Microporous high-penetration-resistance high-aluminum casting material, and preparation method and application method thereof

A high-alumina castable and microporous technology, applied in the field of refractory materials, can solve the problems of structural spalling and damage of refractory materials, and achieve the effects of easy mining, large storage capacity and wide distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

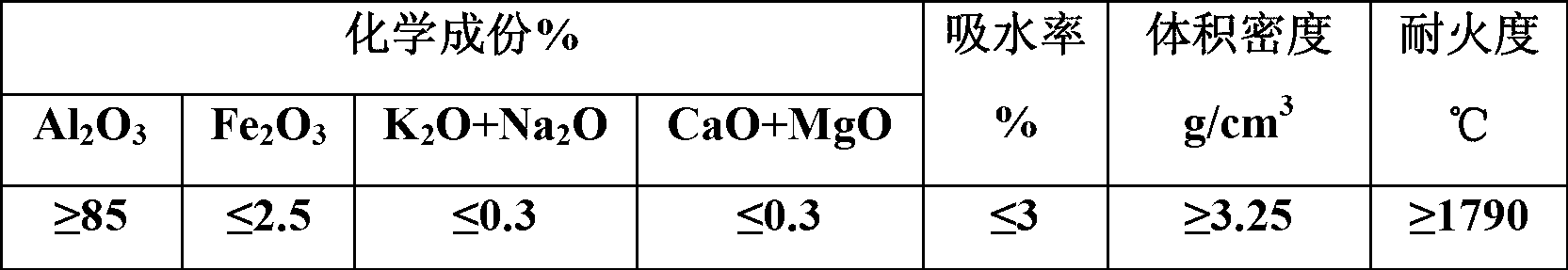

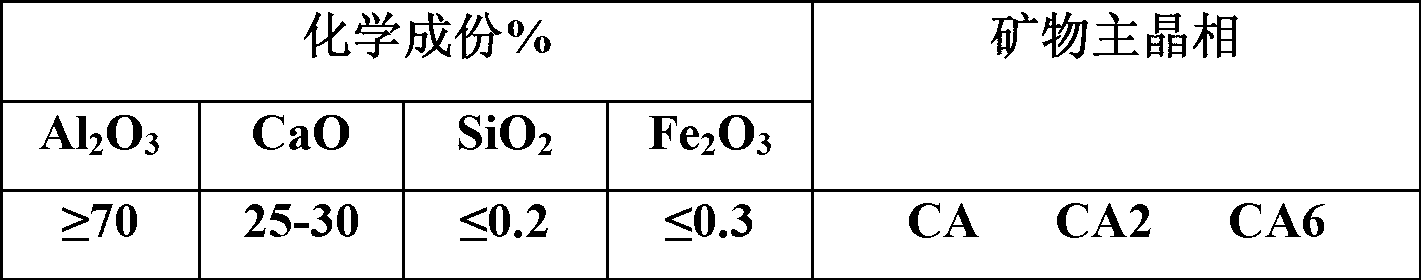

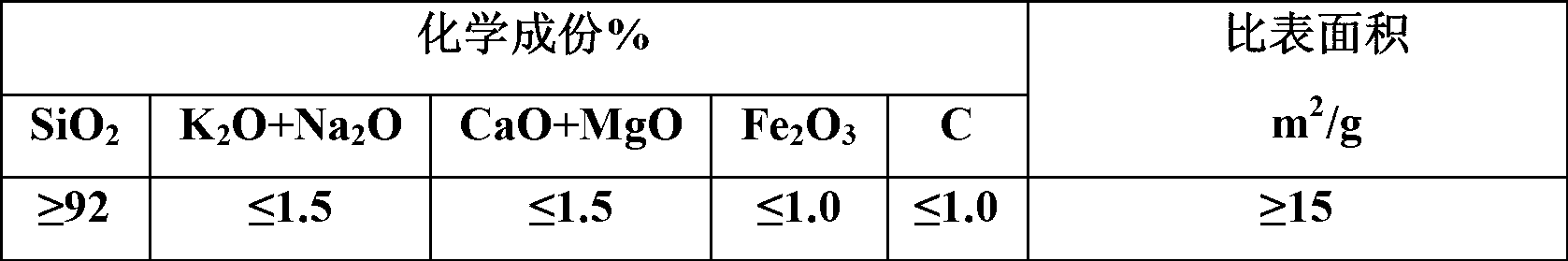

[0073]Embodiment 1: Take the special-grade rotary kiln bauxite clinker, grind it through the jaw crusher and the cone crusher successively, and then pass through the vibrating screen, and the under-sieve material enters the particle size of 8-5mm, 5-3mm, 3mm respectively. -1mm, 1-0.5mm, 0.5-0.088mm bins; feed the sieve material with a particle size > 8mm into a Ф1.5×4.7m ball mill, and grind it to obtain 180 mesh special-grade rotary kiln bauxite fine powder; Weigh 10g of special-grade rotary kiln bauxite clinker with a particle size of 8-5mm, 10g of special-grade rotary kiln bauxite clinker with a particle size of 5-3mm, and 10g of special-grade rotary kiln bauxite clinker with a particle size of 3-1mm. 20g of material, 15g of special grade rotary kiln bauxite clinker with a particle size of 1-0.5mm, 15g of special grade rotary kiln bauxite clinker with a particle size of 0.5-0.088mm, 8g of 180 mesh special grade rotary kiln bauxite fine powder , 800 mesh super rotary kiln ba...

Embodiment 2

[0075] Embodiment 2: Take the special-grade rotary kiln bauxite clinker, grind it through the jaw crusher and the cone crusher successively, and then pass through the vibrating screen, and the under-sieve material enters the particle size of 8-5mm, 5-3mm, 3mm respectively. -1mm, 1-0.5mm, 0.5-0.088mm bins; feed the sieve material with a particle size > 8mm into a Ф1.5×4.7m ball mill, and grind it to obtain 180 mesh special-grade rotary kiln bauxite fine powder; Weigh 15g of special-grade rotary kiln bauxite clinker with a particle size of 8-5mm, 15g of special-grade rotary kiln bauxite clinker with a particle size of 5-3mm, and 15g of special-grade rotary kiln bauxite clinker with a particle size of 3-1mm. 13g of material, 12g of special grade rotary kiln bauxite clinker with particle size of 1-0.5mm, 12g of special grade rotary kiln bauxite clinker with particle size of 0.5-0.088mm, 10g of special grade rotary kiln bauxite fine powder of 180 mesh , 800 mesh super rotary kiln b...

Embodiment 3

[0077] Embodiment 3: Take the special-grade rotary kiln bauxite clinker, grind it through the jaw crusher and the cone crusher successively, and then pass through the vibrating screen, and the under-sieve material enters the particle size of 8-5mm, 5-3mm, and 3 mm respectively. -1mm, 1-0.5mm, 0.5-0.088mm feed bins; feed part of the sieve material with a particle size > 8mm into a ball mill for grinding to obtain 180 mesh super rotary kiln bauxite fine powder, and partly feed into a Raymond mill for grinding Obtained 800 mesh special-grade rotary kiln bauxite fine powder; Taking by weighing particle diameter is the special-grade rotary kiln bauxite clinker 20g of 8-5mm, particle diameter is the special-grade rotary kiln bauxite clinker 20g of 5-3mm, grain 12g of special-grade rotary kiln bauxite clinker with a diameter of 3-1mm, 8g of special-grade rotary kiln bauxite clinker with a particle size of 1-0.5mm, and special-grade rotary kiln bauxite clinker with a particle size of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com