Tooth and Adaptor Assembly

a technology of adaptors and teeth, applied in the field of mining and construction industries, can solve the problems of extreme wear on teeth, inconvenient casting, and inability to meet the needs of use, and achieve the effects of reducing high stress regions, easy casting, and extreme difficulty in removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

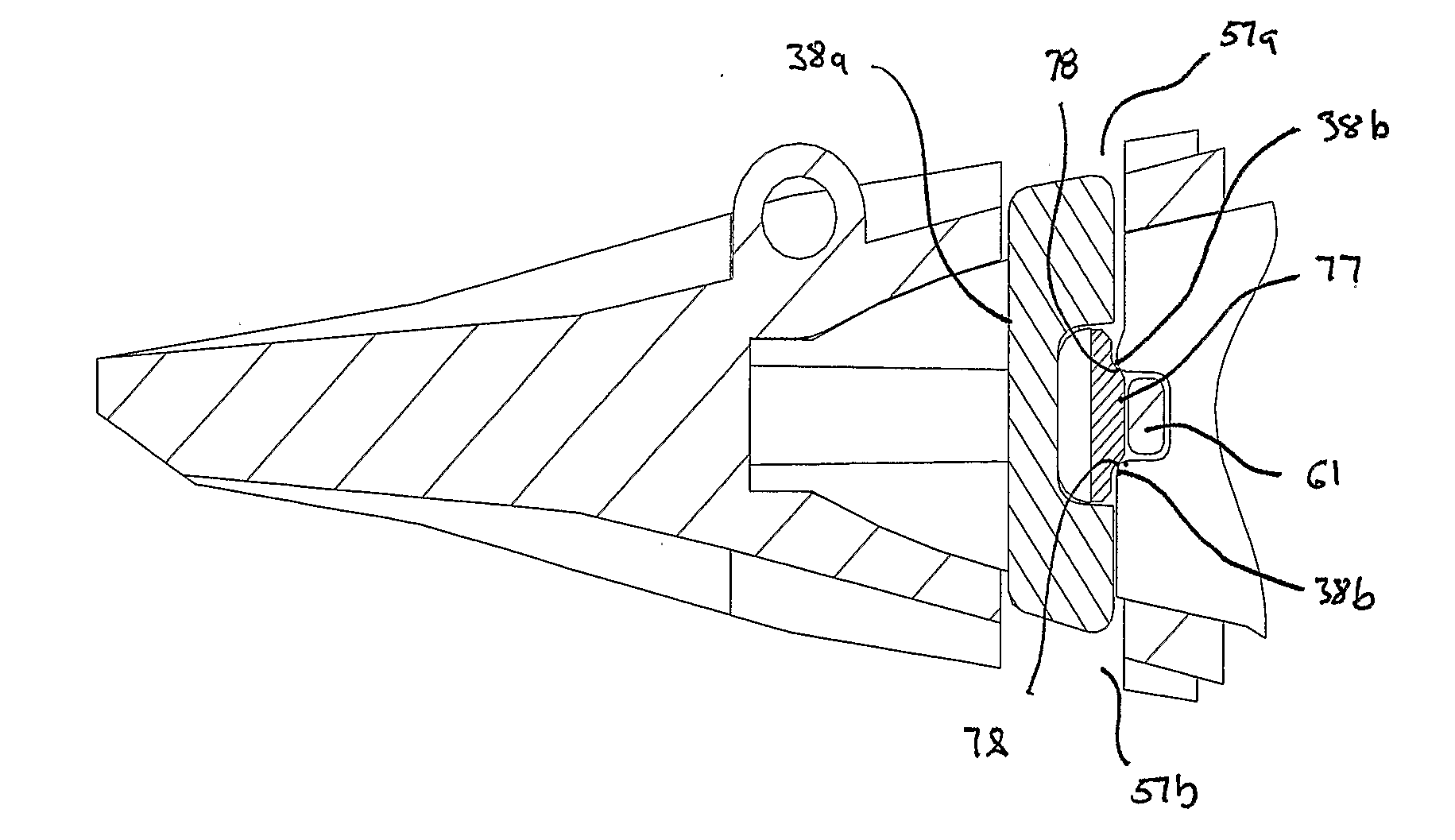

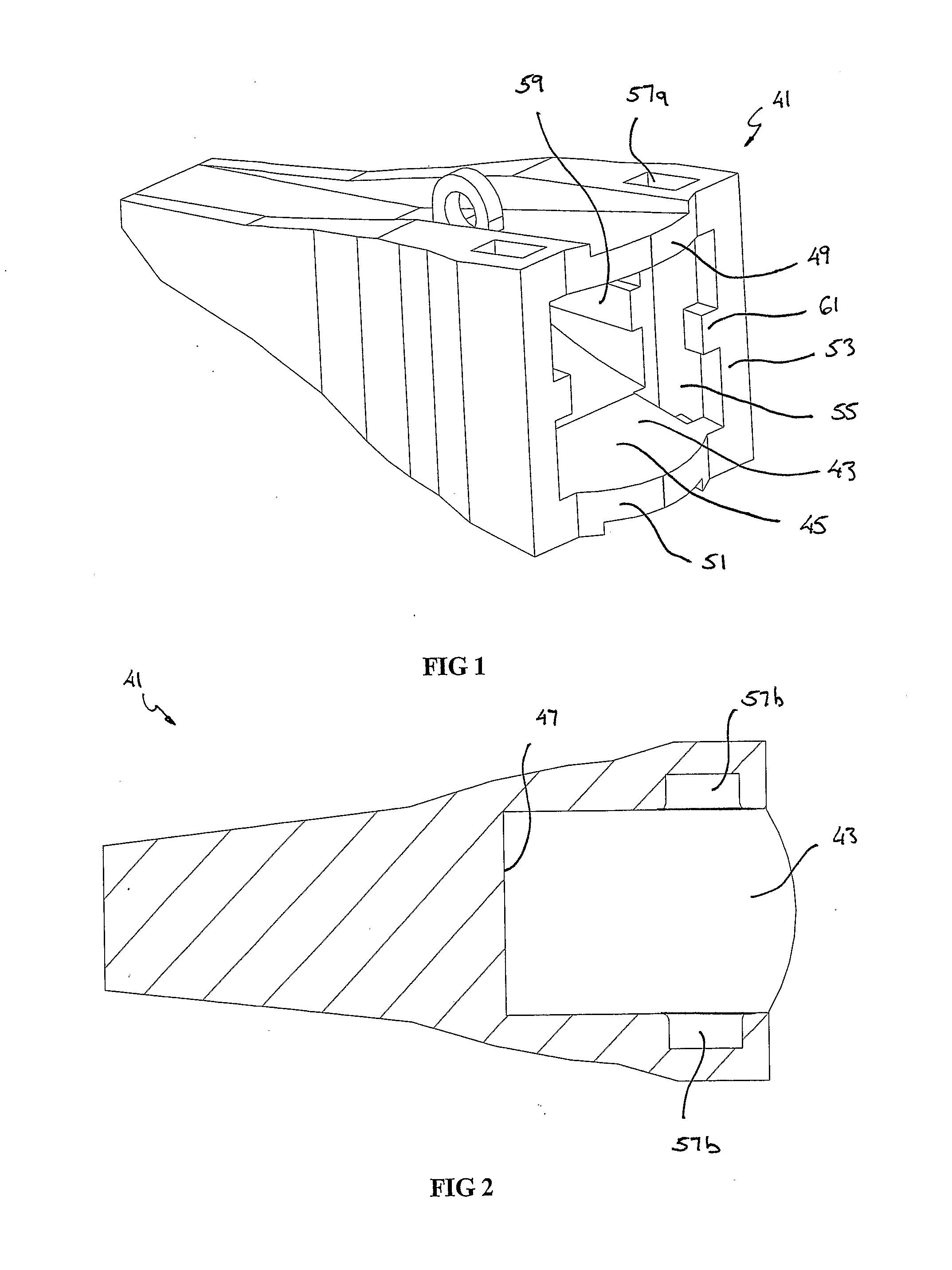

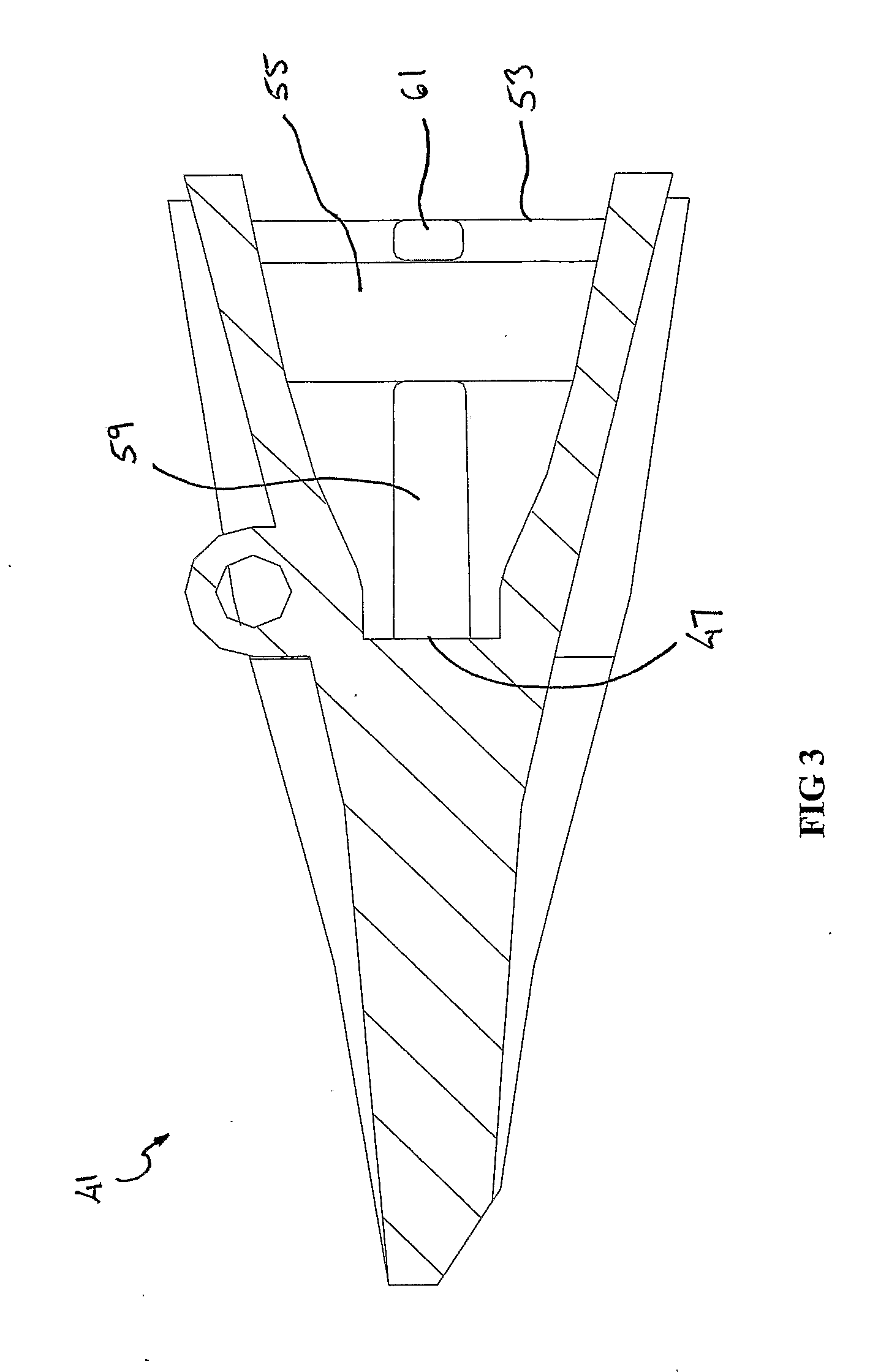

[0116]Referring to the FIGS. 1 to 19, the invention according to a first embodiment of the invention comprises a tooth and adaptor assembly 11 for use on earthmoving or similar machinery. The assembly 11 comprises an adaptor 21, having a first end 23 adapted to receive a tooth 41, with a locking mechanism 71 being received therein to lock the tooth 41 relative to the adaptor 21.

[0117]Shown in FIGS. 9 to 14 is the adaptor 21. The adaptor 21 has a second end 25 adapted to be secured to a bucket or like component on the earthmoving machinery (not shown). The configuration of the second end 25 varies according to its particular application.

[0118]The adaptor 21 comprises a nose 27 at the first end 23. The nose 27 diverges outwardly in a rearward direction from a front surface 29. The nose 27 comprises an upper surface 31, a lower surface 33, both having a curved contour, and two sidewalls 35.

[0119]Each sidewall 35 incorporates a first channel 37 extending longitudinally along the nose 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com