Corrosive agent and corrosion method for second phase of zirconium alloy

A kind of corrosive agent and zirconium alloy technology, which is applied in the field of corrosion analysis of zirconium alloy microstructure, to achieve the effect of simple and efficient research work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

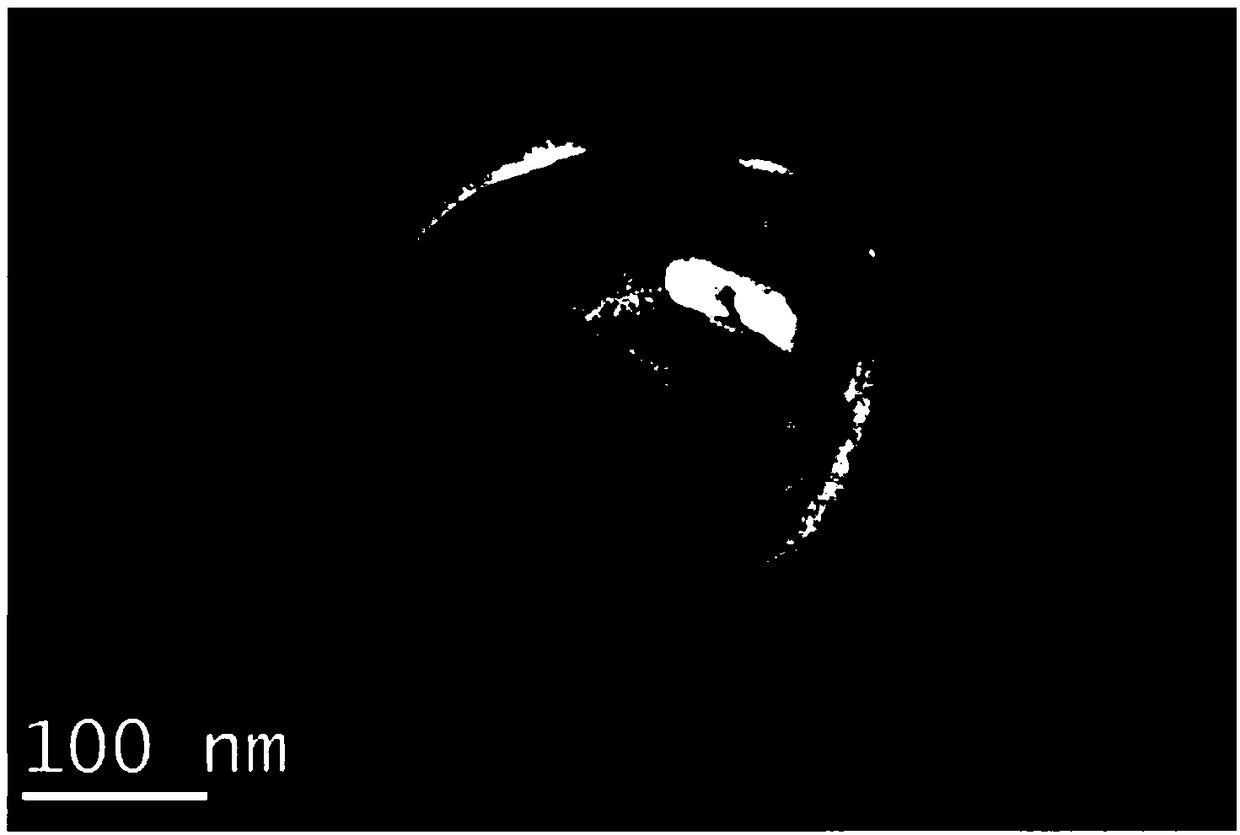

[0033] Zircaloy-4 alloy, its nominal composition is Zr-1.5Sn-0.2Fe-0.1Cr (wt.%). The alloy has excellent corrosion resistance and is widely used as cladding material for pressurized water reactors and heavy water reactors. This embodiment adopts the Zircaloy-4 alloy (hereinafter referred to as the annealed Zircaloy-4 alloy) of forging + annealing treatment, and its matrix structure is a typical equiaxed structure, the grain size is 5-16 μm, and the type of phase is HCP structure The α phase, the specific organization is as attached figure 2 shown. The second phase in the alloy was observed in STEM mode by transmission electron microscopy. as attached image 3 shown, with image 3 Round or oval grains with medium black contrast are the second phase in the alloy.

[0034] The second phase etchant of the annealed Zircaloy-4 alloy consists of hydrofluoric acid (HF), nitric acid (HNO 3 ) and water (H 2 O) composition, the volume proportion of its each component is: 20 μ l (...

Embodiment 2

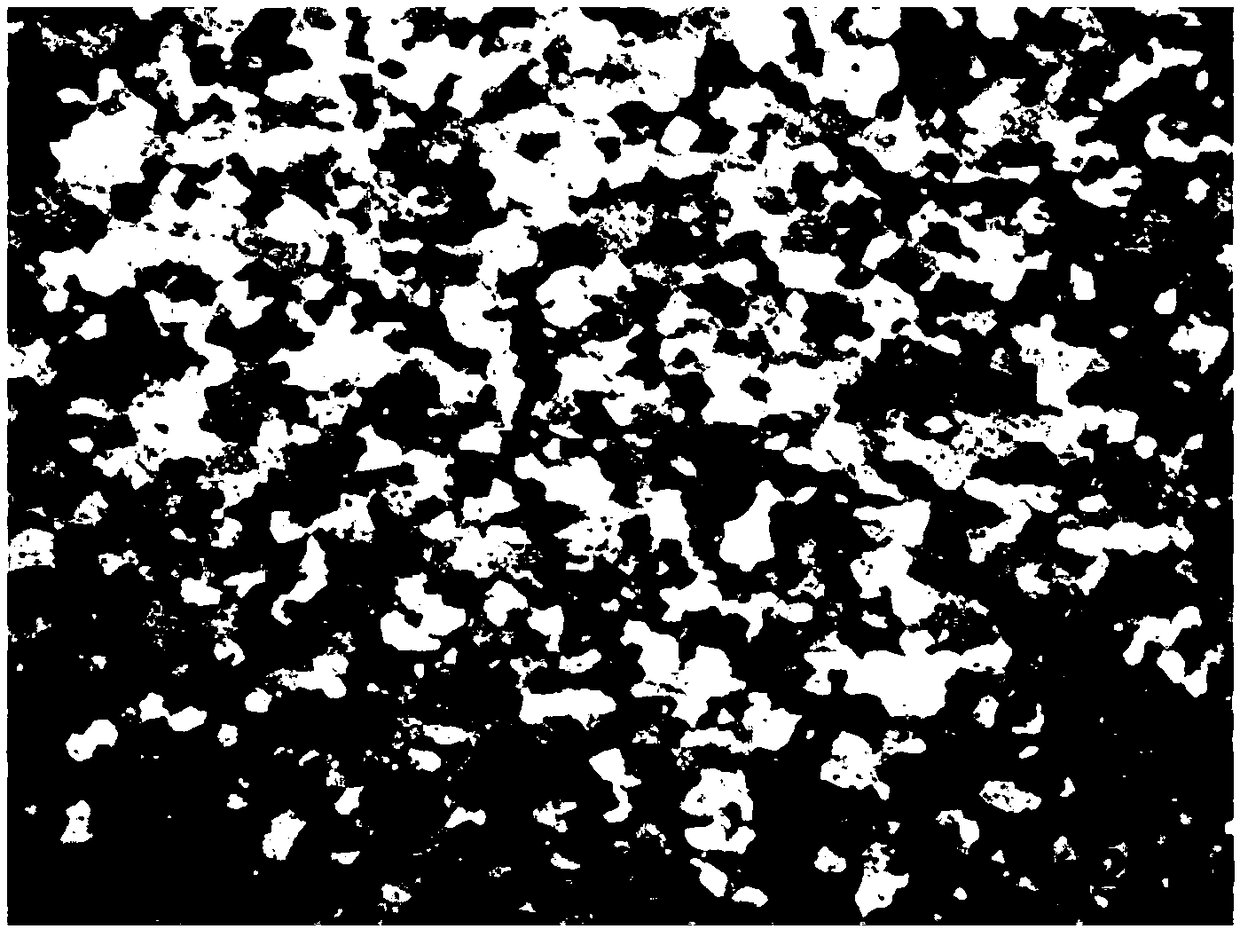

[0046] For the annealed Zircaloy-4 alloy in Example 1, the volume of HF in the second-phase etchant must be controlled at about 20 μl (provided that the volumes of water and nitric acid are both 70ml), if the volume of HF is too small, you can use extended However, if the concentration of HF in the etchant is too high or the corrosion time is too long, the corrosion effect will be poor or even distorted. For example: using corrosive agent: 100μl hydrofluoric acid, 70ml nitric acid, 70ml H 2 O, corrosion time 0.5min. The corroded samples were observed under a scanning electron microscope, and the obtained morphology was as attached Figure 6 It can be seen that severe pitting corrosion has occurred on the polished surface of the alloy, and sharp corrosion holes will be left after the substrate is corroded (the corrosion holes of the second phase are rounder). These traces of local corrosion have covered up the second phase At this time, the specific information of the second ...

Embodiment 3

[0048] Zircaloy-2 is a commercial zirconium alloy widely used in nuclear reactor cladding materials. The organization of Zircaloy-2 in the as-cast state is attached Figure 7 As shown, the organization is a lamellar α-phase interlaced weaving. Observe the second phase in the alloy in STEM mode. as attached Figure 8 shown, with Figure 8 Round or oval grains with medium black contrast are the second phase in the alloy.

[0049] The second phase corrosion agent of as-cast Zircaloy-2 alloy consists of hydrofluoric acid (HF), nitric acid (HNO 3 ) and water (H 2 O) composition, the volume proportion of its each component is: 10 μ l (40wt.%) HF+60ml (65wt.%) HNO 3 +60ml H 2 O. The disposition method of this etchant is the same as embodiment 1.

[0050] The second phase corrosion method of as-cast Zircaloy-2 alloy comprises the steps:

[0051] ① Firstly, a block sample with a size of 10*10*10mm is intercepted by wire cutting method;

[0052] ② Grinding with 150#, 400#, 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com