TWIP (twinning induced plasticity) steel metallographic phase specimen preparation agent and use method thereof

A metallographic sample preparation and etching agent technology, applied in the field of metal materials, can solve the problems of incomplete display of grain boundaries, poor picture quality, and indistinguishability, etc., and achieve simple cleaning agents and cleaning methods, improve TW quality, and clear grain boundaries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

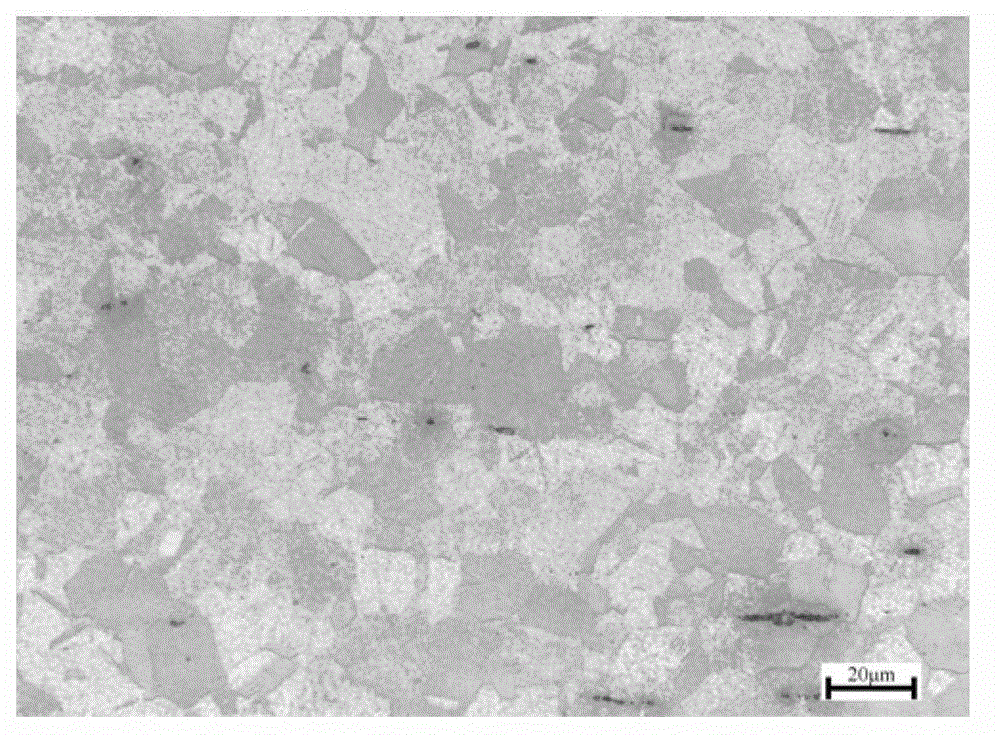

[0031] Taking undeformed Mn18 steel as an example, immerse the polished metallographic grinding surface in a volume ratio of 1:0.5:100 nitric acid (37%)+hydrochloric acid (69%)+alcohol etchant for 45 seconds. Then put it into the cleaning agent of hydrochloric acid (37%) + deionized water with a volume ratio of 0.4:100, clean it with ultrasonic vibration for 60 seconds, and dry it with a hair dryer to make a metallographic sample.

[0032] Effect see picture description figure 2 . The grain boundaries are complete and clear. In the case of little contrast between grains, there are no undisplayed grain boundaries, and the annealing twin grain boundaries are obvious.

Embodiment 2

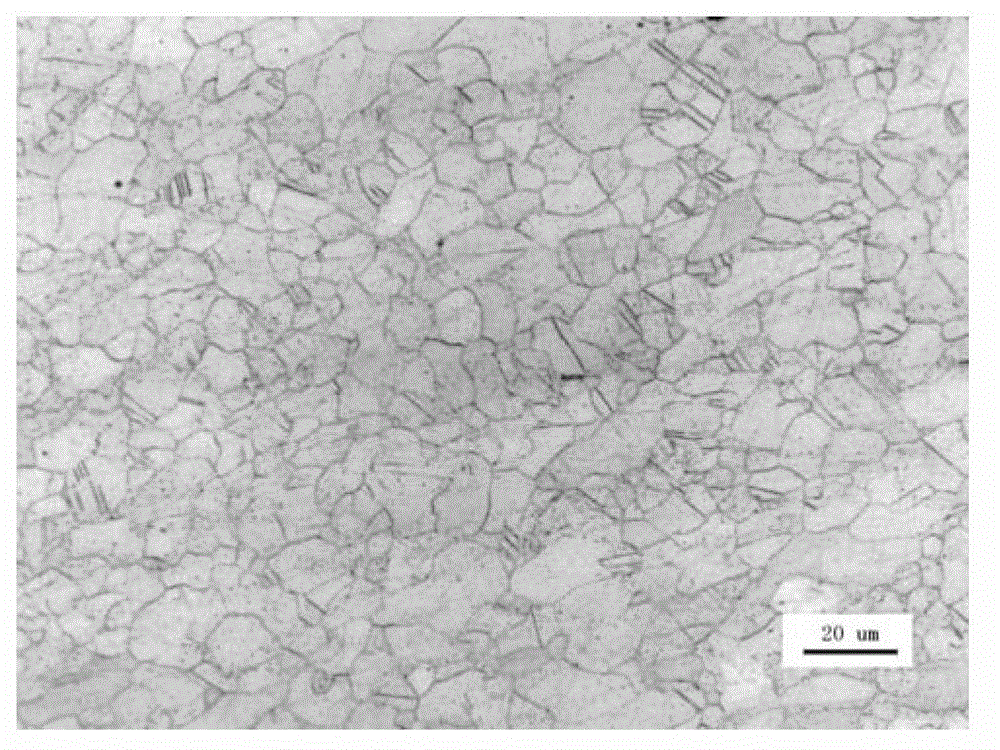

[0034] Taking undeformed Mn25 steel as an example, immerse the polished metallographic grinding surface in an etchant with a volume ratio of 1.8:0.2:100 nitric acid (69%)+hydrochloric acid (37%)+alcohol for 60 seconds. Then put it into the cleaning agent of hydrochloric acid (37%) + deionized water with a volume ratio of 0.2:100, clean it with ultrasonic vibration for 75 seconds, and dry it with a hair dryer to make a metallographic sample.

[0035] Effect see picture description image 3 . The grain boundary is complete and clear, and there is no incomplete grain boundary, and the annealed twin grain boundary is also very obvious.

Embodiment 3

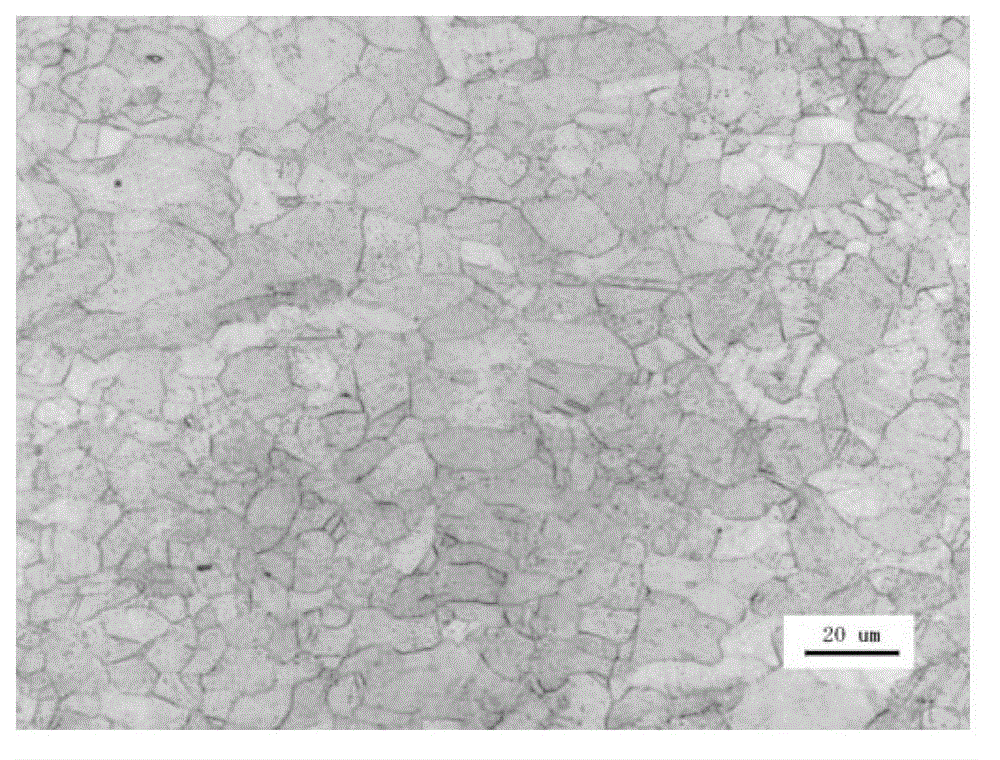

[0037] Taking the deformed Mn18 steel as an example, immerse the polished metallographic grinding surface in an etchant with a volume ratio of 3:0.4:100 nitric acid (69%)+hydrochloric acid (37%)+alcohol for 50 seconds. Then put it into the cleaning agent of hydrochloric acid (37%)+deionized water with a volume ratio of 0.3:100, clean it with ultrasonic vibration for 80 seconds, and dry it with a hair dryer to make a metallographic sample.

[0038] Effect see picture description image 3 . It clearly shows that the contrast between different grains due to the deformation texture is increased, the grain boundaries are clear, the annealing twins can still be distinguished, and the dense deformation twins are also very clear.

[0039] Using the etchant and method of the invention to prepare TWIP steel metallographic samples has the advantages of clear structure and complete grain boundaries compared with conventional metallographic sample preparation methods. This method is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com