Self-inspection method and system for engine electronic injection executer

An actuator and engine technology, applied in the direction of engine control, machine/engine, electrical control, etc., can solve problems such as affecting driving safety, inability to identify it, reducing power and economy, and achieving the effect of ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

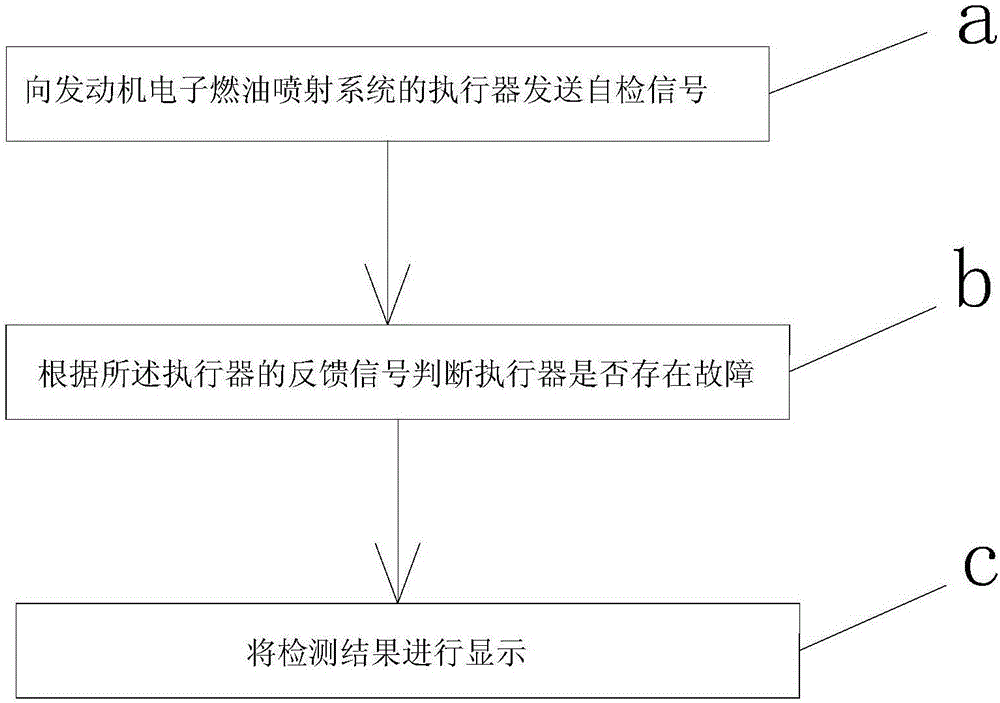

[0018] figure 1 It is a logic control diagram of the self-checking method of the engine electronic fuel injection actuator of the present invention; as shown in the figure: the self-checking method of the engine electronic fuel injection actuator of the present embodiment comprises the following steps: a. Send a self-test signal; b. judge whether there is a fault in the actuator according to the feedback signal of the actuator; c. display the detection result, through the self-check module in the existing electronic controller (ECU) of the engine in the present embodiment Send a self-test signal to the actuator and judge whether the actuator has a fault according to the feedback signal, and display the judgment result on a display such as an instrument panel. The self-test system of this embodiment can quickly and effectively identify the fault of the actuator of the EFI system , and display the cause of the failure to ensure that the user can grasp the working status of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com