A centrifugal separator

A technology for centrifugal separators and conveyors, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of increased energy, complexity, and difficulty in discharging hard solid blocks of screw conveyors, and achieve reduction effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

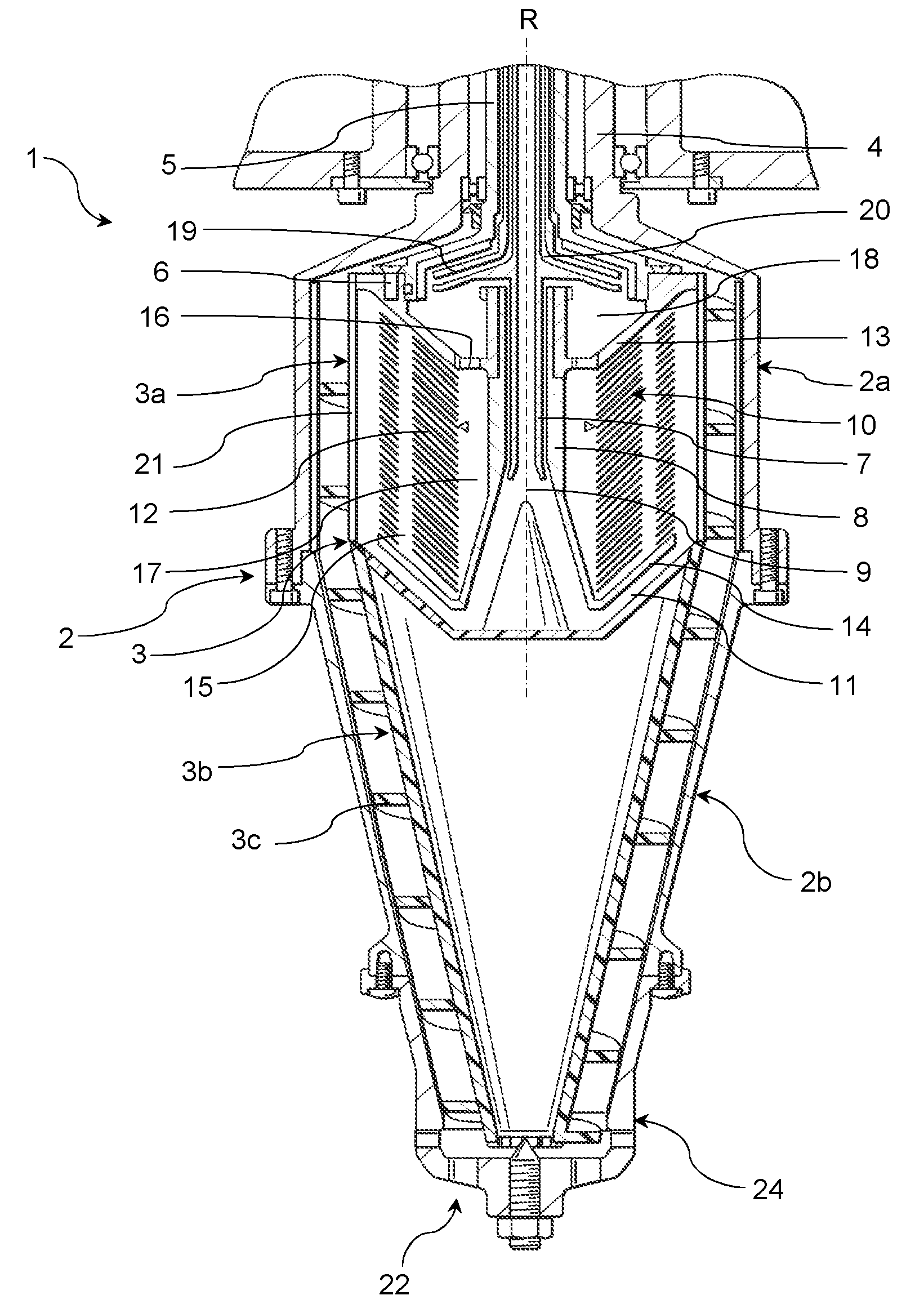

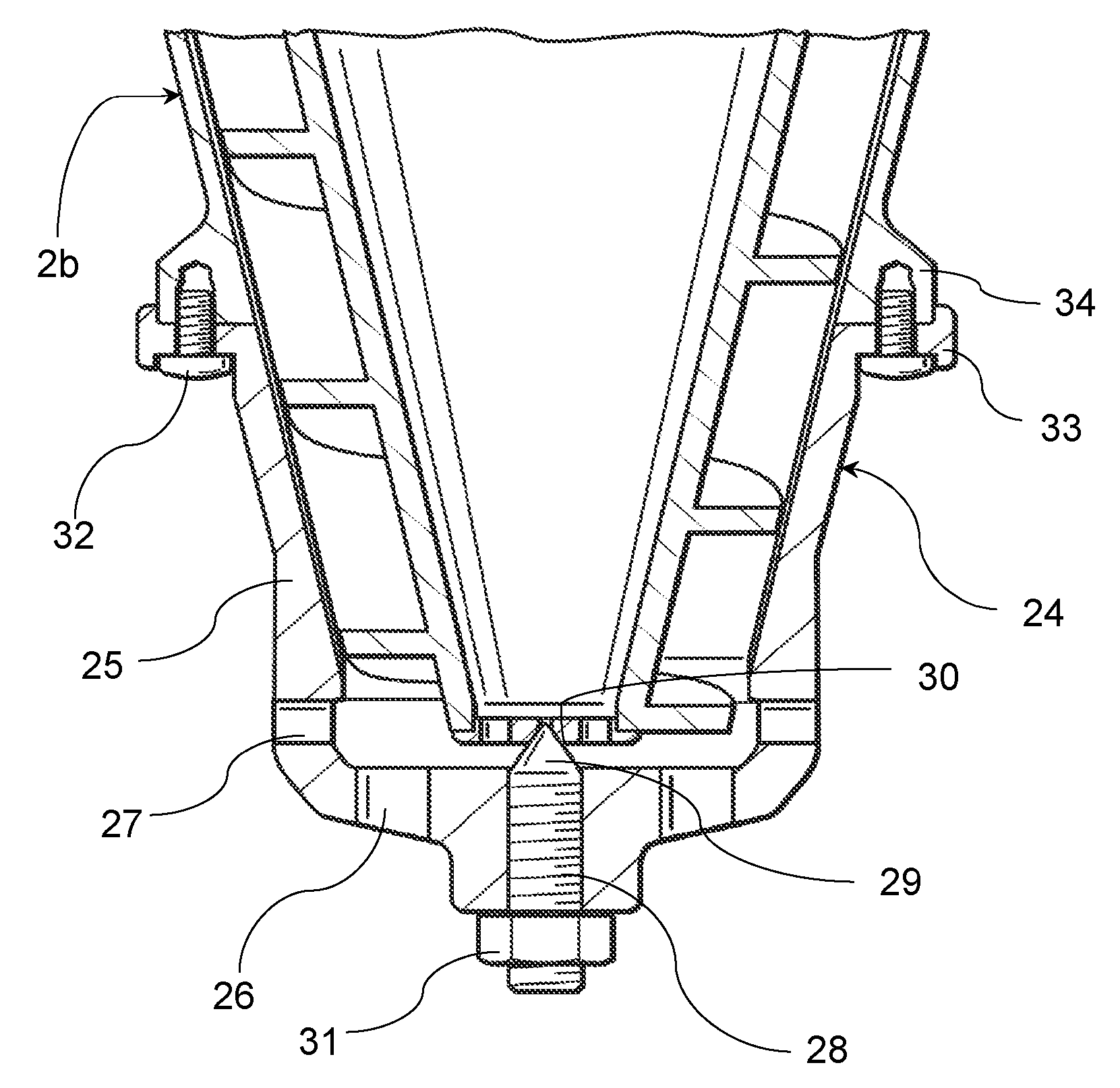

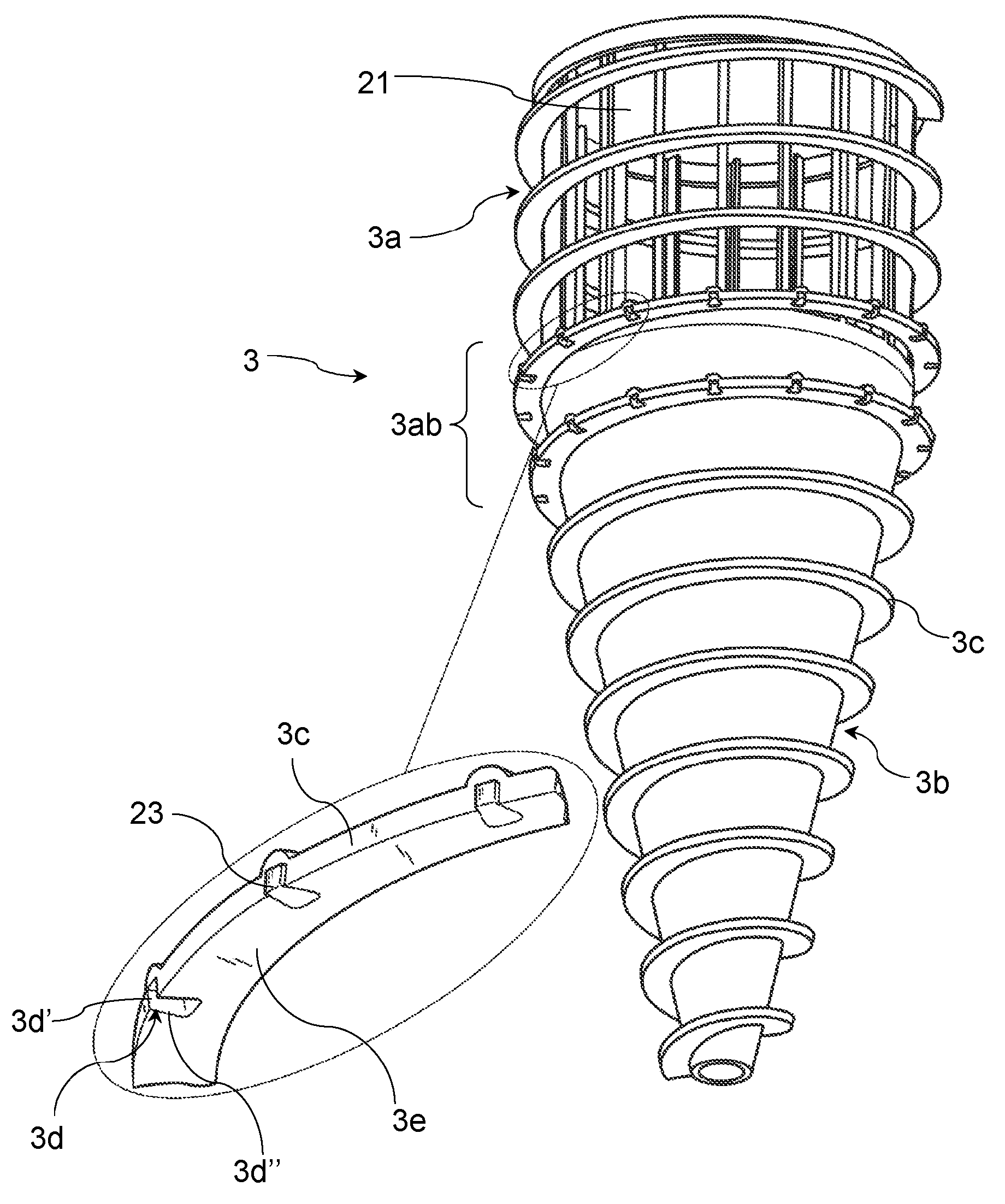

[0026] figure 1 A centrifugal separator 1 according to an embodiment of the invention is shown. The centrifugal separator 1 comprises: a rotor 2 which can rotate at a certain speed about a vertical axis of rotation R; The rotation speed is the speed at which to rotate.

[0027] The centrifugal separator 1 is intended to be suspended vertically in the manner indicated by WO 99 / 65610 A1. The means required to suspend and drive the centrifugal separator 1 are therefore not described here.

[0028] The rotor 2 has a substantially cylindrical upper rotor part 2a and a substantially conical lower rotor part 2b, the rotor parts 2a and 2b being connected to each other by screws. Optional connection parts can of course be used. The cylindrical rotor part 2a comprises an axially upward extension in the form of a hollow rotor shaft 4 which is connected to drive means (not shown) for rotating the rotor 2 about an axis R of rotation.

[0029] A further hollow shaft 5 extends through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com