Diesel lubricant oil, preparation method thereof, and application thereof in diesel engines

A diesel engine oil and lubricating base oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of insufficient oil film strength, insufficient strong and durable output power, and high fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

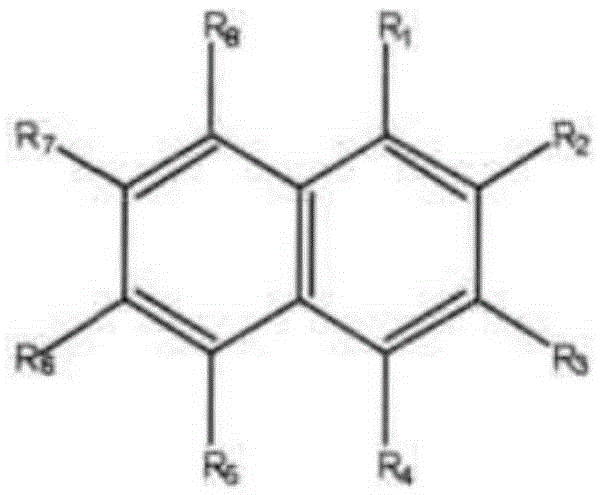

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: prepare diesel engine oil

[0063] The used raw material of preparation diesel engine oil (based on the gross weight of described diesel engine oil, the percentage used is percentage by weight) is as follows: base oil A (PAO6) 64%, base oil B (AN23) 20%, base oil C (PAO100) 12.5%, T106B 1.5%, T2022%.

[0064] The preparation method is as follows: Weigh the above base oil components according to the above mass ratio, add PAO6 into the reactor, control the temperature of the reactor at 35°C, add alkylnaphthalene base oil AN23 into it, stir After uniformity, add PAO100 preheated to 60°C to it, and continue stirring for 30 minutes after the addition is completed. Then add dispersant T106B and antioxidant T202 at room temperature, stir for 60 minutes, and sieve through stainless steel to obtain the product.

Embodiment 2

[0065] Embodiment 2: prepare diesel engine oil

[0066] The used raw material of preparation diesel engine oil (based on the gross weight of described diesel engine oil, the percentage used is percentage by weight) is as follows: base oil A (PAO8) 60%, base oil B (AN12) 18%, base oil C (PAO150) 18%, T106B2%, T2022%.

[0067] The preparation method is as follows: Weigh the above base oil components according to the above mass ratio, add PAO8 into the reaction kettle, control the reaction temperature at 35°C, add alkylnaphthalene base oil AN12 to it, stir After uniformity, add PAO150 preheated to 60°C to it, and continue stirring for 30 minutes after the addition is completed. Then add dispersant T106B and antioxidant T202 at room temperature, stir for 60 minutes, and sieve through stainless steel to obtain the product.

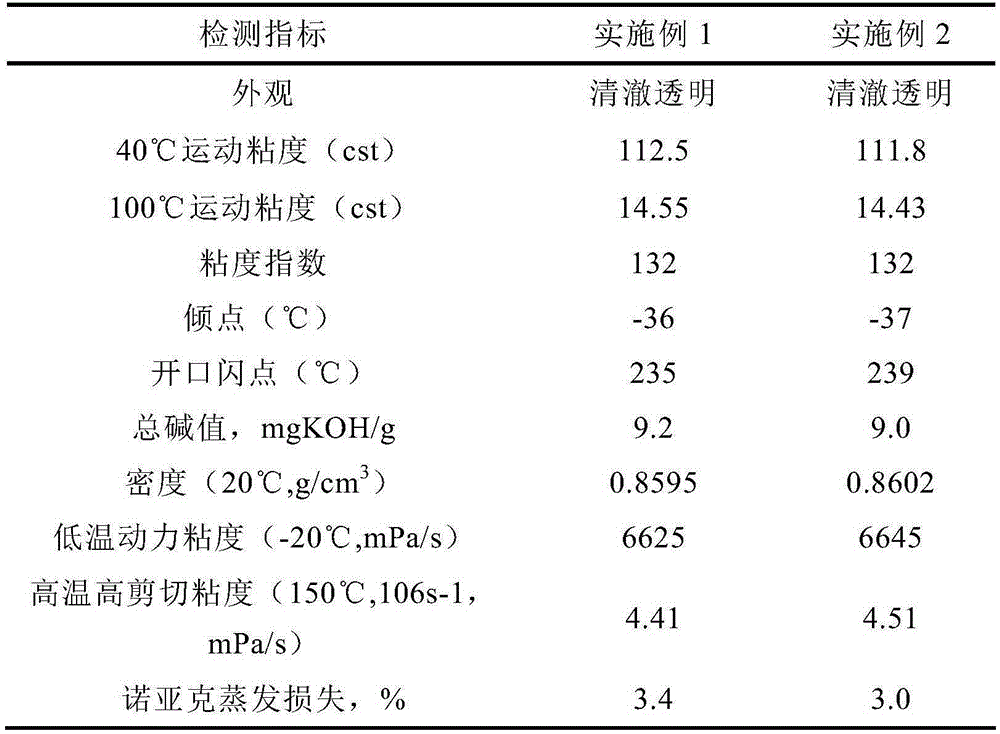

[0068] The performance data of the products obtained in Examples 1-2 of the present invention are shown in Table 1.

[0069] Table 1 Performance data

[00...

Embodiment 3

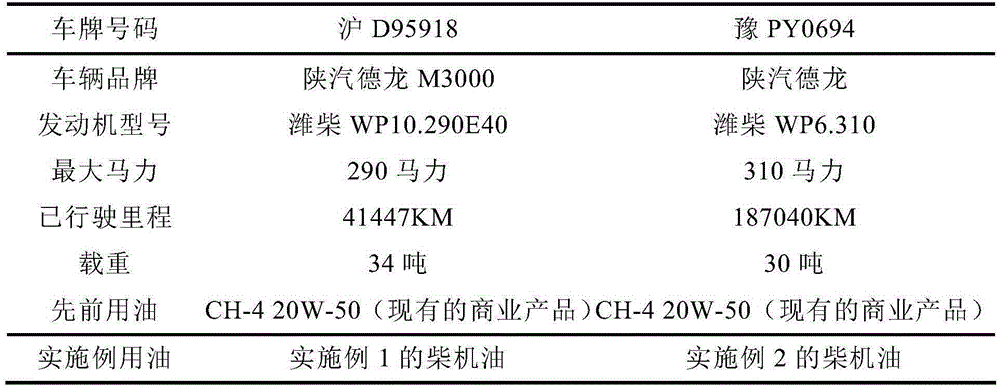

[0071] Embodiment 3 Diesel engine oil performance test

[0072] For detecting the performance of the diesel engine oil of the present invention, the diesel engine oil of the present invention is used for the diesel engine of the heavy-duty truck of Shanghai D95918 and Henan PY0694 with the grade, and the concrete situation of these two heavy-duty trucks is as shown in table 2.

[0073] Table 2 Heavy Truck Information

[0074]

[0075] In order to ensure the accuracy of the test results, to prevent the quality change caused by the mixing of different oil products, before the test starts, the old oil of the two test vehicles is completely emptied, and new filters are replaced, and the diesel oil of the present invention is added. For engine oil, after the above steps are completed, the test officially begins, and the sampling mileage is set as: 3000-5000 kilometers, 10000 kilometers, 20000 kilometers, 30000 kilometers, 45000 kilometers, 60000 kilometers. The inventor used sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com