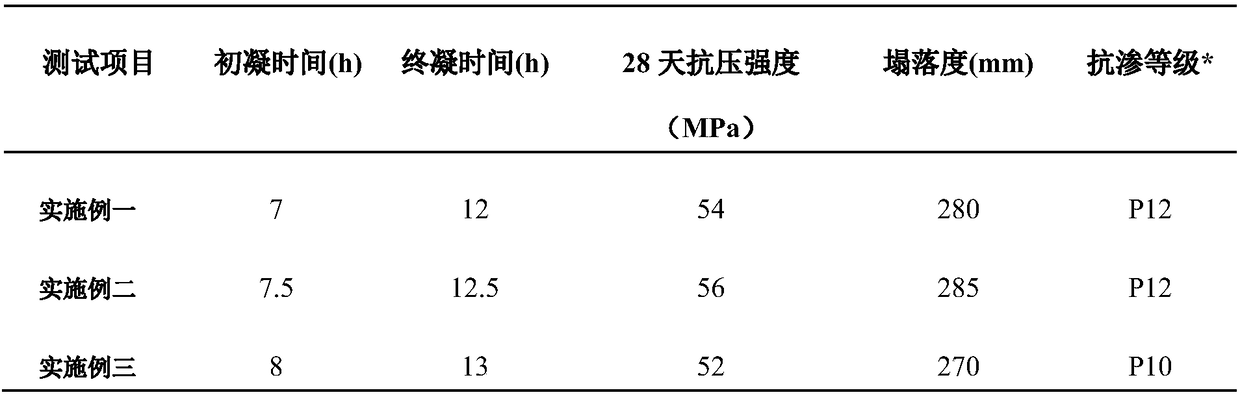

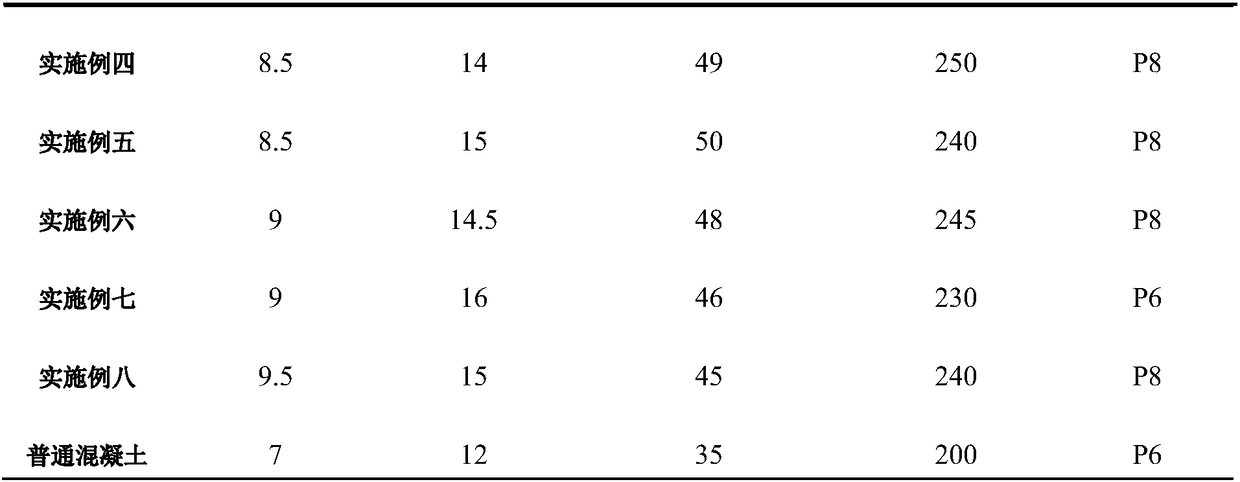

Sulfate-resistant concrete and preparation method thereof

The invention belongs to the technical field of concrete preparation, and provides a sulfate-resistant concrete. The sulfate-resistant concrete is characterized by being prepared from, by weight, 60-70 parts of sulfate-resistant cement, 30-40 parts of mineral admixture, 50-90 parts washed sand, 40-80 parts of machine-made sand, 110-160 parts of coarse aggregate, 4-6 parts of polypropylene fiber, 2-3 parts of carboxymethylcellulose, 70-90 parts of slurry forming water, 0.5-0.8 part of anhydrous ethanol, 2-3 parts of SBT-RMA concrete corrosion inhibitor and 1-2 parts of additive. The sulfate-resistant concrete solves the problems that the damage of corrosion to reinforced concrete is very serious, and sulfate-resistant concrete in the market is poor in anti-corrosion performance and short inservice life.

Owner:石家庄金隅混凝土有限公司

Double-phase stainless steel casting blank microstructure display chromatic corrosive and corrosion method

InactiveCN102768143ANo pollution in the processResponse is smooth and safePreparing sample for investigationCorrosion reactionDouble phase

The present invention relates to a double-phase stainless steel casting blank microstructure display chromatic corrosive and a corrosion method, and is suitable for the detection of double-phase stainless steel. The corrosive comprises components of: 1-8g of potassium metabisulfite, 10-25ml of hydrochloric acid with mass percent concentration of 40%, 5-5ml of nitric acid with mass percent concentration of 68% and 150-230ml of deionized water. The invention has advantages of reasonably designed formula, good corrosion effect, good display effect of structure of a corroded specimen, no pollution, stable corrosion reaction, and easy configuration.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Preparation method of refined chromite-based stuffing sand

The invention discloses a preparation method of refined chromite-based stuffing sand and belongs to the technical field of iron and steel smelting. The method comprises the steps that 60-65 wt% of chromium ore and 25-33 wt% of quartz sand are blended for 3-5 minutes in a mixing device, 4-7 wt% of potash feldspar is added and blended for 12-15 minutes, 2-3 wt% of low-grade silicon carbide is added and blended for 10-15 minutes, 1-2 wt% of carbon black is added and blended for 10-15 minutes, and then a chromite-based stuffing sand mixture is obtained; the mixture is placed into a rotary drying furnace for baking, the baking temperature ranges from 170 DEG C to 200 DEG C, the baking time ranges from 25 minutes to 30 minutes, the mixture is sieved, and then the chromite-based stuffing sand with the particle size ranging from 0.15 mm to 1.5 mm is obtained. The chromite-based stuffing sand has the advantages of being good in high-temperature sintering performance, good in erosion resistance to molten steel and molten slag, uniform in particle size distribution, good in fluidity, low in thermal expansivity and high in automatic casting ratio.

Owner:MAANSHAN NINGSHENG REFRACTORIES

Preparation method of aluminum-magnesium carbon steel ladle refractory bricks

The invention discloses a preparation method of aluminum-magnesium carbon steel ladle refractory bricks. A refractory brick consists of the following components in parts by weight: 28-32 parts of alpha-corundum, 38-42 parts of fused magnesite, 6-8 parts of fused aluminum-magnesium spinel, 3-4 parts of aluminum oxide micro powder, 1-2 parts of silicon carbide powder, 1.5-2.5 parts of metal aluminum powder, 3-5 parts of phenolic resin and 3-5 parts of crystalline flake graphite. The preparation method comprises the following steps: 1) mixing: firstly mixing the alpha-corundum, fused magnesite and fused aluminum-magnesium spinel in a mixer for 4-6 minutes, adding the phenolic resin, and mixing for 5-8 minutes; adding the crystalline flake graphite and mixing for 12-16 minutes; adding the aluminum oxide micro powder, silicon carbide powder and metal aluminum powder, and mixing for 20-30 minutes; 2) moulding with a press; 3) baking in a drying kiln, wherein the hot air temperature in the kiln body is kept at 200-250 DEG C, and the baking time is not shorter than 12 hours; 4) picking and packaging.

Owner:WUXI CHENGBO SCI & TECH DEV

Method for processing micro slot array on borosilicate glass surface

The invention provides a method for processing micro slot array on borosilicate glass surface which comprises sputtering Chromium copper seed layer onto the surface of cleaned boron-silicon glass sheets, forming mask window of processed glass deep groove array through photo-etching, placing the boron-silicon glass sheets into Chromium copper seed layer in the etching solution removing window, striping the analytical pure acetone through ultrasound, employing a plating method for electroplating copper masks, then plating gold masks onto the copper masks, etching continuously so as to obtain micro-trench array with smooth bottoms on the surface of the boron-silicon glass.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com