Ultraphonic elliptical vibration and extrusion processing device based on double-excitation longitudinal bending elliptical energy converter

A technology of elliptical vibration and extrusion processing, which is applied in the direction of auxiliary devices, metal processing equipment, and fluids utilizing vibration, etc. It can solve the problems of restricting the popularization and use of vibration extrusion processing technology, the decline of extrusion processing quality, and the reduction of tool life. , to reduce processing costs, reduce impact and scratches, and increase reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings.

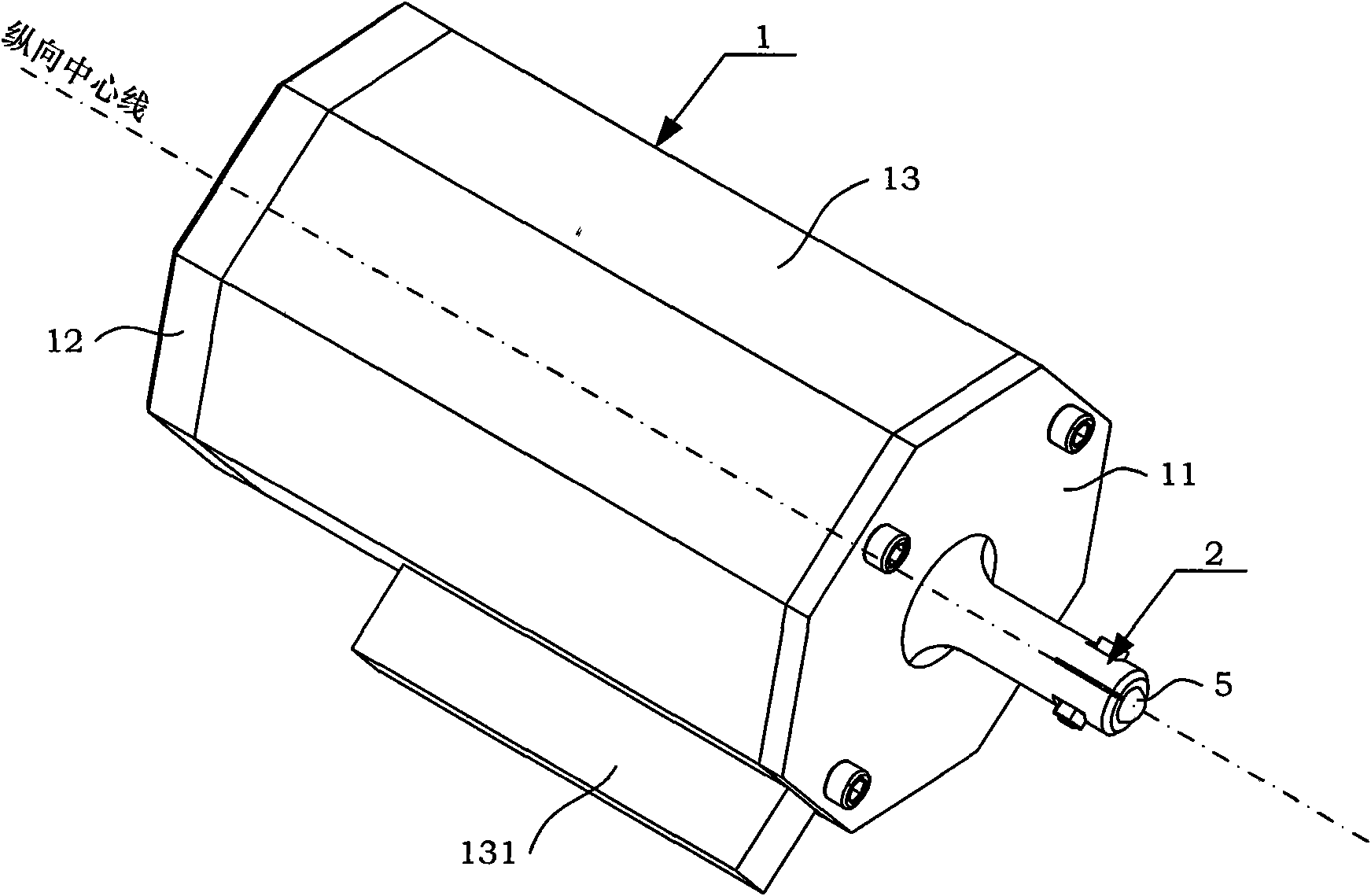

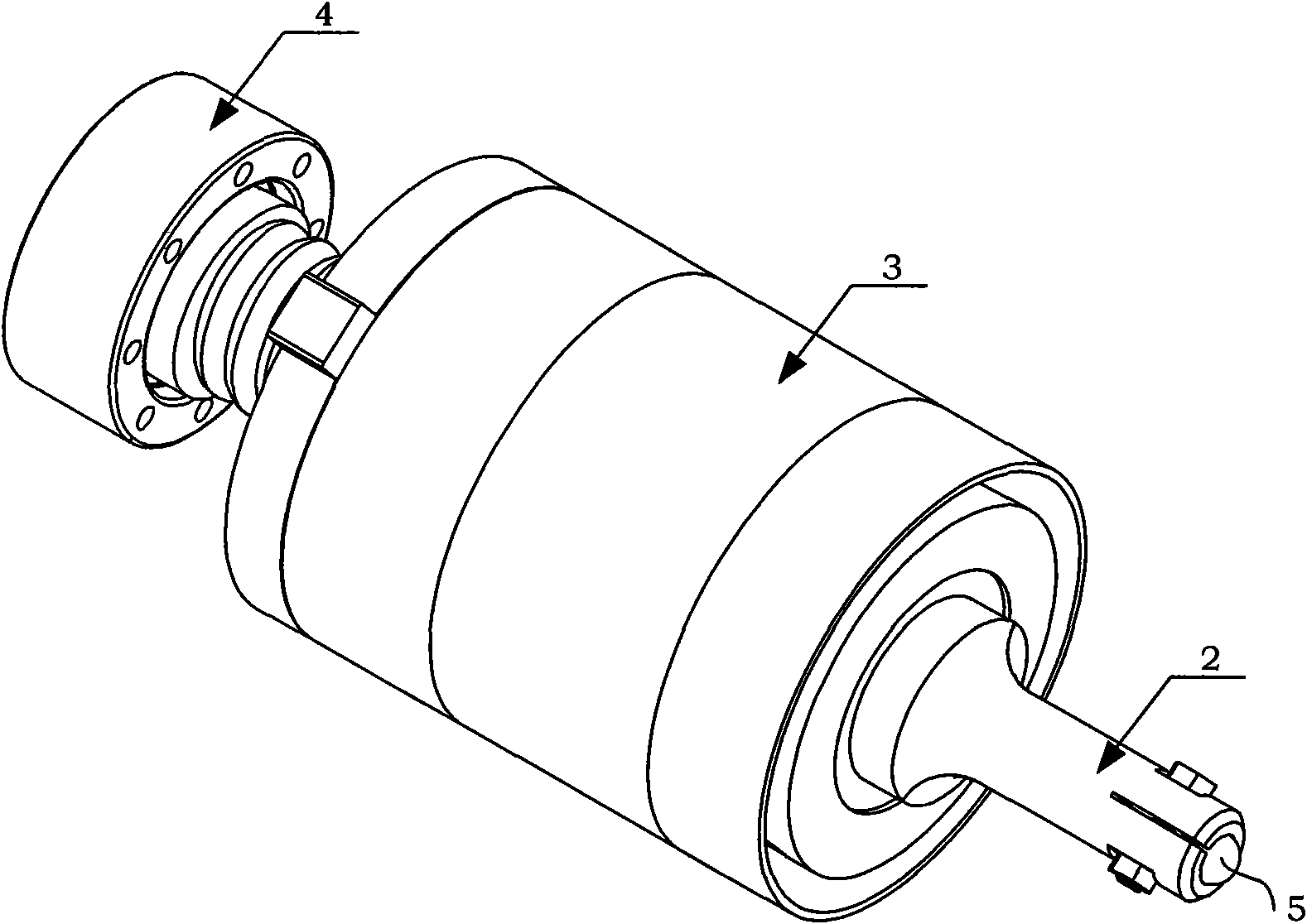

[0043] see figure 1 , Figure 1A , Figure 1B , Figure 1C As shown, an ultrasonic elliptical vibration extrusion processing device based on dual excitation longitudinal bending elliptical transducers of the present invention includes a shell assembly 1 , a vibration assembly 2 , a sliding assembly 3 and a pressure assembly 4 .

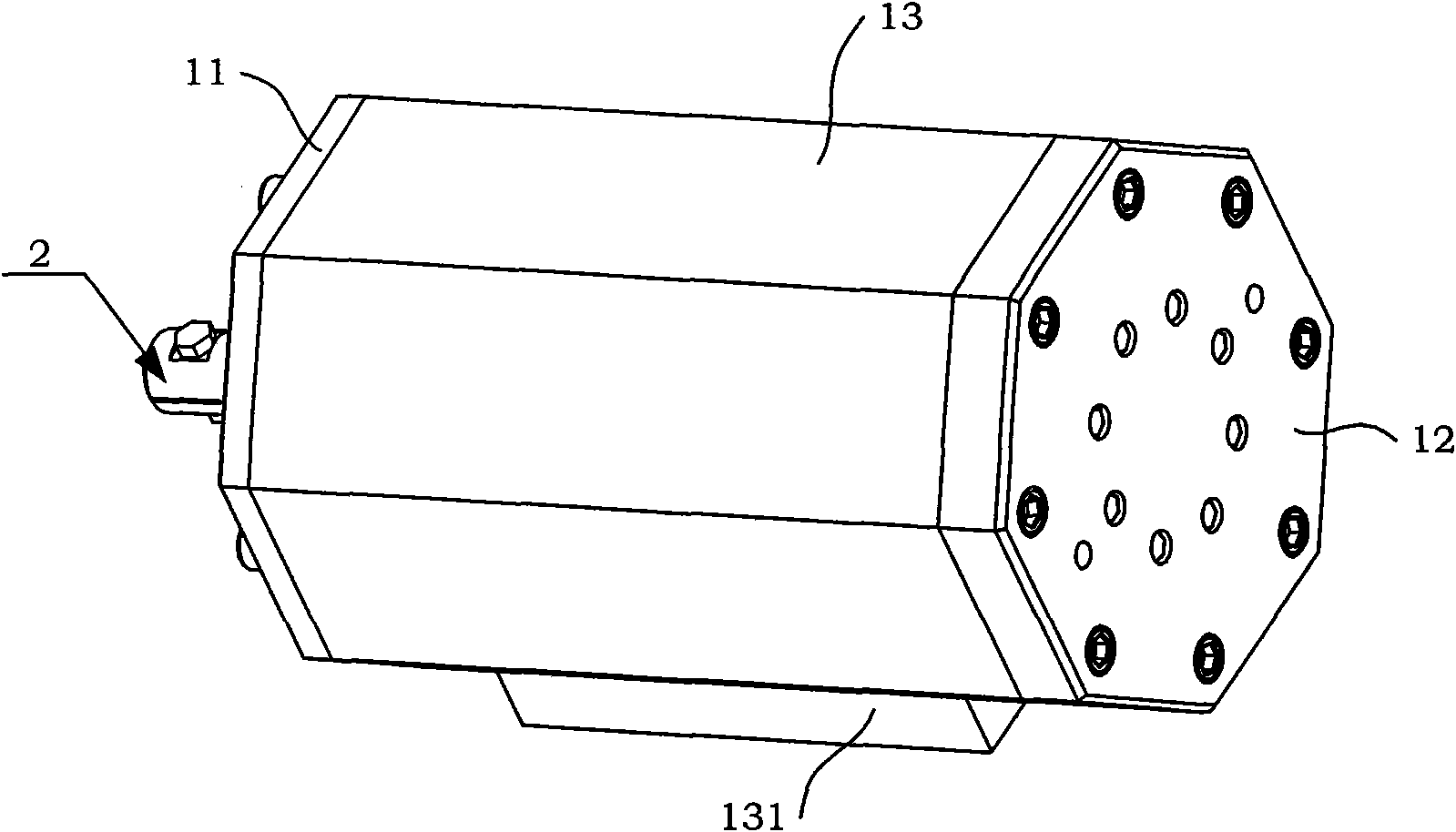

[0044] 1. Shell components

[0045] see figure 1 , Figure 1A , figure 2 , Figure 2A , Figure 2B As shown, the housing assembly 1 includes a front cover 11 , a rear cover 12 and a base 13 .

[0046]The front cover 11 is provided with an X through hole 111 and an A through hole 112 , and the A through hole 112 is set at the center of the front cover 11 , and the A through hole 112 is used for the output end 21 a of the horn 21 to pass through. The X through hole 111 is arranged around the A through hole 112. The X through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com