Double-phase stainless steel casting blank microstructure display chromatic corrosive and corrosion method

A duplex stainless steel and microstructure technology, which is applied in the field of duplex stainless steel billet microstructure display color etchant and corrosion, can solve the problems of poor thermal processing performance and surface cracks of duplex stainless steel, and achieve good erosion effect and easy corrosion. Operational, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

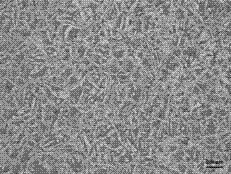

Embodiment 1

[0026] The following part of this example describes a duplex stainless steel slab microstructure revealing color etchant.

[0027] This metallographic etching agent is made of hydrochloric acid, nitric acid, potassium metabisulfite and deionized water, and each composition is respectively: potassium metabisulfite 6g; Hydrochloric acid (mass percentage concentration is 40%) 15ml and nitric acid (mass percentage concentration is 40%) 68%) 10ml, deionized water 150ml.

[0028] The following part of this embodiment describes a method for disposing a colored etchant for displaying the microstructure of a cast slab of duplex stainless steel.

[0029] Prepare corrosive agent according to the following order: first weigh potassium metabisulfite 6g; measure hydrochloric acid (mass percentage concentration is 40%) 15ml and nitric acid (mass percentage concentration is 68%) 10ml, then measure deionized water 150ml, in After mixing in a glass, stir well with a glass rod and let it stand...

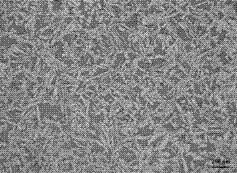

Embodiment 2

[0035] The following part of this example describes a duplex stainless steel slab microstructure revealing color etchant.

[0036] This metallographic etching agent is made of hydrochloric acid, nitric acid, potassium metabisulfite and deionized water, and each composition is respectively: potassium metabisulfite 6g; Hydrochloric acid (mass percentage concentration is 40%) 10ml and nitric acid (mass percentage concentration is 40%) 68%) 5ml, deionized water 200ml.

[0037] The following part of this embodiment describes a method for disposing a colored etchant for displaying the microstructure of a cast slab of duplex stainless steel.

[0038] Prepare corrosive agent according to the following order: first weigh potassium metabisulfite 6g; measure hydrochloric acid (mass percentage concentration is 40%) 10ml and nitric acid (mass percentage concentration is 68%) 5ml, then measure deionized water 200ml, in After mixing in a glass, stir well with a glass rod and let it stand f...

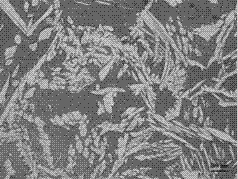

Embodiment 3

[0044] The following part of this example describes a duplex stainless steel slab microstructure revealing color etchant.

[0045] This metallographic etching agent is made of hydrochloric acid, nitric acid, potassium metabisulfite and deionized water, and each composition is respectively: potassium metabisulfite 5g; Hydrochloric acid (mass percentage concentration is 40%) 15ml and nitric acid (mass percentage concentration is 40%) 68%) 10ml, deionized water 150ml.

[0046] The following part of this embodiment describes a method for disposing a colored etchant for displaying the microstructure of a cast slab of duplex stainless steel.

[0047] Prepare corrosive agent according to the following order: first weigh potassium metabisulfite 5g; measure hydrochloric acid (mass percentage concentration is 40%) 15ml and nitric acid (mass percentage concentration is 68%) 10ml, then measure deionized water 150ml, in After mixing in a glass, stir well with a glass rod and let it stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com