Ball pin and ball joint

一种球头销、球头节的技术,应用在球头节领域,能够解决相互排斥等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

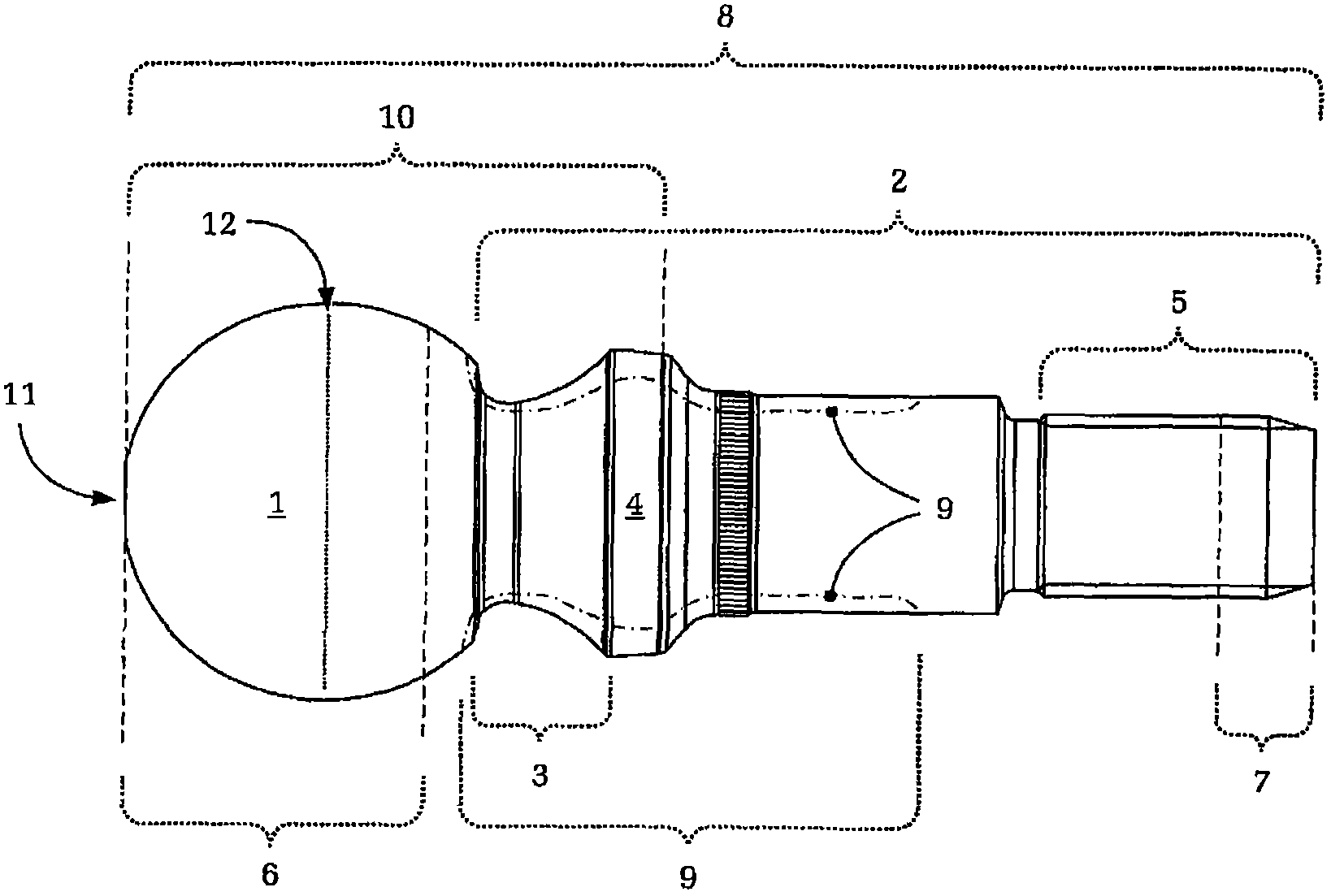

[0031] It can be seen from the figure that the ball stud has an articulation ball 1 , a shank area 2 , a neck area 3 , a sealing area 4 (for abutting against a sealing capsule) and a threaded area 5 .

[0032] The ball stud shown here is provided with a nitrided layer in the partial region 6 of the joint ball 1 extending from the dome 11 to the equator 12 and in the region 7 of the threaded end. Here, the nitrided layer in the regions 6 and 7 serves not only as usual for good corrosion protection, but also, as known to the applicant, in particular for protection against wear. The ball stud shown is therefore particularly suitable for high static initial loads and / or frequent operating periods with micro-movements, in which solid-body friction prevails between the ball stud and the spherical socket.

[0033] The illustrated embodiment of the ball pin also has an oxide layer, in particular an iron oxide layer, over its entire length or on the surface 8 . This oxide layer furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com