Patents

Literature

55results about How to "Response is smooth and safe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

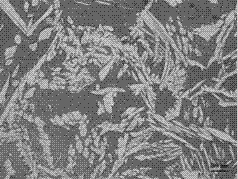

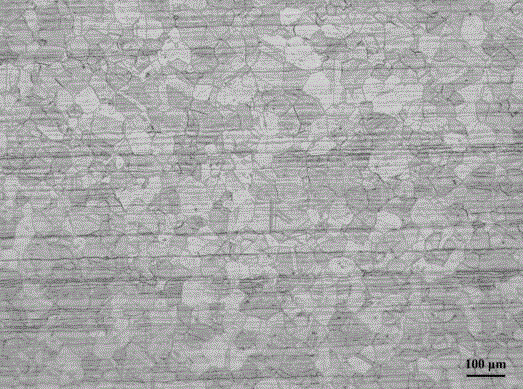

Metallographic etchant and erosion method of austenitic stainless steel

ActiveCN102517585AClear grain boundariesErosion is slowPreparing sample for investigationSS - Stainless steelAustenite

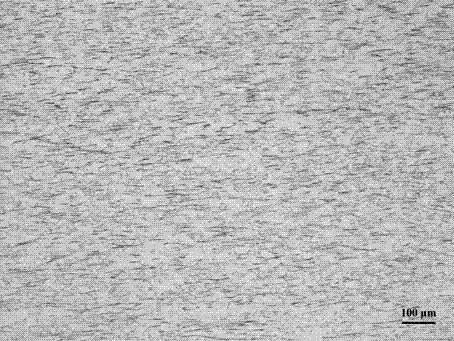

The invention relates to a metallographic etchant and an erosion method of austenitic stainless steel, which are especially suitable for metallographic erosion of 316 / 316L / 316H / 317 / 317L austenitic stainless steels. The metallographic etchant of the invention is composed of the following ingredients in percentage by volume: 30-35% of hydrochloric acid with mass percent concentration of 40%, 15-20%of nitric acid with mass percent concentration of 68%, 30-35% of propanetriol, and 15-20% of hydrogen peroxide solution with mass percent concentration of 30%. The metallographic etchant of the invention has the advantages of reasonable design, good erosion effect, good tissue display effect of eroded sample, non-pollution and slow and stable erosion reaction.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

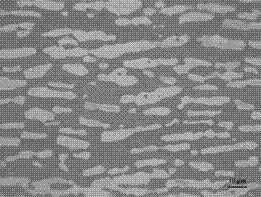

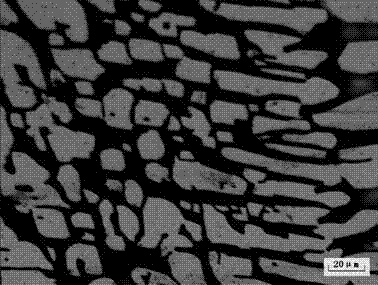

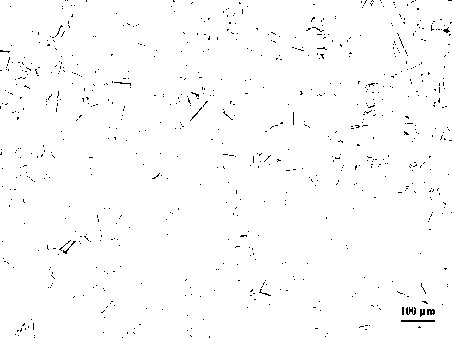

Double-phase stainless steel microstructure and sigma mesophase chromatic corrosive and corrosion method

InactiveCN102766869AResponse is smooth and safeEasy to operatePreparing sample for investigationCorrosion reactionHydrofluoric acid

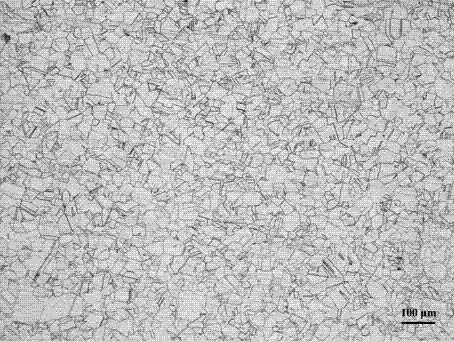

The present invention relates to a double-phase stainless steel microstructure and sigma mesophase chromatic corrosive and a corrosion method, and is suitable for the detection of double-phase stainless steel. The corrosive comprises components of: 0.1-2g of potassium metabisulfite, 5-25ml of hydrochloric acid with mass percent concentration of 40%, 5-15ml of nitric acid with mass percent concentration of 68%, 5-15ml of hydrofluoric acid with mass percent concentration of 40% and 150-300 ml of deionized water. The invention has advantages of good corrosion effect, good display effect of structure of a corroded specimen, no pollution, stable corrosion reaction, and easy configuration.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

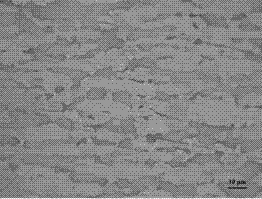

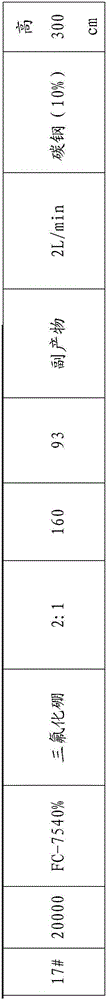

Metallographical corrosive liquid and preparation method thereof and 2205 duplex stainless steel metallographical display method

InactiveCN103924246AResponse is smooth and safeEasy to operatePreparing sample for investigationMicroscopic observationDistilled water

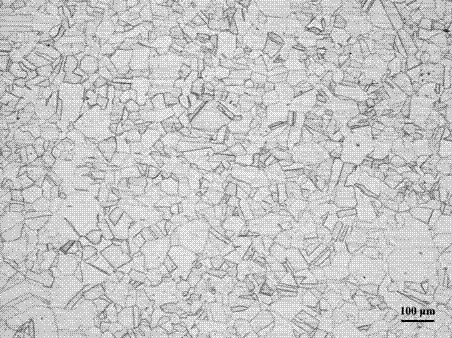

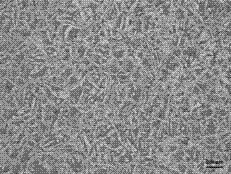

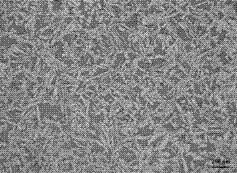

The invention discloses a metallographical corrosive liquid and a preparation method thereof and a 2205 duplex stainless steel metallographical display method. The metallographical corrosive liquid is composed of potassium metabisulfite, hydrochloric acid and distilled water. The preparation method comprises the following steps: dissolving potassium metabisulfite with distilled water at the temperature of 50-60 DEG C, then adding hydrochloric acid and uniformly stirring, so that the metallographical corrosive liquid is prepared. The 2205 duplex stainless steel metallographical display method comprises the following steps: polishing, cleaning and drying a 2205 duplex stainless steel sample, so that a sample to be detected is obtained; corroding for 10-20 minutes by adopting the metallographical corrosive liquid until the metallographical surface of the sample turns black, so that a sample for observation is obtained, and observing by adopting a metallographical microscope. Compared with the prior art, the invention has the advantages and characteristics that the corrosive liquid is simple to prepare and pollution-free; the preparation method is simple and rapid, and black ferrite crystal particles and white austenite crystal particle tissue can be observed more obviously.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

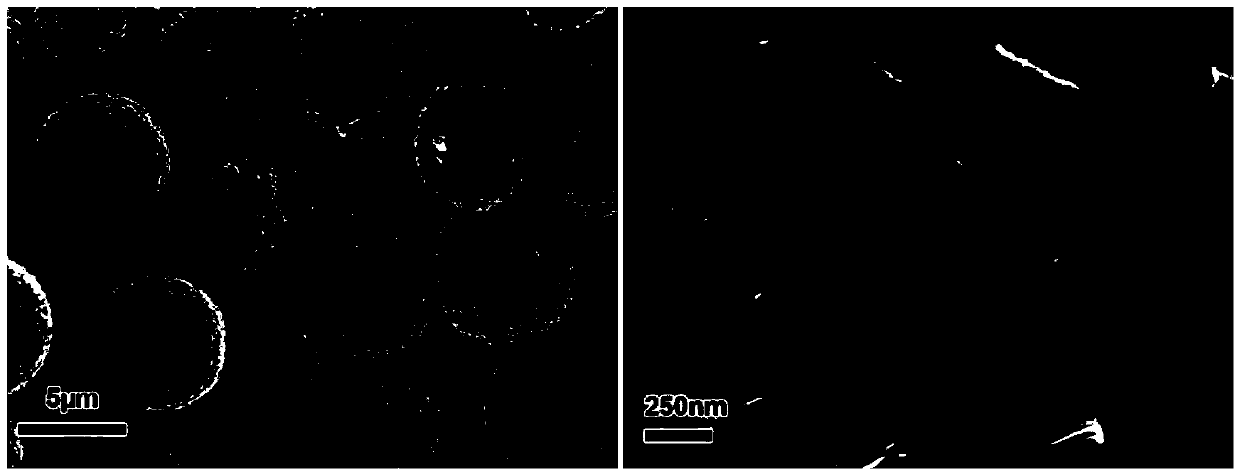

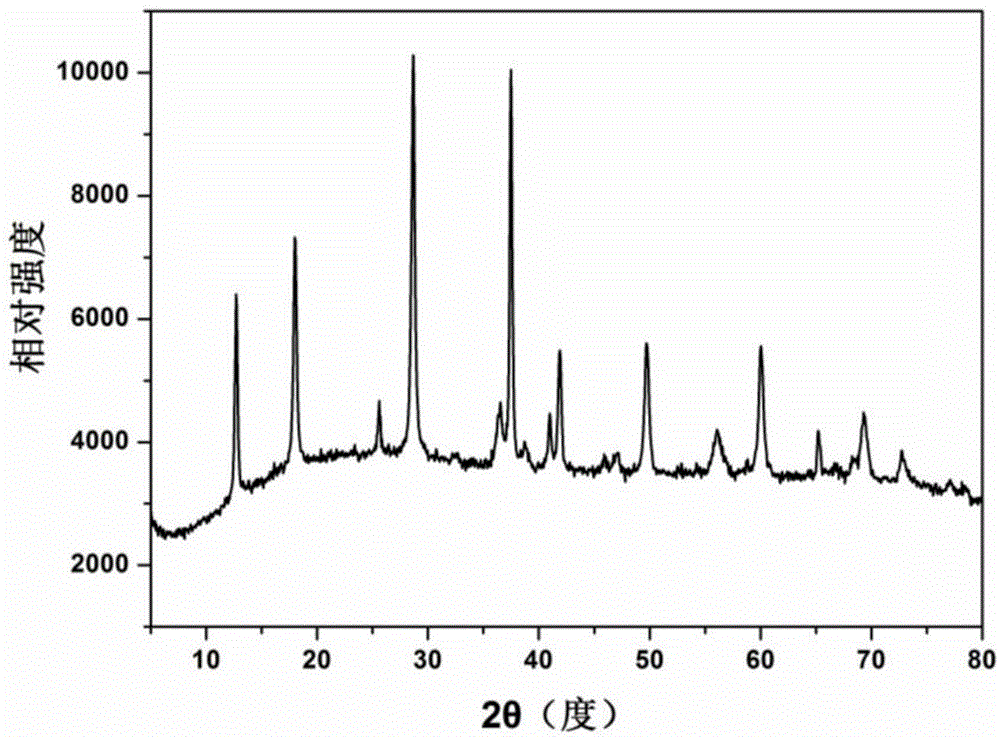

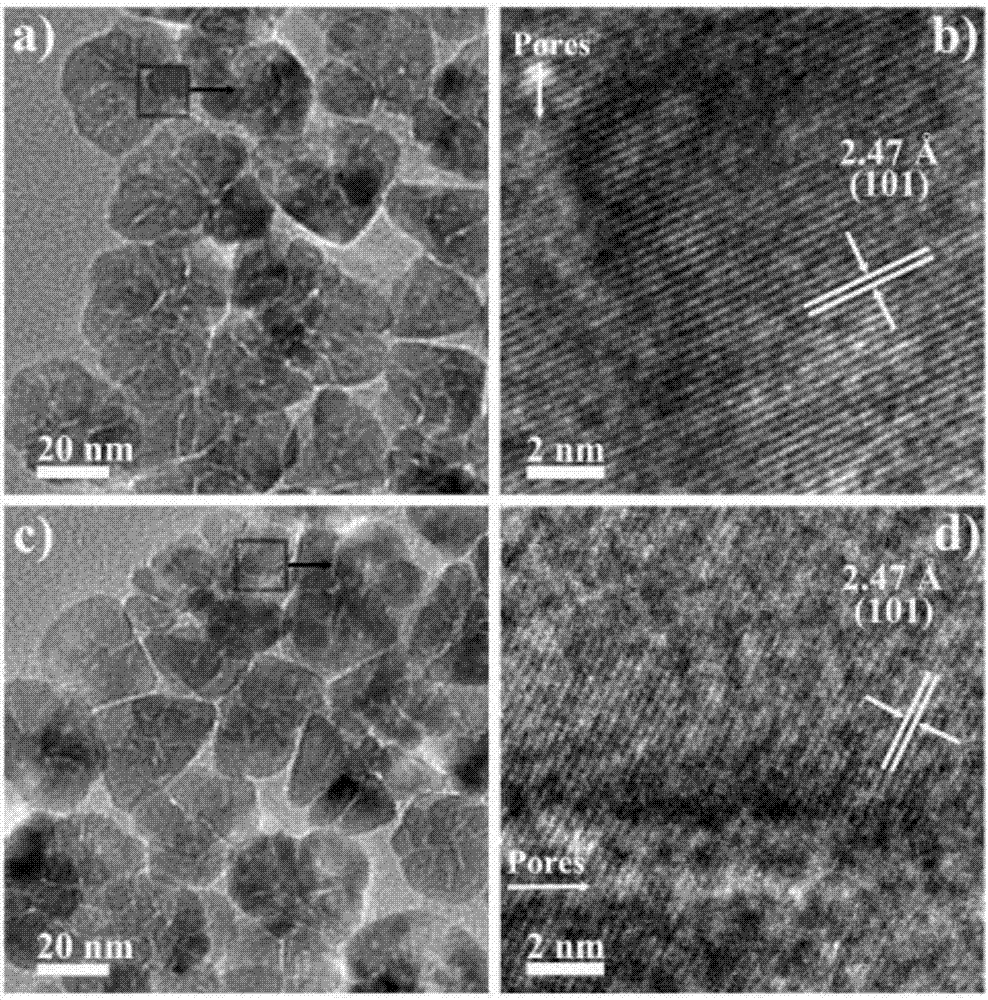

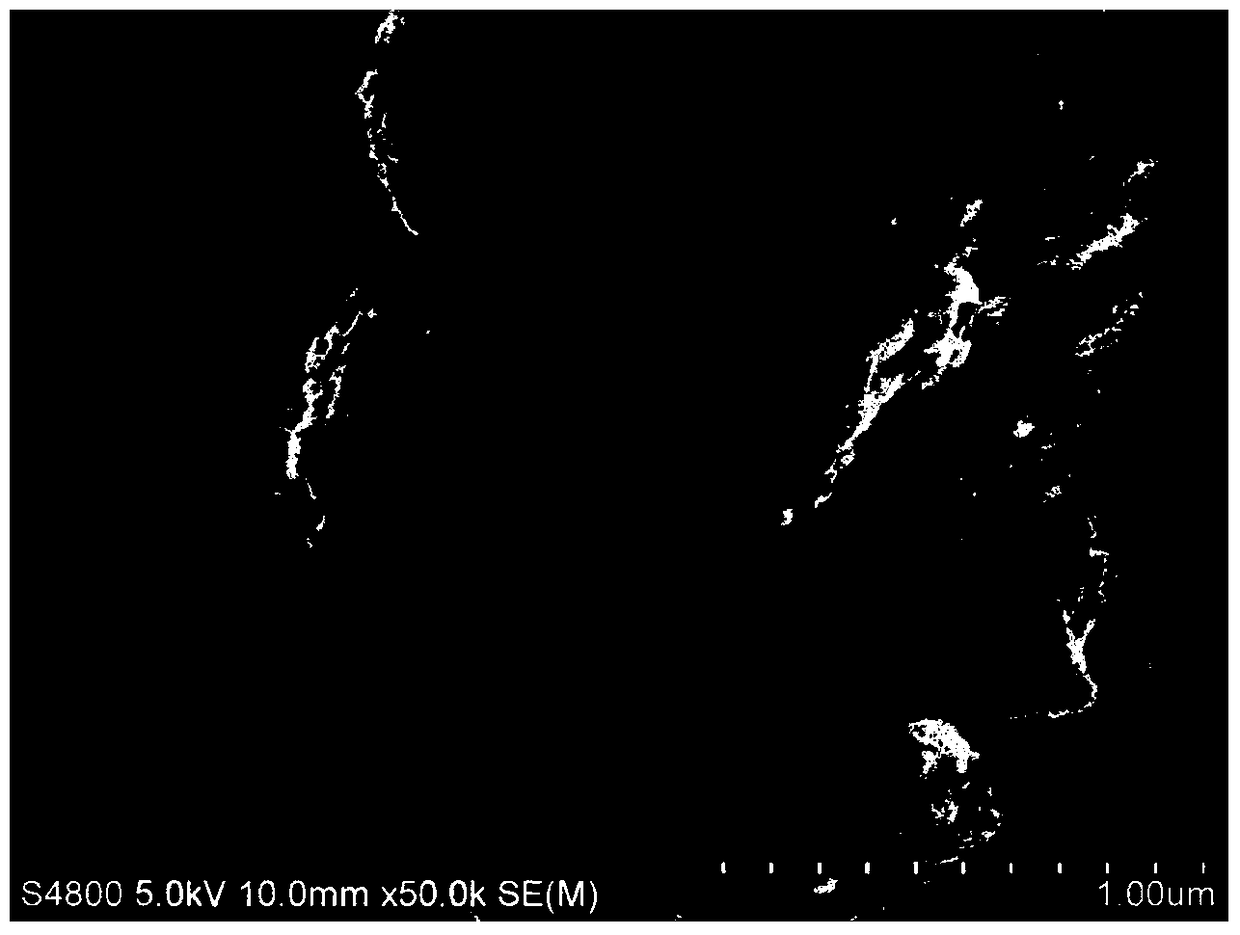

Graded porous vanadium oxide microspheres and preparation method and application thereof

InactiveCN104176778ANo pollution in the processProcess environmental protectionCell electrodesVanadium oxidesArgon atmosphereMicrosphere

The invention relates to graded porous vanadium oxide microspheres and a preparation method and application thereof. The size of the graded porous vanadium oxide microsphere is 4-10 micrometers, and the graded porous vanadium oxide microspheres are structurally formed by stacking a plurality of nano particles in a staggered way. The preparation method of the graded porous vanadium oxide microspheres comprises the following steps of: dissolving ammonium metavanadate in an organic solvent, carrying out condensation refluxing for 1-4 hours at constant temperature of 150-190 DEG C so that ammonium metavanadate has a reduction reaction to obtain bluish violet vanadium alkoxide precipitate; placing the bluish violet vanadium alkoxide precipitate in an argon atmosphere and calcining at 200-700 DEG C for 3-6 hours to obtain the graded porous vanadium oxide microspheres. According to the preparation method, the graded porous vanadium oxide microspheres are prepared by adopting constant-temperature liquid-phase reaction, related raw materials are common and nontoxic, the used process is simple and easy to operate, and high output is achieved; and the obtained graded porous vanadium oxide microsphere has important application value in the field of electrodes of lithium ion batteries.

Owner:WUHAN UNIV OF TECH

2, 3-dichloropyridine preparation method

ActiveCN105399663AAvoid problems prone to side effectsThorough responseOrganic chemistryOrganic solventDistillation

The present invention discloses a 2, 3-dichloropyridine preparation method comprising the following steps: (1) 2,3-dimethylamide pyridine is dissolved in water, then a caustic soda aqueous solution and a sodium hypochlorite aqueous solution are successively added, after the addition is completed, the mixture is heated for full reaction, after the reaction is completed, the system is adjusted to be neutral or acidic by use of hydrochloric acid, and water is removed by distillation to obtain a 2,3-diaminopyridine crude product; (2) the 2,3-diaminopyridine crude product is dissolved in hydrochloric acid, a catalyst is added, then a sodium nitrite aqueous solution is added dropwise, after the addition is complete, the2,3-diaminopyridine crude product is completely reacted, and after the reaction is completed, a 2, 3-dichloropyridine crude product is obtained by distillation; and (3) the 2, 3-dichloropyridine crude product is added into an organic solvent for complete dissolving, then cooled for recrystallization, crystals are filtered off and dried to obtain a 2, 3-dichloropyridine finished product. The method avoids the problem of very low tendency for side effects of 2-site chlorination, the production process is simple, the reaction is smooth and steady, production cost is low, product yield is high, and product purity is high.

Owner:SHANDONG TIANXIN CHEM

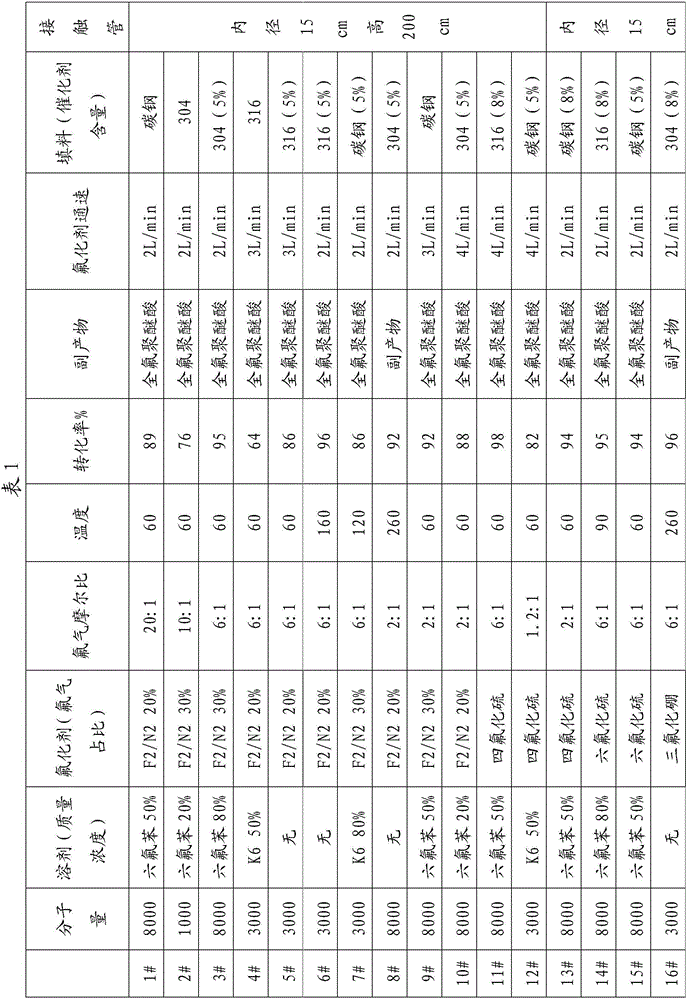

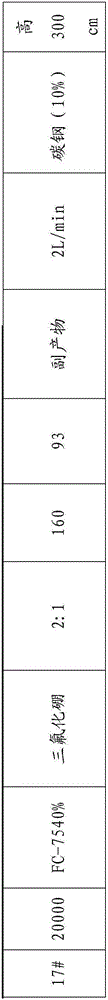

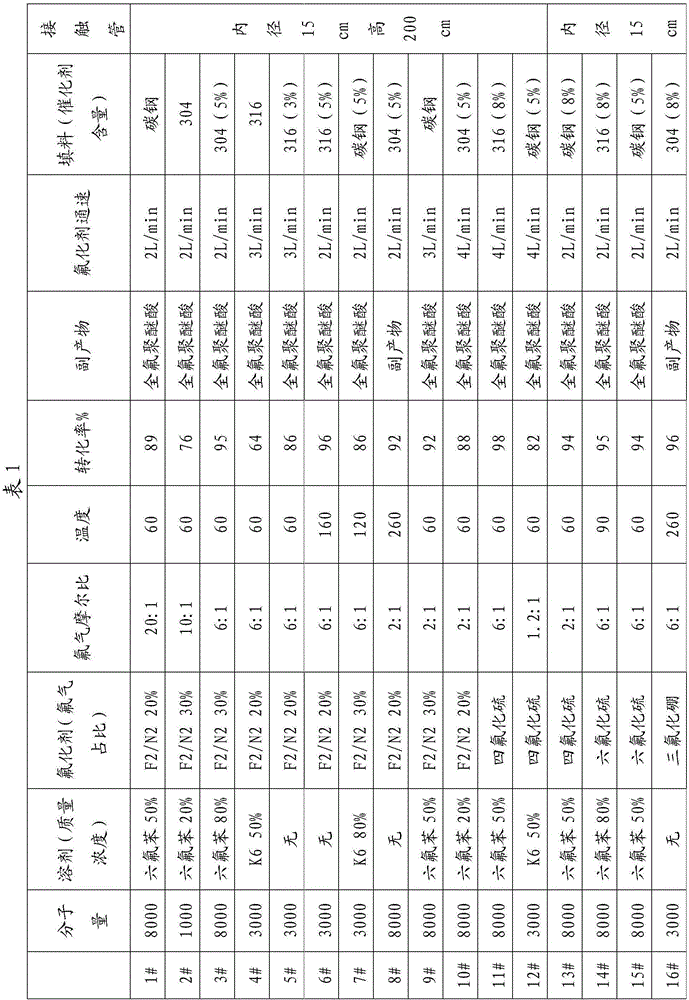

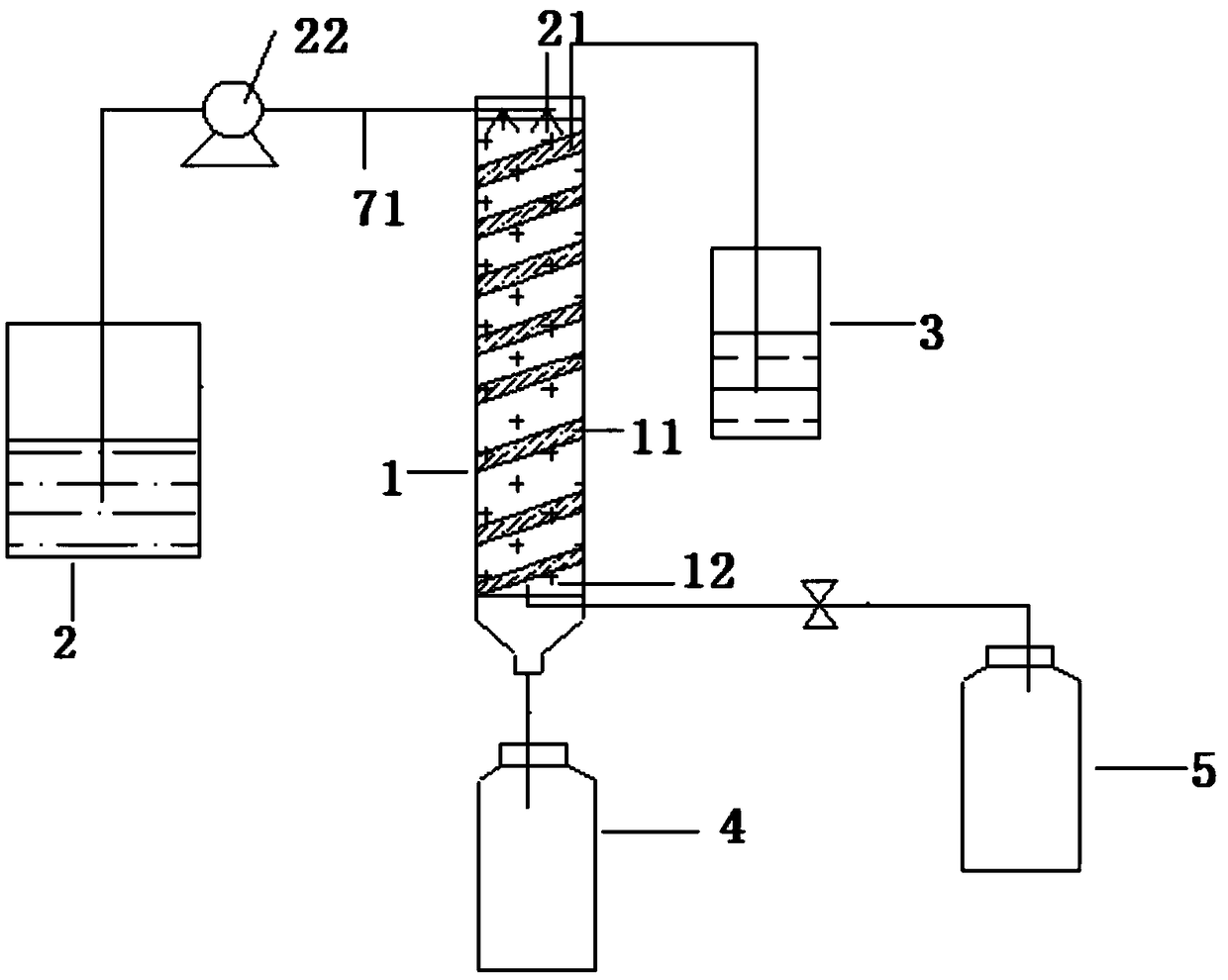

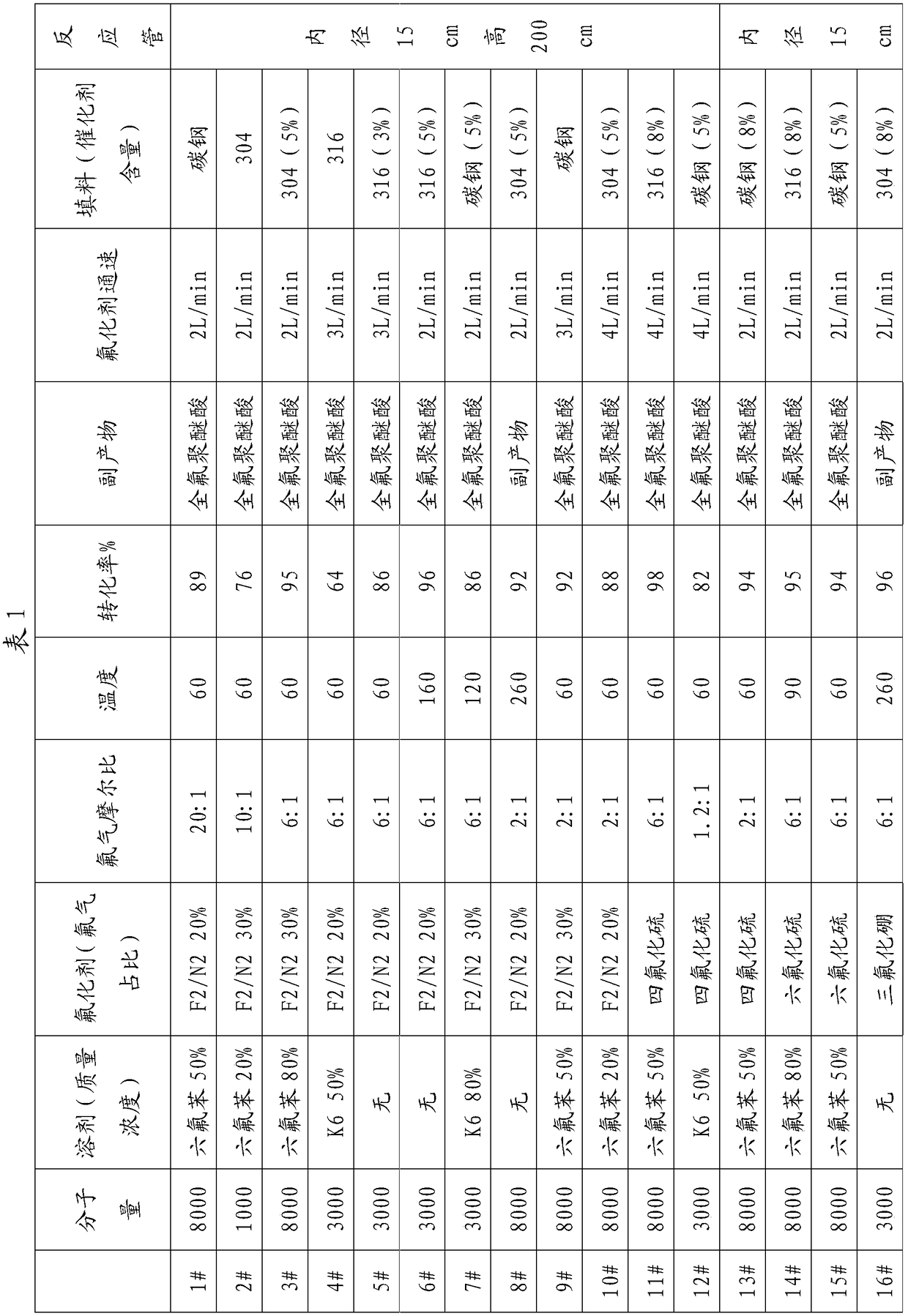

Fluorination method for end groups of perfluoropolyether acid

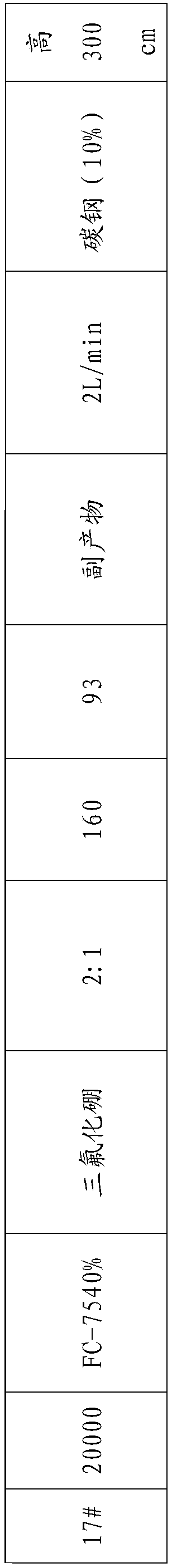

The invention belongs to the field of fluorine chemical synthesis and particularly relates to a fluorination method for end groups of perfluoropolyether acid. The perfluoropolyether acid and a fluorinating agent are taken as raw materials for synthesis in a gas-liquid contact reaction tube with fluorine gas passivated filler as a filling agent, and the filler adopts one or a mixture of carbon steel, stainless steel 304 and stainless steel 316. The perfluoropolyether acid or a solution thereof sprays downwards from the top of the gas-liquid contact reaction tube, a fluorinating agent gas makes sufficient contact with perfluoropolyether continuously from bottom to top through filler gaps in the gas-liquid contact reaction tube, maximized gas-liquid contact is realized, so that the utilization of the fluorinating agent is realized to the greatest extent, and fluorination of the perfluoropolyether is sufficient and complete. Besides, the perfluoropolyether is subjected to continuous fluorination, the problem of kettle-by-kettle fluorination in the prior art is solved, and the operation procedure is simplified. Few by-products are produced during fluorination of the perfluoropolyether, the operation is simple, continuous production can be realized, reactions are safe and stable, and the method is suitable for industrial mass production and application.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD +1

Alkylol amine and preparation method

InactiveCN103204779AGood colorHigh purityOrganic compound preparationAmino-hyroxy compound preparationChemical structureCement grinding

The invention discloses alkylol amine and a preparation method. Alkylol amine is one of preparation materials of a grinding aid for grinding cement. The chemical structure of alkylol amine is expressed as follows: N[C2H4O][C3H6O]2. Alkylol amine is prepared by performing a circular reaction of monoethanolamine and epoxypropane under the condition of vacuum, negative pressure and moderate temperature. Compared with the prior art, the technical scheme of alkylol amine and the preparation method provided by the invention has the remarkable advantages that alkylol amine obtained by the method is good in luster and high in purity, and the yield of cement can be improved by the cement grinding aid prepared by alkylol amine; and meanwhile, the preparation method is simple, the process is controllable, and the reaction is stable and safe.

Owner:FUCLEAR SCI & TECH (SUZHOU) CO LTD

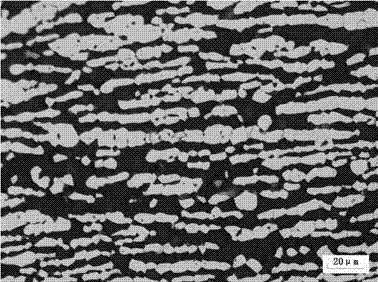

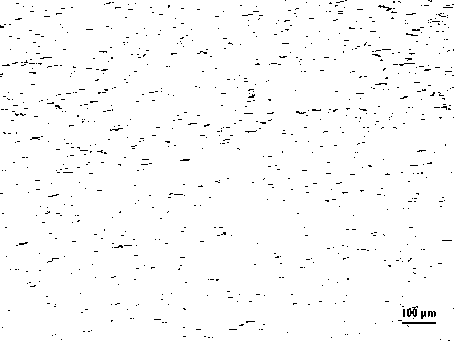

Corrosive agent and corrosion method for carbon steel and austenitic stainless steel composite material microscopic structure

InactiveCN108179420ANo pollution in the processNo action requiredPreparing sample for investigationCorrosion reactionOperability

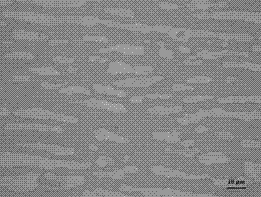

The invention provides a corrosive agent and a corrosion method for a carbon steel and austenitic stainless steel composite material microscopic structure. According to the corrosive agent and the corrosion method, the safety is achieved, the operability is good, the erosion effect is good, the corroded sample tissue is good in display effect, the pollution is little, and the corrosion reaction isstable. The method comprises the steps that firstly, a first corrosive agent or a second corrosive agent is prepared, wherein the content of all components of the first corrosive agent comprises 0.1-0.2g of copper sulfate, 5-25 ml of nitric acid, 5-20 ml of absolute ethyl alcohol and 150-200 ml of deionized water, and the content of all components of the second corrosive agent comprises 0.2-0.5gof copper sulfate, 5-25ml of hydrochloric acid, 5-15 ml of hydrogen peroxide and 150-200 ml of deionized water; the sample is prepared into a sample to be tested; the sample to be tested is fully immersed in the first corrosive agent or the second corrosive agent to be corroded for 15-120 seconds to obtain a roughly corroded sample; the roughly corroded sample is washed, is cleaned with alcohol after being washed, and then is blown to be dried by cold air, and metallographic corrosion is completed.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Double-phase stainless steel casting blank microstructure display chromatic corrosive and corrosion method

InactiveCN102768143ANo pollution in the processResponse is smooth and safePreparing sample for investigationCorrosion reactionDouble phase

The present invention relates to a double-phase stainless steel casting blank microstructure display chromatic corrosive and a corrosion method, and is suitable for the detection of double-phase stainless steel. The corrosive comprises components of: 1-8g of potassium metabisulfite, 10-25ml of hydrochloric acid with mass percent concentration of 40%, 5-5ml of nitric acid with mass percent concentration of 68% and 150-230ml of deionized water. The invention has advantages of reasonably designed formula, good corrosion effect, good display effect of structure of a corroded specimen, no pollution, stable corrosion reaction, and easy configuration.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

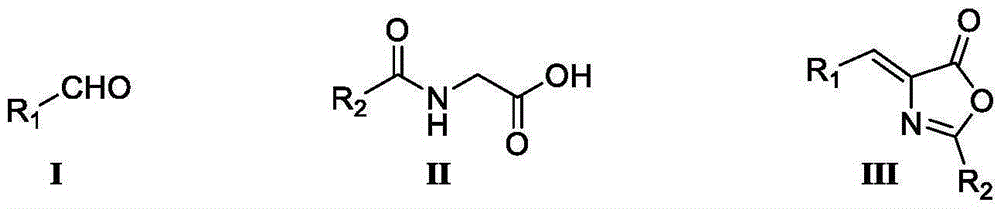

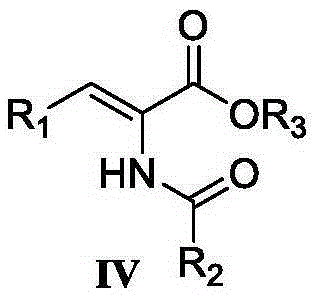

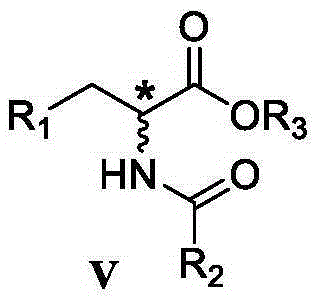

Preparation method of chiral alpha-amino acid

InactiveCN105330557ASimple processSafe, stable and reliable productionOrganic compound preparationAmino-carboxyl compound preparationGlycineAcid hydrolysis

The invention discloses a preparation method of chiral alpha-amino acid. Initial raw materials comprising aldehyde and N-acryl substituted glycine undergo Erlenmeyer-Plochl cyclization, hydrolysis or alcoholysis, asymmetric catalytic hydrogenation and acid hydrolysis to obtain the chiral alpha-amino acid compound. The method adopting the above synthesis route has the advantages of mild reaction conditions, simple technological operation, safe and stable production, realization of high yield, good chemical purity and good optical purity of the above obtained product, wide application range, and suitableness for industrial production.

Owner:天台宜生生化科技有限公司

High molecular weight unsaturated polyether macromonomer, and preparation method and application thereof

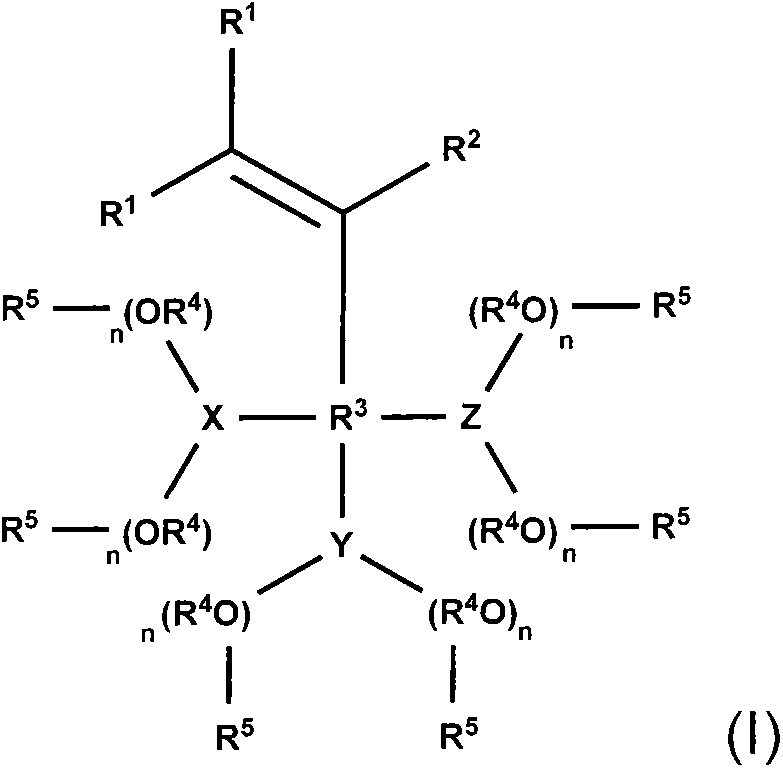

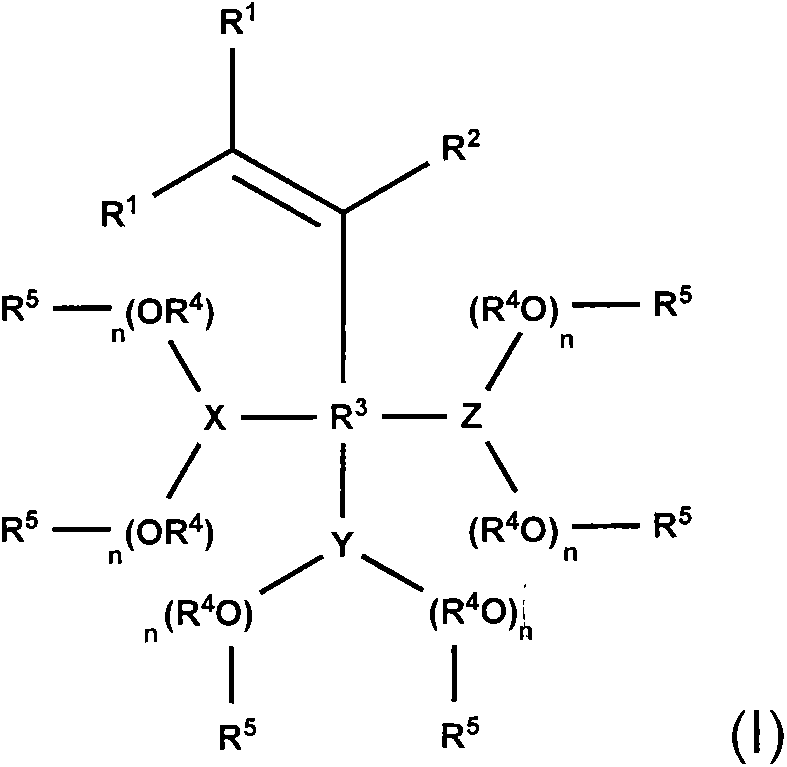

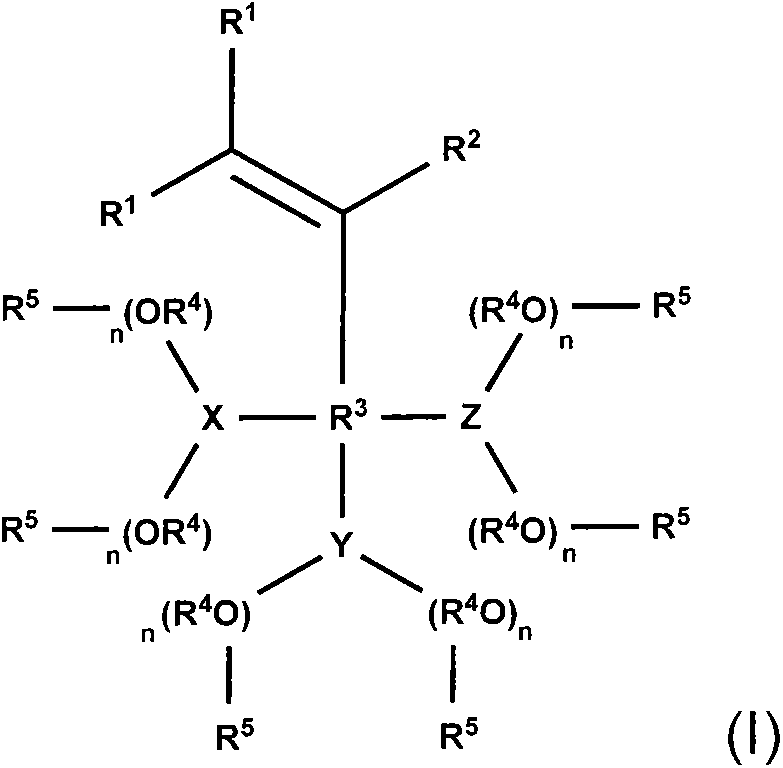

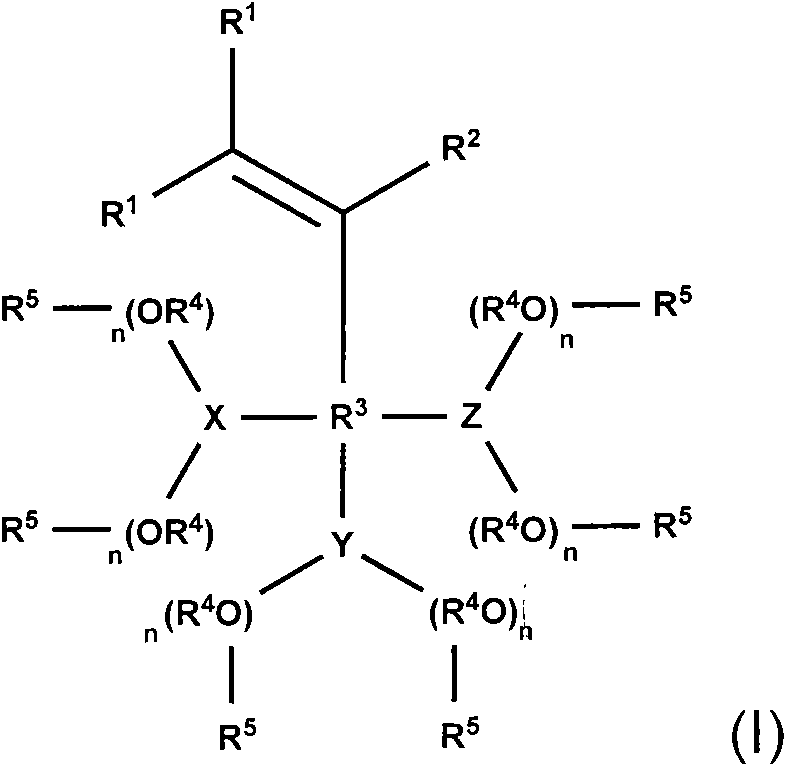

The invention provides a high molecular weight unsaturated polyether macromonomer which is characterized in that the polyether macromonomer is at a liquid state at normal temperature, and the structural formula (I) thereof is expressed in the specification, wherein R<1> is same or different, and represents a hydrogen atom or alkyl with 1-20 carbon atoms; R<2> represents alkyl with 1-20 carbon atoms; R<3> represents alkyl or carbonyl with 1-10 carbon atoms; R<5> represents a hydrogen atom or alkyl with 1-20 carbon atoms; R<4>O is different, and represents oxyalkenyl with 2-18 carbon atoms; n represents the average addition mole number of the oxyalkenyl, and 5<=n<=300; and X, Y and Z are same or different, and represent -N, -O or H. By optimally designing the molecular structure, the high molecular weight unsaturated polyether macromonomer provided by the invention ensures the liquid state thereof at normal temperature while the molecular polymerization reaction activity is ensured. Besides, a preparation method of the high molecular weight unsaturated polyether macromonomer provided by the invention is simple, and the conditions are easy to control; and the product does not need slicing post-treatment, the production cost is low, and the economic benefits are increased.

Owner:联泓(江苏)新材料研究院有限公司

Preparation method of halohydrocarbon-free alpha-cyanoacrylate

ActiveCN102030681ANot easy to hydrolyzeEasy to controlCarboxylic acid nitrile preparationOrganic compound preparationHalohydrocarbonMethyl carbonate

The invention relates to a preparation method of halohydrocarbon-free alpha-cyanoacrylate, which comprises the following steps: mixing cyanoacetate and methyl carbonate in a reaction kettle, simultaneously mixing formaldehyde and a base catalyst in a charging hopper, then adding the mixture of the formaldehyde and the base catalyst to the reaction kettle at twice, performing a refluxing and condensation reaction at 78 DEG C under normal pressure, adding a dehydration solvent methyl carbonate to dehydrolyze after the condensation reaction is finished, adding an anionic polymerization inhibitor phosphorus pentoxide and a free radical polymerization inhibitor, and depolymerizing and distilling at 155-210 DEG C at a vacuum degree of 0.5-30 mmHg to obtain an alpha-cyanoacrylate coarse monomer; and rectifying the coarse monomer to obtain a high-purity alpha-cyanoacrylate refined monomer, wherein the yield of the alpha-cyanoacrylate refined monomer is more than 75%, and the purity of the alpha-cyanoacrylate refined monomer is 99%. The invention has the advantages of no pollution, energy conservation and high yield and high purity of the obtained product, and is stable in reaction, thereby being suitable for popularization and application.

Owner:山东禹王和天下新材料有限公司

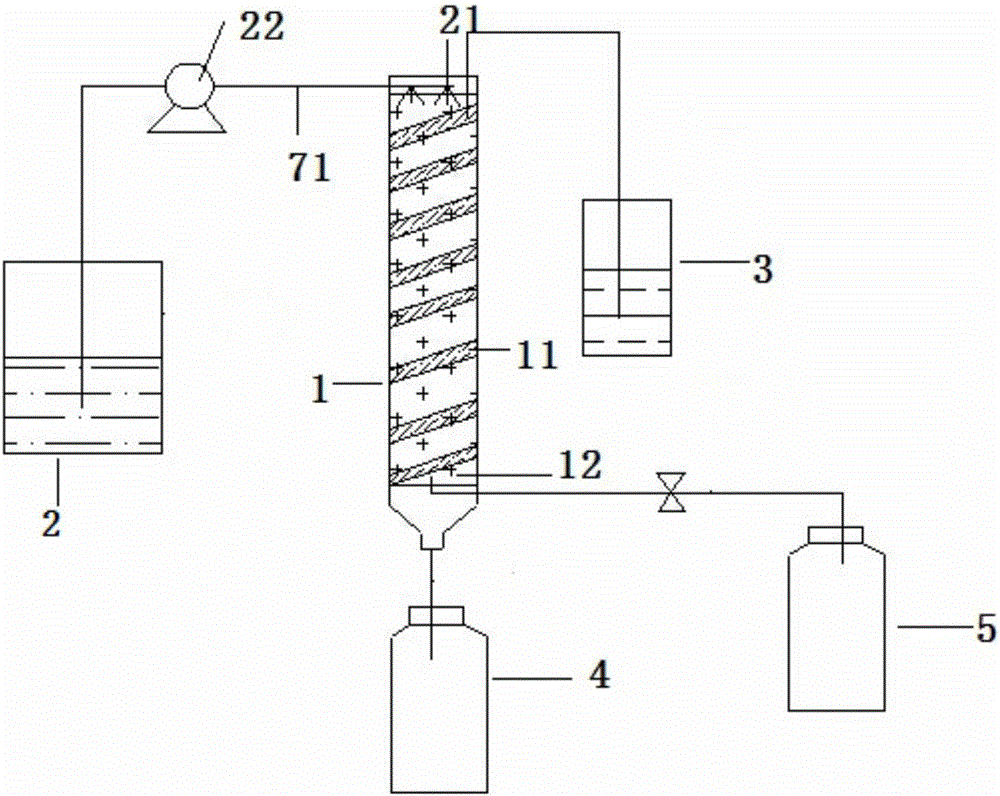

Application of gas-liquid contact reaction device to fluorination of perfluoropolyether acid

ActiveCN106311097AAchieve utilizationFull fluorination reactionChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesChemical synthesisPerfluoropolyether

The invention belongs to the field of fluorine chemical synthesis and particularly relates to application of a gas-liquid contact reaction device to fluorination of perfluoropolyether acid. The gas-liquid contact reaction device comprises a gas inlet cylinder for containing fluorinating agent gas, a reaction tube filled with filler, a liquid cylinder, a product collecting cylinder and a tail gas treatment device, wherein a liquid outlet connected with the product collecting cylinder and a gas inlet connected with the gas inlet cylinder are formed in the bottom of the reaction tube, a spray head is arranged at the top end of the reaction tube and is connected with the liquid cylinder through a liquid pump, a gas outlet connected with the tail gas treatment device is formed in the top of the reaction tube, and heating strips are arranged on the outer wall of the reaction tube. The gas-liquid contact reaction device is capable of fluorinating the perfluoropolyether acid by fluorine gas effectively.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD +1

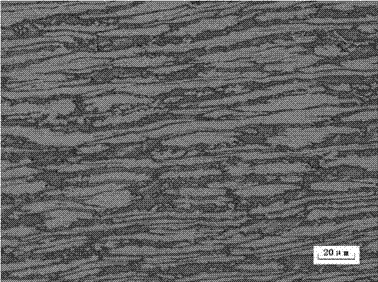

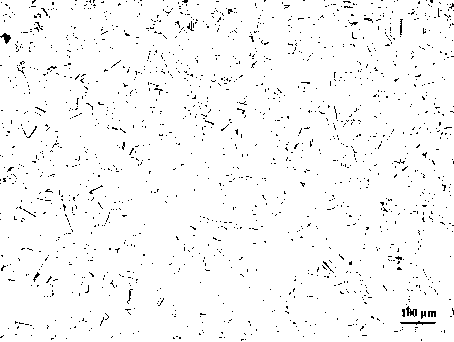

High-alloy austenitic stainless steel microscopic structure, sigma intermediate-phase color corrosive agent and corrosion method

ActiveCN106757031AErosion effect is goodGood reproducibilityPreparing sample for investigationCorrosion reactionGreek letter sigma

The invention provides a high-alloy austenitic stainless steel microscopic structure, a sigma intermediate-phase color corrosive agent and a corrosion method. The high-alloy austenitic stainless steel microscopic structure, the sigma intermediate-phase color corrosive agent and the corrosion method have the advantages of being good in corrosion effect, good in display effect, free of pollution and stable in corrosion reaction. The corrosion method includes the steps of uniformly stirring raw materials by using a glass rod, allowing the raw materials to stand for 15-30 minutes, and preparing the corrosive agent, wherein the corrosive agent comprises the flowing components: 0.1-2g of potassium permanganate, 5-25ml of hydrochloric acid with the mass percentage concentration being 35%, 5-30ml of nitric acid with the mass percentage concentration being 68%, 0.1-1.2g of copper sulfate and 150-300ml of deionized water; and carrying out coarse grinding, fine grinding and polishing on a sample, washing the sample with absolute ethyl alcohol, then carrying out blow-drying, soaking the sample to be tested in the corrosive agent for corrosion for 15-300 seconds, placing the corrosion surface of the sample upwards until the metallographic-phase surface of the sample is corroded to be yellow, washing the obtained rough corrosion test sample under a water faucet, cleaning the obtained rough corrosion test sample with 95% alcohol after washing, and then carrying out blow-drying by using cold air to complete metallographic-phase corrosion of the stainless steel structure.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Method for synthesizing resin with high water absorption from polyaminoester

A process for preparing high-hydroscopicity resin from polyurethane includes such steps as dissolving polyurethane in solvent mixture, using alkali solution to neutralize acrylic acid, mixing them together, adding disperser, trigger and cross-linking agent, and high-speed shearing while reaction in protective atmosphere.

Owner:NANJING NORMAL UNIVERSITY

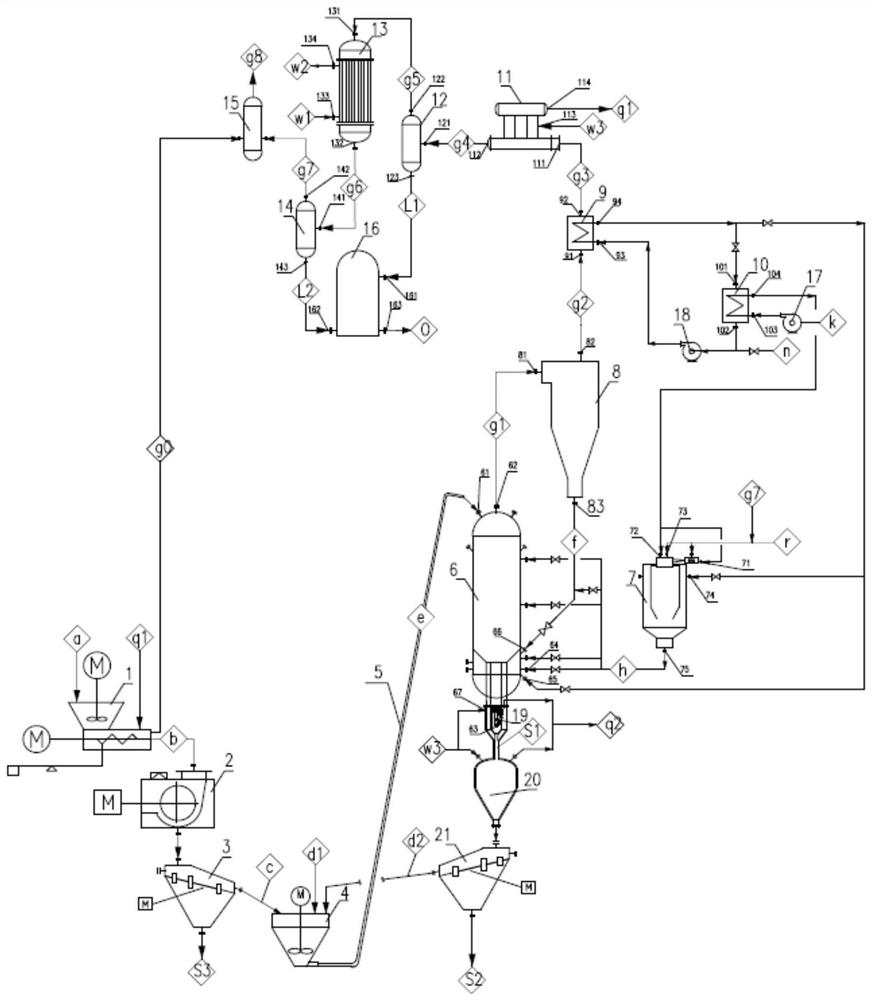

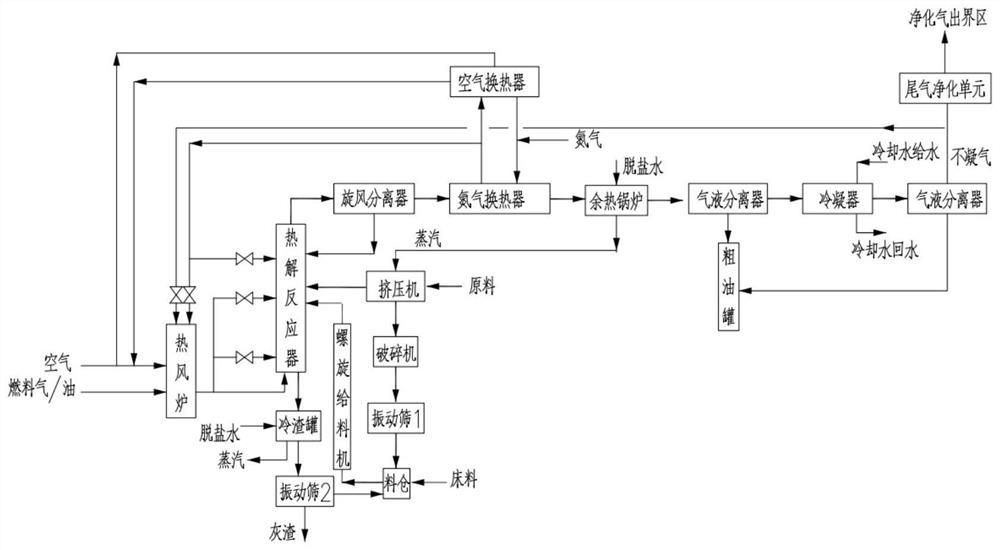

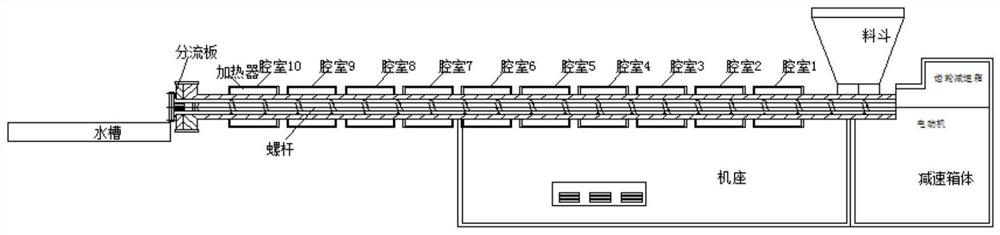

Process method and device for producing oil by pyrolysis of high-molecular polymerization waste

PendingCN113122300AFeeding form is flexible and convenientGuaranteed pyrolysis temperatureLiquid hydrocarbon mixture productionHydrocarbon oils treatmentFixed bedEngineering

The invention discloses a process method and device for producing oil by pyrolysis of high-molecular polymerization waste. The process method comprises the following steps of extruding the high-molecular polymerization waste through an extruder, mixing the extruded high-molecular polymerization waste with a bed material, feeding the mixture into a fixed bed pyrolysis reactor, carrying out pyrolysis reaction, removing fly ash from the generated high-temperature oil gas through a cyclone separator, and carrying out heat exchange with nitrogen, then entering a waste heat boiler to recover heat energy, carrying out gas-liquid separation, feeding liquid into a crude oil tank to be stored, and further condensing gas to obtain crude oil, combusting fuel in the inert gas generator to generate oxygen-deficient hot air which is fed into the fixed bed pyrolysis reactor to be in full contact with the mixture, and providing heat for the pyrolysis reaction, and cooling and screening the waste residue, and recycling the bed material for reutilization. The high-molecular polymerization waste is dechlorinated and deacidified after being extruded, so that the problem of corrosivity of a reaction system caused by chlorine and acid gas generated by pyrolysis is solved, the pyrolysis temperature in the reactor is ensured by adopting a multi-section heat supply mode, and the problems of poor heat conductivity and non-uniform reaction heating of the high-molecular polymerization waste are solved.

Owner:渭沣洁净技术(上海)有限公司 +1

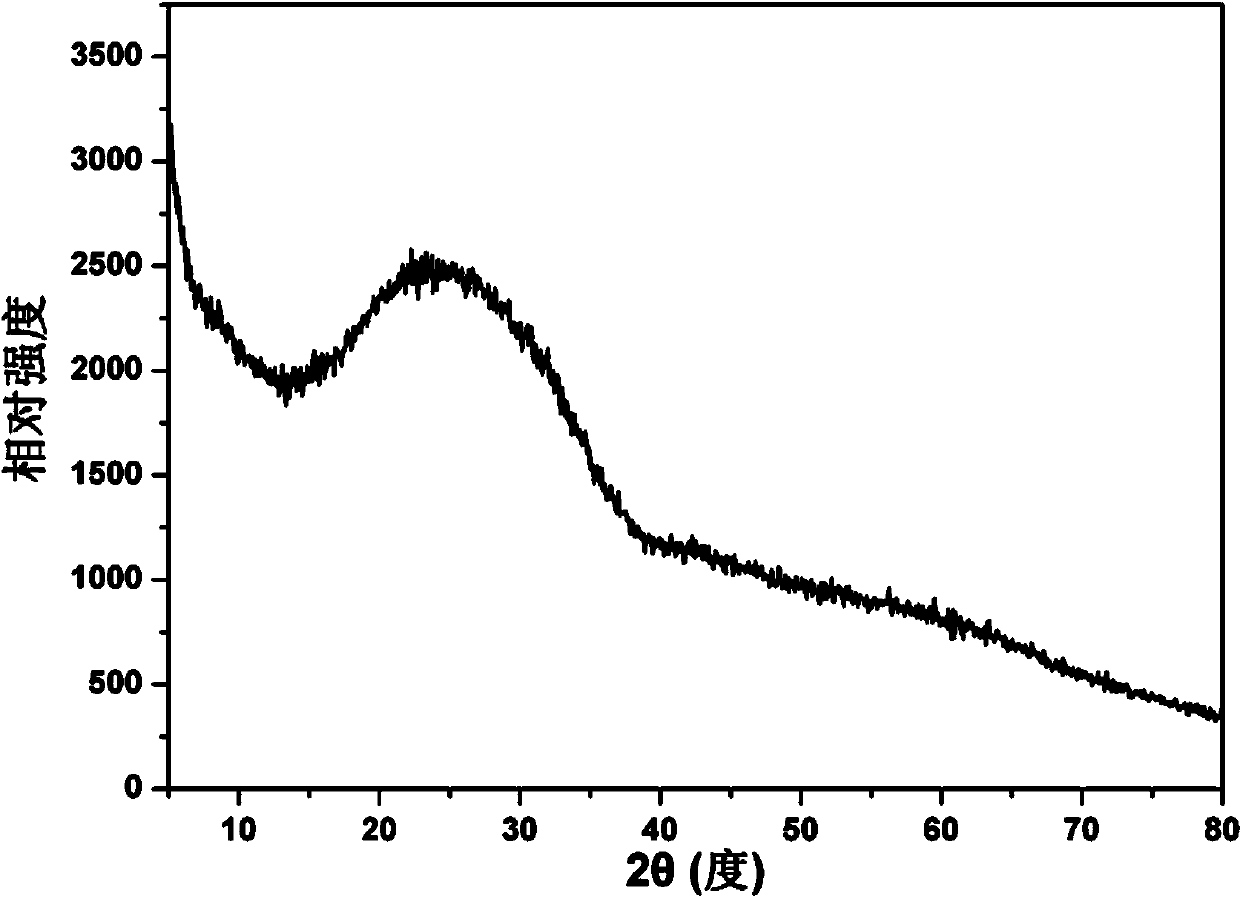

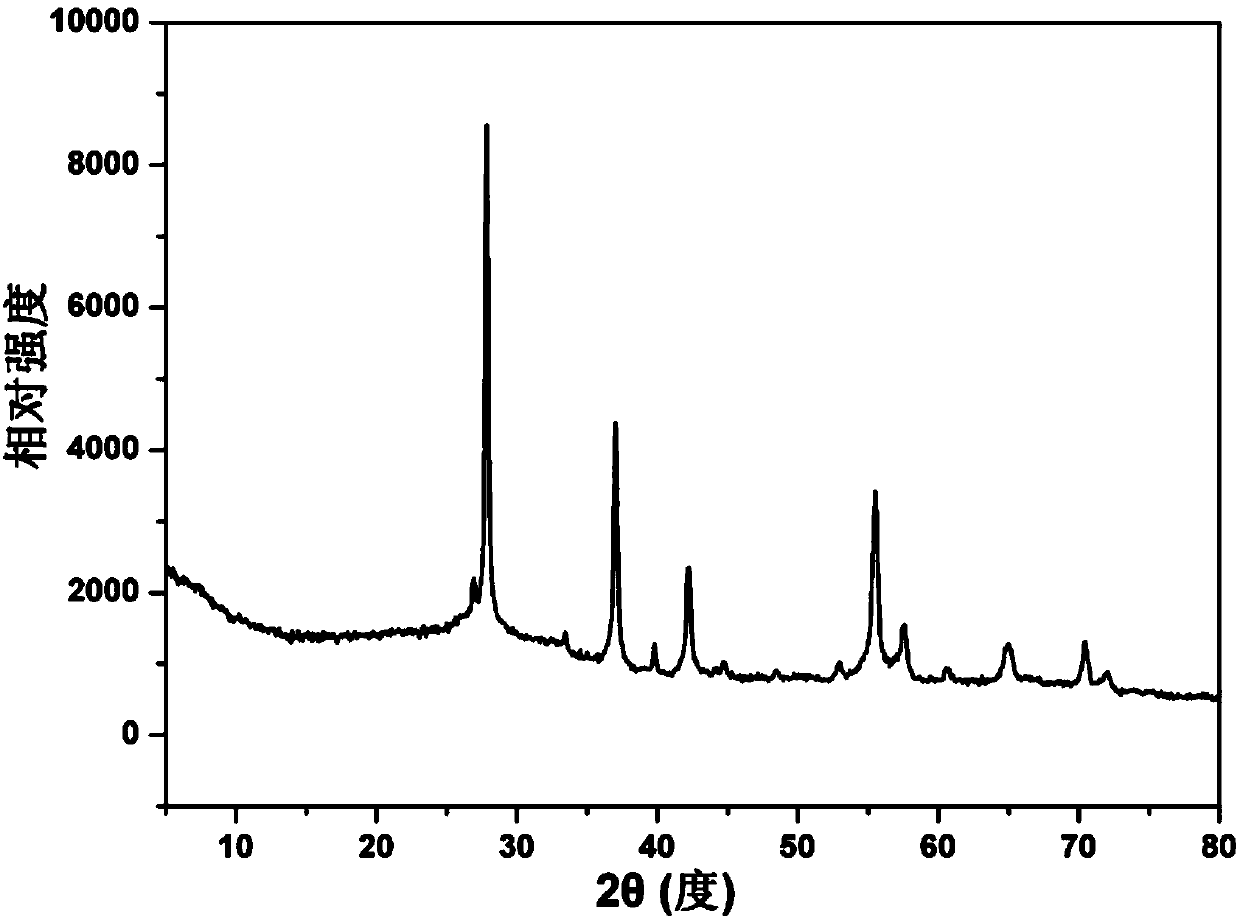

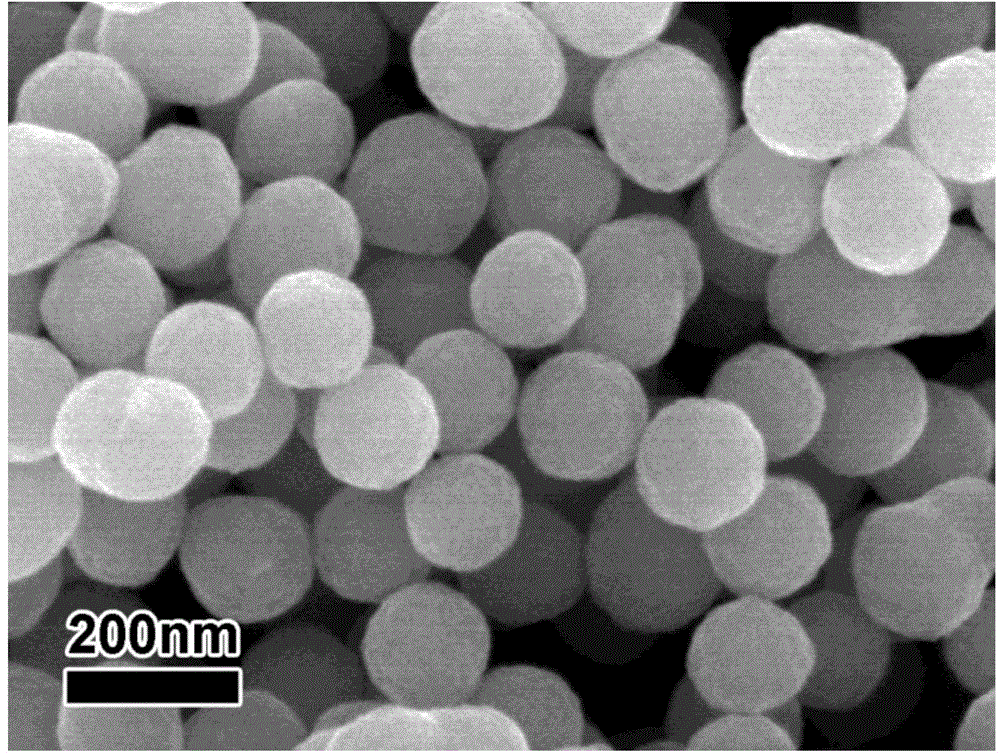

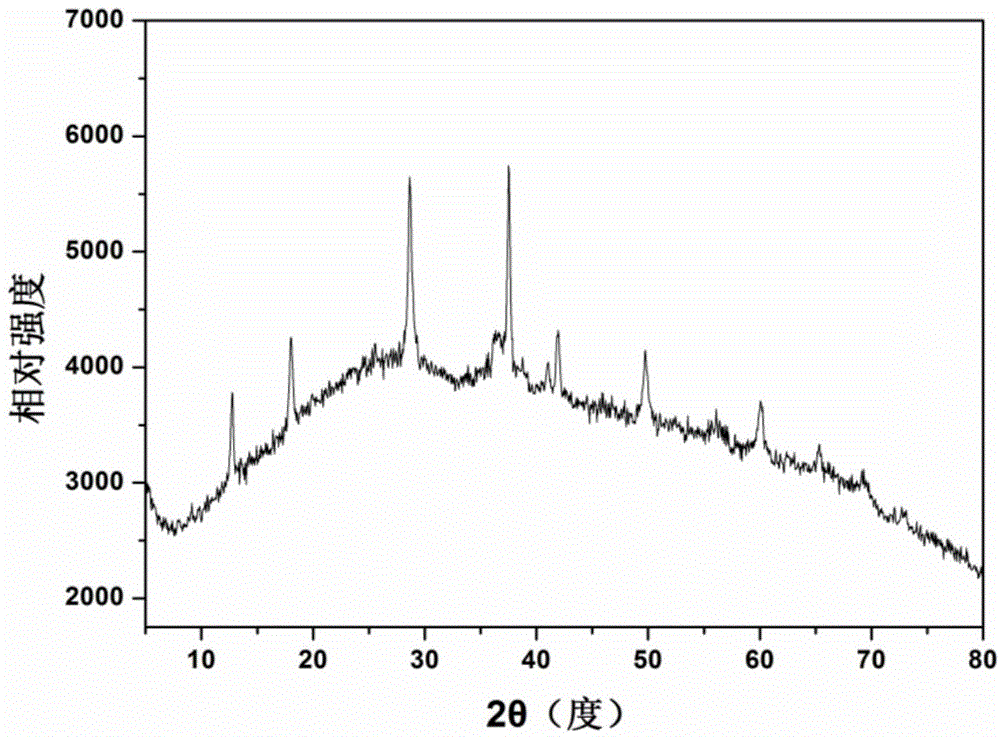

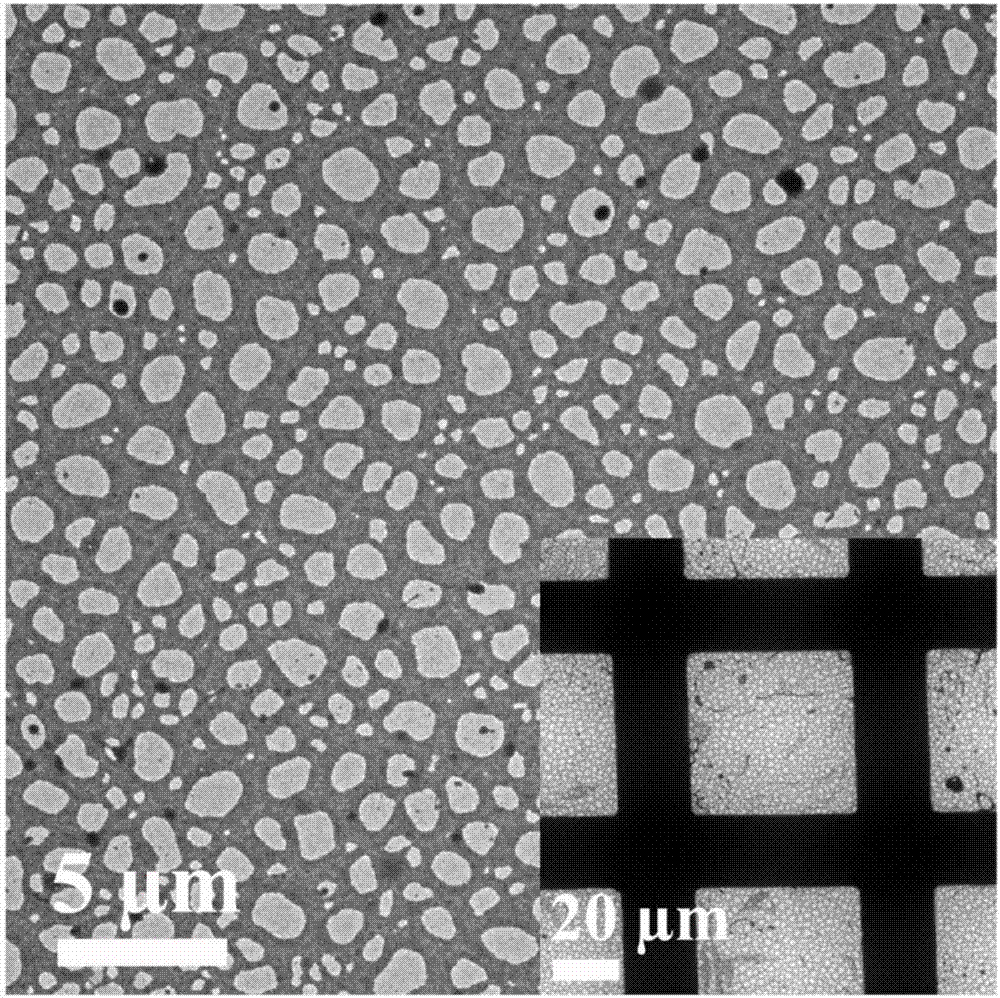

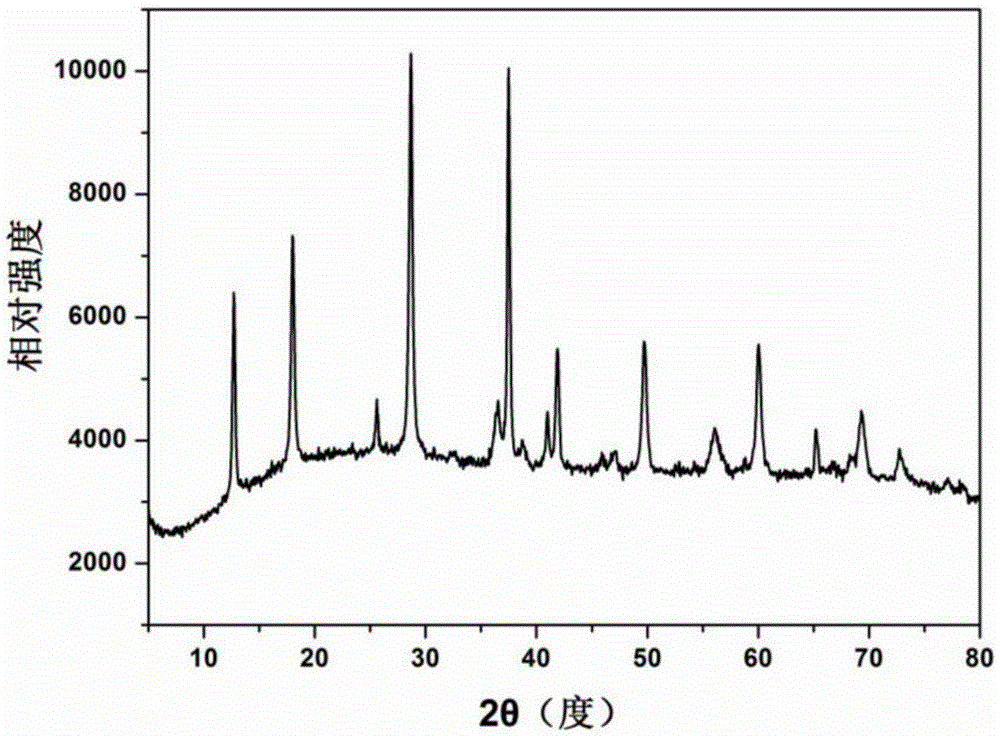

Synthesis method and use of monodispersed KMn8O16 nanospheres

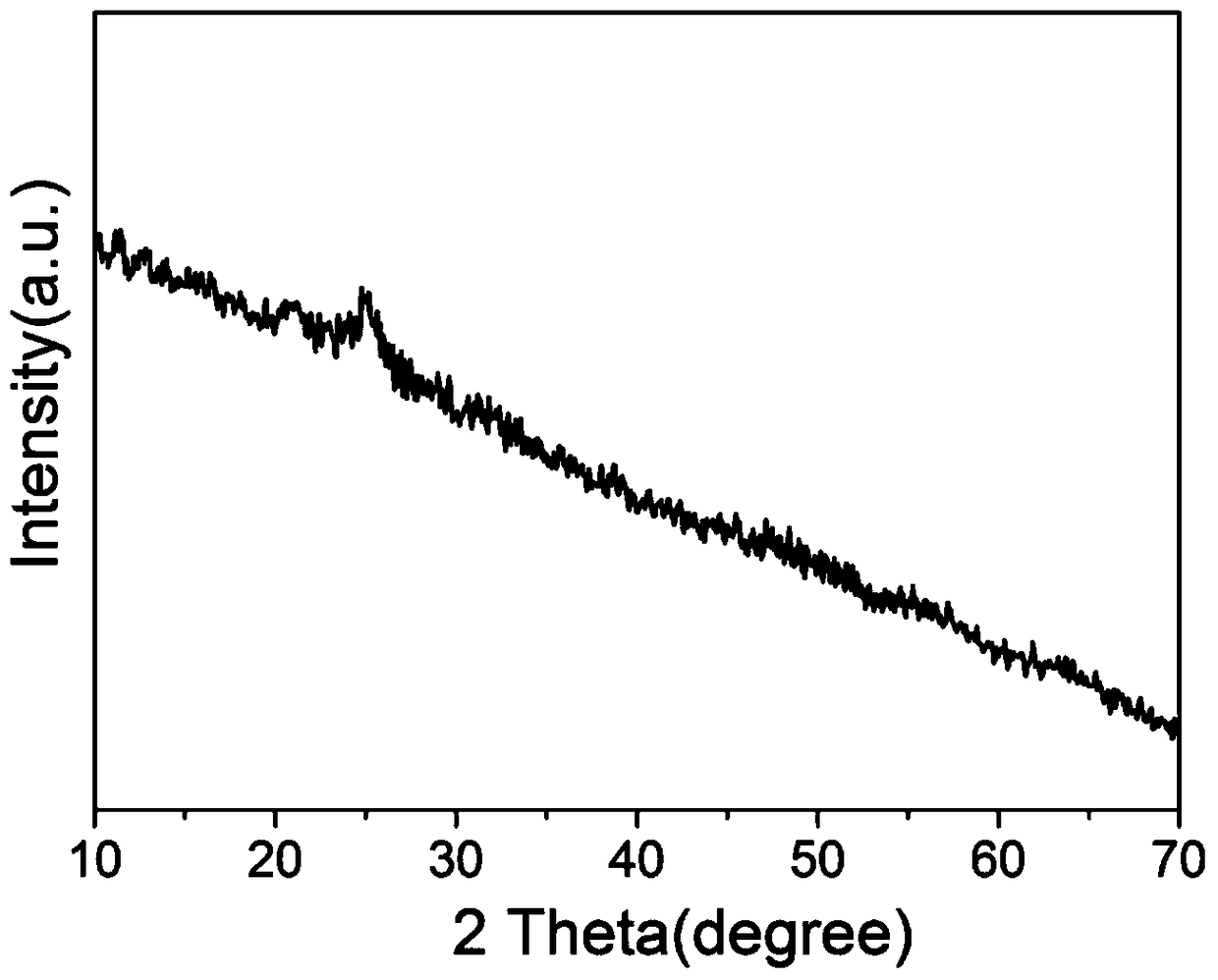

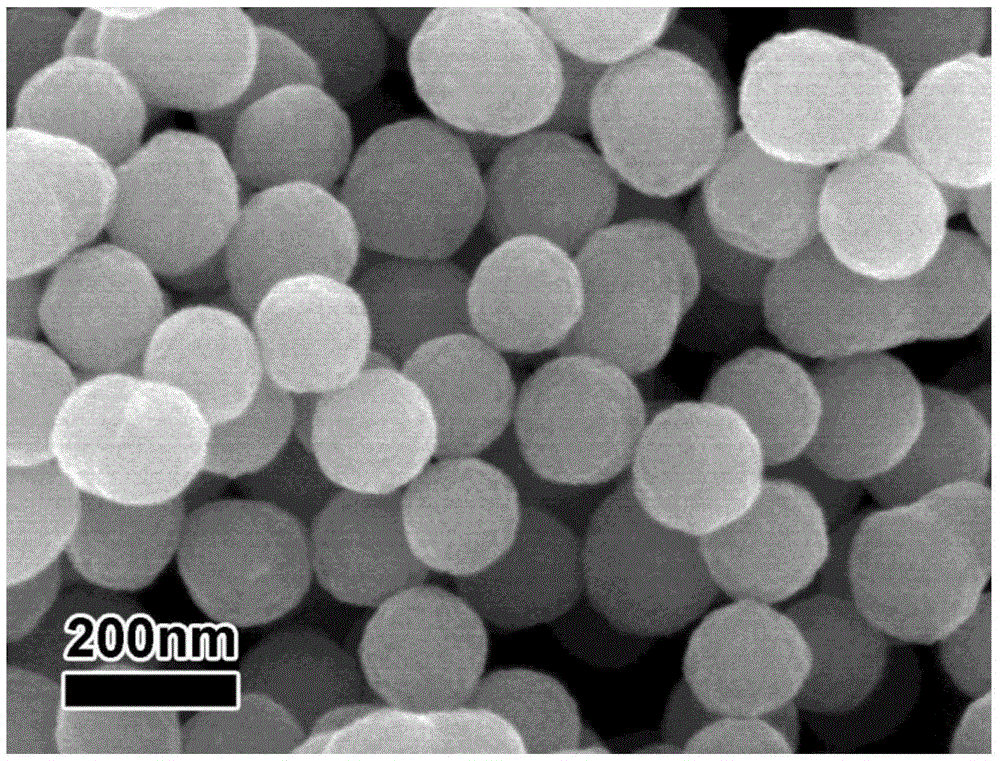

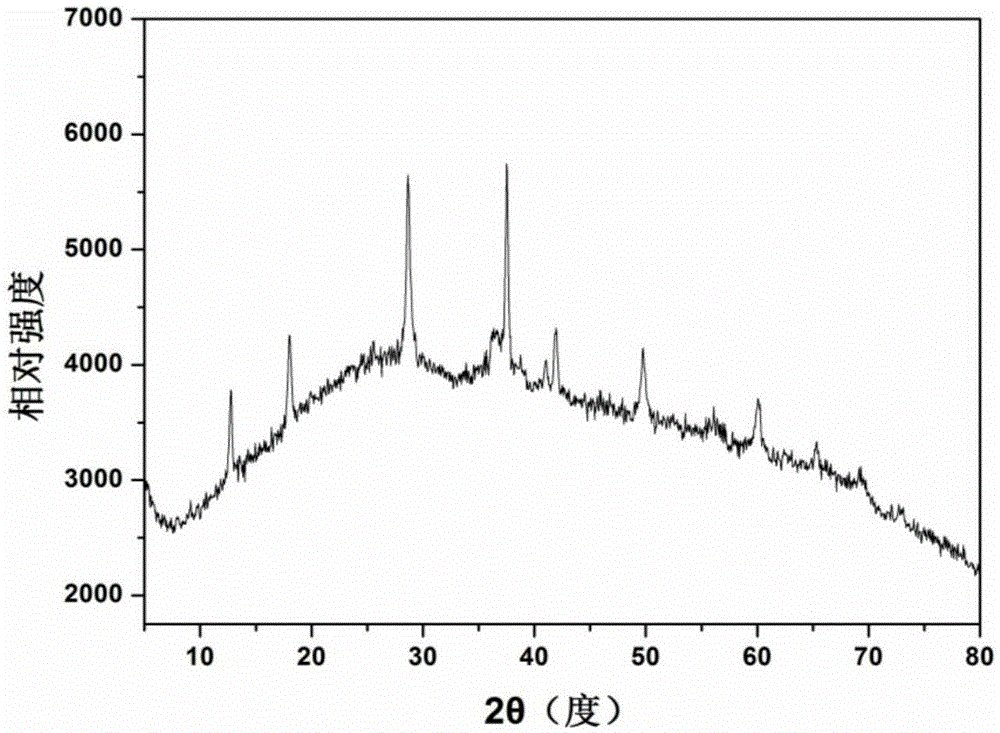

InactiveCN104129815ASimple reaction conditionsGood repeatabilityMaterial nanotechnologyCell electrodesArgon atmosphereSynthesis methods

The invention discloses a synthesis method and a use of monodispersed KMn8O16 nanospheres. The synthesis method of the monodispersed KMn8O16 nanospheres comprises the following steps of dissolving potassium permanganate, polyvinylpyrrolidone and carbonate in deionized water, adding soluble organic alcohol into the solution, carrying out mixing to obtain a uniform mixture, putting the mixture into a thermostatic bath, carrying out a thermostatic reaction process at a temperature of 50-120 DEG C for 1-24h to obtain brownish black precipitates, drying the brownish black precipitates, and calcining the dried brownish black precipitates in an argon atmosphere at a temperature of 300-600 DEG C for 2-20h to obtain the monodispersed KMn8O16 nanospheres. The monodispersed KMn8O16 nanospheres have structured morphology and uniform size adjustable in a range of 80-200nm. The monodispersed KMn8O16 nanospheres are prepared by a constant-temperature liquid phase reaction. The synthesis method is easy and simple and has a large yield. A performance test shows that the monodispersed KMn8O16 nanospheres have a large application prospect in the lithium ion battery energy storage field.

Owner:WUHAN UNIV OF TECH

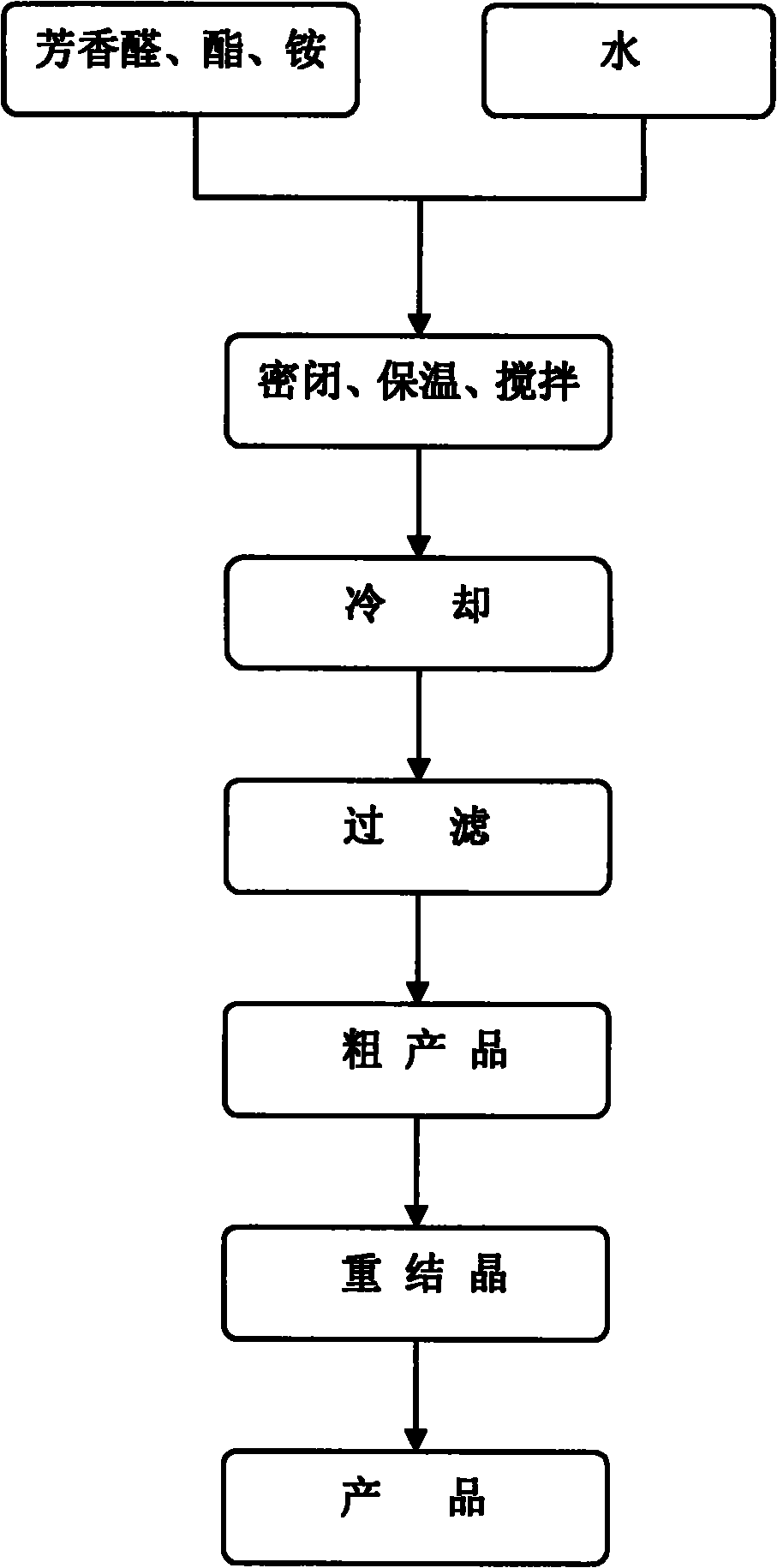

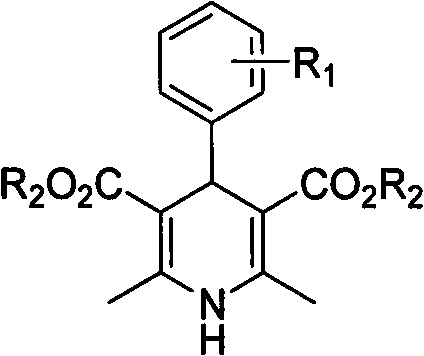

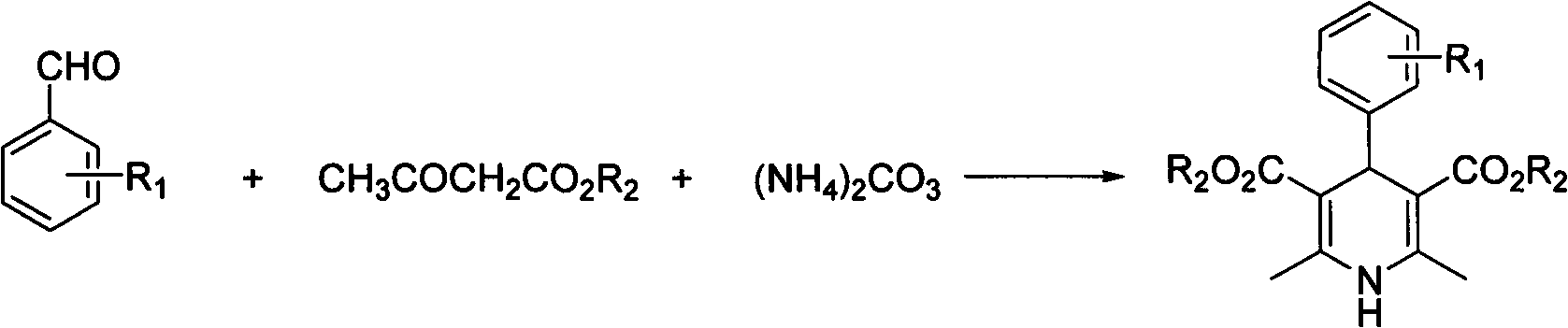

Water phase clean synthesis method of 1,4-dihydropyridine compounds

InactiveCN102174010AWide variety of sourcesEasy to manufactureOrganic chemistryAcetoacetatesOrganic solvent

The invention discloses a water phase clean synthesis method of 1,4-dihydropyridine compounds. The method is as follows: aromatic aldehyde, acetoacetate and ammonium carbonate or ammonium bicarbonate are used as raw materials, no catalyst is added, water is used as the reaction medium to replace organic solvent, the raw materials are heated and stirred in a sealed system to react and synthesize the target compounds. Compared with the prior art, the method has the following advantages: (1) the raw material sources are available, the preparation method is convenient; particularly, compared withorganic ammonium salts such as ammonium formate and ammonium acetate, ammonium carbonate or ammonium bicarbonate used as the source of nitrogen atoms, the cost is low and the material is non-toxic and non-corrosive; (2) water is used as the reaction medium in the synthesis process, the reaction in the sealed system is safe and smooth can easily be industrialized and is an environmentally friendlychemical process; and (3) the reaction does not use catalyst and organic solvent, the operation process is simplified and the effects of energy saving and emission reduction are obvious.

Owner:YANCHENG TEACHERS UNIV

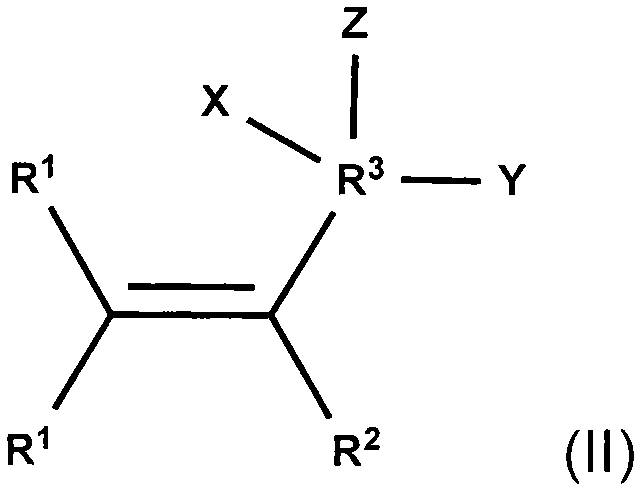

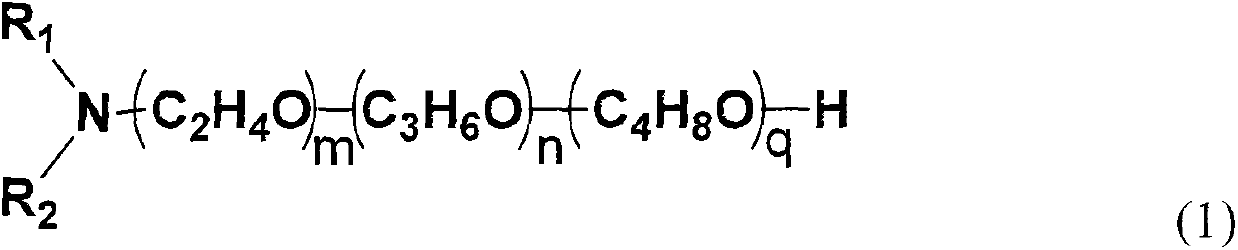

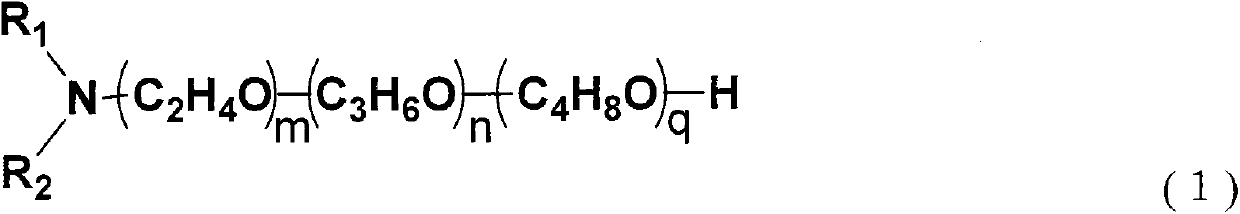

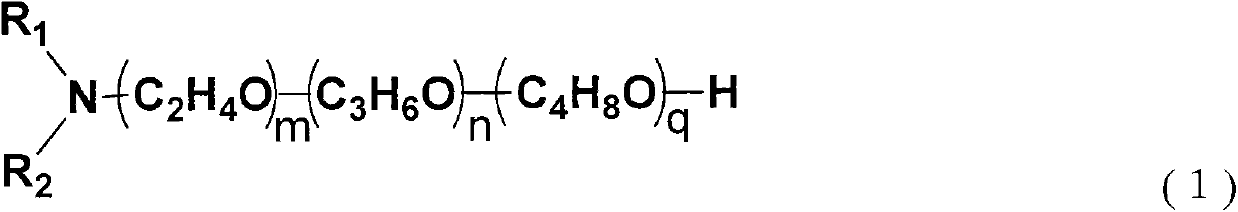

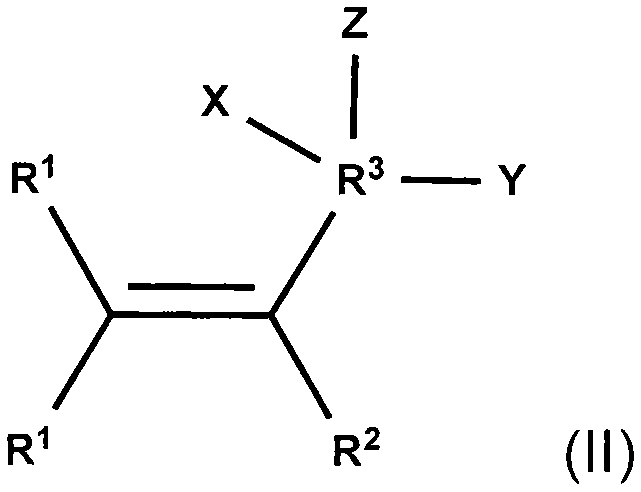

Dialkylene amine polyether and preparation method and application thereof

The invention discloses a dialkylene amine polyether and a preparation method and application thereof. The dialkylene amine polyether is expressed by adopting the following structural formula (1), (img file= 'DSA0000101280160000011.tif' wi= '1420' he= '274' / ), wherein R1 and R2 are alkenyl of which the carbon number is 3-10; m is greater than 1; n is greater than or equal to 0; q is greater than or equal to 0. The dialkylene amine polyether provided by the invention has two unsaturated chain segments and good polymerization activity, and can be applied to synthesis of polymer dispersant and polycarboxylate high-performance water-reducing admixture products, and the dispersibility of each product can be improved. The dialkylene amine polyether provided by the invention is simple in preparation method, easy to control condition, stable and safe in reaction, high in productivity, free of use of an organic solvent, and free of generation of a harmful substance to a human body, and environmental pollution is avoided. Application of the dialkylene amine polyether in synthesis of an industrial high-molecular polymer is also provided by the invention.

Owner:联泓新材料科技股份有限公司

Rubber powder/acrylic acid/montmorillonite high water absorption resin and its synthesis method

The high hydroscopicity rubber / acrylic acid / montmorillonite resin has the material composition of acrylic acid 75-88 wt%, rubber powder 7-20 wt%, cross-linking agent 0.05-0.26 wt%, montmorillonite 2.00-10 wt% and initiator 0.25-0.8 wt%. The preparation process includes the steps of: pre-treating rubber powder with concentrated acid solution, neutralizing acrylic acid, adding montmorillonite and pre-treated rubber powder into neutralized acrylic acid liquid, adding initiator and cross-linking agent in protecting atmosphere, high speed shearing, reaction at constant temperature of 60-80 deg.c, and stoving at 110-130 deg.c to obtain the high hydroscopicity resin. The high hydroscopicity rubber / acrylic acid / montmorillonite resin has deionized water absorbing capacity over 1000 g / g. The present invention may have industrial waste used and has excellent economic and environmental benefit.

Owner:NANJING NORMAL UNIVERSITY

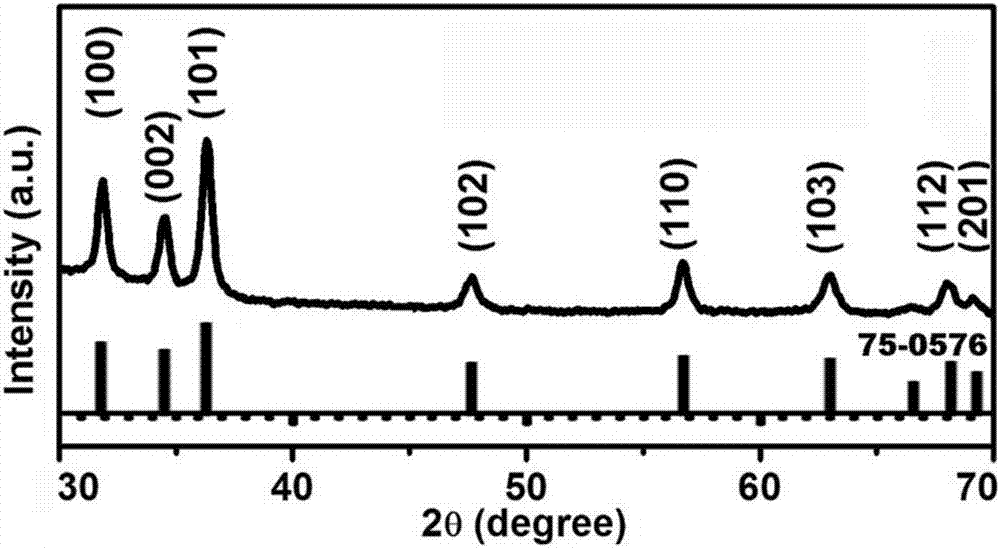

Macroporous-mesoporous-microporous zinc oxide material and preparation method and application thereof

InactiveCN106966423AImprove diffusion abilityNo emissionsZinc oxides/hydroxidesCell electrodesNanoparticlePollutant emissions

The invention discloses a macroporous-mesoporous-microporous zinc oxide material. The macroporous-mesoporous-microporous zinc oxide material is a thin-film material formed by assembly of zinc oxide nanoparticles 25-30 nm in particle size and 100-2000 nm in thickness. The macroporous-mesoporous-microporous zinc oxide material is characterized in that the micropore size is 0.5-2 nm, mesopore size is 2-50 nm and the macropore size is 50-200 nm. A nanoparticle synthesis and self-assembly method is adopted, is mild in reaction conditions, energy saving and free of pollutant discharge, and can be used for preparing nano-porous zinc oxide materials at the normal temperature and at the barometric pressure; the performance of the macroporous-mesoporous-microporous zinc oxide material is substantially improved in the fields of photocatalysis, gas sensitivity and lithium batteries as compared with that of a traditional material, thereby being suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

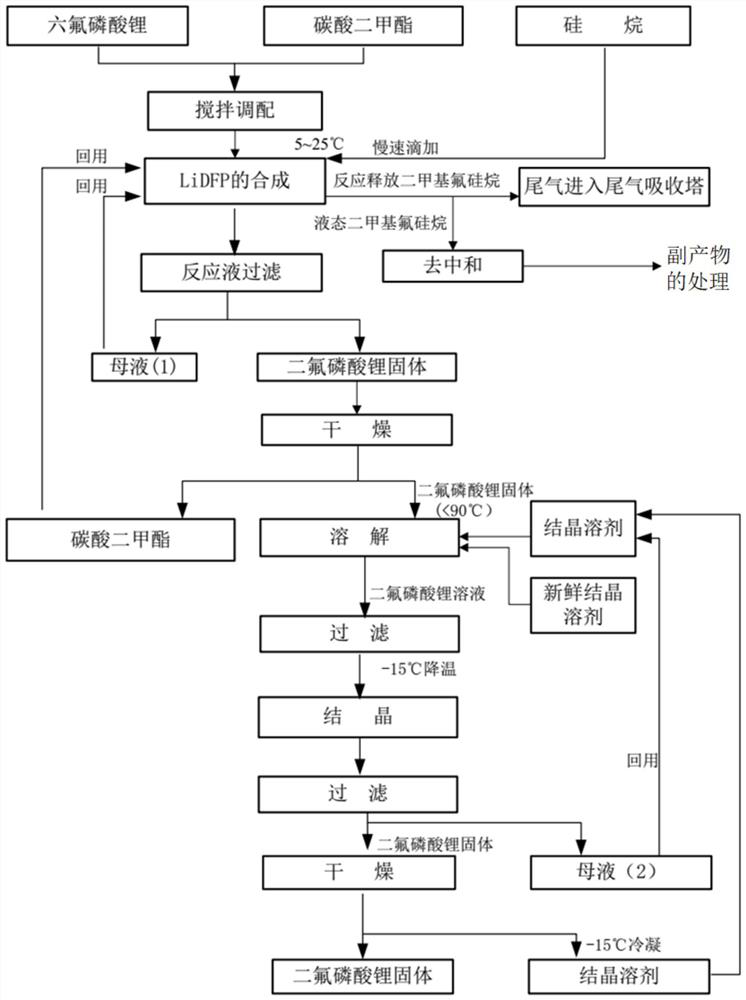

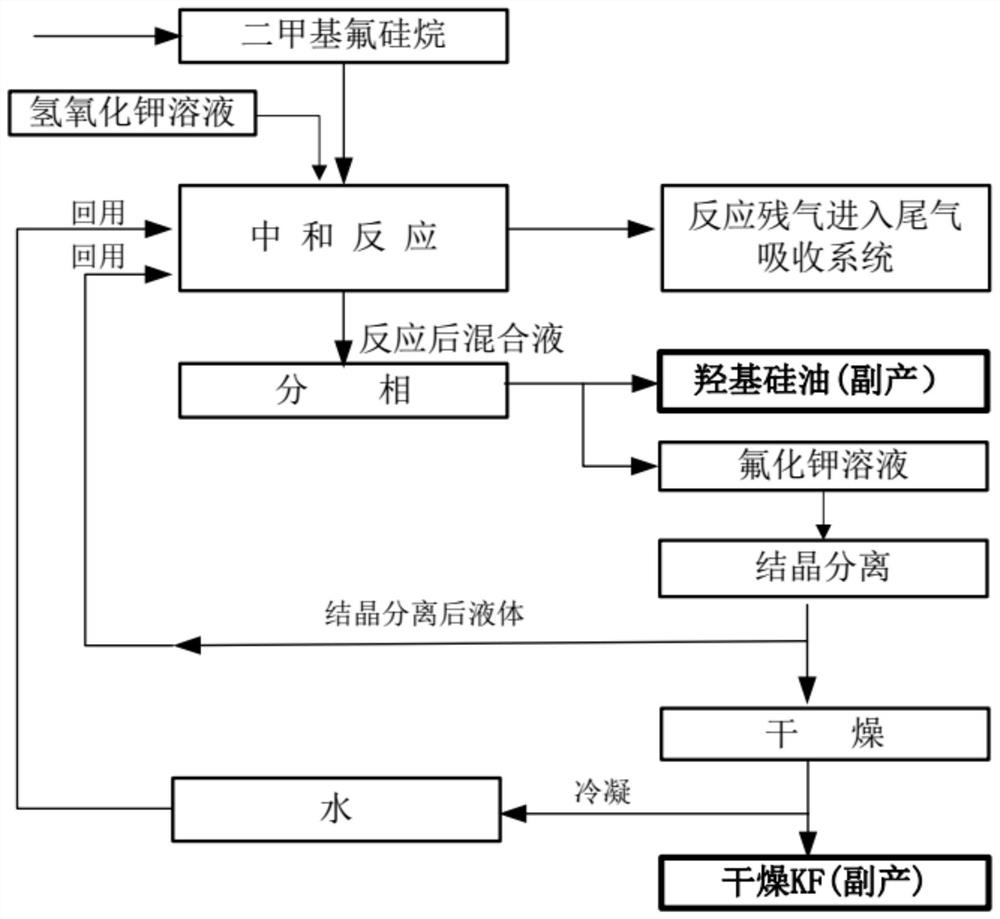

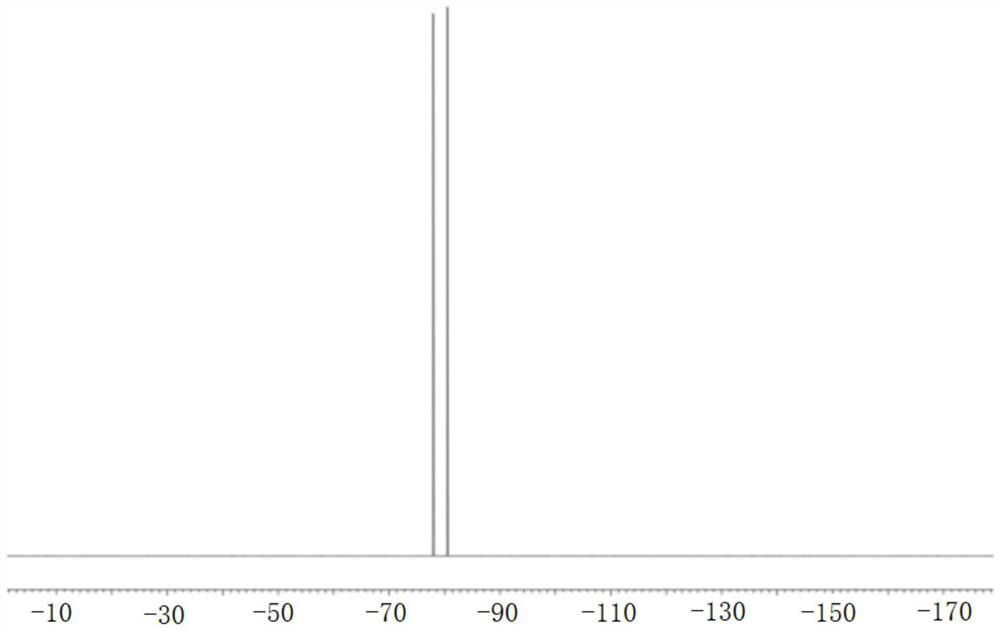

Preparation method of lithium difluorophosphate and byproduct treatment method

InactiveCN111994892AResponse is smooth and safeFastSilicon organic compoundsAlkali metal fluoridesSide productProcess engineering

The invention relates to the technical field of materials for lithium batteries, in particular to a preparation method of lithium difluorophosphate and a byproduct treatment method. The method specifically comprises the following steps of: synthesizing LiPO2F2; crystallizing and purifying; filtering and drying a finished product; and carrying out by-product treatment to obtain high-added-value by-products. Through the reaction process, the inventor adopts a special catalyst and process, the reaction is safe and stable, the speed is high, intermediate materials and solvents are fully recycled and reused in the reaction process, the material consumption is low, and the method is environment-friendly; meanwhile, the product is easy to separate and purify, simple in process preparation and suitable for large-scale production.

Owner:山东森诺威新能源有限公司

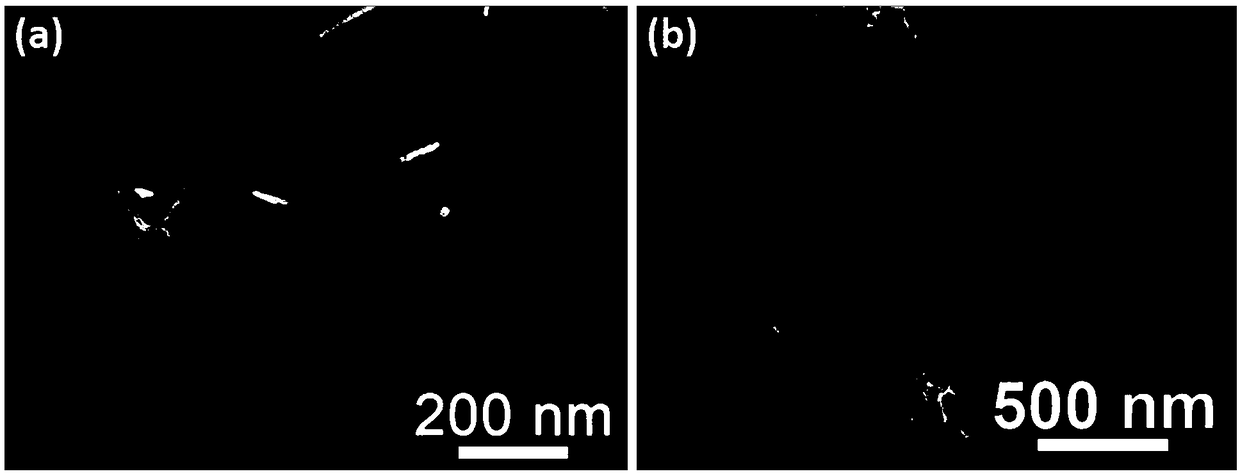

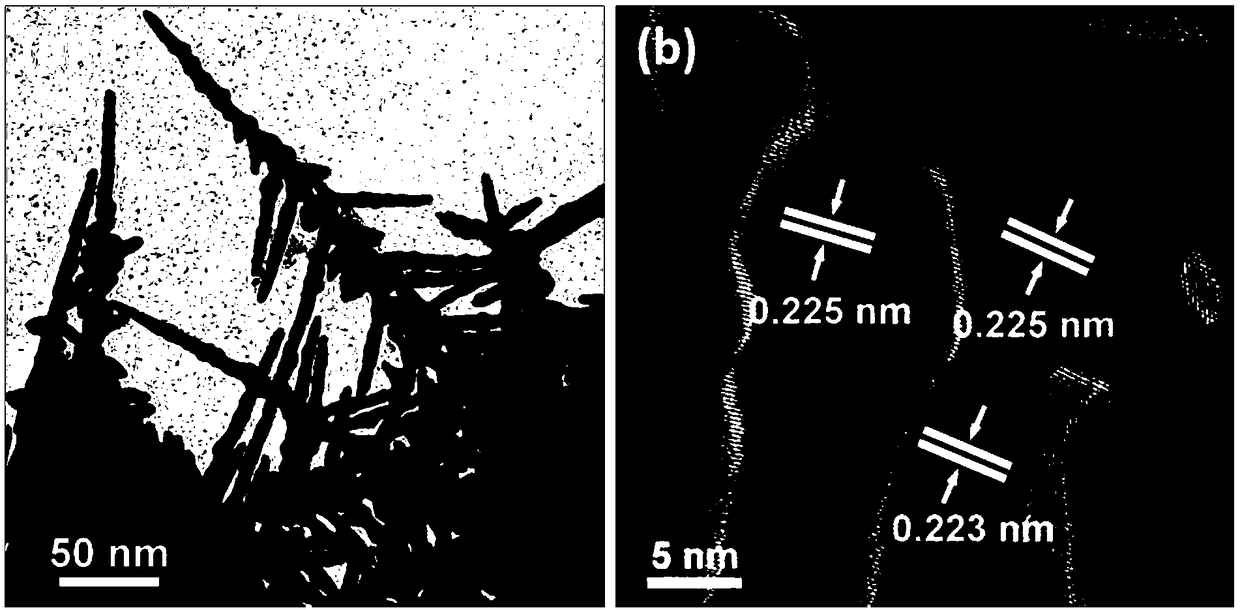

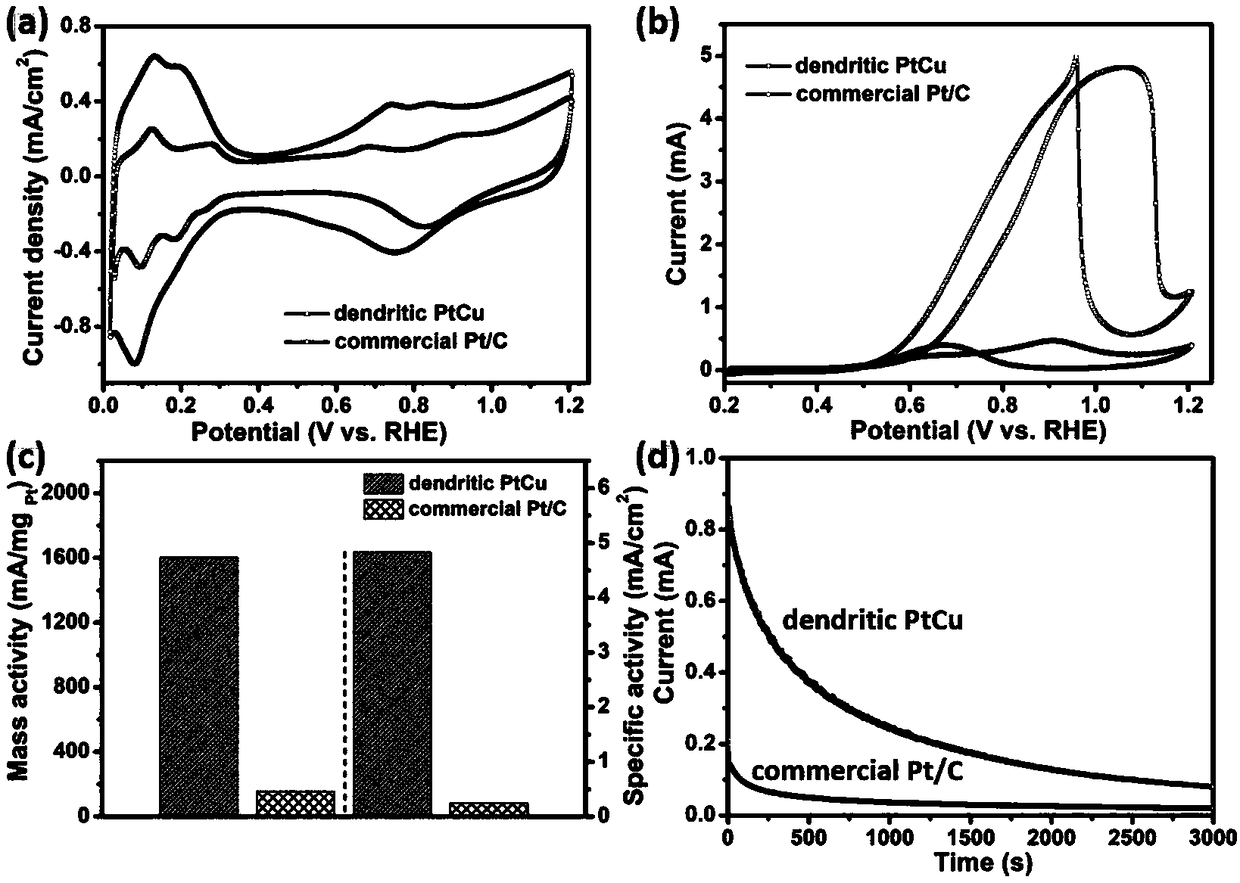

Graded dendritic PtCu electro-catalyst and preparation method thereof

ActiveCN109174119AThe synthesis method is simpleImprove catalytic performanceMetal/metal-oxides/metal-hydroxide catalystsOil phaseSolvent

The invention discloses a graded dendritic PtCu electro-catalyst and a preparation method thereof. The preparation method comprises the following steps: mixing oleylamine with oleic acid, heating, andcarrying out ultrasonic treatment, so as to obtain a colorless settled solution; maintaining the temperature, continuing to add ethanol, and carrying out ultrasonic treatment, so as to obtain a colorless settled solution; maintaining the temperature, continuing to add platinum acetylacetonate and copper acetylacetonate, and carrying out ultrasonic treatment, so as to obtain a light blue settled solution; and heating for reducing the light blue settled solution, so as to prepare graded dendritic PtCu. The method for preparing graded dendritic PtCu by virtue of an oil-phase solvent method is simple, stable and safe in reaction and high in repeatability. Meanwhile, by simply changing the parameters, the preparation of a PtCu nano-particle cube assembly and a PtCu nanometer concave-surface cube assembly can be realized. The method disclosed by the invention has a guiding significance to the preparation of other metal nanostructures.

Owner:WUHAN UNIV OF TECH

A kind of high-alloy austenitic stainless steel microstructure and σ mesophase color etchant and corrosion method

ActiveCN106757031BErosion effect is goodGood reproducibilityPreparing sample for investigationCorrosion reactionGreek letter sigma

The invention provides a high-alloy austenitic stainless steel microscopic structure, a sigma intermediate-phase color corrosive agent and a corrosion method. The high-alloy austenitic stainless steel microscopic structure, the sigma intermediate-phase color corrosive agent and the corrosion method have the advantages of being good in corrosion effect, good in display effect, free of pollution and stable in corrosion reaction. The corrosion method includes the steps of uniformly stirring raw materials by using a glass rod, allowing the raw materials to stand for 15-30 minutes, and preparing the corrosive agent, wherein the corrosive agent comprises the flowing components: 0.1-2g of potassium permanganate, 5-25ml of hydrochloric acid with the mass percentage concentration being 35%, 5-30ml of nitric acid with the mass percentage concentration being 68%, 0.1-1.2g of copper sulfate and 150-300ml of deionized water; and carrying out coarse grinding, fine grinding and polishing on a sample, washing the sample with absolute ethyl alcohol, then carrying out blow-drying, soaking the sample to be tested in the corrosive agent for corrosion for 15-300 seconds, placing the corrosion surface of the sample upwards until the metallographic-phase surface of the sample is corroded to be yellow, washing the obtained rough corrosion test sample under a water faucet, cleaning the obtained rough corrosion test sample with 95% alcohol after washing, and then carrying out blow-drying by using cold air to complete metallographic-phase corrosion of the stainless steel structure.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

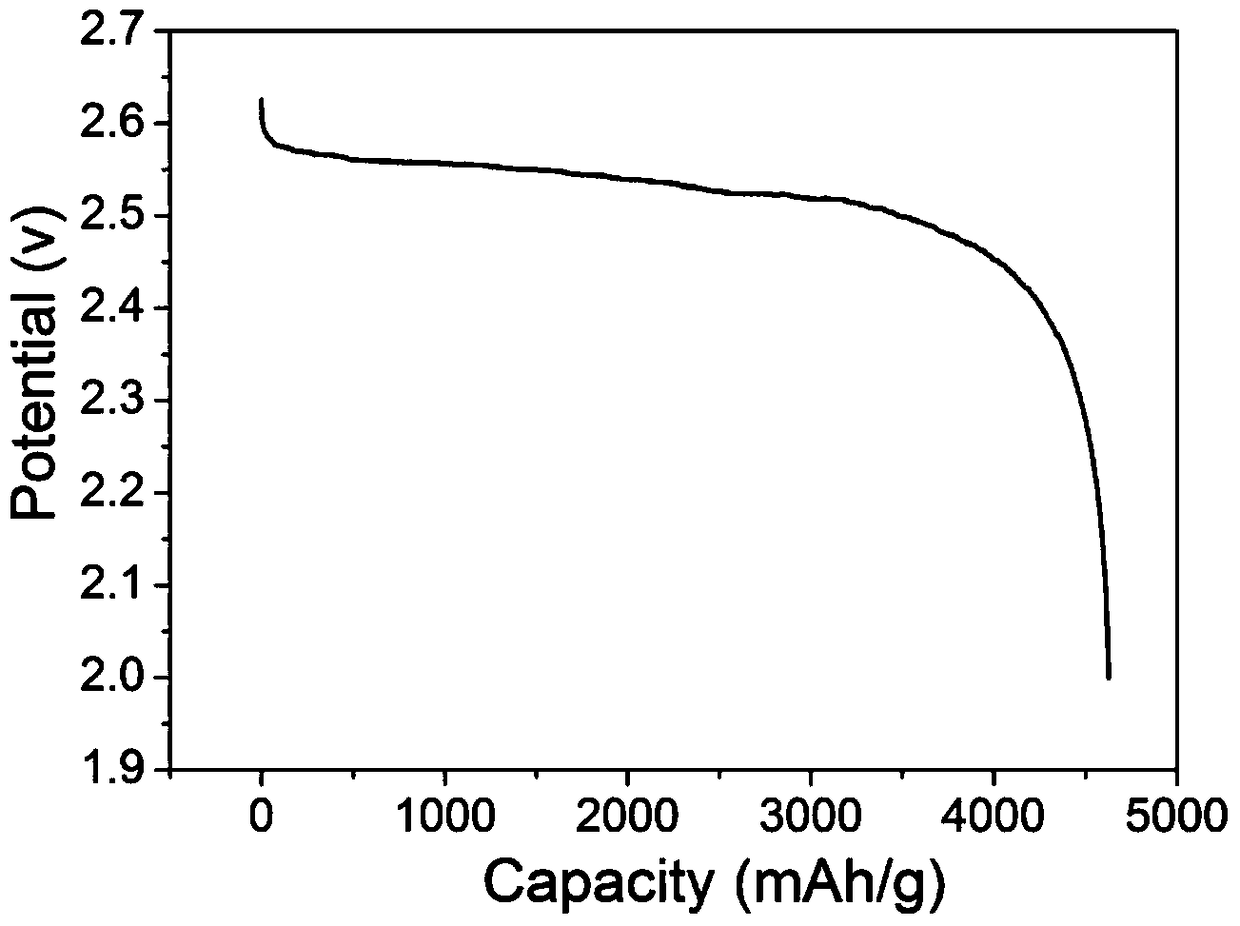

A kind of preparation method of cobalt manganese oxygen catalyst

InactiveCN105390706BSave raw materialsRaw materials are easy to getFuel and primary cellsMaterial nanotechnologyFiltrationLithium–air battery

The invention provides a preparation method of a cobalt-manganese-oxide catalyst and an application of the cobalt-manganese-oxide catalyst in a lithium-air battery. The cobalt-manganese-oxide catalyst is prepared by rapidly stirring a solution at a room temperature. The method specifically comprises the following steps: (1) dissolving potassium permanganate and manganese sulfate into water, mixing the solution evenly, carrying out a reaction at the room temperature and carrying out suction filtration and drying to obtain amorphous MnO2 powder; (2) dispersing the obtained amorphous MnO2 powder and cobalt chloride into water, and stirring and mixing the solution evenly to obtain a mixed liquid I; (3) mixing sodium borohydride and an inorganic base, and dissolving the mixture into water for stirring evenly, so as to obtain a mixed liquid II; and (4) adding the obtained mixed liquid II to the mixed liquid I, carrying out the reaction under a stirring condition, so as to obtain a product, namely the cobalt-manganese-oxide catalyst. The related raw materials are cheap and available; the process is simple and easy to achieve; the yield is relatively high; and the prepared cobalt-manganese-oxide catalyst is in a porous nanosphere shape, and displays excellent electrochemical properties when applied to the lithium-air battery.

Owner:WUHAN UNIV OF TECH

Rubber powder/acrylic acid/montmorillonite high water absorption resin and its synthesis method

Rubber powder / acrylic acid / montmorillonite superabsorbent resin, raw material wt% composition is: acrylic acid 75-88%; rubber powder 7-20%; crosslinking agent 0.05-0.26%; montmorillonite 2.00-10%; initiator 0.25~0.8%. The preparation method is as follows: rubber powder is pretreated with concentrated acid; acrylic acid is neutralized; montmorillonite and pretreated rubber powder are added to acrylic acid neutralization solution; initiator and crosslinking agent are added under protective atmosphere, high-speed shearing, Fully react at a constant temperature of 60-80°C; dry at 110-130°C to obtain a superabsorbent resin. The ability of the invention to absorb deionized water is over 1000g·g-1. Its main raw materials are waste polyethylene film, rubber powder, cheap montmorillonite and acrylic acid, which can recycle industrial resources. It has good economic and environmental benefits.

Owner:NANJING NORMAL UNIVERSITY

Synthesis method and application of monodisperse potassium manganese oxide kmn8o16 nanospheres

InactiveCN104129815BSimple reaction conditionsGood repeatabilityMaterial nanotechnologyCell electrodesSynthesis methodsArgon atmosphere

The invention discloses a synthesis method and a use of monodispersed KMn8O16 nanospheres. The synthesis method of the monodispersed KMn8O16 nanospheres comprises the following steps of dissolving potassium permanganate, polyvinylpyrrolidone and carbonate in deionized water, adding soluble organic alcohol into the solution, carrying out mixing to obtain a uniform mixture, putting the mixture into a thermostatic bath, carrying out a thermostatic reaction process at a temperature of 50-120 DEG C for 1-24h to obtain brownish black precipitates, drying the brownish black precipitates, and calcining the dried brownish black precipitates in an argon atmosphere at a temperature of 300-600 DEG C for 2-20h to obtain the monodispersed KMn8O16 nanospheres. The monodispersed KMn8O16 nanospheres have structured morphology and uniform size adjustable in a range of 80-200nm. The monodispersed KMn8O16 nanospheres are prepared by a constant-temperature liquid phase reaction. The synthesis method is easy and simple and has a large yield. A performance test shows that the monodispersed KMn8O16 nanospheres have a large application prospect in the lithium ion battery energy storage field.

Owner:WUHAN UNIV OF TECH

Application of gas-liquid contact reaction device in fluorinated perfluoropolyether acid

ActiveCN106311097BHeating evenlyStable air speedChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesChemical synthesisPerfluoropolyether

The invention belongs to the field of fluorine chemical synthesis and particularly relates to application of a gas-liquid contact reaction device to fluorination of perfluoropolyether acid. The gas-liquid contact reaction device comprises a gas inlet cylinder for containing fluorinating agent gas, a reaction tube filled with filler, a liquid cylinder, a product collecting cylinder and a tail gas treatment device, wherein a liquid outlet connected with the product collecting cylinder and a gas inlet connected with the gas inlet cylinder are formed in the bottom of the reaction tube, a spray head is arranged at the top end of the reaction tube and is connected with the liquid cylinder through a liquid pump, a gas outlet connected with the tail gas treatment device is formed in the top of the reaction tube, and heating strips are arranged on the outer wall of the reaction tube. The gas-liquid contact reaction device is capable of fluorinating the perfluoropolyether acid by fluorine gas effectively.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

Metallographic etchant and erosion method of austenitic stainless steel

ActiveCN102517585BClear grain boundariesErosion is slowPreparing sample for investigationSS - Stainless steelAustenite

The invention relates to a metallographic etchant and an erosion method of austenitic stainless steel, which are especially suitable for metallographic erosion of 316 / 316L / 316H / 317 / 317L austenitic stainless steels. The metallographic etchant of the invention is composed of the following ingredients in percentage by volume: 30-35% of hydrochloric acid with mass percent concentration of 40%, 15-20%of nitric acid with mass percent concentration of 68%, 30-35% of propanetriol, and 15-20% of hydrogen peroxide solution with mass percent concentration of 30%. The metallographic etchant of the invention has the advantages of reasonable design, good erosion effect, good tissue display effect of eroded sample, non-pollution and slow and stable erosion reaction.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

A kind of high molecular weight unsaturated polyether macromonomer and its preparation method and application

The invention provides a high molecular weight unsaturated polyether macromonomer which is characterized in that the polyether macromonomer is at a liquid state at normal temperature, and the structural formula (I) thereof is expressed in the specification, wherein R<1> is same or different, and represents a hydrogen atom or alkyl with 1-20 carbon atoms; R<2> represents alkyl with 1-20 carbon atoms; R<3> represents alkyl or carbonyl with 1-10 carbon atoms; R<5> represents a hydrogen atom or alkyl with 1-20 carbon atoms; R<4>O is different, and represents oxyalkenyl with 2-18 carbon atoms; n represents the average addition mole number of the oxyalkenyl, and 5<=n<=300; and X, Y and Z are same or different, and represent -N, -O or H. By optimally designing the molecular structure, the high molecular weight unsaturated polyether macromonomer provided by the invention ensures the liquid state thereof at normal temperature while the molecular polymerization reaction activity is ensured. Besides, a preparation method of the high molecular weight unsaturated polyether macromonomer provided by the invention is simple, and the conditions are easy to control; and the product does not need slicing post-treatment, the production cost is low, and the economic benefits are increased.

Owner:联泓(江苏)新材料研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com