Patents

Literature

428 results about "Corrositex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion-resistant electromagnetic screen coating and preparation thereof

ActiveCN101275052AImprove anti-corrosion performancePlay a synergistic roleMagnetic/electric field screeningEpoxy resin coatingsElectromagnetic shieldingSolvent

The present invention provides a corrosion electromagnetic shielding coating and its preparing method, the corrosion electromagnetic shielding coating includes a solute part and a solvent part, the weight percentage of the components of the solute part is : film forming resin 25.4-39.6%, curing agent 3.5-14.8%, conductive filler 37.5-57.5%, anticorrosive agent 3.5-10.5%, coupling agent 0.5-1.5%, anti-sedimentation agent 0.8-2.2%, antioxidant 0.1-1.0%.The coating of the invention has excellent corrosion resistance and electromagnetic shielding effectiveness.

Owner:MARINE CHEM RES INST

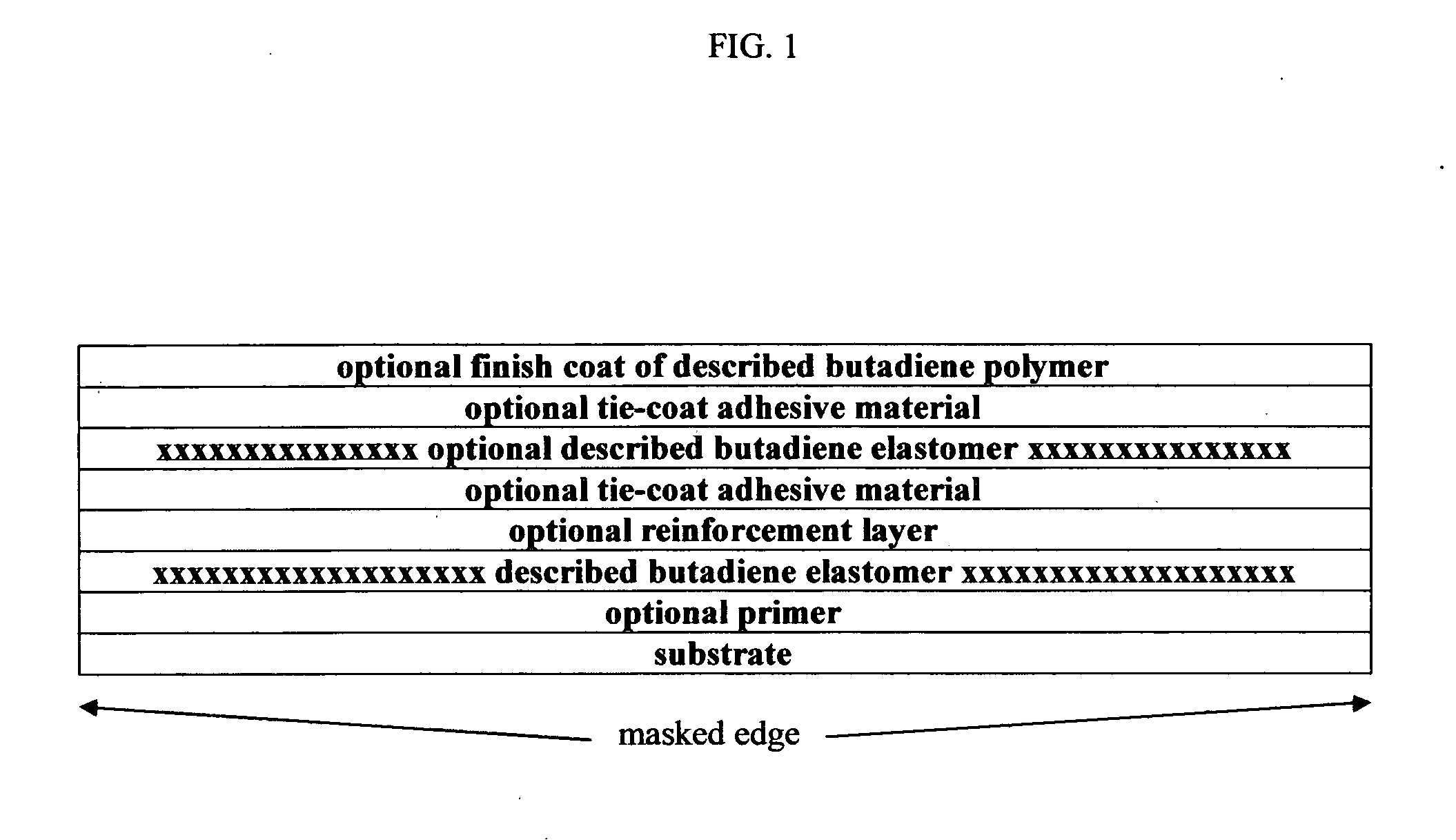

Elastomeric coating for corrosion control and chemical containment

InactiveUS20070249778A1Improve adhesionHigh elongationOrganic dyesPolyurea/polyurethane coatingsElastomerWeather resistance

A cost effective, two component, high-solids elastomeric coating. The coating is comprised of a chemically cross-linked resin for the purpose of substrate corrosion control, and chemical containment service. This invention may be applied by conventional application techniques including, but not limited to: brush applied, squeegee applied, roller applied, trowel applied, and both single and plural component spray applied. The coating may be optionally reinforced with fabric or fiber reinforcement layers, and the system components of the elastomeric coating to provide an engineered composite coating. The coating imparts excellent adhesive properties, in particular to: oil-contaminated substrates, a variety of low surface energy substrates, and on a variety of electronegative substrates. The invention's specific chemical resistive properties are designed such: for exposure to boiling water, resistance to brines, and resistance to a broad spectrum of solid and aqueous acids and caustics. The physical properties include excellent flexibility and the ability to elongate and contract across a broad temperature range (−100° F. to +260° F.). Performance properties of the installed coating include: weatherability, abrasion resistance, impact strength, chip resistance, and dimensional stability. Long-term aging properties of the material are exceptional.

Owner:FORTY TEN

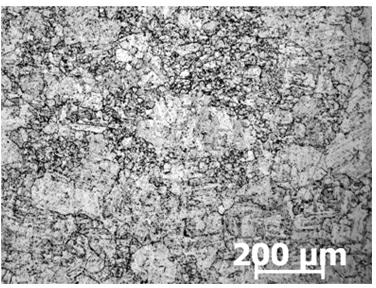

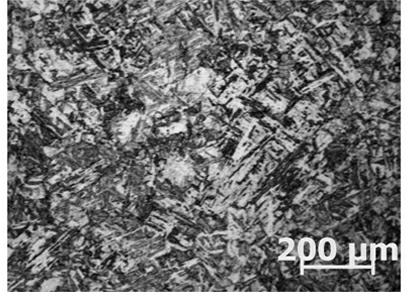

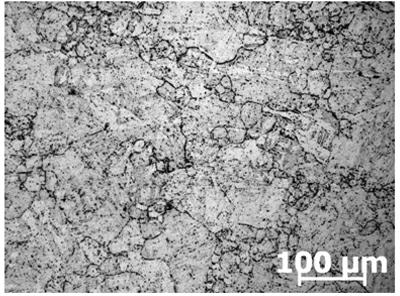

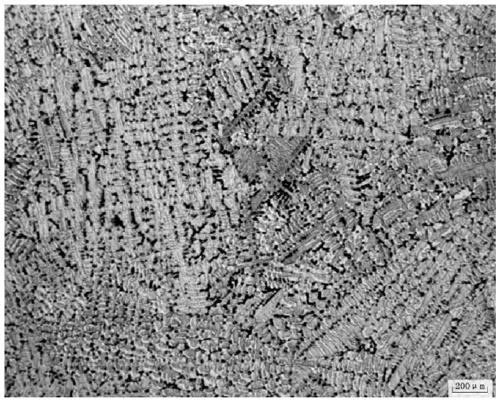

Metallographic etched process for displaying G Cr15 original austenite grain border

InactiveCN101187606AShorten the timeGood reproducibilitySurface/boundary effectPreparing sample for investigationAlcoholMetallography

A metallographic corrosion method for displaying a GCr15 original austenitic grain boundary comprises adding picric acid 5g into distilled water100ml and mixing continuously, then adding sodium dodecyl benzene sulfonate 5ml 50% and mixing, finally adding ferric chloride 2g, and using after placing for 24 hours. A sample is grinded roughly, grinded finely, polished, cleared, dried, immersed into caustic erodent for 2-5 minutes according to normal method under a quenching tempering condition until etched surface is changed into silver grey, cleaned up through flowing water, cleaned with alcohol 95%, and dried. If the sample is over-corroded, polishing paste W0.5-1.0 or metallographic polishing egent0.5-1.0 is added on silk polishing cloth, the sample is polished slightly with hands, then cleaned with alcohol 95%, and dried. According to practical condition, grain granularity measurement can adopt methods of picture contrast, grid, intercept, quantitative metallography, and the like, to assess according to relevant standards.

Owner:LUOYANG BEARING SCI & TECH CO LTD

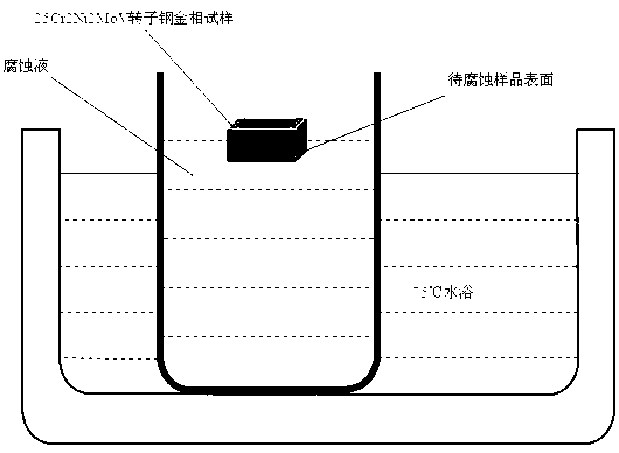

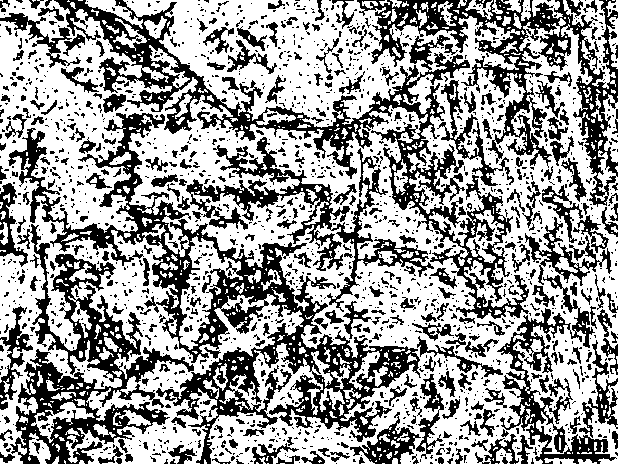

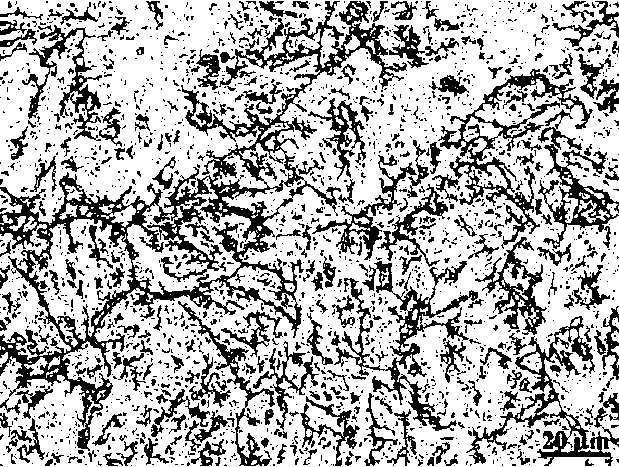

Metallographic corrosion method for clearly displaying original austenite grain boundary of NiCrMoV type rotor steel

The invention relates to a metallographic corrosion method for clearly displaying the original austenite grain boundary of a NiCrMoV type rotor steel, and belongs to the field of metallographic sample preparation. The method comprises the steps of: coarse grinding, fine grinding, polishing and corroding; putting a polished sample into a corrosive liquid of 75 DEG C, wherein the formula of the corrosive liquid comprises 200ml of distilled water, 5g of picric acid, 2ml of 5% diluted hydrochloric acid and 4g of sodium dodecyl benzene sulfonate; etching for 2minutes, taking the sample out, cleaning the sample with flowing water, cleaning the sample with alcohol and drying; and observing the clear original austenite grain boundary through an optical microscope. The method has the advantages that a difficult displaying problem of the original austenite grains of the NiCrMoV type rotor steel is solved, the original austenite grain boundary can be very clearly displayed, and the method is simple and practicable.

Owner:SHANGHAI UNIV +1

Corrosive agent for displaying 9% Cr steel original austenite grain boundary and application thereof

ActiveCN102517586AEasy grain size ratingGood effectPreparing sample for investigationAustenite grainDodecylsulfonic acid

The invention discloses a corrosive agent for displaying 9% Cr steel original austenite grain boundary and an application thereof. The corrosive agent is prepared by fully mixing the following components of: 60-80ml of H2O, 4-8ml of 36 wt% HCl, 2-4g of FeCl3, 0.2-0.5g of picric acid, and 1.0-2.0g of sodium dodecanesulphonate. The corrosive agent provided by the invention can be used as a reagent for 9% Cr steel grain boundary to clearly display the original austenite grain boundary of large crystal grain, large and small mixed crystal grain and small crystal grain of a sample. Under 100 times, it is easy to carry out grain size rating and the effect is good.

Owner:SHANGHAI BOILER WORKS

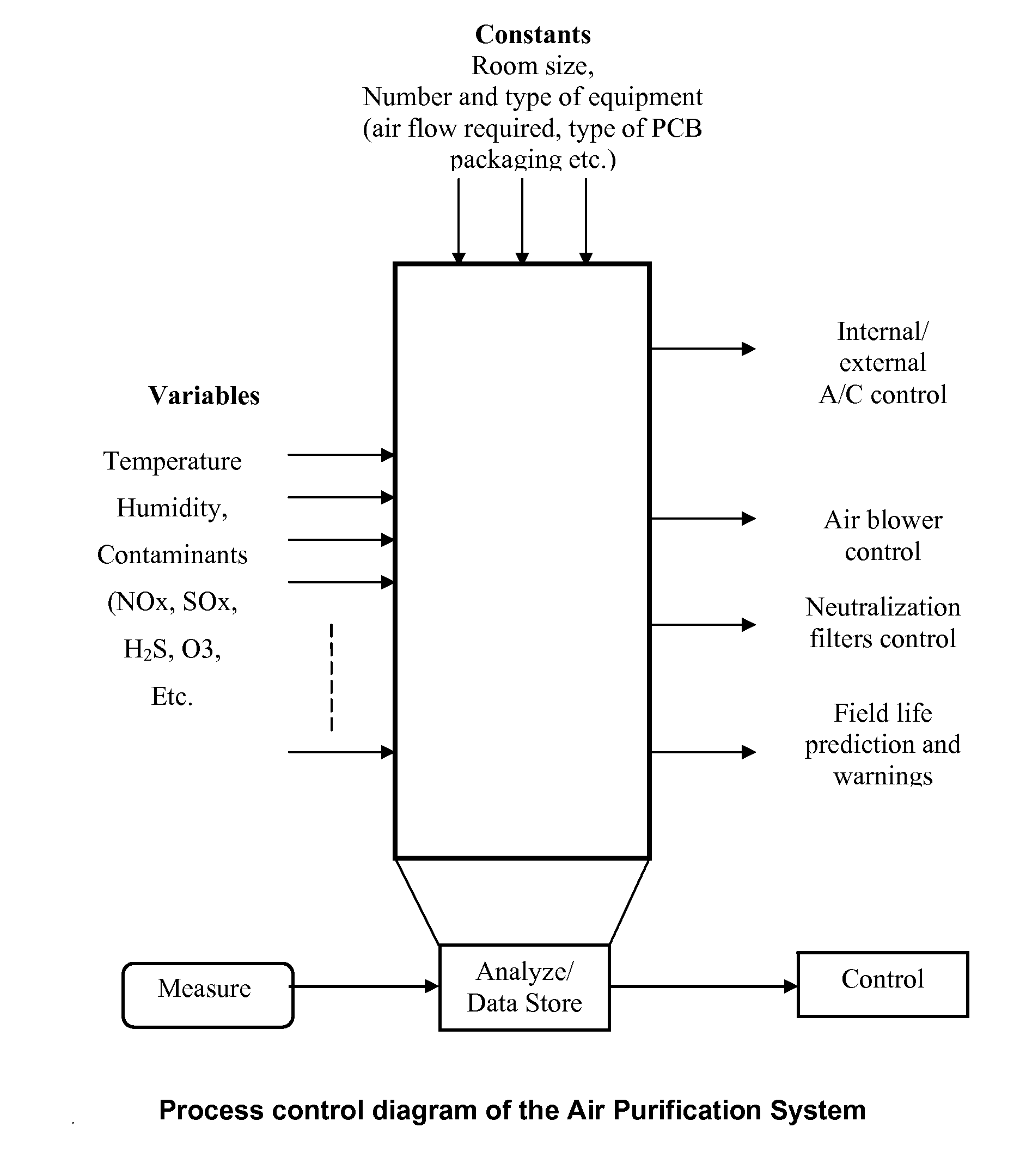

Air purification and decontamination system

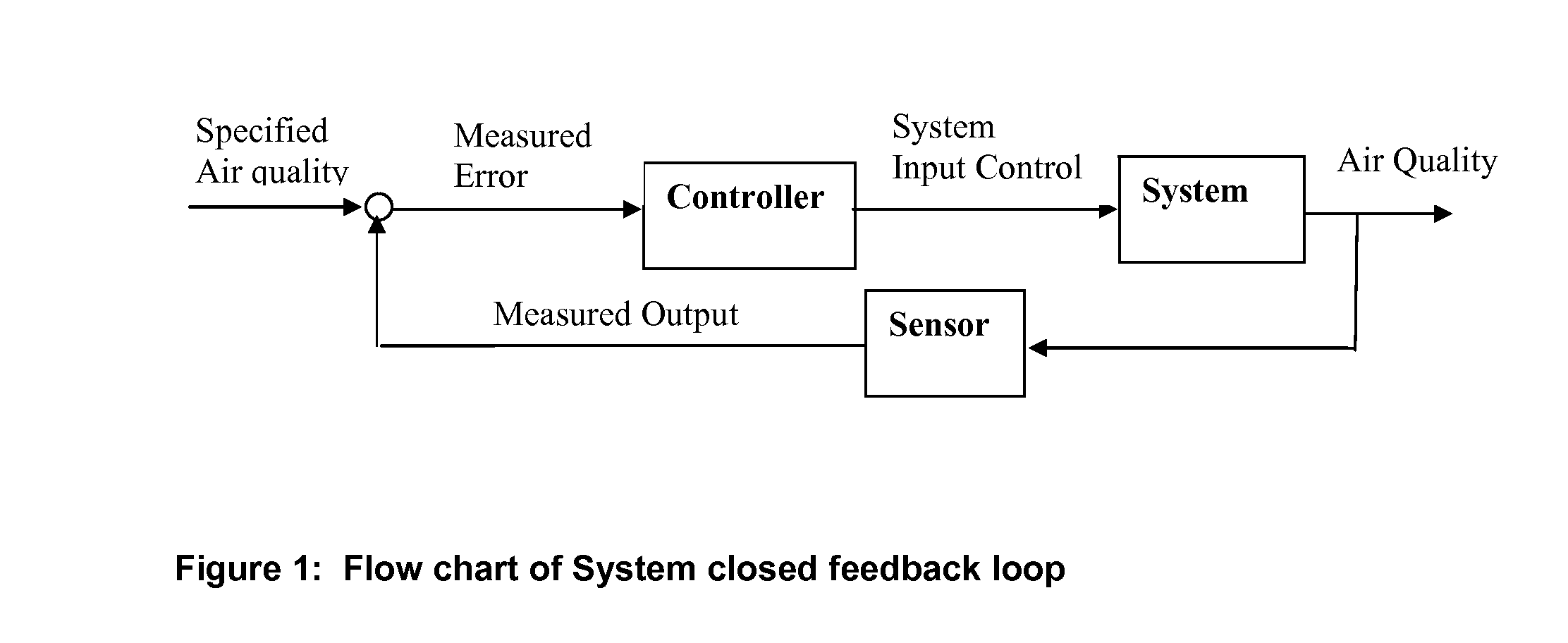

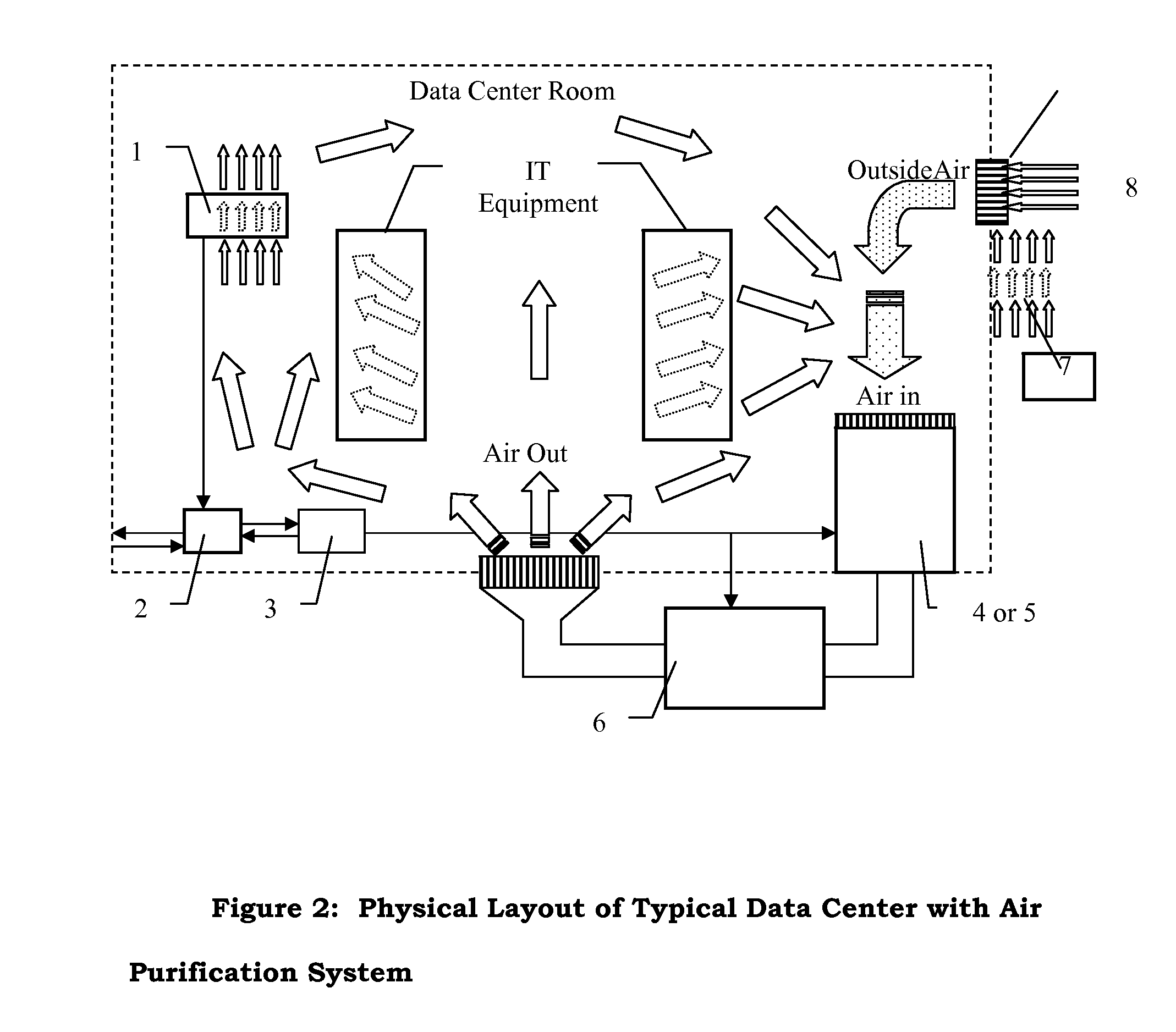

InactiveUS20120111190A1Minimize corrosivenessEffective regulationCombination devicesGas treatmentEnvironment of AlbaniaCorrosion

A closed loop air handling system for monitoring and cleaning air from corrosive contaminants. Commonly occurring corrosive elements found in air can react in combination together and with other environmental conditions to increase the propensity for corrosion to occur. The higher corrosive level of air can react with metals causing degradation, wear and often lead to premature failure. This is especially prevalent in environments using forced air convection for cooling, such as data centers. The electronic circuitry is especially vulnerable to such corrosion and requires an environmentally controlled atmosphere with mild corrosiveness for long term reliability. The invention involves circulating the air in a closed loop and monitors and adjusts parameters of active filtration and purification to minimize corrosive agents. The system maintains a milder corrosive environment and better accommodates the use of “free cooling” from outside air for improved energy efficiency and lower carbon emissions. Air quality data is also collected and used to estimate equipment life time expectancy and substantiate warranty claims over exceeding manufacturers recommended environmental operating conditions.

Owner:DARIAVACH NADER G

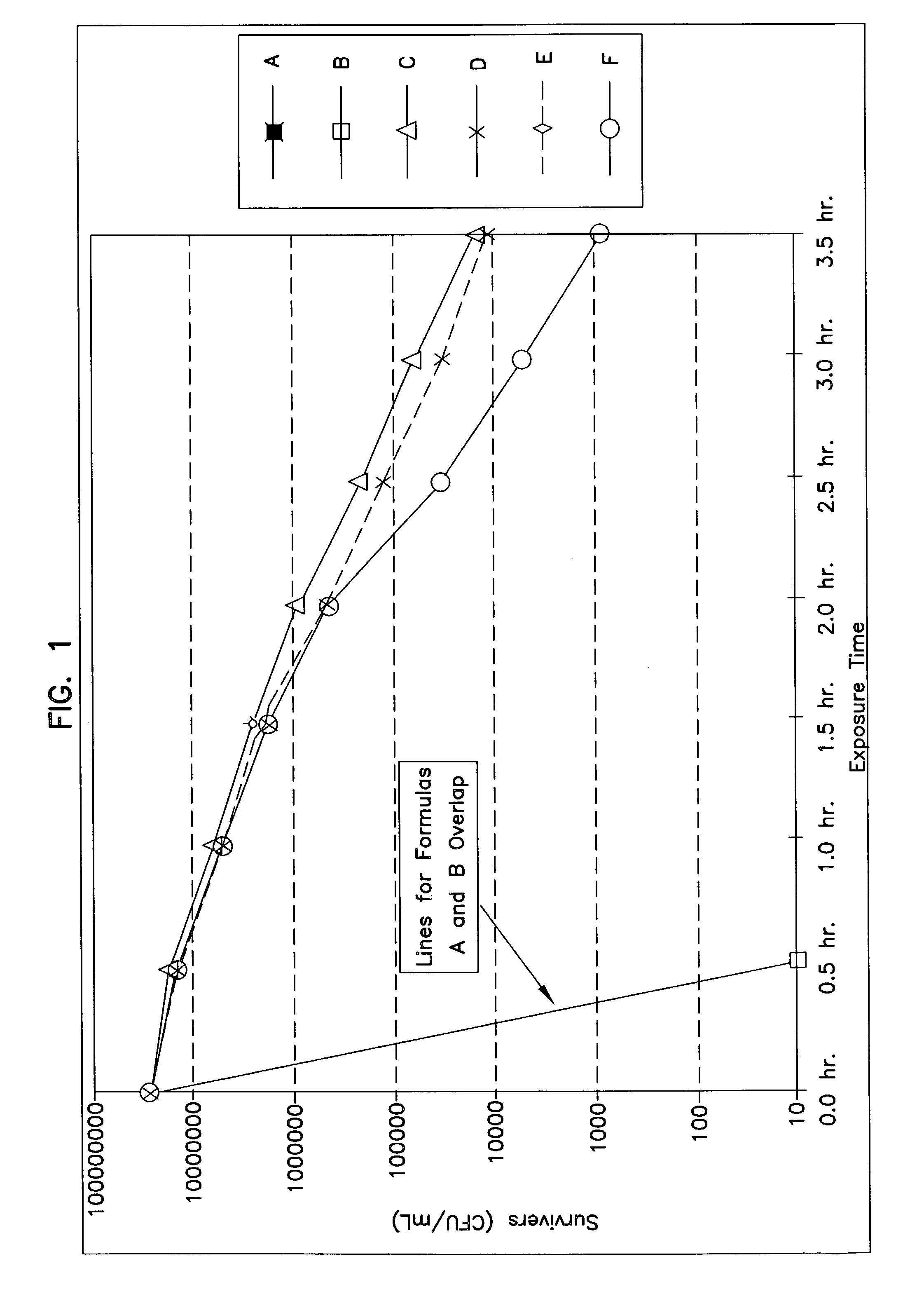

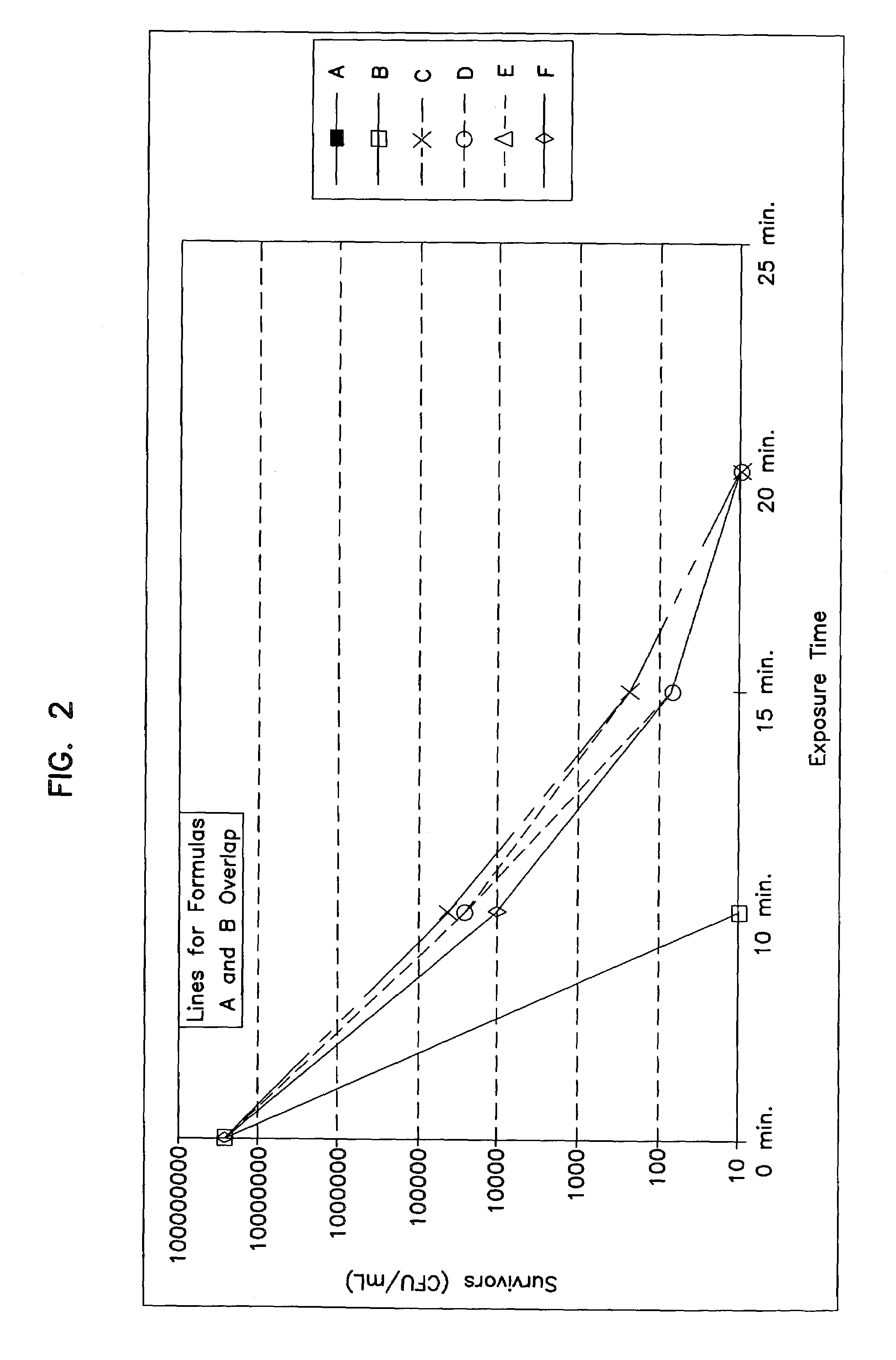

Non-corrosive sterilant composition

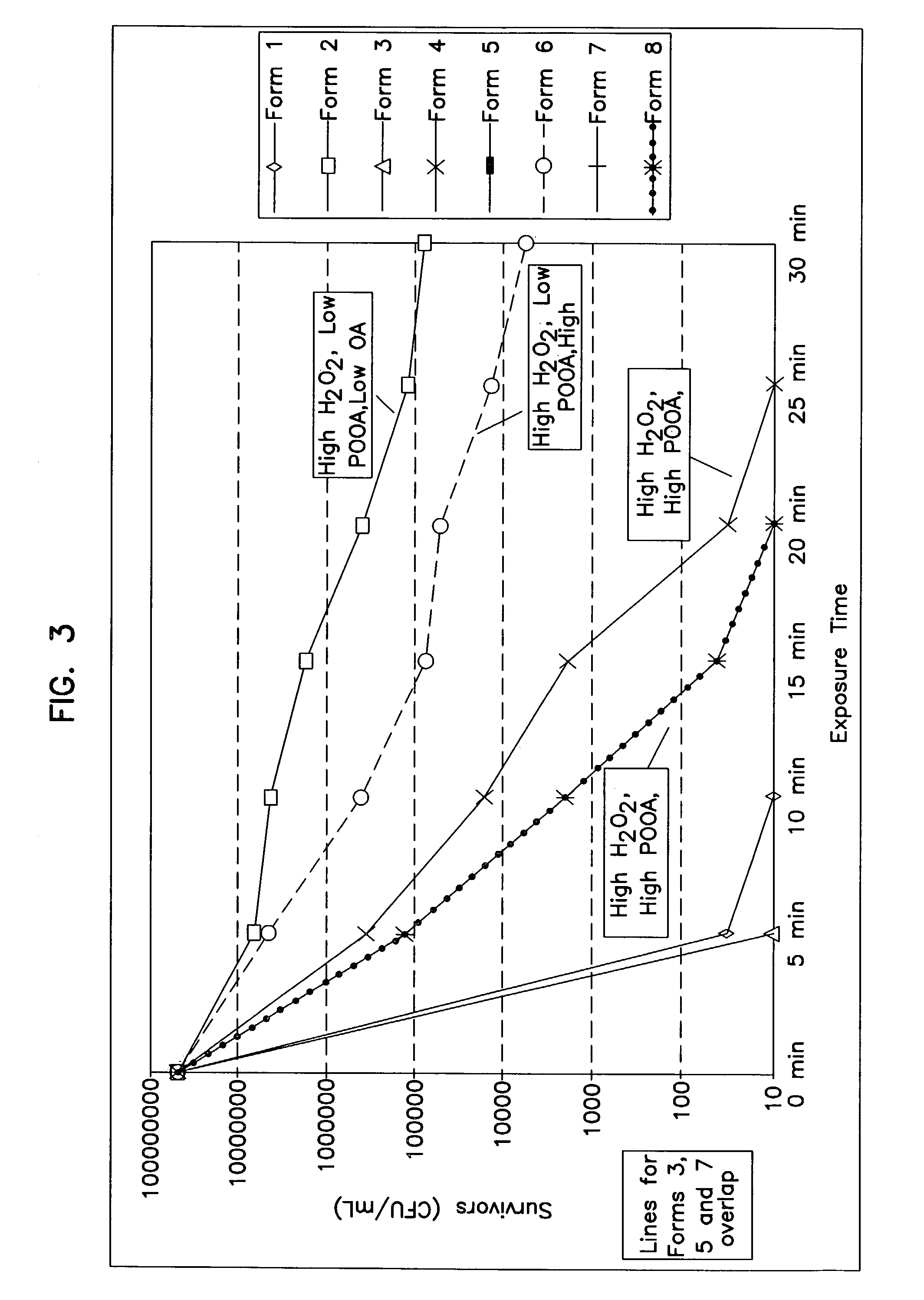

InactiveUS7056536B2Good sterilization abilityComplicates disposalBiocideInorganic phosphorous active ingredientsChemistryBuffering agent

A non-corrosive, liquid, aqueous sterilant composition (as a concentrate or ready-to-use solution), which may be provided in two parts which are mixed prior to application, may comprise a peracid (in an equilibrium solution with an underlying carboxylic acid or mixtures of alkyl carboxylic acids and peroxide), inorganic buffering agent, and water. It has been found that the use of this simplified system, even in the absence of additional components which have been thought to be desirable for sterilants used on metal parts (e.g., copper and brass corrosion inhibitors, chelating agents, anti-corrosive agents) display excellent performance and that these additional components are not necessary, and that the presence of these additional materials at least complicates disposal of the spent solutions and could complicate compatibility of the sterilant solutions with some polymeric materials, especially where organic materials are used as the additional components, which organic materials may interact with, dissolve or solubilize in the polymeric materials.

Owner:ECOLAB USA INC

Negative nano-imprinting method

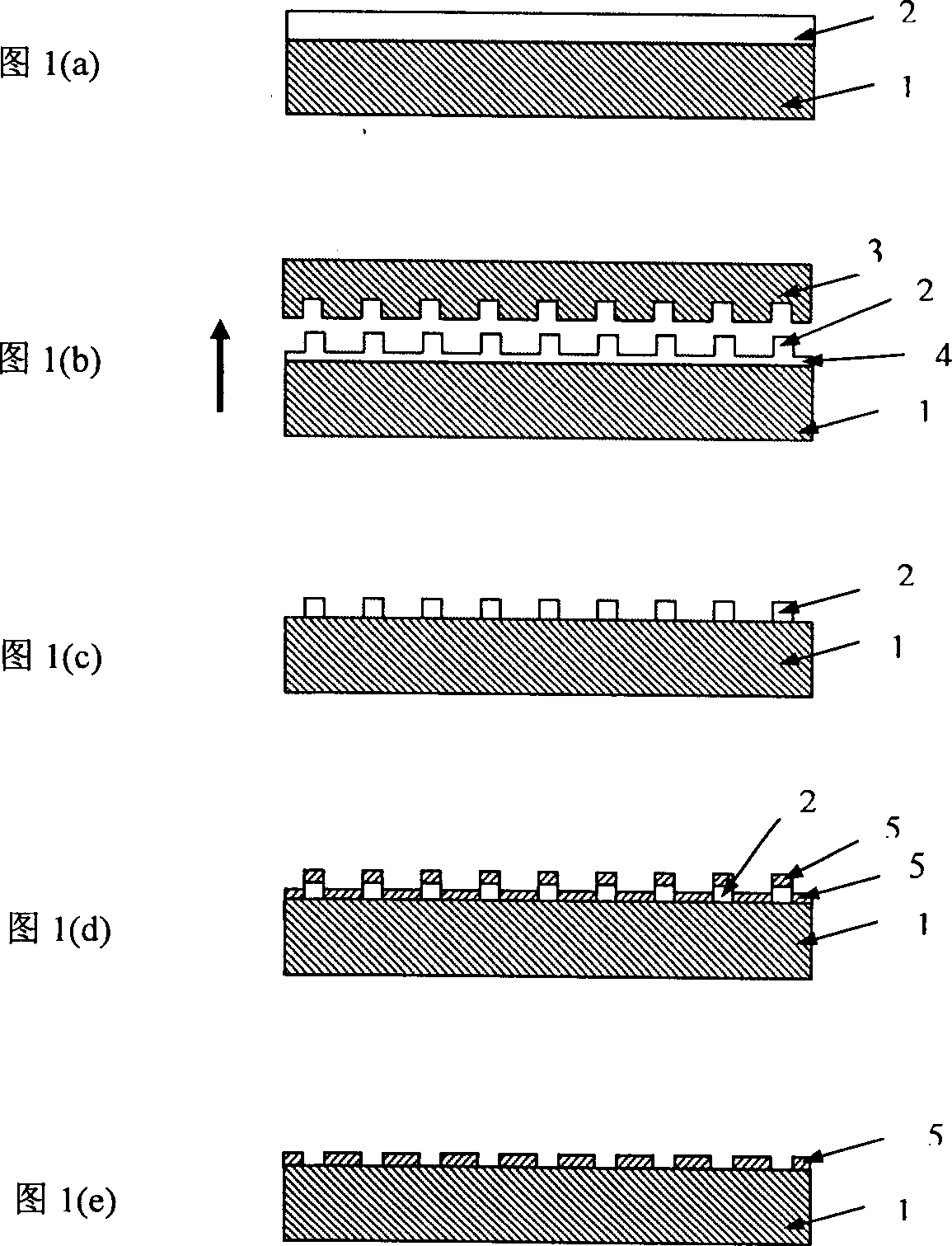

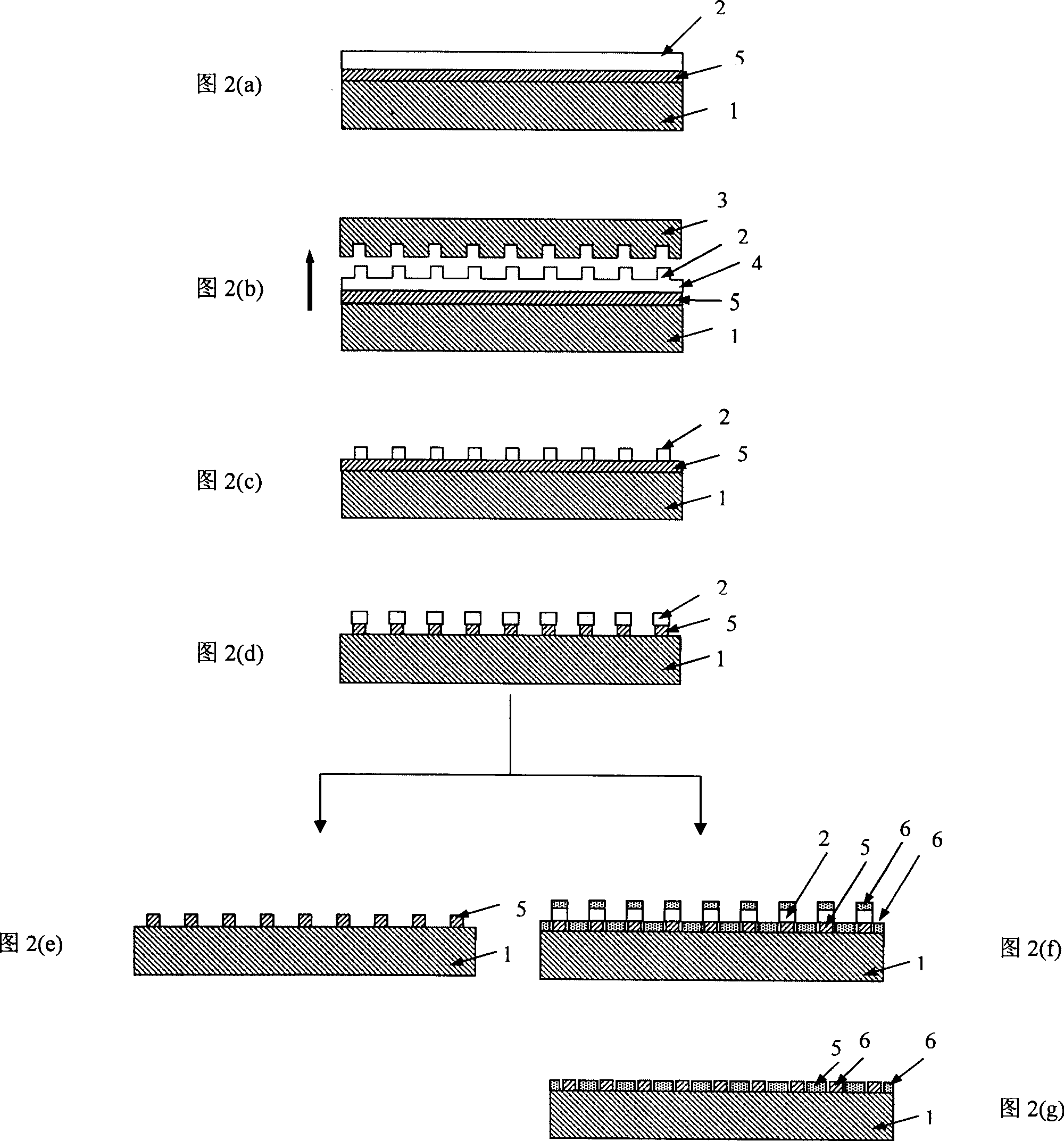

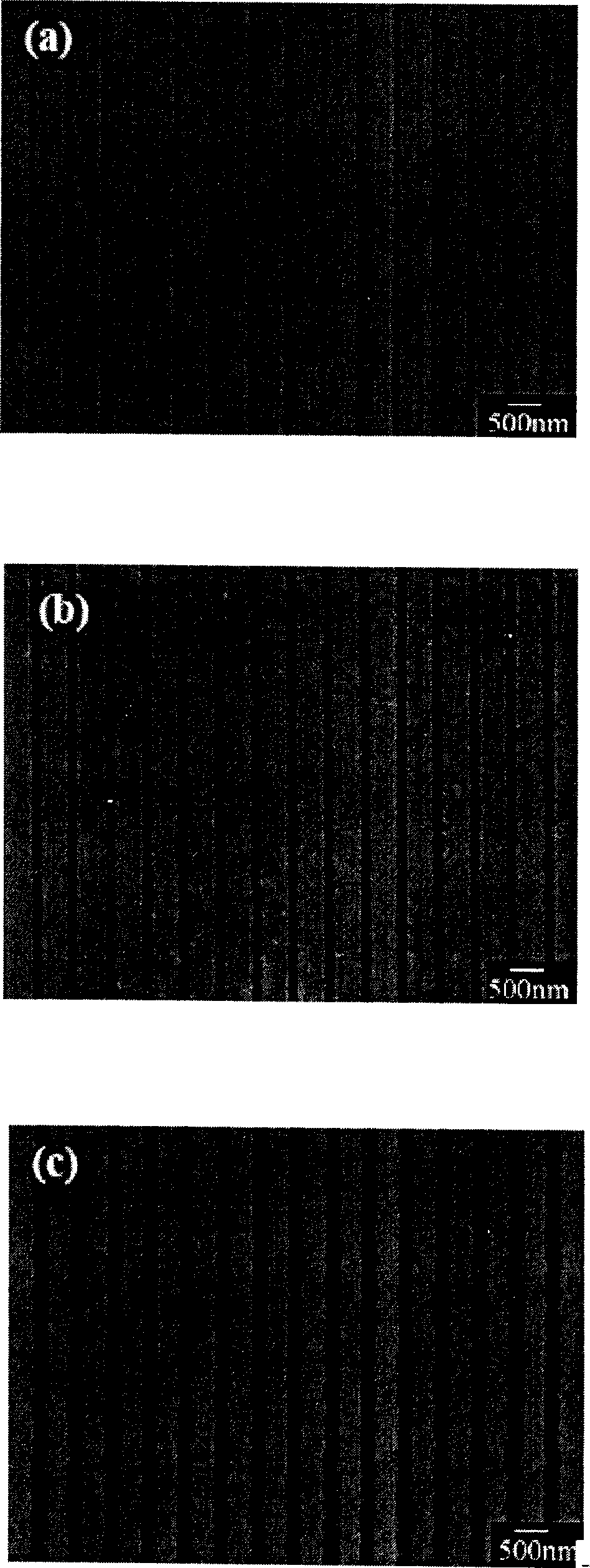

InactiveCN1800984AAvoid stripping processLow priceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusIonNanometre

The invention discloses a negative-type nanometer stamping method, which comprises the following steps: (1) depositing metallized film I on the silicon base; hanging to coat the photo-etching glue on the metallized film I; (2) duplicating the mould plate nanometer pattern to the photo-etching glue in the heating and pressurizing condition; (3) transferring the pattern to the metallized film I through reaction ionic etching technique; (4) adapting photo-etching glue as mask to corrode the uncovered naked metal l; (5) preparing the metal nanometer structure. The invention avoids the traditional striping craft of nanometer stamping technique to produce smooth line metal structure, which reduces the cost and simplifies the control wire breadth through corrosion condition and time adjustment as well as prepares double-metal structure with deposited second metal after chemical corrosion.

Owner:国家纳米技术产业化基地

De-icing solution

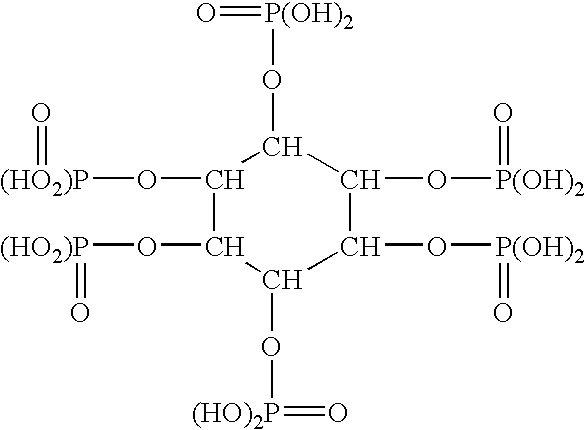

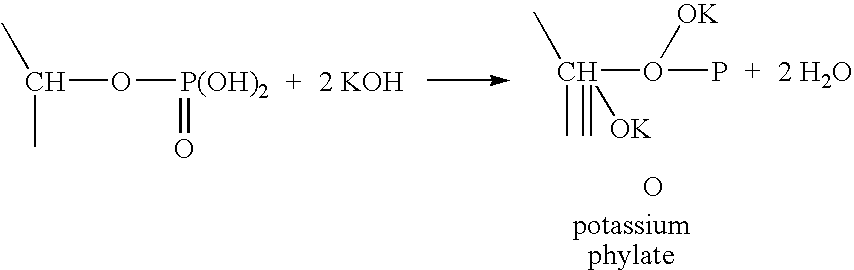

InactiveUS6905631B2More propertyIncreased ice melting propertyLiquid surface applicatorsOther chemical processesPhytic acidDepressant

A de-icing and anti-icing composition in the form of an aqueous solution which includes a carbohydrate, a freezing point depressant and an anti-corrosion agent in the form of phytic acid and its salts.

Owner:SEARS ECOLOGICAL APPL CO

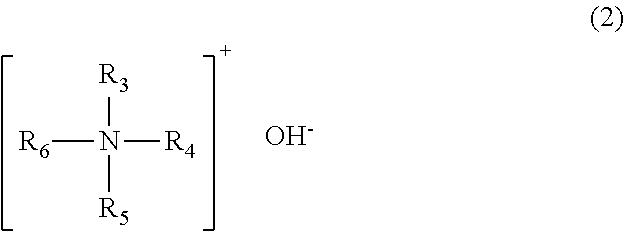

Polishing compsns. and polishing method using same

InactiveCN1369530ADoes not reduce grinding rateInhibits chemical attackPigmenting treatmentOther chemical processesOXALIC ACID DIHYDRATEAlkaline earth metal

A polishing composition, which contains the following components (a)-(g): (a) at least one abrasive selected from silica, alumina, cerium oxide, zirconium oxide and titanium oxide; (b) grease (c) at least one basic compound selected from ammonium salts, alkali metal salts, alkaline earth metal salts, organic amine compounds and quaternary ammonium salts; (d) at least one selected from citric acid, oxalic acid, Polishing-promoting compounds of tartaric acid, glycine, alpha-alanine and histidine; (e) at least one corrosion inhibitor selected from the group consisting of benzotriazole, benzimidazole, triazole, imidazole and toltriazole; (f) ) hydrogen peroxide and (g) water.

Owner:FUJIMI INCORPORATED

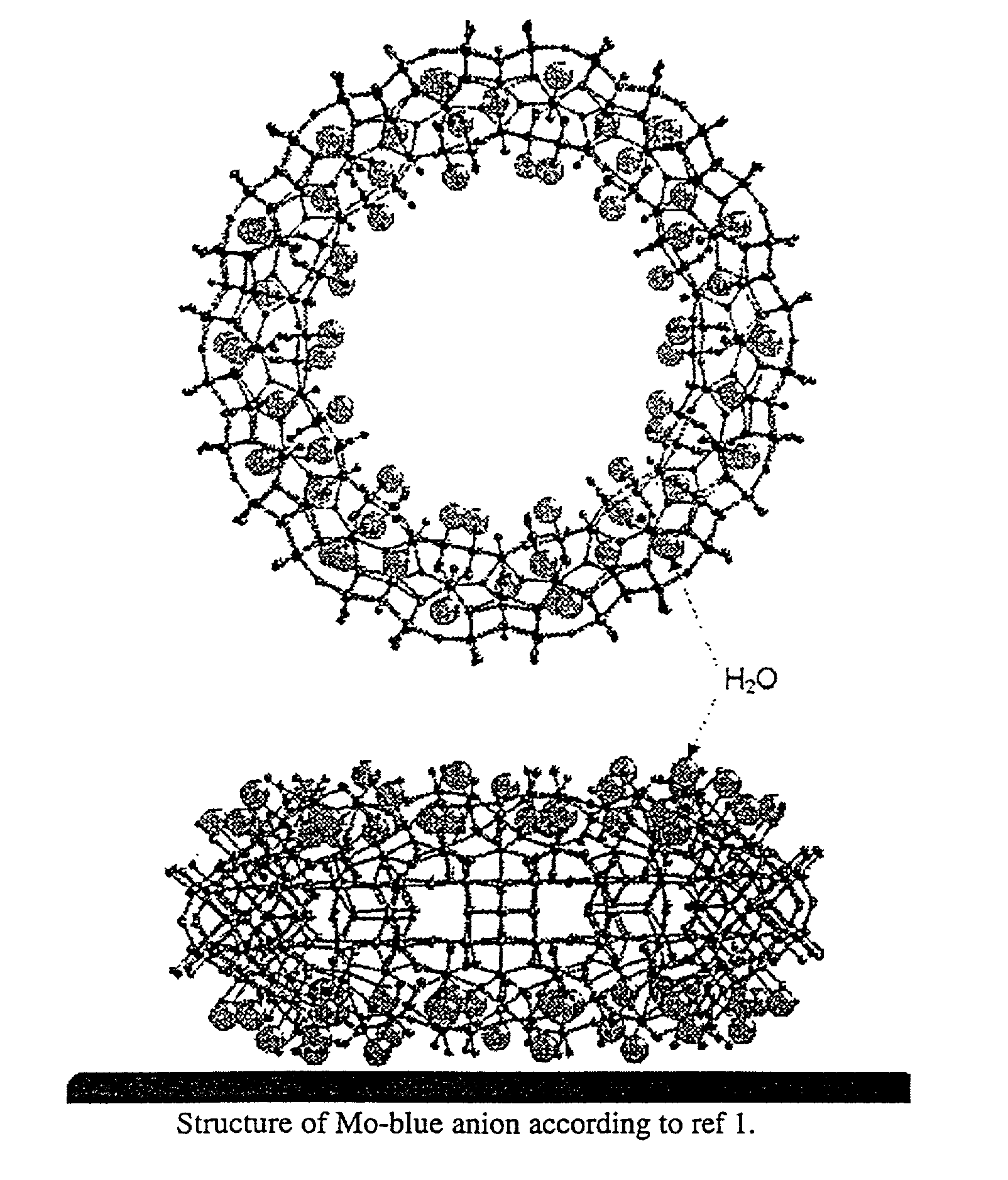

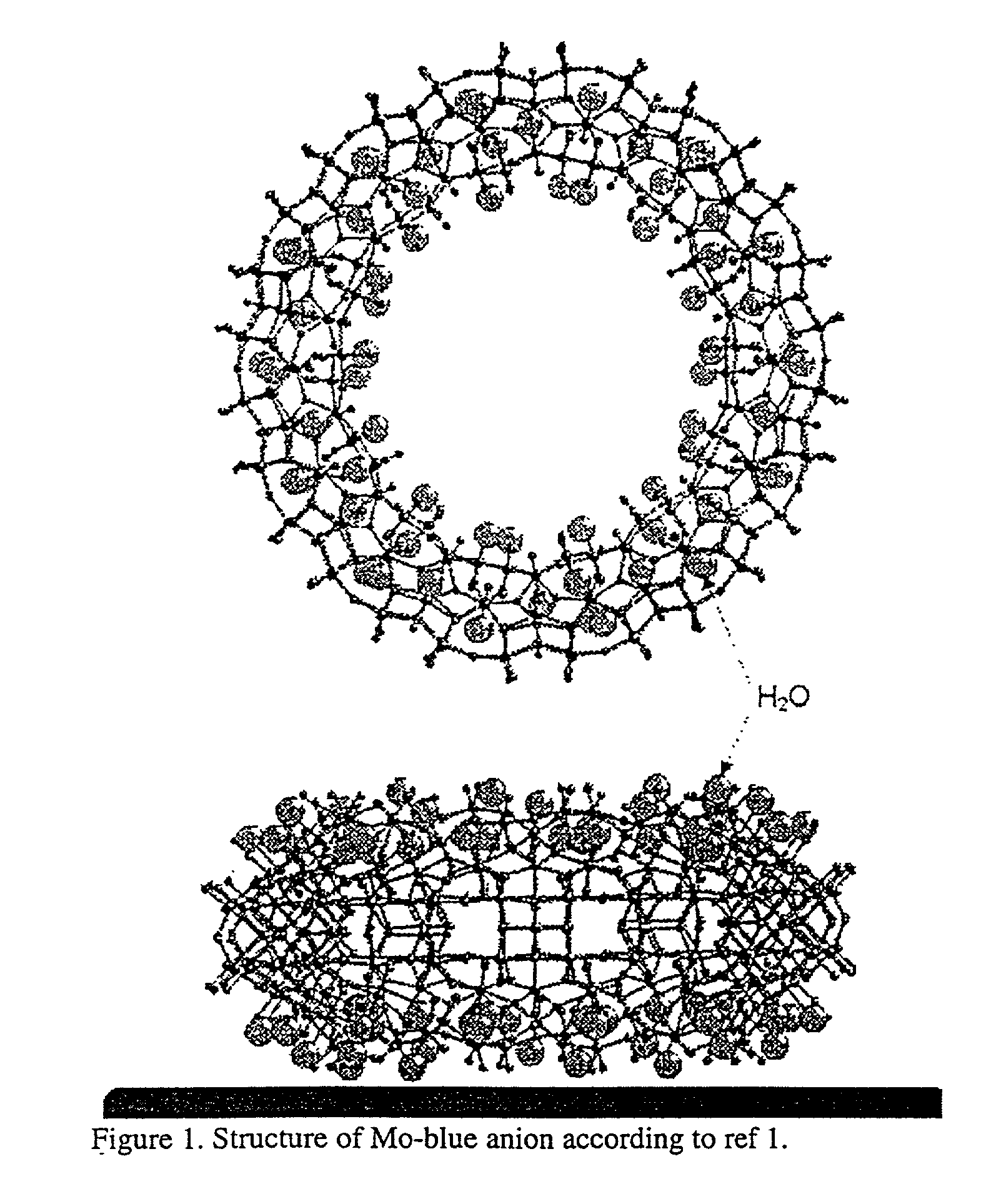

Supramolecular oxo-anion corrosion inhibitors

InactiveUS20030019391A1Hinders its propagationOther chemical processesSurface reaction electrolytic coatingVolatile corrosion inhibitorOxyanion

A corrosion inhibitor is described which includes several supramolecular oxo-anion compositions useful for preventing the propagation of pit corrosion on aluminum and aluminum alloys. The oxo-anion compositions preferably include soluble polymeric oxidic acids comprising combinations of molybdenum, phosphorous, tungsten, and silicon. These compositions are useful as corrosion inhibitors in high-moisture, corrosive environments, such as radiators and cooling systems. For low-moisture environments, these oxo-anion compositions can be reacted with a counter-ion, such as various metals, including, but not limited to the rear earth metals, to form a soluble salt. The salt can then be adsorbed onto a carrier, such as paint pigments, which can then be applied to the surfaces of aluminum and aluminum alloys. These surface adsorbates then become sparingly soluble and are gradually released over time in the presence of an aqueous corrosive agent so as to prevent propagation of pit corrosion.

Owner:THE BOEING CO

Organic modified hydrophobic nano silica hollow ball and preparation method thereof

The invention discloses an organic modified hydrophobic nano silica hollow ball and a preparation method thereof. A microemulsion method is used to prepare an organic modified nano SiO2 solid ball precursor. Hydrochloric acid and other inorganic acid are used as corrosive agents. A chemical corrosion method is used to prepare a hollow nano silicon ball. A general formula OgHS can be used to express the hollow nano silicon ball, wherein Og is one or more of methyl, ethyl, propyl, vinyl, dodecyl, octyl, cetyl, naphthyl, phenyl, trifluoropropyl and pentafluorophenyl, and HS is Hollow Silica. The hollow ball has the characteristics of uniform cavity, large specific surface area, surface hydrophobization and the like, and has a broad application prospect in the aspects of drug slow-release, carrier catalysis, gas storage, pollution absorption and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

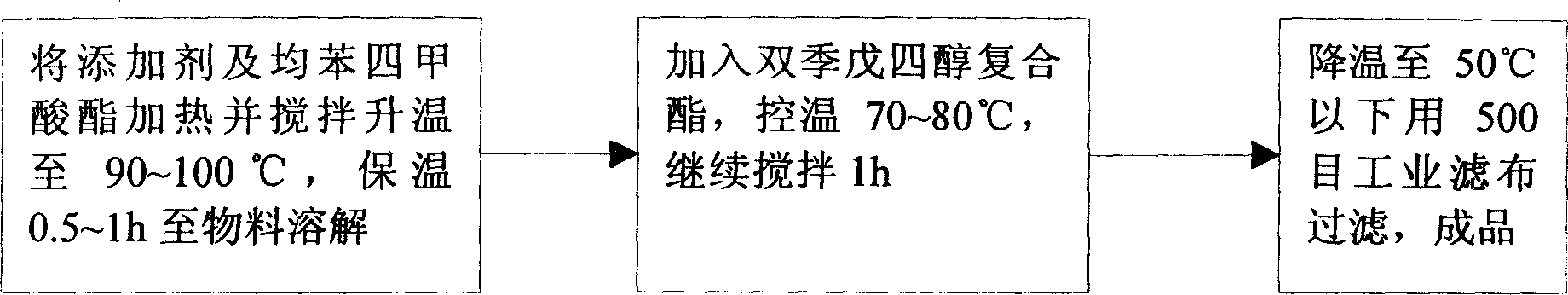

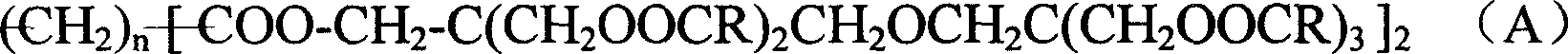

Clean compound ester type high temperature chain oil and preparation method

The present invention discloses a clean compounded ester type high-temperature chain oil and its preparation method. Its composition includes (by wt%) 40-90% of pentaerythritol compounded ester, 10-50% of benzenetetracarboxylic acid ester, 1-5% of high-temperature antioxidant, 1-5% of extreme pressure / anti-scuff agent and 0.02-0.5% of corrosion-resisting agent. Besides, said invention also provides the concrete steps of its preparation method, and provides its application range.

Owner:上海纳克润滑技术有限公司

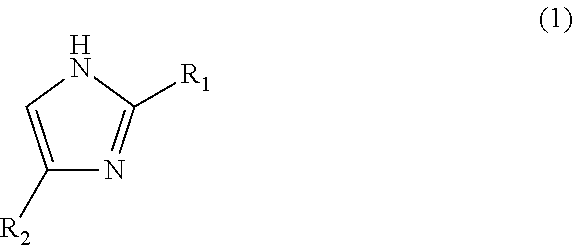

Cleaning liquid for lithography and method for forming wiring

ActiveUS20110129998A1Enhanced inhibitory effectGood removal effectNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingInorganic saltsAryl

Provided are a cleaning liquid for lithography that exhibits excellent corrosion suppression performance in relation to tungsten, and excellent removal performance in relation to a resist film or the like, and a method for forming a wiring using the cleaning liquid for lithography. The cleaning liquid for lithography according to the present invention includes a quaternary ammonium hydroxide, a water-soluble organic solvent, water, an inorganic salt and an anti-corrosion agent represented by a general formula (1) below.In the general formula (1), R1 represents an alkyl group or an aryl group having 1-17 carbon atoms, and R2 represents an alkyl group having 1-13 carbon atoms.

Owner:TOKYO OHKA KOGYO CO LTD

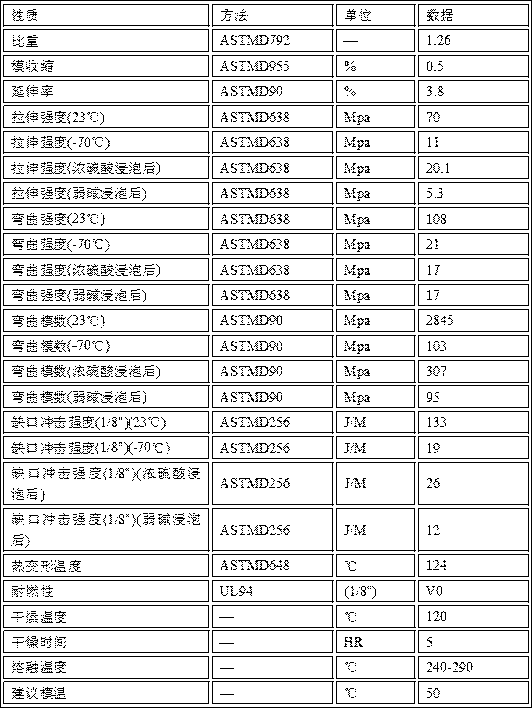

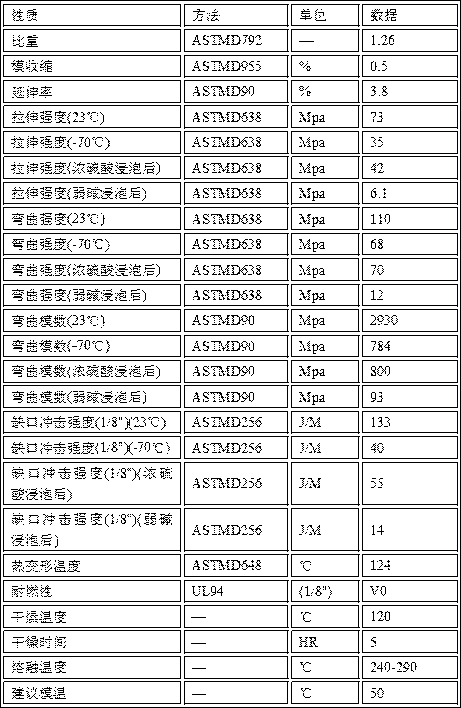

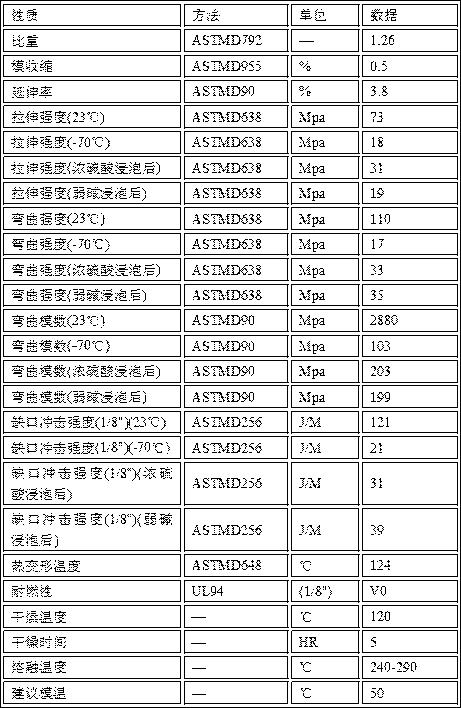

Cold-resistant anti-corrosion glass fiber reinforced polycarbonate composite material as well as preparation method and applications thereof

ActiveCN103265801ALow temperature resistanceHigh mechanical strength and impact resistancePolycarbonateAntioxidant

The invention discloses a cold-resistant anti-corrosion glass fiber reinforced polycarbonate composite material as well as a preparation method and applications thereof. According to the formula, the polycarbonate composite material comprises raw materials: polycarbonate, glass fiber, an antioxidant, a flexibilizer, an anti-ultraviolet agent, a lubricant, and an anti-corrosion agent. The composite material has the characteristics of high performance, high cold resistance, hihg corrosion resistance, high stability, electrostatic resistance and the like, is applicable to preparation of anti-impact and high-strength parts, protective covers, precise instrument parts, plugging elements, high-frequency tuners, printed circuit sockets, intelligent electric meter shells and terminal boards in mechanical industry.

Owner:广州仕天材料科技有限公司

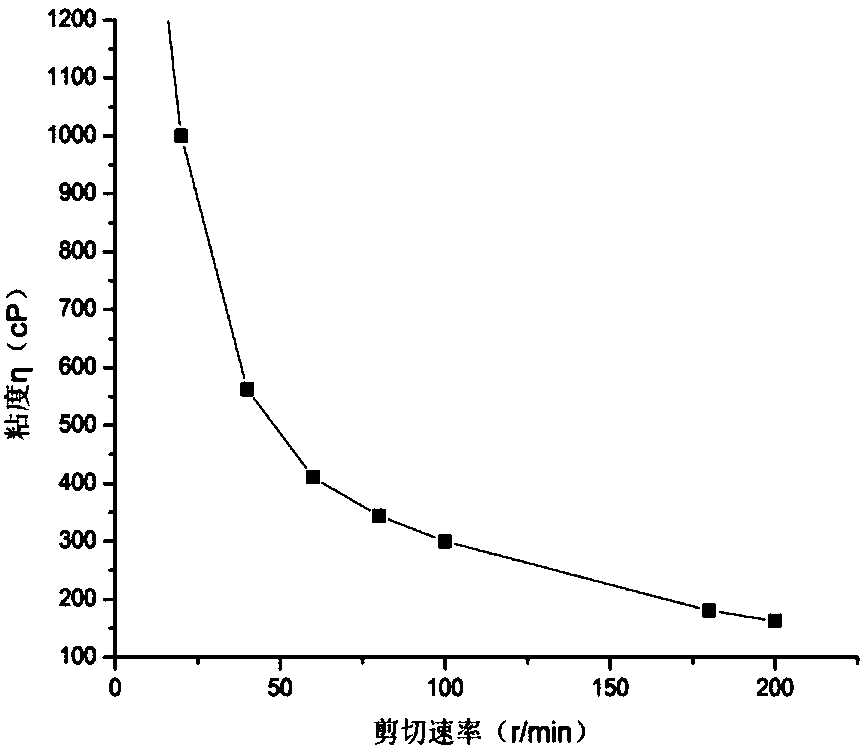

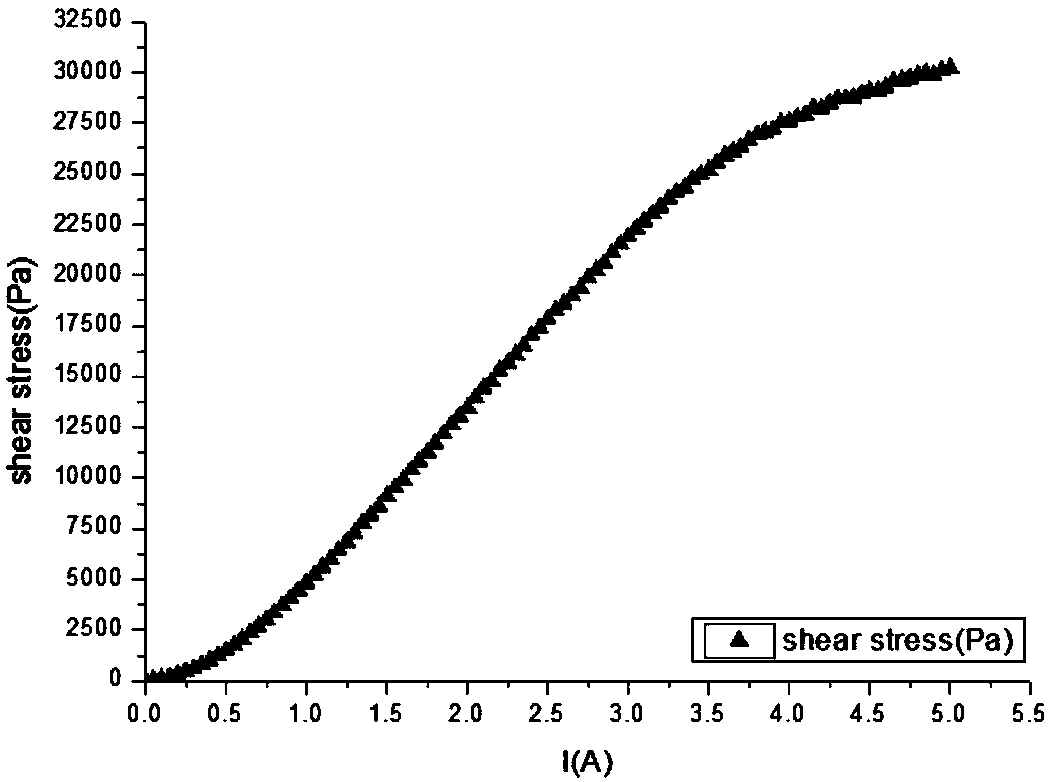

High-stability magnetorheological polishing liquid for optical part processing and preparation method thereof

InactiveCN107936847AGood dispersionLow zero field viscosityPolishing compositions with abrasivesMaterial removalSurface-active agents

The invention provides high-stability magnetorheological polishing liquid for optical part processing. The high-stability magnetorheological polishing liquid consists of the following components in percentage by weight: 30-40 percent of magnetic particles, 1-3 percent of a wetting agent, 0.1-0.5 percent of a pH regulating agent, 0.1-0.5 percent of a corrosion inhibitor, 1-5 percent of a surface active agent, 0.1-1 percent of a thixotropic agent, 0.1-0.5 percent of a polishing powder and 50-60 percent of deionized water. A preparation method of the high-stability magnetorheological polishing liquid comprises the following steps: mixing and stirring the surface active agent and the deionized water in proportion for 0.5-1 hour; adding the thixotropic agent; sequentially adding the wetting agent and the corrosion inhibitor; adding the pH regulating agent to regulate the pH value to 10; then stirring the carbonyl iron powder and the polishing powder in proportion for 1 hour, adding obtainedinitial mixed magnetorheological polishing liquid in an emulsifying machine for stirring to obtain the high-stability magnetorheological polishing liquid for optical part processing. The high-stability magnetorheological polishing liquid for optical part processing, provided by the invention, is larger in magnetorheological liquid shear stress, good in re-dispersion performance and higher in material removal efficiency and can maintain long-term polishing stability on a machine tool, and the production process is simple and easy to implement, can be used for mass production and can also meetthe demands on ultra-precision machining of advanced optical parts.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

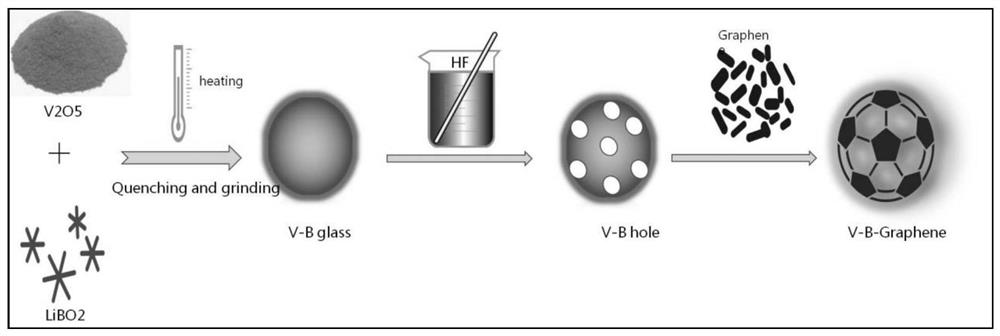

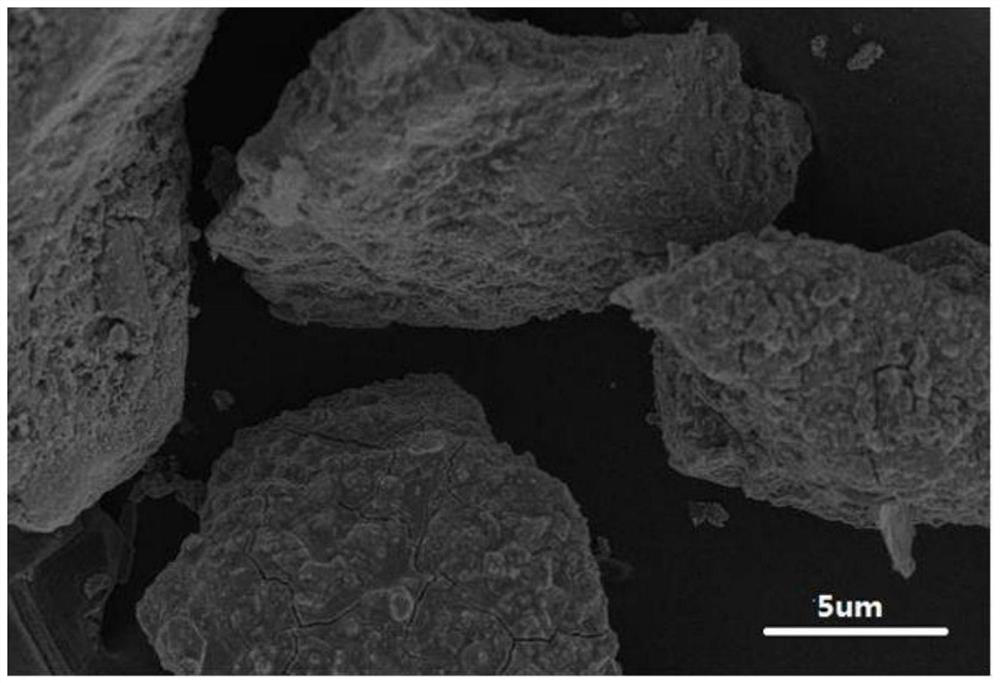

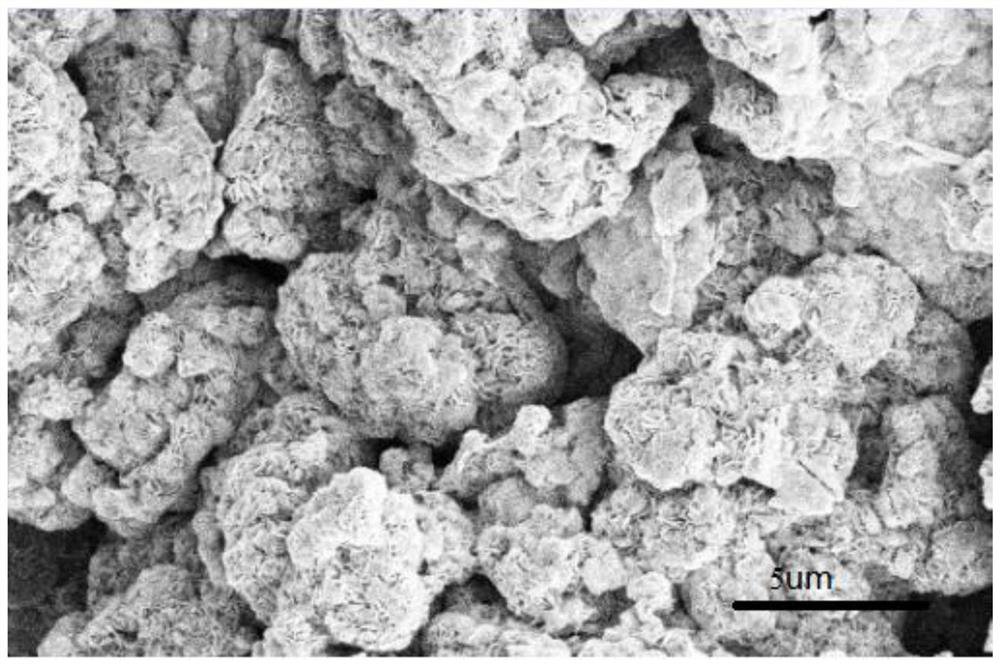

Vanadium pentoxide-lithium borate-graphene glass positive electrode material and preparation method and application thereof

ActiveCN111668468AImprove conductivityHigh reversible specific capacityCell electrodesSecondary cellsElectrical batteryGlass particle

The invention provides a V2O5-LiBO2-graphene glass positive electrode material and a preparation method and application thereof. The method comprises the following steps: a) uniformly mixing V2O5 andLiBO2, heating, keeping the temperature, and quenching; carrying out heat preservation again, cooling, and carrying out ball milling to obtain powder with the particle size D50 of less than 10mu m; b)mixing the powder with corrosion, forming pores, and ultrasonically mixing with the flake graphene dispersion liquid to obtain a precursor; and c) in an Ar atmosphere, annealing the precursor, and carrying out heat preservation to obtain the glass positive electrode material. According to the preparation method, through introducing flaky graphene into V2O5-LiBO2, using the flaky graphene as a strong conductive agent, using a corrosive agent for corrosion pore forming, and then performing heat treatment and ultrasonic treatment, the V2O5-LiBO2 glass particles are assembled, embedded and filledwith flaky graphene, the defects of vanadium-boron glass used as an electrode of the lithium ion battery are overcome, and the lithium ion battery has the performance advantages of high conductivity,high reversible specific capacity and high battery cycling stability.

Owner:HAINAN UNIVERSITY

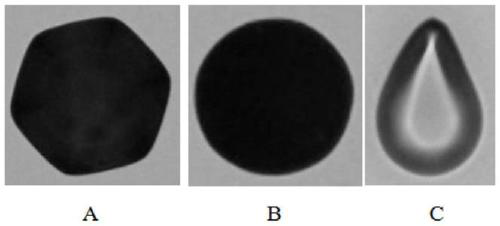

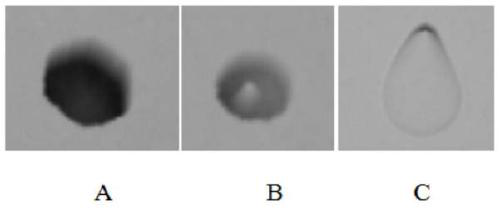

Dislocation identification method of silicon carbide crystal

PendingCN111238910AShort corrosion timeWell representedPreparing sample for investigationOptically investigating flaws/contaminationCarbide siliconErosion corrosion

The invention provides a dislocation identification method of a silicon carbide crystal. The method comprises the following steps: (1) corroding the silicon carbide crystal in an alkaline corrosive agent; and (2) after the corrosion is completed, observing the morphology of a dislocation corrosion pit so as to identify blade dislocation, screw dislocation and base plane dislocation in the siliconcarbide crystal, wherein the silicon carbide crystal comprises high-purity silicon carbide and nitrogen-doped silicon carbide, the corrosion time of the high-purity silicon carbide is 5-7 minutes, andthe corrosion time of the nitrogen-doped silicon carbide is 7-9 minutes. According to the method, the corrosion time of alkaline corrosion is optimized, and the corrosion time of high-purity siliconcarbide and nitrogen-doped silicon carbide is controlled to be less than 10 minutes so that three dislocations including edge dislocations, screw dislocations and base plane dislocations in the high-purity silicon carbide or the nitrogen-doped silicon carbide can be accurately distinguished; the corrosion time is short; and three dislocations in the crystal can be accurately identified.

Owner:SICC CO LTD

Austenite grain size display method of wire rod for prestressed steel stranded wire

InactiveCN102374962AGuaranteed accuracyPreparing sample for investigationParticle size analysisWire rodAustenite grain

The invention discloses a method capable of completely and clearly displaying the Austenite grain size of a wire rod for a prestressed steel stranded wire. The method is realized through the following steps of: preparing a test specimen to be tested: putting a 15cm-long wire rod in a muffle furnace at 860 DEG C plus or minus 10 DEG C for heating and then quenching and cooling the wire rod in cooling water at room temperature; tempering the wire rod for one hour in a furnace at approximately 200 DEG C; preparing corrosive agent: adding 6g of picric acid into 100ml of distilled water, continuously agitating, then adding five drops of cleanser essence, agitating, finally adding 3g of copper sulfate and placing for 12 hours; heating the corrosive agent to 60 DEG C, putting the test specimen to be tested in the corrosive agent to corrode the test specimen to be tested for 1.5 minutes, taking out the test specimen to be tested, repeating the corrosion and polishing steps for 3-5 times and finally conducting assessment through a comparison method against a standard map. The Austenite grain size testing method provided by the invention is a simple, convenient and high-efficiency 82B steel Austenite grain size testing method.

Owner:天津荣程联合钢铁集团有限公司

Gasholder sealing oil composition with high corrosion resistance and oxidation resistance

ActiveCN102337174AImprove corrosion resistanceImprove antioxidant capacityAdditivesDemulsifierChemical composition

The invention provides a gasholder sealing oil composition with high corrosion resistance and oxidation resistance. The gasholder sealing oil composition comprises the following components in percentage by weight: 0.1 to 1.2 percent of antioxidant, 0.01 to 0.8 percent of dispersant, 0.05 to 1.0 percent of antioxidant and anti-corrosion agent, 0.01 to 1.0 percent of cleaning agent, 0.01 to 0.2 percent of demulsifier, 1 to 11 percent of viscosity index improver, 0.1 to 2 percent of pour point depressant and the balance of base oil. The gasholder sealing oil composition has excellent antioxidation stability, is suitable for various working conditions and has long service life; raw materials are reasonably mixed; and the preparation method has the advantages of simplicity, wide application range and readily available raw materials.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly combustion-supporting diesel fuel additive and preparation method thereof

InactiveCN109207212AImprove qualityEmission reductionLiquid carbonaceous fuelsFuel additivesChemical industryParticulates

The invention belongs to the technical field of chemical industry, and particularly relates to an environment-friendly combustion-supporting diesel fuel additive and a preparation method thereof. Theenvironment-friendly combustion-supporting diesel fuel additive is prepared from the following raw materials in percentage by weight: 2 to 5 percent of cetane number improvers, 0.5 to 1.0 percent of ferrocene, 0.2 to 0.4 percent of rare earth metal salts, 1 to 3 percent of anti-corrosion agents, 5 to 15 percent of plant oil and the balance of aviation kerosene. The prepared environment-friendly combustion-supporting diesel fuel additive has the advantages that the preparation process is simple; the cost is low; the energy-saving environment-friendly diesel fuel additive has good cleaning and purification effects; the diesel fuel quality can be effectively improved; the hexadecane number of the diesel fuel is increased; the diesel fuel combustion efficiency is improved; the full combustionof the fuel is promoted; the oil consumption is reduced; the carbon deposit in an engine cylinder body is reduced; the engine dynamic property is improved; the discharging of harmful substances of theengine tail gas is reduced; the discharging of black smoke and particulate matters is obviously reduced; the diesel fuel is effectively saved; the tail gas exhaust is reduced; the tail gas exhaust pollution is reduced; the environment-friendly effect is promoted.

Owner:卢宝良

Environment-friendly concentrated solution for hydraulic support

ActiveCN103266004AGood resistance to hard waterStorage stability and biodegradabilityLubricant compositionAntifoam agentCorrosion resistant

The invention relates to an environment-friendly concentrated solution for a hydraulic support. The environment-friendly concentrated solution comprises the following components in percentage by mass: 12%-25% of composite lubricant, 0.005%-0.015% of antifoam agent, 0.005%-0.02% of foam inhibitor, 1.0%-7.0% of water treatment agent, 8%-15% of composite rust protection corrosive, 12%-25% of compound emulsifier and the balance of deionized water. The environment-friendly concentrated solution for the hydraulic support has good freezing and thawing property, good hard water resistance, stable storage property and biodegradability, and good rust protection and corrosion resistant performances, and can be used for preventing a working solution from corroding equipment, thereby prolonging the service life of relative equipment and improving the safety. The environment-friendly concentrated solution has good lubricating property and airtightness and material compatibility, the abrasion and leakage of a support hydraulic moving part in a use process are effectively reduced, the cost for maintenance and use is lowered, and the requirement of the hydraulic support working in a harsh work condition can be met.

Owner:营口福斯油品有限公司

Vehicle brake branch pump guide pin lubricating grease

InactiveCN104403766AImprove water resistanceReduce coefficient of frictionLubricant compositionAntioxidantPulp and paper industry

The present invention relates to the technical field of lubricating grease industry, especially to a vehicle brake branch pump guide pin lubricating grease and a preparation process thereof. The vehicle brake branch pump guide pin lubricating grease comprises, by weight, 50-70% of a base oil, 25-50% of a thickener, 0.5-3% of an antioxidant, 0.1-1% of an anti-corrosion agent, 1-5% of an extreme pressure anti-wear agent, and 0.3-1% of an anti-rust agent. The technical scheme of the present invention comprises the following steps: a, sequentially pouring base oil, antioxidant, an anti-corrosion agent, an extreme pressure anti-wear agent and an anti-rust agent into a reaction kettle to carry out stirring heating, and carrying out homogenization degassing to obtain the finished product. Compared with the vehicle brake branch pump guide pin lubricating grease in the prior art, the vehicle brake branch pump guide pin lubricating grease of the present invention has advantages of good water resistance, extremely low friction coefficient, effective noise reducing, good lubricity, good protection property, good thermal stability, high and low temperature property, colloidal stability, anti-oxidation, anti-corrosion stability and tightness.

Owner:WUXI FEITIAN GREASE

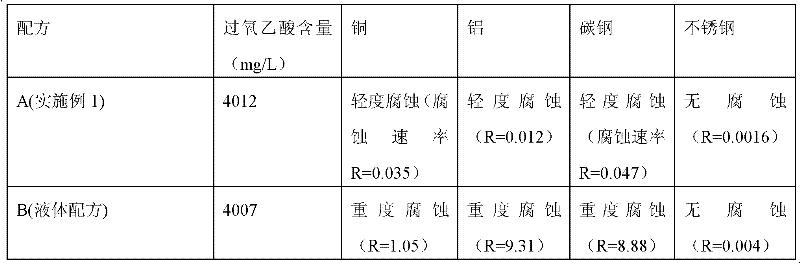

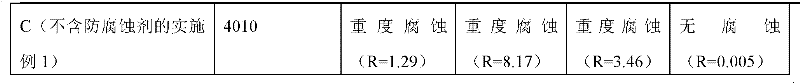

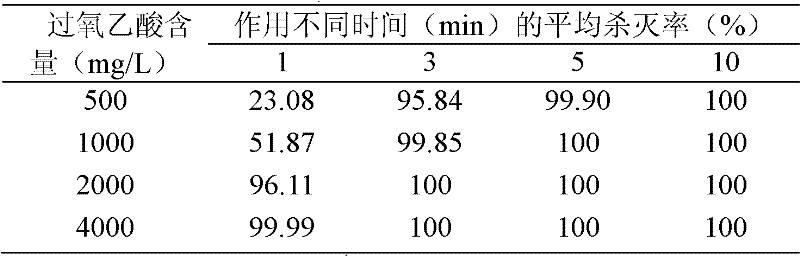

Low-corrosion peracetic acid solid generating agent as well as preparation method and application thereof

ActiveCN102415380AHigh active oxygen contentLow active oxygenBiocideDisinfectantsEthylene diamineActive agent

The invention discloses a peracetic acid solid generating agent as well as a preparation method and an application thereof. The peracetic acid solid generating agent consists of tetra acetyl ethylene diamine, anion active agents and antiseptic agents. A reagent kit used for preparing the peracetic acid consists of peracetic acid solid generating agents and sodium percarbonate. The mol ratio of tetra acetyl ethylene diamine to sodium percarbonate to anion active agents to antiseptic agents is 1 / (0.5 to 2) / (0.2 to 0.5) / (0 to 0.5). The peracetic acid solid generating agent can accelerate the preparation speed of the peracetic acid and is favorable for maintaining effective ingredients of solution, and simultaneously, the washing and cleaning effect of the solution can also be enhanced. The antiseptic agents are added into the system, the corrosion effect of the peracetic acid on various kinds of metals can be reduced, and the stability of the solution is enhanced.

Owner:INST OF PLA FOR DISEASE CONTROL & PREVENTION

Preparation method of modified fly ash microbead rubber and plastic filler

Owner:淮南市金源粉煤灰有限责任公司

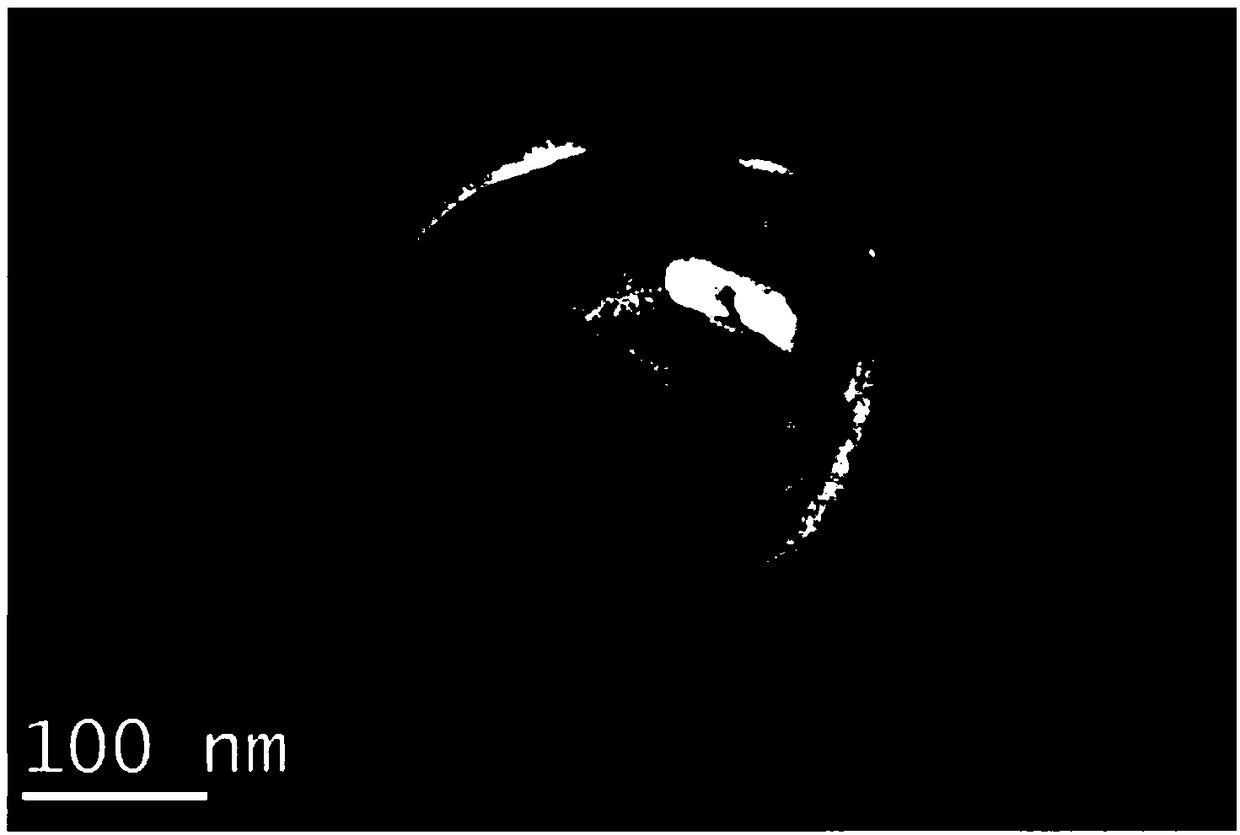

Corrosive agent and corrosion method for second phase of zirconium alloy

InactiveCN109060857AAddress gaps in researchSimple and efficient macro distribution researchMaterial analysis using wave/particle radiationHydrofluoric acidZirconium alloy

The invention aims at providing a corrosive agent and corrosion method for a second phase of zirconium alloy. The corrosive agent is characterized by being prepared from hydrofluoric acid, nitric acidand water according to a certain proportion. By corroding the second phase in the zirconium alloy through the corrosive agent, the macroscopic distribution and the particle size of the second phase of the zirconium alloy can be clearly observed. According to the corrosive agent and corrosion method for the second phase of the zirconium alloy, the problem that a blank exists in research on the second phase of the zirconium alloy can be well solved, and work such as macroscopic distribution research and particle size statistics of the second phase of the zirconium alloy and research on the relation between the second phase of the zirconium alloy and a substrate become simple and efficient.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Metallographical corrosive for medium entropy high-temperature alloy and corrosion method

ActiveCN111041486AClear display of microstructureEasy to operatePreparing sample for investigationElectrolysisSS - Stainless steel

The invention relates to a metallographical corrosive for a medium entropy high-temperature alloy and a corrosion method and belongs to the technical field of metal functional materials. The corrosiveis prepared by mixing 5-10 g of copper sulfate, 15-30 ml of hydrochloric acid, 10-25 ml of water, 2-3 g of ferric chloride and 2-4 ml of nitric acid. The corrosion method comprises the following steps of putting a test sample in the corrosive for electrolytic corrosion, wherein a stainless steel plate is taken as a cathode, the test sample as an anode, the electrolytic voltage is 1.5-5 V, the electrolytic current is 0.1-0.3 A and electrolytic time is 20-60 s; and taking out the sample, cleaning the sample with alcohol, blow-drying the sample, and observing microstructures of the sample under a microscope. The corrosive has the advantages that microstructure and morphology of the medium entropy high-temperature alloy can be corroded relatively clearly, and the method is simple and feasible. The corrosive is suitable for displaying microstructure and morphology of the medium entropy high-temperature alloy with various components.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Waterless abrasive-free polishing solution for chemical-mechanical polishing of flexible, crisp and deliquescent crystals

InactiveCN102660198AReduce surface damageImprove surface qualityPolishing compositionsMetallurgyActive agent

A waterless abrasive-free polishing solution for chemical-mechanical polishing of flexible, crisp and deliquescent crystals is characterized in that the solution comprises 0.5-40% of an organic corrosion agent, 0.5-20% of an organic corrosion inhibitor, 0.5-15% of an organic surfactant, 0.01-10% of an organic pH adjustment agent, and 30-95% of an organic solvent. The waterless abrasive-free polishing solution contains no water, so a problem of easy deliquescent cracking of the flexible, crisp and deliquescent crystals when meeting water is avoided. Simultaneously the waterless abrasive-free polishing solution which contains no abrasives has small damages to surfaces of the flexible, crisp and deliquescent crystals, allows the flexible, crisp and deliquescent crystals can have nondestructive and super-smooth surfaces to be obtained, does not precipitate, and can be preserved and used for a long time. The waterless abrasive-free polishing solution has the advantages of good stability, good fluidity, easy cleaning, and small corrosion to equipment. The waterless abrasive-free polishing solution prepared in the invention is specially used for the chemical-mechanical polishing of the flexible, crisp and deliquescent crystals, has the advantages of no water and no abrasives, and allows flexible, crisp and deliquescent materials to have high surface qualities, and the high surface quality obtaining method is simple, is easy to implement, and costs low.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Methanol fuel

The present invention relates to a methanol fuel, and belongs to a power equipment raw material. The methanol fuel contains 0.3-0.4% of ferrocene, 4-5% of a starting aid, 0.3-0.5% of an anti-corrosion agent, 0.3-0.5% of an anti-explosion agent, 1-2% of a co-solvent, 1% of a wear-resistant anti-swelling agent, 0.5% of a lubricant, 0.3-0.4% of a stabilizer, and the balance of methanol, wherein the starting aid is dimethyl ether or 120# solvent oil, the anti-corrosion agent is benzotriazole, the anti-explosion agent is methyl tert-butyl ether, the co-solvent is dimethoxymethane, the wear-resistant anti-swelling agent is triethanolamine, and the lubricant is silicone oil. The methanol fuel of the present invention has advantages of enough power, environmental protection and engine cleaning; and compared with the use of other vehicle fuels, the use of the methanol fuel f the present invention has the following advantages that after the locomotive uses the methanol fuel, the engine is clean and the service life is long.

Owner:贵州众燃新能源有限责任公司

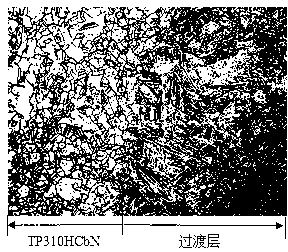

Metallographic corrosive liquid for bimetal composite pipe with transition layer and etching method of metallographic corrosive liquid

ActiveCN103074630AControl etching timeEasy to operatePreparing sample for investigationBonding processSS - Stainless steel

The invention discloses metallographic corrosive liquid for a bimetal composite pipe with a transition layer, belonging to the technical field of detection of bimetal composite pipes. The corrosive liquid is prepared by adding ferric trichloride to a concentrated hydrochloric acid ethanol solution with the volume ratio of 35-60 percent, wherein the ferric trichloride addition amount is 0.01-0.04g / ml. The corroding method comprises the following steps of: completely immersing a polished sample to the corrosive liquid, and maintaining for 0.3-2Min. The invention provides the corrosive liquid which is suitable for daily metallographic inspection, low in cost and free of pollution and a corroding method of the corrosive liquid aiming at a metallic stainless steel and low alloy steel composite pipe which is produced by adopting a metallurgical bonding process and is provided with a wide transition layer at a bonding surface between stainless steel and low alloy steel. The corrosive liquid and the corroding method disclosed by the invention can be used for simultaneously corroding metallic tissues from the stainless steel, the low alloy steel and the wide transition layer for the purpose of detection.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com