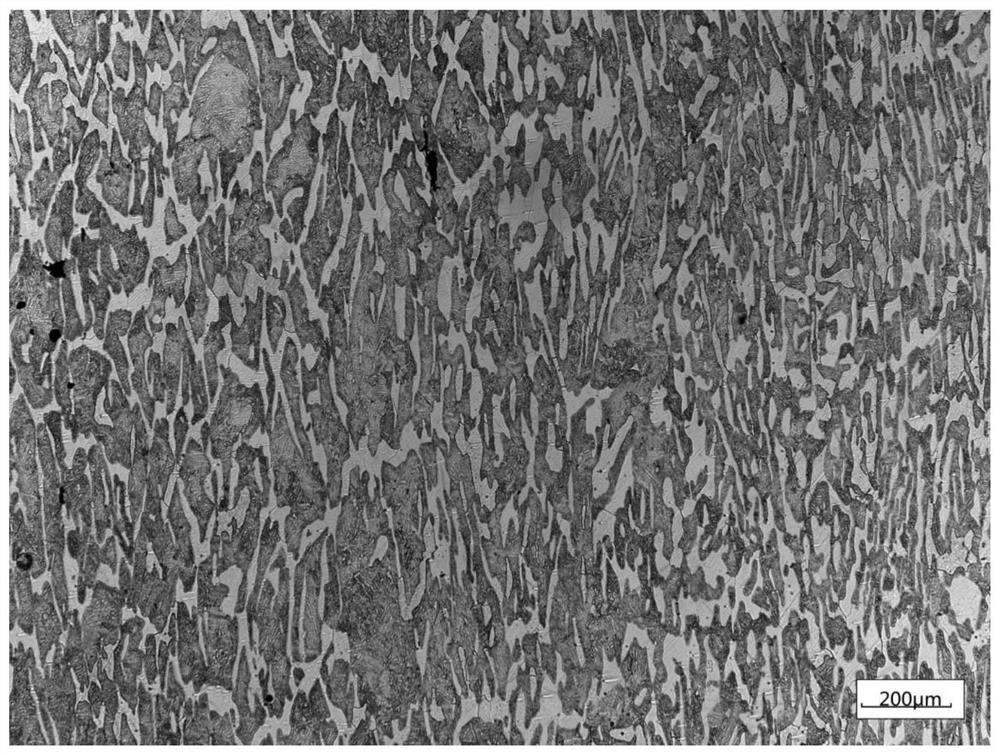

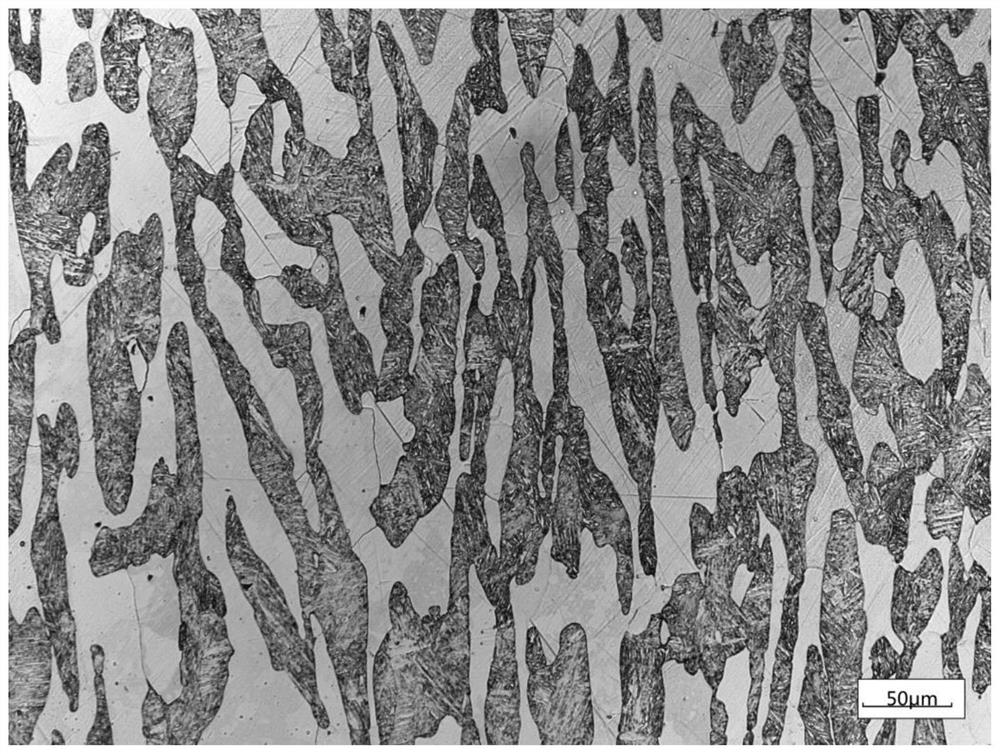

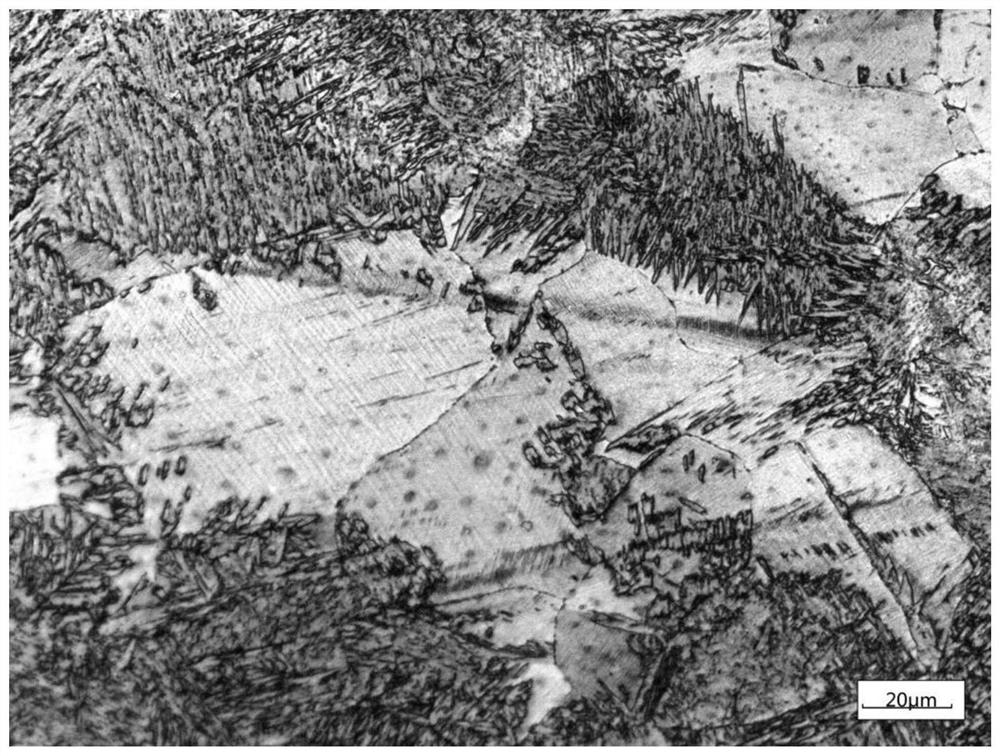

Metallographic corrosive agent for double-phase medium manganese steel and metallographic structure display method

A technology of metallographic structure display and corrosive agent, which is applied in the preparation of test samples, instruments, analysis materials, etc., can solve the problems of unsatisfactory metallographic corrosion effect, difficult to grasp the corrosion effect, unclear corrosion effect, etc., and achieve the corrosion effect. Good, easy to corrode, smooth and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a metallographic etchant for dual-phase medium manganese steel, which is prepared by the following method:

[0037] First measure 30ml of deionized water, then measure 25ml of absolute ethanol and add it to the deionized water, then measure 6ml of concentrated sulfuric acid and add it, measure 40ml of hydrochloric acid and add it, weigh 2g of sodium chloride and add it, and finally weigh 5g of copper chloride dihydrate Add to beaker and stir with glass rod until completely dissolved.

Embodiment 2

[0039] This embodiment provides a metallographic etchant for dual-phase medium manganese steel, which is prepared by the following method:

[0040] First measure 40ml of deionized water, then measure 30ml of absolute ethanol and add it to deionized water, then measure 8ml of concentrated sulfuric acid and add it, measure 55ml of hydrochloric acid and add it, weigh 2g of sodium chloride and add it, and finally weigh 15g of copper chloride dihydrate Add to beaker and stir with glass rod until completely dissolved.

Embodiment 3

[0042] This embodiment provides a metallographic etchant for dual-phase medium manganese steel, which is prepared by the following method:

[0043] First measure 55ml of deionized water, then measure 40ml of absolute ethanol and add it to deionized water, then measure 8ml of concentrated sulfuric acid and add it, measure 65ml of hydrochloric acid and add it, weigh 3g of sodium chloride and add it, and finally weigh 15g of copper chloride dihydrate Add to beaker and stir with glass rod until completely dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com