Metallographic corrosive liquid for bimetal composite pipe with transition layer and etching method of metallographic corrosive liquid

A technology of bimetal composite pipe and corrosive liquid, which is applied in the preparation of test samples, etc., can solve the problems of wide transition layer, cracks, pores, etc., and achieve the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Corrosion solution composition: 0.02-0.03g / ml ferric chloride; 50% concentrated hydrochloric acid (analytical pure) ethanol (analytical pure) solution (volume ratio of concentrated hydrochloric acid to ethanol).

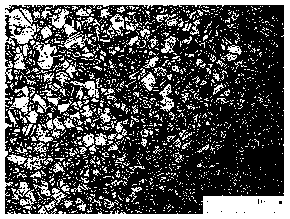

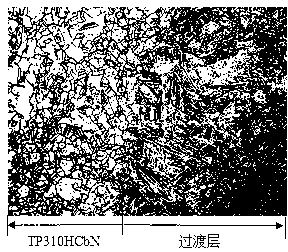

[0037] The ground and polished SA-213 TP310HCbN and SA-213 T11 (the said TP310HCbN and T11 are seamless austenitic and ferritic alloy steel pipes for boilers, superheaters and heat exchangers, ASME SA-213 / The listed steel number in SA-213M, ASME Ⅱ-A-2010 SA-213 / SA-213M P315~326 pages) The composite pipe sample is immersed in the prepared corrosive solution, the polished surface of the sample is facing upward, completely Immerse in the liquid, during this period, you can dip the absorbent cotton ball into the corrosion solution to slightly wipe the polished surface, keep it for 1.5Min, take out the sample after the specified time, rinse it in still water and dry it with hot air for microscopic observation . Microscopic results such as Figures 1 to 6 shown,...

Embodiment 2

[0039] Corrosion solution composition: 0.01-0.02g / ml ferric chloride; 55% concentrated hydrochloric acid (analytical pure) ethanol (analytical pure) solution (volume ratio of concentrated hydrochloric acid to ethanol).

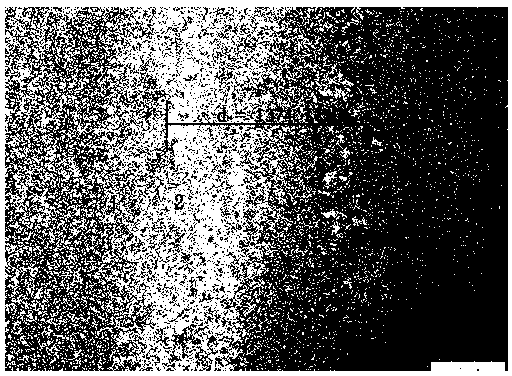

[0040]Immerse the ground and polished SA-213 TP310HCbN and SA-213 T11 composite pipe sample in the prepared corrosive solution, with the polished side of the sample facing up, and completely immerse in the liquid. During this period, you can use absorbent cotton balls to immerse in the corrosive solution Slightly wipe the polished surface and keep it for 1Min. After the specified time, take out the sample, rinse it in still water and dry it with hot air for microscopic observation. Microscopic results such as Figure 7-12 shown. in Figure 7 It is the microscopic appearance map of the overall composite tube observed under the microscope at 50 magnifications (the position of the observation point at 200 magnifications is marked in the figure, where d represen...

Embodiment 3

[0042] Corrosion solution composition: 0.03g / ml ferric chloride; 40-45% concentrated hydrochloric acid (analytical pure) ethanol (analytical pure) solution (volume ratio of concentrated hydrochloric acid to ethanol).

[0043] Immerse the ground and polished SA-213 TP310HCbN and SA-213 T11 composite pipe sample in the prepared corrosive solution, with the polished side of the sample facing up, and completely immerse in the liquid. During this period, you can use absorbent cotton balls to immerse in the corrosive solution Slightly wipe the polished surface and keep it for 1Min. After the specified time, take out the sample, rinse it in still water and dry it with hot air for microscopic observation. Microscopic results such as Figure 13-18 shown. in Figure 13 It is the microscopic appearance map of the overall composite tube observed under the microscope at 50 magnifications (the position of the observation point at 200 magnifications is marked in the figure, where d represe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com