Sulfate-resistant concrete and preparation method thereof

A technology of anti-sulfate and anti-sulfate cement, applied in the field of concrete preparation, can solve the problems of shortening the life of buildings, insufficient attention to durability, etc., and achieves enhanced impermeability, strong sulfate corrosion resistance, and improved compressive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

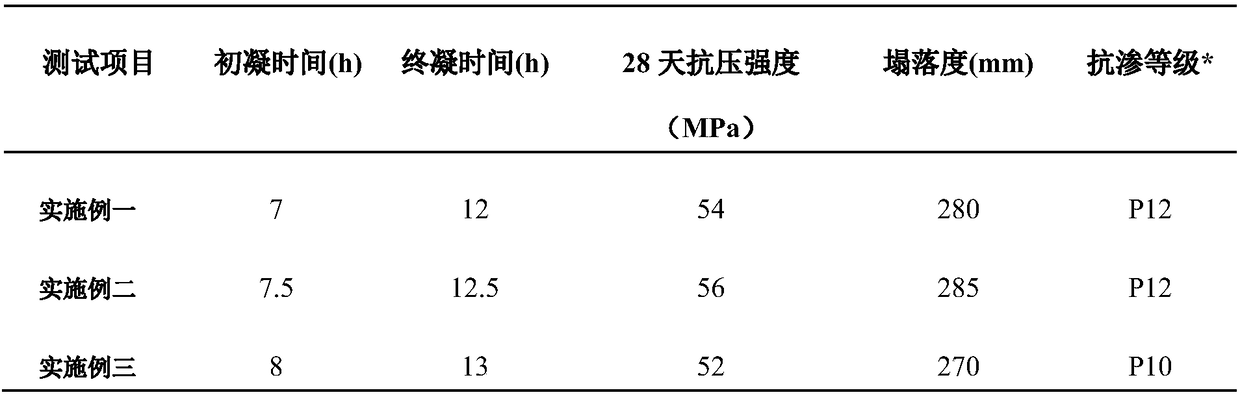

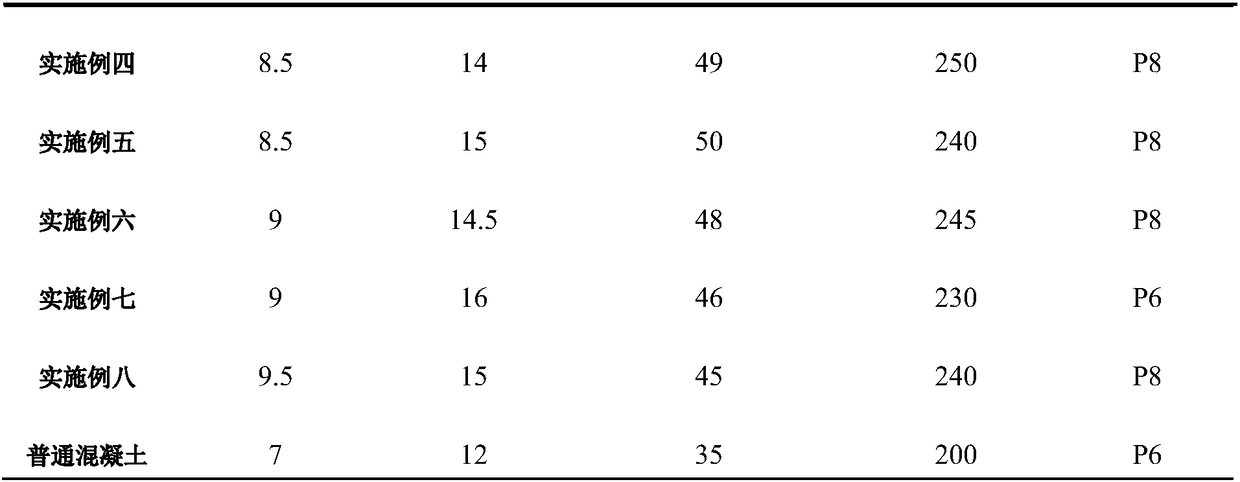

Examples

Embodiment 1

[0023] Embodiment 1: a kind of concrete for long wall engineering, characterized in that it is made of the following components in parts by weight: 60 parts of sulfate-resistant cement, 40 parts of mineral admixture, 50 parts of washed sand, mechanism 40 parts of sand, 110 parts of coarse aggregate, 4 parts of polypropylene fiber, 2 parts of carboxymethyl cellulose, 70 parts of mixing water, 0.5 part of absolute ethanol, 2 parts of SBT-RMA concrete preservative, and 1 part of admixture.

[0024] The mineral admixture is made by mixing 20 parts of fly ash and 30 parts of granulated blast furnace slag powder. The coarse aggregate is made by mixing 80 parts of crushed stone and 20 parts of pebble. 5-10mm, the admixture is composed of 9 parts of organic synergist, 5 parts of retarder, 10 parts of titanium dioxide, and 3 parts of waterproofing agent.

[0025] The organic synergist consists of 5 parts of silane coupling agent, 40 parts of epoxy resin powder, 5 parts of polyether typ...

Embodiment 2

[0031] Embodiment 2: a kind of concrete for long wall engineering is characterized in that it is made of the following components in parts by weight: 70 parts of sulfate-resistant cement, 30 parts of mineral admixture, 90 parts of washed sand, mechanism 80 parts of sand, 160 parts of coarse aggregate, 6 parts of polypropylene fiber, 3 parts of carboxymethyl cellulose, 90 parts of mixing water, 0.8 part of absolute ethanol, 3 parts of SBT-RMA concrete preservative, and 2 parts of admixture.

[0032] The mineral admixture is made by mixing 40 parts of fly ash and 50 parts of granulated blast furnace slag powder.

[0033] Coarse aggregate is made by mixing 120 parts of crushed stone and 30 parts of pebble. The particle size of crushed stone is 5-20mm, and the particle size of pebble is 5-10mm. 7 parts, 10-15 parts of titanium dioxide, 3-5 parts of waterproofing agent,

[0034] The organic synergist consists of 5 parts of silane coupling agent, 40 parts of epoxy resin powder, 5 p...

Embodiment 3

[0035] Embodiment three: a kind of concrete for long wall engineering, characterized in that it is made of the following components in parts by weight: 75 parts of sulfate-resistant cement, 35 parts of mineral admixture, 70 parts of washed sand, mechanism 60 parts of sand, 130 parts of coarse aggregate, 5 parts of polypropylene fiber, 2.5 parts of carboxymethyl cellulose, 80 parts of mixing water, 0.7 part of absolute ethanol, 2.5 parts of SBT-RMA concrete preservative, and 1.5 parts of admixture. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com