Preparation method of lithium difluorophosphate and byproduct treatment method

A technology of lithium difluorophosphate and processing method, which is applied in phosphorus compounds, alkali metal fluorides, chemical instruments and methods, etc., can solve the problem of high production cost of lithium difluorophosphate, unsuitable for large-scale manufacturing, low utilization rate of raw materials, etc. problem, to achieve the effect of easy separation and purification, fast speed, safe and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0045] 1. Synthesis of lithium difluorophosphate

[0046] The reaction principle is that lithium hexafluorophosphate and siloxane react in a benign non-aqueous solvent, and the reaction equation is:

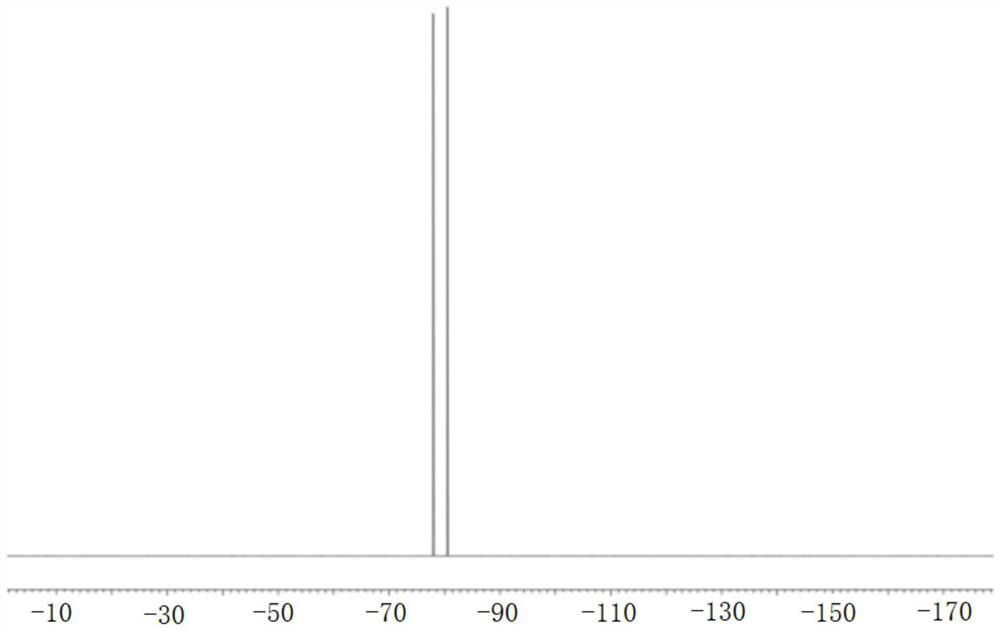

[0047]

[0048] Among them, R 1 and R 2 Both are methyl. The benign non-aqueous solvent required for the reaction is dimethyl carbonate.

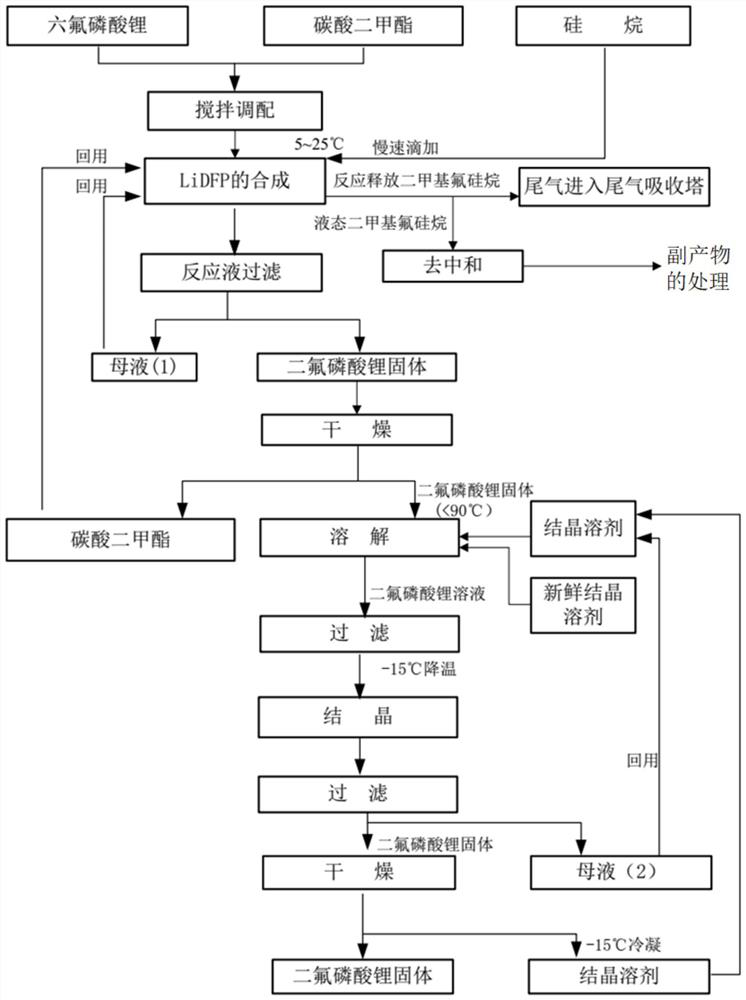

[0049] The reaction process is as figure 1 As shown, the specific steps are as follows:

[0050] (1) Preparation of solution

[0051] Open the nitrogen valve and vent valve of the solution preparation kettle to maintain a slight nitrogen protection. Open the nitrogen valve on the dimethyl carbonate (DMC) storage tank, open the discharge valve, accurately measure and put an appropriate amount of solvent into the blending kettle, and start stirring, and control the temperature in the kettle to maintain at 5-25°C.

[0052] Connect the pipeline between the mixing kettle and the lithium hexafluorophosphate container. Open the solid feedi...

Embodiment 5-9

[0085] The specific experimental steps are the same as in Examples 1-4, except that the type of reaction solvent is changed. The experimental parameters involved in the experimental process of Examples 5-9 and the yield of the final product are specifically shown in Table 2:

[0086] Experimental parameters involved in the experimental process of table 1 and the yield of final product

[0087]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com