Poly-gama-glutamic acid building fertilizer

A glutamic acid and fertilizer technology, applied in the form of fertilizer, fertilizer mixture, fertilization device, etc., can solve the problems of inconvenient application process, loose fertilizer combination, and reduce the use efficiency of poly-γ-glutamic acid, so as to achieve fertilizer utilization rate Improve, save fertilizer, improve activity and the effect of plant root vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The synergistic urea in the molten state is added at a constant rate (2.5kg / hour, 3.75kg / hour and 4.25kg / hour) by a metering pump in the urea pilot plant with an annual output of 12,000 tons before granulation The poly-γ-glutamic acid fermentation broth with a weight concentration of 1% is mixed with molten urea to make synergistic urea with a diameter of 2.0 to 3.0 mm in a prilling tower. The specifications of the obtained urea are shown in the table below;

Embodiment 2

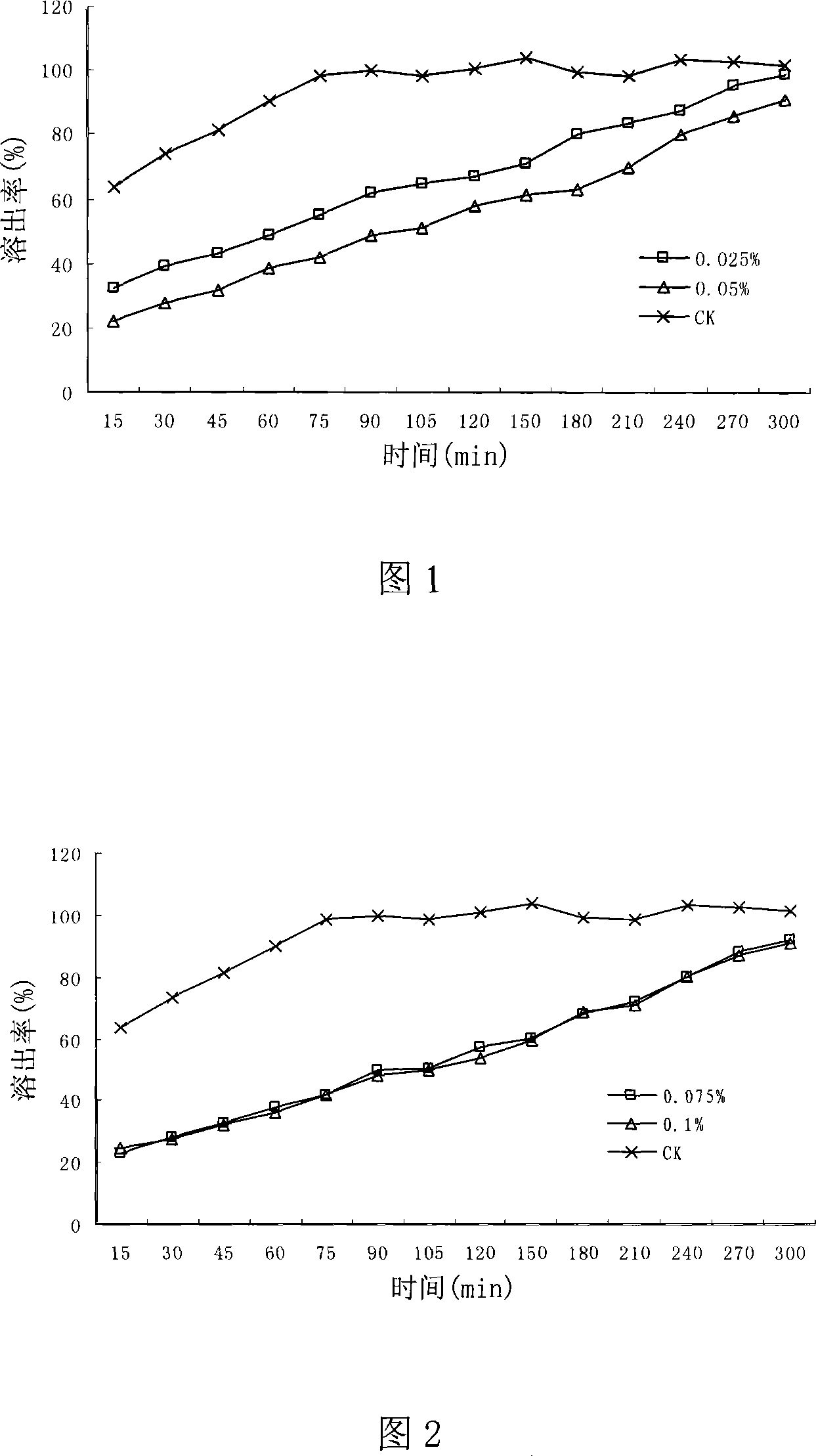

[0042] The production of coated synergistic urea is to use a spray device to spray the aqueous solution containing poly-γ-glutamic acid with a weight concentration percentage of 1% and a pH of 3.5 on the surface of urea particles under the condition of 80°C. Poly-γ-glutamic acid or its salt solution is transported into the nozzle through a peristaltic pump, and sprayed on the surface of the finished urea granules to make it fully coated. According to the concentration and volume of the sprayed poly-γ-glutamic acid or its salt, Coated urea can be produced with different concentrations of poly-gamma-glutamic acid or its salts. The content of poly-γ-glutamic acid is 0.025%, 0.05%, 0.075% and 0.1% coated urea by weight, and the urea concentration released into the environment is measured by an ultraviolet spectrophotometer, and the stripping rate of urea is calculated to make its slow release curve (Figure 1, Figure 2). The release time of the coated urea with a poly-γ-glutamic a...

Embodiment 3

[0044] Coated synergistic compound fertilizer is to use a spray device to spray the sodium salt solution of poly-γ-glutamic acid with a weight concentration of 2% and a pH of 3.0 on the surface of the compound fertilizer particles under the condition of 80°C. The compound fertilizer comprises potassium sulfate compound fertilizer, N-P-K content weight ratio is the inorganic compound fertilizer of 15: 15: 15, and N-P-K content 15: 15: 15, the high concentration organic-inorganic compound fertilizer of organic matter content 20% and N-P-K content 9: 7:9, low-concentration organic-inorganic compound fertilizer with an organic matter content of 15%. Poly-γ-glutamic acid or its salt solution is transported into the nozzle through a peristaltic pump, sprayed on the surface of the compound fertilizer particles to make it fully coated, according to the concentration and volume of the sprayed poly-γ-glutamic acid or its salt solution Different, coated compound fertilizers containing di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com