High-stability magnetorheological polishing liquid for optical part processing and preparation method thereof

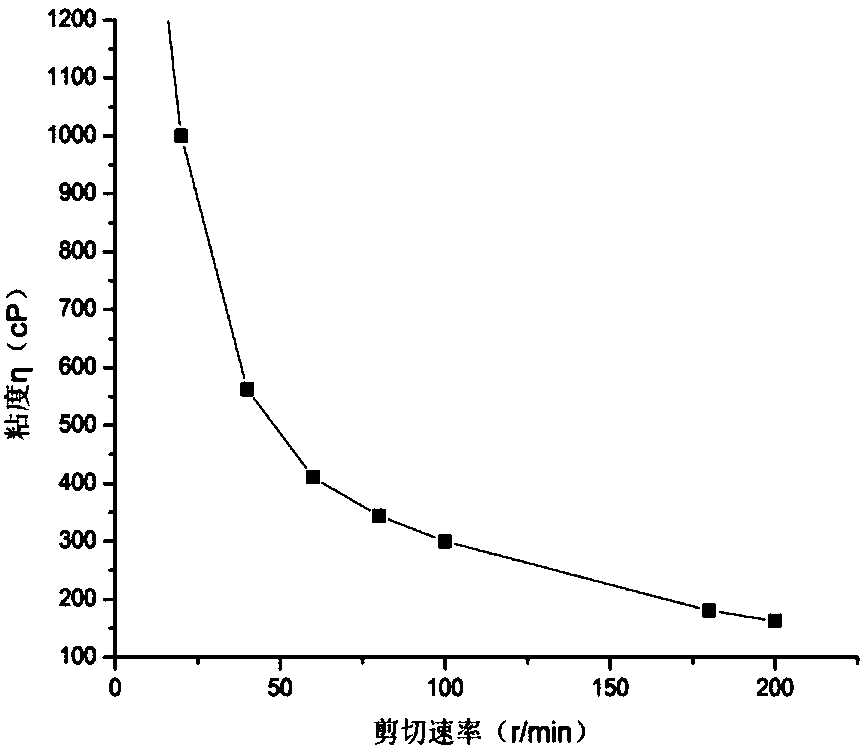

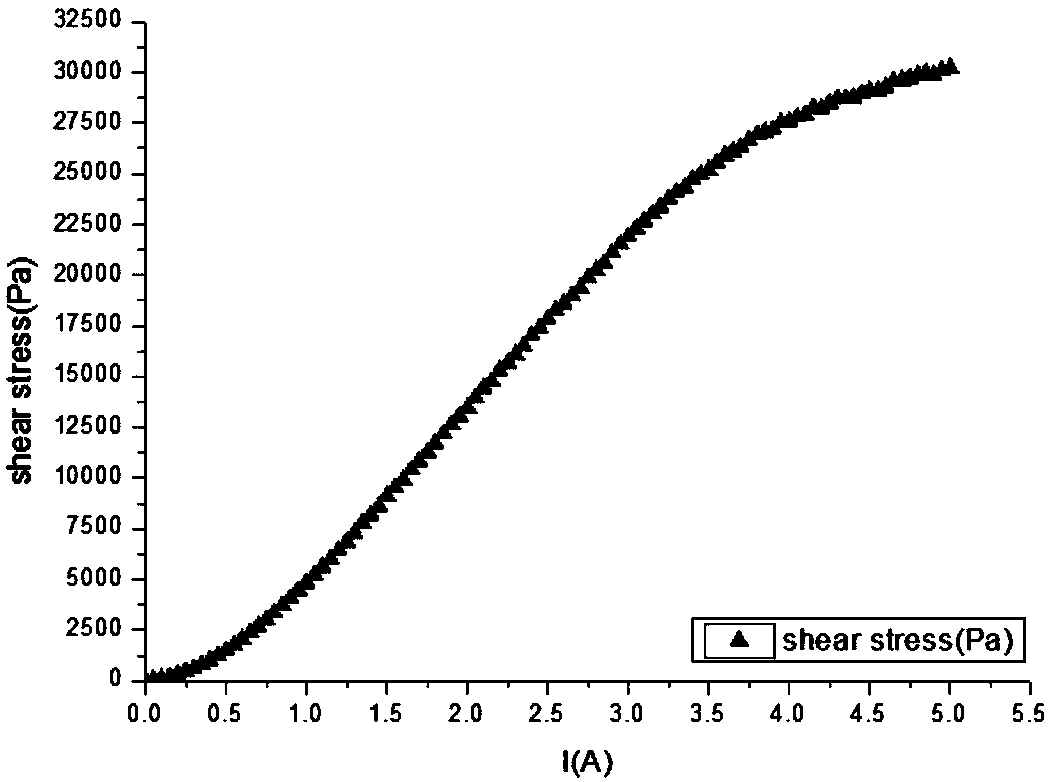

A magnetorheological polishing, high-stability technology, applied in polishing compositions containing abrasives, etc., can solve the problems of low removal efficiency and low yield stress on the surface of optical parts, and achieve improved material volume removal efficiency and redispersion. The effect of strong performance and excellent flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the high-stability magnetorheological polishing fluid for the optical parts is as follows:

[0032] 1. According to the volume fraction content of 52% deionized water and 3% sodium hexametaphosphate, add sodium hexametaphosphate to deionized water, and stir at 300r / min at room temperature for 0.5 hours to obtain sodium hexametaphosphate solution;

[0033] 2. According to the content of 1% volume fraction of nano-magnesium-aluminum silicate, add nano-magnesium-aluminum silicate to sodium hexametaphosphate solution, and stir at 300r / min for 1 hour at room temperature to obtain a mixed solution;

[0034]3. According to the content of 2% volume fraction of glycerol, add it to the mixture, and stir at 300r / min for 30min at room temperature until fully dissolved;

[0035] 4. According to the content of 0.5% volume fraction of sodium benzoate, add it to the mixture, and stir at 300r / min for 30min at room temperature;

[0036] 5. According to the cont...

Embodiment 2

[0043] The preparation method of the high-stability magnetorheological polishing fluid for the optical parts is as follows:

[0044] 1. According to the volume fraction content of 56.2% of ionized water and 1% of sodium polyacrylate, sodium polyacrylate was added to deionized water, and stirred at 350r / min at room temperature for 1 hour to obtain sodium polyacrylate solution;

[0045] 2. Add nano-silica to the sodium polyacrylate solution according to the content of 0.2% volume fraction of nano-silica, and stir at 350 r / min for 1 hour at room temperature to obtain a mixed solution;

[0046] 3. According to the content of 2% volume fraction of glycerol, add it to the mixture, and stir at 350r / min for 30min at room temperature until fully dissolved;

[0047] 4. According to the content of 0.5% volume fraction of sodium benzoate, add it to the mixture, and stir at 350r / min for 30min at room temperature;

[0048] 5. According to the content of 0.1% volume fraction of sodium carbo...

Embodiment 3

[0055] The preparation method of the high-stability magnetorheological polishing fluid for the optical parts is as follows:

[0056] 1. According to the content of 58% deionized water and 1% volume fraction of sodium lignosulfonate, add sodium lignosulfonate to deionized water, stir at 400r / min at room temperature for 1 hour, and obtain sodium lignosulfonate solution ;

[0057] 2. Add nano-silica to the sodium lignosulfonate solution according to the volume fraction of 0.4% of nano-silica, and stir at 400 r / min for 0.5 hours at room temperature to obtain a mixed solution;

[0058] 3. According to the content of 1% volume fraction of glycerol, add it to the mixture, and stir at 400r / min for 30min at room temperature until fully dissolved;

[0059] 4. According to the content of 0.5% volume fraction of sodium benzoate, add it to the mixture, and stir at 400r / min for 30min at room temperature;

[0060] 5. According to the content of 0.1% volume fraction of sodium carbonate, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com