Patents

Literature

42results about How to "Master the working status" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

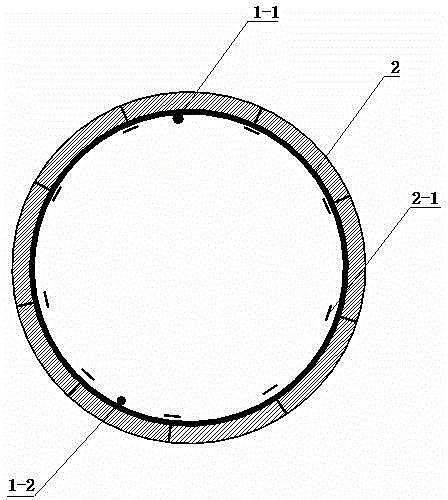

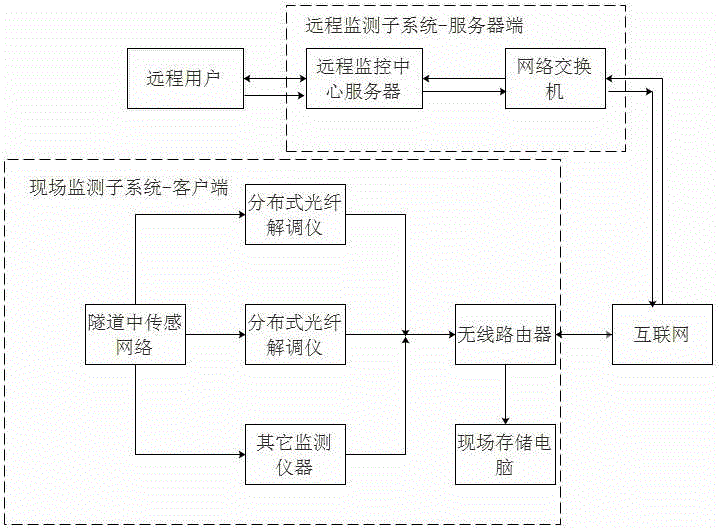

Tunnel structure monitoring system and tunnel structure monitoring method based on distributed long-gauge fiber bragg grating

The invention discloses a tunnel structure monitoring system and a tunnel structure monitoring method based on a distributed long-gauge fiber bragg grating. The system comprises distributed long-gauge fiber bragg grating sensors which are comprehensively distributed in a monitored range along the axial direction and the cross section of a tunnel; and longitudinal sedimentation of the tunnel and change conditions of various ring joints of the shield tunnel are monitored. The method comprises the following steps of arranging the distributed long-gauge fiber bragg grating sensors; and acquiring, transmitting and processing data. By the tunnel structure monitoring system and the tunnel structure monitoring method based on the distributed long-gauge fiber bragg grating, full-life monitoring on a tunnel structure in a construction period and a running period can be carried out, and longitudinal sedimentation, convergence deformation, joint deformation, duct piece internal force, strain and the like of the tunnel structure are dynamically monitored in real time.

Owner:SOUTHEAST UNIV +2

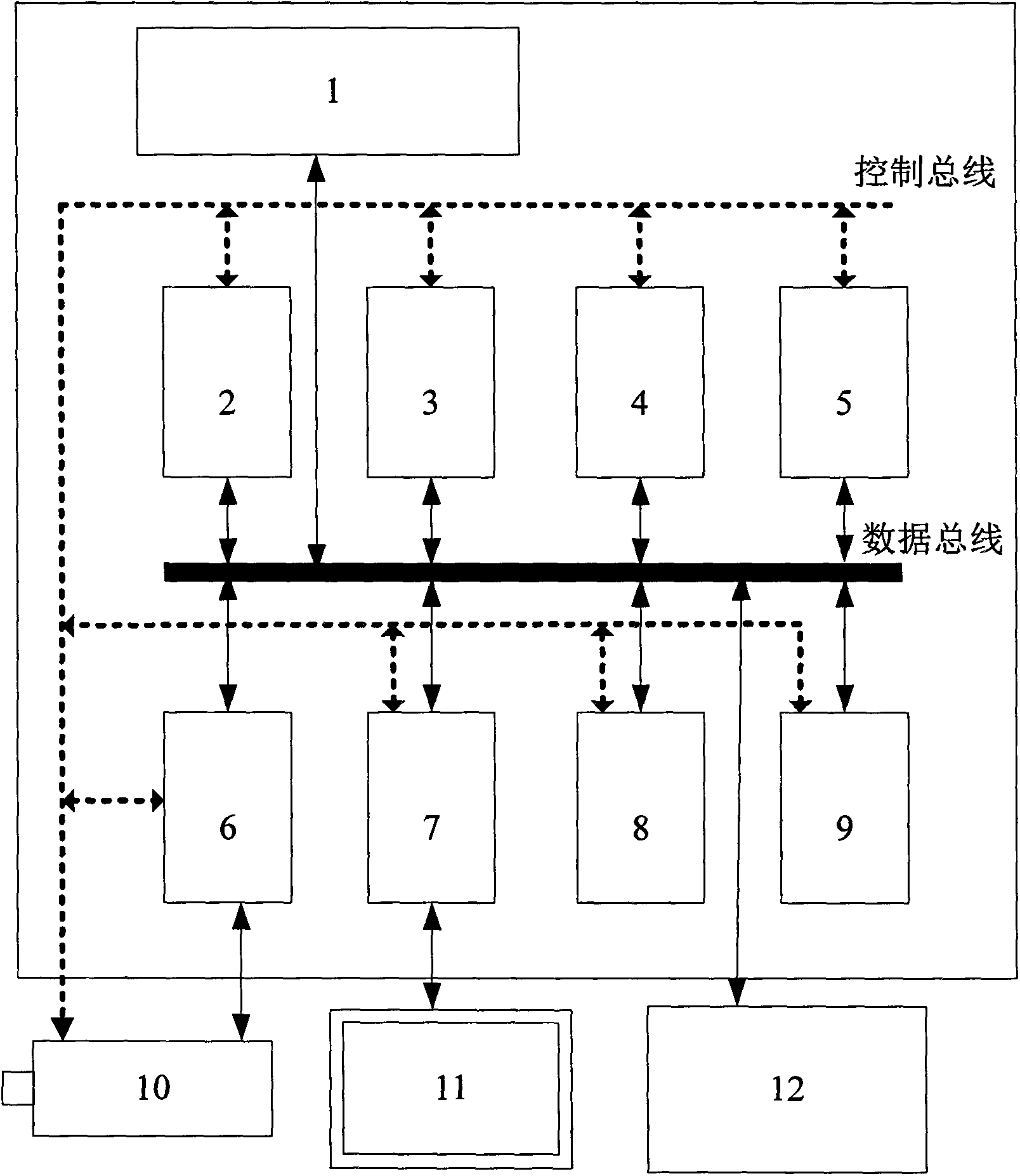

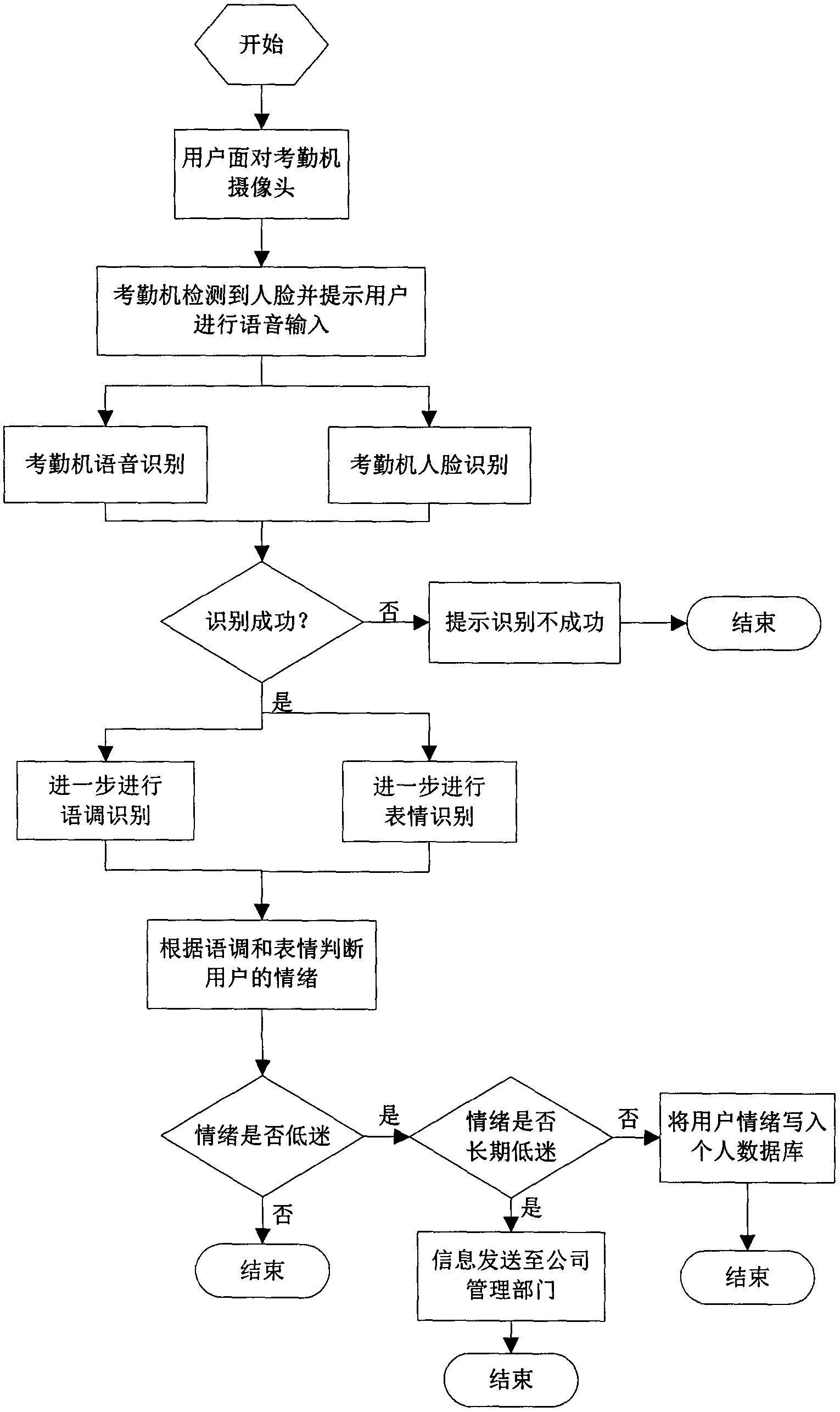

Attendance recording system having emotion identification function, and method thereof

InactiveCN103530912ASolve the defects of single function and impersonalizationMaster the working statusRegistering/indicating time of eventsSpeech identificationImage code

An attendance recording system having an emotion identification function is characterized in that the system comprises a central processor, a face and expression identification unit, a voice and tone identification unit, an emotion discrimination unit, an image memory, a bus, an image coding / decoding circuit, a sound processing portion, a database, an image input circuit, an LCD output circuit, an LCD display and an image acquisition device. The intelligent attendance recording system identifies the employee identity through dual examination comprising face identification and voice recognition, and more importantly, the system can discriminate the emotion and state of an employee through the face expression and the sound tone of the employee. The system allows the manager of a company to conveniently master the work states of employees everyday and helps the adjustment of the employees to an active work state.

Owner:深圳市迈瑞思智能技术有限公司

Performance evaluation system and method of photovoltaic system

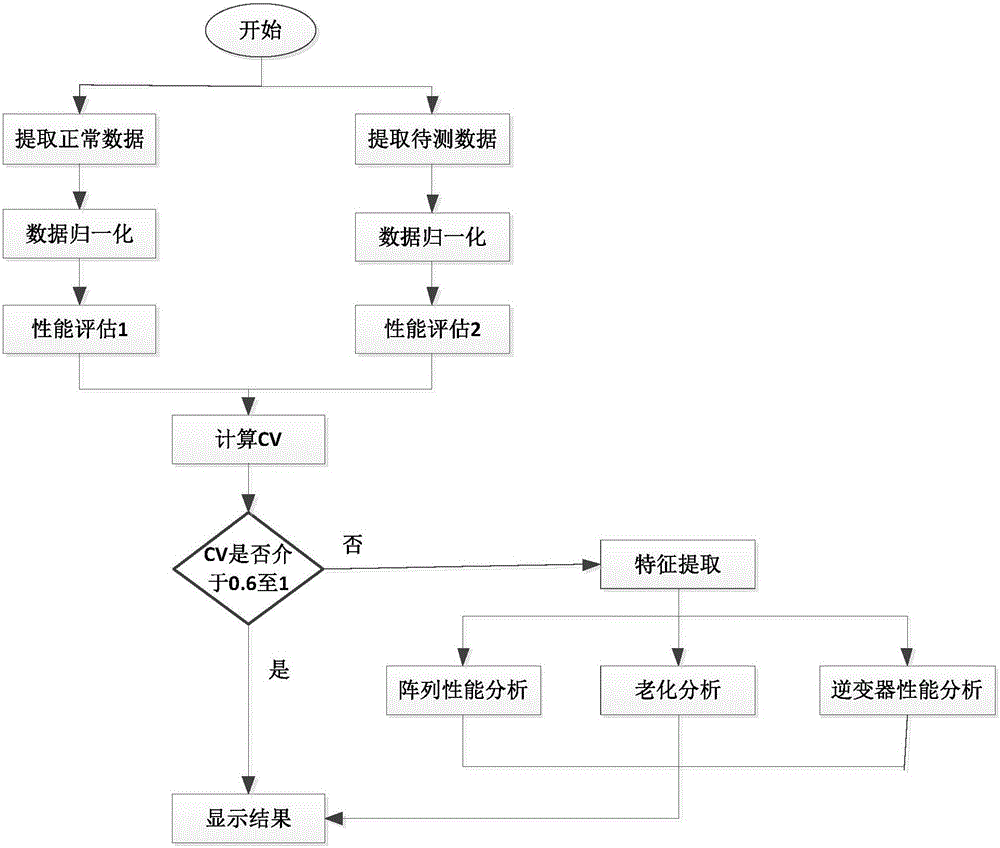

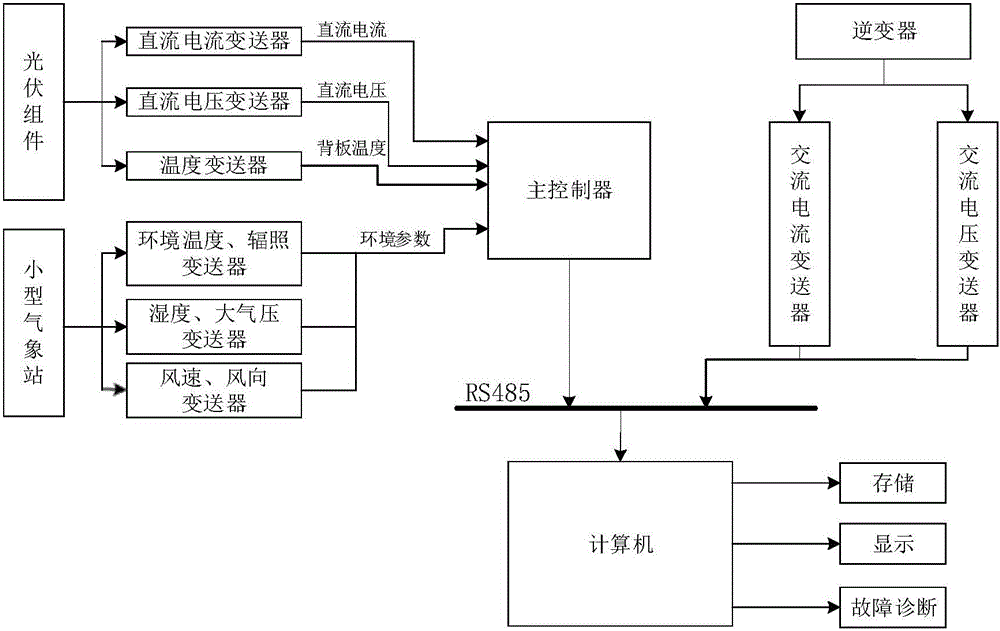

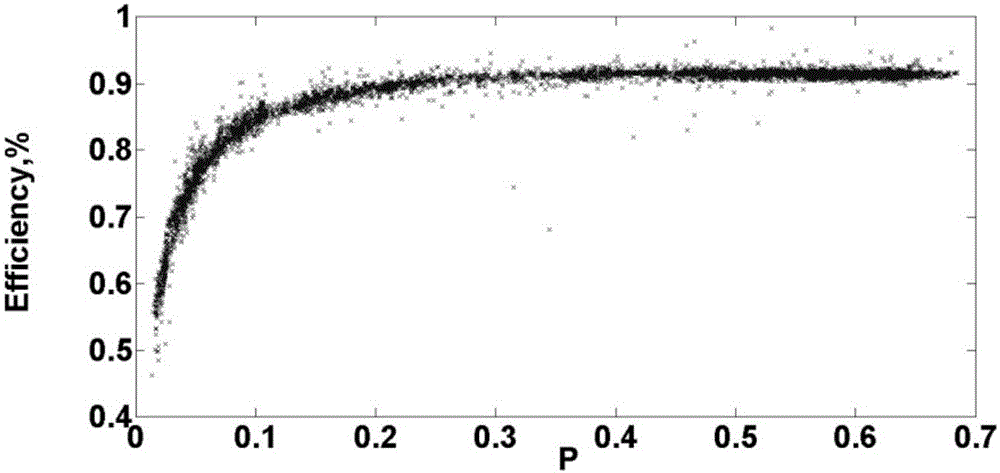

InactiveCN105024644AMaster the working statusImprove stabilityPhotovoltaic monitoringPhotovoltaic energy generationPrincipal component analysisData acquisition

The invention discloses a performance evaluation system and method of a photovoltaic system. The system comprises a data acquisition module and a performance evaluation unit. With utilization of direct-current data, alternating-current data, and meteorological data collected by the data acquisition module, normal working data and to-be-tested data form samples; standardization is carried out and a mahalanobis distance is used as a performance evaluation index to carry out direct-current power evaluation; a similarity level CV value of evaluation done twice is calculated; if the CV is larger than 0.8 and is less than 1 or is larger than 0.6 and is less than 0.8, the system performance is indicated to be good and then new round evaluation is carried out; and if the CV is larger than 0 and is less than 0.6, the system performance is indicated to be poor, a main factor influencing the system performance is extracted by using a principal component analysis method, and the photovoltaic array performance, assembling aging, and inverter performance are analyzed, and then the analysis result is displayed on an upper computer interface. According to the invention, the implementation process is simple and is easy to do; the photovoltaic system performance can be analyzed timely; the working state of the photovoltaic system can be gotten accurately; and the stability and reliability of the system are improved.

Owner:HOHAI UNIV CHANGZHOU

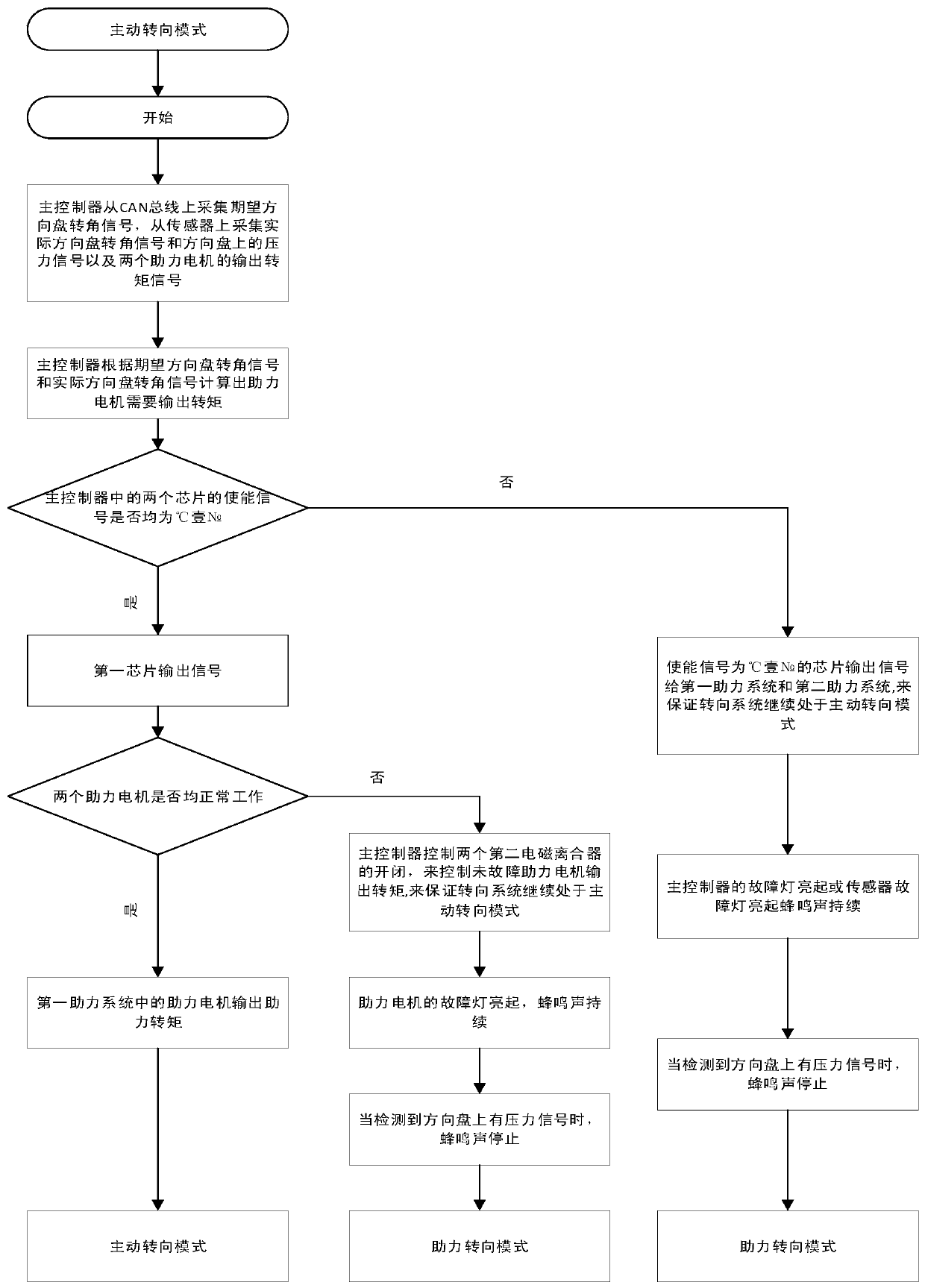

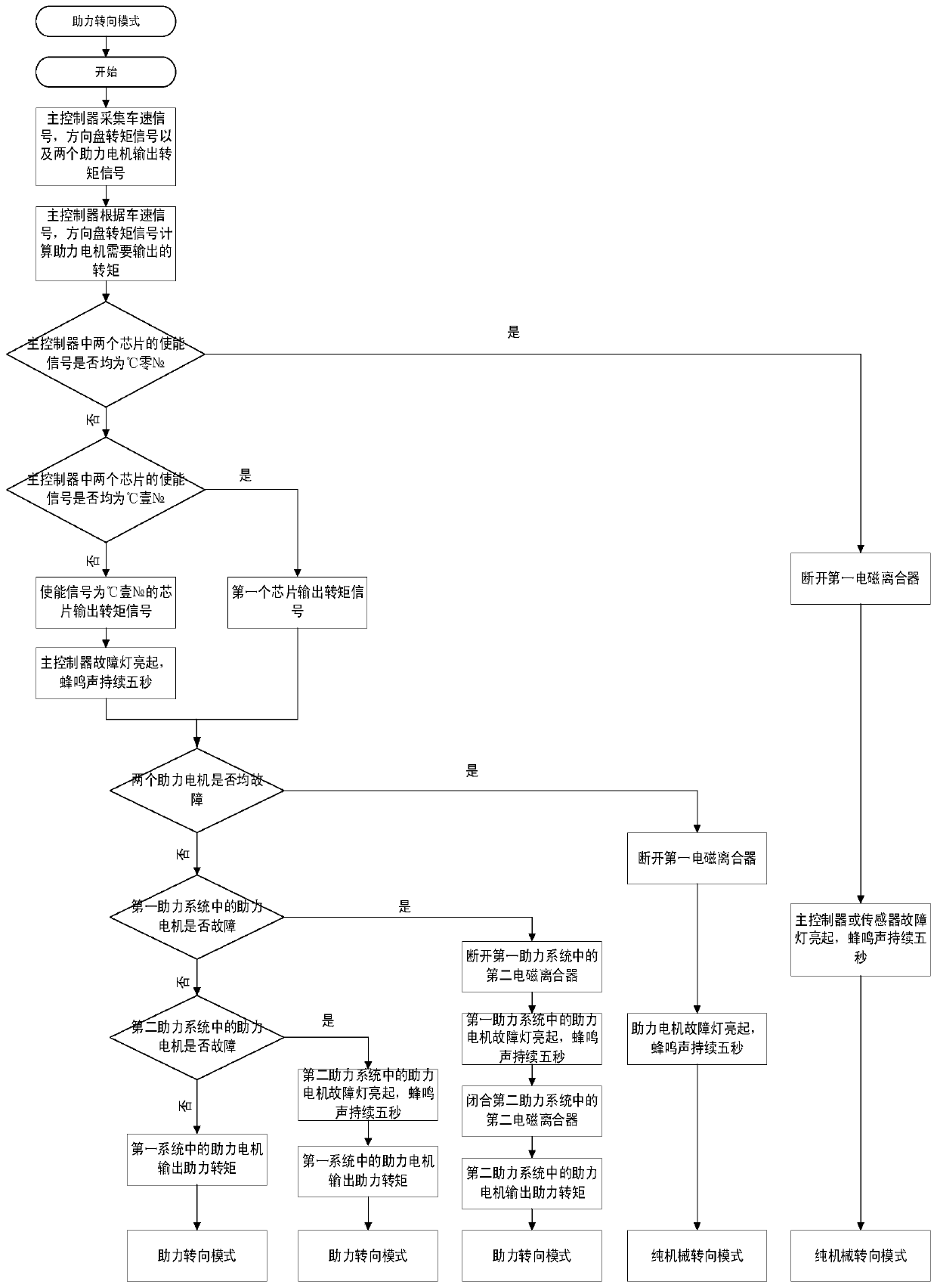

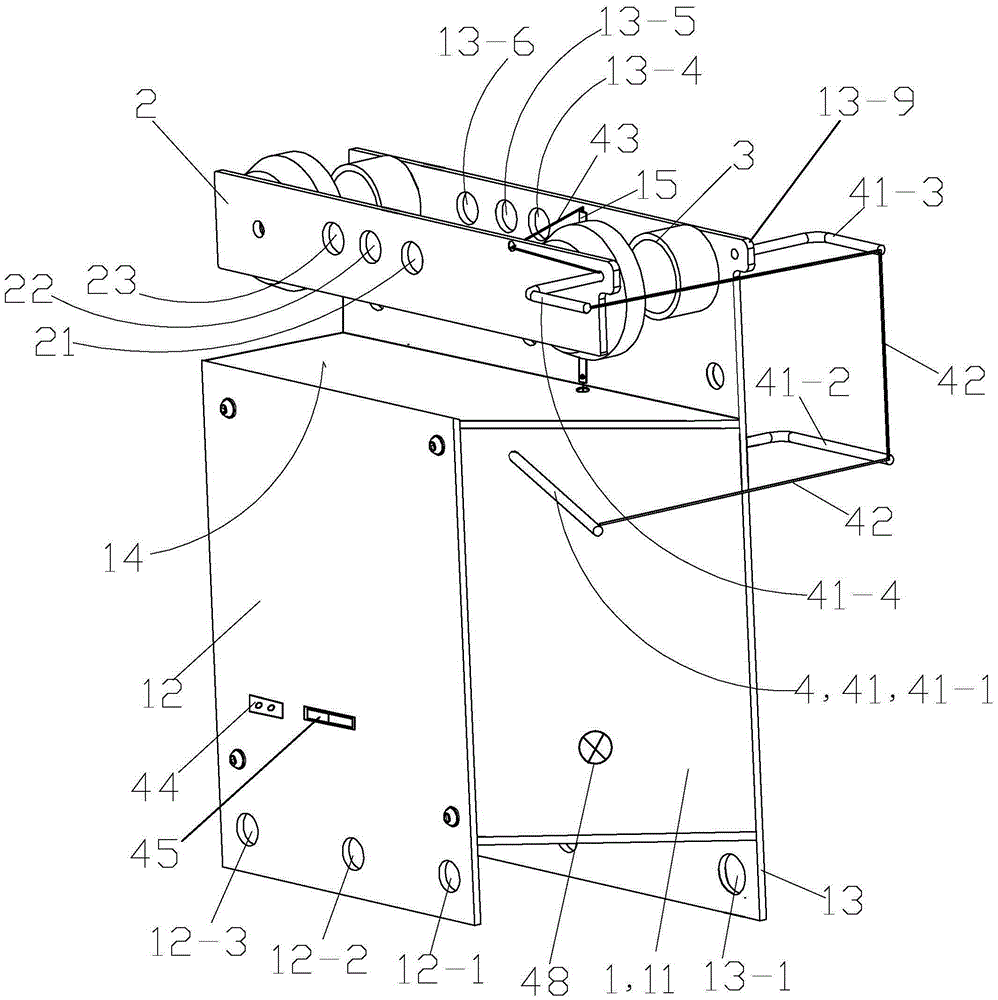

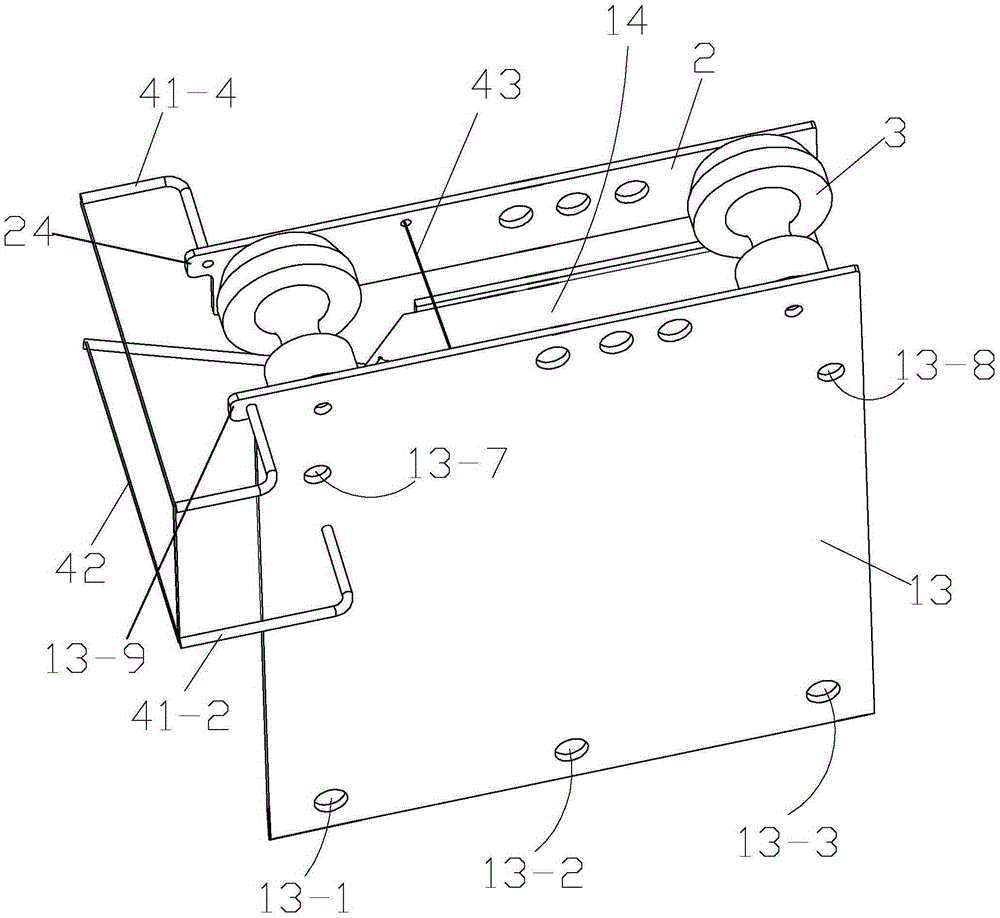

Redundant electric assisting steering system of automobile driving vehicle and control method of redundant electric assisting steering system

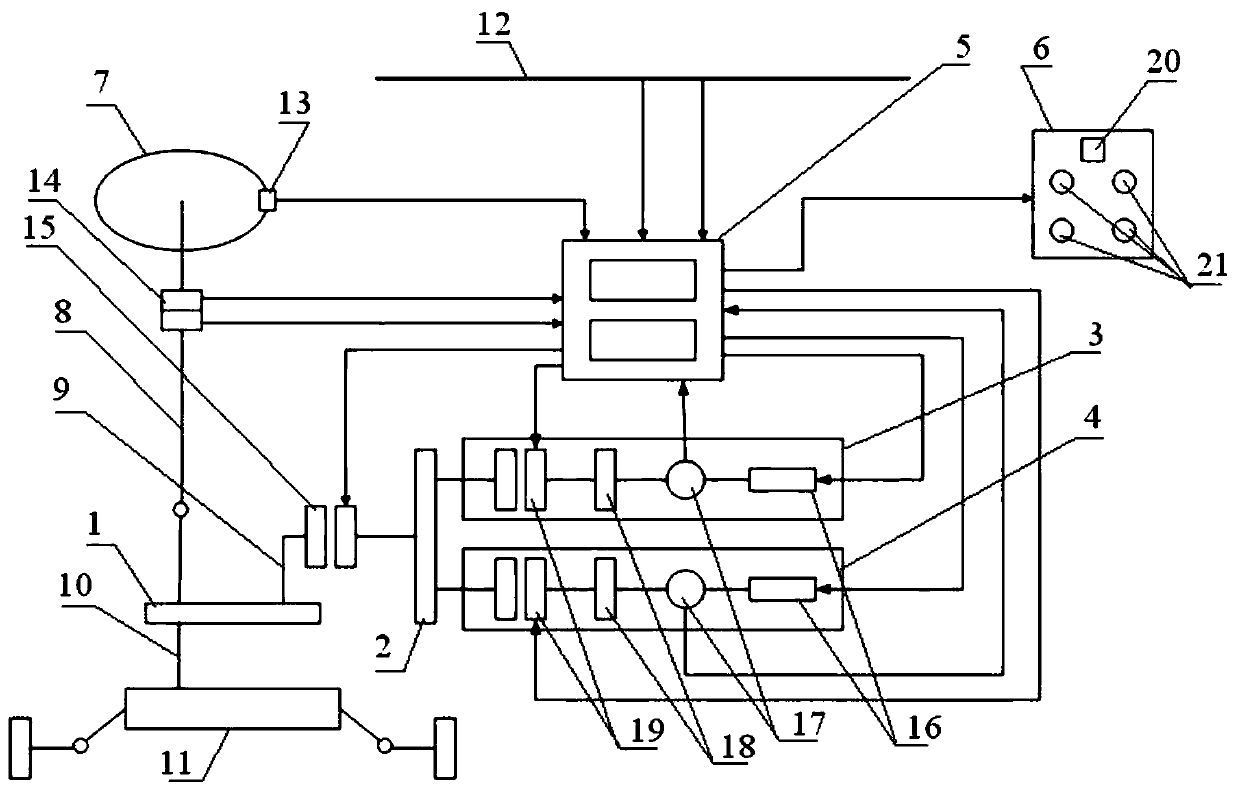

PendingCN110712677AMeet active steering requirementsStrong security and reliabilitySteering linkagesAutomatic steering controlSteering wheelDriver/operator

The invention discloses a redundant electric assisting steering system of an automobile driving vehicle and a control method of the redundant electric assisting steering system. The electric assistingsteering system comprises a first torque coupler, a second torque coupler, a first assisting system, a second assisting system, a main controller and an alarming device. A steering wheel is connectedwith the first torque coupler through a first intermediate shaft, after being connected in parallel, the first assisting system and the second assisting system are connected with the second torque coupler through output shafts, the second torque coupler is connected with the first torque coupler through a second intermediate shaft, and the first torque coupler is connected with a steering devicethrough a third intermediate shaft. The control method includes the two portions of a control method in an active steering manner and a control method in an assisting steering manner. The redundant electric assisting steering system of the automobile driving vehicle and the control method of the redundant electric assisting steering system have the beneficial effects that sufficient time can be reserved for a driver to take over the steering wheel, the driver is prompted through the alarming device, and the safety of a steering system is effectively guaranteed.

Owner:JILIN UNIV

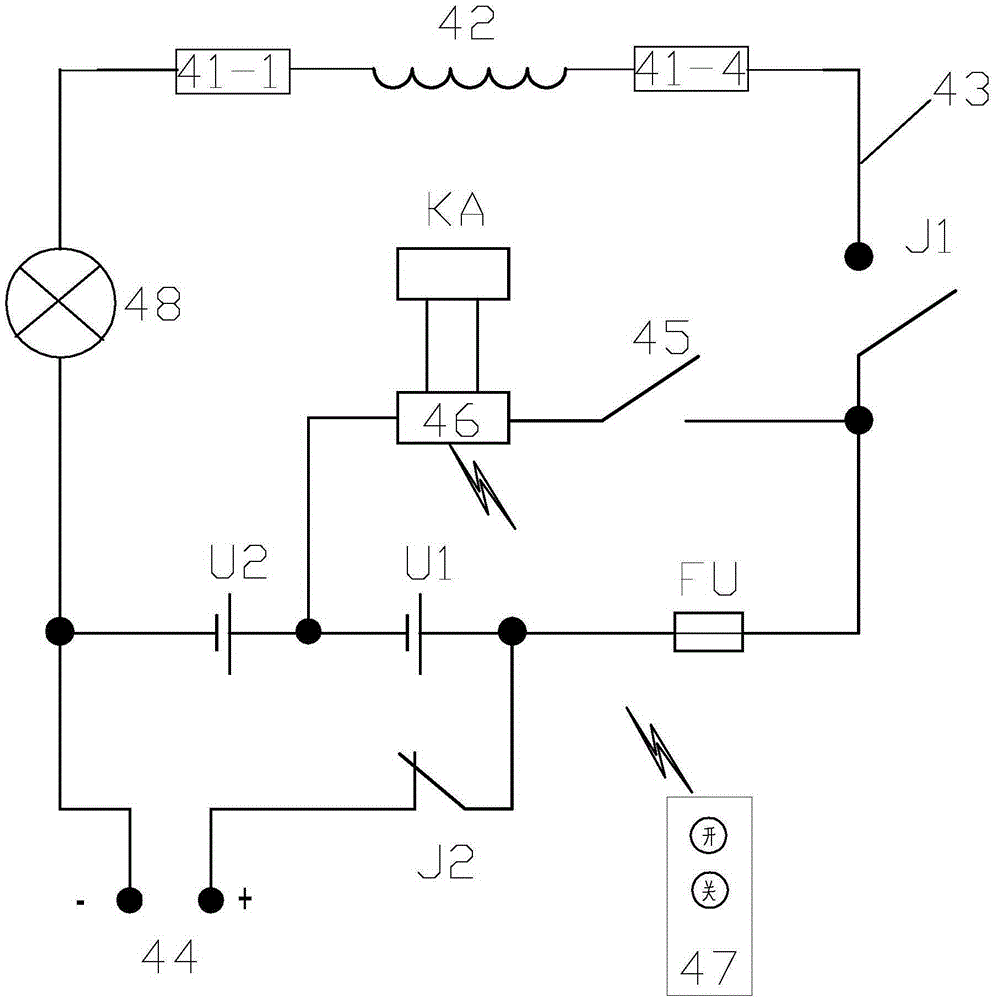

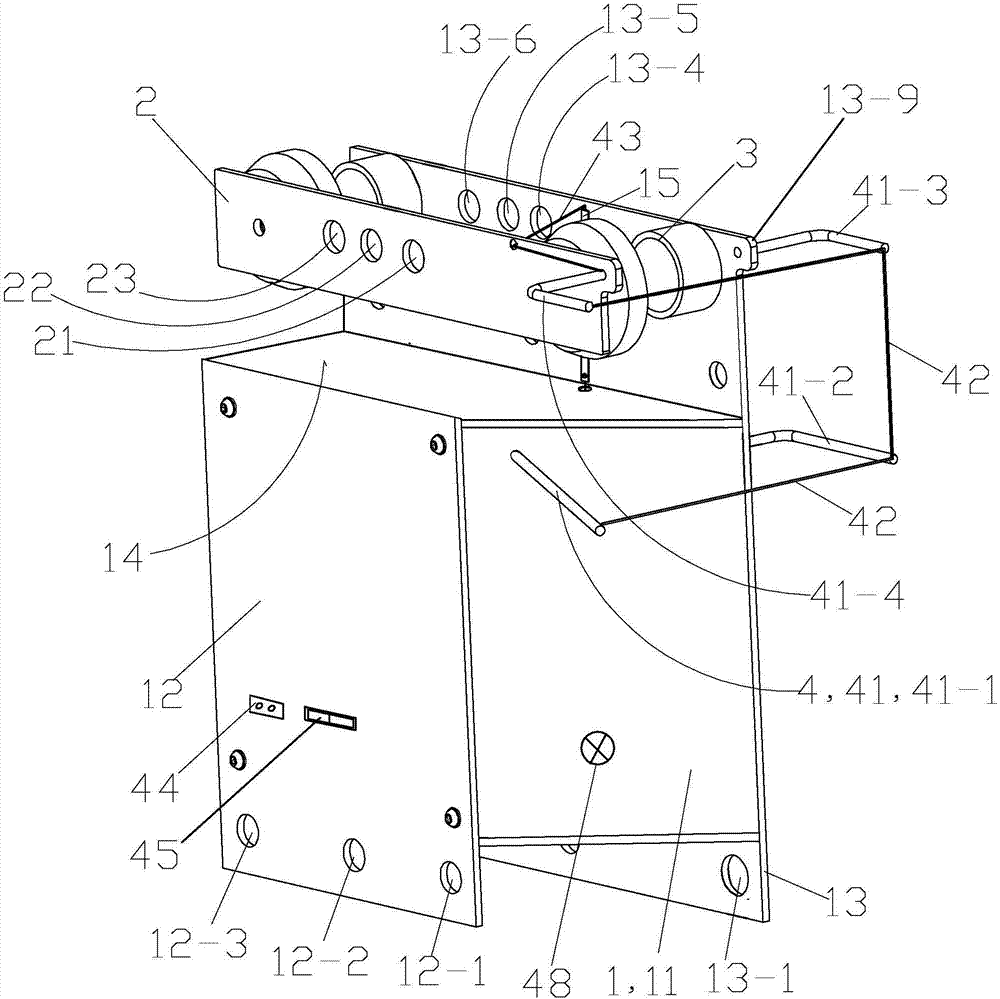

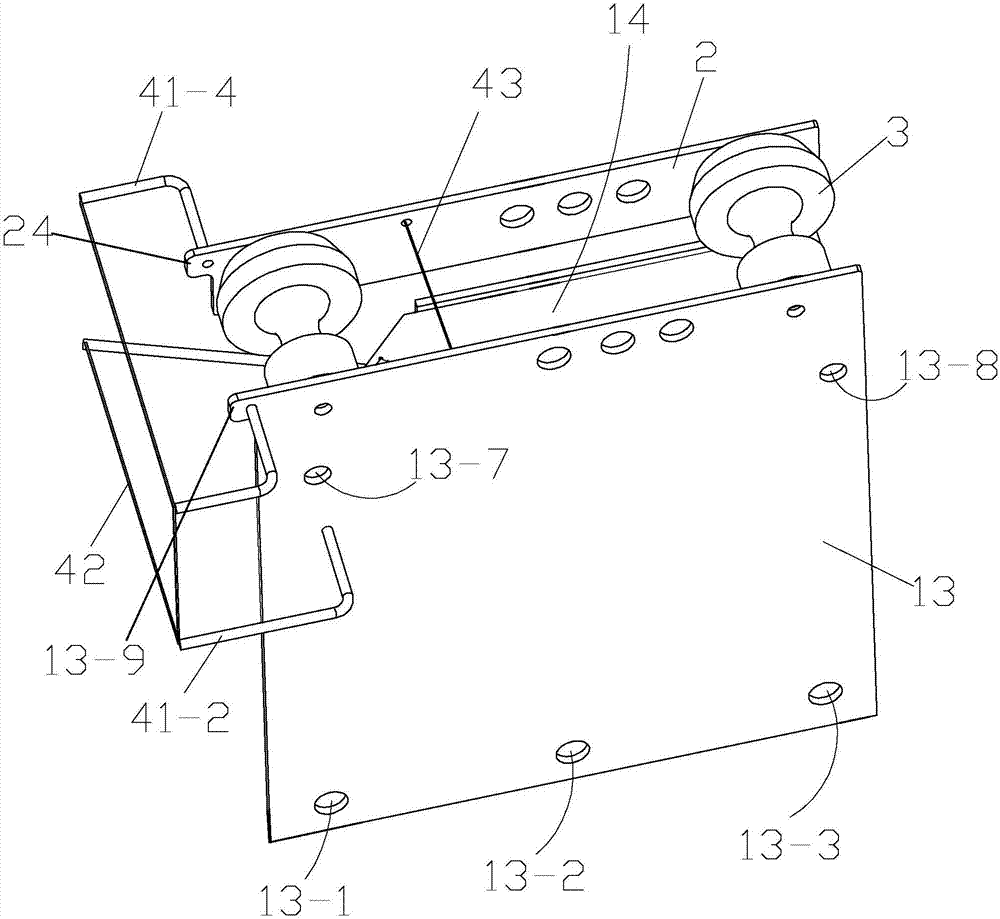

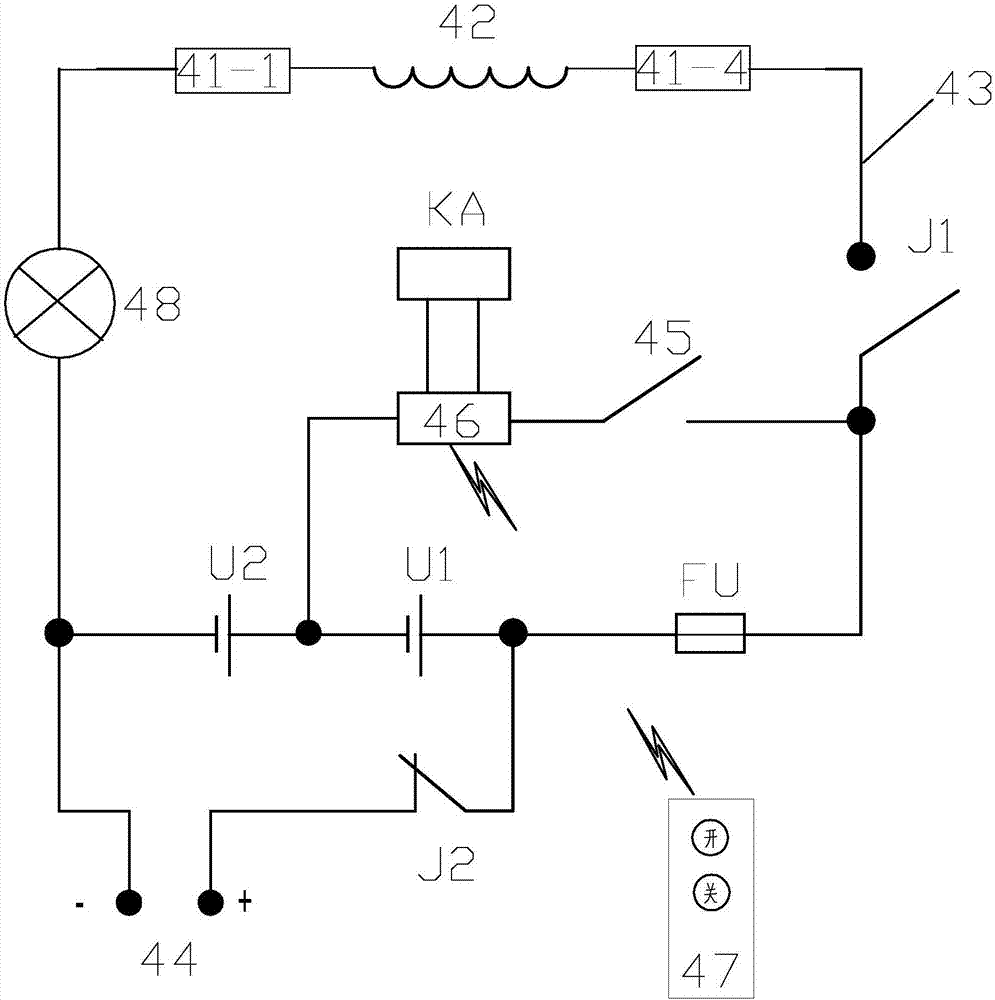

Overhead transmission line foreign body removing device

ActiveCN105356366AEfficient removalClean up thoroughlyApparatus for overhead lines/cablesRemote controlResistance wire

The invention provides an overhead transmission line foreign body removing device which comprises an installation cabinet, a hanging plate, two roller wheels and a circuit assembly. The installation cabinet is provided with a traction hole group; the installation cabinet and the hanging plate are respectively provided with a hanging hole group; the two roller wheels are fixedly arranged between the upper end of the installation cabinet and the hanging plate; and the circuit assembly comprises a conductive support rod group fixedly arranged to the installation cabinet and the hanging plate, resistance wires fixedly arranged on the conductive support rod group and used for carrying out thermal cutting on foreign bodies on the transmission lines, a storage battery arranged in the installation cabinet and used for providing power for the resistance wires, a relay KA arranged in the installation cabinet and used for controlling the connection and disconnection of a power supply of the resistance wires, a remote control receiver arranged in the installation cabinet and used for controlling the action of the relay KA, and a handheld remote control emitter for sending an on / off command to the remote control receiver wirelessly. The overhead transmission line foreign body removing device is simple in structure, low in cost, easy to carry and convenient to use during operation, and capable of removing various foreign bodies on the power transmission lines through thermal cutting safely, quickly and thoroughly.

Owner:CHANGZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +2

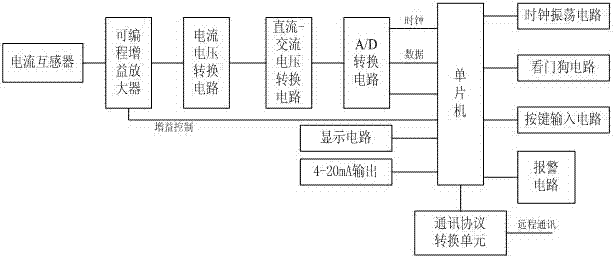

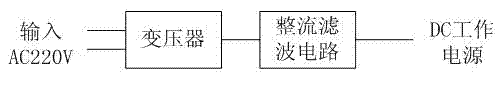

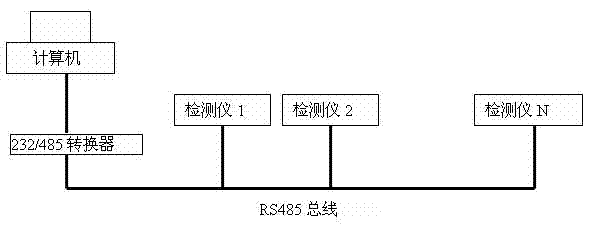

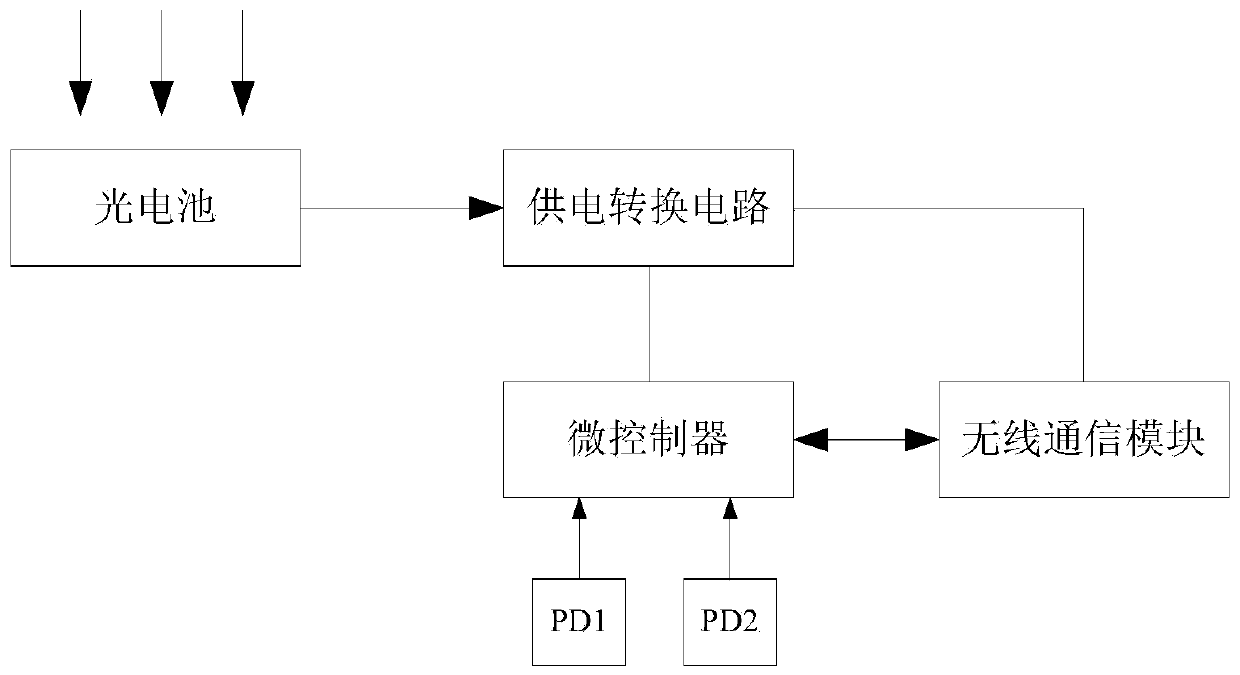

Transformer iron core ground connection electric current monitor

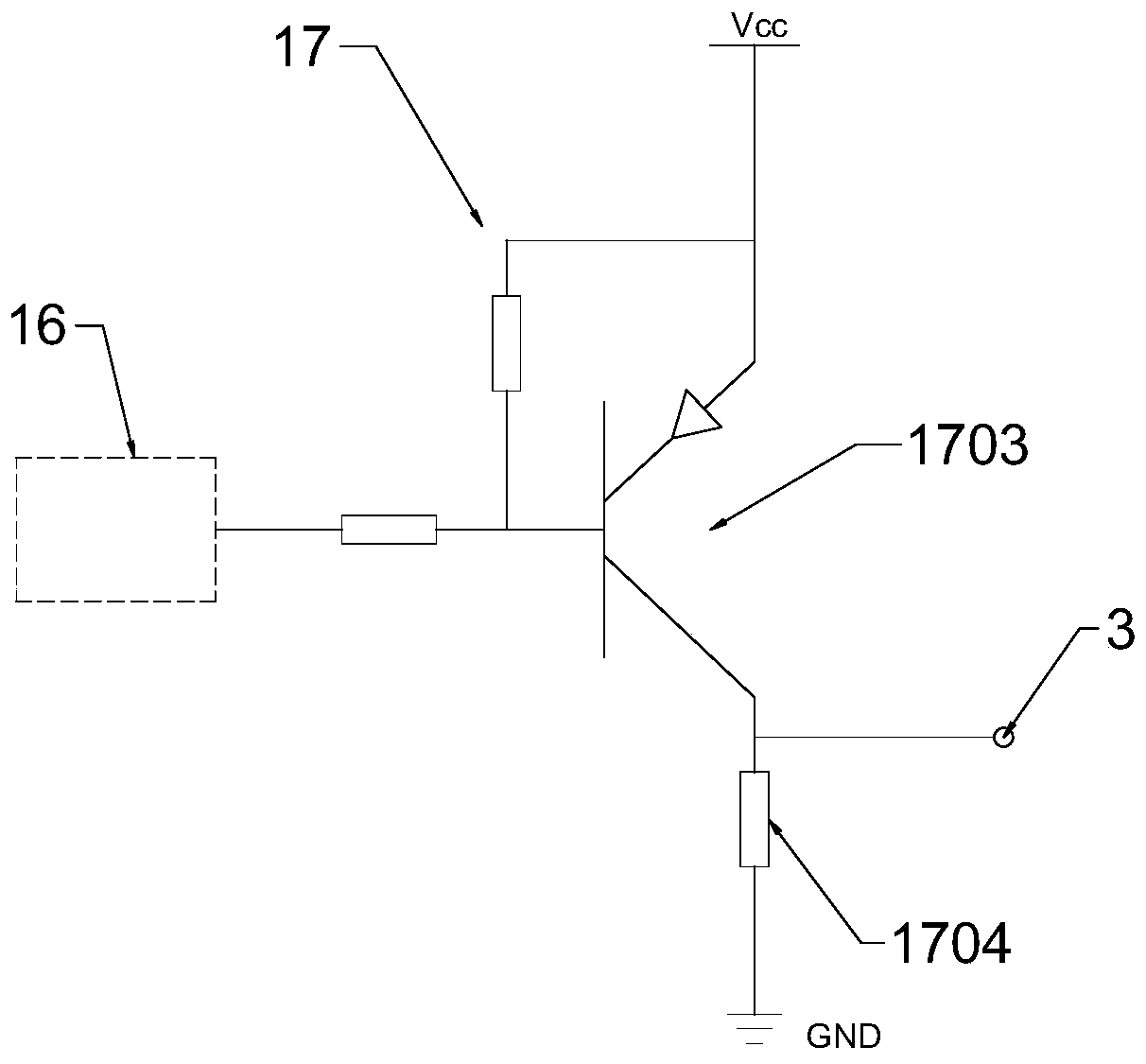

InactiveCN103116063AEasy for users to grasp the working statusMaster the working statusMeasurement using digital techniquesMicrocontrollerTime of use

The invention discloses a transformer iron core ground connection current monitor. A current mutual inductance device inputs a detected transformer iron core current to a current-voltage transform circuit after the transformer iron core current is adjusted by a programmable gain amplifier. An output end of the current-voltage transform circuit is connected with an input end of an alternating current-direct current voltage transform circuit, and an output end of the alternating current-direct current voltage transform circuit is connected with an input end of an A / D transform circuit. An output end of the A / D transform circuit is connected with a singlechip. According to the transformer iron core ground connection current monitor, a current value of 0 to 100A can be measured, a maximum current value can be displayed, and time when the maximum occurs can be displayed. A user can conveniently master a working state of the transformer. In time of using the iron core ground connection current monitor, a single turn of a main change iron core ground connection down lead penetrates out of a hole of the top of the monitor, an original wire connection manner of a measured transformer iron core is not changed, and any potential safety hazard can not be caused on the transformer in operation. The transformer iron core ground connection current monitor has the advantages of being capable of preventing interference of electromagnetism and an electric field from the outside, high in measuring precision, accurate in numerical value, small in size, light in weight and easy to install.

Owner:大连新安越电力设备有限公司

Simulation object test method, equipment and system

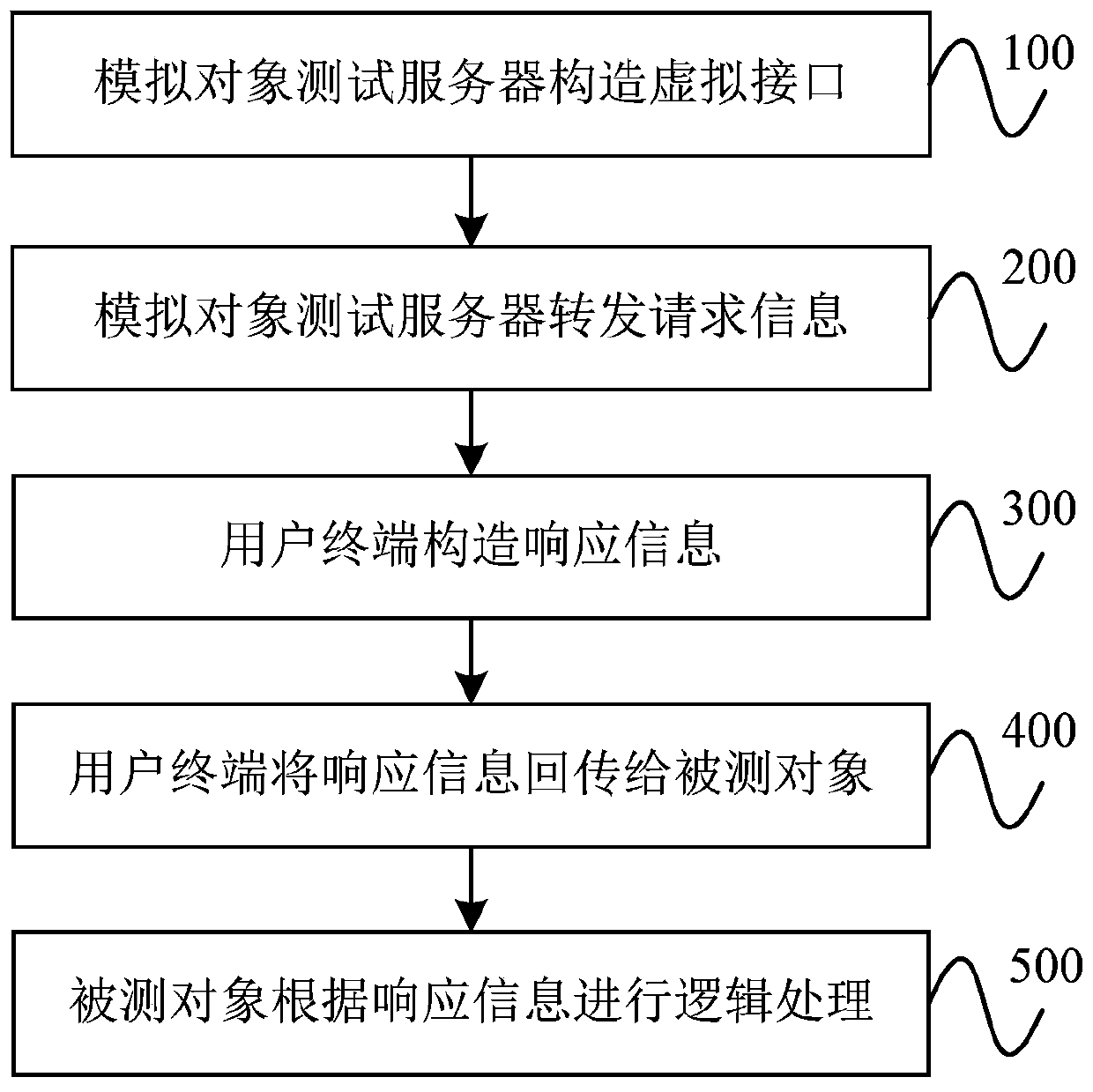

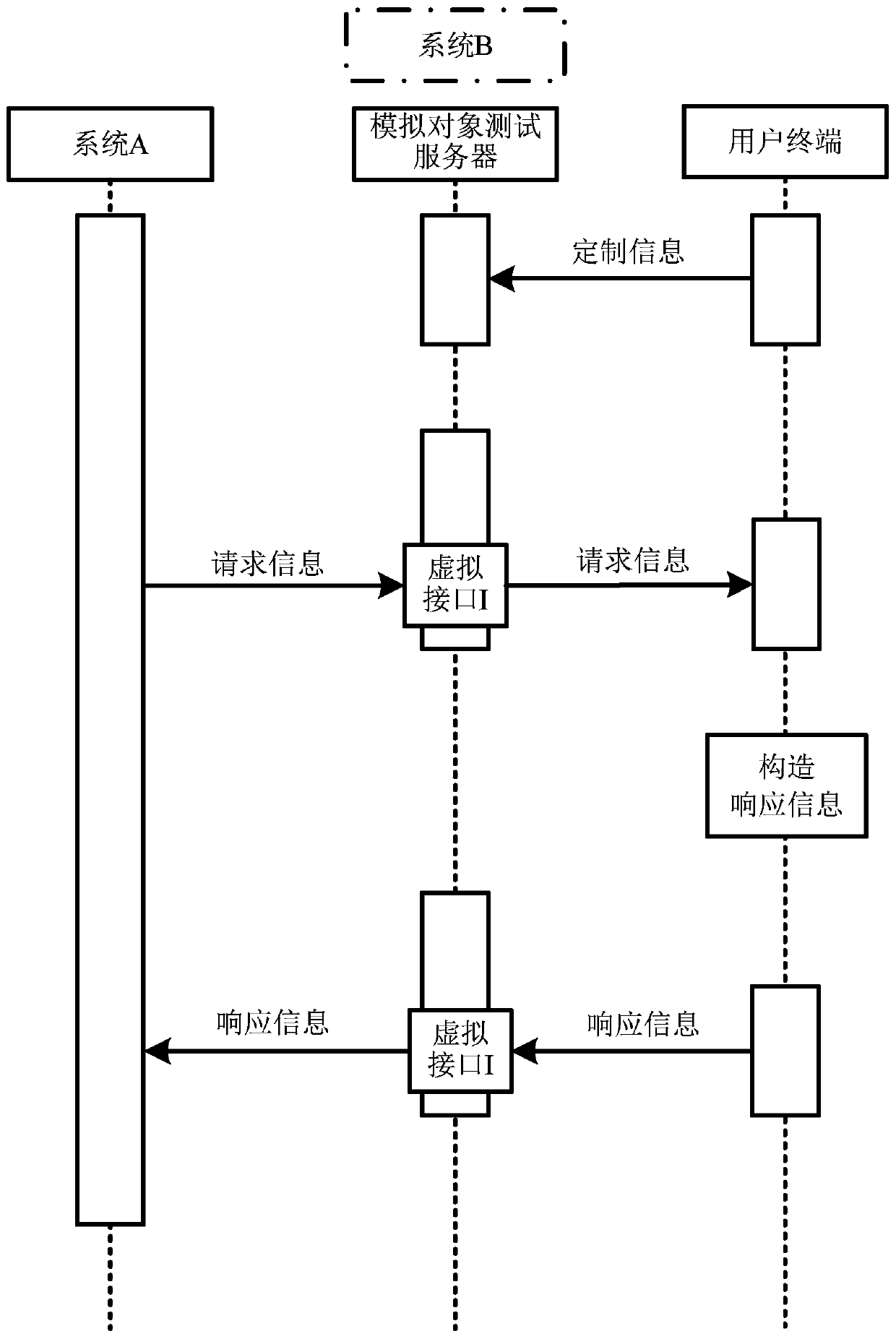

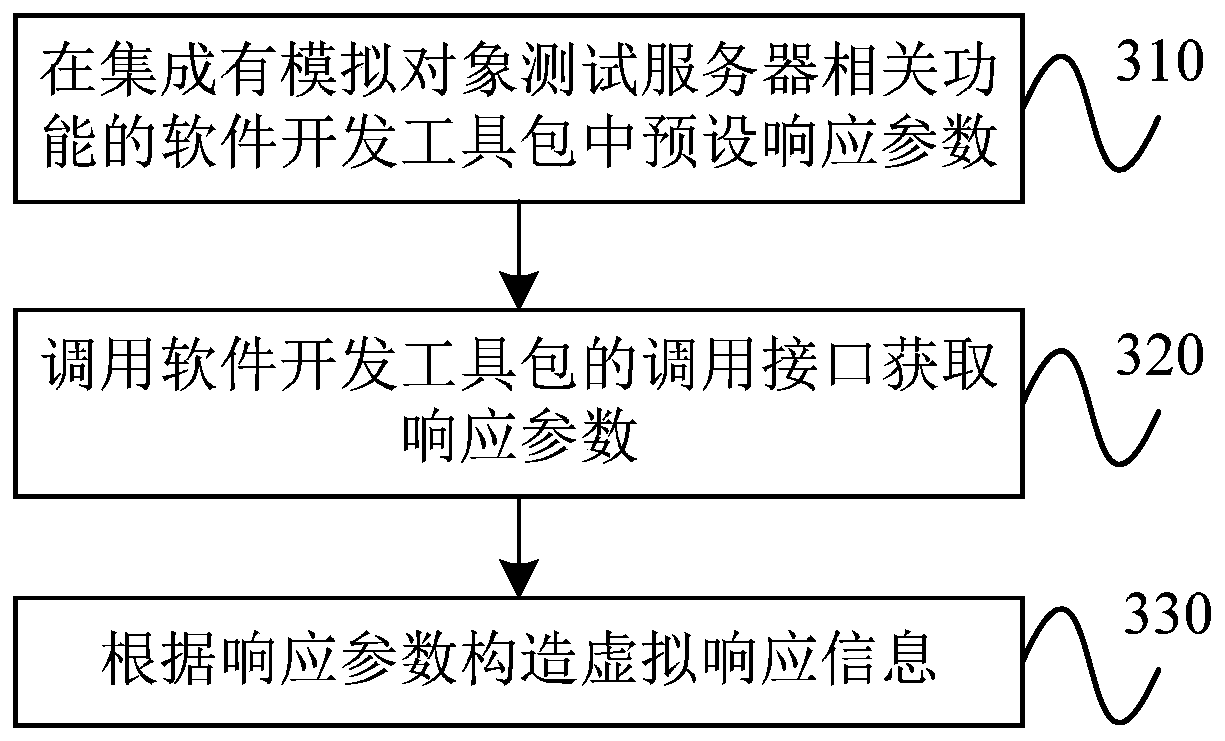

ActiveCN111522727AFlexible configurationIncrease flexibilitySoftware testing/debuggingTest objectSystem testing

The invention discloses a simulation object test method, equipment and a system. The simulation object test method comprises the steps of: constructing a virtual interface according to received interface information from a user terminal by a simulation object test server; when the simulation object test server receives request information from a tested object through the virtual interface, forwarding the request information to the user terminal; and when the simulation object test server receives response information from the user terminal through the virtual interface, returning the responseinformation to the tested object through the virtual interface. According to the simulation object test method, the user terminal is used for constructing the interface on the simulation object test server, and the simulated alternative interface is used for system test, so that the simulation object test method has the advantages of flexible configuration, high expandability and easiness in learning.

Owner:ALIBABA GRP HLDG LTD

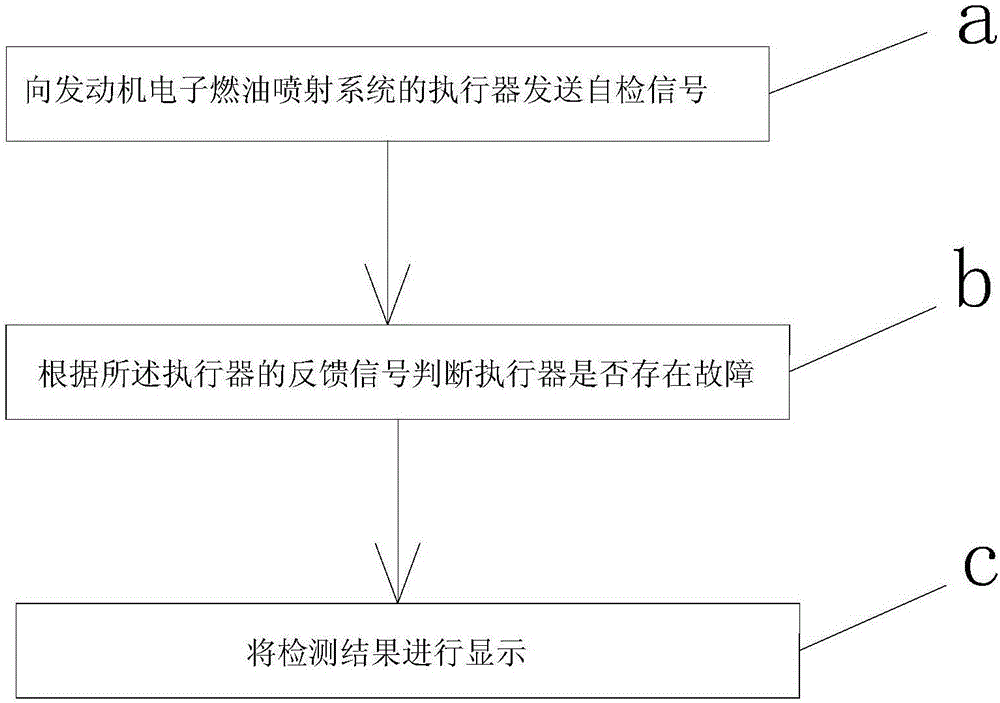

Self-inspection method and system for engine electronic injection executer

InactiveCN106224108AMaster the working statusEnsure safetyElectrical controlMachines/enginesActuatorFuel injection

The invention discloses a self-inspection method and system for an engine electronic injection executer. The method comprises the following steps that a, a self-inspection signal is sent to the executer of an engine electronic fuel injection system; b, whether a fault exists in the executer or not is judged according to a feedback signal of the executer; and c, a detection result is displayed. The system comprises the engine electronic injection executer, a self-inspection controller and a display module. By means of the method and system, the fault of the electronic injection system executer can be rapidly and effectively recognized, the fault reason is displayed, it is ensured that a user masters the work state of the electronic injection system of a whole vehicle immediately, and the traveling safety is guaranteed.

Owner:CHONGQING LONCIN MOTOR

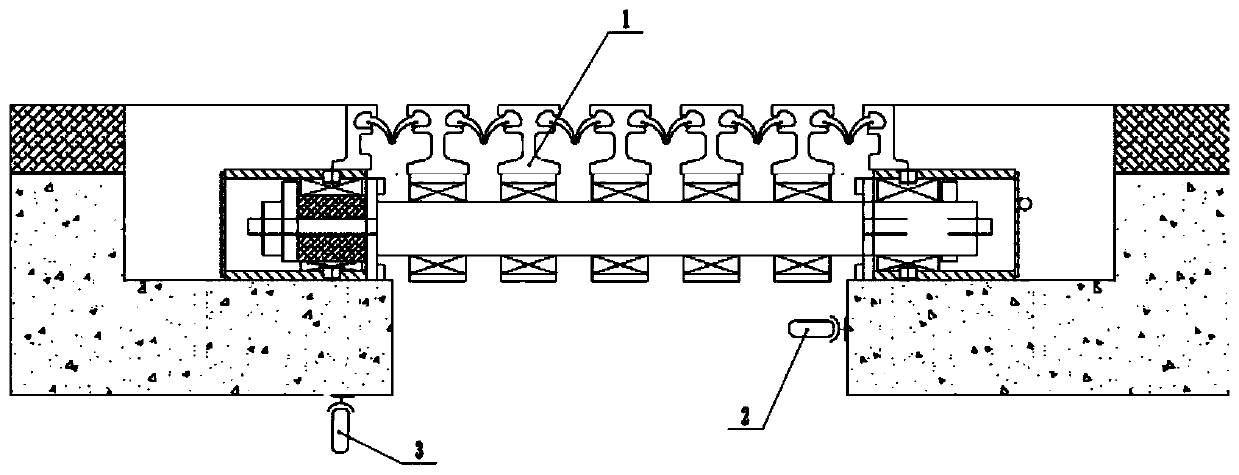

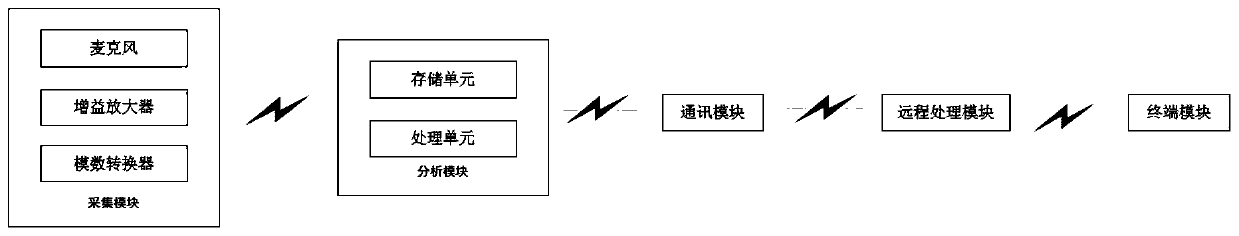

Bridge expansion joint monitoring device

InactiveCN110794032AReduce distractionsImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansFast Fourier transformFrequency spectrum

The invention relates to the technical field of bridge monitoring, in particular to a bridge expansion joint monitoring device. The bridge expansion joint monitoring device comprises an acquisition module and an analysis module, wherein the acquisition module is used for collecting sound wave signals when a vehicle passes through an expansion joint, and carrying out gain amplification on the soundwave signals and converting the sound wave signals into digital signals; the analysis module comprises a storage unit and a processing unit, wherein a normal state frequency spectrum is pre-stored inthe storage unit; and the processing unit draws a spectrum to be analyzed of the digital signals through a fast Fourier transform method, compares the spectrum to be analyzed with the normal state frequency spectrum, judges the state of the expansion joint, and generates state information. By adoption of the technical scheme, whether an expansion joint combining piece is damaged or not can be monitored.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

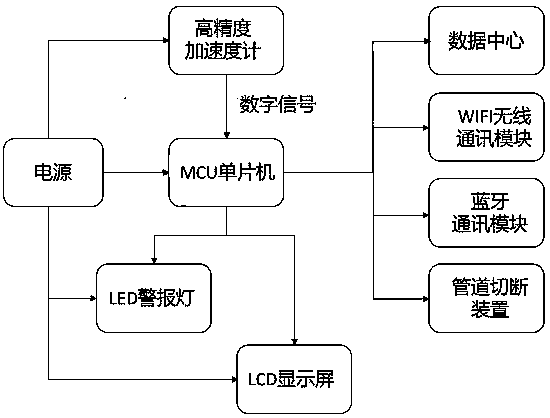

Novel intelligent earthquake monitoring device and control method thereof

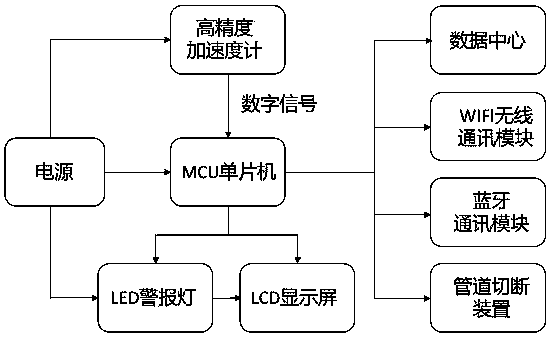

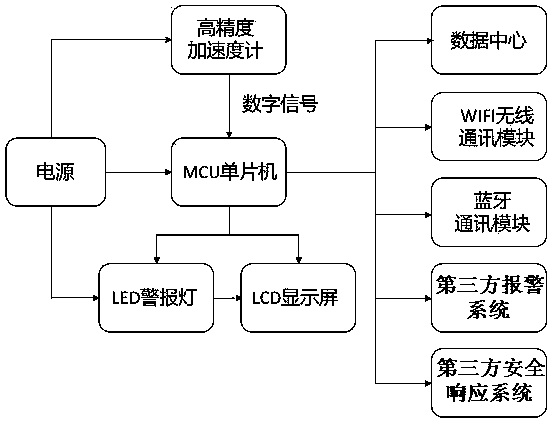

PendingCN107741601AAvoid casualtiesMaster the working statusEarthquake measurementSeismic signal receiversThird partyEarthquake monitoring

The invention discloses a novel intelligent earthquake monitoring device and a control method thereof. The novel intelligent earthquake monitoring device comprises an acceleration sensor and a controlunit connected with the acceleration sensor, and a third party system is connected to the control unit used for sorting and responding to earthquake waves. The invention discloses the control methodof the novel intelligent earthquake monitoring device. The control unit obtains mixed vibration wave information of a surrounding environment from the acceleration sensor and sorts out earthquake waveinformation, predicts the earthquake level according to the earthquake wave information and conducts an alarm response motion according to the earthquake level. The novel intelligent earthquake monitoring device and the control method thereof effectively avoid losses and casualties caused by secondary disasters of fires, explosions, earth leakage, fuel gas leakage and the like caused by earthquake damage; by the adoption of high precision hardware and software equipment low in power consumption, low in cost and high in performance, the cost is lowered.

Owner:高梧

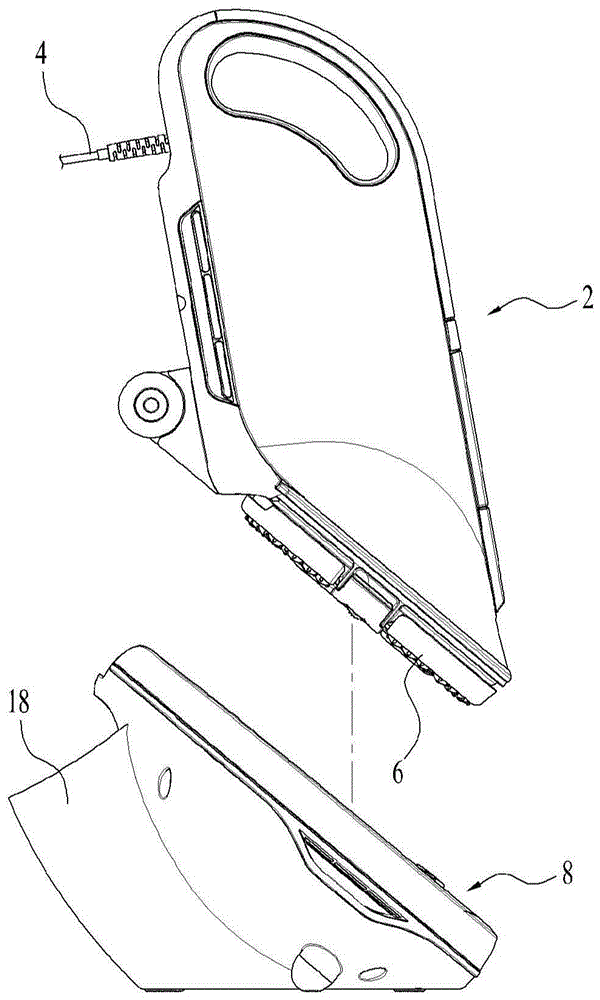

Device and method for updating control program of portable electric tool

PendingCN110727239AReduce the difficulty of updatingShorten update timeProgramme control in sequence/logic controllersProgrammerUSB

The invention relates to a device and a method for updating the control program of a portable electric tool. The device comprises a programmer, a USB interface used for connecting a PC terminal and the programmer, a program output terminal electrically connected with the programmer, a program updating control button used for sending a programming instruction to the programmer and a program checking code reading button used for sending a checking instruction to the programmer, wherein the program output terminal is used for being connected with a battery pack temperature detection terminal in abattery clamp of an electric tool. According to the device, the program output terminal, the program updating control button and the program checking code reading button which are in butt joint withthe battery pack temperature detection terminal are arranged on the programmer to realize the program updating of an electric tool control chip by the updating device through the battery pack temperature detection terminal, so that the control program of the electric tool can be updated without disassembling the electric tool, the program updating difficulty of the electric tool is effectively reduced, and the program updating time of the electric tool is shortened.

Owner:ZHANGJIAGANG HUAJIE ELECTRONICS

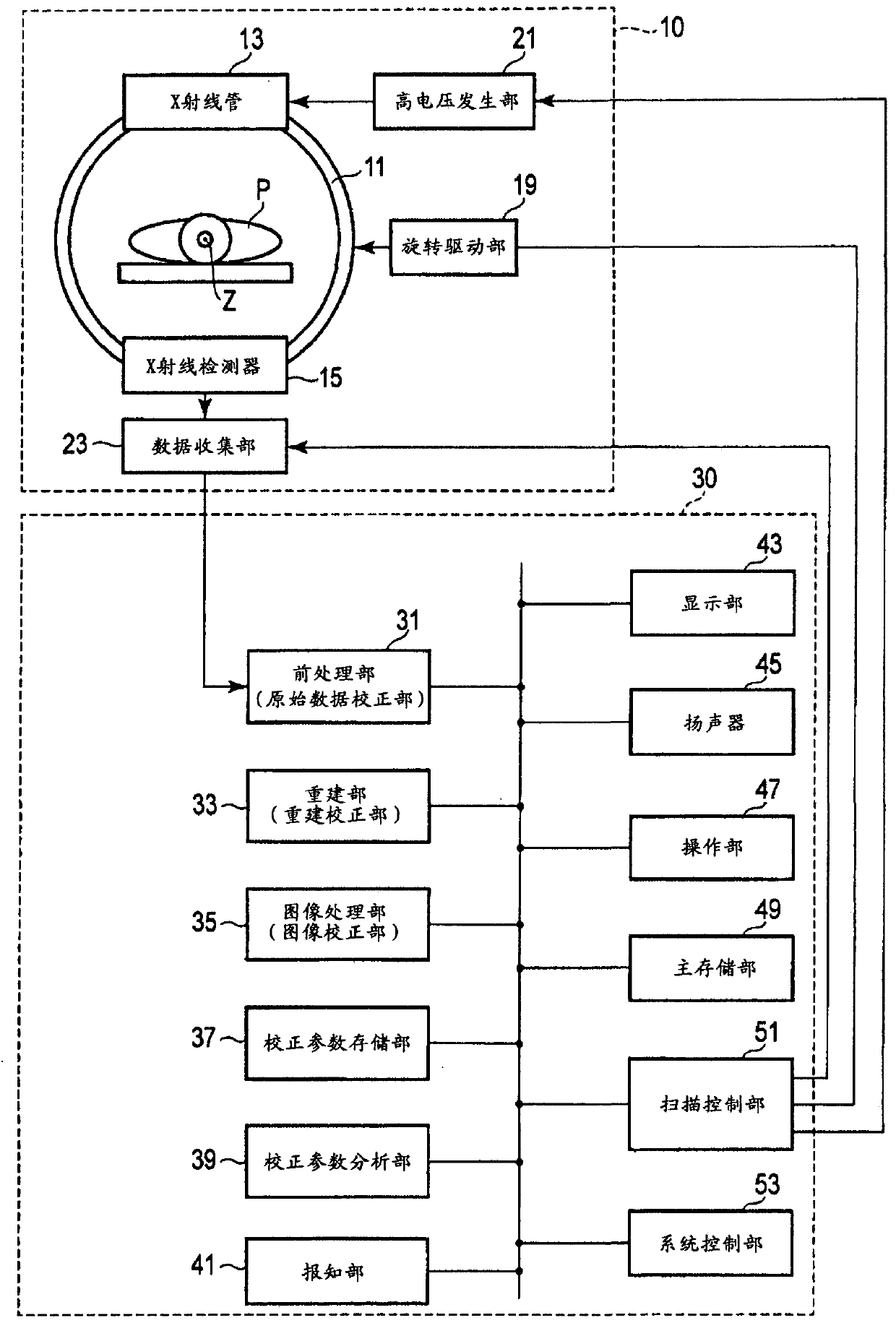

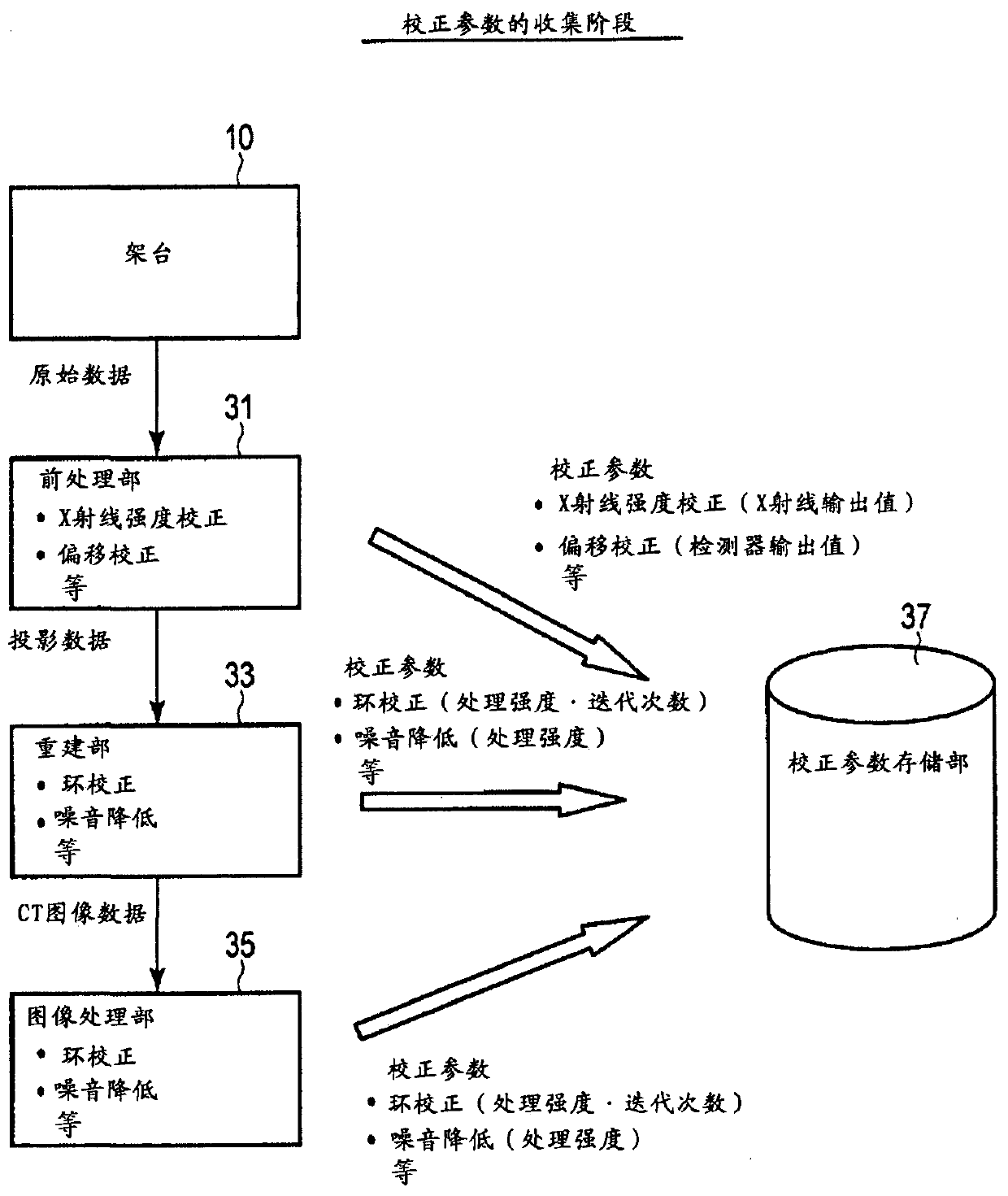

X-ray computed tomography device and information processing device

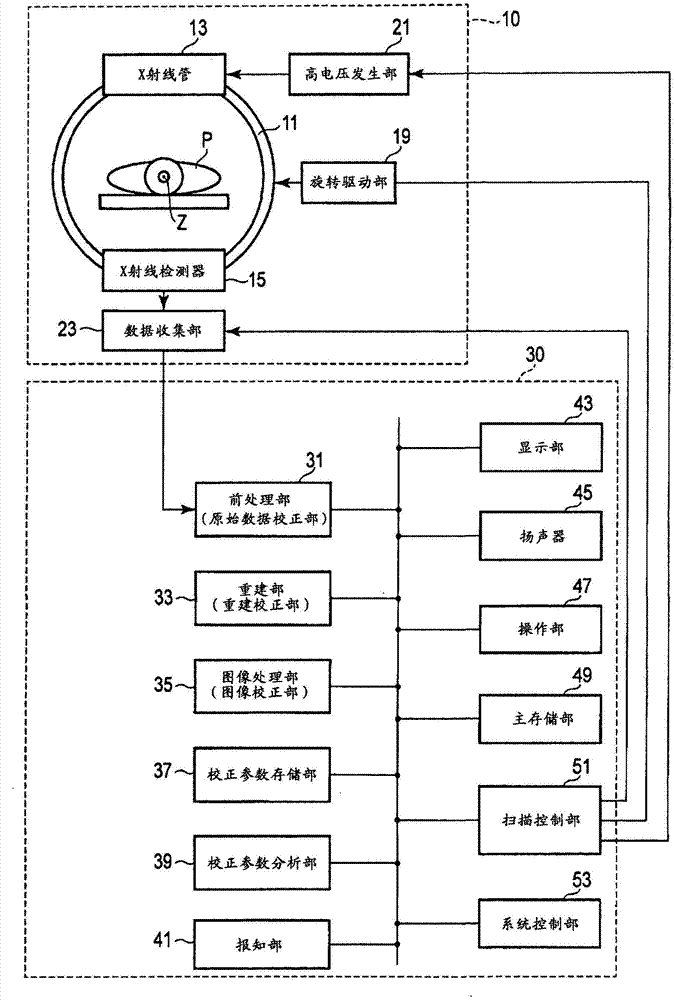

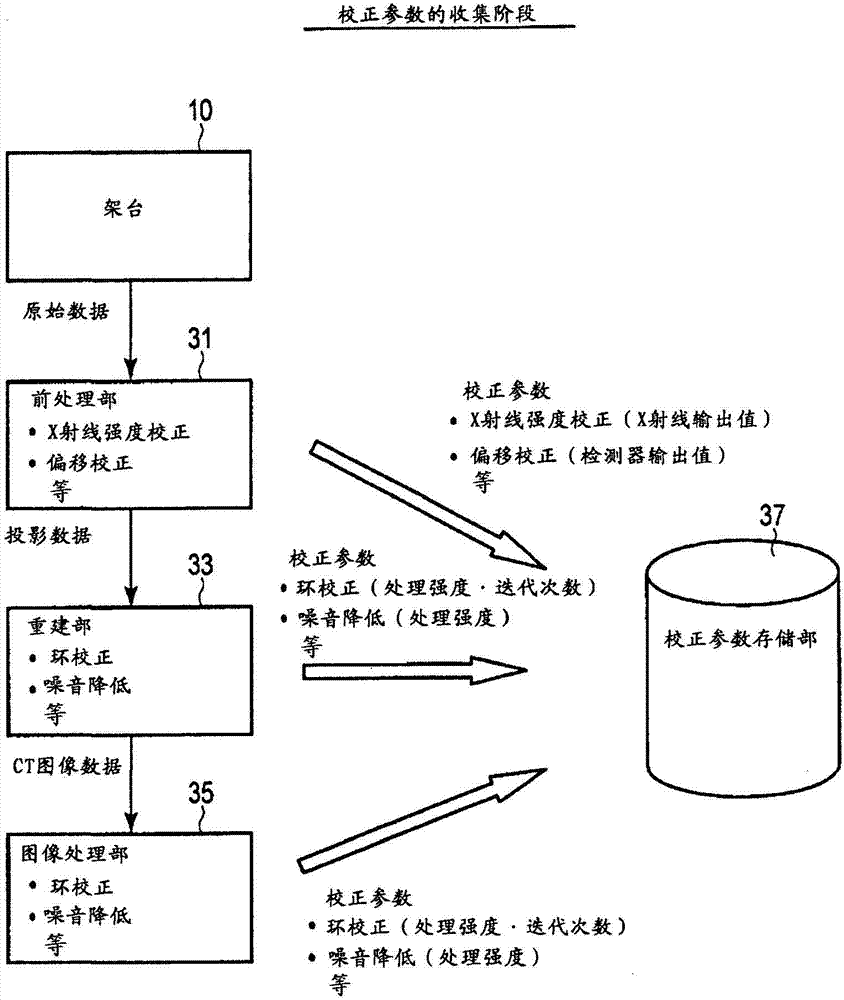

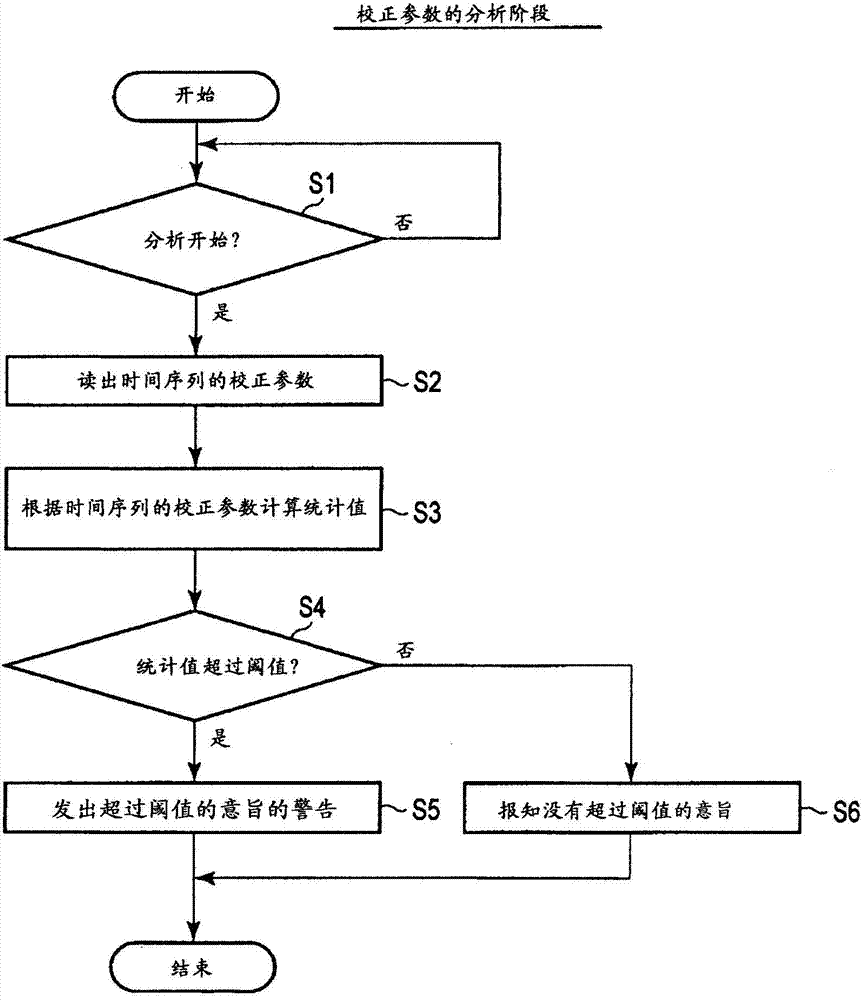

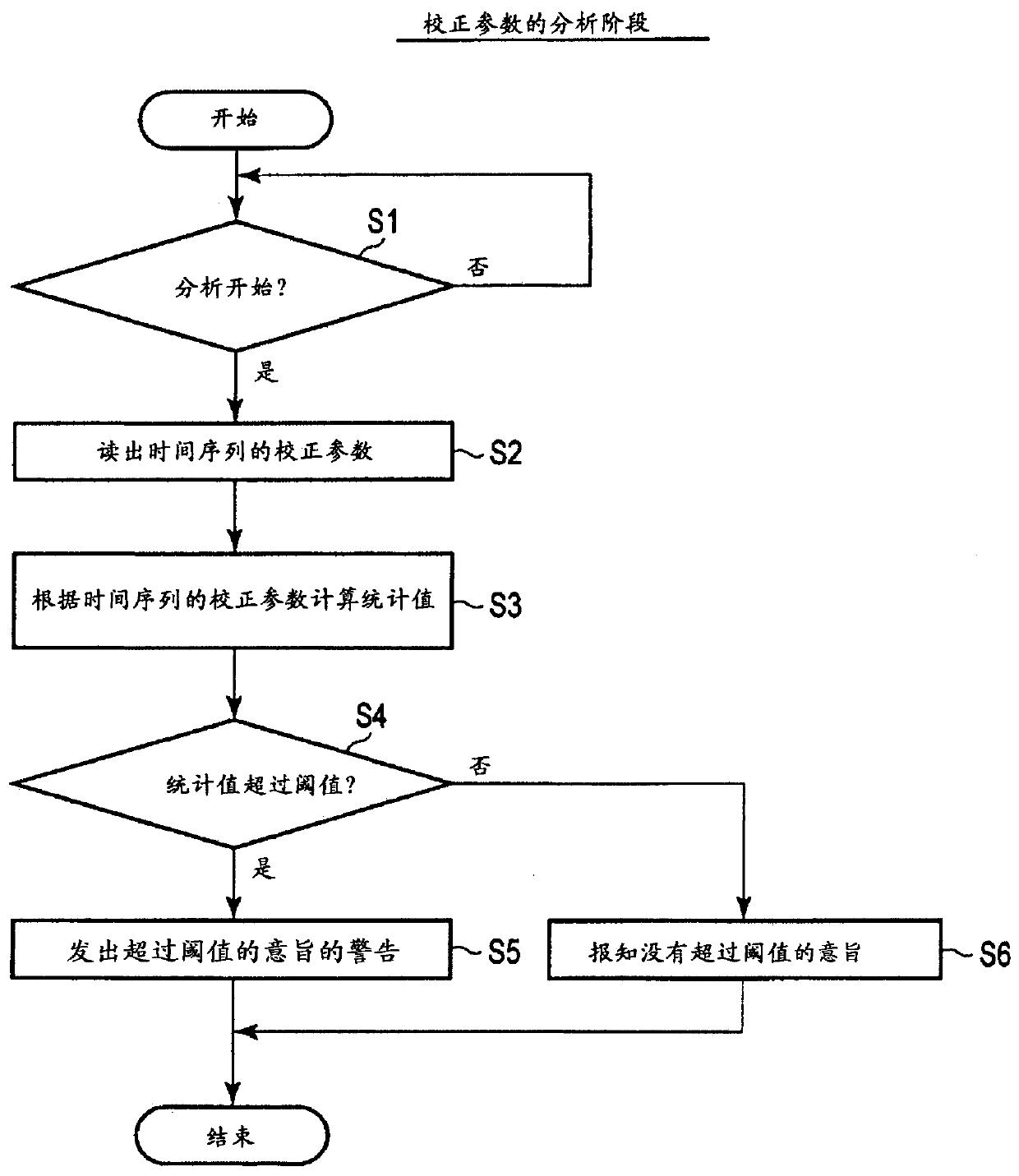

ActiveCN104780844AMaster the working statusImage enhancementImage analysisInformation processingTemporal change

A reconstruction unit (a pre-processor, a reconstruction unit and an image processor) generates a reconstruction image based on output from the X-ray detector. A correction parameter storage stores correction parameters in time series, the correction parameters being used for correction by which noise or artifact is reduced in processing performed by the reconstruction image unit. A correction parameter analysis unit determines whether or not an abnormal condition occurs based on a temporal change in the correction parameters stored in the correction parameter storage. A notification unit issues a notification indicating the occurrence of an abnormal condition where the correction parameter analysis unit determines that the abnormal state has occurred.

Owner:TOSHIBA MEDICAL SYST CORP

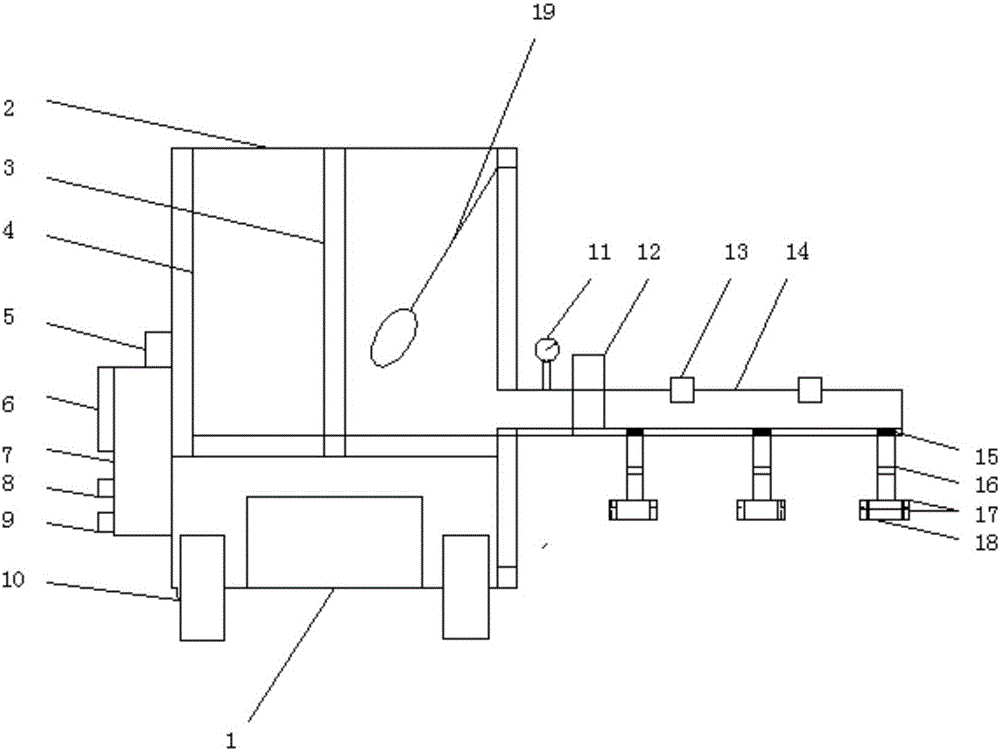

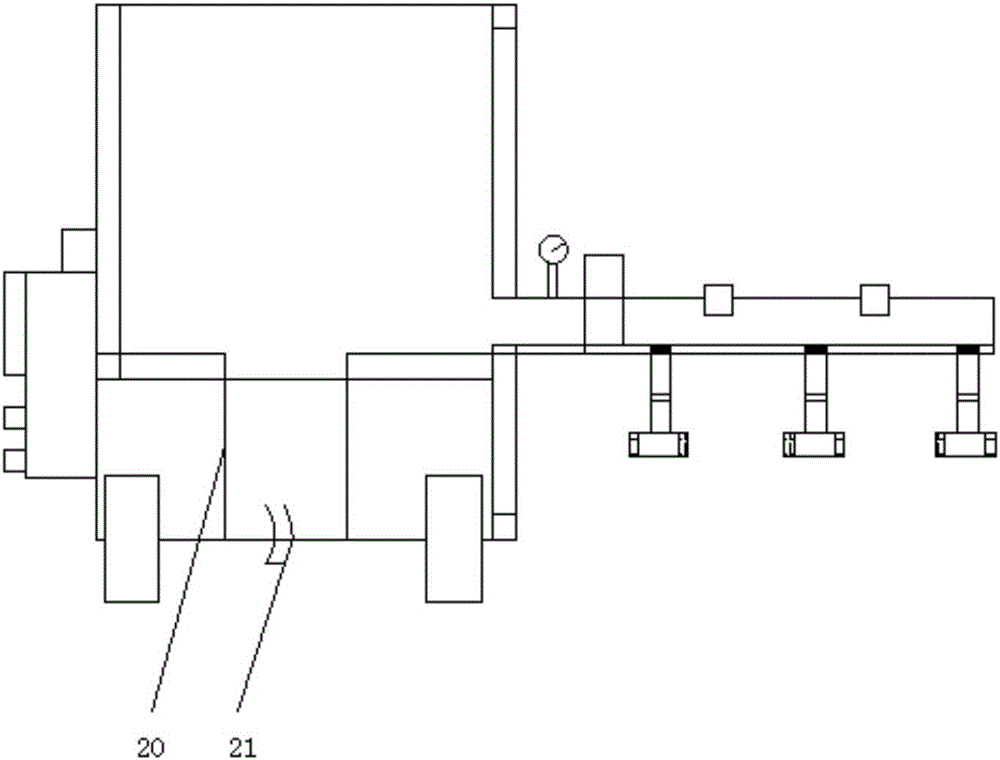

Wired/wireless remote control system device of down-the-hole drill

InactiveCN102828738AImprove operational safetyQuick evacuationAutomatic control for drillingAutomatic controlEngineering

The invention relates to a wired / wireless remote control system device of a down-the-hole drill, and the wired / wireless remote control system device consists of four units including a vehicle-mounted receiving unit, a handle control unit, a hydraulic system interface unit and an electrical interface unit, and the device can realize the wired control, wireless sighting distance control and wireless remote control of the down-the-hole drill. Due to the adoption of the wired / wireless remote control system device, the drilling safety coefficient, the drilling precision and the operation flexibility of working personnel can be improved, the state of the drill can be monitored in real time, and intelligent, continuous and automatic control of the drilling can be realized.

Owner:BEIJING ELINKCS SCI & TECH CO LTD

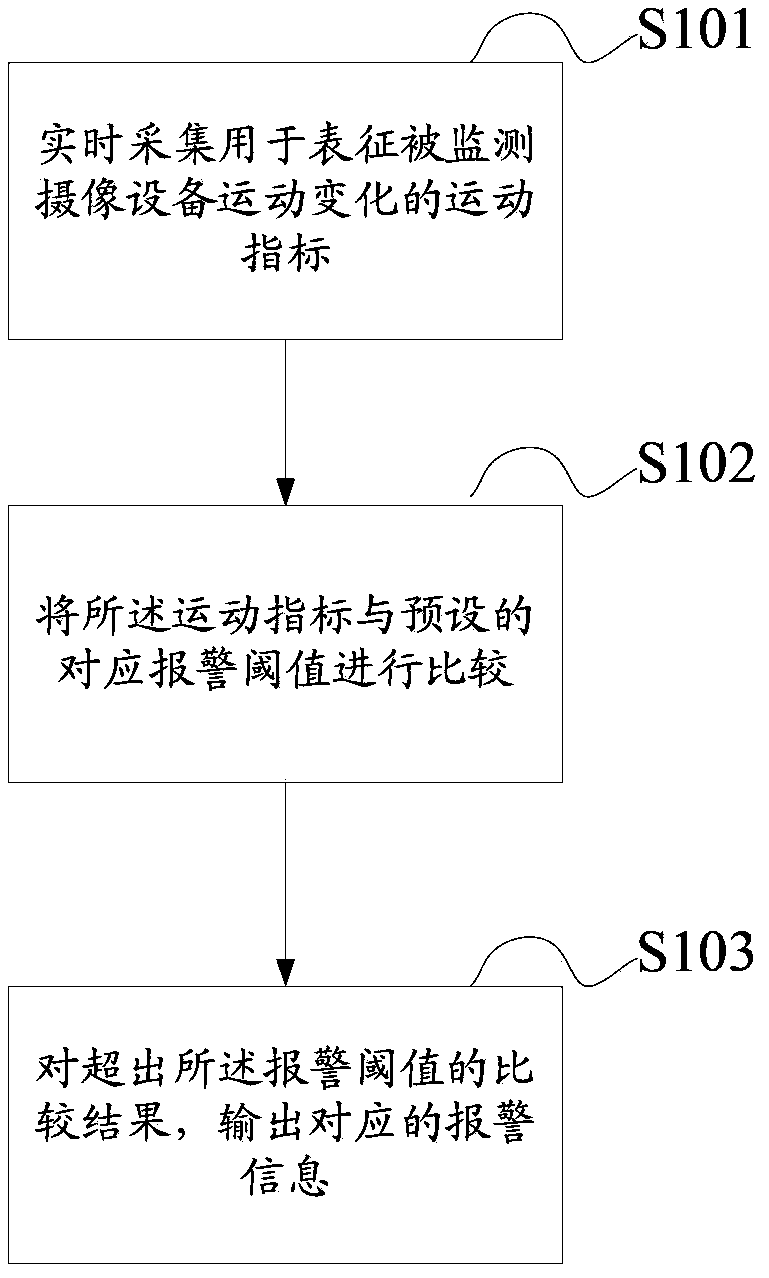

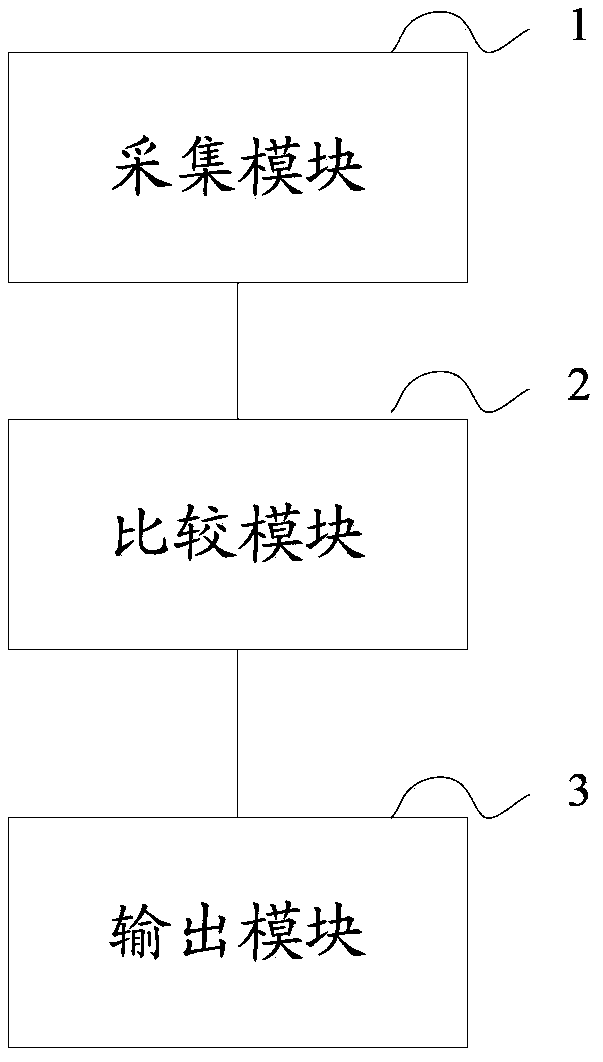

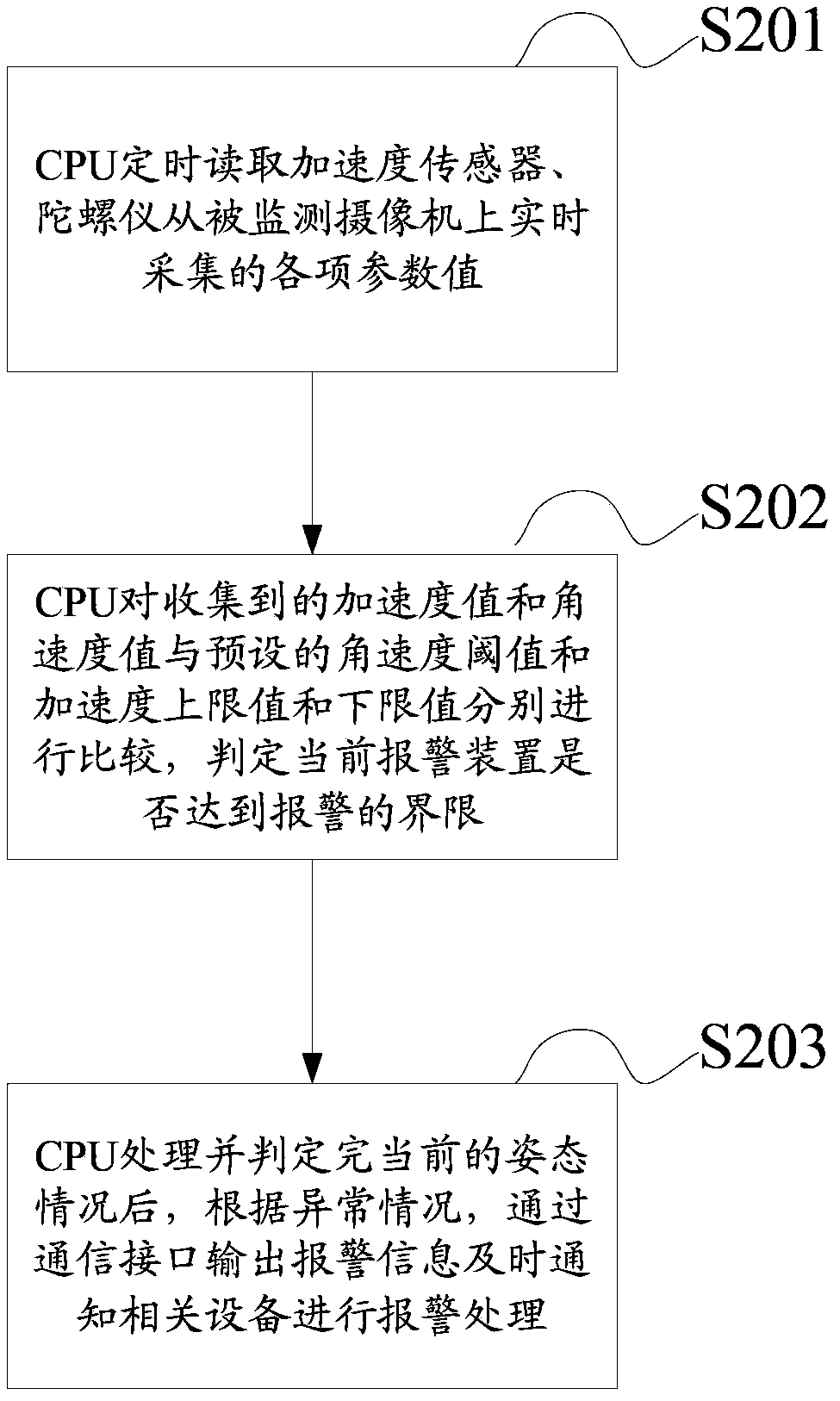

Camera monitoring alarm method and device

InactiveCN104240433AGrasp the dynamic situation in real timeMaster the working statusAlarmsReal time acquisitionVideo camera

Owner:ZHEJIANG DAHUA TECH CO LTD

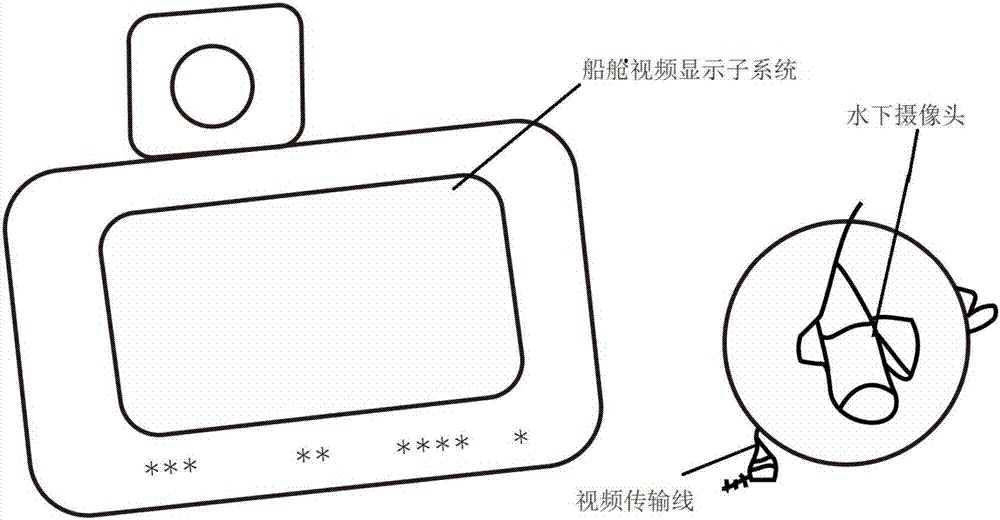

Real-time image monitoring system for ship podded propeller

InactiveCN107071366ATo achieve the purpose of monitoringMaster the working statusVessel partsClosed circuit television systemsUnderwaterVideo transmission

The invention discloses a real-time image monitoring system for a ship podded propeller. The real-time image monitoring system comprises a cabin video display subsystem and an underwater camera; and the underwater camera is arranged on the podded propeller, and connected with the cabin video display subsystem through a video transmission line. The real-time image monitoring system for the ship podded propeller provided by the invention realizes the purpose that an operator monitors at a remote end; and besides, in the course of steering and propelling, the working condition of the underwater podded propeller and the surrounding environment are mastered in time so that the propeller failure can be processed timely.

Owner:WUHAN UNIV OF TECH

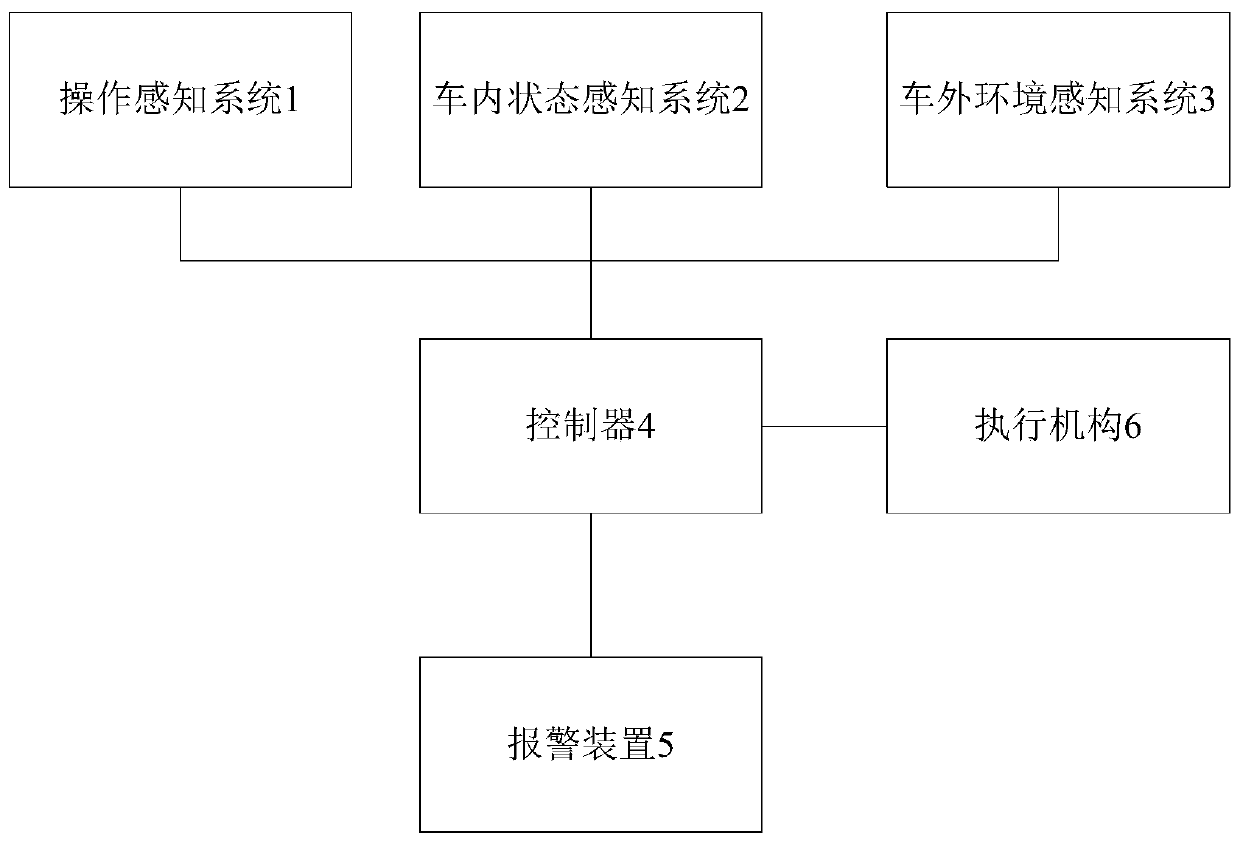

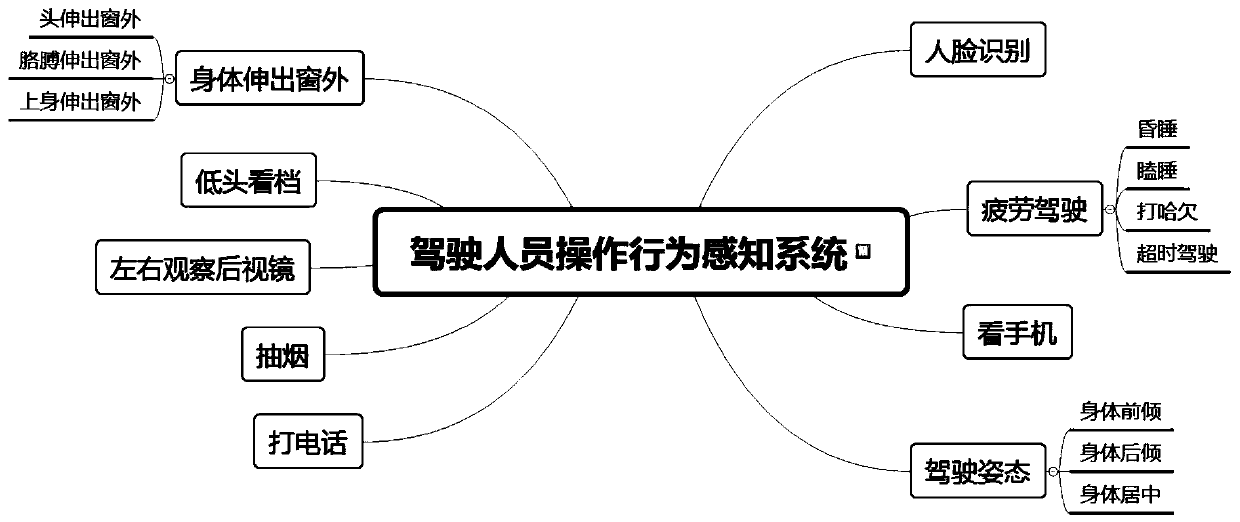

Vehicle comprehensive control system

InactiveCN111532279ARealize monitoringReal time monitoringControl devicesControl systemControl engineering

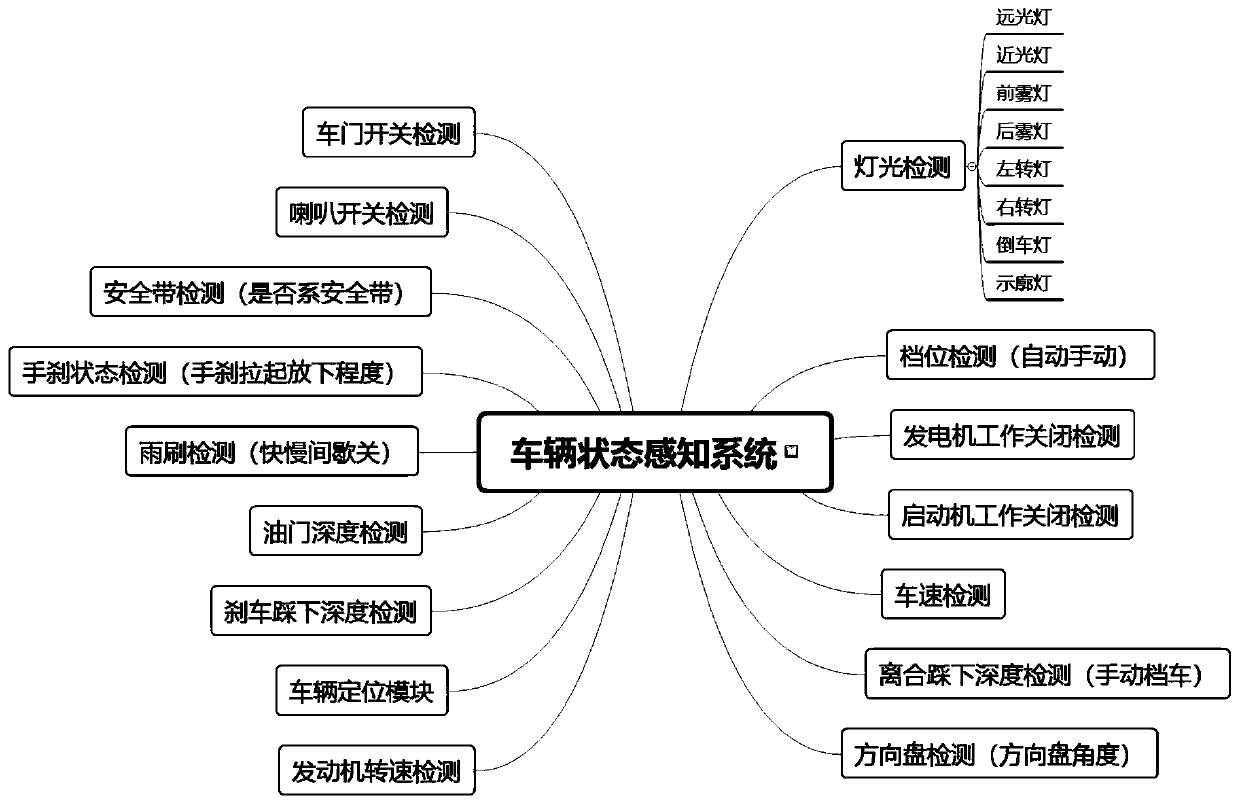

The invention discloses a vehicle comprehensive control system, and relates to the field of vehicle control. The system comprises an operation sensing system, an in-vehicle state sensing system, an out-vehicle environment sensing system, a controller, an alarm device and an execution mechanism. By using the vehicle control system, an operation behavior of a driver can be scientifically and comprehensively detected, the driver can master the working state of the vehicle more comprehensively and accurately, a fault can be found in the first place when working parts break down, and obstacles canbe effectively avoided, real-time detection of environmental obstacles outside the vehicle is achieved, an application range is wide, and a market prospect is very large.

Owner:易显智能科技有限责任公司

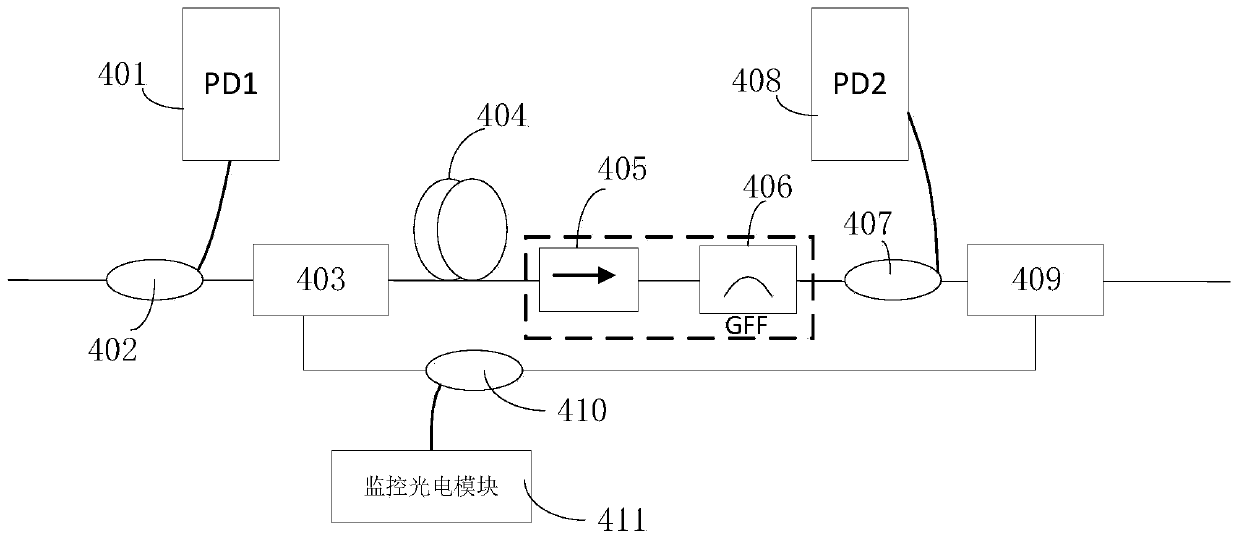

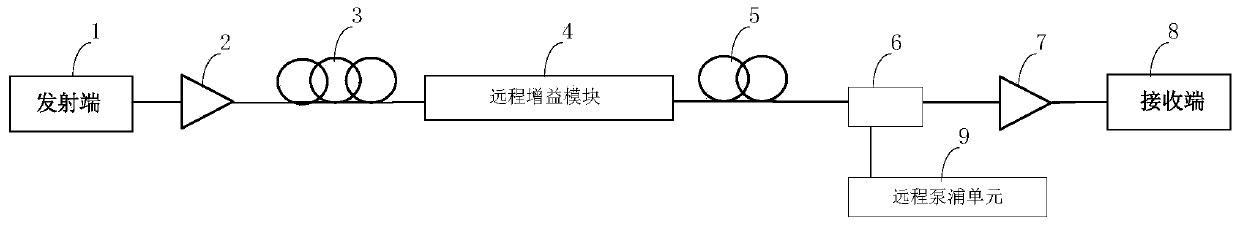

Remote passive gain module and relay-free transmission system capable of realizing state monitoring

PendingCN110266376ASelf-poweredMaster the working statusElectromagnetic transmission optical aspectsIsolatorOptical isolator

The invention provides a remote passive gain module capable of realizing state monitoring. The remote passive gain module comprises a first monitoring optical splitter the input end of which is connected with a front transmission optical fiber, wherein the secondary light splitting end of the first monitoring light splitter is connected with the first light detector, and the main light splitting end is connected with the signal end of a first signal pumping combiner; the common end of the first signal pumping combiner is connected with one end of the erbium-doped optical fiber; the other end of the erbium-doped optical fiber is connected with the input end of the unidirectional optical isolator; the output end of the unidirectional optical isolator is connected with one end of a filter, the other end of the filter is connected with the input end of a second monitoring optical splitter, the secondary optical splitting end of the second monitoring optical splitter is connected with a second optical detector, the main optical splitting end of the second monitoring optical splitter is connected with the signal end of a second signal pumping combiner, and the common end of the second signal pumping combiner is used for being connected with a post-transmission optical fiber; the reflection end of the second signal pumping combiner is connected with the input end of the pumping light splitter, and the secondary light splitting end of the pumping light splitter is connected with the monitoring photoelectric module. And the state of the remote passive gain module can be effectively monitored.

Owner:无锡瀚诺光电科技有限公司

Overhead power transmission line foreign matter cleaning device

ActiveCN107425472AEfficient removalClean up thoroughlyApparatus for overhead lines/cablesForeign matterTransmitter

The invention provides an overhead transmission line foreign matter cleaning device. The overhead power transmission line foreign matter cleaning device comprises a mounting cabinet, a hanging plate, two rollers and a circuit component, wherein the mounting cabinet is provided with a traction hole group; the mounting cabinet and the hanging plate are provided with hanging hole groups; two rollers are fixedly arranged between an upper end of the mounting cabinet and the hanging plate; the circuit component comprises a conductive support rod group which are fixedly arranged on the mounting cabinet and the hanging plate, an electric resistance wire which is fixedly arranged on the conductive support rod and is applied to thermal cutting of foreign matters on a power transmission line, a storage battery which is arranged in the mounting cabinet and is used for supplying working power to the electric resistance wire, a relay KA which is arranged in the mounting cabinet and is used for controlling the on / off of the power supply of the electric resistance wire, a remote receiver which is arranged in the mounting cabinet and is used for controlling the action of the relay KA, and a handheld remote transmitter which is used for wirelessly transmitting an on / off command to the remote receiver. The overhead power transmission line foreign matter cleaning device is simple in structure, is low in cost, is easy to carry, and is convenient to operate in use, the thermal cutting is adopted, so that various foreign matters on the power transmission line can be cleaned safely, rapidly and completely.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD +1

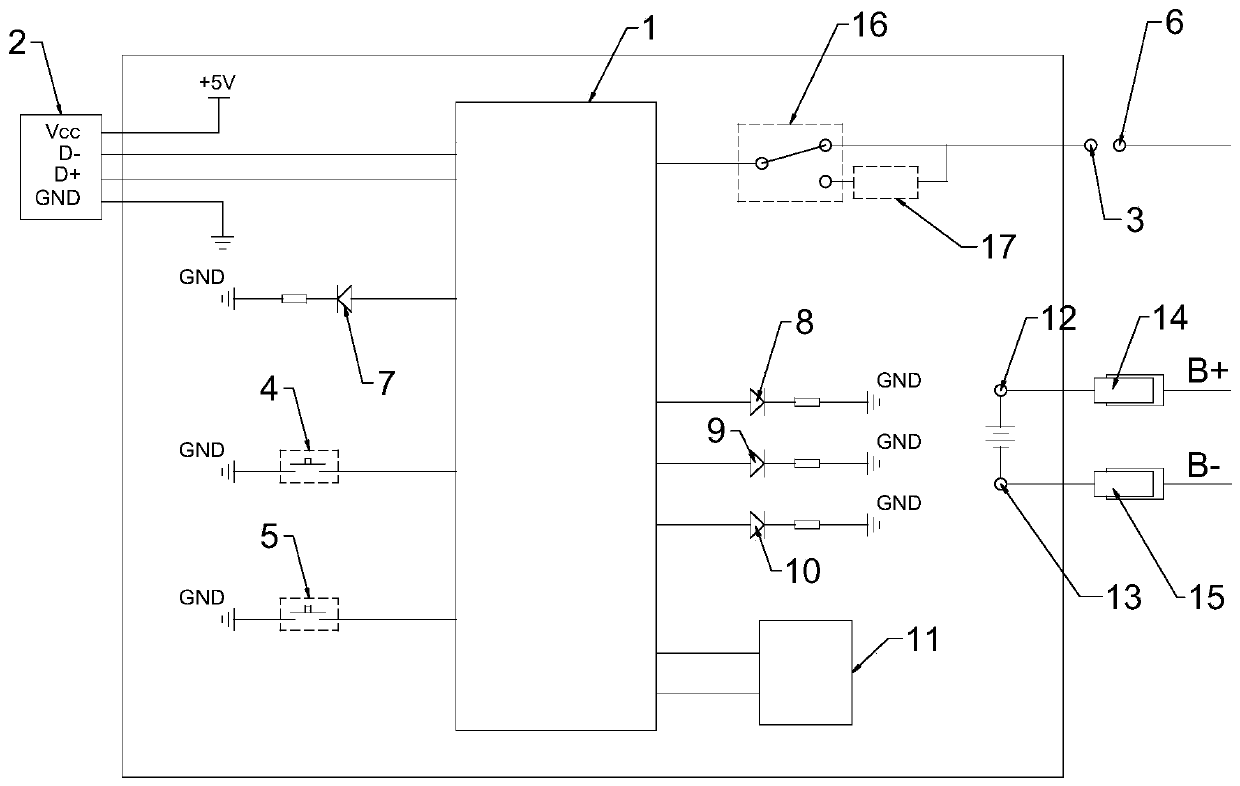

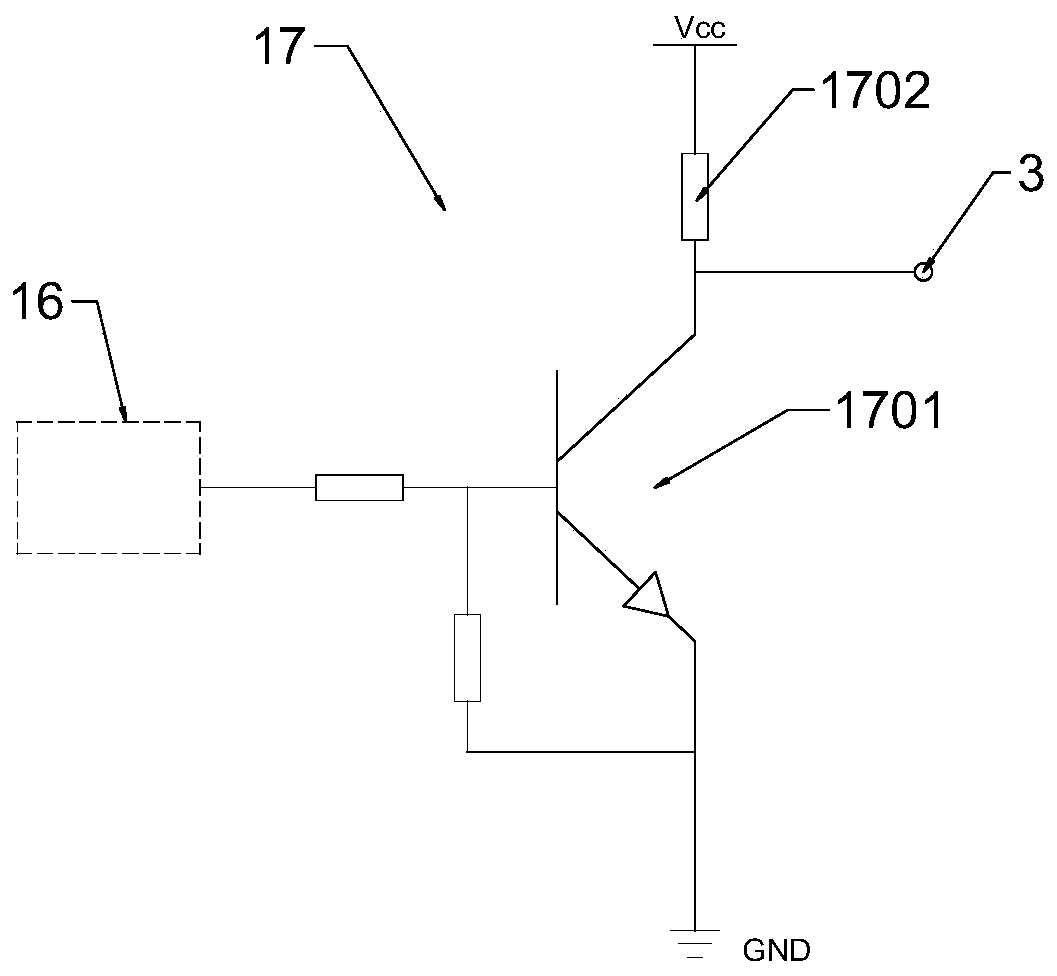

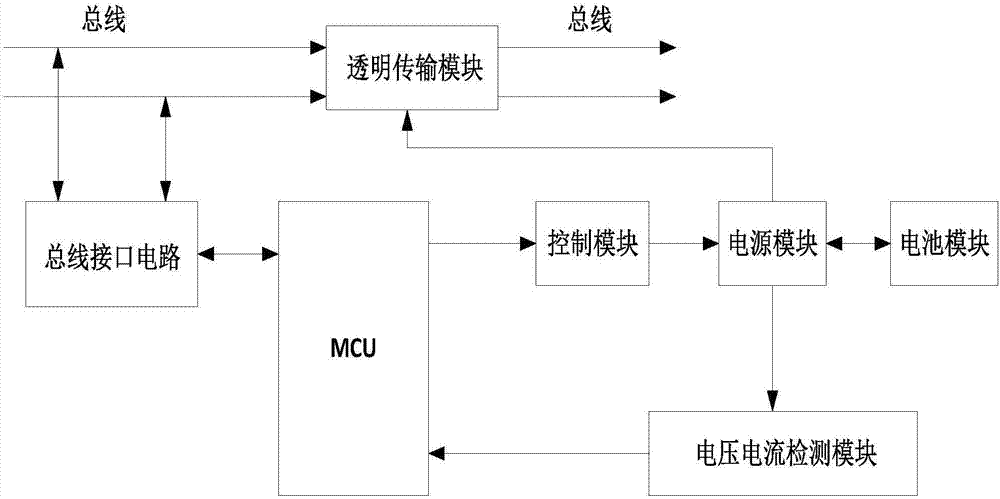

Self-check power supply device hung to fire fighting bus

InactiveCN107221990ADoes not affect communicationGuaranteed normal startupBatteries circuit arrangementsElectric powerControl powerEngineering

The invention discloses a self-check power supply device hung to a fire fighting bus, which is mainly used to solve the problem that an external control power supply cannot be supervised in the prior art. The self-check power supply device comprises a transparent transmission module, a bus interface circuit, an MCU, a control module, a power supply module, a voltage and current detection module, and a battery module. The transparent transmission module is hung to a fire fighting bus, and connected with the power supply module. The bus interface circuit is connected with the fire fighting bus and the MCU. The MCU is connected with the control module. The control module is connected with the power supply module. The voltage and current detection module is connected with the power supply module and the MCU. The battery module is connected with the power supply module. Through the scheme, the self-check power supply device has such advantages as reliable power supply, real-time monitoring, lower patrol workload and good expansion performance, and has very high practical value and promotion value in the technical field of fire fighting.

Owner:SICHUAN SAIKE SECURITY TECH CO LTD

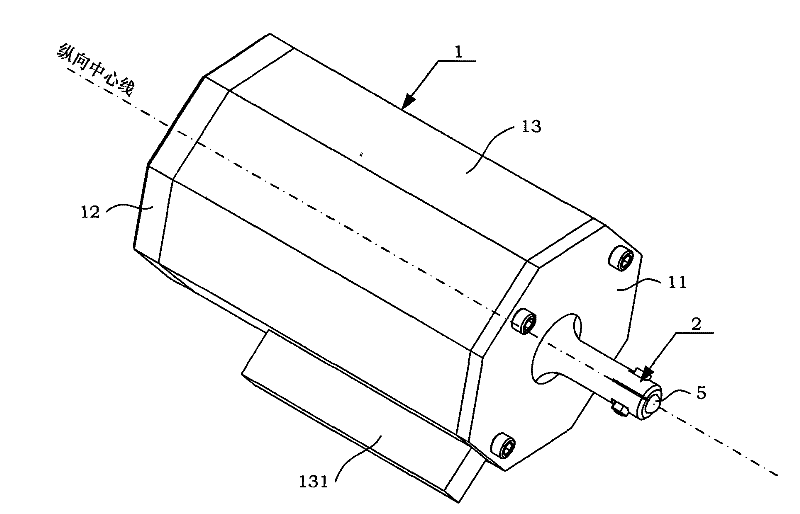

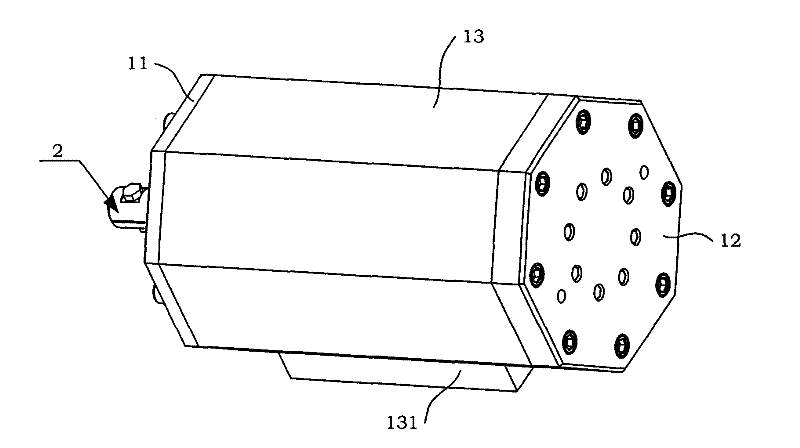

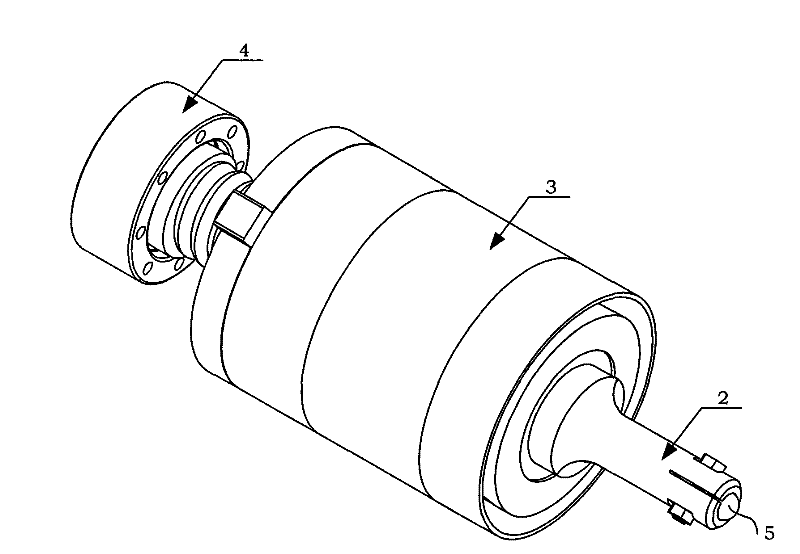

Ultraphonic elliptical vibration and extrusion processing device based on double-excitation longitudinal bending elliptical energy converter

InactiveCN101633048BExtended service lifeReduce or even avoid sliding frictionAuxillary equipmentMechanical vibrations separationEnergy converterMechanical engineering

The invention discloses an ultraphonic elliptical vibration and extrusion processing device based on a double-excitation longitudinal bending elliptical energy converter, comprising a shell assembly, a vibration assembly, a sliding assembly and a pressure assembly, wherein the sliding assembly is sleeved on the excircle surface of the vibration assembly; the pressure assembly is arranged on the tail part of the vibration assembly; and the assembled vibration assembly, the sliding assembly and the pressure assembly are arranged in the shell assembly. The structure of the ultraphonic ellipticalvibration and extrusion processing device is designed by combining a flexible extrusion requirement with a langevin energy converter principle, when the ultraphonic elliptical vibration and extrusionprocessing device is adopted to carry out extrusion processing, the double-excitation longitudinal bending elliptical energy converter of the ultraphonic elliptical vibration and extrusion processingdevice can drive a cutter to cautiously take longitudinal bending elliptical vibration, tracks of the longitudinal bending elliptical vibration are tangent with tracks of the turning motion of a workpiece and is reverse to the turning direction of the workpiece, when the turning speed of the longitudinal bending elliptical vibration is equal or approximately equal to the turning speed of the workpiece, the cutter is equivalent to make pure rolling on the surface of the workpiece so that relative sliding between the cutter and the processing surface disappears, and the mechanical abrasion caused by sliding friction is effectively prevented, and the purpose of prolonging the service life of the cutter is achieved.

Owner:BEIHANG UNIV

Movable watering machine

InactiveCN106171858AEasy to controlHeight adjustableWatering devicesCultivating equipmentsFault indicatorWater flow

The invention discloses a mobile watering machine, comprising a watering machine body, a water flow control knob, a water tank, a water pressure gauge, a screw nozzle and an adjusting rod. A power switch is installed on the left side of the water machine body, and a water flow control knob is installed on the upper side of the power switch, a touch screen is installed on the upper side of the water flow control knob, and a fault indicator light is installed on the upper right side of the touch screen. A water tank is installed inside, and a buoy is installed inside the water tank, a thick water pipe is installed on the lower right side of the water tank, a water pressure gauge is installed on the upper left side of the thick water pipe, and a flow control valve is installed on the right side of the water pressure gauge. A spiral nozzle is installed on the lower right side of the water machine body, and spray nets are installed on both sides of the spiral nozzle. Through the pressure sensor, the present invention can detect and repair the water pipe failure state.

Owner:王羽萍

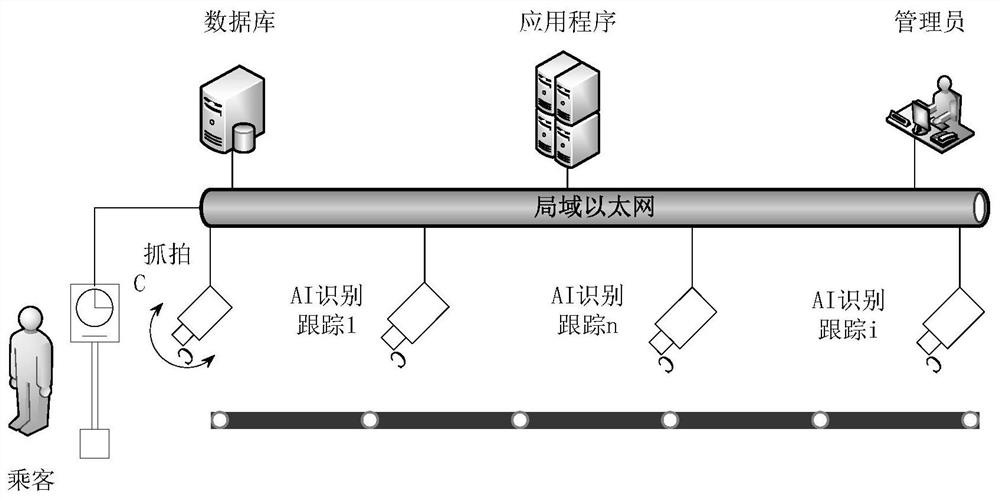

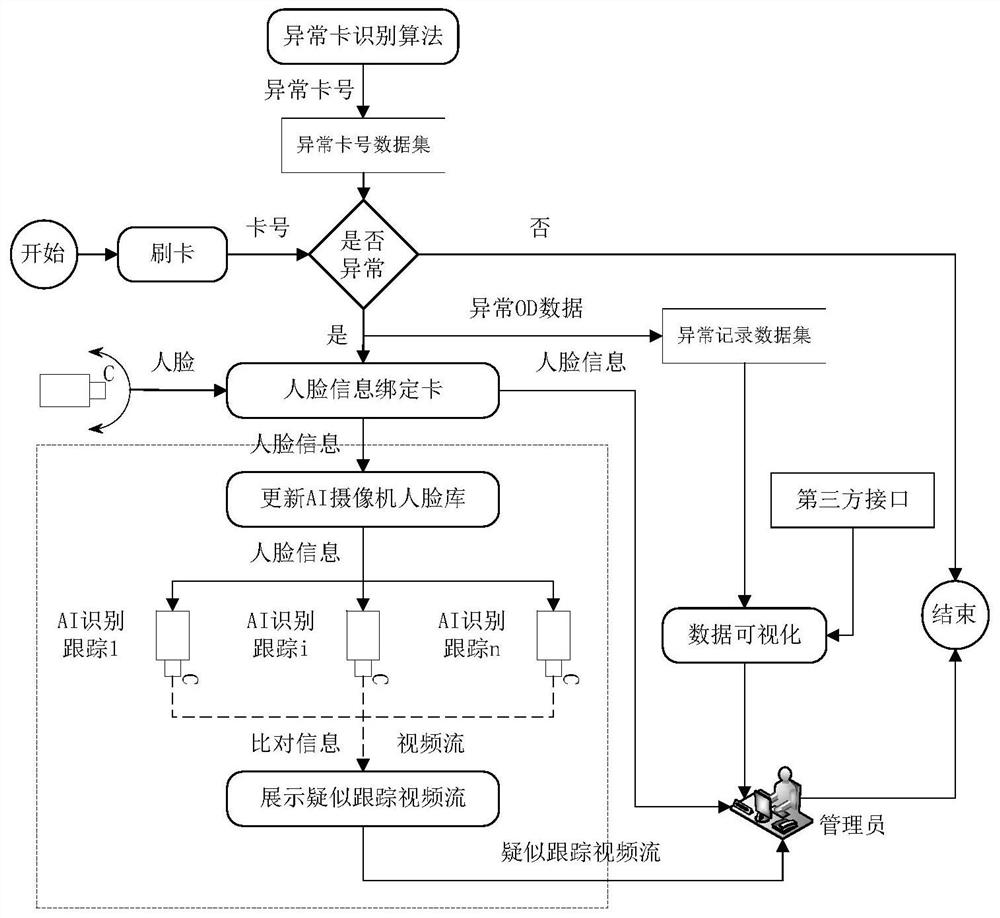

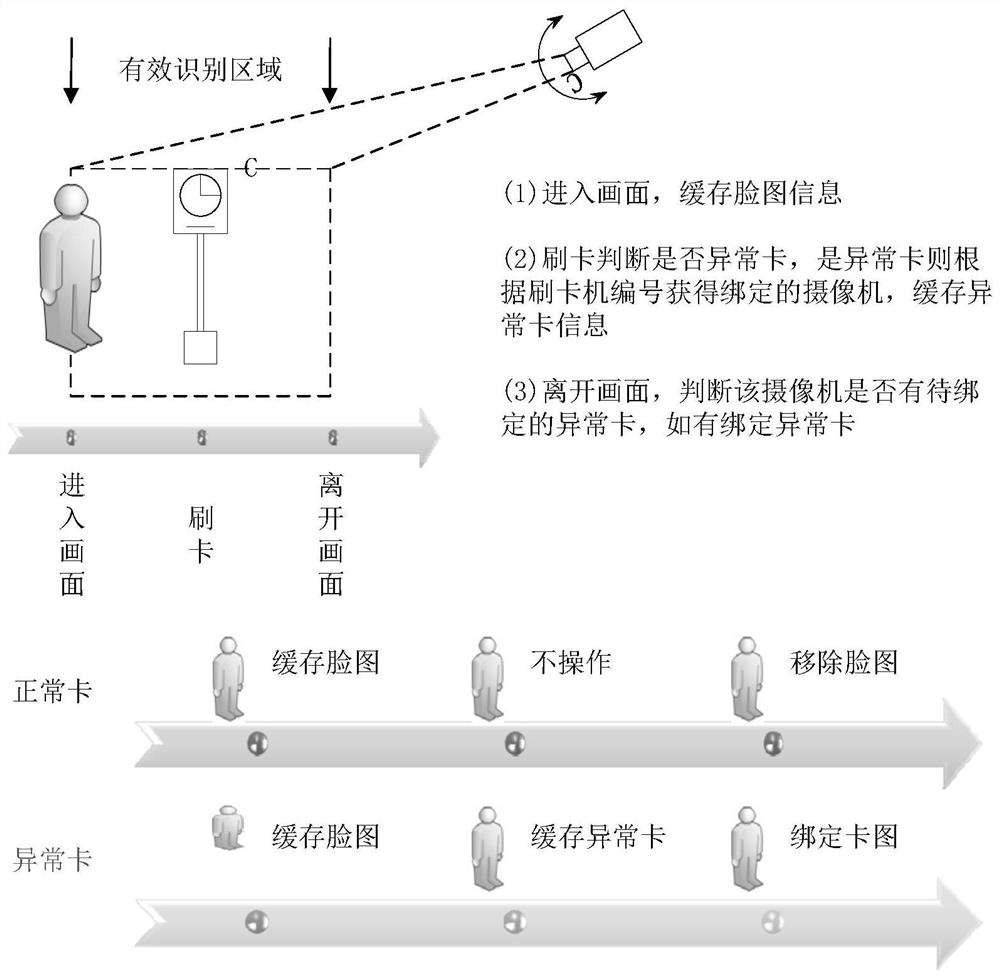

Rail transit passenger flow abnormal mode identification method based on big data

PendingCN111798356ARealize managementMaster the working statusCharacter and pattern recognitionNeural architecturesRail transitServer

The invention discloses a rail transit passenger flow abnormal mode identification method based on big data. The rail transit passenger flow abnormal mode identification method comprises the steps of:acquiring card swiping information of a passenger, and judging whether a card belongs to an abnormal card or not, wherein the abnormal card is used for representing that abnormal behaviors exist in card swiping records; and if the card is judged to be an abnormal card, acquiring face image information and human body characteristics of the abnormal card passenger; binding the abnormal card numberwith the face image information; and publishing the face image information corresponding to the abnormal card to a plurality of tracking cameras, respectively comparing the face image information acquired by the plurality of tracking cameras according to a local face recognition library by means of the plurality of tracking cameras, and if the face information in the local face recognition library is retrieved, uploading a comparison result and a video stream of the corresponding camera to a target server. According to the rail transit passenger flow abnormal mode identification method, abnormal cards and abnormal behaviors can be accurately identified, and abnormal behavior paths and time periods can be counted and analyzed.

Owner:BEIJING JIAOTONG UNIV

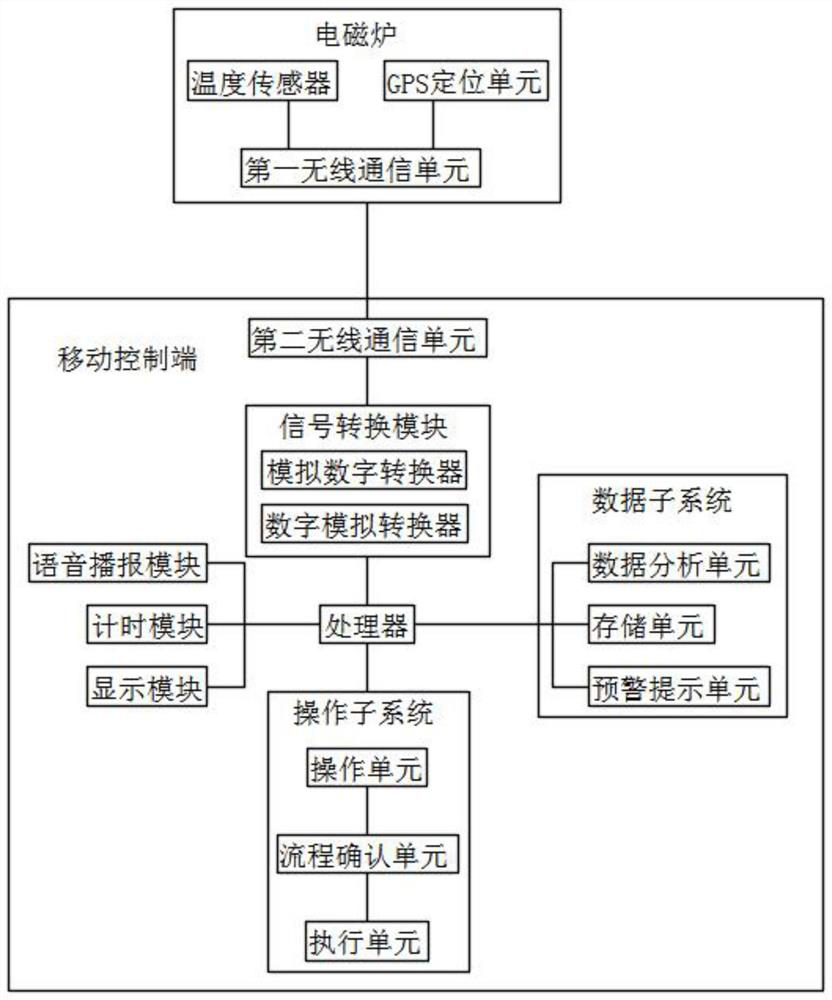

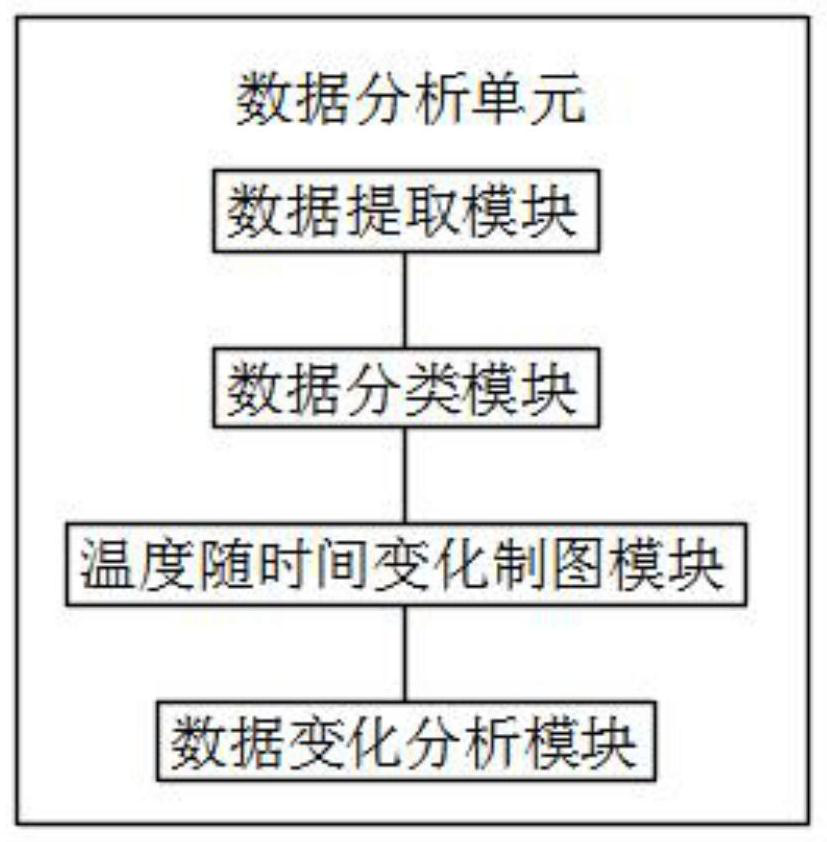

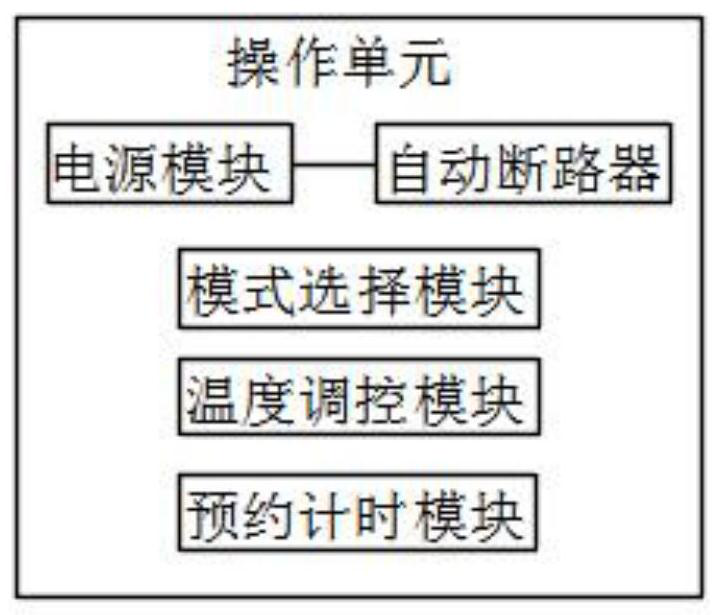

Induction cooker for smart home

PendingCN112714524AMaster the working statusEasy to operateInduction heating controlCommunication unitControl engineering

The invention discloses an induction cooker for smart home.The induction cooker comprises an induction cooker body and a mobile control terminal, a temperature sensor is installed in the induction cooker body, a GPS positioning unit is installed in the induction cooker body, a first wireless communication unit is installed in the induction cooker body, and the mobile control terminal comprises a processor, an operation subsystem, a data subsystem, a second wireless communication unit, a signal conversion module, a voice broadcast module, a timing module and a display module. The invention relates to the technical field of induction cookers. According to the induction cooker for the smart home, the induction cooker is started through the power supply module in the operation unit of the operation subsystem in the mobile control terminal, so that a user can control the induction cooker conveniently even if the user is not at home, the life of the user is facilitated, the user can master the working state of the induction cooker conveniently through temperature and time data analysis, and through long-time drawing analysis, subsequent maintenance and use are also facilitated.

Owner:佛山市易豆科技有限公司

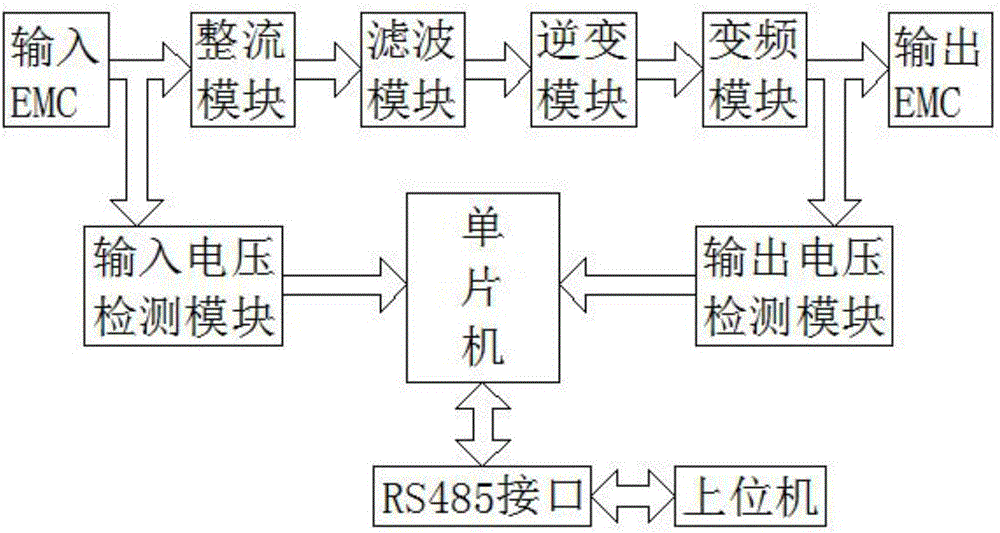

Air conditioner drive power supply testing system based on single chip microcomputer control

InactiveCN106019176AImprove reliabilityImprove stabilityPower supply testingMicrocontrollerMicrocomputer

The invention discloses an air conditioner drive power supply testing system based on single chip microcomputer control. The air conditioner drive power supply testing system comprises an input EMC, a rectifier module, a filter module, an inversion module, a frequency conversion module and an output EMC which are sequentially connected; the input EMC and the output EMC are connected to the input end of a single chip microcomputer through an input voltage detection module and an output voltage detection module respectively; the single chip microcomputer achieves interaction communication with an upper computer through an RS485 interface. According to the system, an electric signal is subjected to a series of processing and then output to be used by an air conditioner, and the reliability and the stability of air conditioner power supply are improved; the air conditioner running speed is regulated and controlled through the frequency conversion module, and therefore the automation degree and the stability degree of speed regulation of the air conditioner are increased; an input voltage signal and an output voltage signal are collected by the input voltage detection module and the output voltage detection module respectively, and therefore the stability of a power supply is conveniently monitored to master the working state of the power supply; monitor data of the single chip microcomputer is acquired by the upper computer through the RS485 interface in real time.

Owner:HEFEI TONGYONG POWER EQUIP

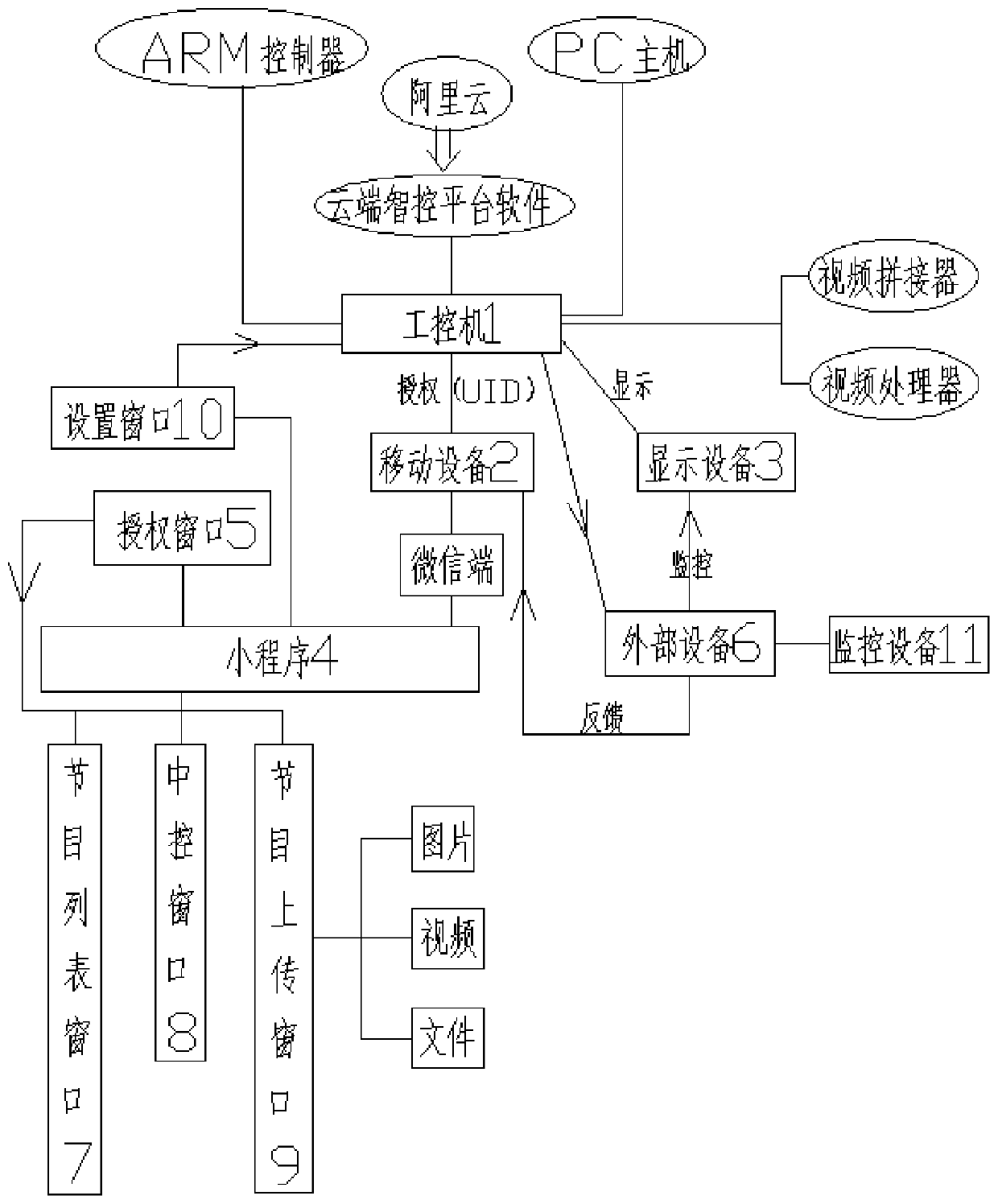

Intelligent control system platform based on WeChat end

InactiveCN109884945AImprove playbackTo achieve the purpose of remote controlProgramme controlComputer controlRemote controlDisplay device

The invention discloses an intelligent control system platform based on a WeChat end. The intelligent control system platform based on the WeChat end consists of three parts of an industrial computer,a mobile device and a display device; cloud intelligent control platform software is embedded in the industrial computer; the cloud intelligent control platform software is built relying on Alibaba Cloud; the cloud intelligent control platform software enables each industrial computer to generate a unique two-dimensional code; the mobile device binds to the industrial computer by scanning the two-dimensional code; then the bound mobile device is authorized through the cloud intelligent control platform software; a user controls the industrial computer through a small program on the mobile device WeChat end, and adjusts the content played on the display device. When in use, the user can perform operations such as playing, pausing, replacing and the like on the content displayed on the display device, and can also remotely control the peripheral associated device of the serial port of the industrial computer; therefore, the remote control of different functions is realized, unified management of data, programs, video, and audio is realized, and centralized management and flexible configuration of scheduling, computing, storage, and network are realized.

Owner:杭州格瑞普光电科技有限公司

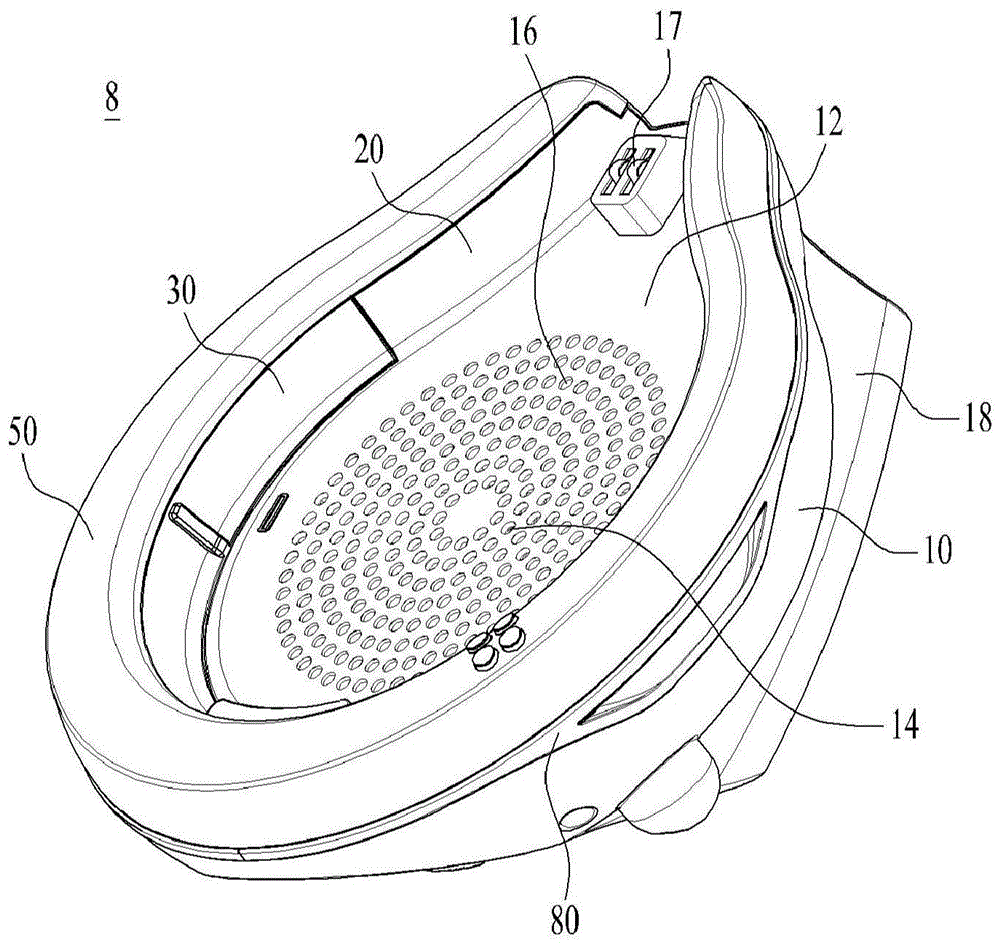

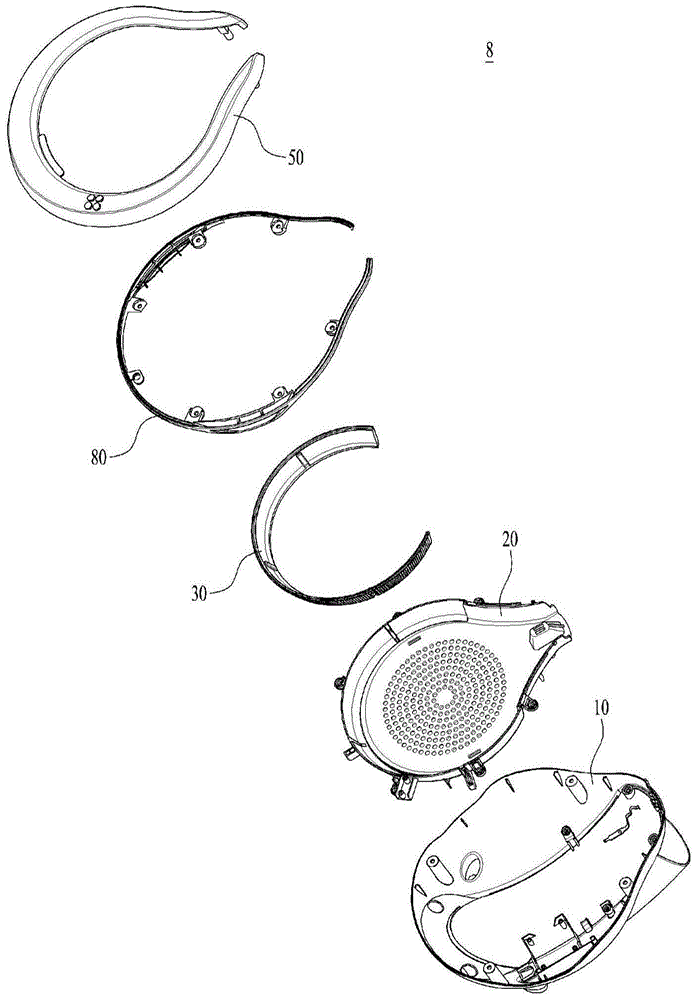

Stand for bedding cleaner

InactiveCN103892745BMaster the working statusTidy upElectric equipment installationRadiationEngineeringLight source

The present invention relates to a supporter of a cleaner for bedding. According to the present invention, the supporter includes a body for holding a main body; a light source installed in the body; a diffusion part diffusing light emitted from the light source; and a cover forming the upper appearance of the body. The body includes a bottom part touch the absorption nozzle of the main body and a sidewall part extended and bent to the bottom part. The diffusion part is installed in the sidewall part.

Owner:LG ELECTRONICS INC

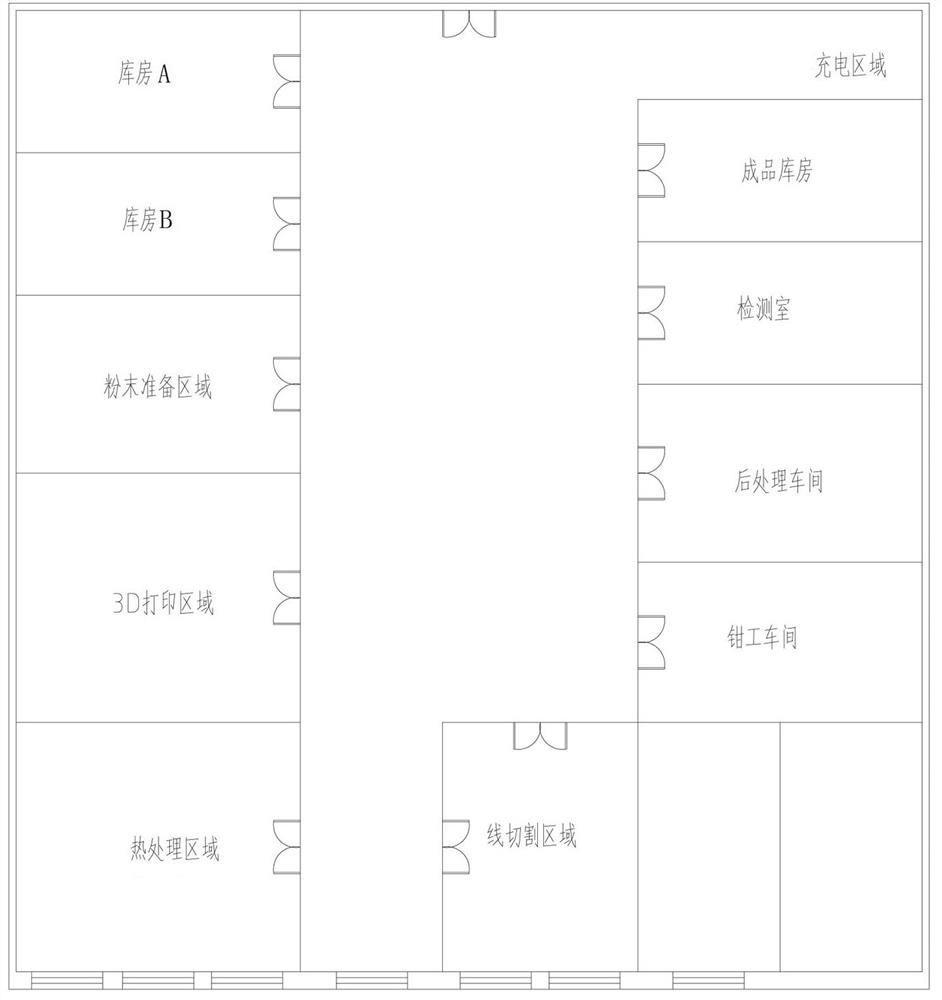

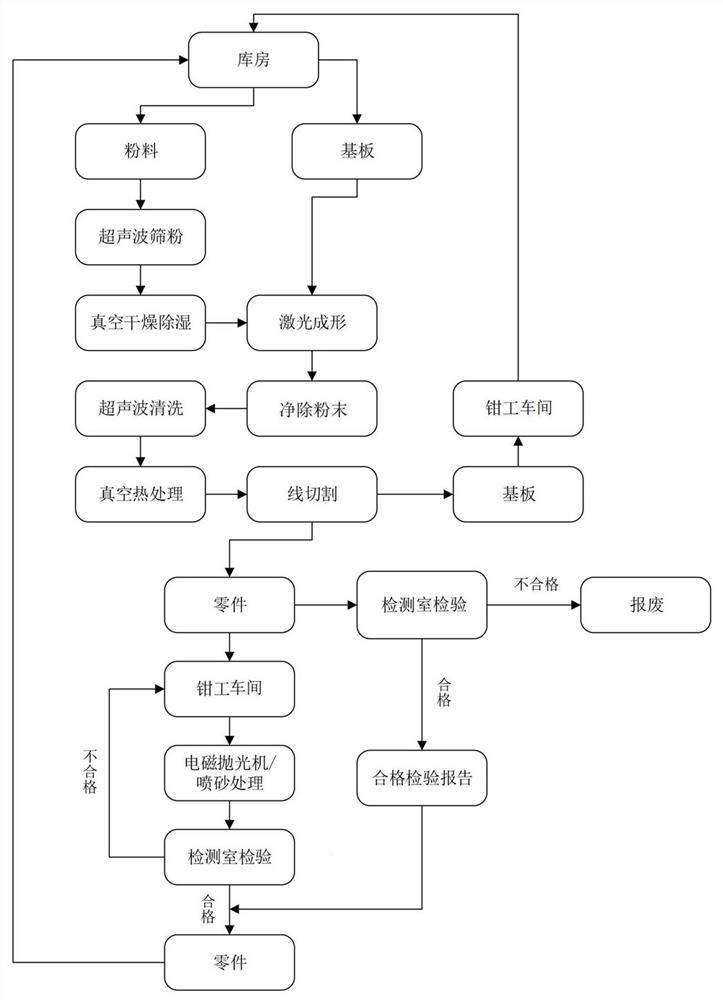

3D printing workshop based on additive manufacturing industry internet platform

PendingCN114801162AImprove transmission efficiencyComplete efficientlyAdditive manufacturing apparatus3D object support structuresLogistics managementSand blasting

According to the 3D printing workshop based on the additive manufacturing industry internet platform, an AGV conveys powder to a powder preparation area, treated powder and a substrate are conveyed to a 3D printing area to produce parts, the parts are conveyed to a heat treatment area to be subjected to heat treatment, the parts subjected to heat treatment are conveyed to a linear cutting area to be cut and separated, and the AGV conveys the parts and the substrate separately; and the parts are conveyed to a bench worker workshop to be treated, subjected to ultrasonic cleaning, polishing or sand blasting treatment in a post-treatment workshop and conveyed to a detection room to be detected, and qualified parts are conveyed to a finished product warehouse to be registered and put in storage. The AGV trolley is used for completing material carrying, the carrying route is adjusted along with the production technological process, manpower is saved, logistics management is improved, the material conveying efficiency is improved, and safety is improved; the AGV trolley transmits the information to the Internet platform, so that the working state of the trolley can be mastered conveniently, the information feedback time is shortened, the equipment utilization rate and the production efficiency are improved, the cost is reduced, and the benefit is improved.

Owner:山东变量空间科技有限公司

X-ray computed tomography apparatus and information processing apparatus

ActiveCN104780844BMaster the working statusImage enhancementImage analysisInformation processingTemporal change

Grasp the working status of the device at any point in time. The reconstructed image generation unit (preprocessing unit 31 , reconstruction unit 33 , image processing unit 35 ) generates a reconstructed image based on output data based on electrical signals from the X-ray detector 15 . The correction parameter storage unit 37 stores correction parameters related to correction performed to reduce noise or artifacts in time series during the process of the reconstructed image generation unit. The correction parameter analysis unit 39 determines whether or not an abnormality has occurred based on temporal changes in the correction parameters stored in the correction parameter storage unit 37 . When it is determined by the correction parameter analysis unit 39 that an abnormality has occurred, the notification unit 41 notifies that the abnormality has occurred.

Owner:TOSHIBA MEDICAL SYST CORP

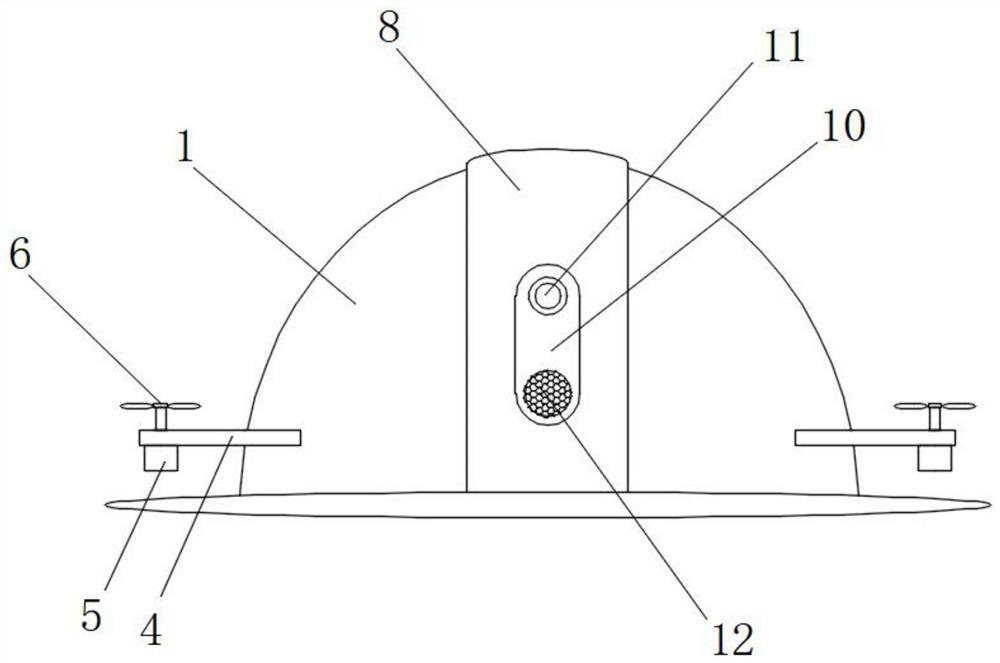

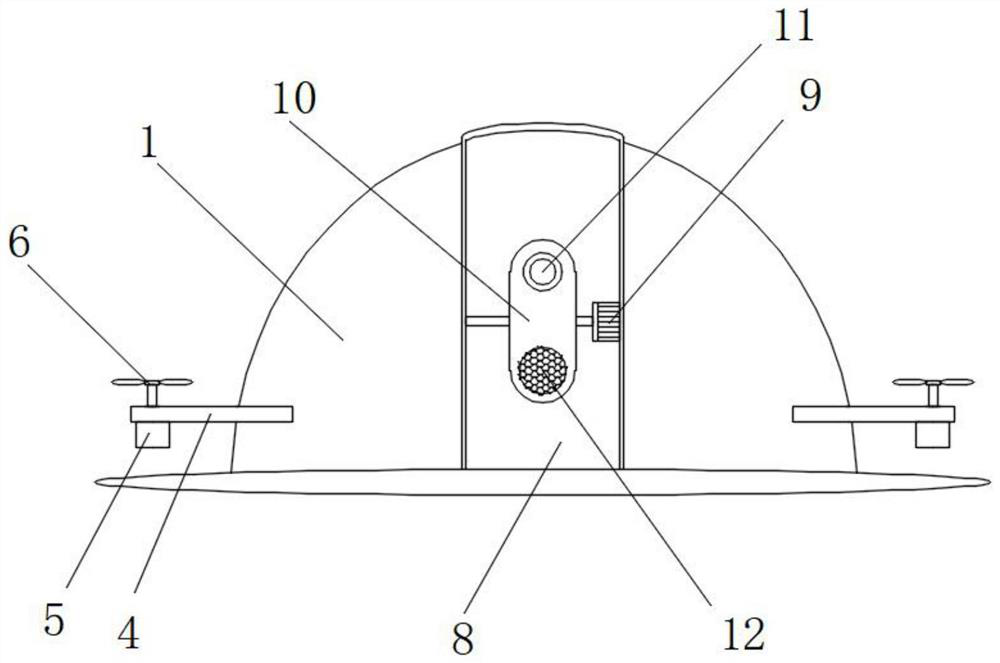

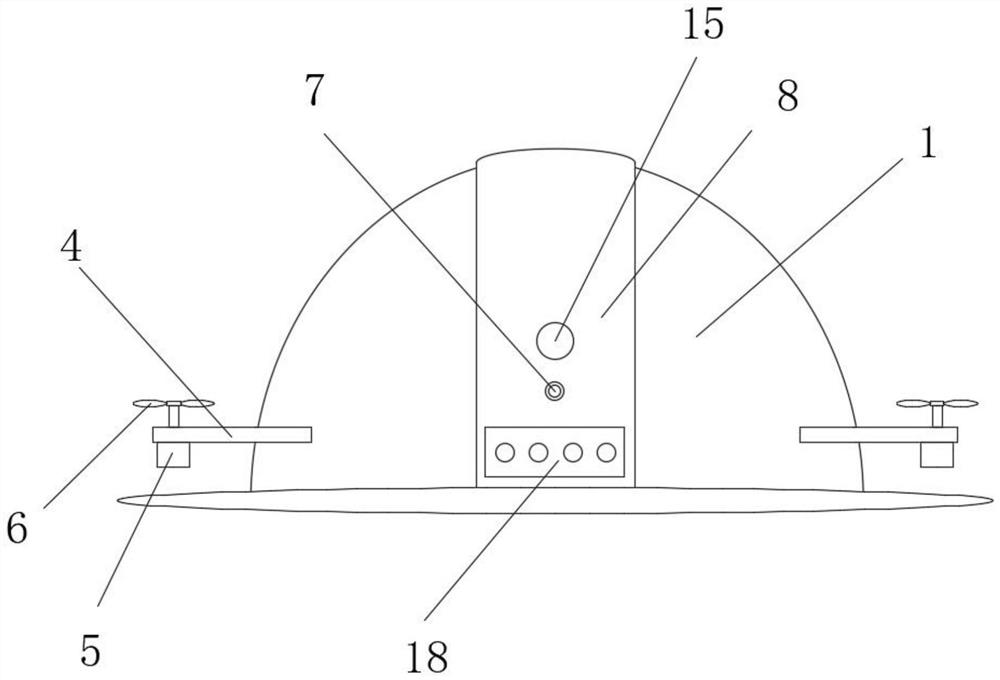

Safety helmet with supervision function

PendingCN113273757AMaster the working statusEasy to reportHelmetsHelmet coversElectric machineryDrive motor

The invention relates to the technical field of safety helmets, and discloses a safety helmet with a supervision function, the safety helmet comprises a helmet body, a remote controller and a terminal, the left front side, the left rear side, the right front side and the right rear side of the helmet body are all horizontally provided with supports, and the outward ends of the bottoms of the four supports in the horizontal direction are all fixedly provided with first driving motors; and motor shafts of the four first driving motors vertically and movably penetrate through the corresponding supports. Through a camera, a first call module, a second call module and a second driving motor, when the device is used, a power supply of the device is turned on through the control panel, a worker can wear the helmet on the head, and the camera monitors and shoots the work content, so that the picture is transmitted to the terminal, and the communication between the management personnel and the working personnel can be realized through the first communication module and the terminal, so that the management personnel can master the working state of the worker and the worker can report the working state, and the use effect is excellent.

Owner:江苏中车数字科技有限公司

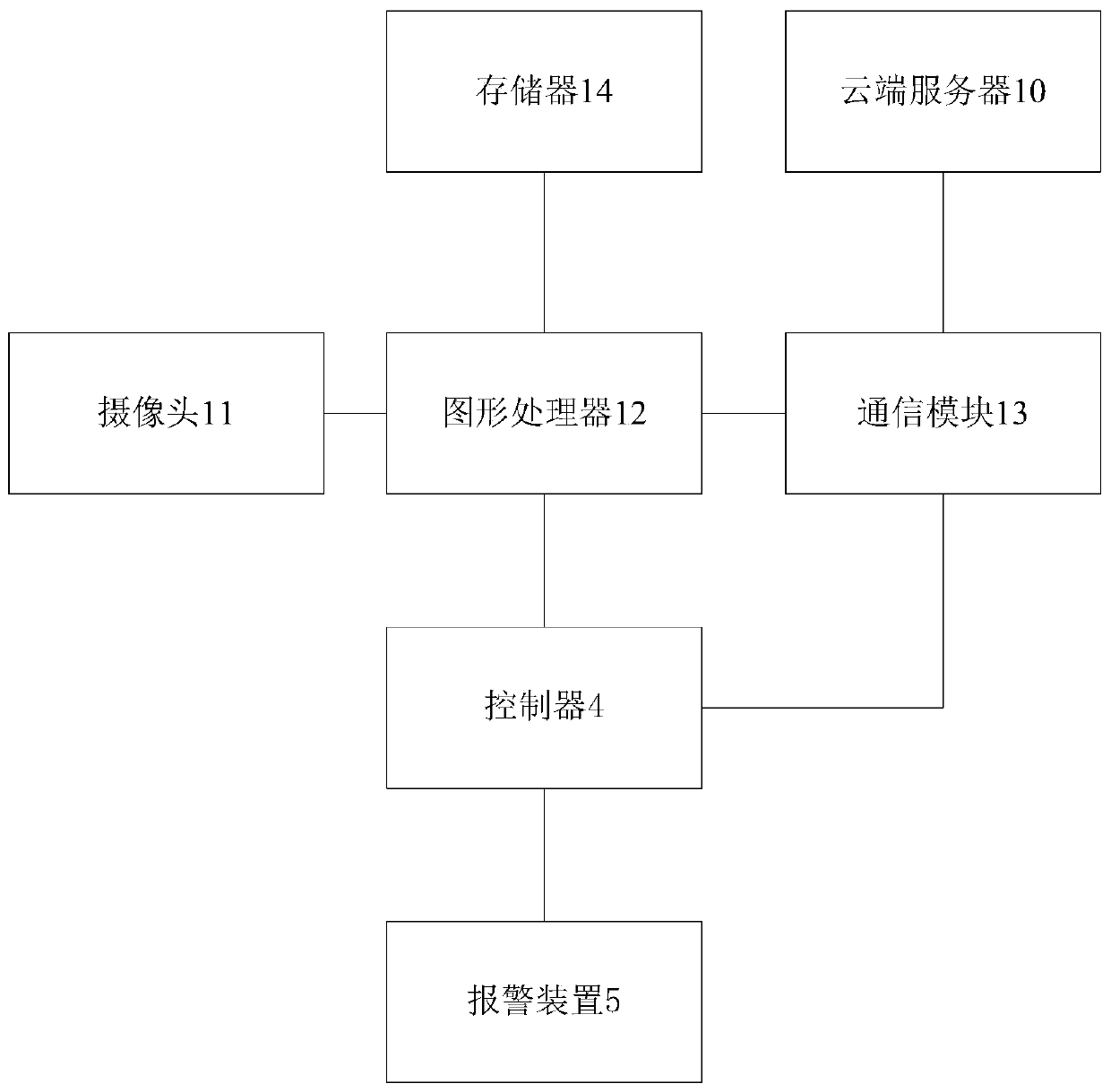

Vehicle control system and method based on in-vehicle state perception

InactiveCN111532203ARealize real-time detectionMaster the working statusSignalling/lighting devicesElectric/fluid circuitControl systemAlarm device

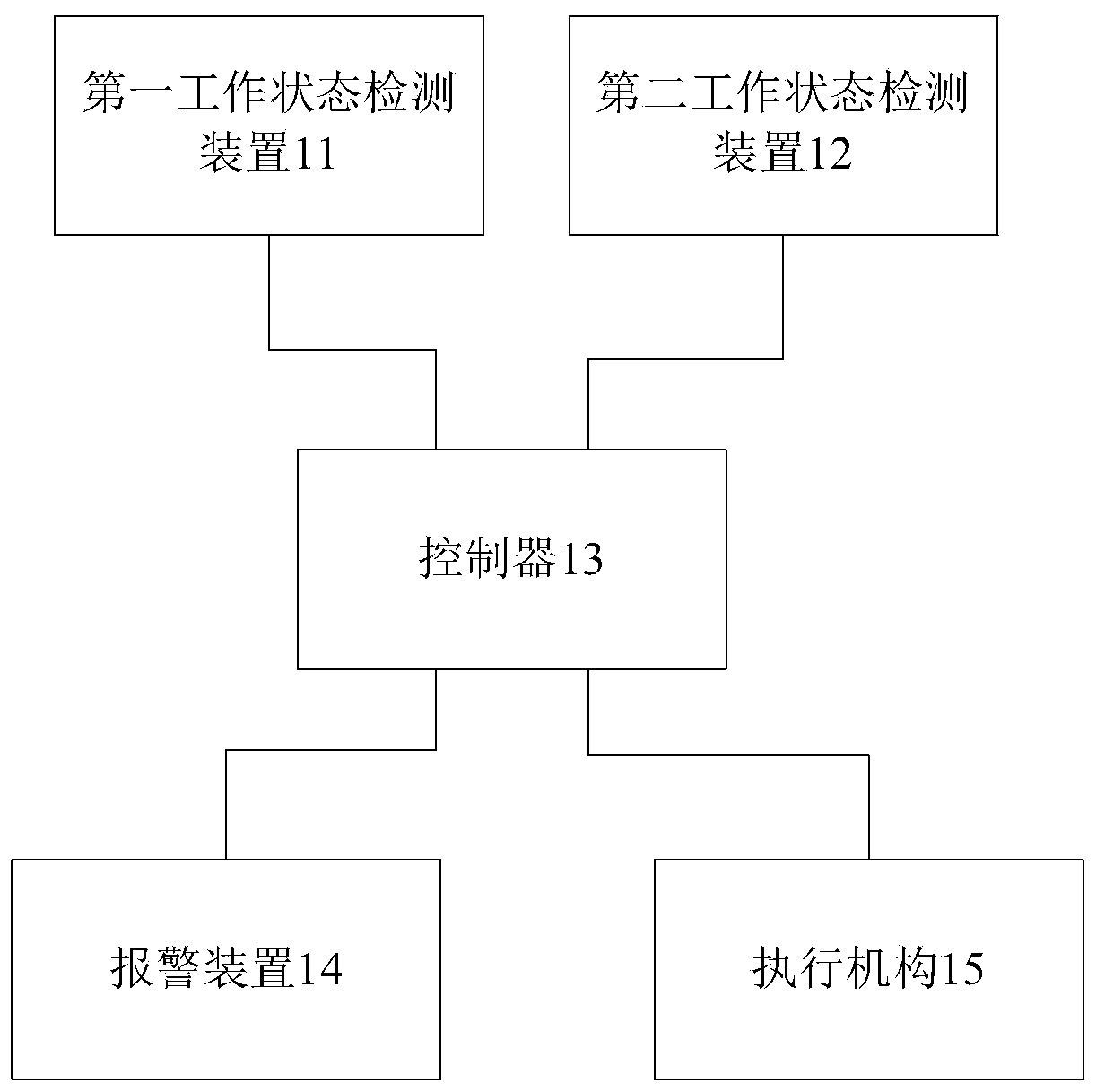

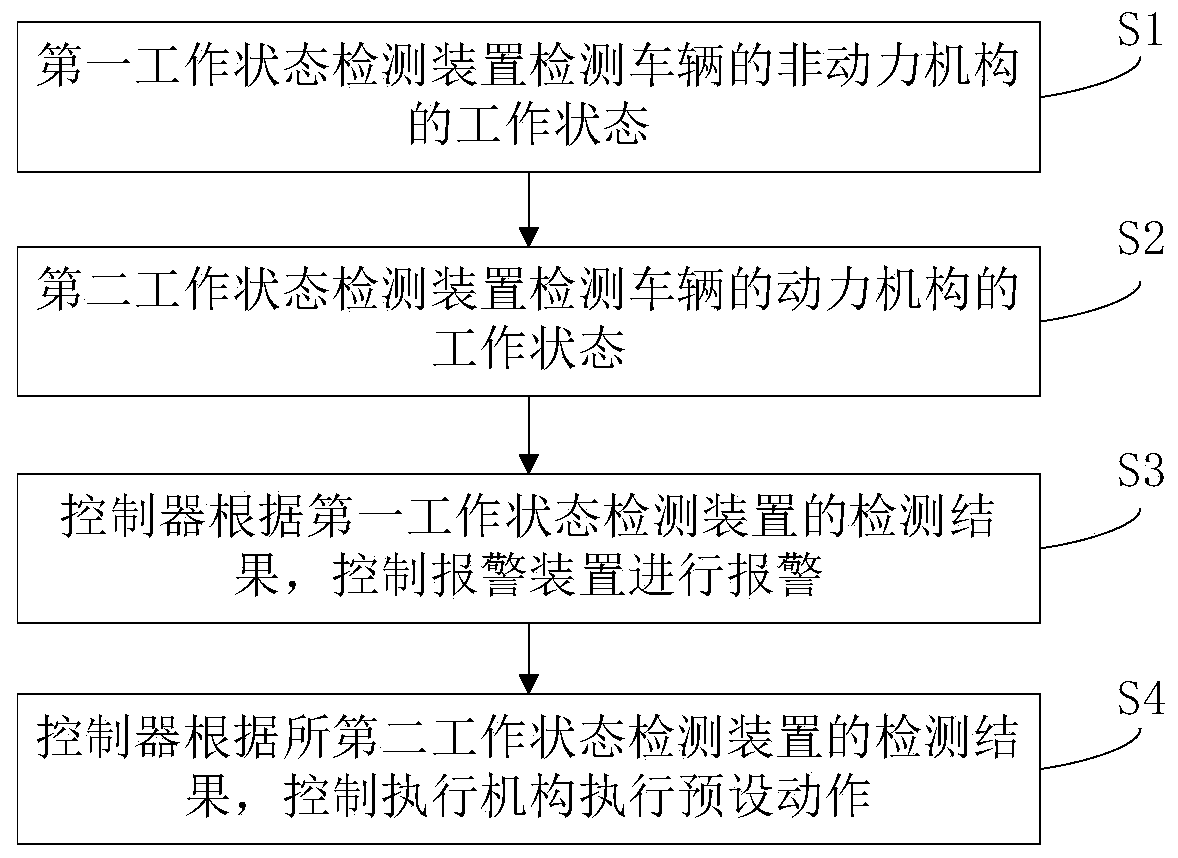

The invention discloses a vehicle control system and method based on in-vehicle state perception, and relates to the field of vehicle control. The system includes a first working state detection device, a second working state detection device, a controller, an alarm device and an execution mechanism. The first working state detection device is used for detecting a working state of a non-power mechanism of the vehicle; the second working state detection device is used for detecting the working state of a power mechanism of the vehicle; and the controller is used for making an alarm device givean alarm according to the detection result of the first working state detection device, and the controller is further used for making an execution mechanism execute a preset function according to thedetection result of the second working state detection device. In the invention, a driver can grasp the working state of the vehicle more comprehensively and accurately, a fault of a working part canbe found at the first time, and a behavior of a driver can be reasonably standardized and corrected.

Owner:易显智能科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com