Cement concrete preventing corrosion of chlorine salt and preparation method thereof

A cement concrete and concrete technology, applied in the field of building materials, can solve the problems of land occupation, large water demand of concrete, slow hydration, etc., reduce carbon emissions and fuel energy consumption, excellent resistance to chlorine salt erosion, and good water retention sex and cohesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

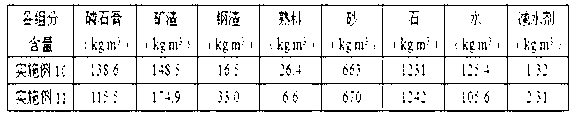

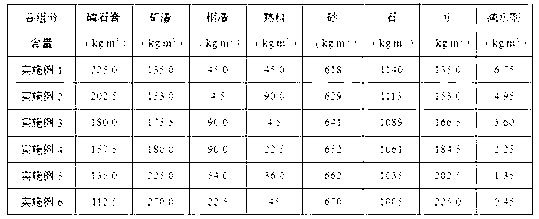

Examples

Embodiment 1-6

[0032] C30 high fluidity anti-chlorine salt erosion concrete is composed of cementitious materials, yellow sand, stones, water, and water reducing agent, in which the concrete density is set to 2350 kg / m 3 , the slump is designed to be 180mm, and the total amount of cementitious material is 450 kg / m 3 , the water-binder ratio is 0.30~0.50, the sand rate is 35~40%, and the amount of water reducer is 0.1~1.5%.

[0033] The selected yellow sand has a particle size of 0-5mm and a fineness modulus of 2.73; the stones are continuously graded gravel with a particle size of 5-25mm, and its crushing value is 8.7%; the water reducer is a naphthalene-based high-efficiency water reducer.

[0034] The components of the cementitious material are: 25-50% phosphogypsum, 30-60% slag, 1-20% steel slag, 1-20% clinker, Portland cement with a strength grade equivalent to 32.5, of which phosphorus Gypsum is pretreated phosphogypsum. The pretreatment process is: mix phosphogypsum, slag, and steel s...

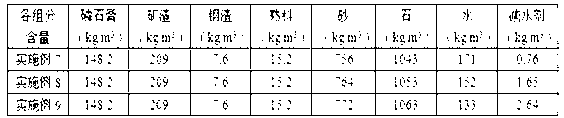

Embodiment 7-9

[0048] C40 Fluid Chlorine Salt Corrosion Resistant Concrete is composed of cementitious material, yellow sand, gravel, water, and water reducing agent. Among them, the bulk density of concrete is set to 2350 kg / m 3 , the design slump is 150mm, and the total amount of gel material is 380 kg / m 3 , the water-binder ratio is 0.35~0.45, the sand rate is 42%, and the amount of water reducer is 0.2~0.8%.

[0049] The selected yellow sand has a particle size of 0-5mm and a fineness modulus of 2.73; the stone is continuously graded crushed stone with a particle size of 5-25mm, and its crushing value is 8.7%; the water reducer is an amino high-efficiency water reducer.

[0050] The components of the cementitious material are: 39% phosphogypsum, 55% slag, 2% steel slag, 4% clinker, Portland cement with a strength grade equivalent to 42.5, of which phosphogypsum is pretreated phosphogypsum , the pretreatment process is: mixing phosphogypsum, slag, and steel slag with a mass ratio of 45:...

Embodiment 7

[0051] Examples 7-9, according to the ingredients in Table 5, repeat the method of Examples 1-6 to prepare cement concrete. Wherein the slag specific surface area of embodiment 7 is 435 m 2 / kg, the slag specific surface area of embodiment 8 is 554 m 2 / kg, the slag specific surface area of embodiment 9 is 612 m 2 / kg; In three embodiments, the specific surface area of phosphogypsum is 198 m 2 / kg, the specific surface area of steel slag is 653 m 2 / kg; the specific surface area of clinker is 385 m 2 / kg.

[0052] The working performance of cement concrete and the test method of compressive strength are the same as Examples 1-6, and the specific test results are shown in the following table 6. The results show that by controlling the specific surface area of slag, the prepared cement concrete can meet the conditions of large flow performance. All of them can meet the C40 intensity grade index.

[0053] The cement concrete that embodiment 7 prepares is carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com