Metallographic etchant and erosion method of austenitic stainless steel

A technology of austenitic stainless steel and corrosive liquid, which is applied in the field of metallographic corrosion, can solve the problems of not being able to clearly display grain boundaries, unsatisfactory structure display, violent reaction, etc., and achieve easy operation, clear austenite grain boundaries, and rapid reaction smooth and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

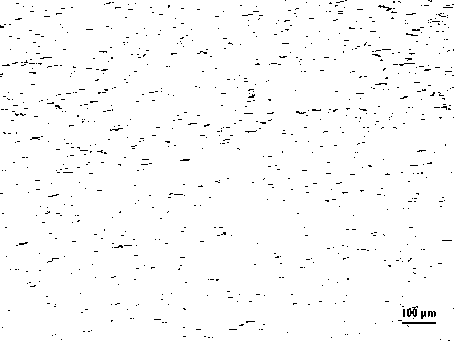

Embodiment 1

[0021] Corrosive formulation.

[0022] The metallographic etchant is a mixed solution of hydrochloric acid, glycerol, nitric acid and hydrogen peroxide, and the volume percentages of each group are: hydrochloric acid (mass percentage concentration is 40%): 33%; nitric acid (mass percentage concentration is 68%): 17%; Glycerol: 33%; Hydrogen peroxide (30% by mass): 17%.

[0023] Corrosive preparation.

[0024] Prepare the corrosive agent in the following order: first take 40ml of hydrochloric acid, then measure 20ml of nitric acid, then measure 40ml of glycerin, and finally mix with 20ml of hydrogen peroxide and make it react fully, and let it stand for about 30 minutes before use.

[0025] Metallographic corrosion.

[0026] The samples were coarsely ground, finely ground, polished, cleaned and dried according to conventional methods.

[0027] Fully immerse the prepared sample in the prepared etchant and corrode for about 20 minutes. The corrosion surface of the sample shou...

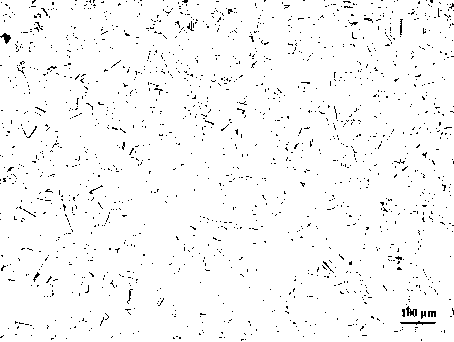

Embodiment 2

[0030] Corrosive formulation.

[0031] The metallographic etchant is a mixed solution of hydrochloric acid, glycerol, nitric acid and hydrogen peroxide, and the volume percentages of each component are: hydrochloric acid (mass percentage concentration is 40%): 33%; glycerol: 30%; nitric acid (mass percentage concentration is 40%): 33%; The percentage concentration is 68%): 20%; hydrogen peroxide (mass percentage concentration is 30%): 17%.

[0032] Corrosive preparation.

[0033] Prepare the corrosive agent in the following order: first take 40 ml of hydrochloric acid, then measure 24 ml of nitric acid, then measure 36 ml of glycerin, and finally mix with 20 ml of hydrogen peroxide and make it react fully, and let it stand for 30 minutes before use.

[0034] Metallographic corrosion.

[0035] The samples were coarsely ground, finely ground, polished, cleaned and dried according to conventional methods.

[0036] Fully immerse the prepared sample in the prepared etchant and c...

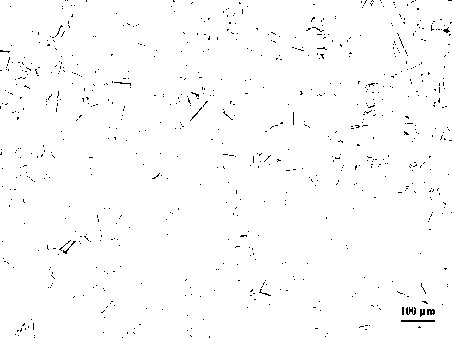

Embodiment 3

[0039] Corrosive formulation.

[0040] The metallographic etching agent is a mixed solution of hydrochloric acid, glycerol, nitric acid and hydrogen peroxide, and the volume percentages of each component are: hydrochloric acid (mass percentage concentration is 40%): 31%; nitric acid (mass percentage concentration is 68%) Glycerol: 19%; Glycerol: 31%; Hydrogen peroxide (mass percentage concentration is 30%): 19%.

[0041] Corrosive preparation

[0042] Prepare the corrosive agent in the following order: first take 37ml of hydrochloric acid, then measure 23ml of nitric acid, then measure 37ml of glycerin, and finally mix with 23ml of hydrogen peroxide and make it react fully, and let it stand for about 30 minutes before use.

[0043] Metallographic corrosion.

[0044] The samples were coarsely ground, finely ground, polished, cleaned and dried according to conventional methods.

[0045] Fully immerse the prepared sample in the prepared etchant and corrode for about 15 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com