Patents

Literature

71results about How to "Good for wear protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

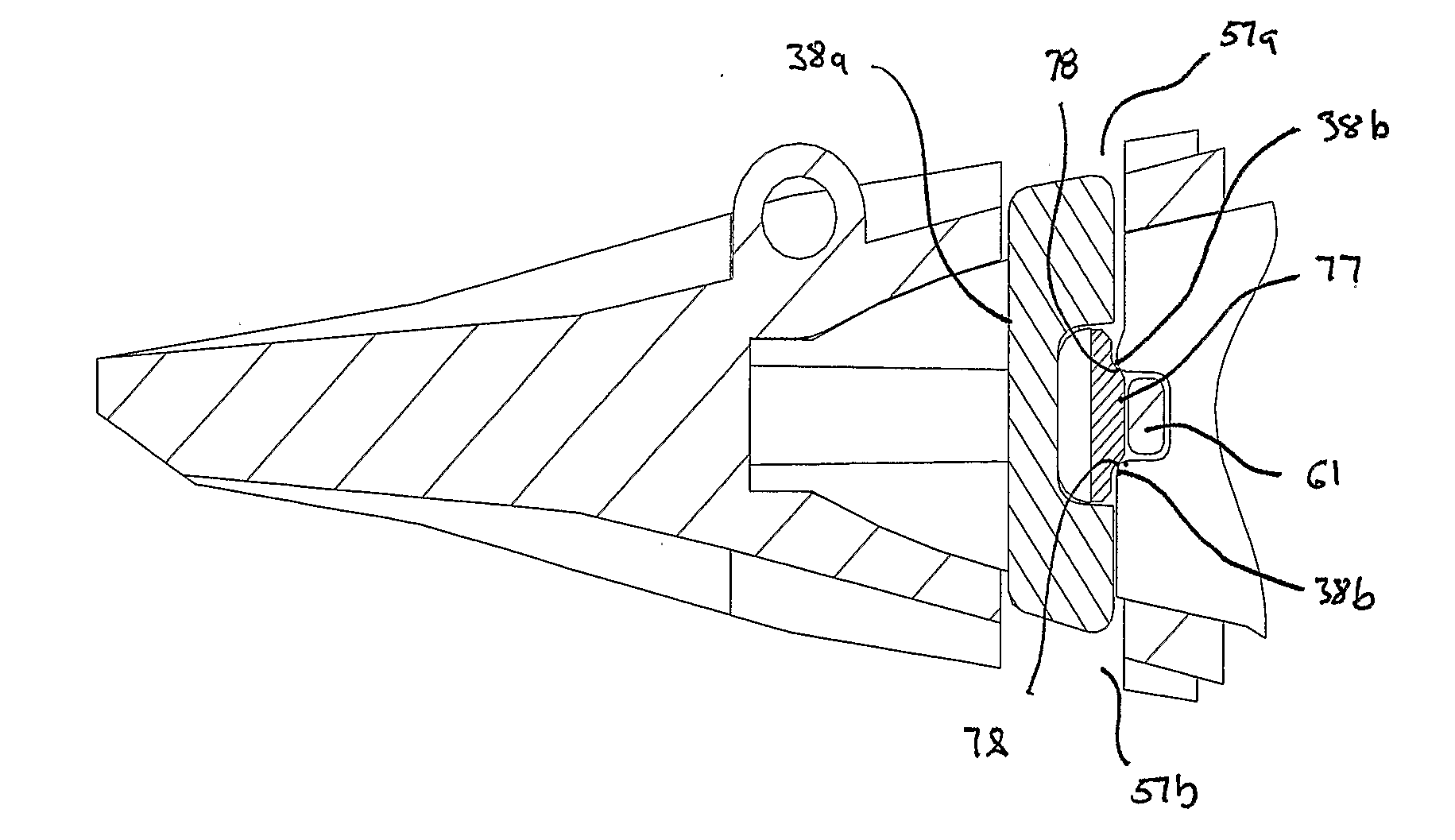

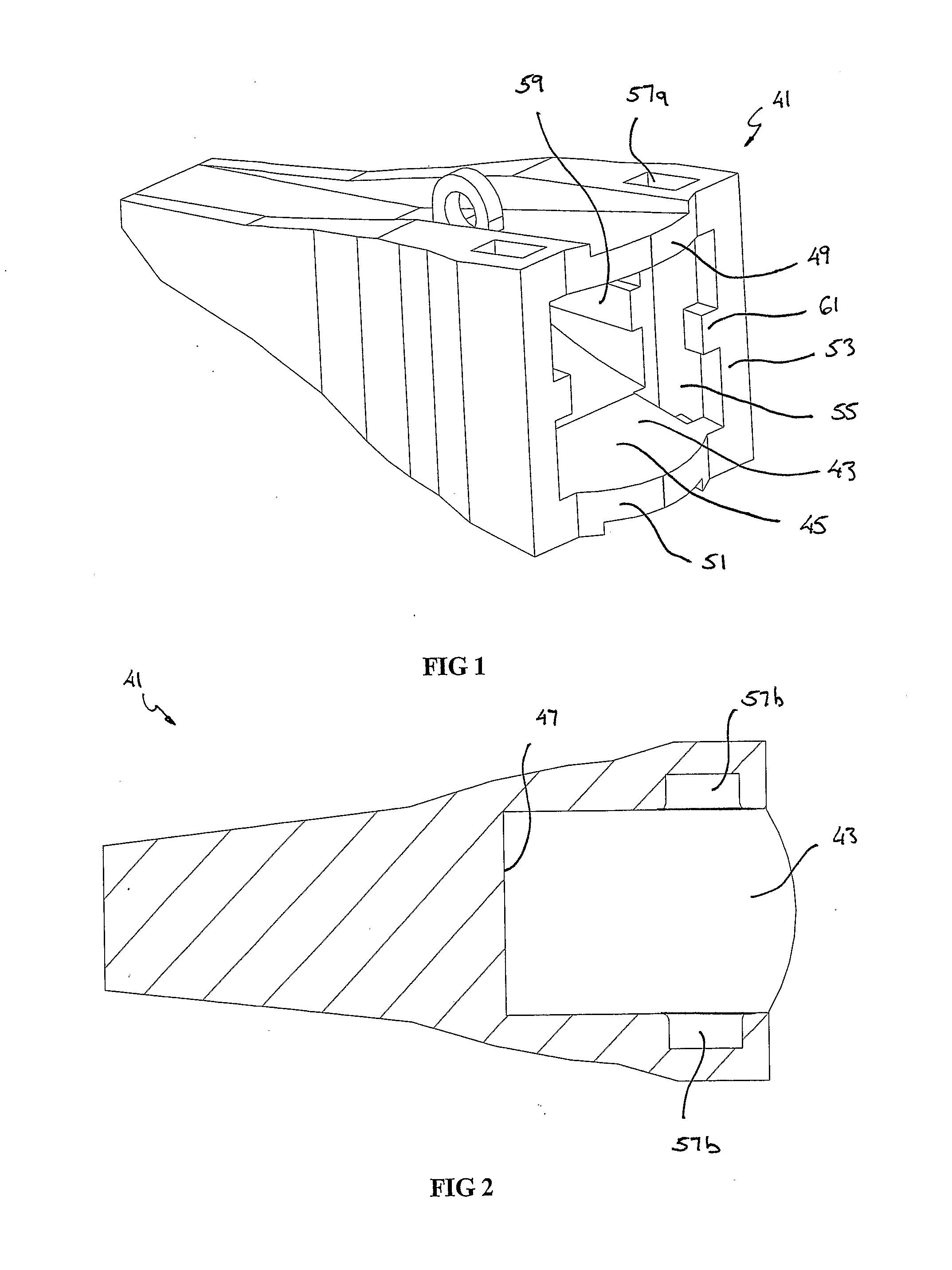

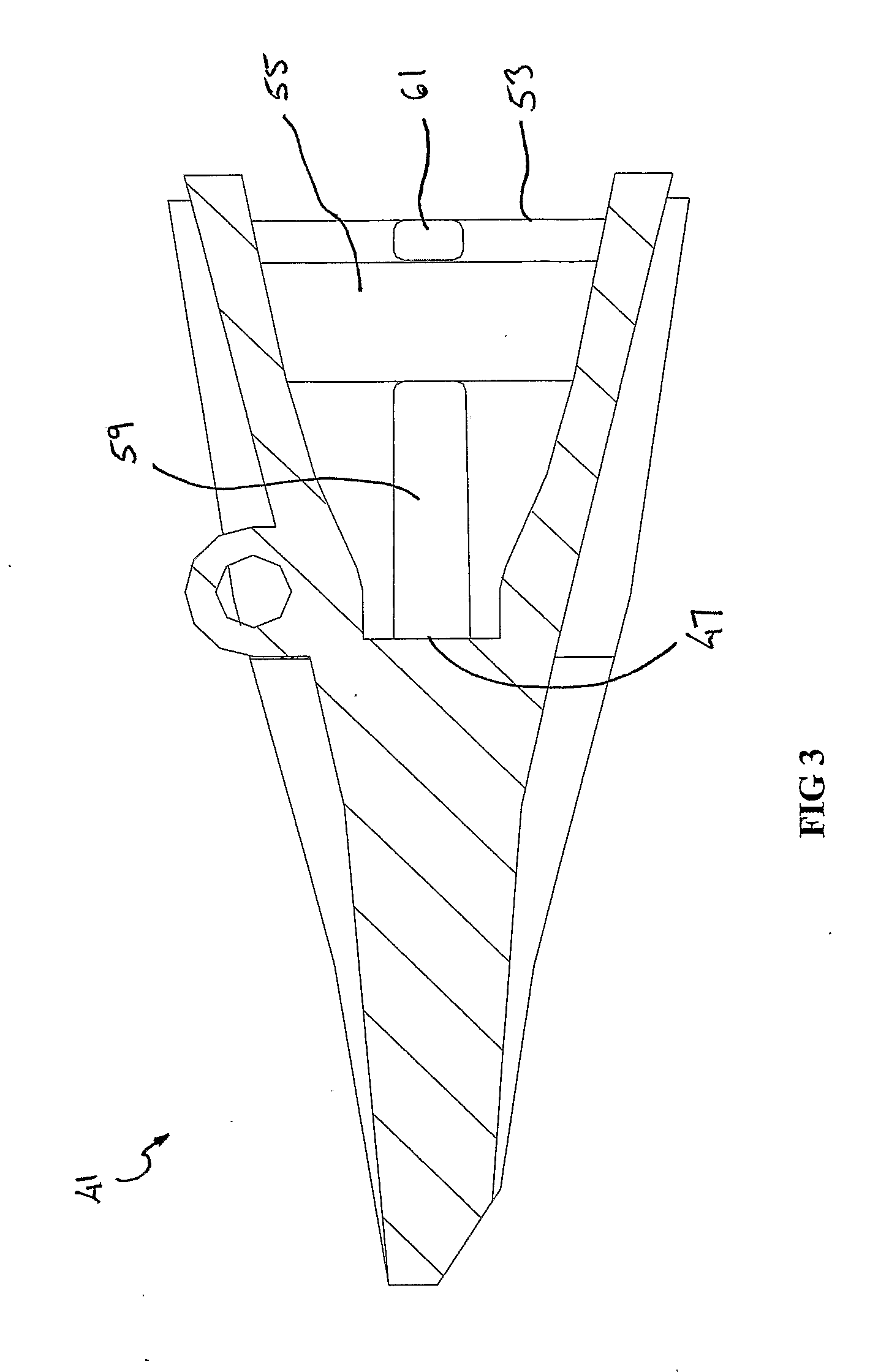

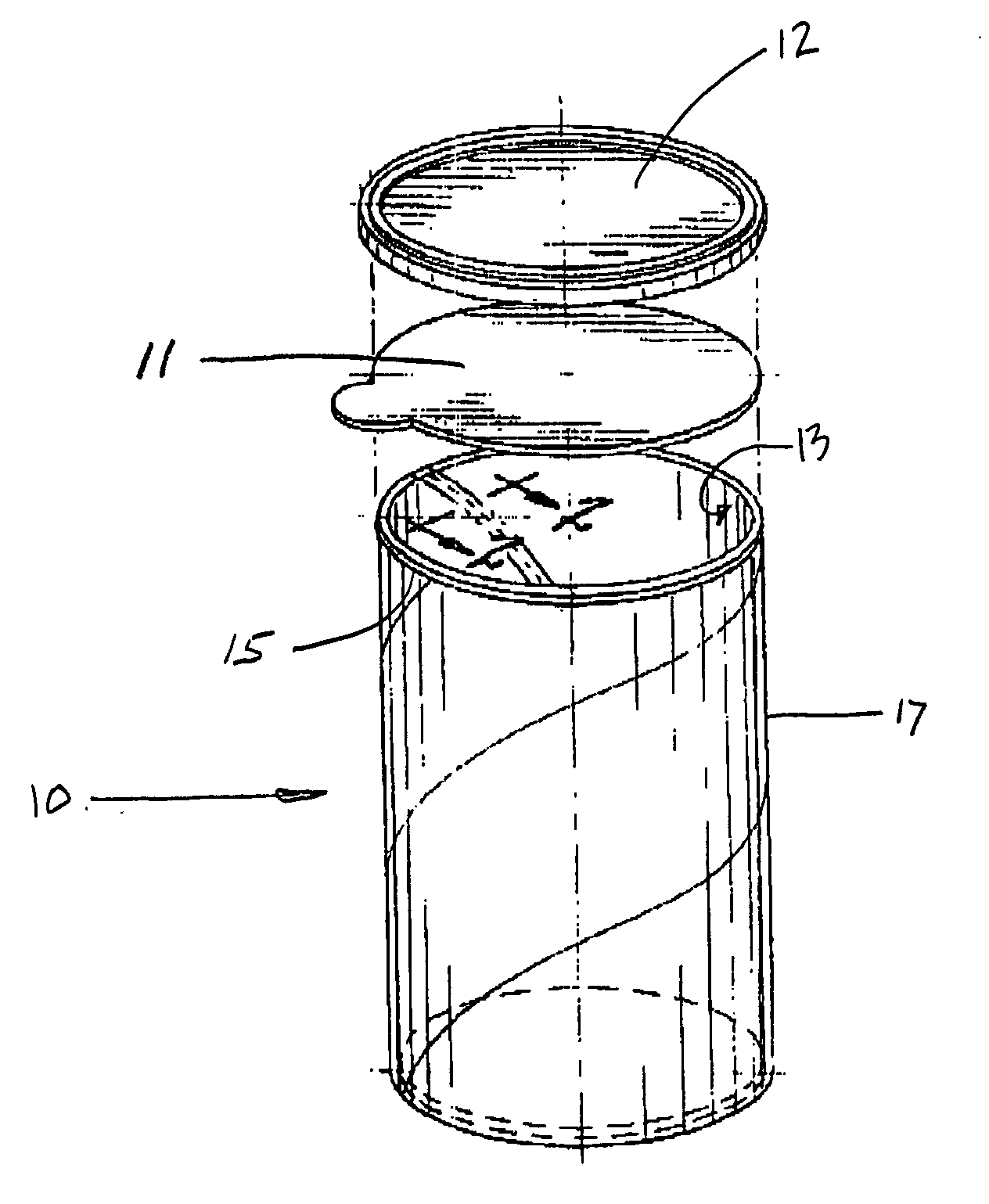

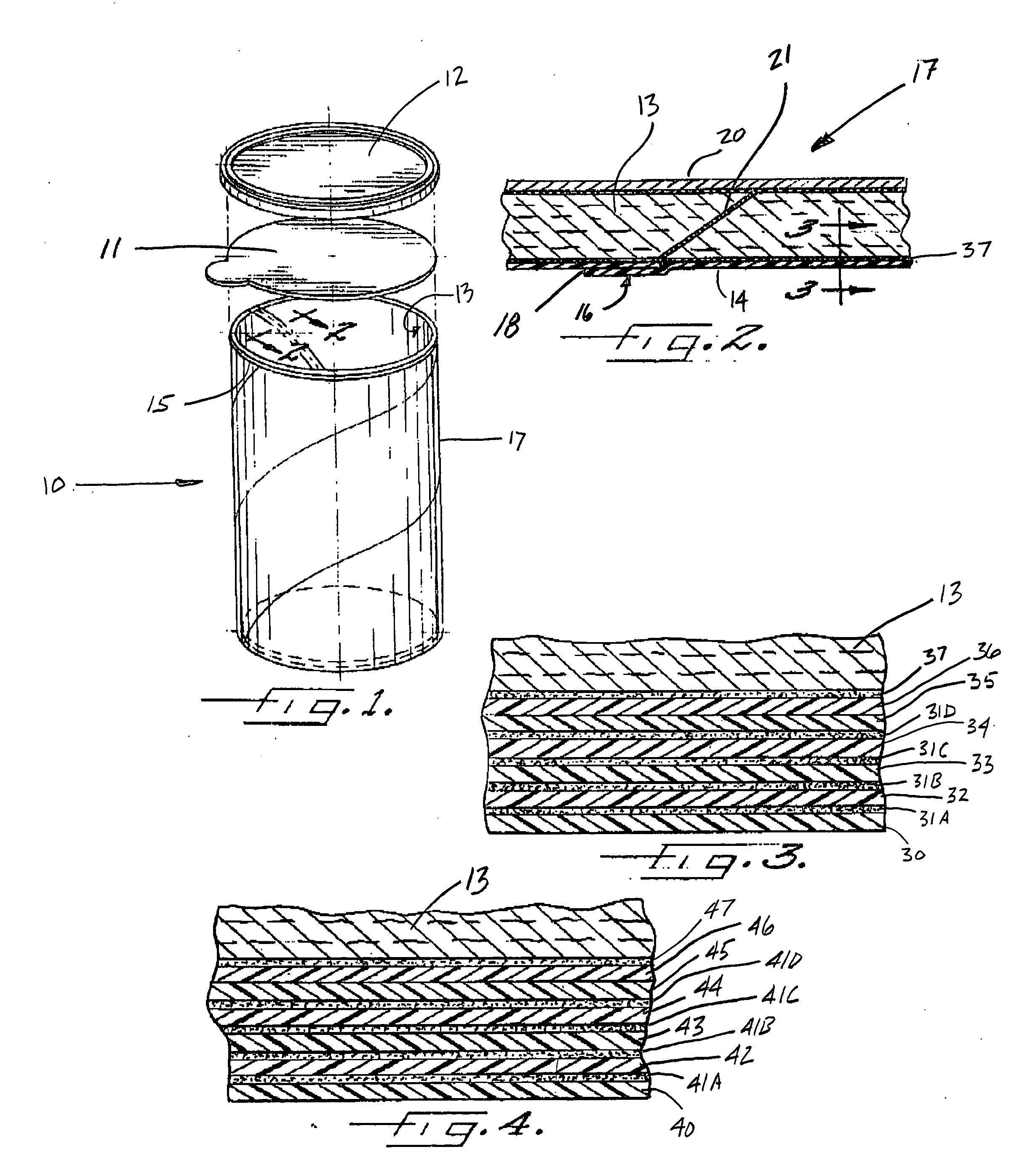

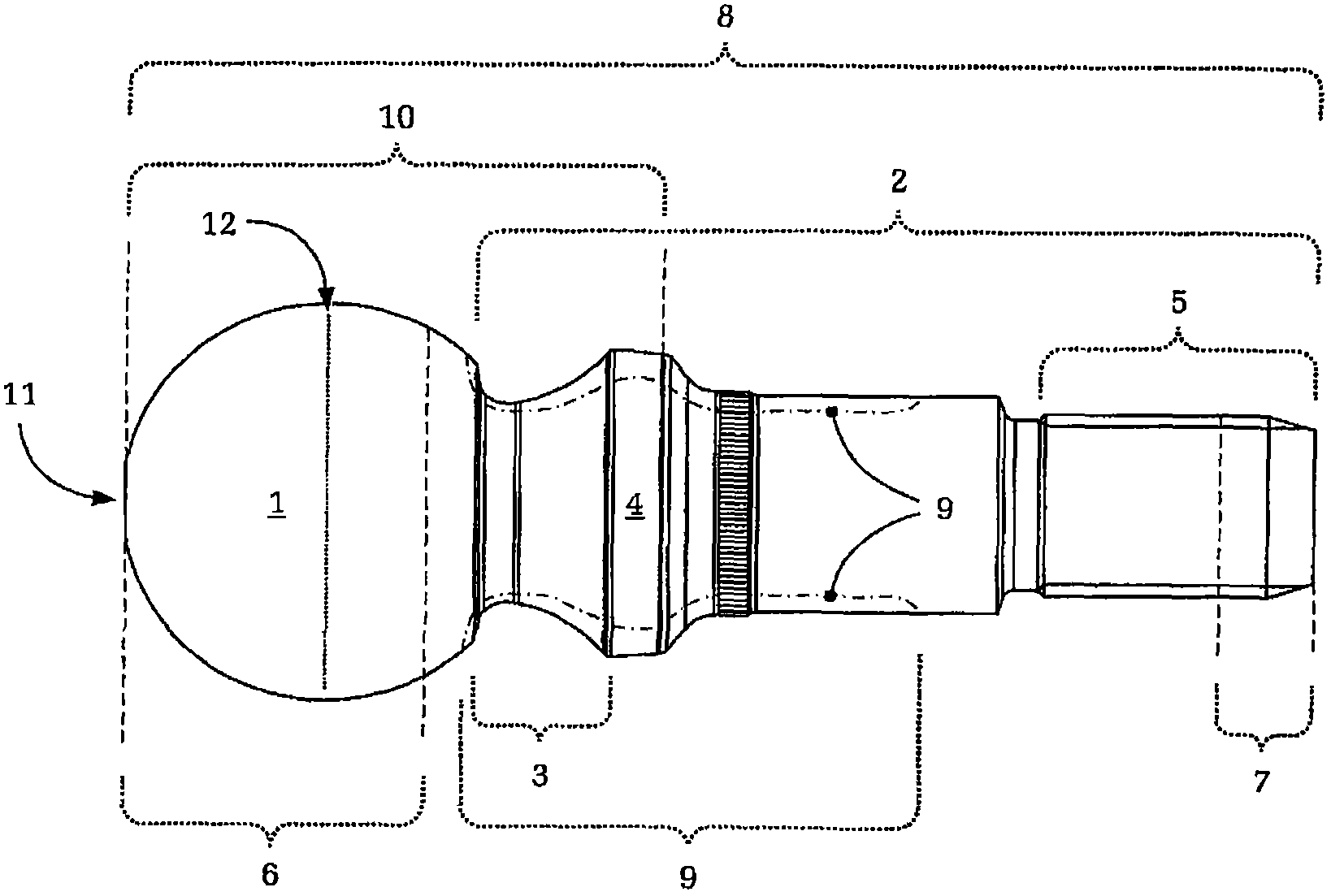

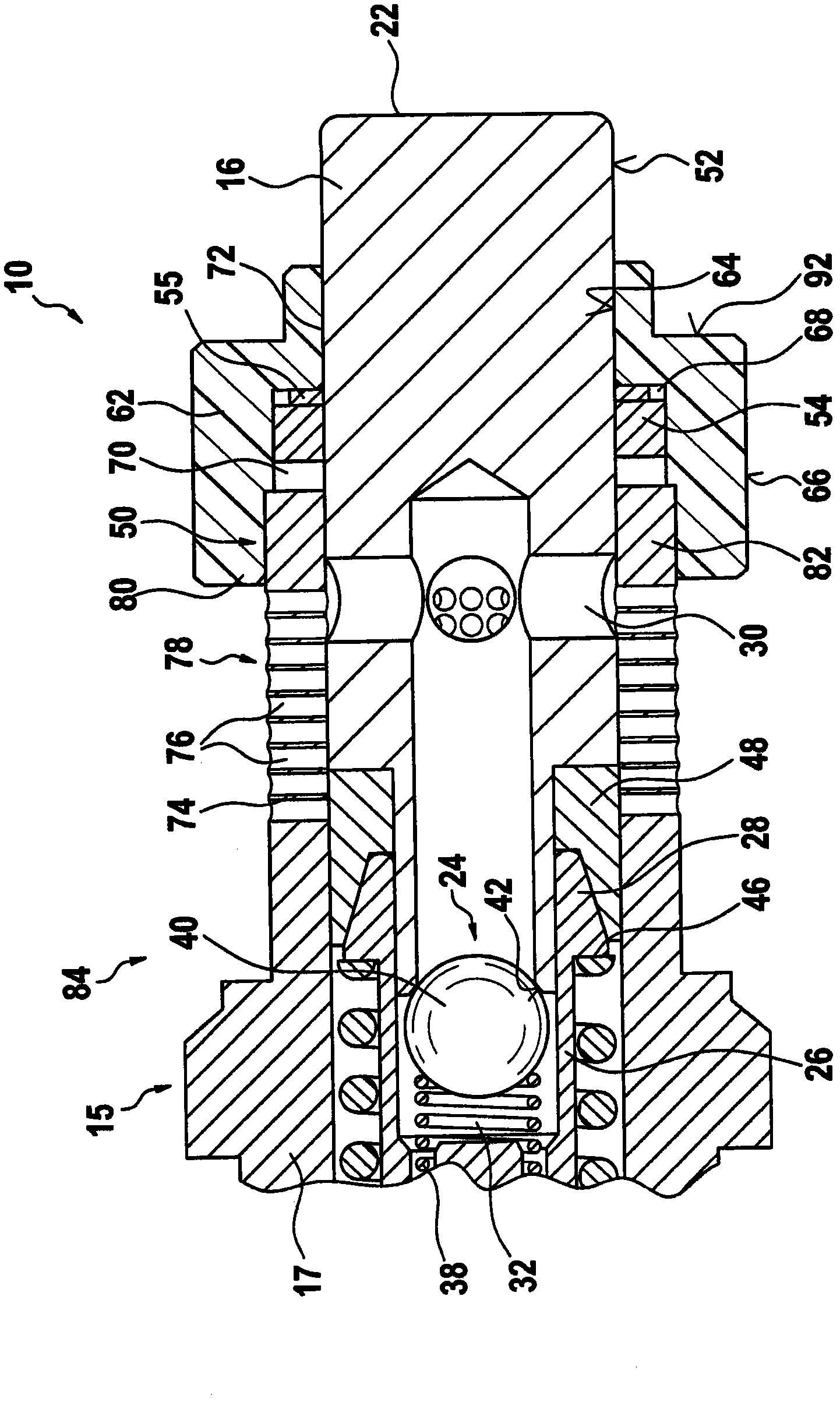

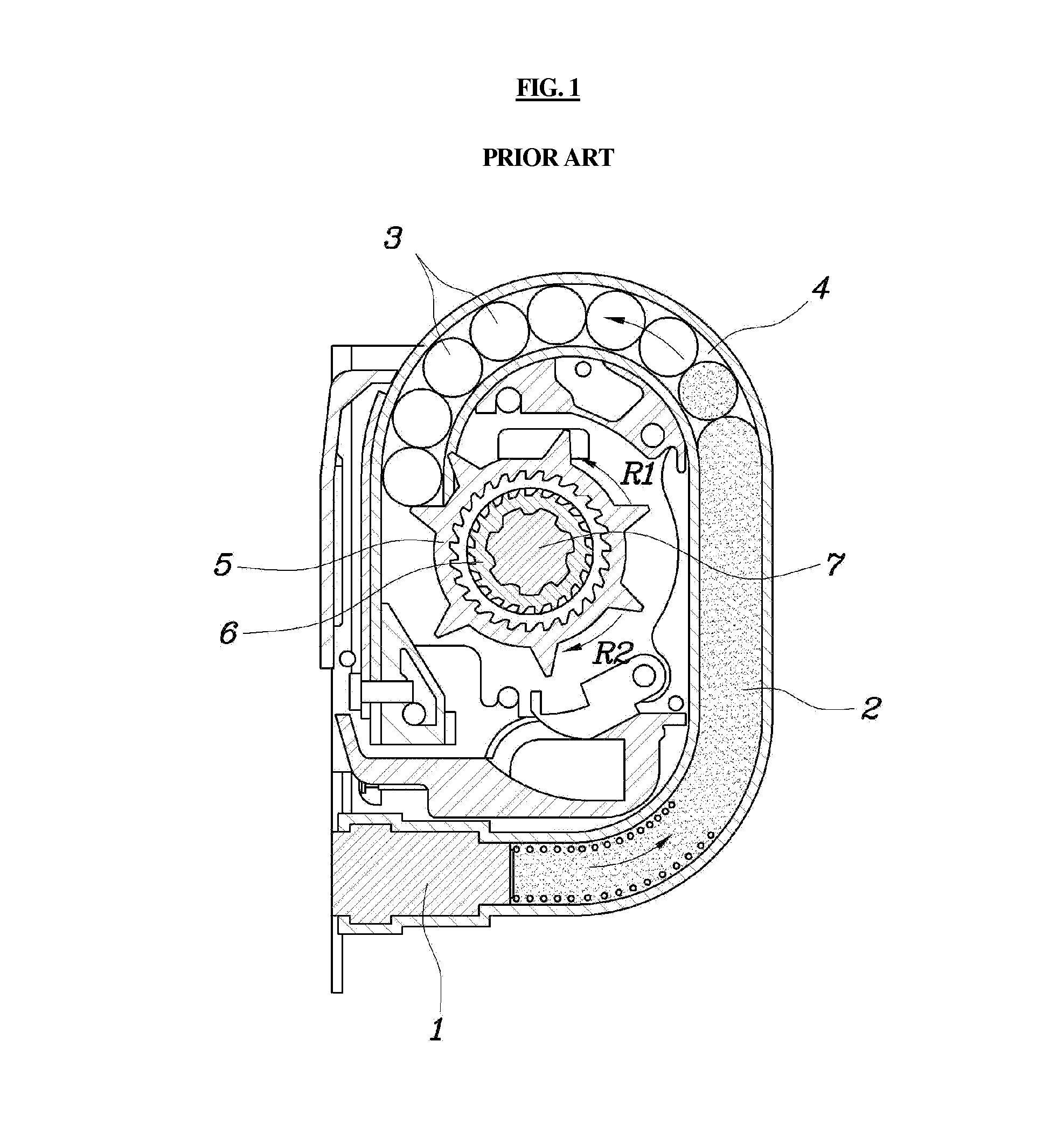

Tooth and Adaptor Assembly

Abstract A tooth and adaptor assembly (11) for use on earthmoving machinery, the assembly comprising an adaptor (21) adapted to be secured to a bucket or like component on the earthmoving machinery. The adaptor (21) comprising a nose (27) having an at least one sidewall (35) incorporating a first channel (37) and a second channel (39) angled relative to each other. The assembly (11) also a tooth (41) adapted to be received on the adaptor (41) and releasably secured thereto. The tooth comprises a socket (43) having sidewalls (53). At least one sidewall (53) incorporates a third channel (55) at an angle complementary to the second channel (39), such that when assembled the two channels (39, 55) co-operate to define an enclosure (91). An upper wall (49 of the socket (43) has at least one aperture (57) therethrough, and which is aligned with the third channel (55). The assembly (11) further comprises at least one locking mechanism (71) for locking the tooth (41) to the adaptor (21). The locking mechanism (71) having at least one projection (77) and adapted to be received through the aperture (57). During assembly the projection (77) moves inwardly with respect to the locking mechanism (71) as it enters the enclosure, the locking mechanism (71) moving towards its normal extended position when the projection (77) aligns with the first channel (37) wherein the assembly (11) is in its locked condition.

Owner:BRADKEN OPERATIONS

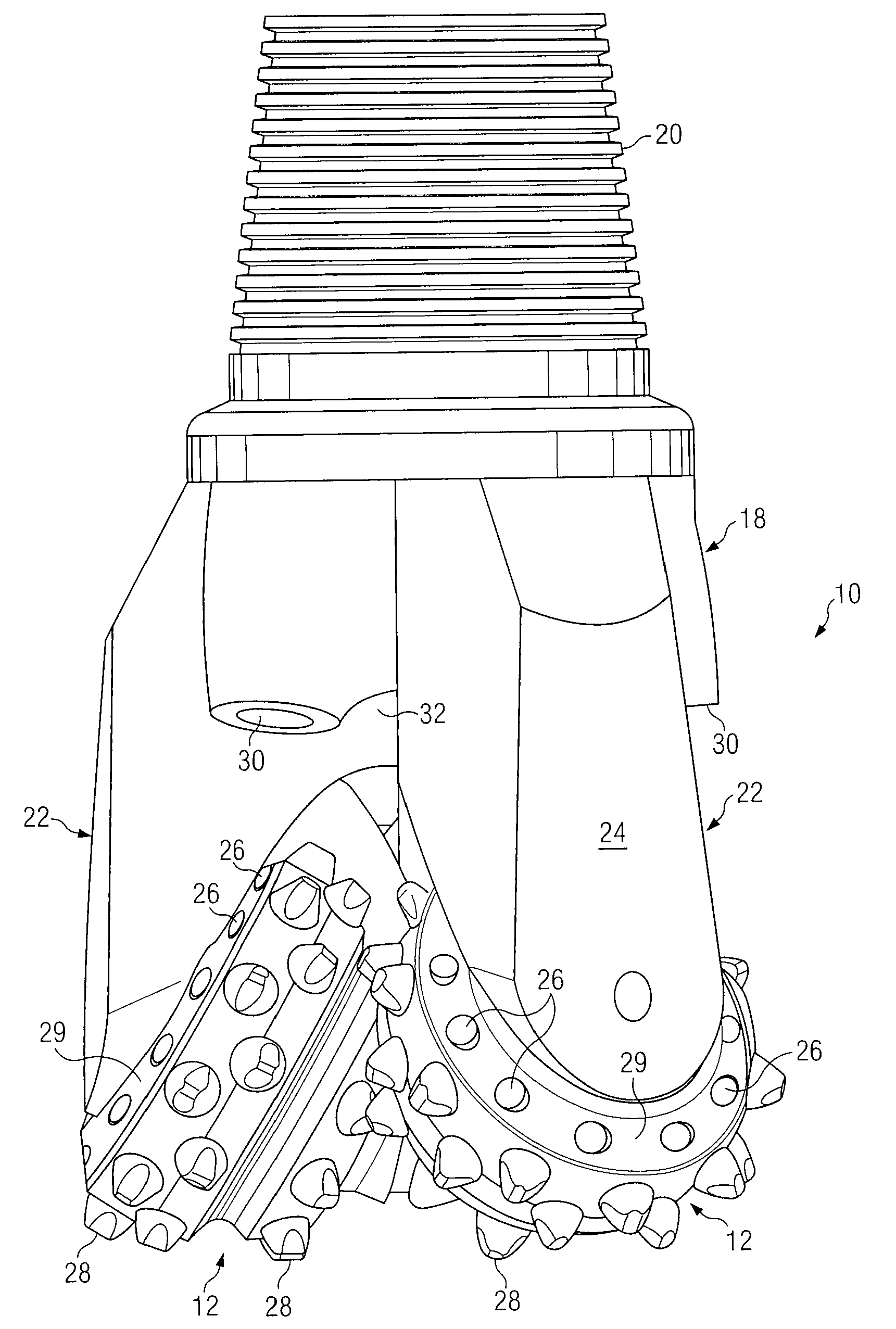

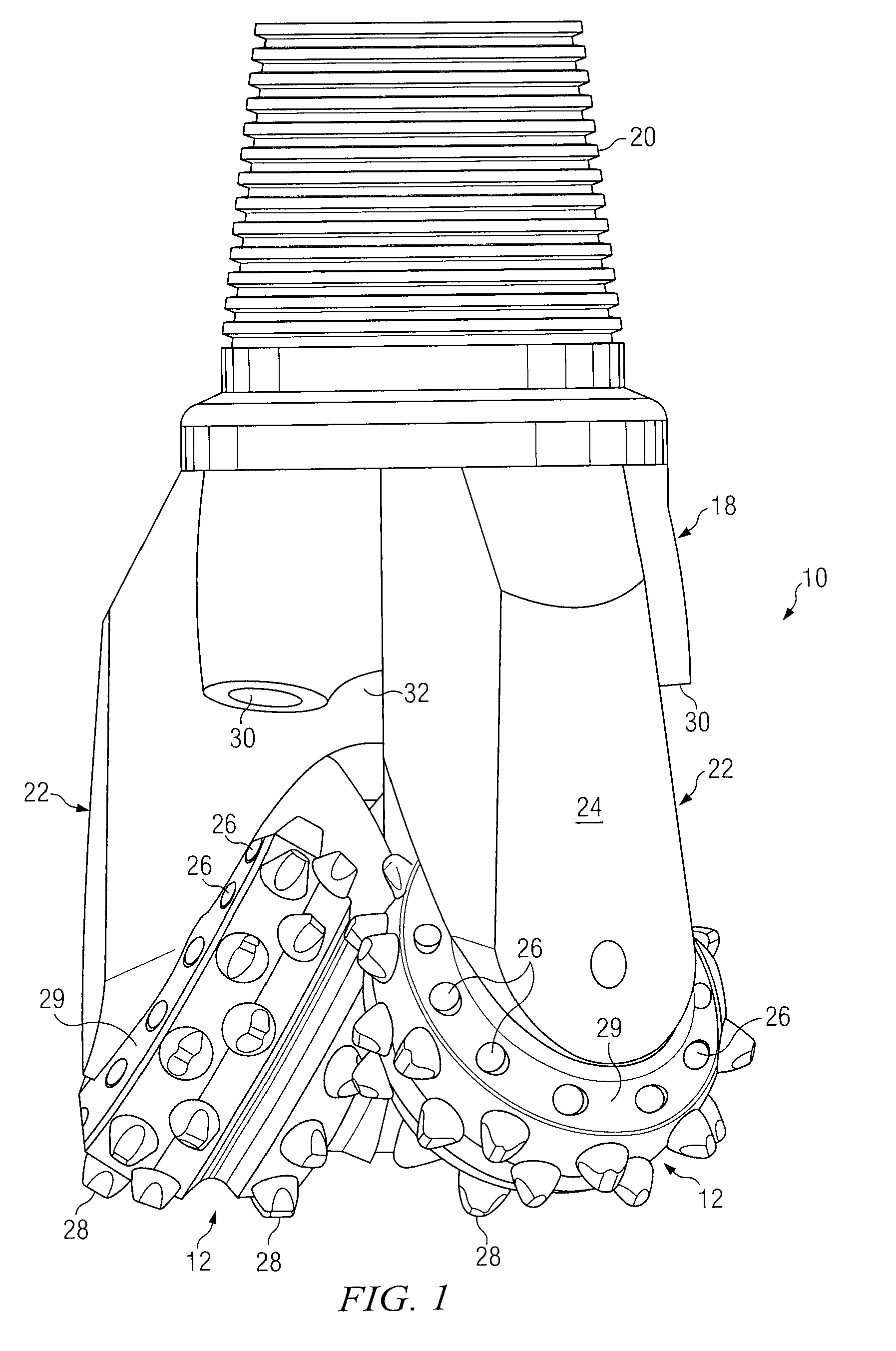

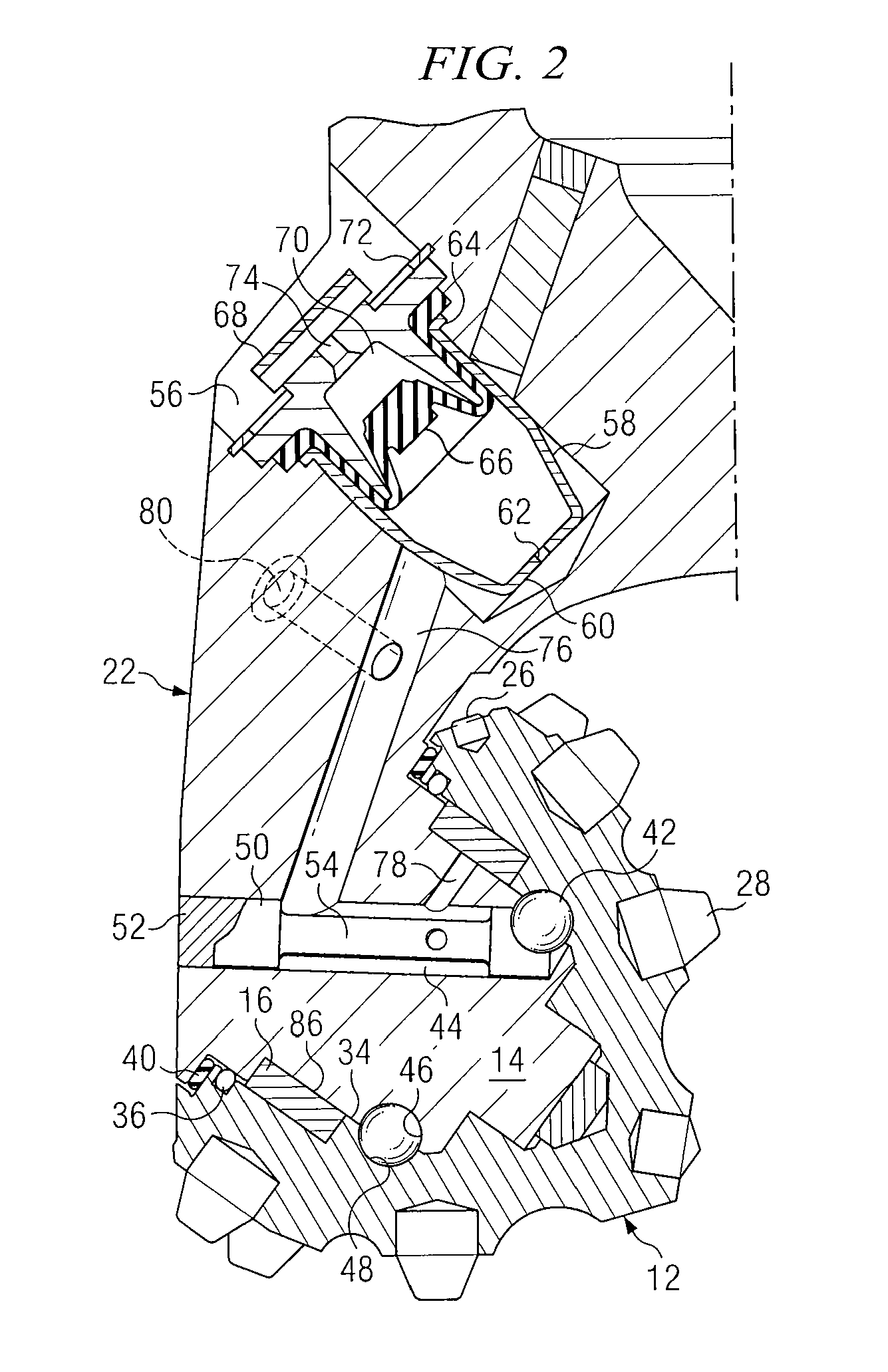

High performance rock bit grease

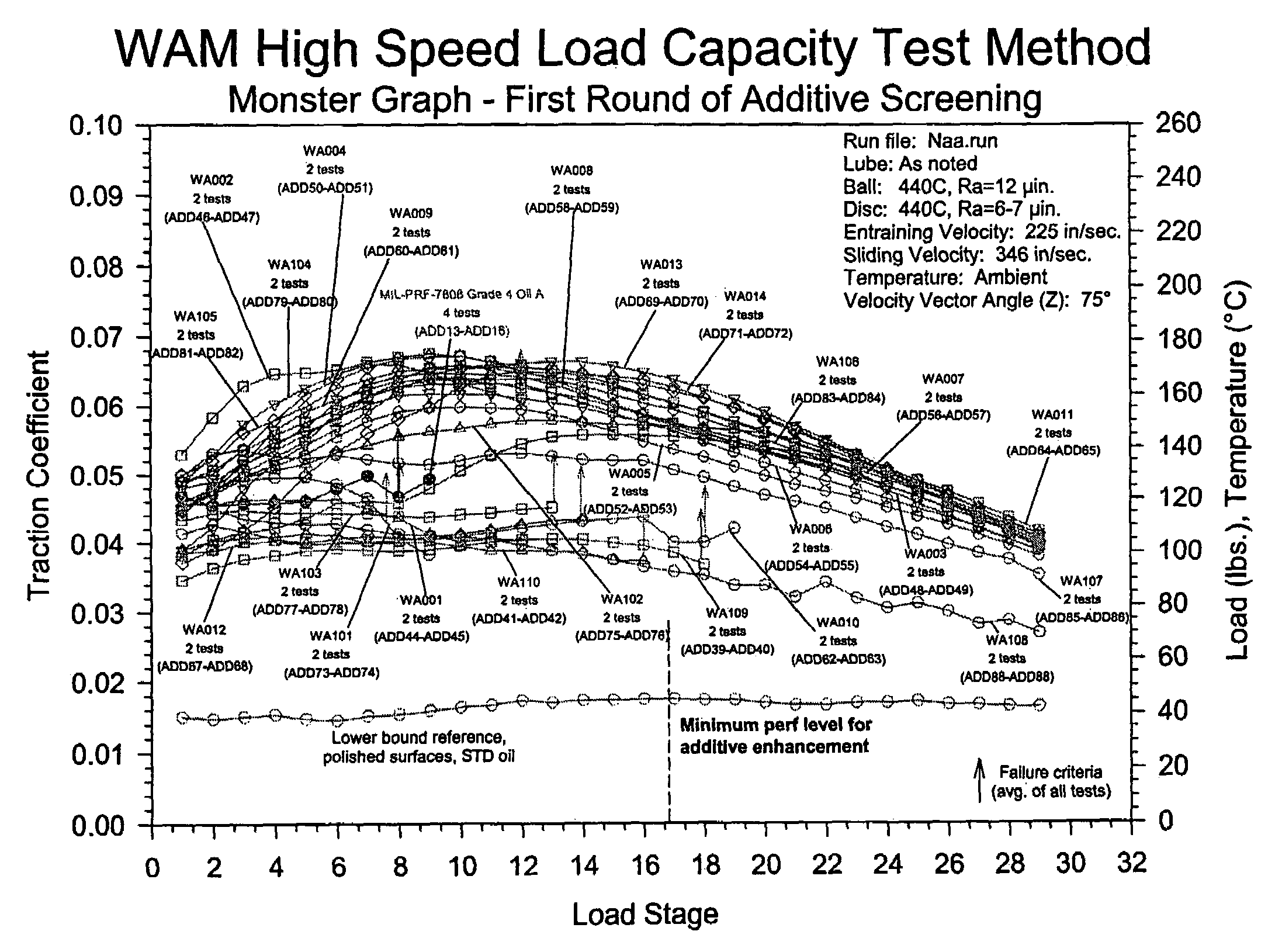

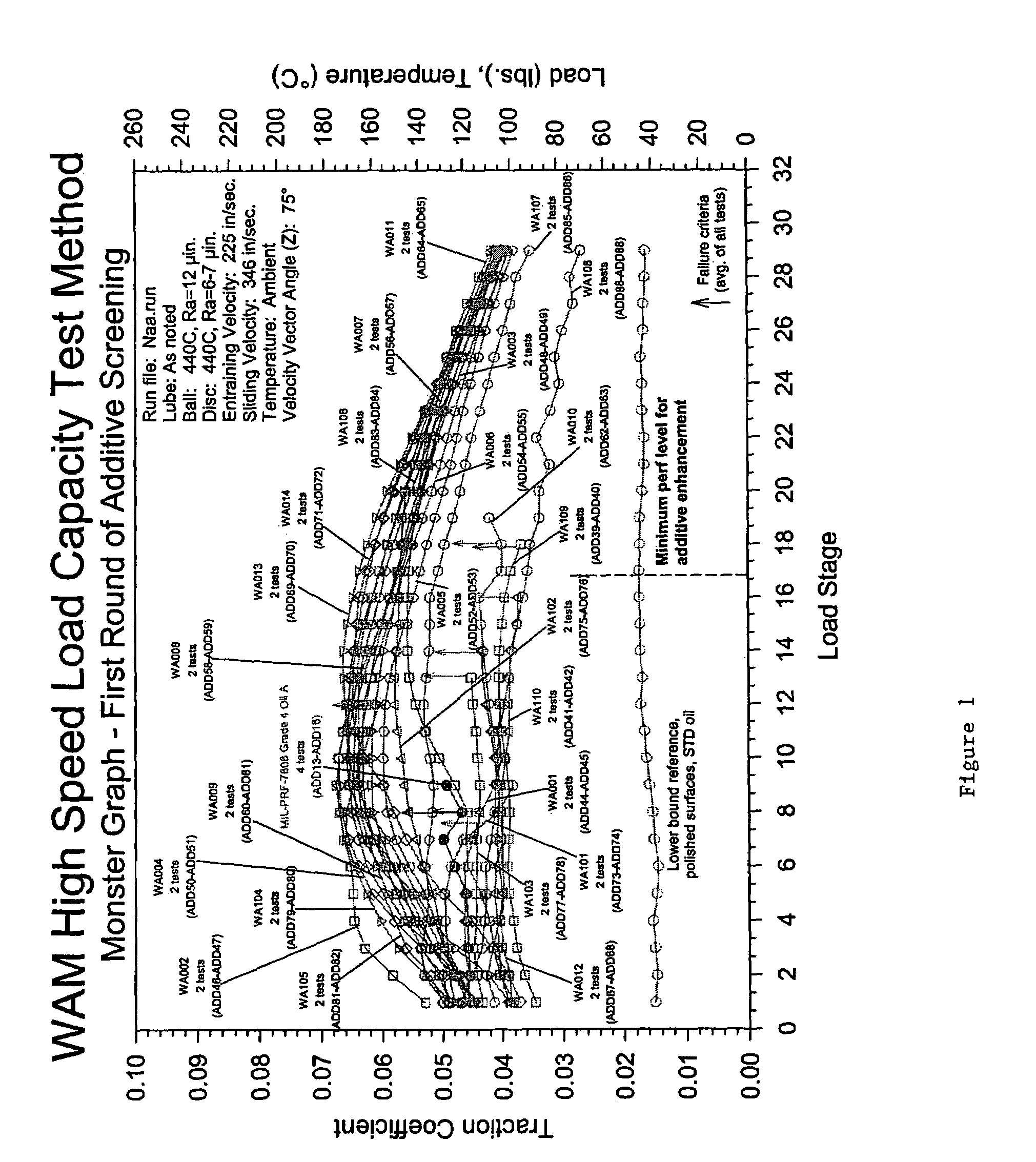

InactiveUS20110048809A1Improved load carryingGood for wear protectionDrill bitsAdditivesSulfonateEngineering

The present disclosure relates to greases containing metal sulfonate thickeners. In one example the thickener may be a calcium sulfonate thickener. In other examples grease may contain a combination of a metal sulfonate thickener and another thickener, such as a metal complex soap grease, detergent, or non-soap thickener. The grease may be formulated to meet specific performance criteria relevant to lubrication of a roller cone drill bit in downhole conditions. The disclosure also relates to a roller cone drill bit containing a grease of the disclosure.

Owner:HALLIBURTON ENERGY SERVICES INC

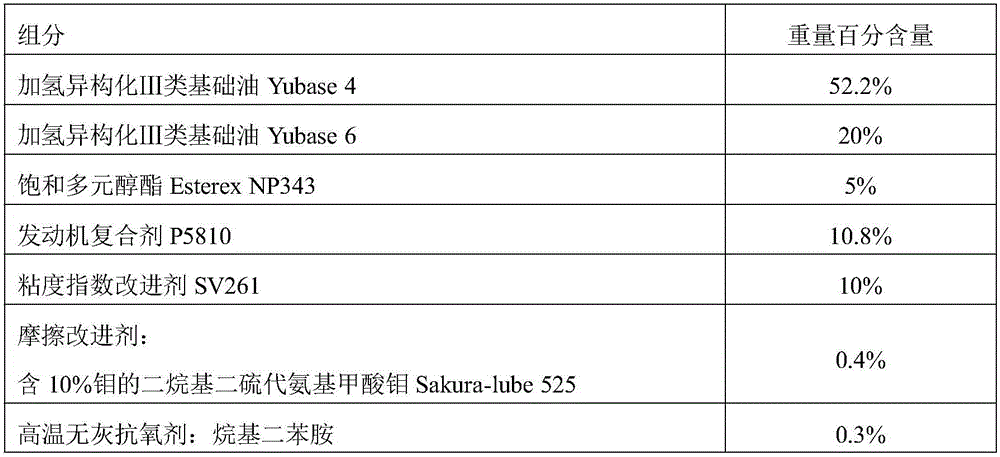

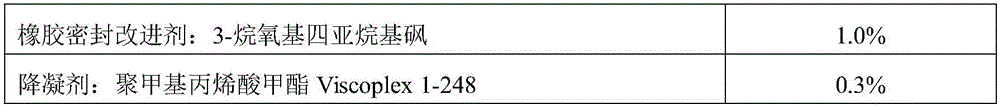

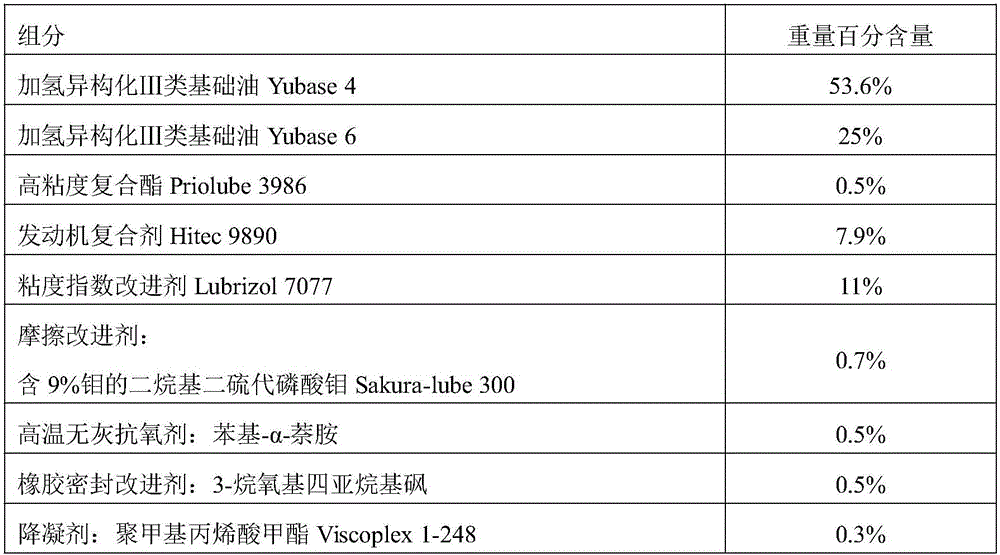

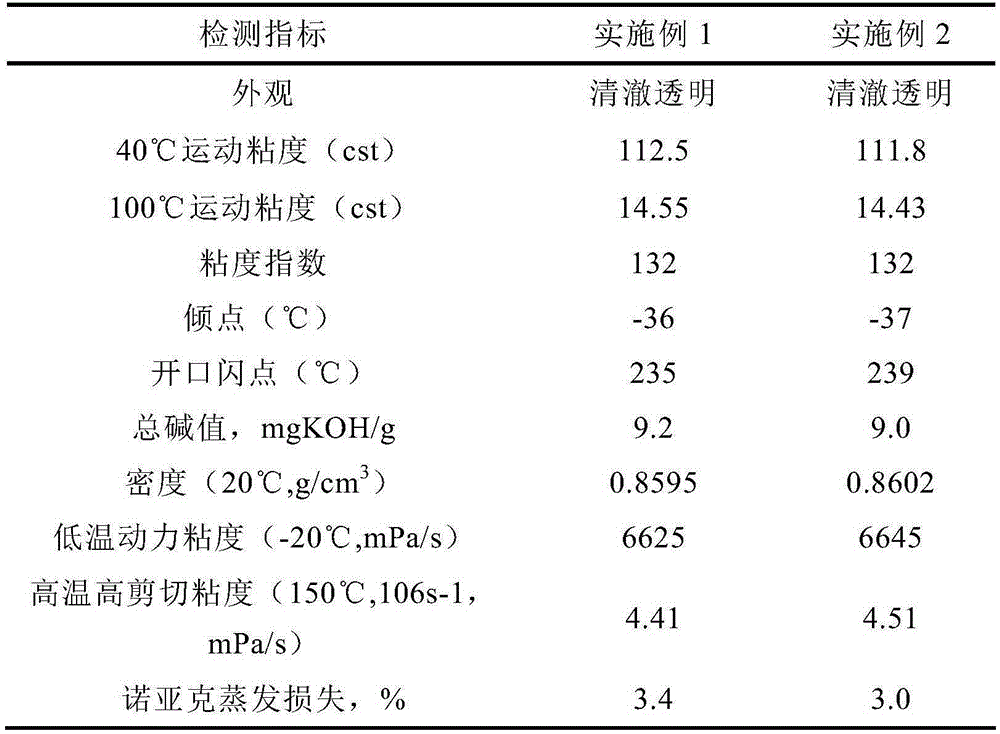

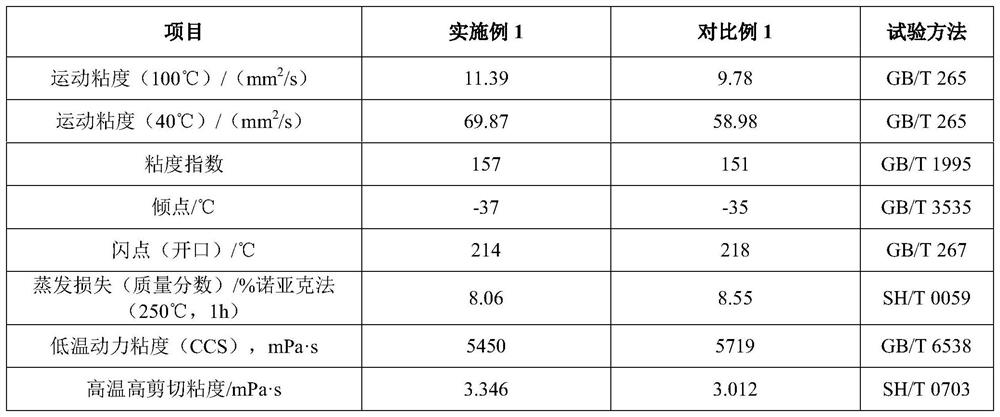

Lubricating oil composition for turbocharging direct injection engine

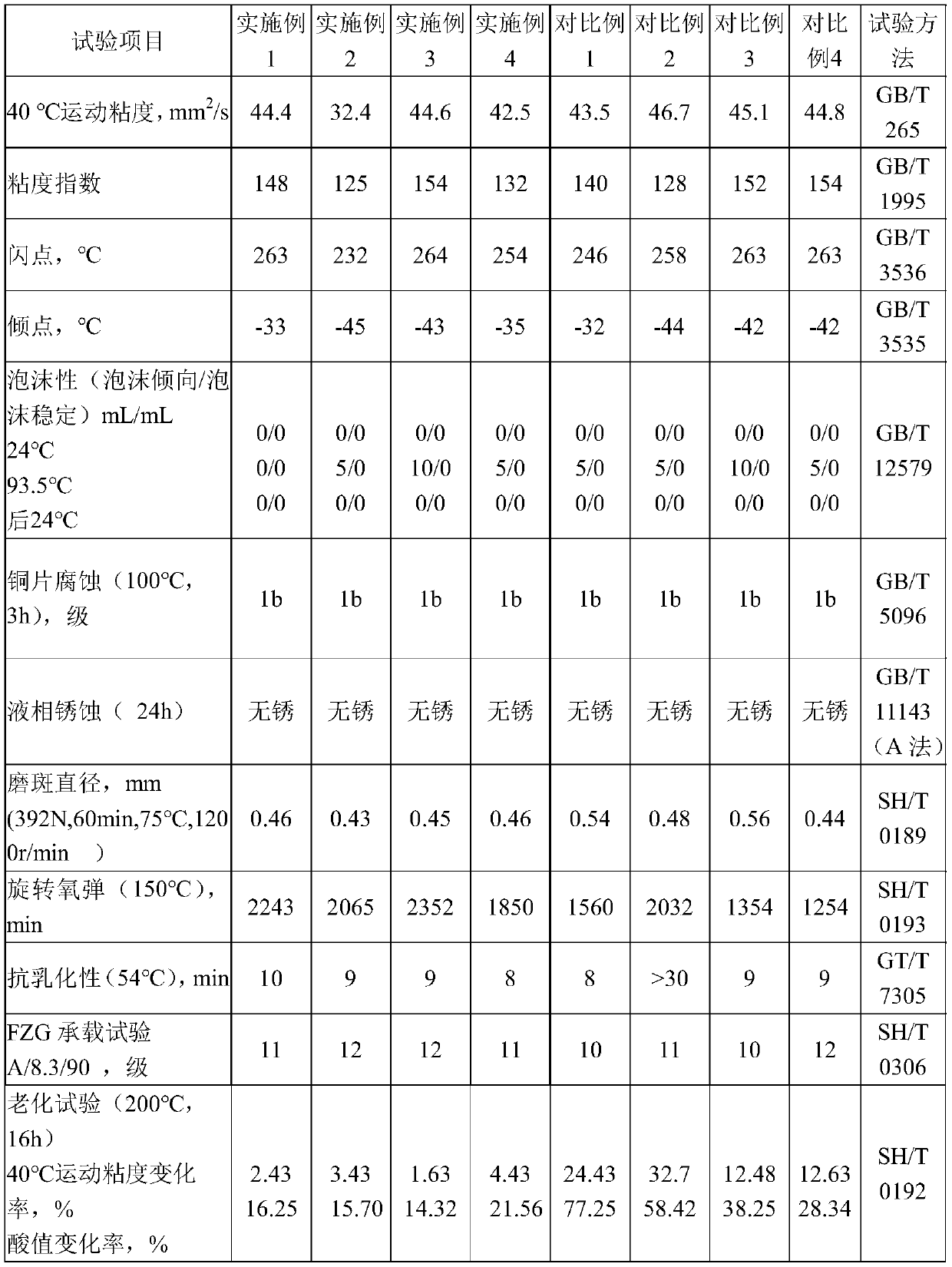

ActiveCN106190505AImprove high temperature detergency and dispersibilityGood for wear protectionLubricant compositionEngineeringViscosity index

The invention discloses a lubricating oil composition for a turbocharging direct injection engine. The composition is prepared from, by weight, 75-85% of base oil, 7-12% of engine oil complexing agent, 4-12% of viscosity index improver, 0.3-1.0% of friction improver, 0.3-1.0% of high-temperature ashless antioxidant, 0.3-2% of rubber seal improver and 0.1-0.5% of pour point reducer. According to the lubricating oil composition, the content of calcium, phosphorus and molybdenum in finished lubricating oil is reasonably controlled, so that the obtained product has excellent high-temperature oxidation resistance and piston cleanliness, high grease controllability and remarkable anti-wear protective property; the occurrence rate of low-speed preignition of the turbocharging direct injection engine can be effectively reduced, the fuel economy of vehicles can be improved, and the service life of the engine can be prolonged.

Owner:JIANGSU LOPALTECH

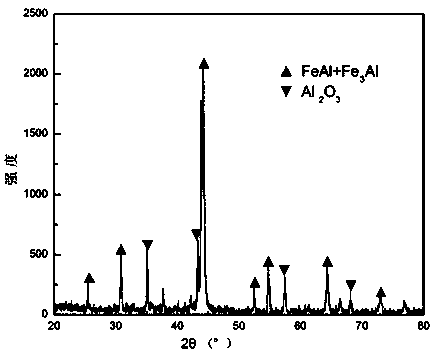

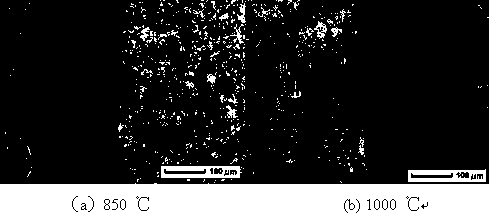

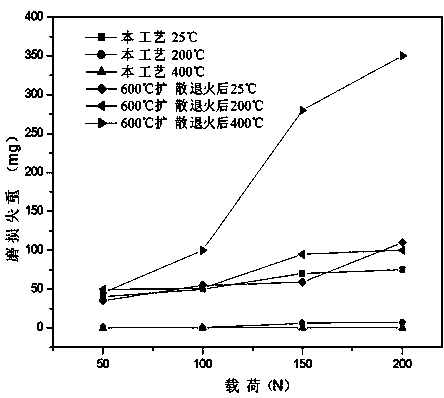

Preparation method of high-temperature wear-resistant coating on surface of steel piece

ActiveCN103628013AImprove corrosion resistanceImprove high temperature resistanceHot-dipping/immersion processesWear resistantWear resistance

The invention relates to the technical field of steel piece surface treatment, and in particular relates to a preparation method of a high-temperature wear-resistant coating on the surface of a steel piece. According to the preparation method, a composite coating of a Fe-Al intermetallic compound and a little Al2O3 is obtained through liquid dip aluminum plating and subsequent compound dispersion treatment. The process flow of the preparation method comprises pretreatment (alkali cleaning, acid pickling and assisted plating), dip aluminum plating and dispersion treatment, wherein the dip aluminum plating is carried out for 1-10 minutes in liquid aluminum at a temperature ranging from 720 DEG C to 800 DEG C; and compound dispersion annealing which is carried out in a protective atmosphere or in vacuum at a temperature ranging from 850 DEG C to 1100 DEG C for 1-5 hours, and in air at a temperature ranging from 400 DEG C to 600 DEG C for 20-30 minutes. The temperature and the time of the dispersion treatment are adjusted so that composite wear-resistant coatings containing the intermetallic compound and a little Al2O3 and are different in thickness can be obtained. The preparation method has the characteristics of simple and convenient process, low cost, high coating binding force, excellent high-temperature wear resistance and the like, and thus can be widely applied to surface strengthening of high-temperature wear resisting steel pieces.

Owner:东台市溱东科技发展有限公司 +1

Long-life air compressor oil composition

InactiveCN111234906AInhibition of viscosity growthGood extreme pressure and anti-wear propertiesLubricant compositionProcess engineeringBase oil

The invention discloses a long-life air compressor oil composition. The long-life air compressor oil composition comprises the following components in percentage by weight: 0.6-1.5% of an ashless composite additive, 0.3%-1.0% of an antioxidant, 0.1%-0.5% of an extreme pressure anti-wear agent, and 0.002% to 0.005% of an anti-foaming agent, with the balance being base oil, wherein the base oil comprises a mixture of III-type hydrogenated base oil and alkyl naphthalene base oil or polyether base oil. The air compressor oil provided by the invention has excellent high-temperature detergency and oxidation resistance, and can effectively avoid the generation of oil sludge and carbon deposit; excellent wear resistance and hydrolytic stability are achieved, and excellent wear resistance protection is provided for the air compressor; the excellent heat conduction efficiency can help to reduce the temperature and oil temperature of the compressor; and the oil change period is long and can reach6000 hours or above. In addition, compared with known long-life air compressor oil, the air compressor oil has the advantages of being low in cost, simple in preparation method, easy to popularize and apply on a large scale and the like.

Owner:LONGPAN LUBRICATION NEW MATERIAL TIANJIN CO LTD +1

Surface activation by plasma jets for thermal spray coating on cylinder bores

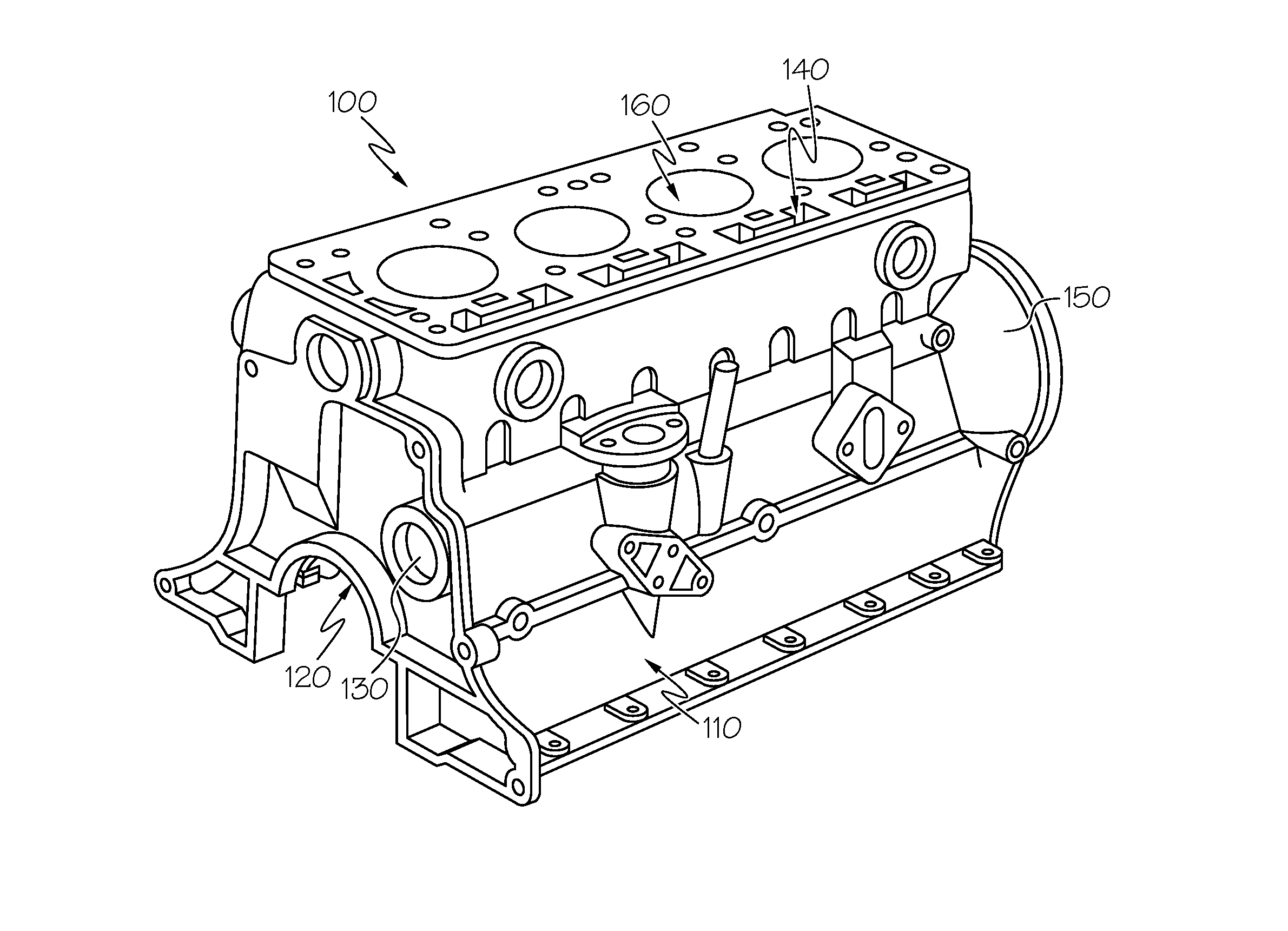

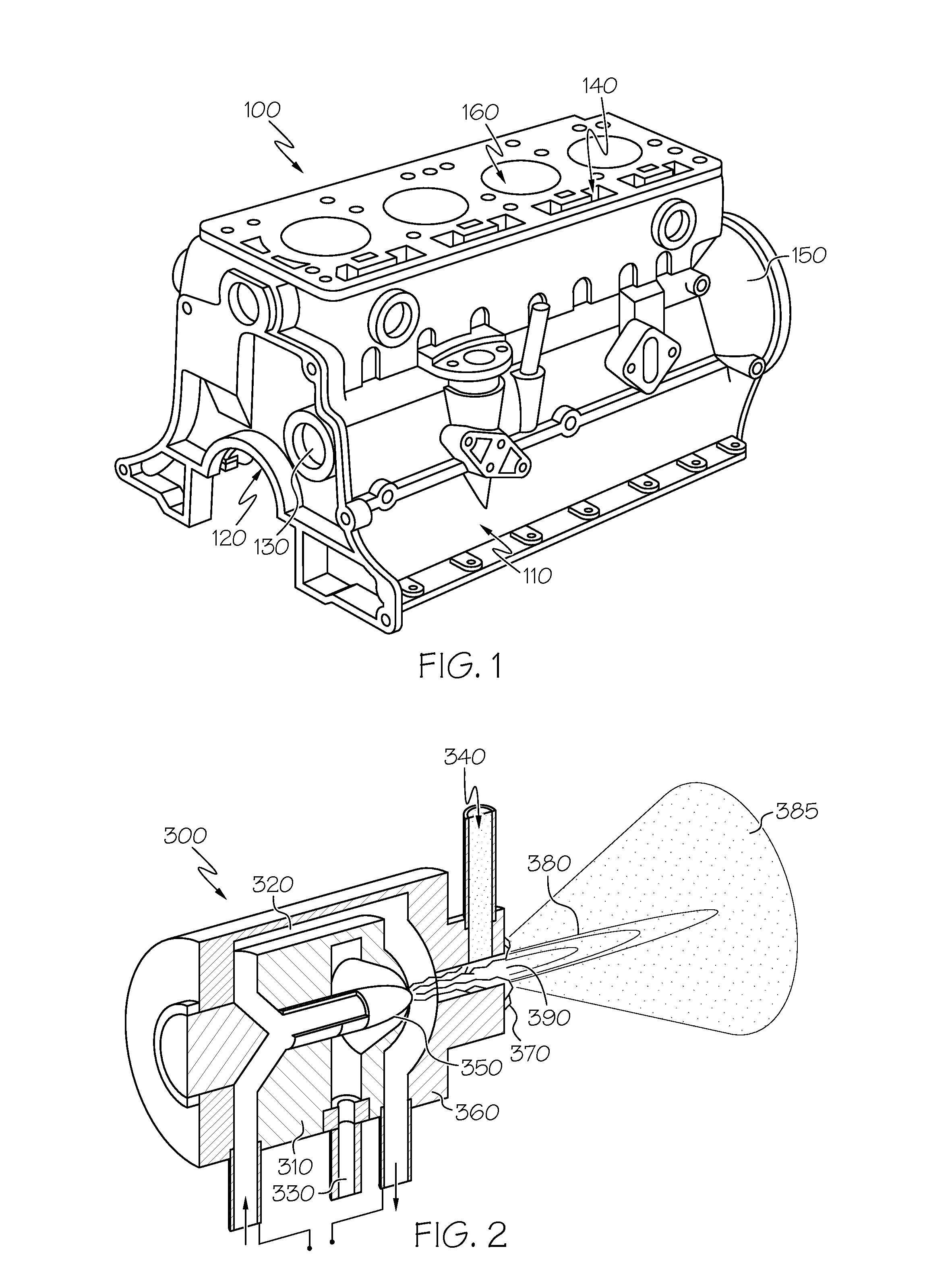

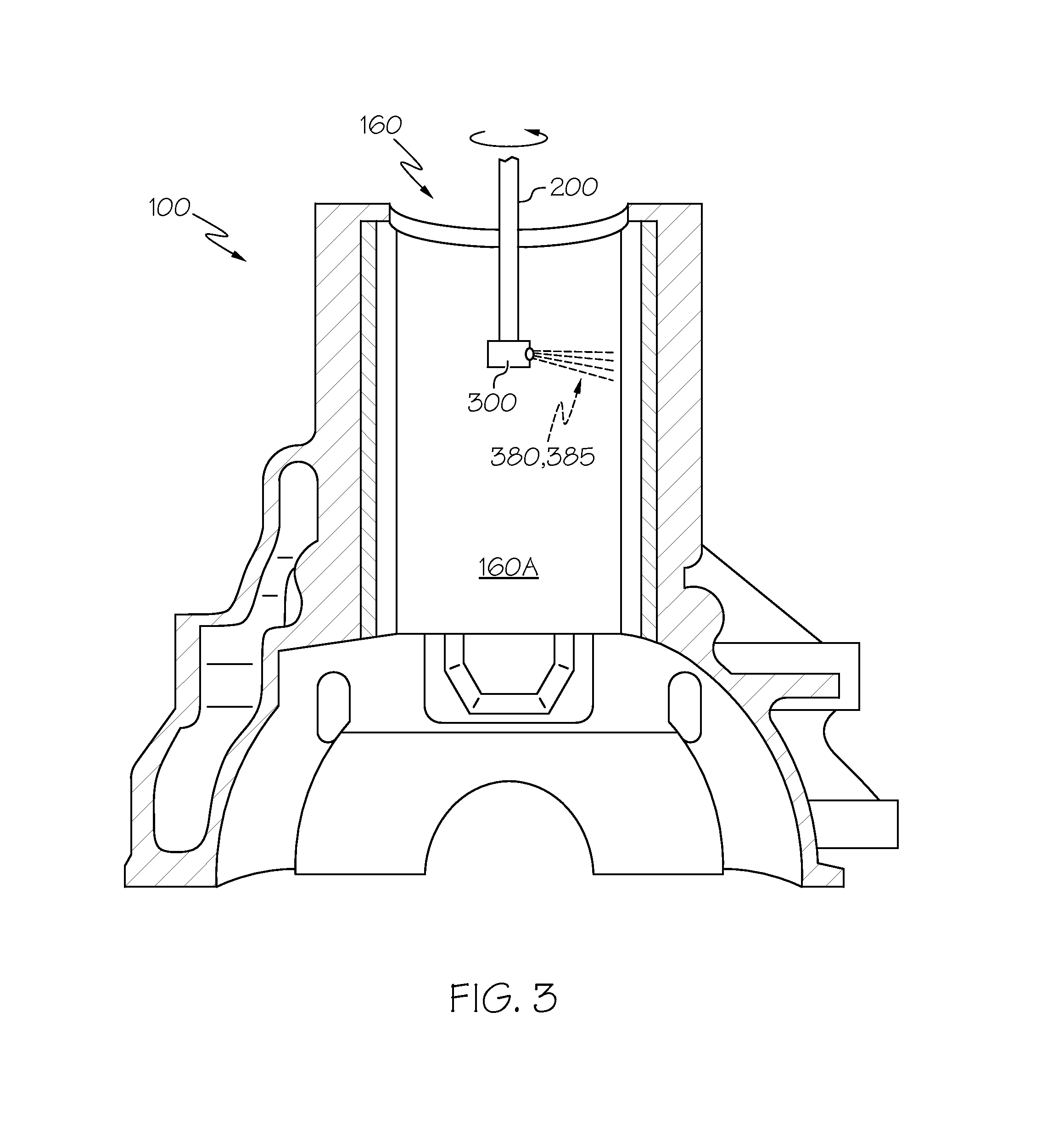

InactiveUS20160130691A1Improve surface propertiesLower power settingsLiquid surface applicatorsMolten spray coatingPlasma jetThermal spraying

A method of activating the surface of an aluminum-based substrate. This method includes cleaning the substrate surface, and operating a plasma spraying device such that a air plasma jet produced by the device is accelerated toward the surface so that it removes or decomposes any remaining oxides and other surface contaminants. In one form, the surface being treated forms part of a cylinder bore of an internal combustion engine block. In a particular form where a protective coating is subsequently being applied to the substrate, a sequential series of plasma spraying devices may be used such that a first—preferably simpler—device is used to perform activation or pretreatment operations, while a second—and more comprehensive—device may be used to deposit the protective layer on the pretreated surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

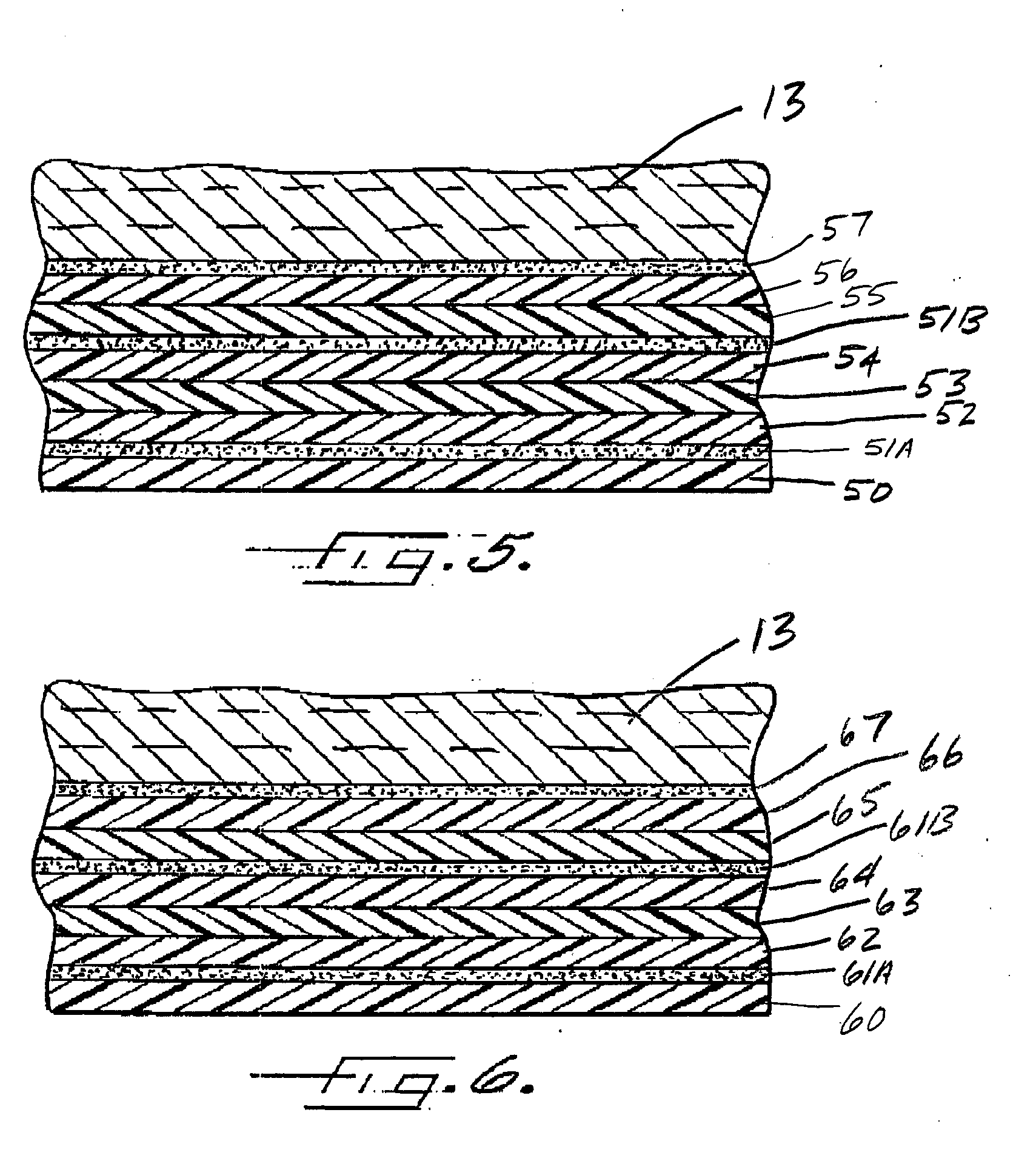

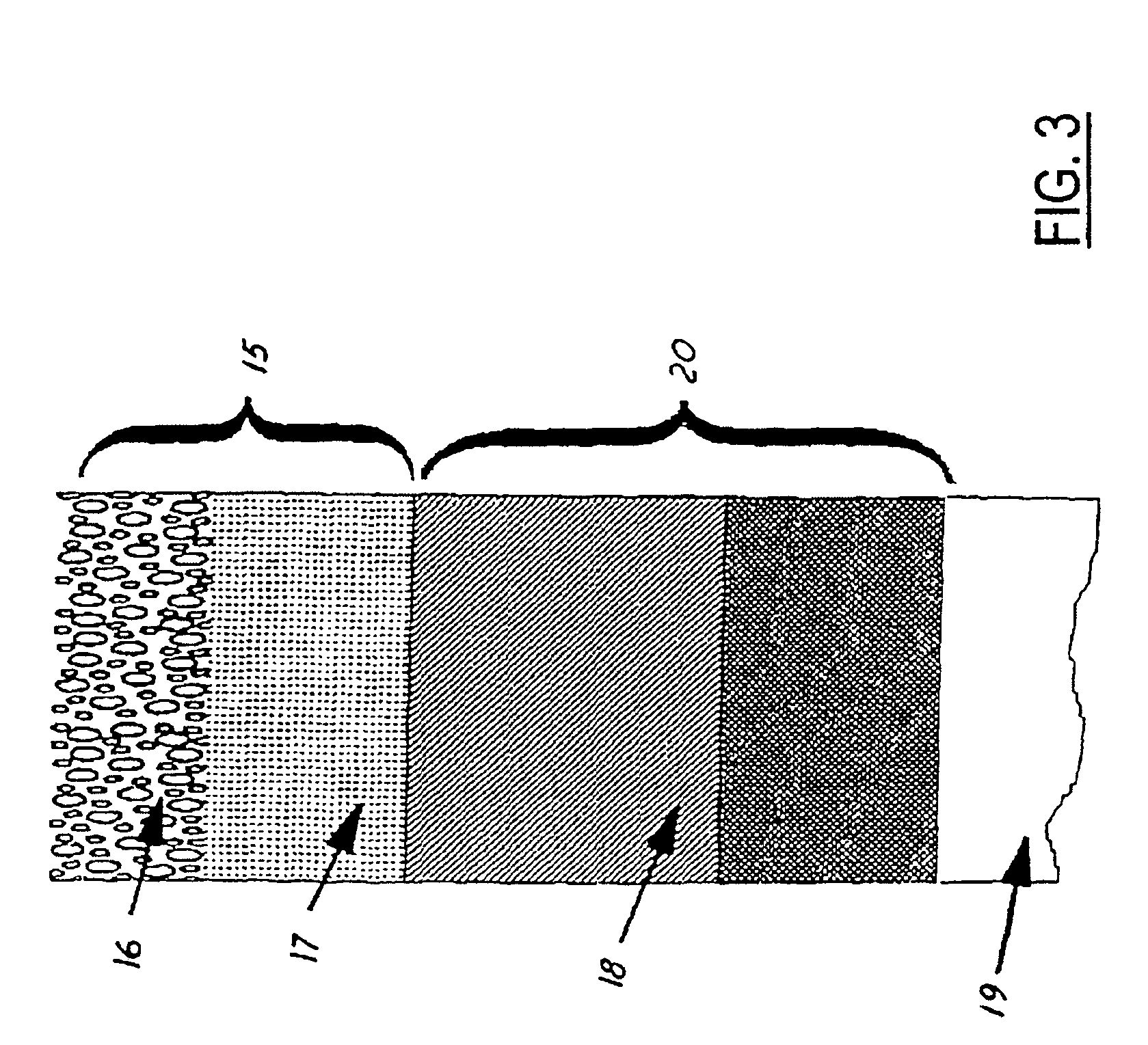

Low cost film composite can liner

InactiveUS20050153085A1Low costEliminate needSynthetic resin layered productsThin material handlingCardboardPolyamide

The present invention includes methods and apparatus for making a tubular composite container having paperboard body plies and an unsupported polymer film liner adhered thereto. The polymer film liner is comprised of, in order, a first sealant layer, a second adhesive layer, a third polyamide layer, a fourth layer comprising an ethylene / vinyl alcohol copolymer, a fifth polyamide layer, a sixth adhesive layer, a seventh high density polyethylene layer and an eighth high density polyethylene layer. The resulting liner and the paperboard body plies are wound about the tube forming mandrel and adhered together so as to produce a lined tubular composite container.

Owner:SONOCO DEV INC

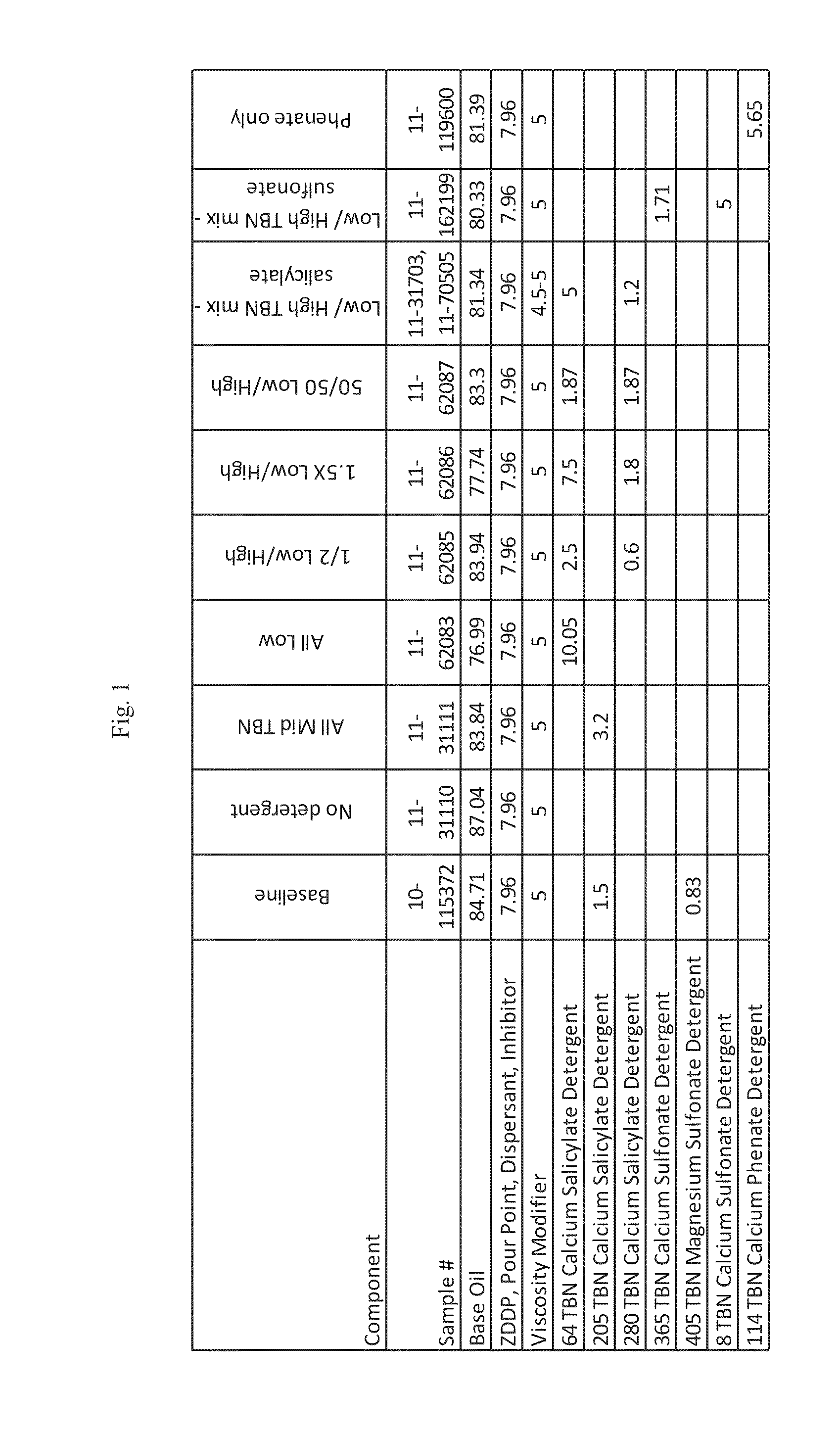

Method for improving engine fuel efficiency

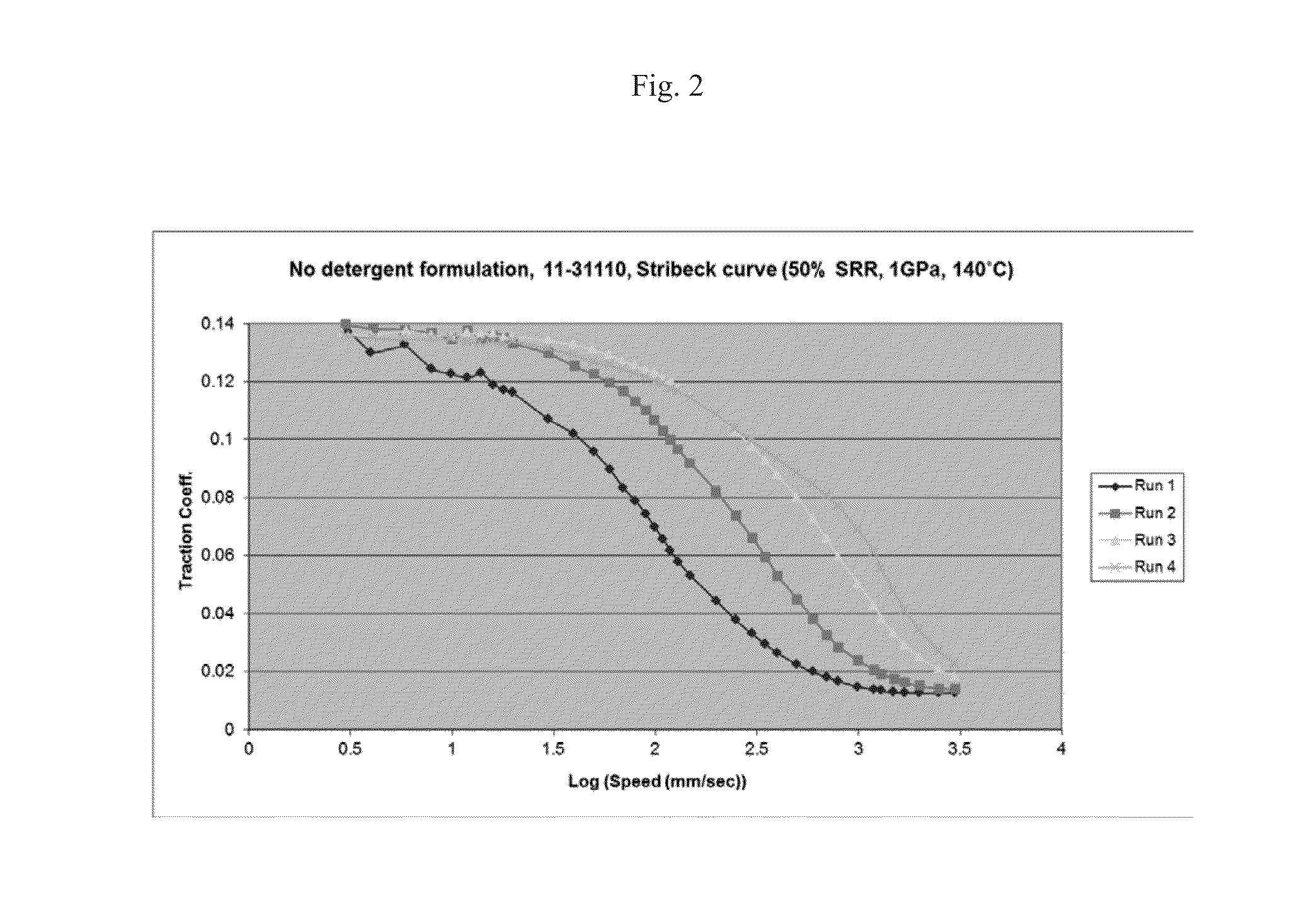

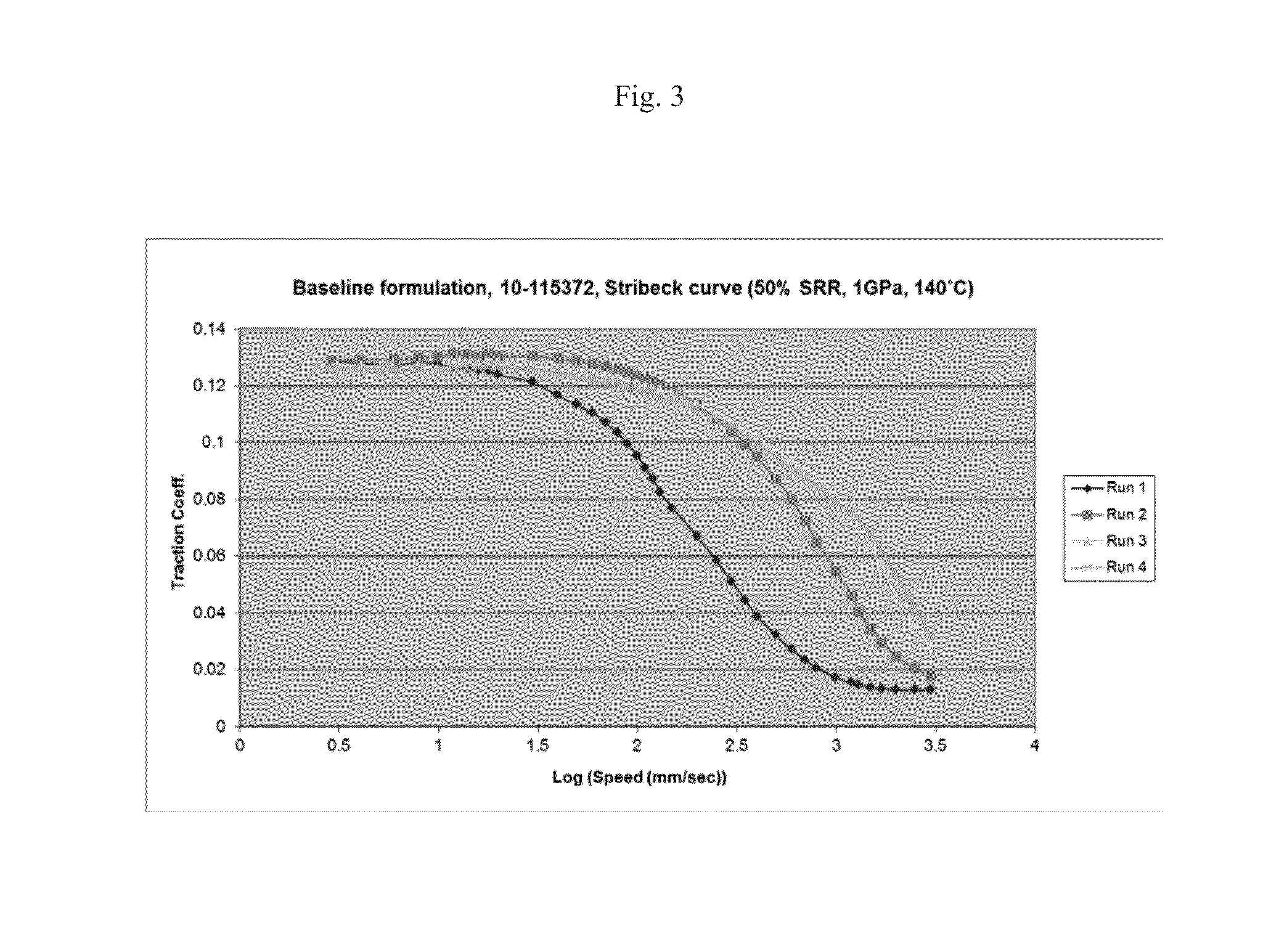

InactiveUS20140221260A1Improve efficiencyIncrease frictionAdditivesFriction reductionFuel efficiency

A method for improving friction reduction and fuel efficiency, while maintaining or improving wear protection, in an engine lubricated with a lubricating oil by using as the lubricating oil a formulated oil. The formulated oil has a composition comprising a lubricating oil base stock as a major component; and a detergent mixture comprising a first detergent having a TBN of less than about 100, and at least one other detergent different from said first detergent, as a minor component. The composition contains greater than about 4 weight percent of the first detergent, based on the total weight of the formulated oil. Friction reduction and fuel efficiency are improved and wear protection is maintained or improved as compared to friction reduction, fuel efficiency and wear protection achieved using a lubricating engine oil containing a detergent mixture having other than the first detergent having a TBN of less than about 100.

Owner:EXXON RES & ENG CO

Energy-saving and emission-reducing diesel engine oil formula

The invention provides an energy-saving and emission-reducing diesel engine oil formula which comprises the following raw materials in percent by mass: 77.2% of base oil, 5.65% of an index improver, 0.56% of a pour depressant, 6.9%-15.57% of an American Infineum diesel engine oil complex agent D3451, 1%-10.57% of an extreme pressure anti-wear agent and the balance of an anti-foaming agent. By adopting the diesel engine oil formula provided by the invention, the wear resistance of equipment is greatly improved, the thermal stability and the oxidation resistance of an oil product are enhanced, the service life is prolonged, and the effects of high efficiency, oil saving, energy saving and environmental pollution are achieved.

Owner:SHANGHAI NEWSNUG LUBRICATION TECH CO LTD

Hardened steel components and process of treating the same

InactiveUS6982120B2Reduce hardnessReduce stressClutchesRecord information storageConstant-velocity jointHardened steel

Owner:GKN DRIVELINE DEUTSCHLAND GMBH

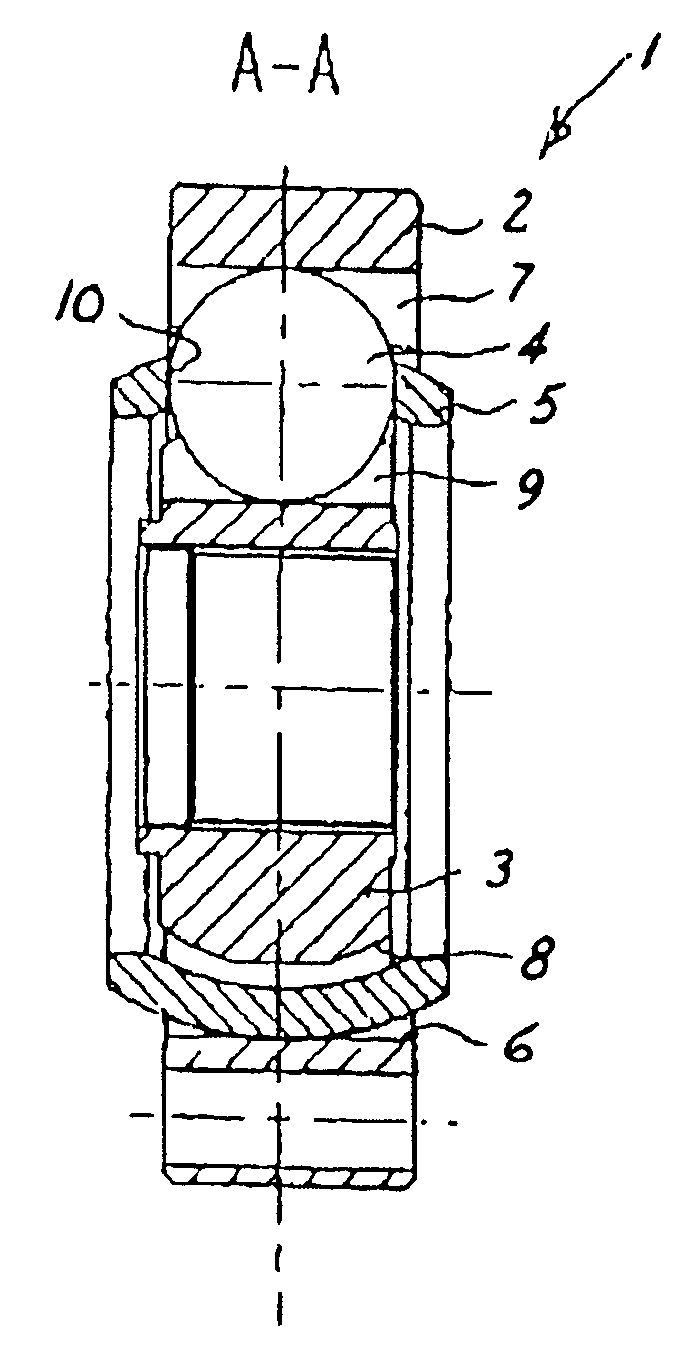

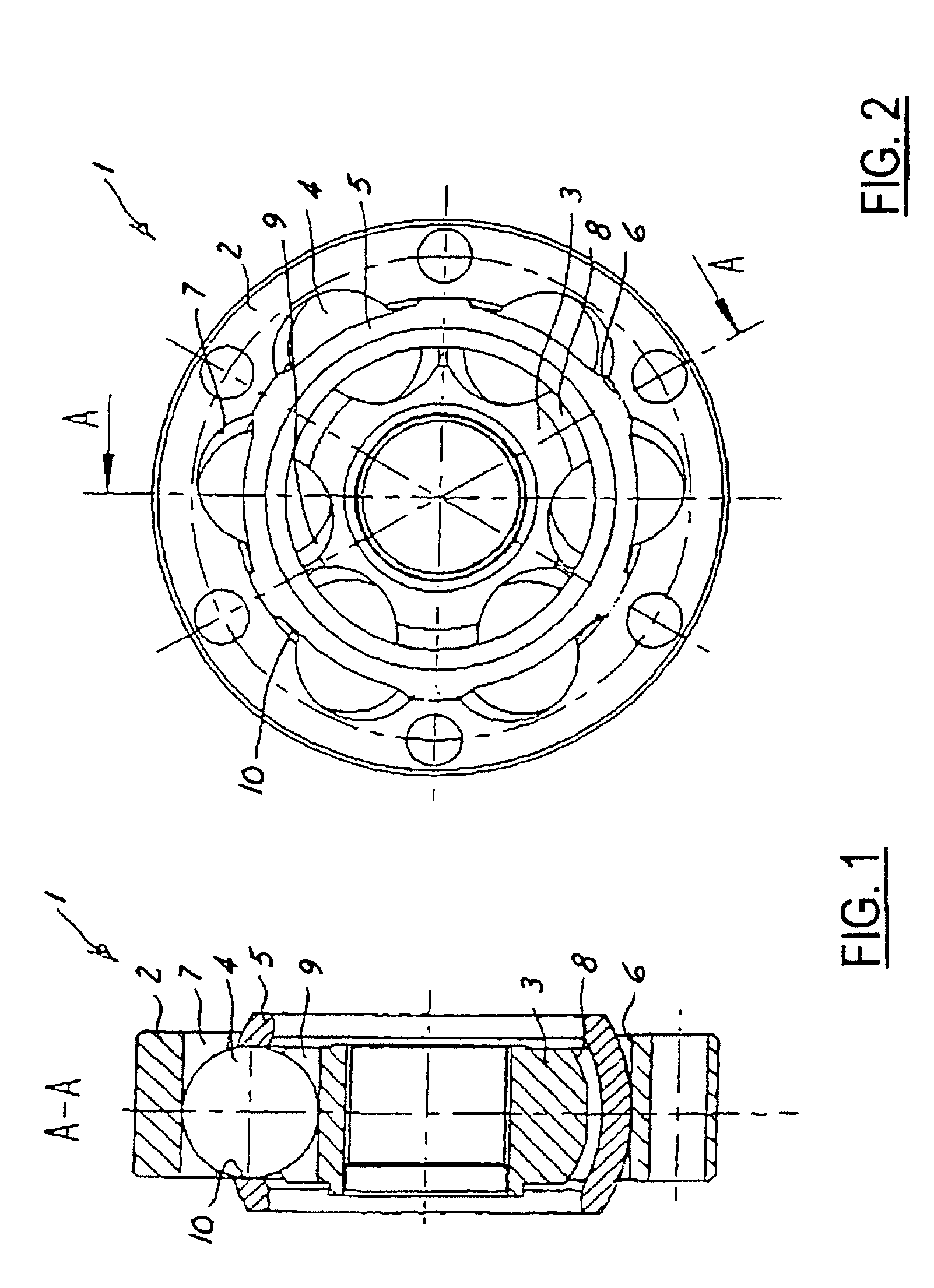

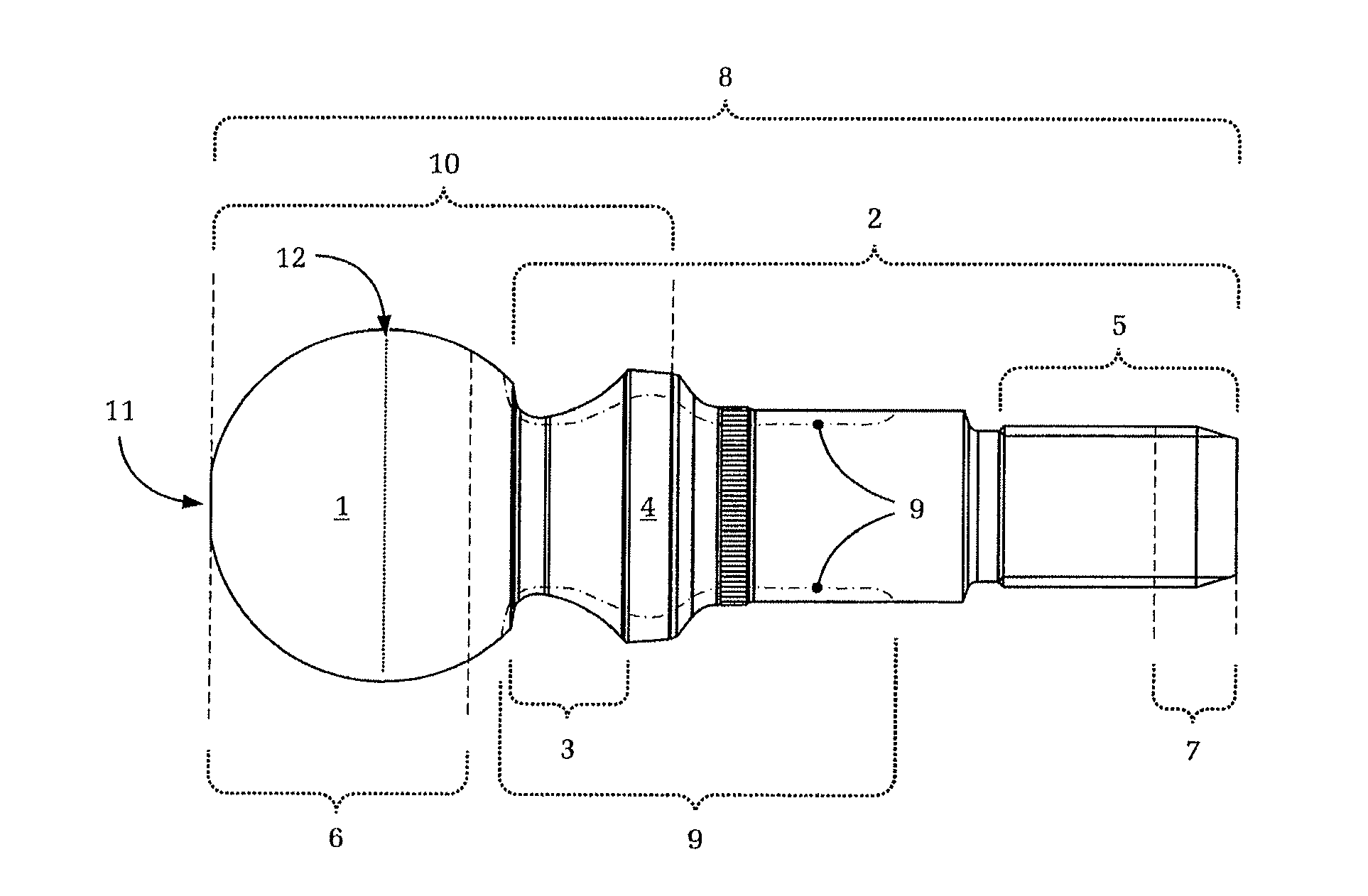

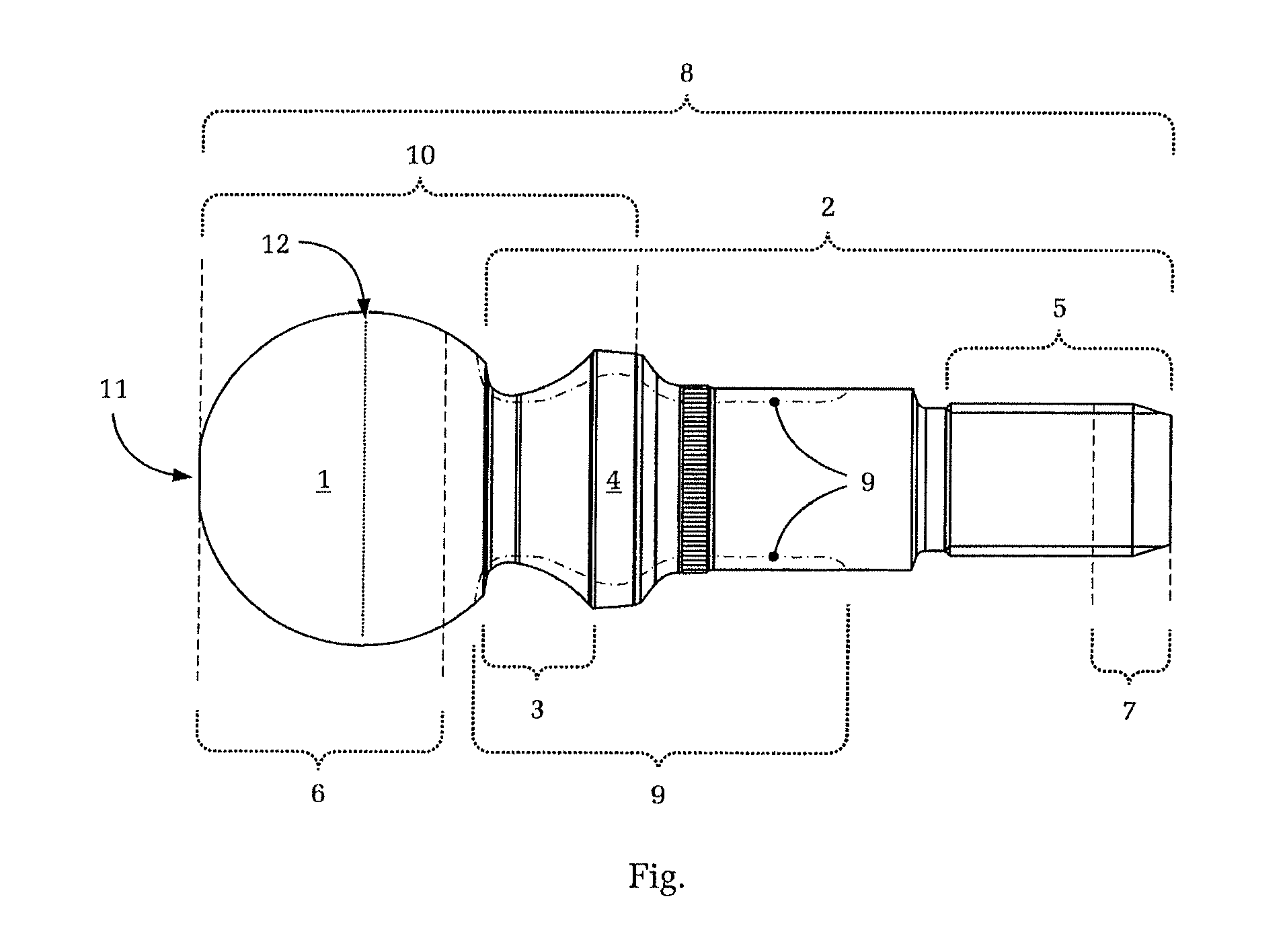

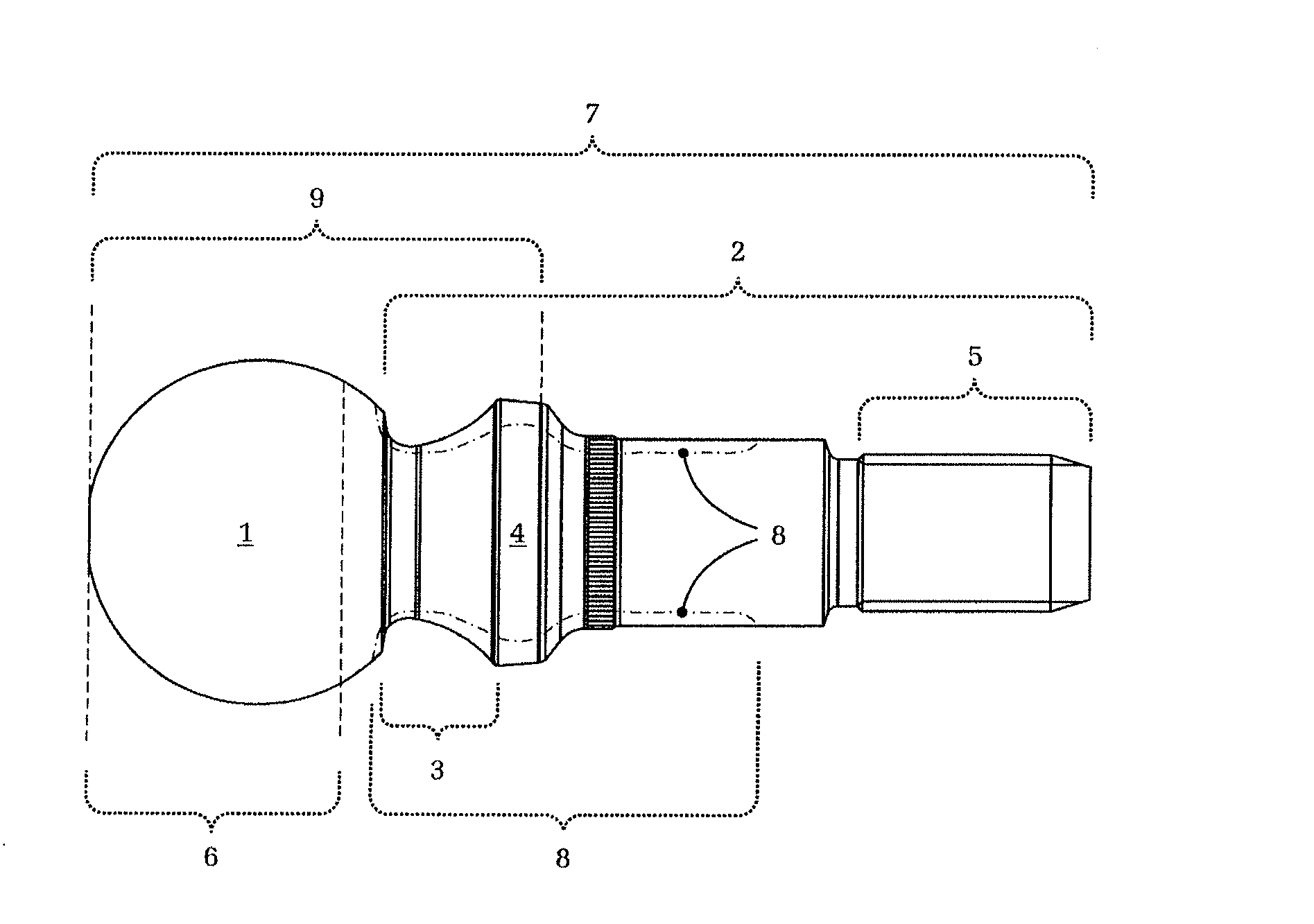

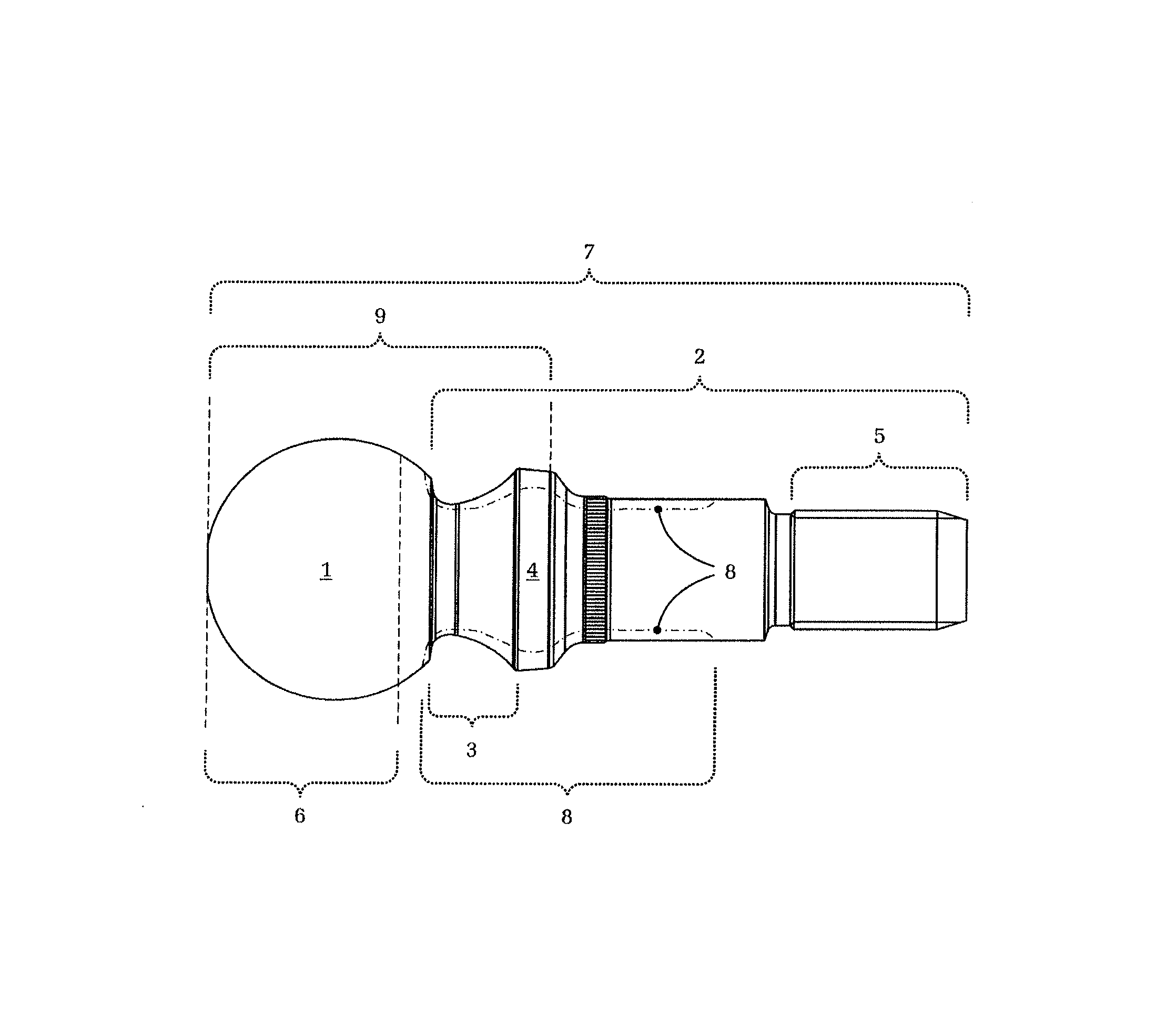

Ball pin and ball joint

ActiveCN102996618AImprove fatigue strengthGood for wear protectionShaftsSolid state diffusion coatingSurface layerEngineering

A ball joint with a ball pin and a steel ball pin with a joint ball (1). The ball joint and ball pin are suitable for use when, for example, solid-on-solid friction predominates under high static pre-loading or high operational loads and with small joint movements. A portion of the surface of the ball pin has surface layer hardening (9) in order to increase a fatigue strength of the ball pin. The ball pin and the ball joint, on portion of the ball pin without the any surface layer hardened, includes a nitrided layer (6) as wear protection. The ball pin and the ball joint provide an advantageous combination of high fatigue strength, good corrosion protection and high wear-resistance. The nitrided layer of ball joints, previously only regarded as improving corrosion protection, also functions as a wear protection. Thus, these ball pins overcome the mutual exclusion between surface layer hardening and nitriding.

Owner:ZF FRIEDRICHSHAFEN AG

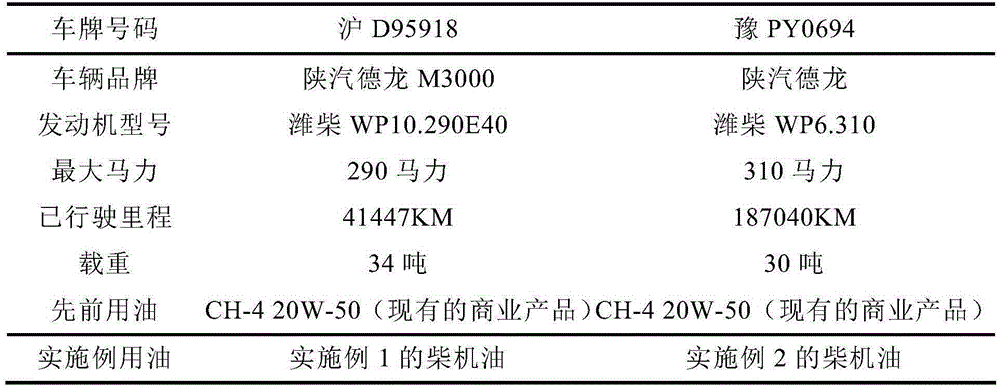

Diesel lubricant oil, preparation method thereof, and application thereof in diesel engines

The invention provides diesel lubricant oil, a preparation method thereof, and an application thereof in diesel engines, wherein the diesel lubricant oil comprises, by weight, 38-70% of synthetic basic oil A, 10-25% of synthetic basic oil B, 10-25% of synthetic basic oil C, 0.1-6% of a cleaning agent and 0.1-6% of an antioxidant.

Owner:上海纳克润滑技术有限公司

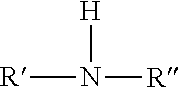

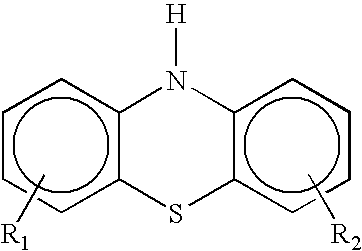

Lubricating compositions having improved friction properties

ActiveUS20090048131A1Reducing fluid frictionImprove fuel efficiencyLubrication of auxillariesOther chemical processesAlcoholPhosphate

The present invention provides an additive composition comprising (a) at least one ash-containing phosphorus compound prepared by a primary or secondary alcohol or mixtures thereof, and (b) a salt of at least one hydrocarbylamine and at least one hydrocarbyl acid phosphate. Further, the present invention provides a lubricating composition comprising (a) at least one ash-containing phosphorus compound prepared by a primary or secondary alcohol or mixtures thereof, and (b) a salt of at least one hydrocarbylamine and at least one hydrocarbyl acid phosphate, and methods of use thereof.

Owner:AFTON CHEMICAL

Ball pin and ball joint

ActiveUS20130071175A1Improve fatigue strengthImprove wear resistanceShaftsCouplings for rigid shaftsSteel ballHigh wear resistance

A ball joint with a ball pin and a steel ball pin with a joint ball. The ball joint and ball pin are suitable for use when, for example, solid-on-solid friction predominates under high static pre-loading or high operational loads and with small joint movements. A portion of the surface of the ball pin has surface layer hardening in order to increase a fatigue strength of the ball pin. The ball pin and the ball joint, on portion of the ball pin without the any surface layer hardened, includes a nitrided layer as wear protection. The ball pin and the ball joint provide an advantageous combination of high fatigue strength, good corrosion protection and high wear-resistance. The nitrided layer of ball joints, previously only regarded as improving corrosion protection, also functions as a wear protection. Thus, these ball pins overcome the mutual exclusion between surface layer hardening and nitriding.

Owner:ZF FRIEDRICHSHAFEN AG

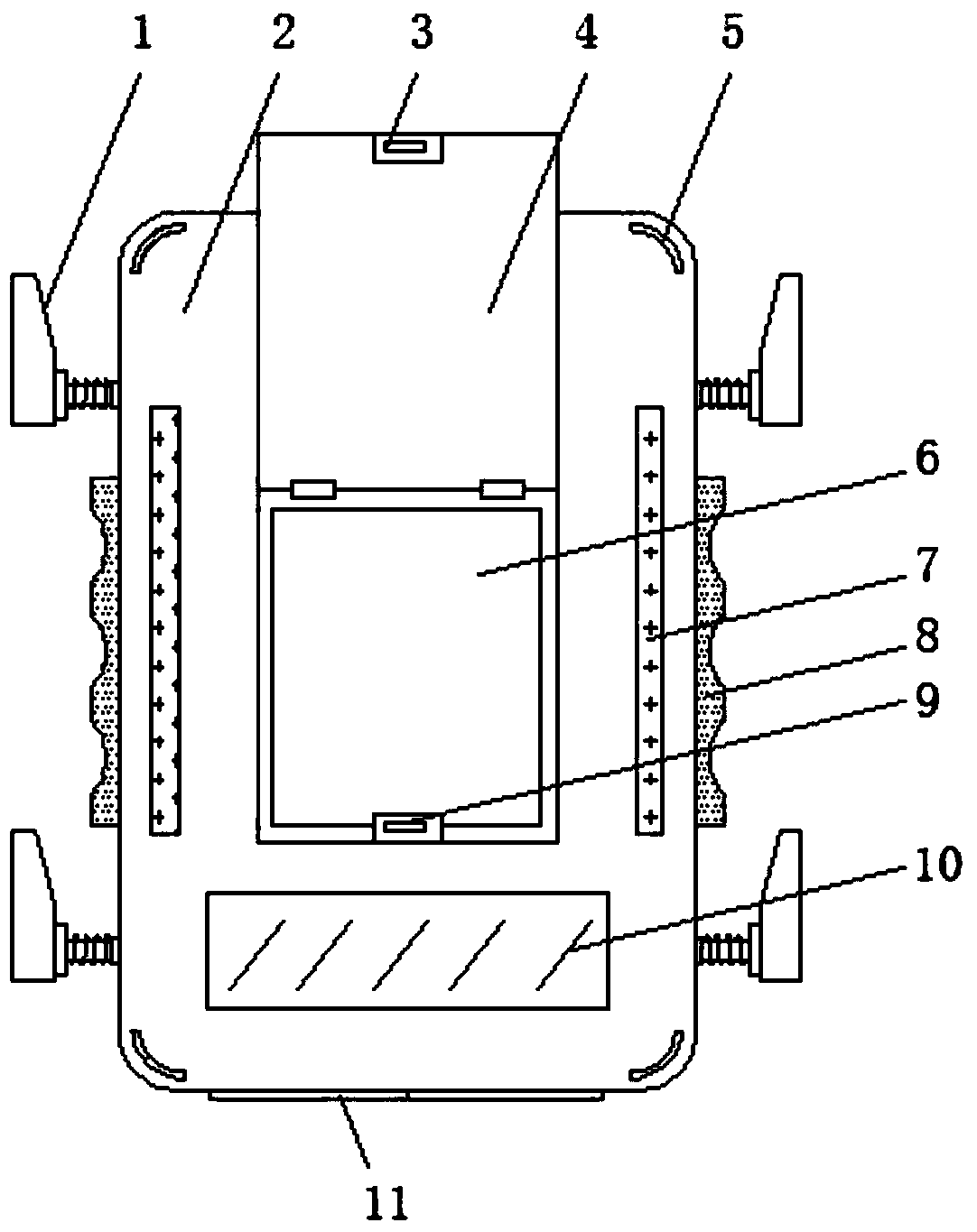

Charging device being convenient to use

PendingCN108695922AEasy to useEasy to carryBatteries circuit arrangementsElectric powerData linesUSB

The invention discloses a charging device being convenient to use. The charging device comprises a charging device body. A USB placing slot is formed in the surface of the charging device body. Light-emitting strips are arranged at the two sides of the USB paying-off slot. A first groove is formed in the back of the charging device body; and a micro cooling fan is arranged in the first groove. Second grooves are formed in the upper ends and the lower ends of the two sides of the charging device body; clamping plates are arranged in the second grooves; the clamping plates and the second groovesare connected by tension springs; and rotating rings are arranged between the tensions springs and the clamping plates. Anti-skid holding sleeves are arranged between the second grooves at the two sides of the charging device body. A USB wiring port and a charging port are formed in the front side end surface of the charging device body; and protection covers are arranged outside the USB wiring port and the charging port. According to the invention, a mobile phone can be fixed with the charging device based on needs when being charged, so that the user can use the mobile phone conveniently; and after charging completion, the USB data cable can be stored in the USB placing slot, so that the charging device can be carried conveniently and is not easy to lose.

Owner:JIANGSU JUNHOU TECH CO LTD

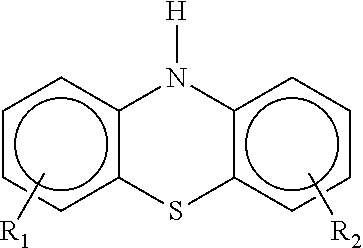

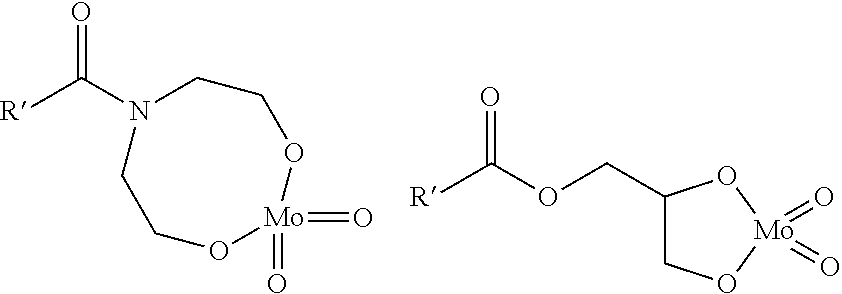

Lubricating compositions containing synthetic ester base oil, molybdenum compounds and thiadiazole-based compounds

ActiveUS7763574B2Good for wear protectionImprove anti-wear performanceOrganic chemistryAdditivesCompound aEther

A lubrication composition providing excellent anti-wear protection for corrosion-resistant materials which comprises a major amount of a synthetic ester base oil, and a minor amount of a molybdenum compound and an anti-wear additive selected from the group consisting of 1,3,4-thiadiazole derivative as an anti-wear additive, the reaction products of 2,5-dimercapto-1,3,4-thiadiazole dimers and poly(ether)glycols, and 2,5-dimercapto-1,3,4-thiadiazole monomer and mixtures thereof. Also described is a method for imparting anti-wear properties to a corrosion resistant material, comprising using the lubricating composition of the invention.

Owner:VANDERBILT CHEM LLC

Energy-saving emission-reducing lubricant composition

InactiveCN106350170AGood viscosity retentionImprove the lubrication effectLubricant compositionWear resistantClearing Agent

The invention provides an energy-saving emission-reducing lubricant composition, made from, by weight, 80-90% of basic oil and 10-20% of additives; the additives include a viscosity index modifier, a pour point depressant, a clearing agent, an extreme pressure agent, an antioxidant anticorrosion antirust agent, an antifriction wear-resistant synergist, and a defoaming agent; the energy-saving emission-reducing lubricant composition is low in friction efficient and good in antifriction synergic effect, and has significant energy-saving and emission-reducing effects.

Owner:湖南路驰能源科技有限公司

High-temperature-resistant inorganic composite adhesive and preparation method thereof

InactiveCN105623532ASimple recipeDesign scienceNon-macromolecular adhesive additivesInorganic adhesivesMicrosphereRare earth

The invention relates to a high-temperature-resistant inorganic composite adhesive and a preparation method thereof and belongs to the technical field of adhesive materials. The high-temperature-resistant inorganic composite adhesive is prepared from, by weight, 10-20 parts of aluminum hydroxide, 3-8 parts of zirconium sol, 0.2-0.5 part of rare earth oxide, 15-20 parts of palygorskite powder, 15-30 parts of silicate, 5-10 parts of an active filling agent, 3-10 parts of hollow microspheres and 30-55 parts of water. The adhesive is simple in formula and scientific in design, has the advantages of being excellent in corrosion resistance, high temperature resistance, abrasion resistance, short in curing time and the like, and is safe, saves energy and is environmentally friendly and wide in application range. Meanwhile, the invention provides the simple and practical preparation method of the high-temperature-resistant inorganic composite adhesive.

Owner:淄博市新材料研究所

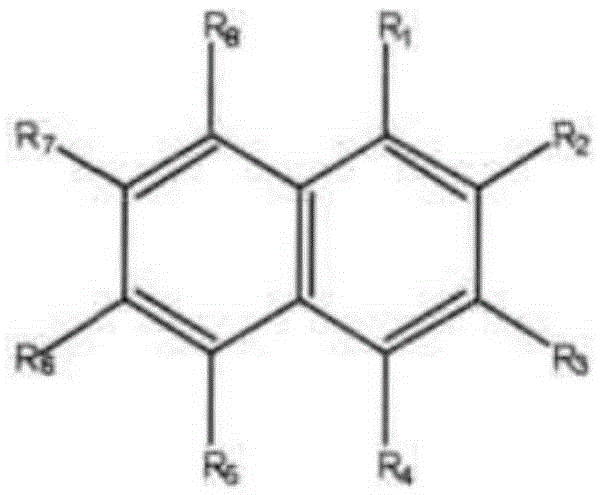

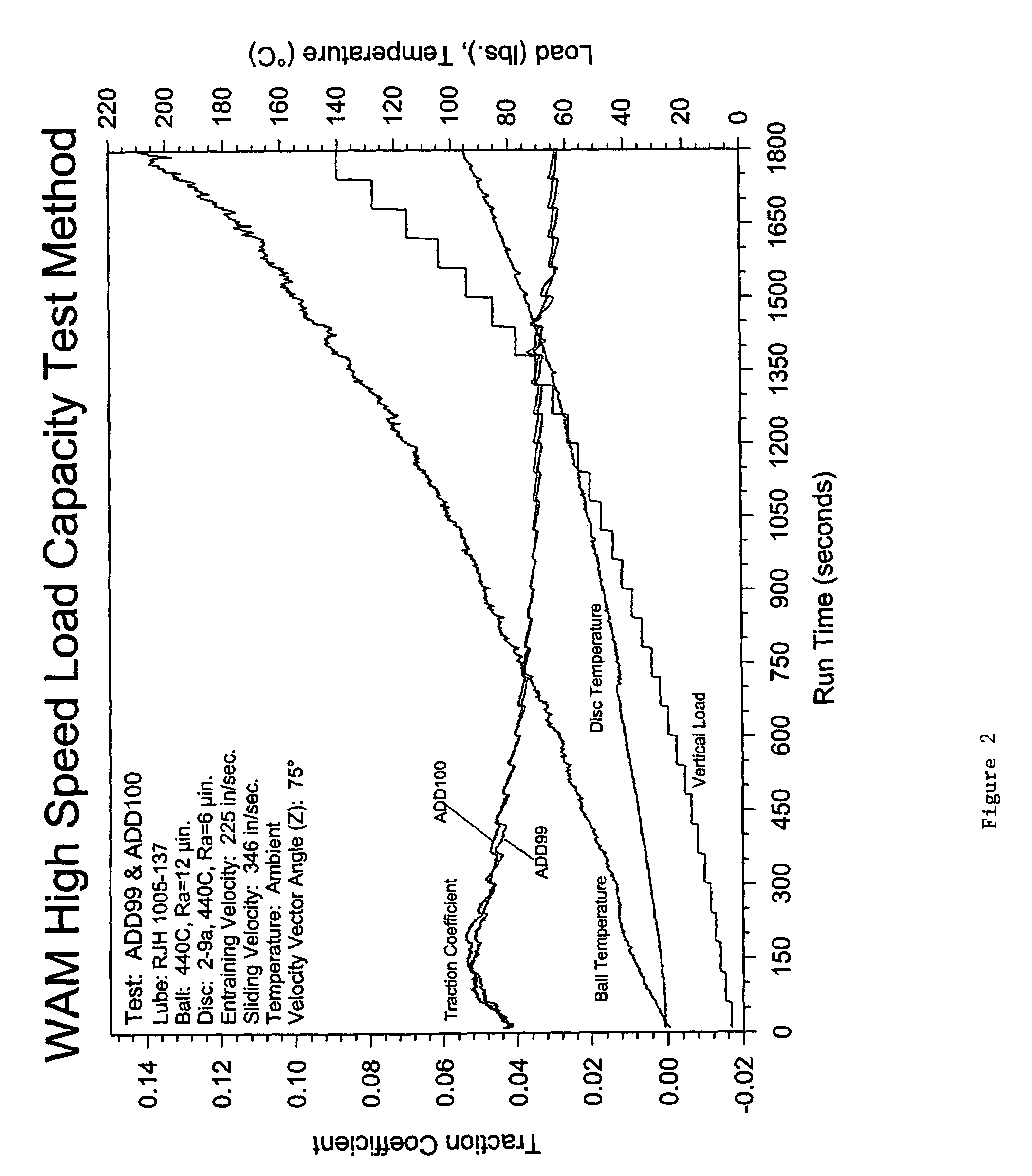

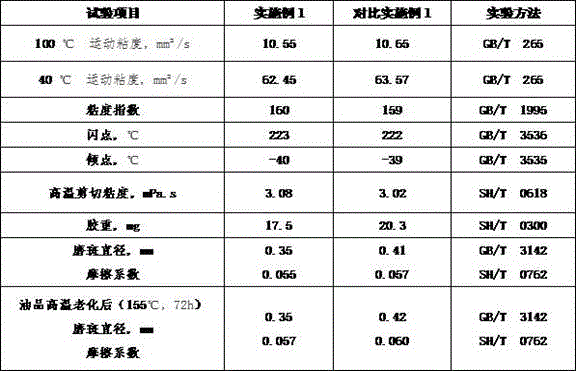

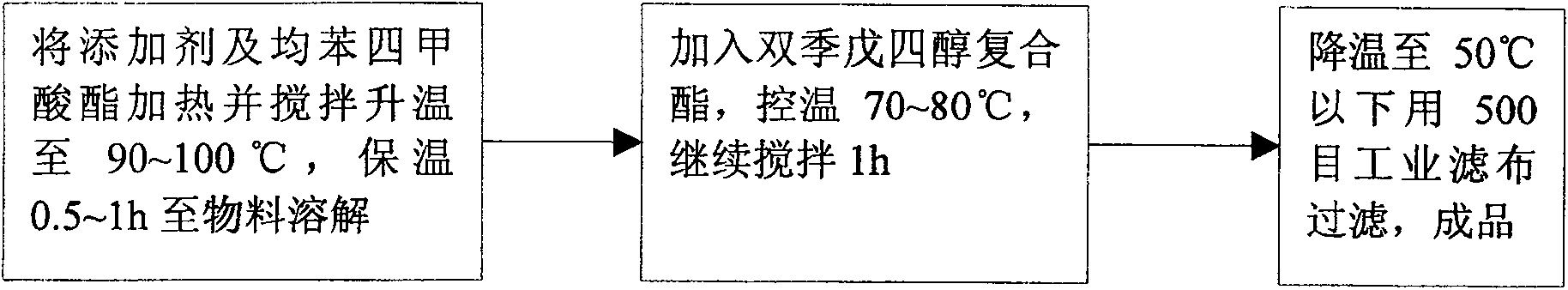

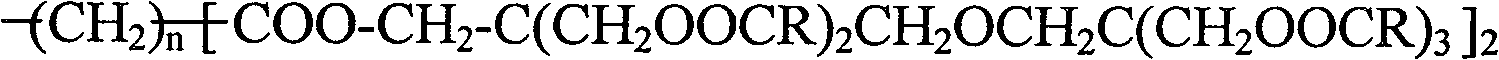

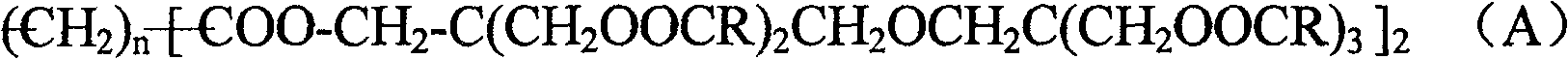

Clean compound ester type high temperature chain oil and preparation method thereof

InactiveCN100580069CGuaranteed cleanlinessGood for wear protectionAdditivesFormic Acid EstersPolymer science

The present invention discloses a clean compounded ester type high-temperature chain oil and its preparation method. Its composition includes (by wt%) 40-90% of pentaerythritol compounded ester, 10-50% of benzenetetracarboxylic acid ester, 1-5% of high-temperature antioxidant, 1-5% of extreme pressure / anti-scuff agent and 0.02-0.5% of corrosion-resisting agent. Besides, said invention also provides the concrete steps of its preparation method, and provides its application range.

Owner:上海纳克润滑技术有限公司

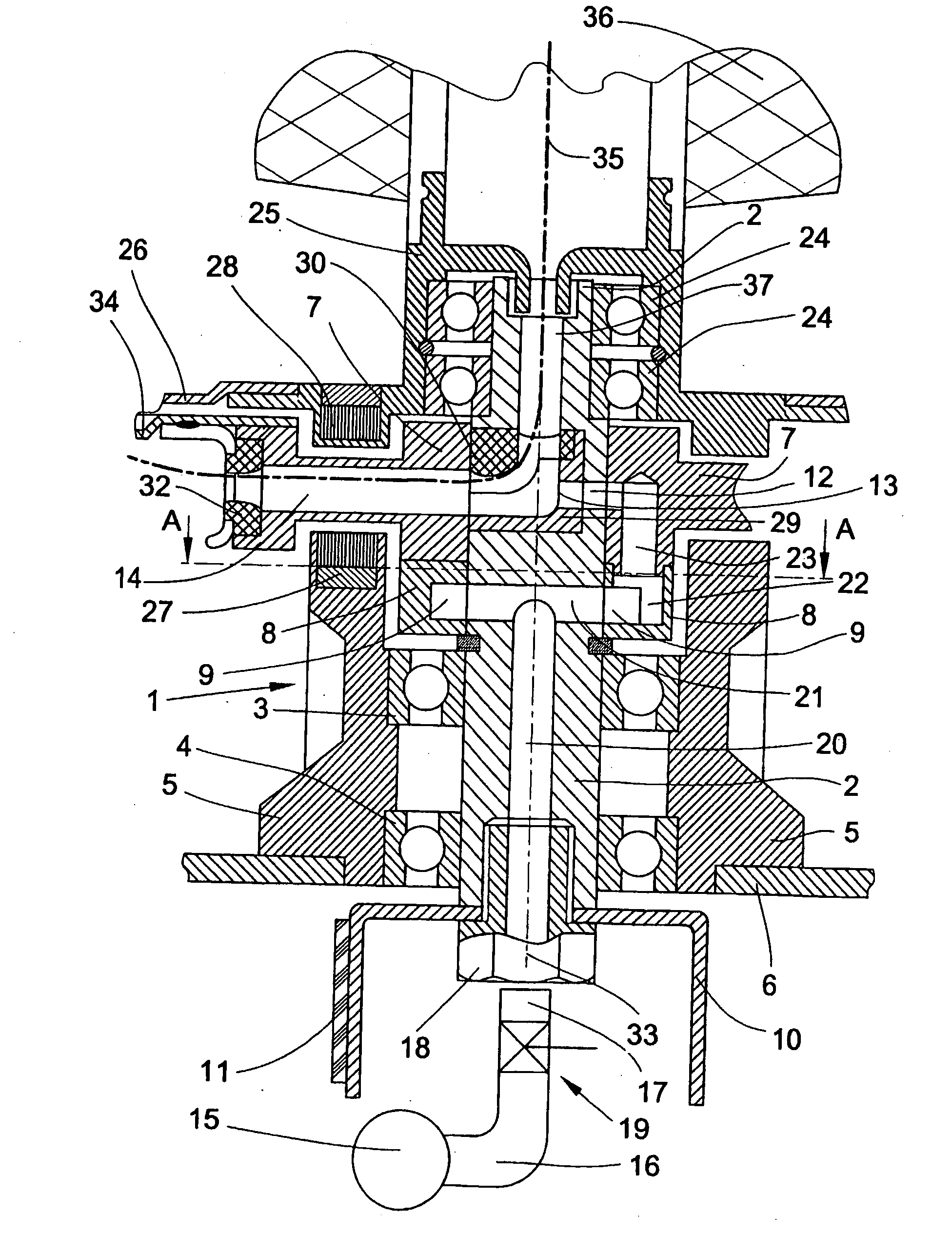

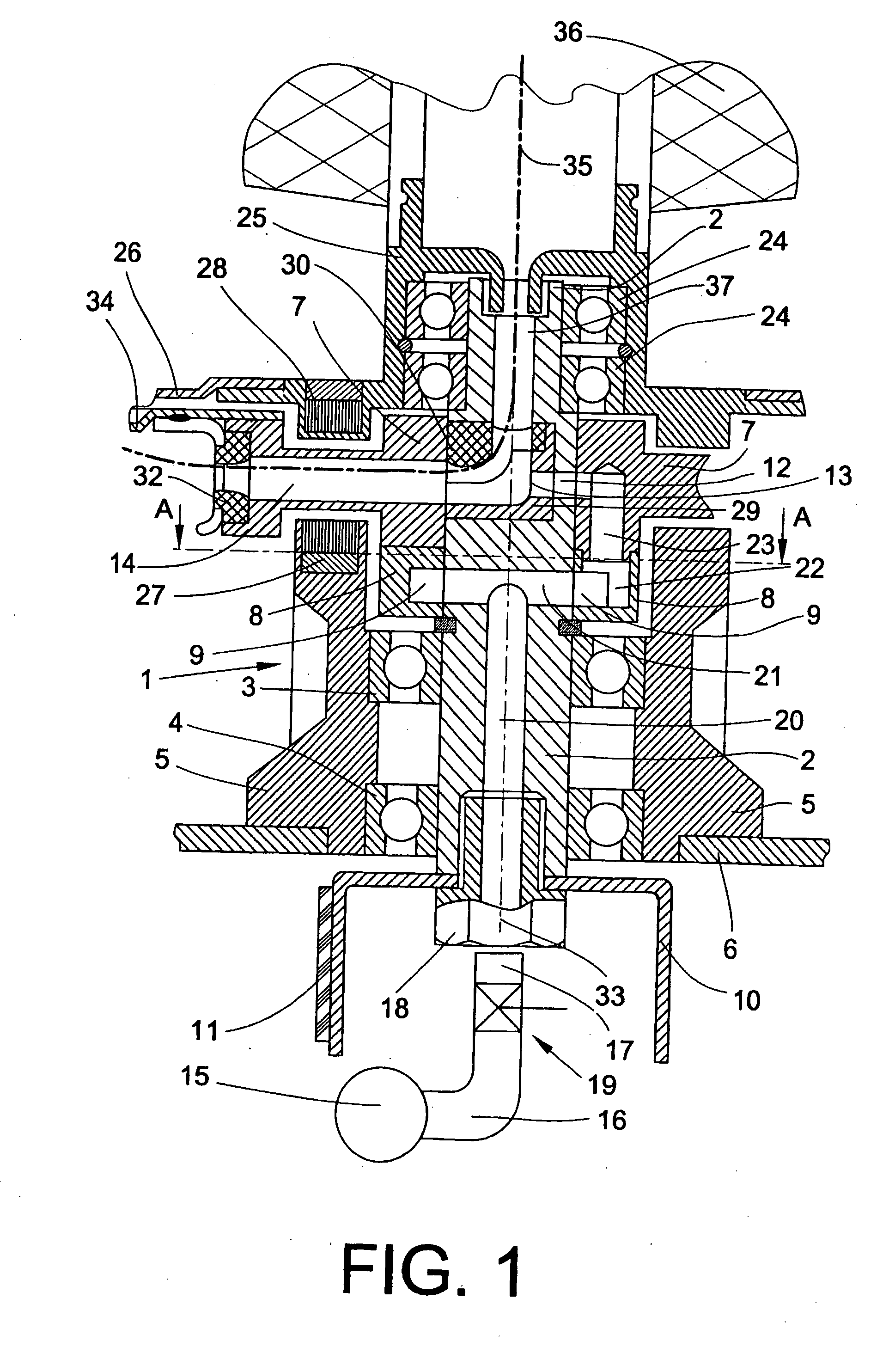

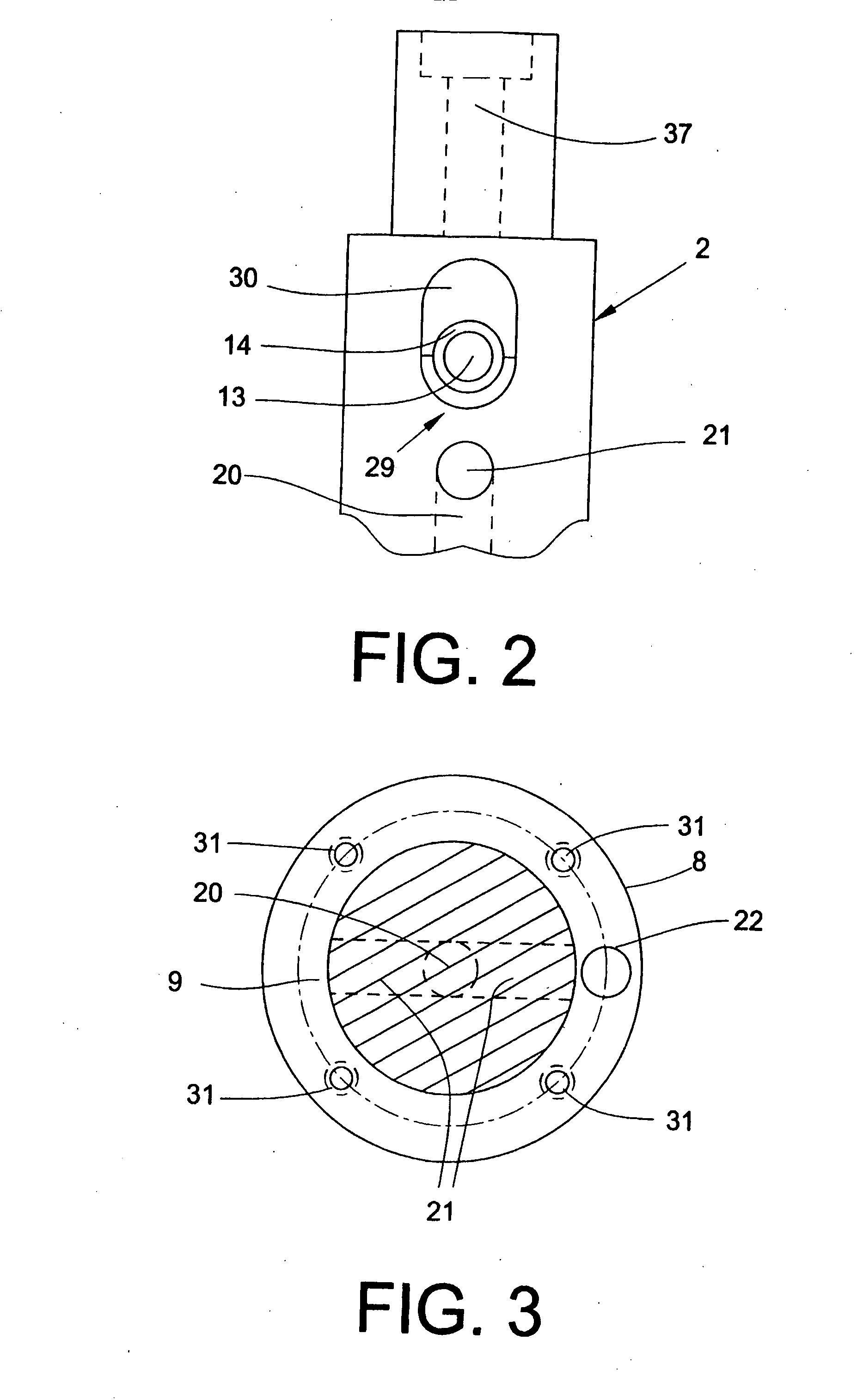

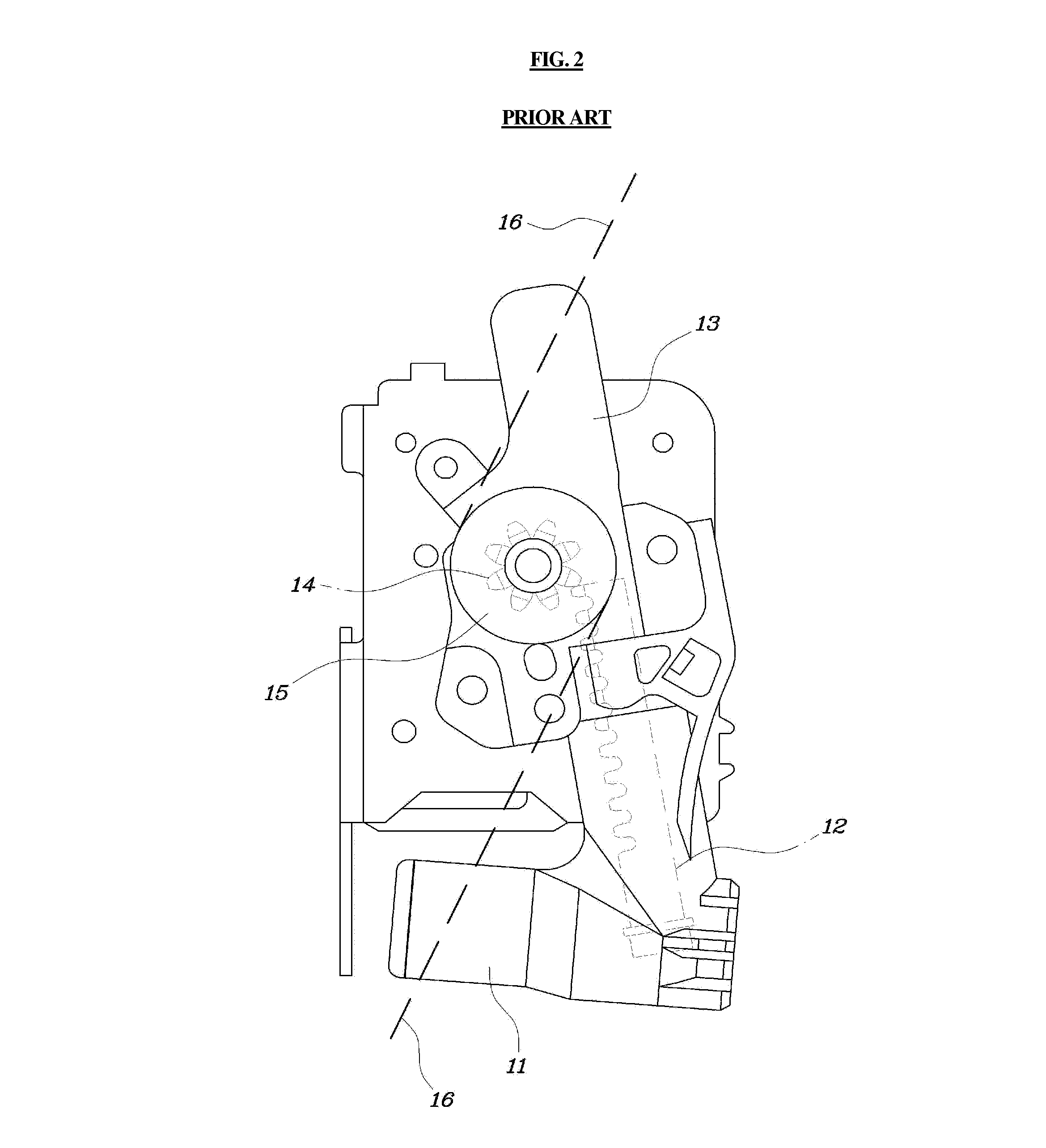

Two-For-One Twisting Spindle Comprising A Pneumatically Actuated Threading Device

InactiveUS20080047250A1Save weight and spaceEasy to producePiercing arrangementsDrafting machinesEngineeringFlange

Disclosed is a two-for-one twisting spindle comprising a pneumatically actuated threading device, a spindle bolt (2) that is rotatable about the vertical rotary shaft (33) thereof, and an injector (12) which extends into a thread guiding channel (14). Said injector (12) can be temporarily connected to a compressed air source (15). The thread (35) is conveyed through the thread guiding channel (14) by means of an air flow during the threading process. The compressed air supply unit is provided with an annular chamber (9) which is mounted upstream of the injector (12) and is formed by a rigid annular flange (8) that extends around the spindle bolt (2) and is joined thereto in a fixed manner. The invention can be used in two-for-one twisters.

Owner:SAURER GERMANY GMBH & CO KG

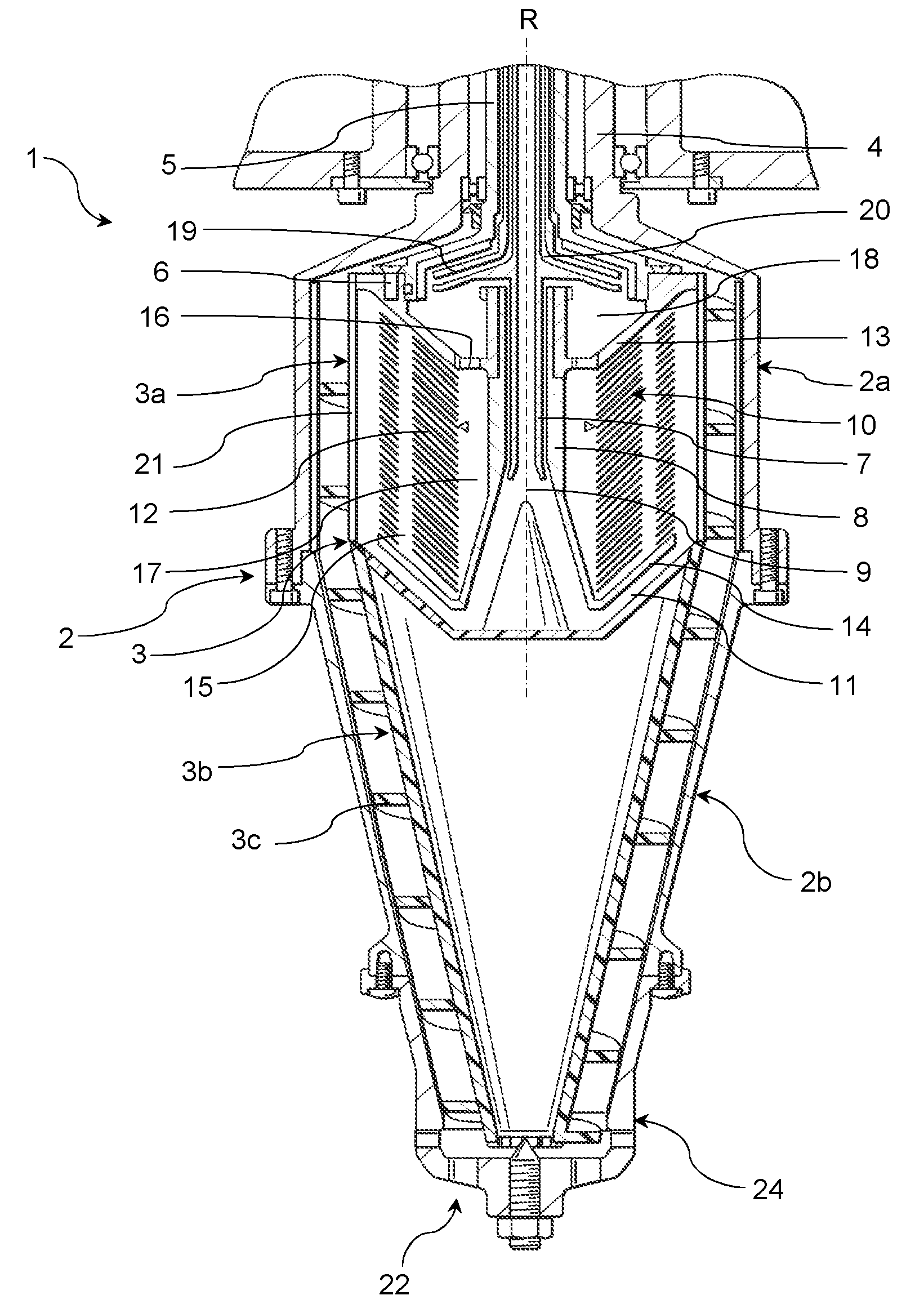

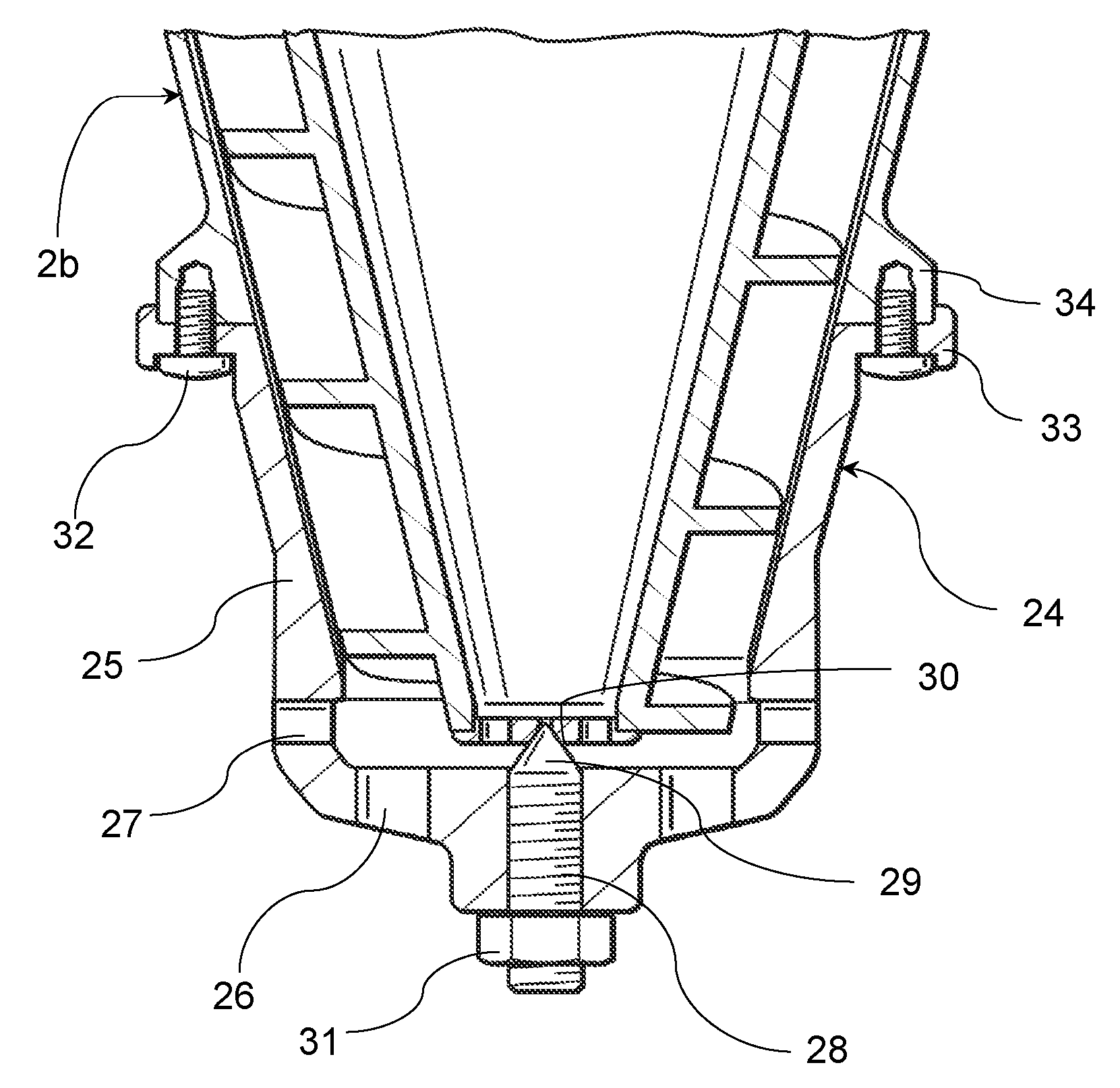

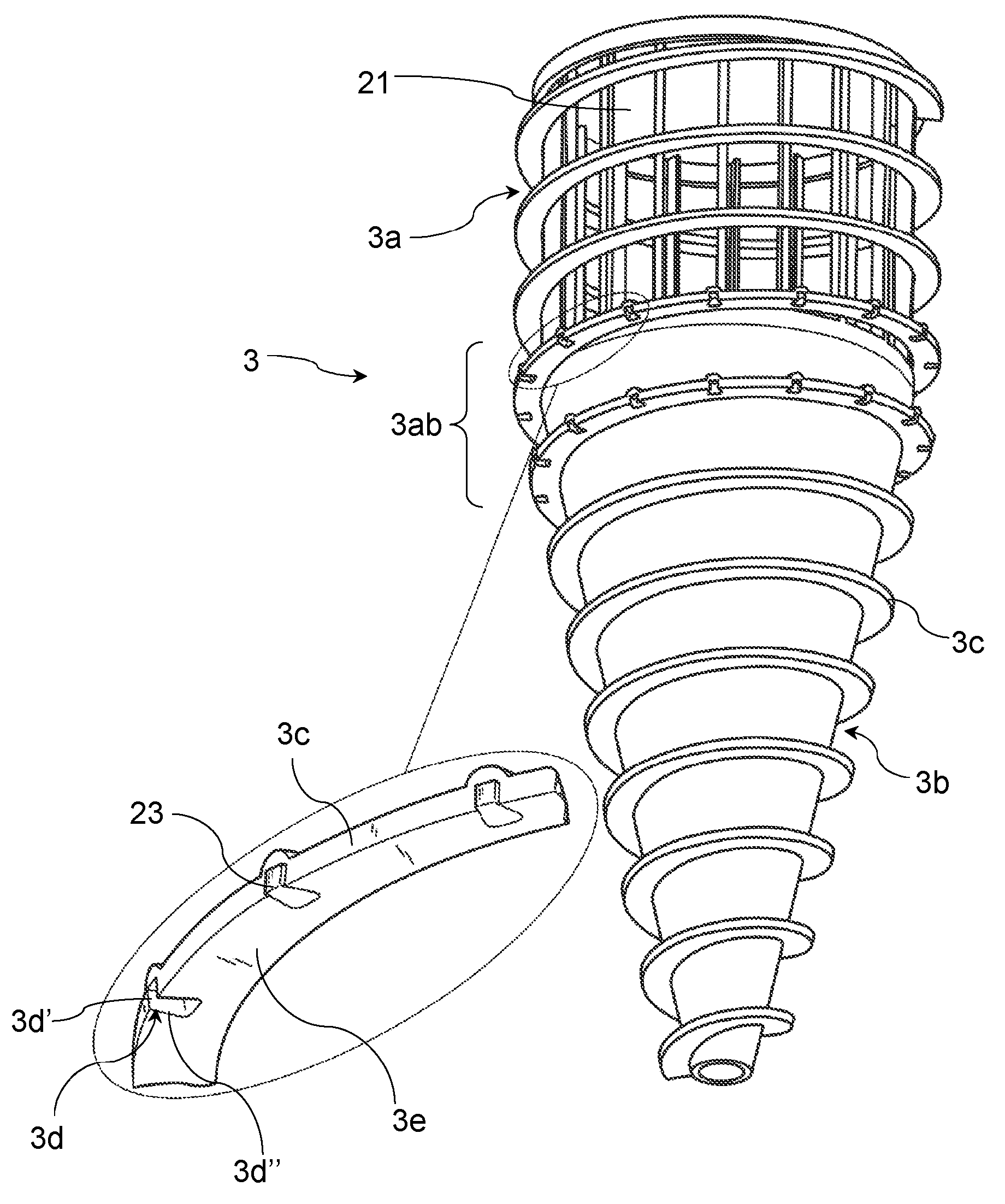

A centrifugal separator

InactiveCN103052448AReduce weightReduced characteristicsRotary centrifugesWear resistantSolid particle

The present invention relates to a centrifugal separator (1) comprising a rotor (2) which is rotatable around an axis of rotation (R), the rotor (2) comprising a separation chamber (10) with an inlet (7, 9, 11) for a liquid mixture containing solid particles, at least one liquid outlet (18, 19, 20) for a separated liquid from the liquid mixture, and a solids outlet (22, 26, 27) for the separated solid particles, wherein a screw conveyor (3) is arranged to rotate inside the rotor (2) around the axis of rotation (R), at a different speed than the rotor (2), the screw conveyor (3) having at least one conveyor flight (3c) for transporting the separated solid particles in the separation chamber (10) towards and out of the solids outlet (22), wherein the conveyor flight (3c) is provided with wear resistant elements (23) arranged along its edge and the wear resistant elements (23); are spaced apart with an interspace (23a) between mutually adjacent wear resistant elements (23).

Owner:ALFA LAVAL CORP AB

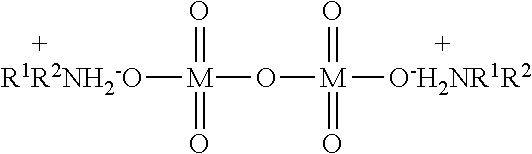

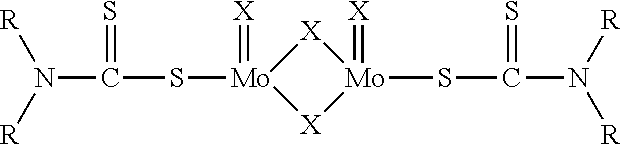

Organometallic salt composition, a method for its preparation and a lubricant additive composition

ActiveUS20180194707A1Improve impactTrend downOrganic compound preparationAdditivesCarboxylic acidBase oil

The purpose of the present invention is to provide organometallic salt compositions that are useful as lubricant additives and / or in lubricant additive compositions to reduce friction and wear, and also have improved solubility in all four types of hydrocarbon base oils (Groups I-IV) at a variety of concentrations and under a variety of conditions. The organometallic salt composition is derived from at least one long chain monocarboxylic acid and a single metal in combination with at least one short or medium branched-chain monocarboxylic acid. The compositions are particularly useful in combination with activated complexes comprising a first metal component, a second metal component and particles comprising the first metal component.

Owner:NANOL TECH

Ultra Low Phosphorus Lubricant Composition Incorporating Amine Tungstate

A low-phosphorus lubricating composition having less than 600 ppm phosphorus, comprising at least 85 weight % of a lubricating base blend, and an additive comprising the following, as a weight % of the total composition:(1) an amine tungstate compound at an amount which provides about 0.1 to 1400 ppm W;(2) an alkylated diphenylamine at about 0.1-2%; and(3) a zinc dithiocarbamate at about 0.1-2%.

Owner:VANDERBILT CHEM LLC

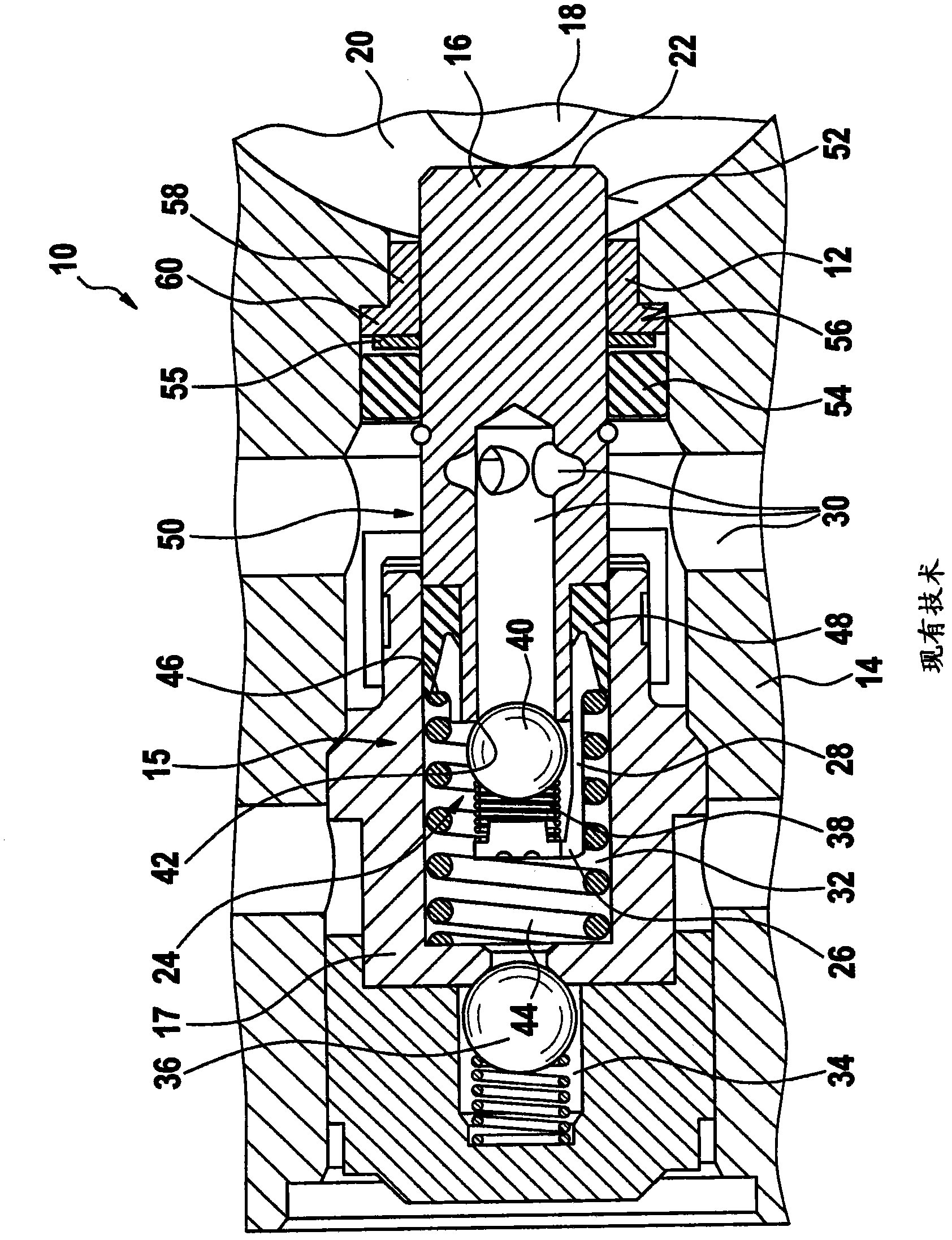

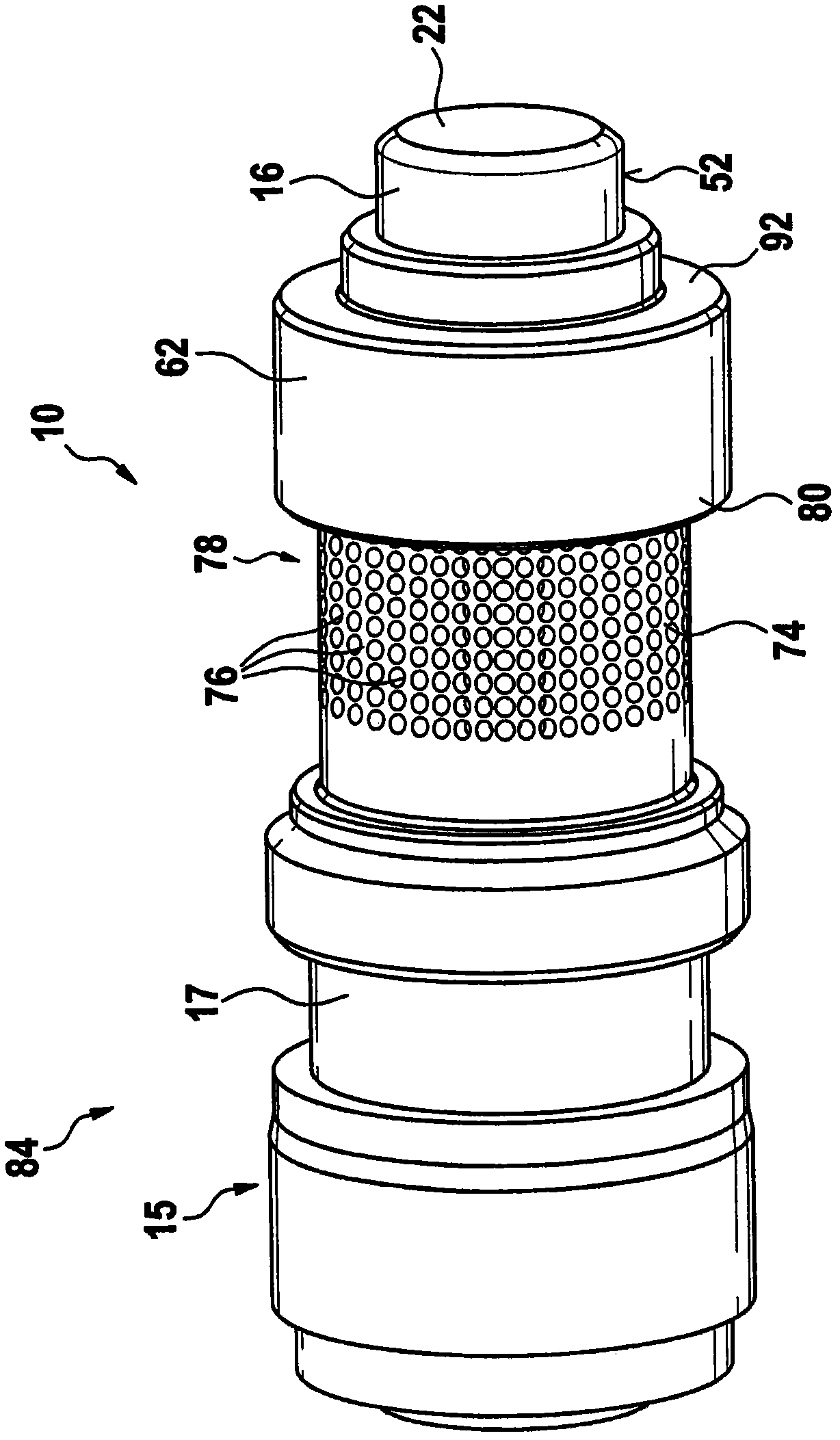

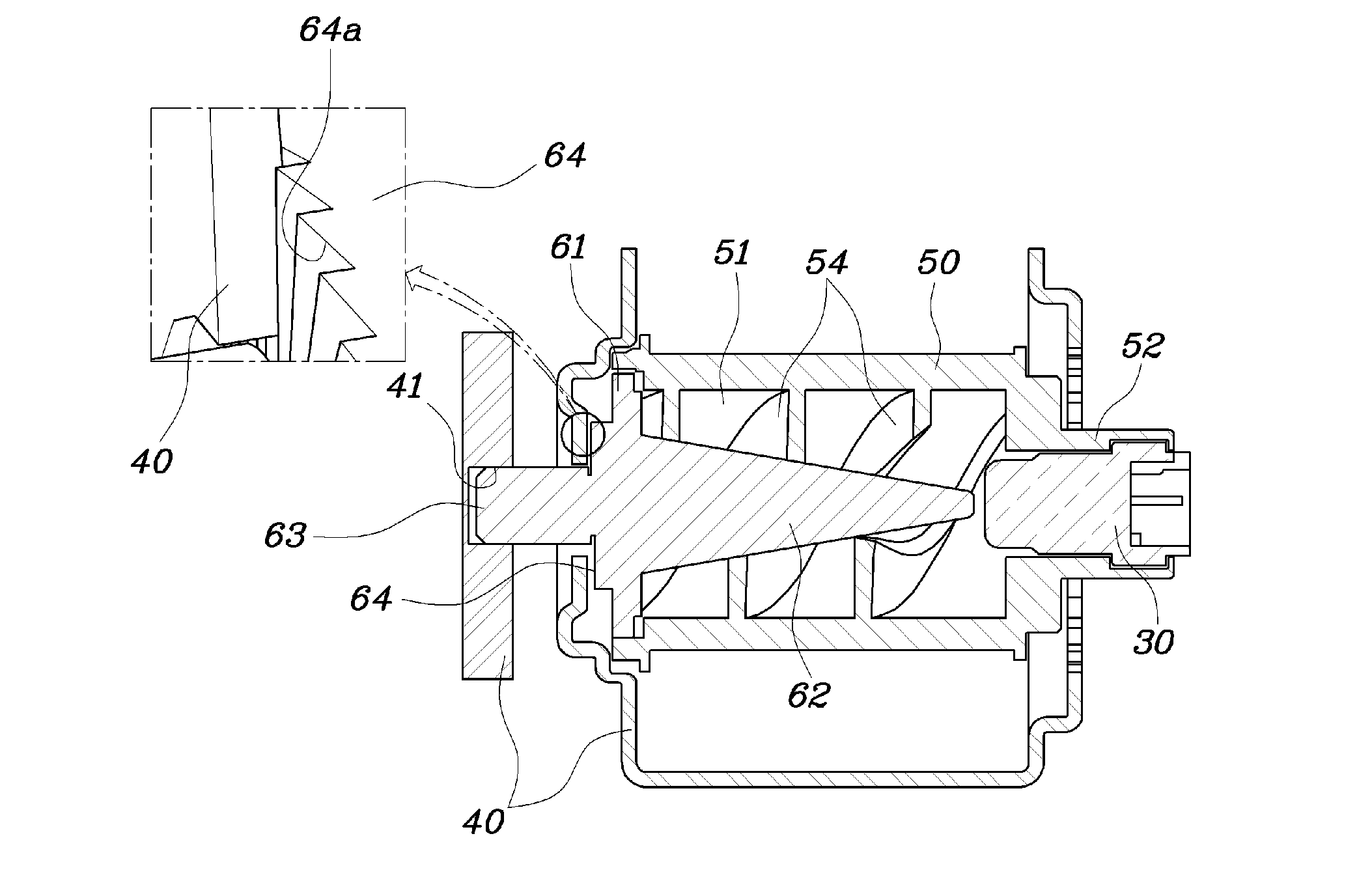

Piston guiding element, particularly piston guiding element for cylinder piston pump

InactiveCN102410208AFree from damageDamage no longerPositive displacement pump componentsPositive-displacement liquid enginesButt jointPiston Guide

The invention relates to a piston guiding element (62), particularly a piston guiding element (62) for a cylinder piston pump (10), the piston guiding element has one side that is in a butt joint with an inner lateral area (56) of the pump housing (14) and the other side that is capable of being movably supported at an outer curved surface area (52) of a piston (16) in order that the piston guiding element can guide the piston (16) capable of moving inside the pump housing (14) and provided with a low pressure side sealing unit (54) that is arranged on the outer curved surface area (52). According to the piston guiding element, the piston guiding element (62) covers the low pressure-sided sealing element (54) on its side that is facing towards the inner lateral area (56) of the pump housing (14) with a section.

Owner:ROBERT BOSCH GMBH

Engine wear protection in engines operated using ethanol-based fuel

ActiveUS20090111722A1Easy to wearGood for wear protectionOrganic compound preparationGroup 5/15 element organic compoundsEngineeringEngine wear

Owner:AFTON CHEMICAL

Ball pin and ball joint

ActiveUS20130071174A1Improve fatigue strengthImprove wear resistanceShaftsCouplings for rigid shaftsSurface layerSteel ball

A ball joint with a ball pin and a steel ball pin with a joint ball. The ball joint and ball pin are suitable for use when solid-on-solid friction predominates, for example under high static pre-loading or under high operational loads and with small joint movements. At least in a bearing contact area, between the joint ball and the bearing shell, does not include any nitrided layer. The surface of the ball pin has an oxide layer, provided as wear protection, at least in the bearing contact area of the joint ball. The oxide layer in the ball joints, previously regarded (as part of the nitriding treatment) as only improving corrosion protection functions as a form of wear protection. Thus, the mutual exclusion between increasing the fatigue strength (by surface layer hardening) and improving the wear resistance (by nitriding / oxidation) is overcome with such ball pins.

Owner:ZF FRIEDRICHSHAFEN AG

SP-grade gasoline engine oil and preparation method thereof

InactiveCN113201386AImprove antioxidant capacityImprove cleanlinessLubricant compositionGasolineProcess engineering

The invention discloses SP-grade gasoline engine oil and a preparation method thereof, and belongs to the technical field of lubricating oil. The gasoline engine oil comprises the following raw materials in percentage by mass: 5%-12% of a gasoline engine oil complexing agent; 4%-10% of a viscosity index improver; 0.1%-0.5% of a pour point depressant; 10%-30% of base oil A; and 50%-80% of base oil B. The preparation method comprises the following steps: sequentially adding the pour point depressant, the viscosity index improver, the gasoline engine oil complexing agent, the base oil A and the base oil B into a blending kettle, uniformly conducting mixing, and conducting stirring and filtering to obtain the SP-level gasoline engine oil. By adopting the technical scheme of the invention, a product with excellent comprehensive performance can be obtained, the viscosity-temperature performance is higher, the low-temperature fluidity is more excellent, the fuel economy is better, the shearing resistance is better, the important progressive significance is realized, and better protection is provided for a novel engine adaptive to National Six Emission Regulations.

Owner:金雪驰科技(马鞍山)有限公司 +1

Retractor pretensioner of seat belt for vehicle

Disclosed herein is a retractor pretensioner of a vehicle seat belt. The retractor pretensioner of the present invention may prevent an overshoot phenomenon in which residual pressure of gas impedes reverse rotation of a spool when the pretensioner operates as a load limiter. The pretensioner includes a spool around which the seat belt is wound and wherein the spool is rotatably installed in a frame to rotate the spool relative to the frame by gas pressure transmitted from a gas generator to the spool. In addition, the pretensioner includes a valve shaft that is installed in the spool, wherein the valve shaft operates as a rotating shaft of the gas generator with respect to the frame when the gas generator is not operated and as a valve, through which the gas is discharged out of the spool, when the gas generator is operated.

Owner:HYUNDAI MOTOR CO LTD

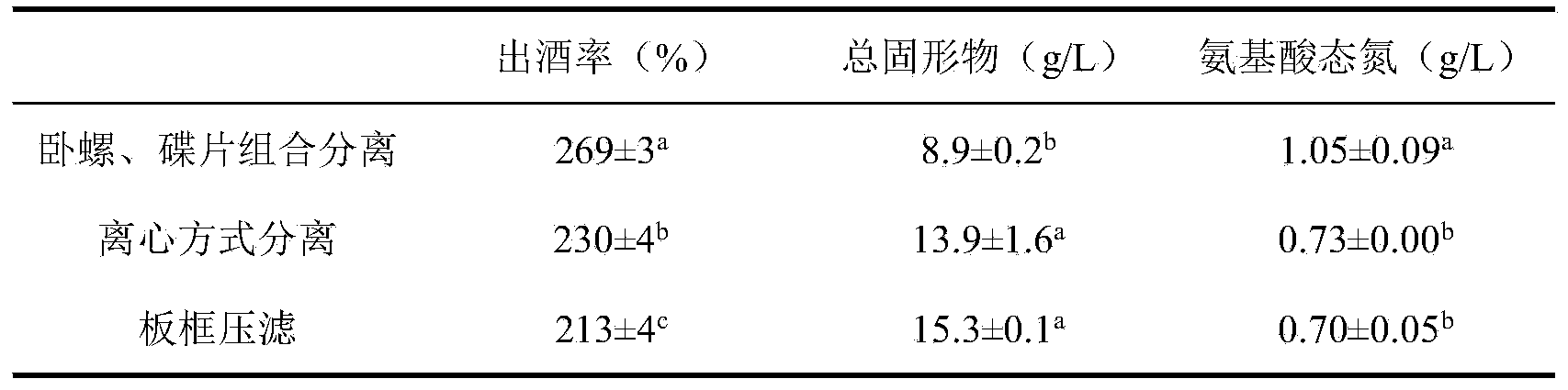

Method for centrifugal production of yellow wine employing horizontal screw-disk combination

InactiveCN104388287ABeautiful shapeReduce volumeAlcoholic beverage preparationSeparation factorEconomic benefits

The invention discloses a method for centrifugal production of yellow wine employing horizontal screw-disk combination, and belongs to the technical field of brewing. According to the method, solid-liquid separation on fermented mash of the yellow wine is carried out by adopting a combination of a horizontal screw centrifuge and a disc centrifuge; the squeezing process of the fermented mash of the yellow wine is regulated and controlled by adjusting the rotating speeds, differential speeds, separation factors, feeding flows and the like of the centrifuges; and the wine yield, total solid matter and amino acid nitrogen of the obtained yellow wine are evaluated. The fermented mash of the yellow wine is processed by adopting the horizontal screw centrifuge and the disk centrifuge, so that the wine yield of the yellow wine is obviously increased; the total solid matter in the obtained yellow wine is reduced; the amino acid nitrogen is increased; the quality of the yellow wine is improved; meanwhile, the method disclosed by the invention can be applied to industrial production; the squeezing process of the yellow wine is continuously operated; a lot of labor force and the space occupied by equipment are saved; and the method has great significance for technical progress of an enterprise and improvement of economic benefits.

Owner:JIANGNAN UNIV

Ultra low phosphorus lubricant composition

A low-phosphorus lubrication composition has less than 600 ppm phosphorus, comprising at least 85 weight % of a lubricating base blend, and an additive comprising the following, as weight % of the total composition:(1) an organomolybdenum compound at an amount which provides about 0.1-800 ppm Mo;(2) a hindered phenol at about 0.1-2%; and(3) a dithiocarbamate at about 0.1-2%;with a first proviso that where the dithiocarbamate does not comprise a metal dithiocarbamate, the additive additionally comprises:(4) an alkylated diphenylamine at about 0.1-2%,and with a second proviso that where the organomolybdenum compound comprises molybdenum dithiocarbamate, it is considered a metal dithiocarbamate for purposes of the first proviso, but is considered an organomolybdenum compound for the purposes of calculation of the amount present in the total composition.

Owner:VANDERBILT CHEM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com