Patents

Literature

2995results about "Induction heating control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

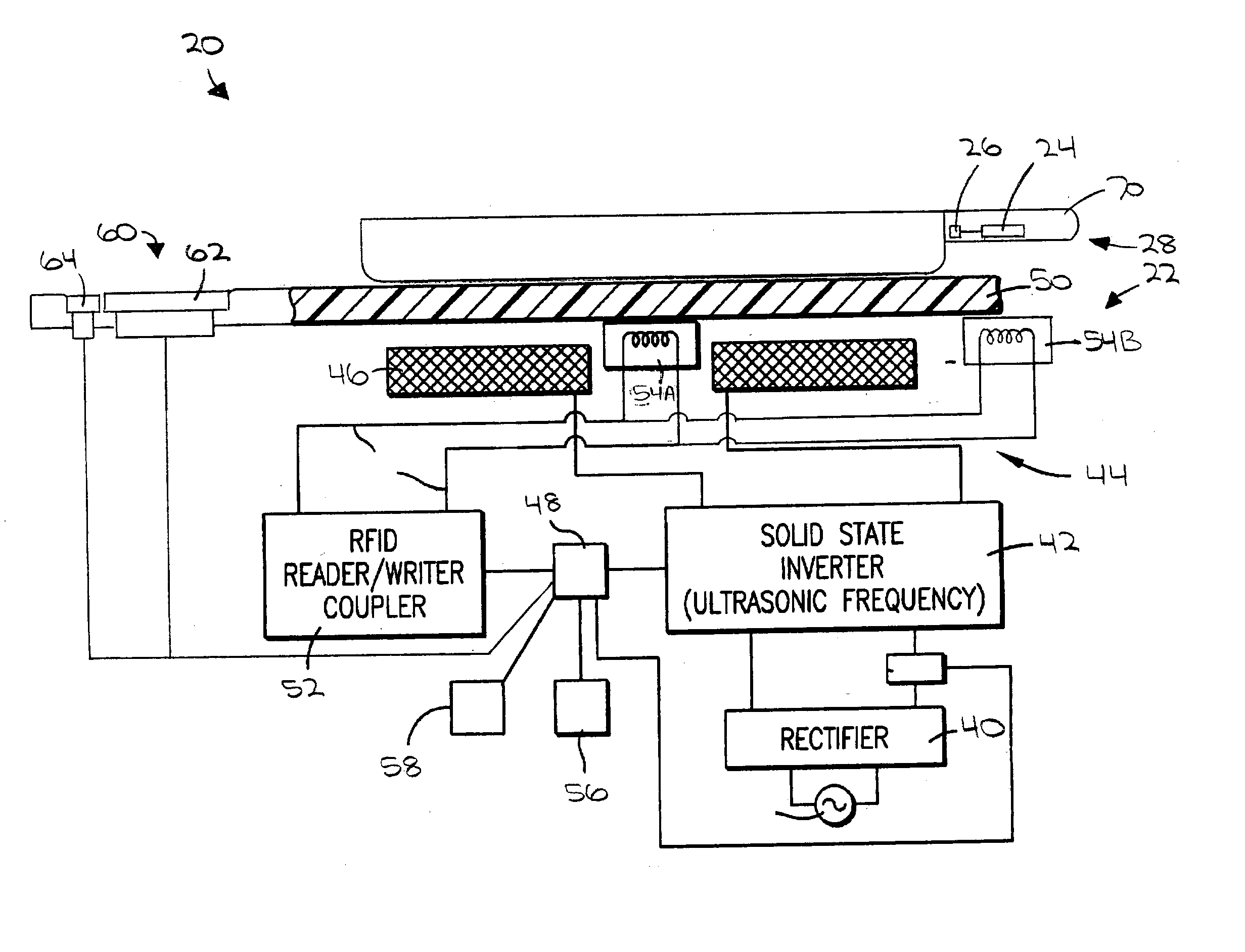

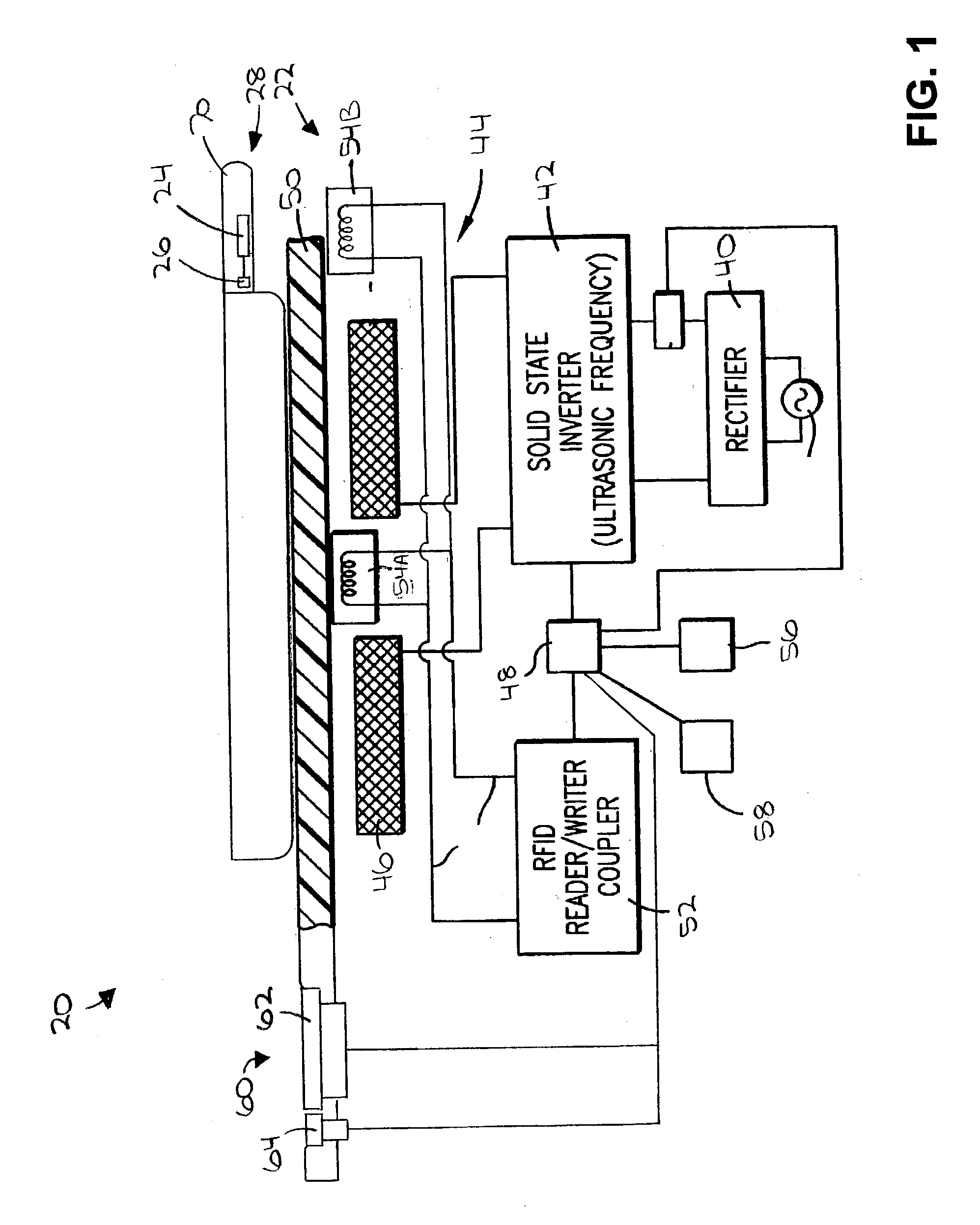

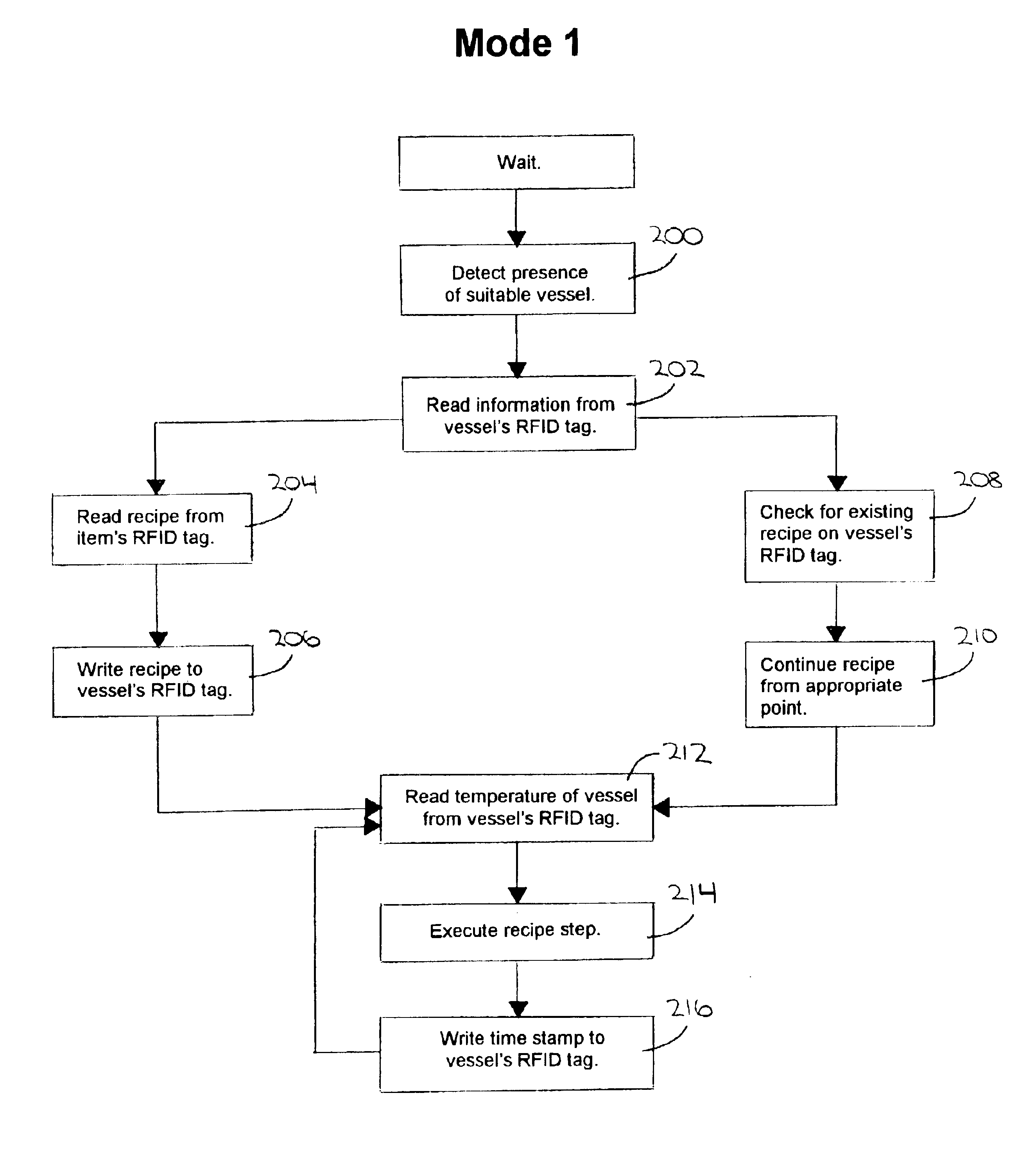

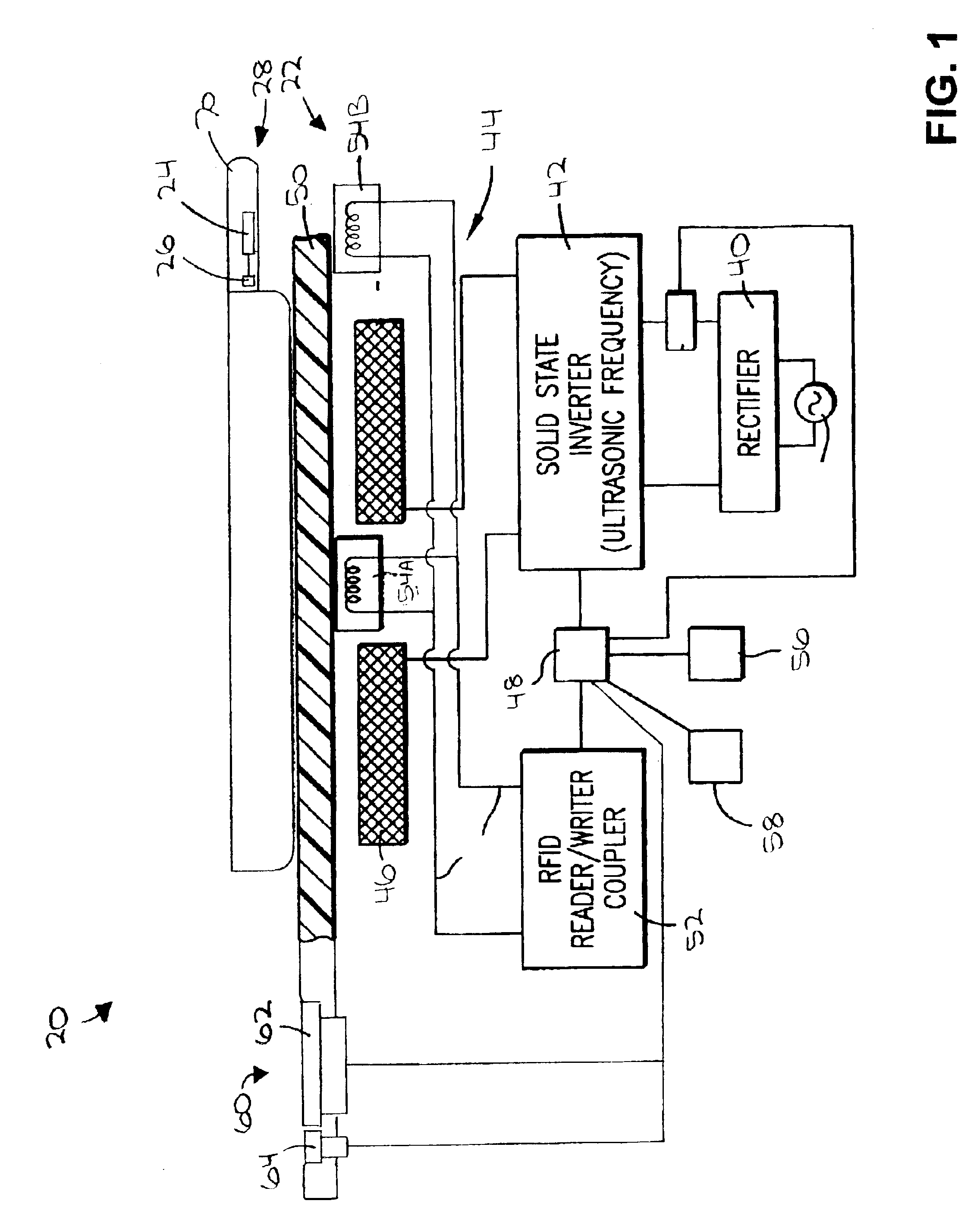

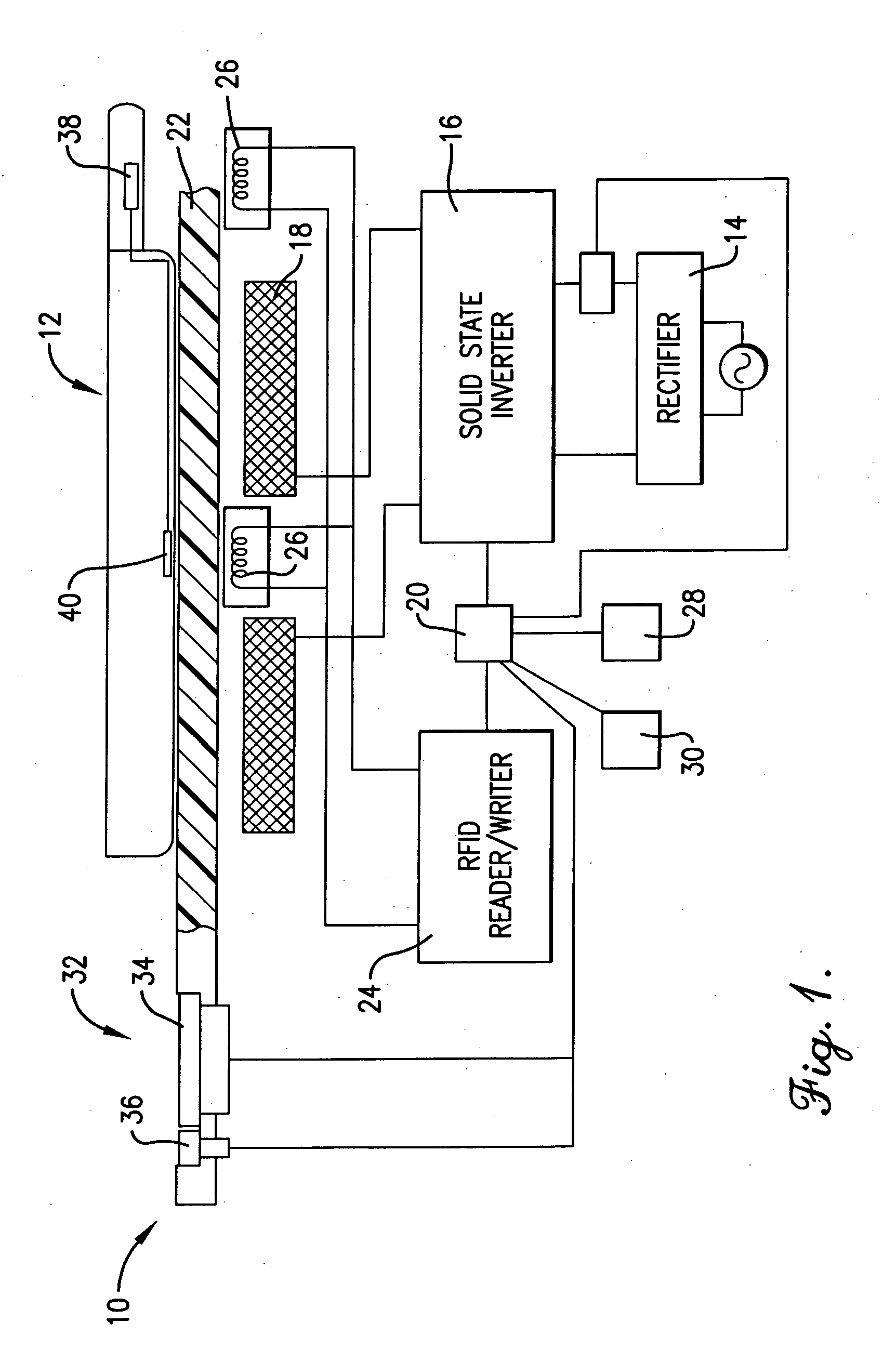

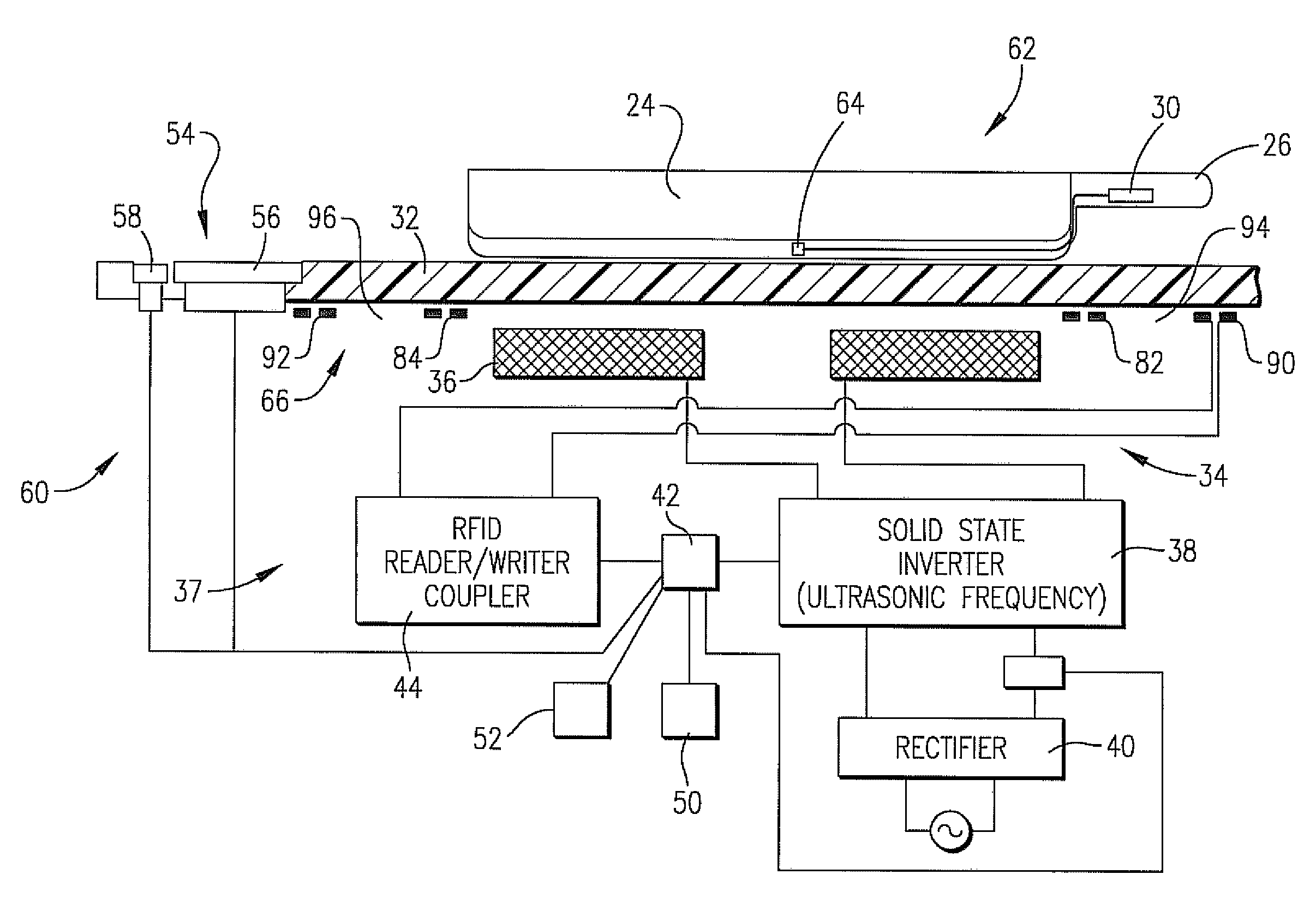

RFID-controlled smart induction range and method of cooking and heating

A system and method for providing multiple cooking modes and an ability to automatically heat cooking vessels and other objects using RFID technology, and an ability to read and write heating instructions and to interactively assist in their execution. An induction heating range is provided with two antennas per hob, and includes a user interface display and input mechanism. The vessel includes an RFID tag and a temperature sensor. In a first cooking mode, a recipe is read by the range and the range assists a user in executing the recipe by automatically heating the vessel to specified temperatures and by prompting the user to add ingredients. The recipe is written to the RFID tag so that if the vessel is moved to another hob, into which the recipe has not been read, the new hob can read the recipe from the RFID tag and continue in its execution.

Owner:HR TECH

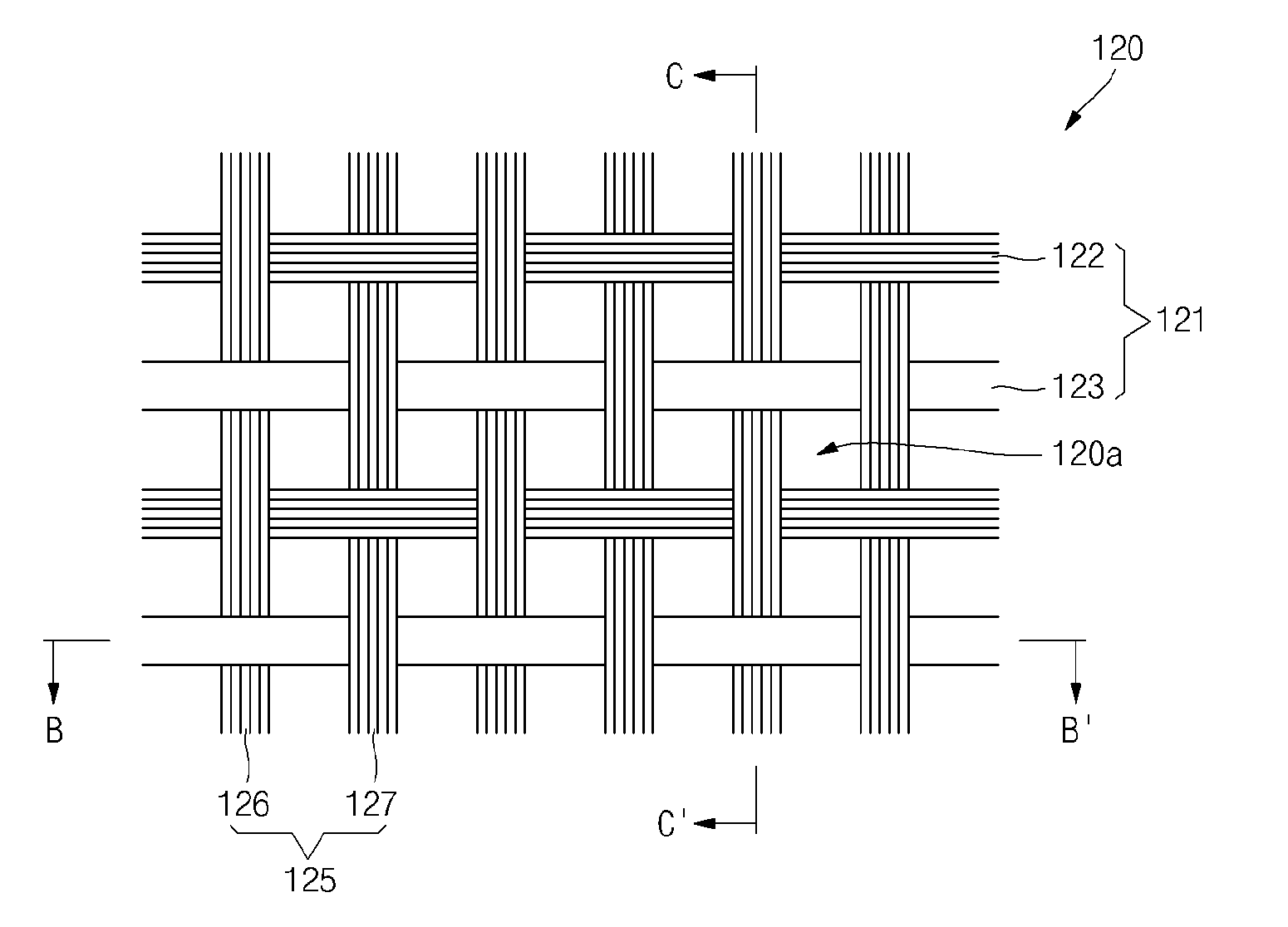

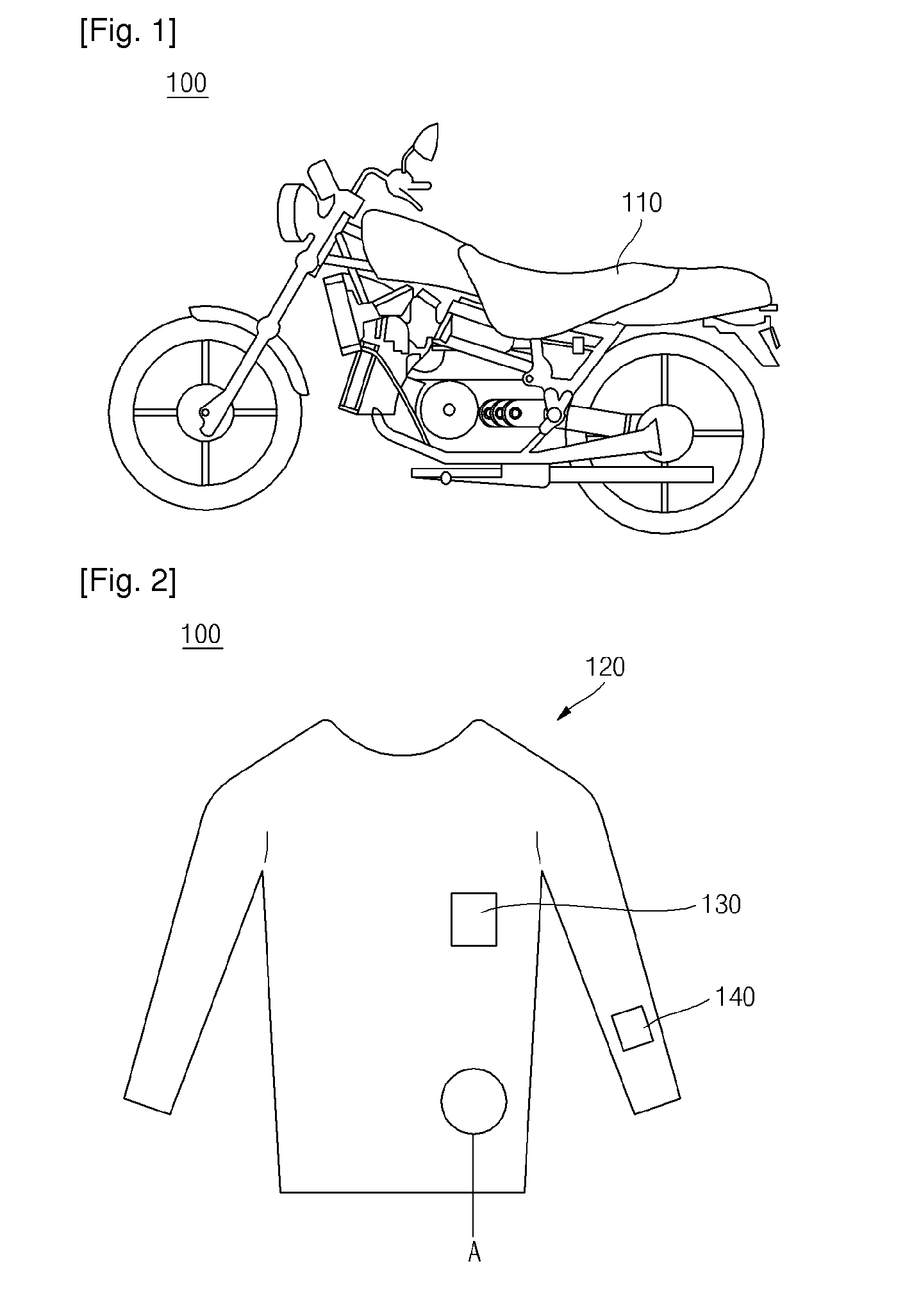

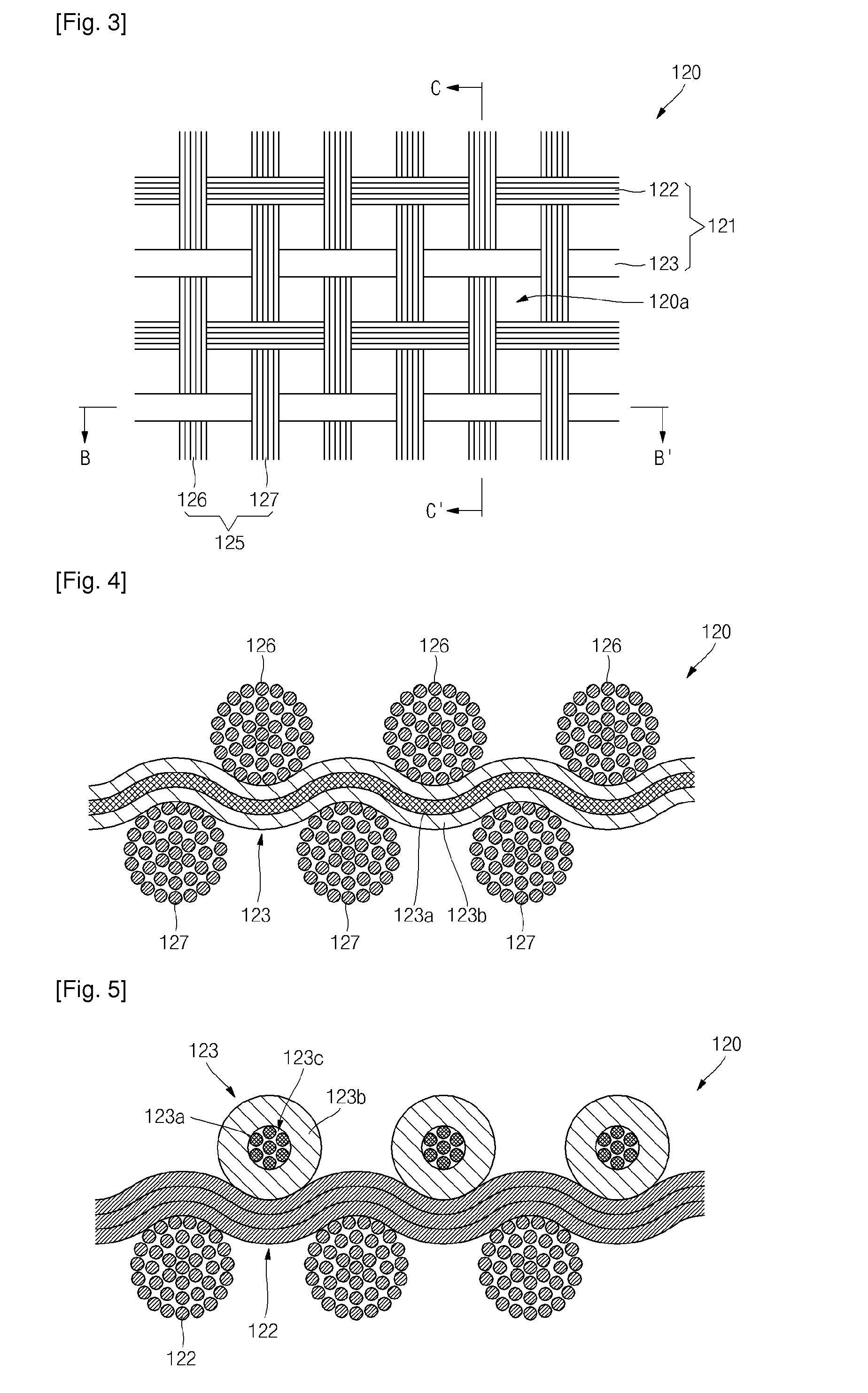

Contactlessly chargeable heater

ActiveUS20130032589A1Increasing user 's convenienceEasily transfers heatTransformersOhmic-resistance heatingYarnEngineering

The present invention relates to a contactlessly chargeable heater. In one example, the contactles sly chargeable heater includes: a charging patch emitting magnetic force by means of current applied to an inner coil; and a heating body, receiving the magnetic force from the charging patch to perform a contactless charging operation, and including a digital yarn for emitting heat via the power generated through the contactless charging operation. The digital yarn is woven together using threads within the heating body.

Owner:GAIA HEALTHCARE INC

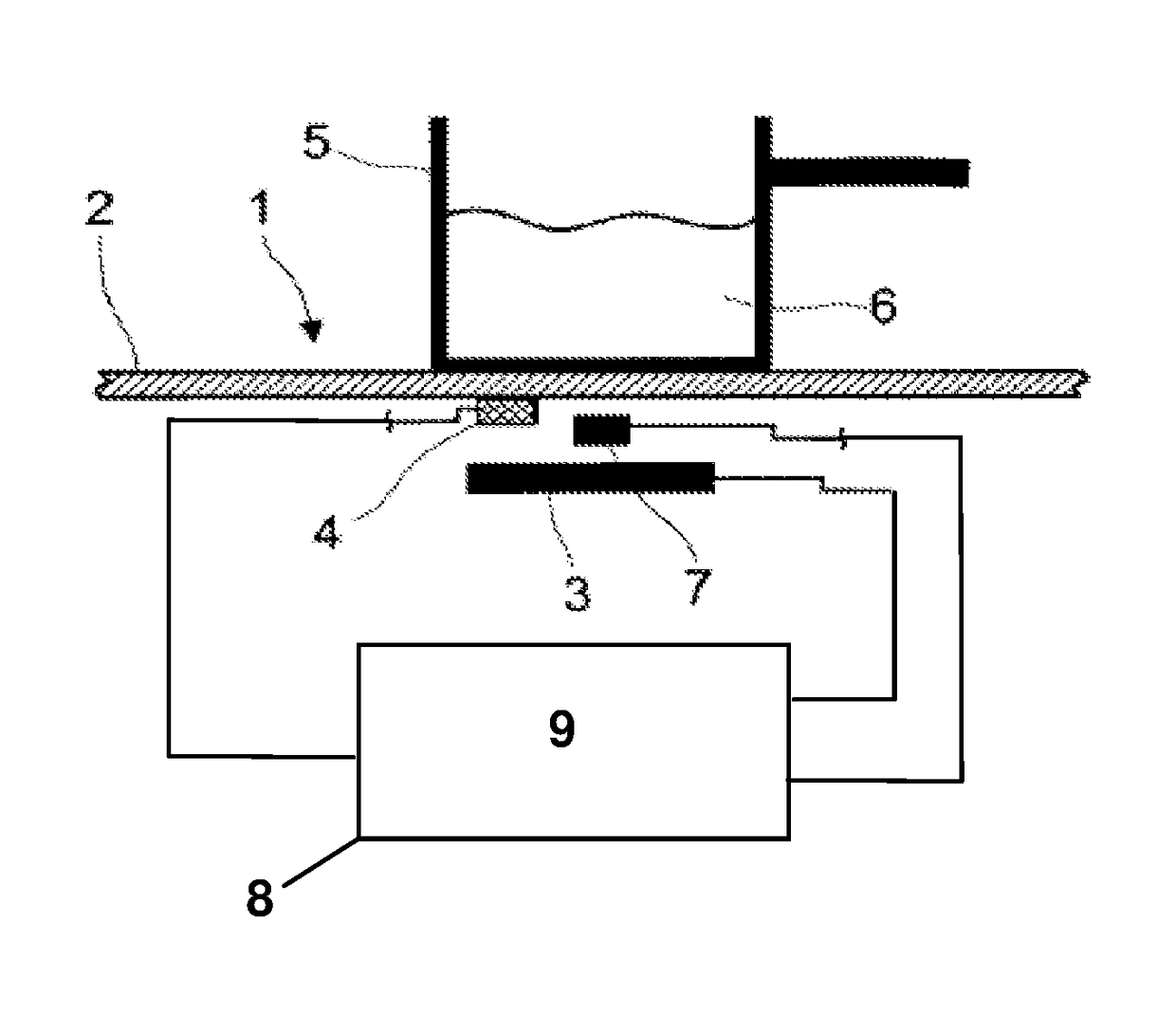

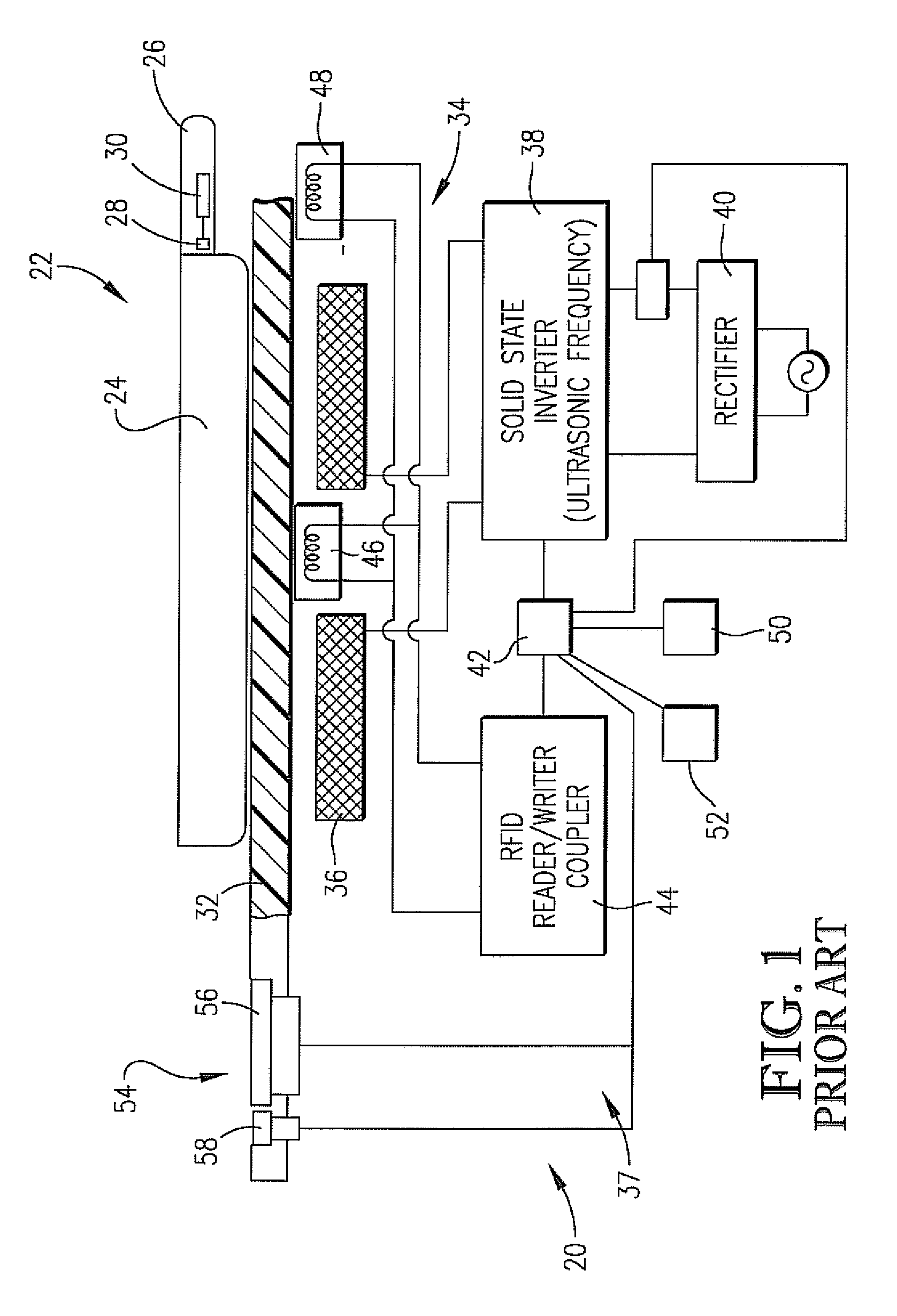

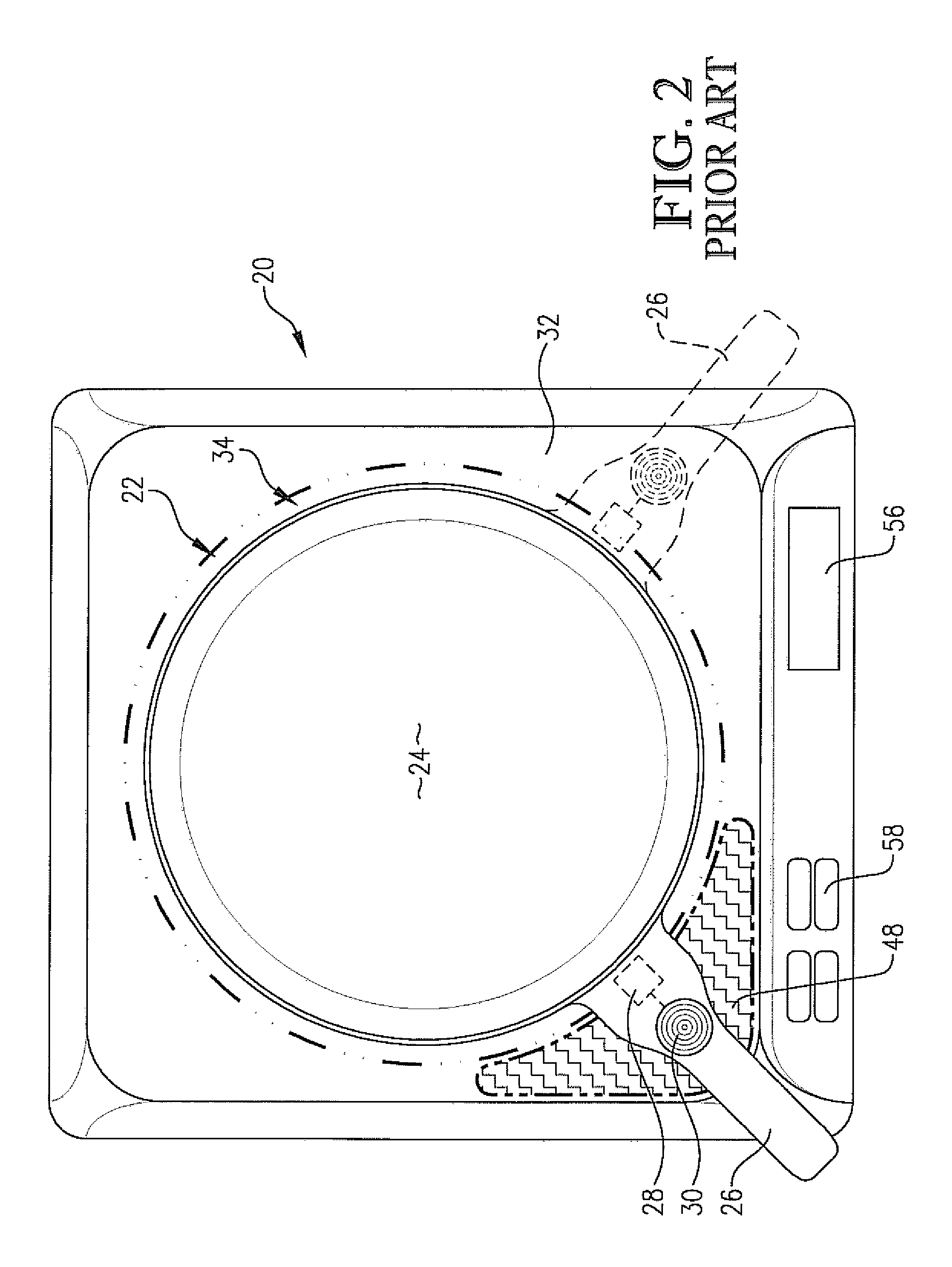

RFID-controlled smart range and method of cooking and heating

InactiveUS6953919B2Facilitate communicationFacilitates informationCooking vesselsDeep fat fryersAdditive ingredientEngineering

A system and method for providing multiple cooking modes and an ability to automatically heat cooking vessels and other objects using RFID technology, and an ability to read and write heating instructions and to interactively assist in their execution. An induction heating range is provided with two antennas per hob, and includes a user interface display and input mechanism. The vessel includes an RFID tag and a temperature sensor. In a first cooking mode, a recipe is read by the range and the range assists a user in executing the recipe by automatically heating the vessel to specified temperatures and by prompting the user to add ingredients. The recipe is written to the RFID tag so that if the vessel is moved to another hob, into which the recipe has not been read, the new hob can read the recipe from the RFID tag and continue in its execution.

Owner:HR TECH

Cooking tool

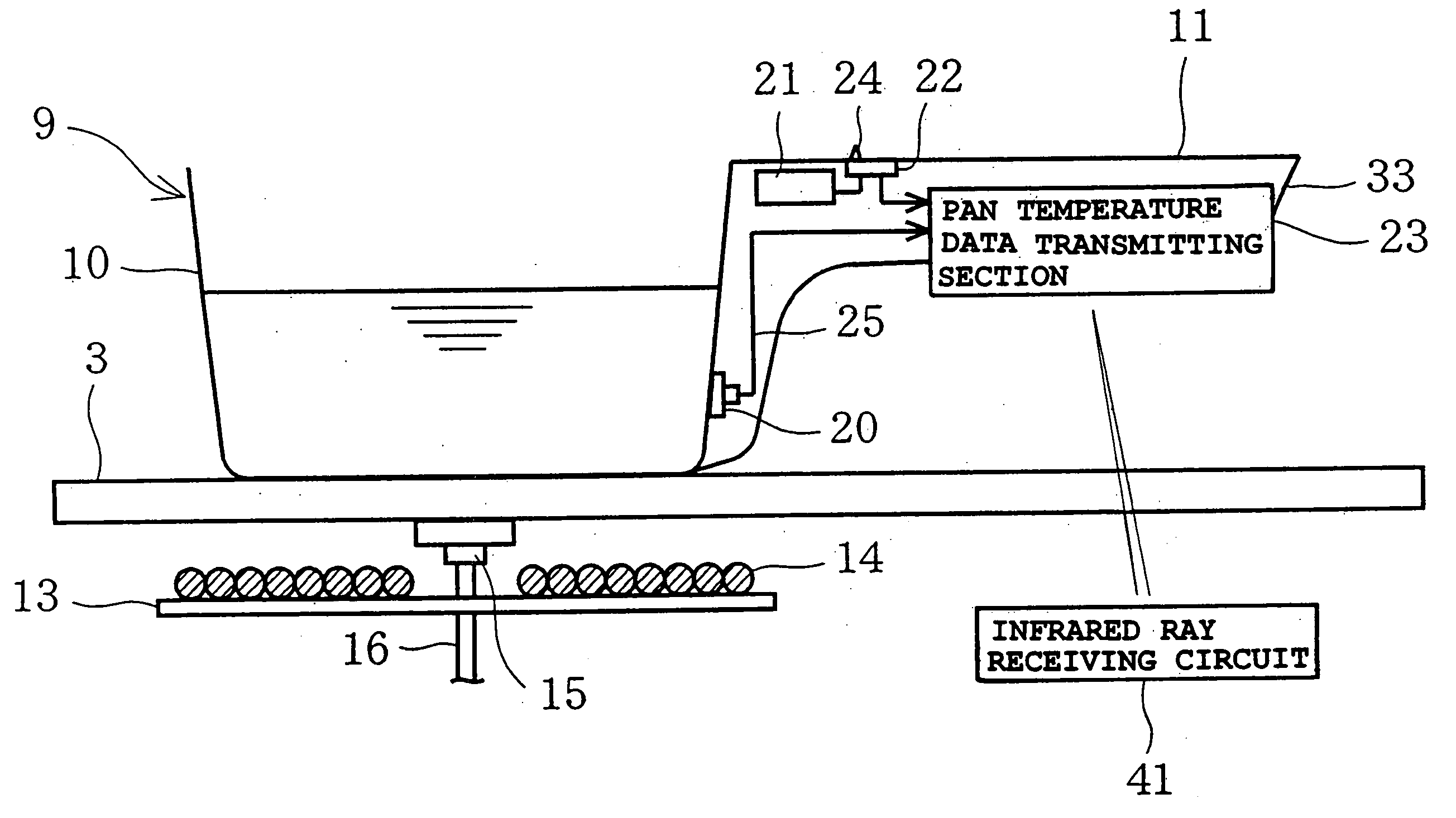

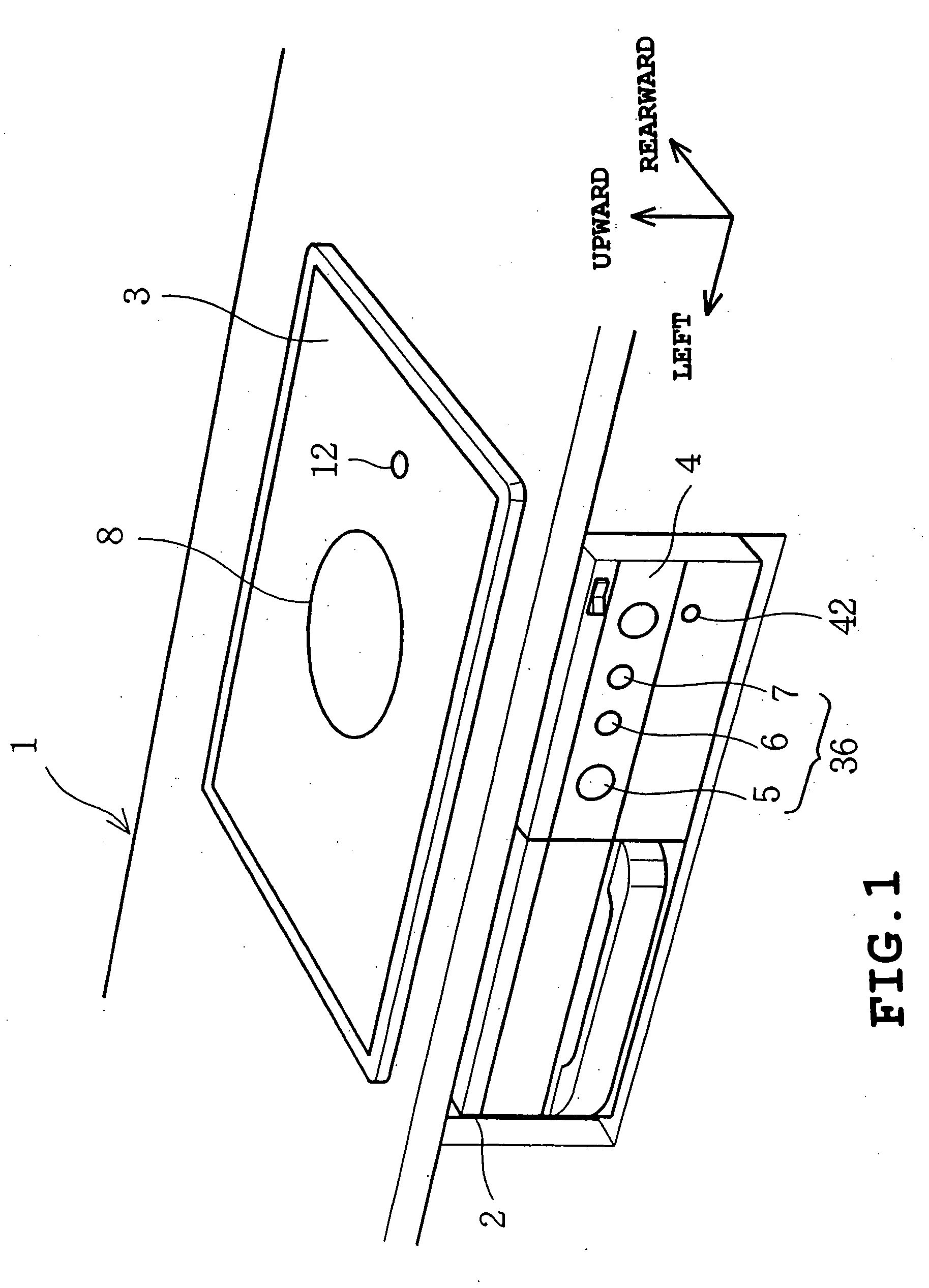

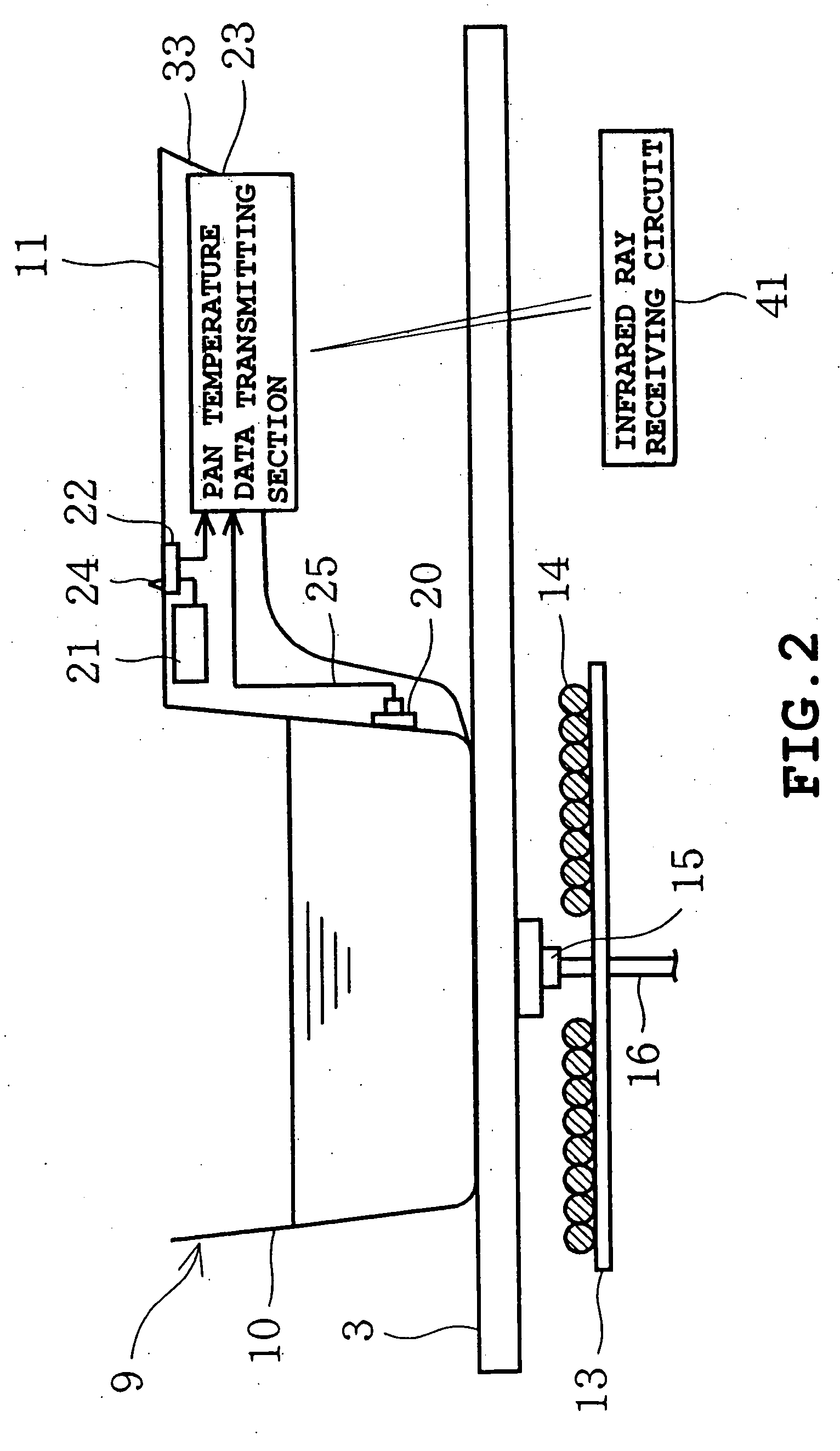

InactiveUS7473872B2Little strengthAvoid it happening againCooking vesselsInduction heating controlInfraredData control

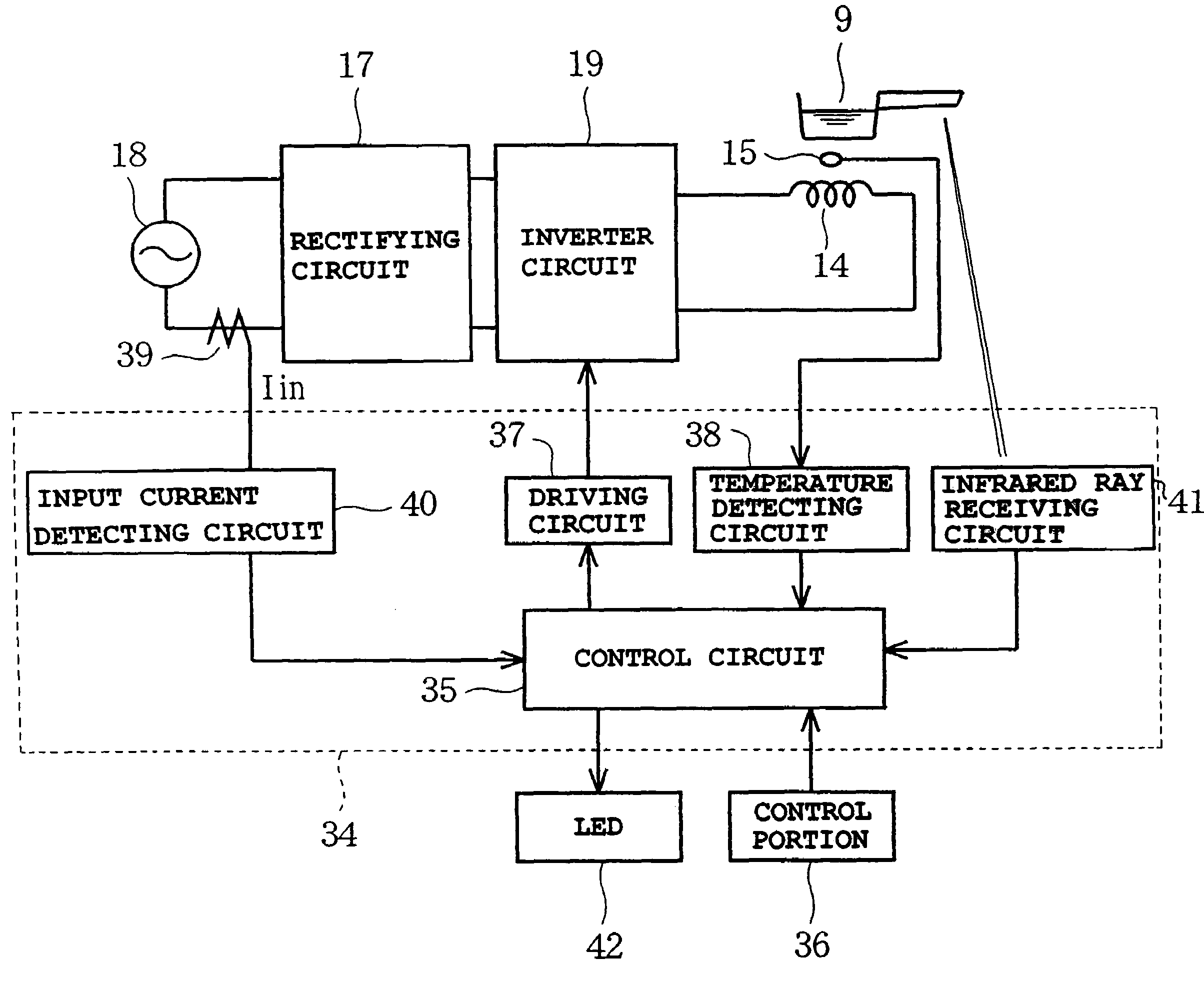

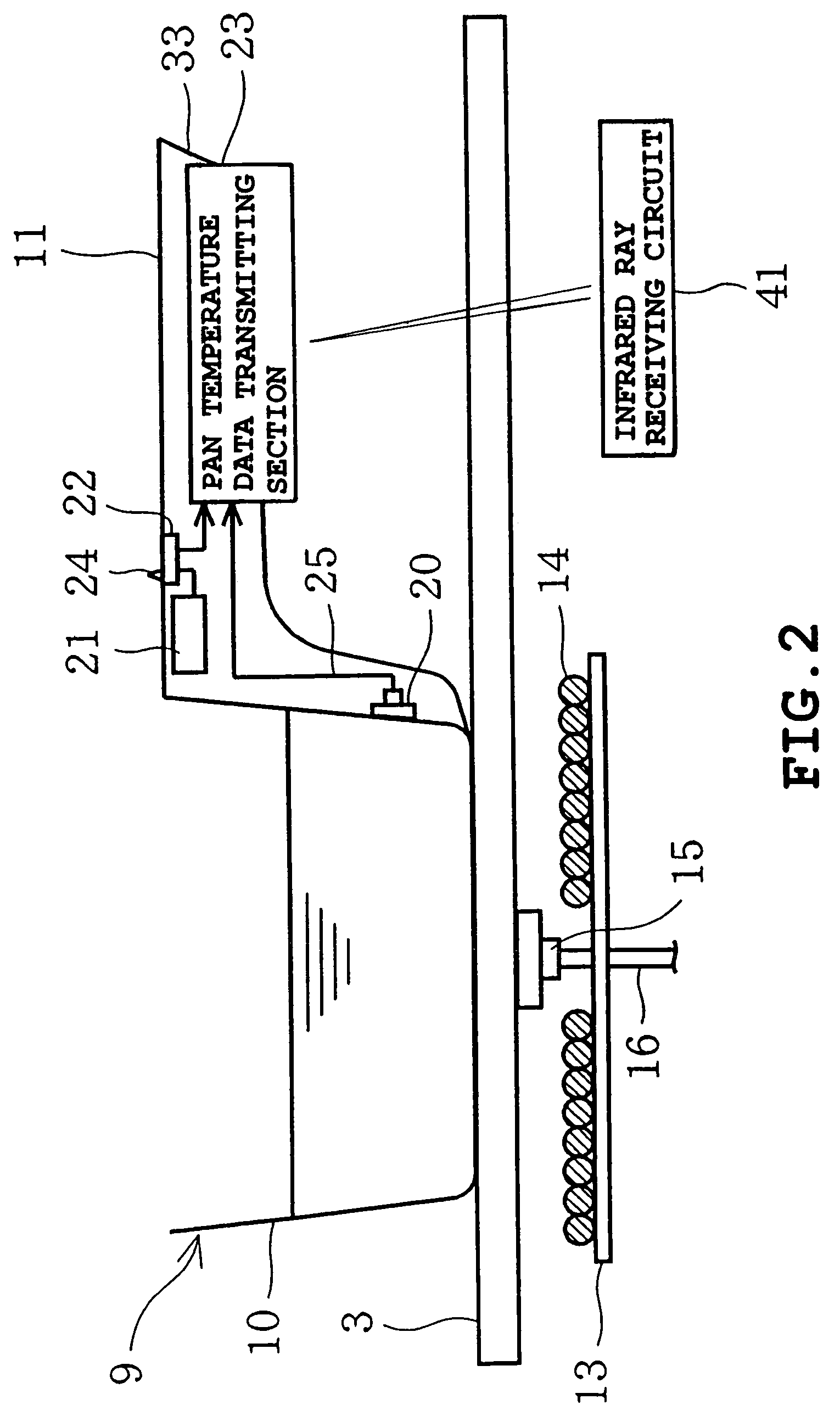

A heat cooking apparatus includes a supporting unit for supporting a cooking tool, a heating unit for heating the cooking tool, a receiving unit capable of receiving temperature data of the cooking tool transmitted in the form of infrared rays from the exterior, and a controlling unit for controlling the heating unit on the basis of temperature data received by the receiving unit.

Owner:IRIS OHYAMA

Radio frequency (RF) heating system

An RF heating system for bonding a first element to a second element. In one embodiment, the RF heating system includes: (a) a composition, which functions as an adhesive, interposed between the first and second elements, the composition including an ionomer and a polar carrier, wherein the ionomer and / or the carrier are present in amounts effective to allow the composition to be headed by a fringe RF field; and (b) a radio frequency (RF) heating apparatus for producing the fringe RF field.

Owner:AMBRELL CORP

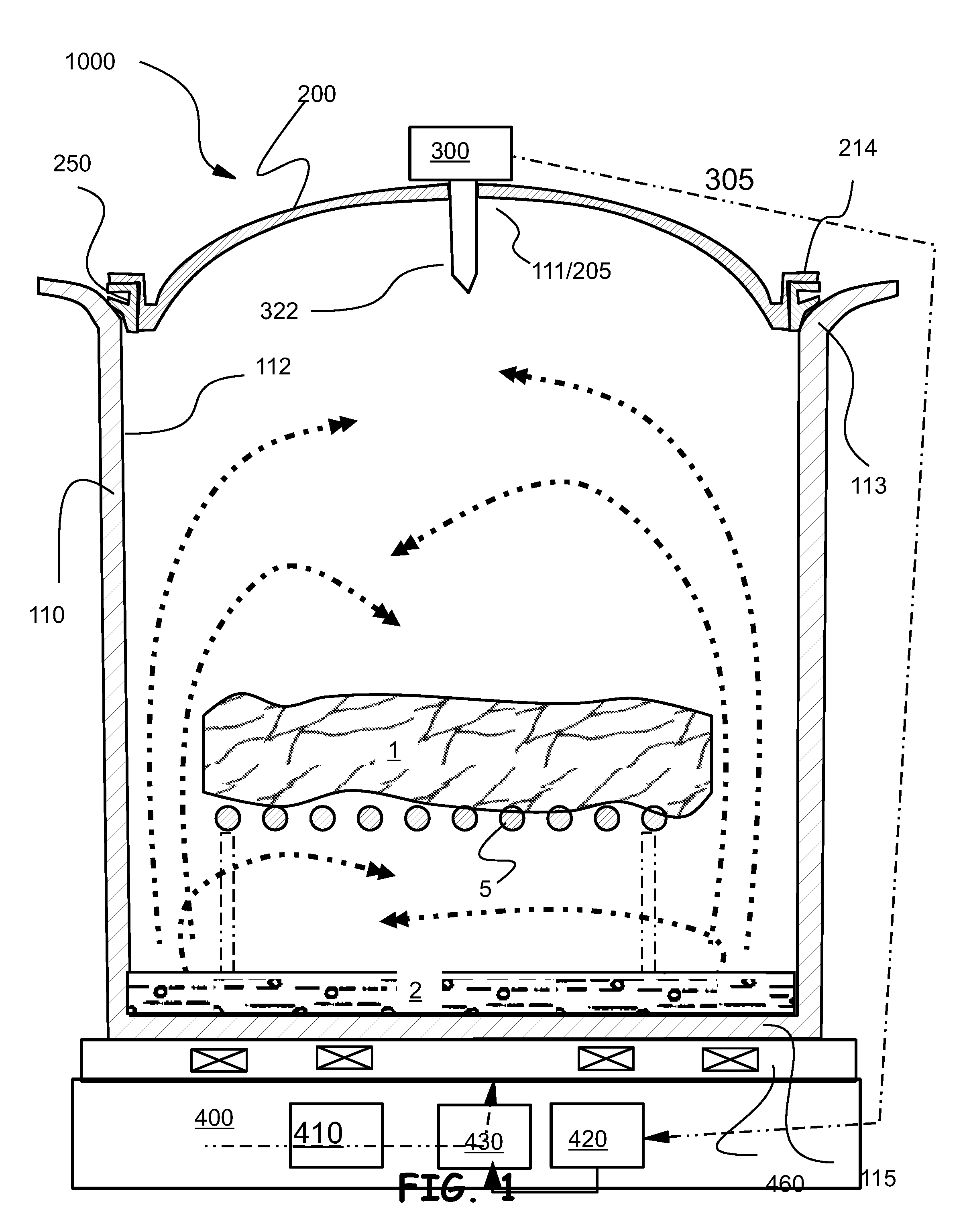

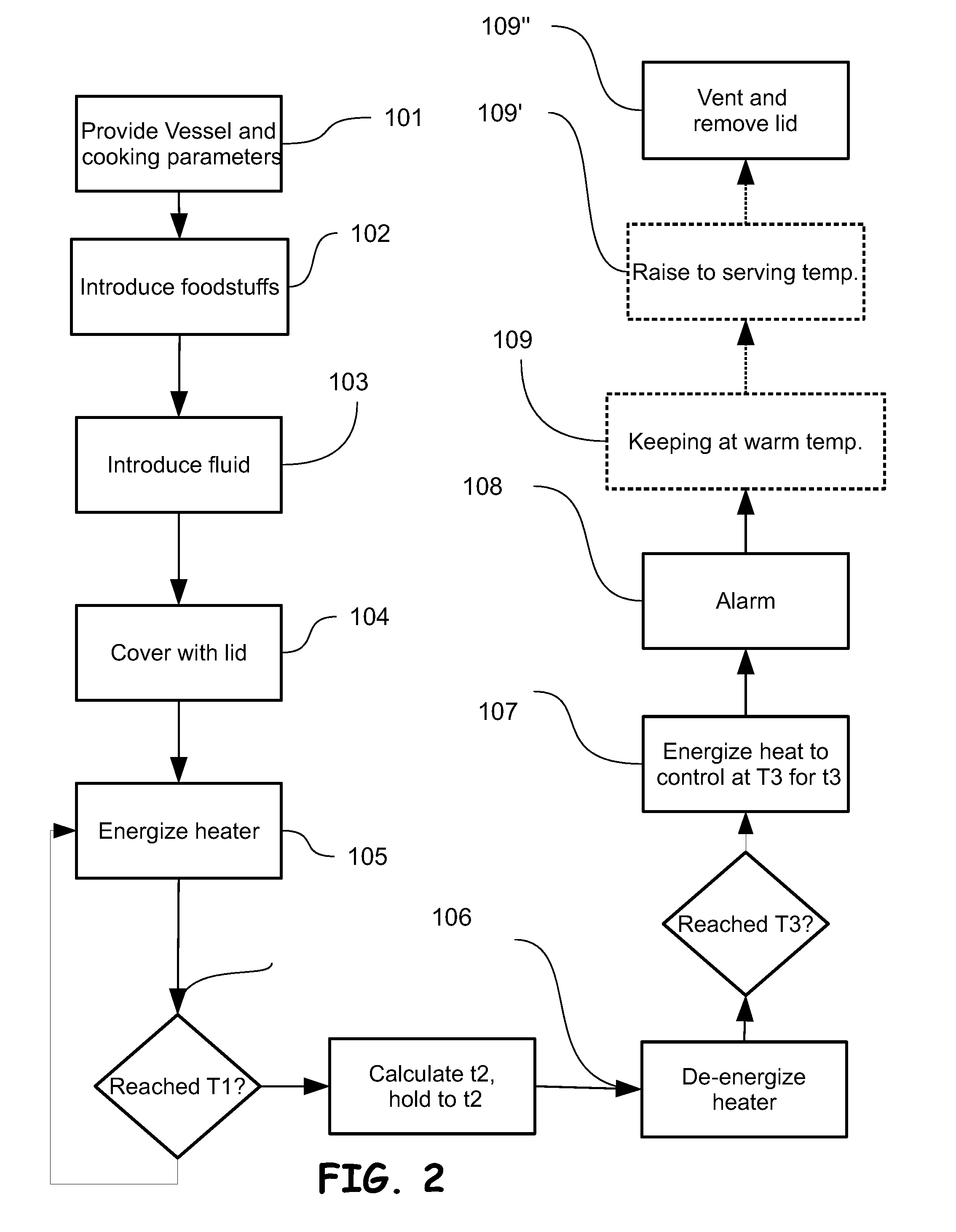

Low-pressure cooking method and cookware vessel adapted for the same

ActiveUS20140348987A1Long cooking timeReduce heating powerBoiling over preventionSteam cooking vesselsTemperature controlWater vapor

Food stuffs are cooked at precise temperatures, which are optionally below 100° C., in a vessel that is evacuated to exclude air, in which low pressure steam replaces the air. When a sufficient quantity of air is excluded and replaced with water vapor, the temperature of vapor is accurately measured inside the vessel below the lid to control the temperatures within about 1° C. Air is preferably excluded via a controlled heated process for a relatively short period of time at high temperature to generate steam, the temperature is lowered to condense water vapor upon which the lid will sealingly engage the rim of the vessel, forming a partial vacuum in the cooking vessel.

Owner:MEYER INTPROP

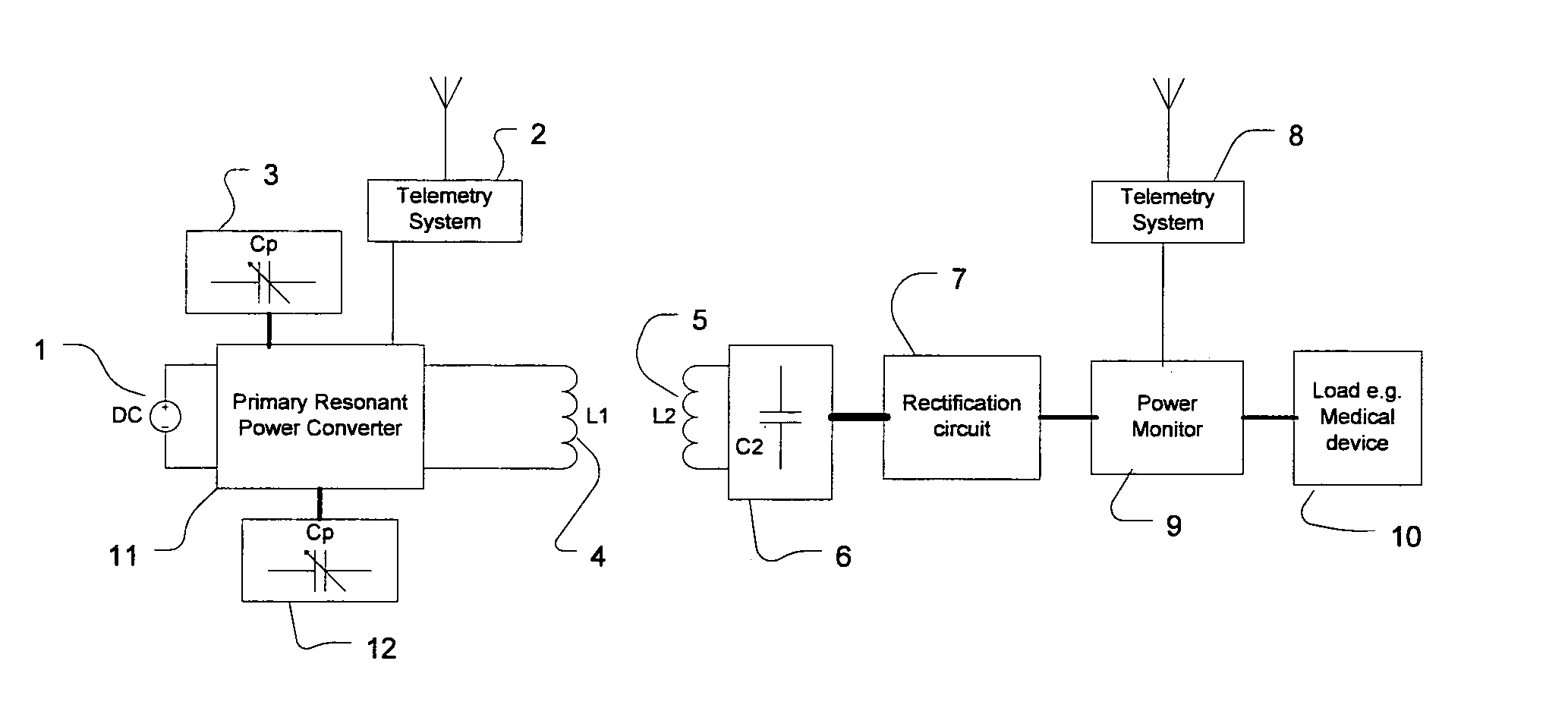

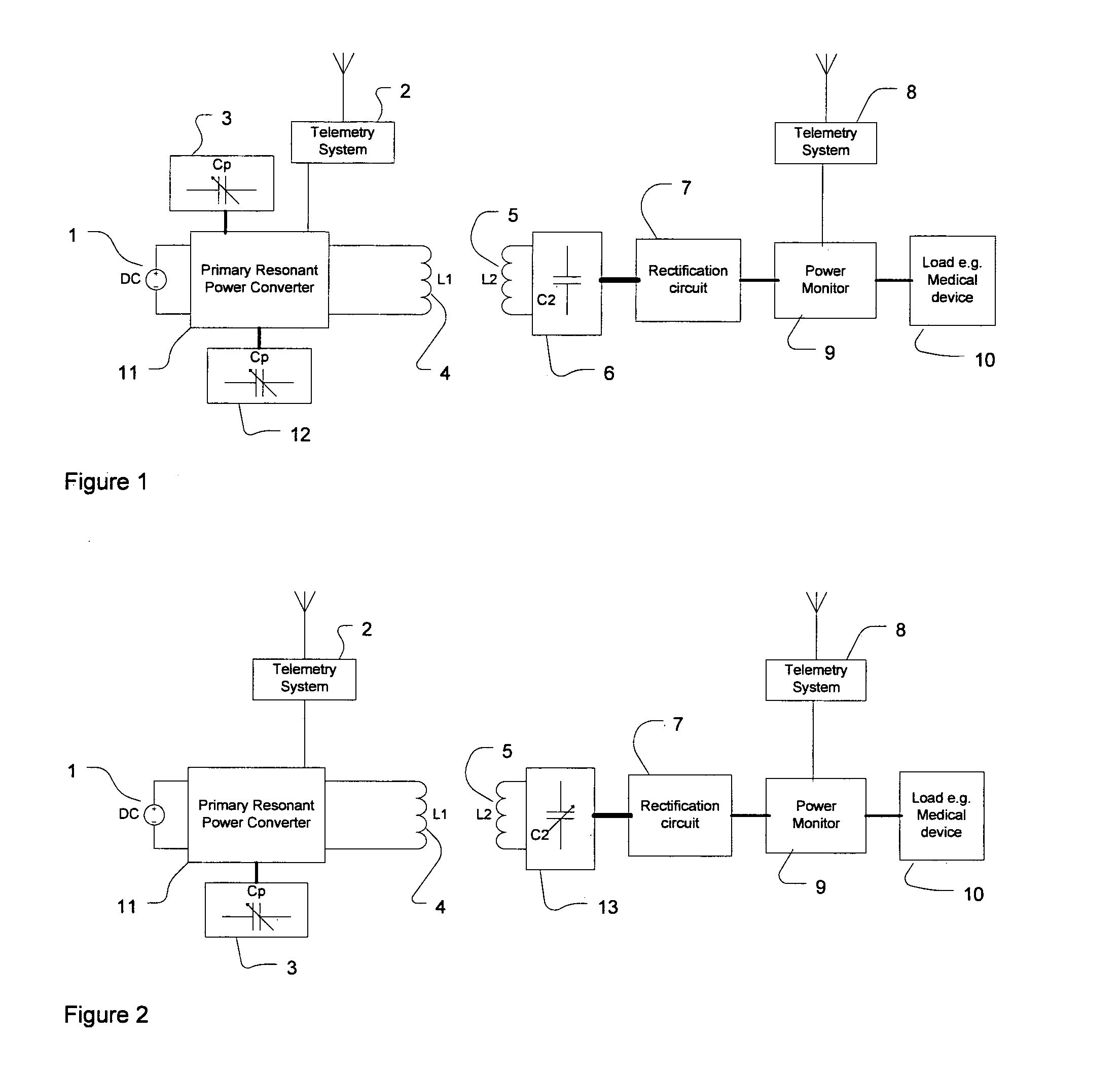

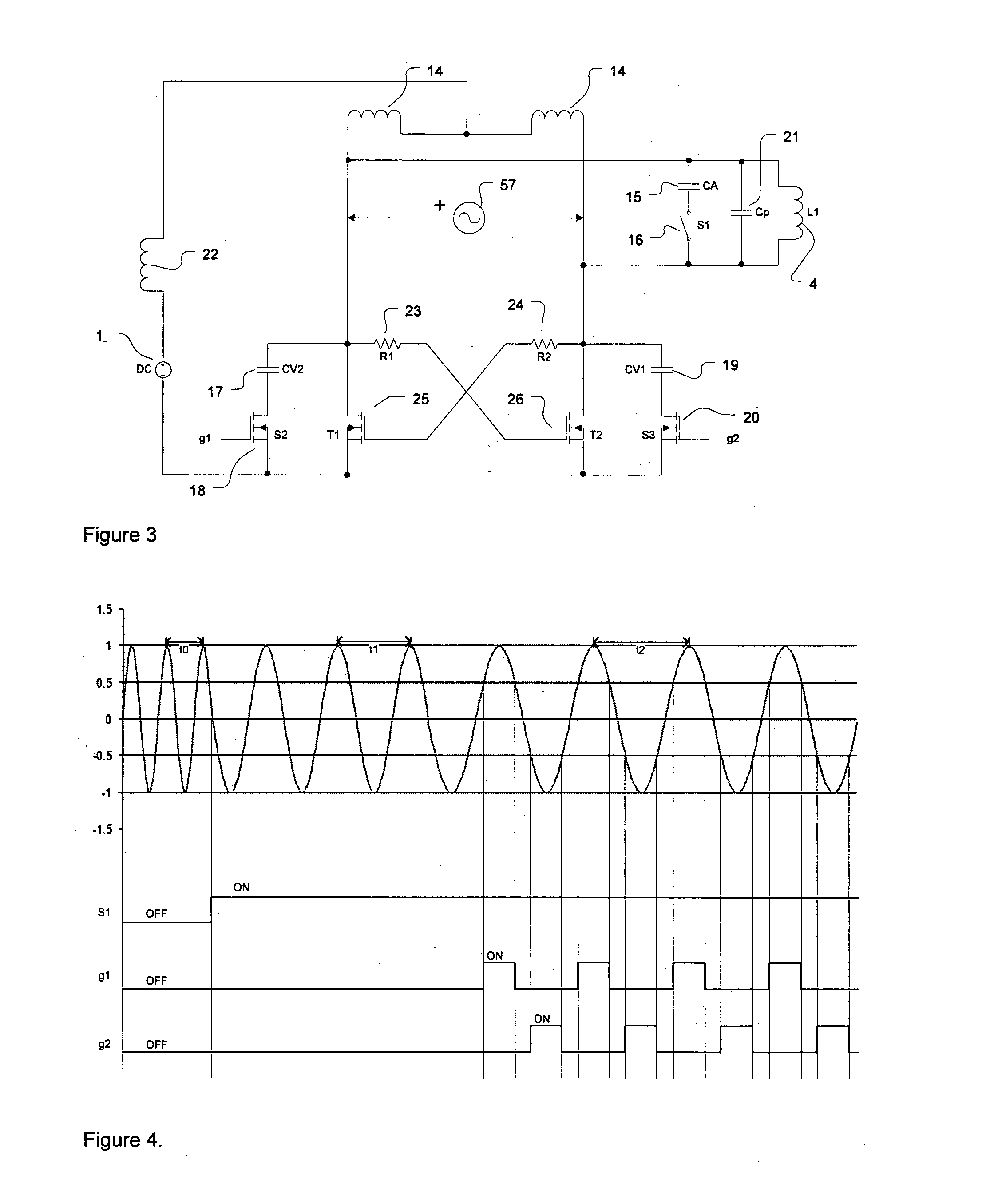

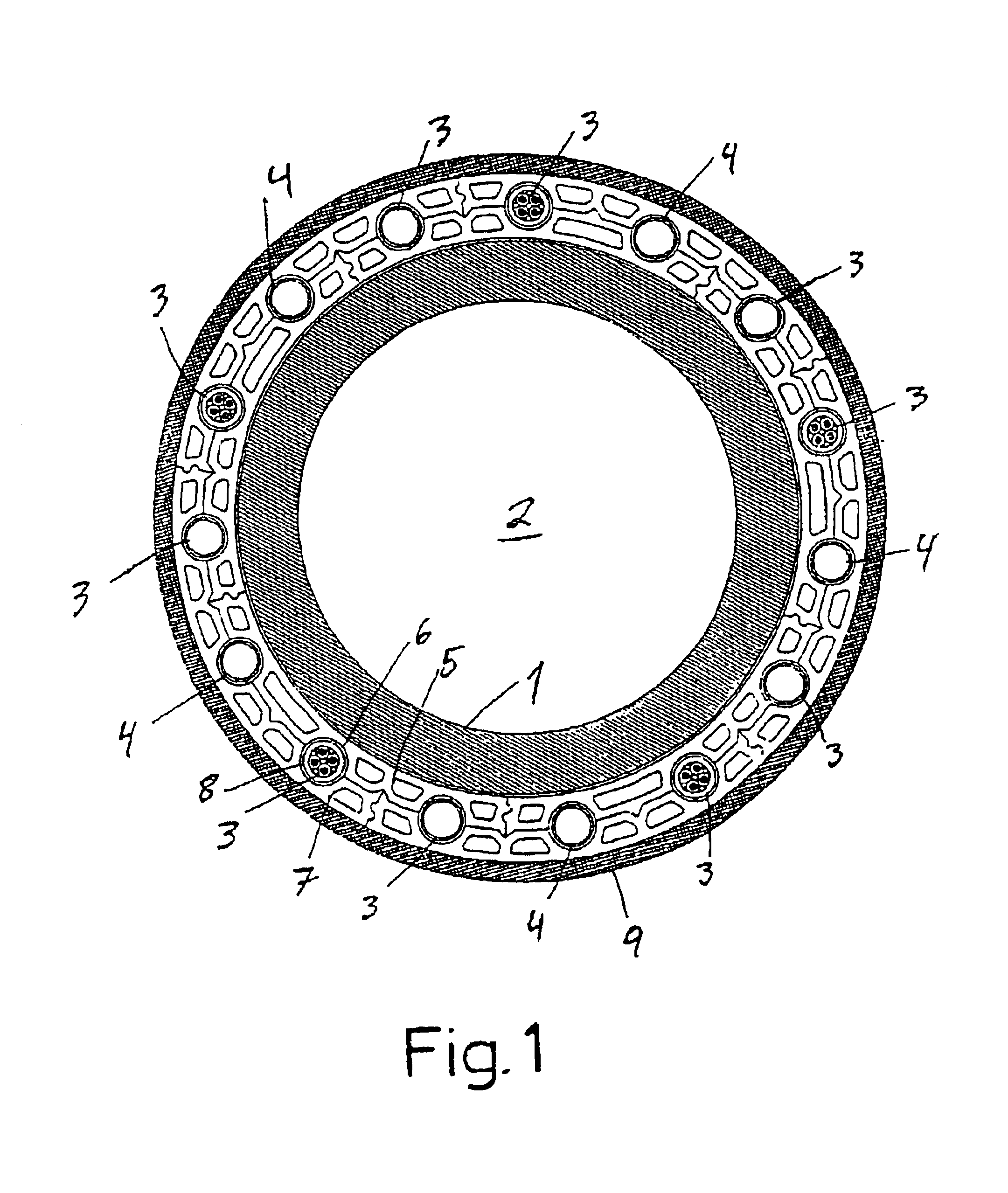

Selectable resonant frequency transcutaneous energy transfer system

InactiveUS20110101790A1Reduce power lossIncrease rangeElectrotherapyTransformersEnergy transferControl power

An inductive power transfer system includes a number of controllable reactive components (3, 6, 12, 13, 16) that allow the resonant frequency of a primary and / or secondary resonant circuit to be controllably varied to thereby control power available to a load (10).

Owner:MILLAR INSTR

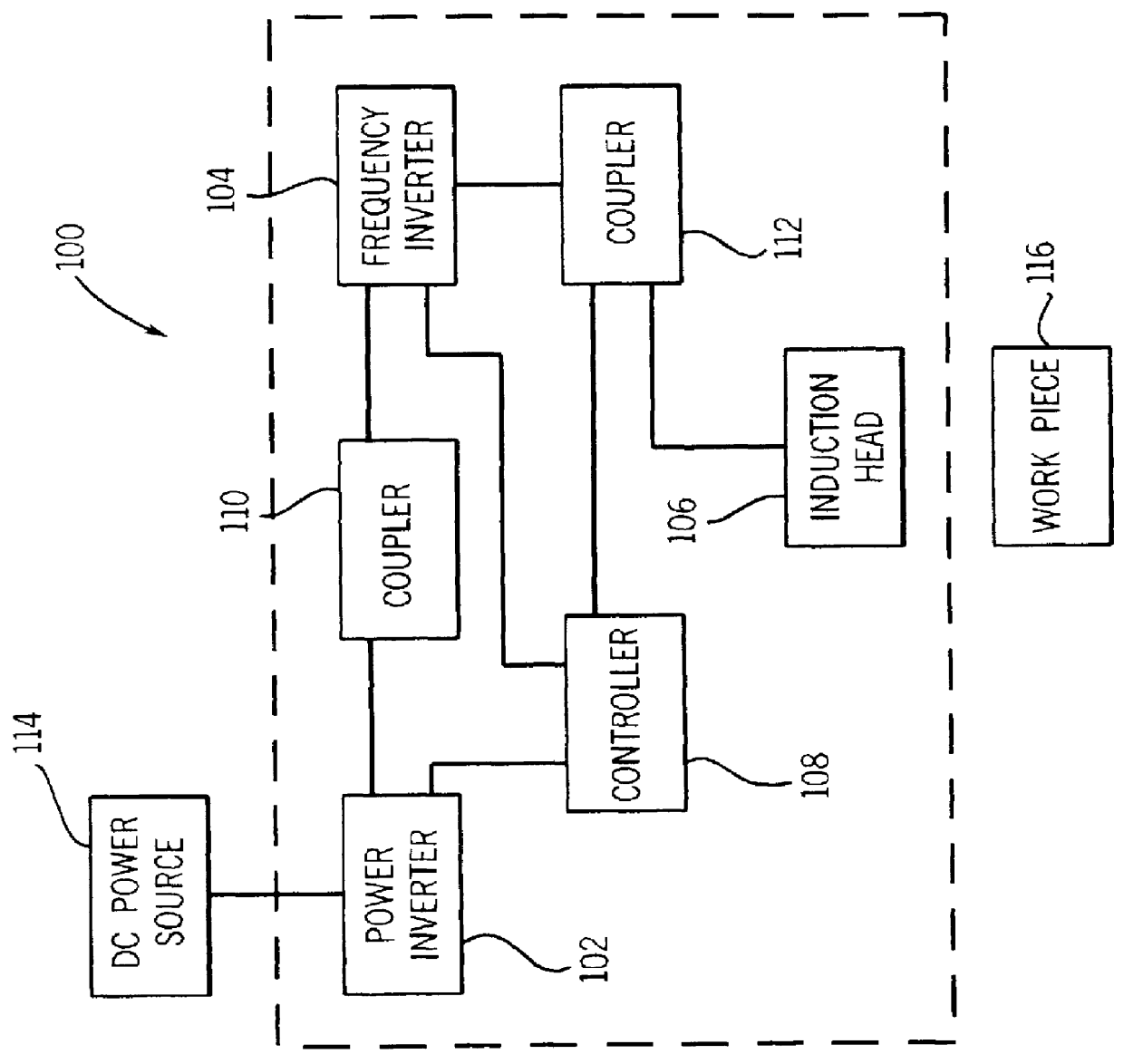

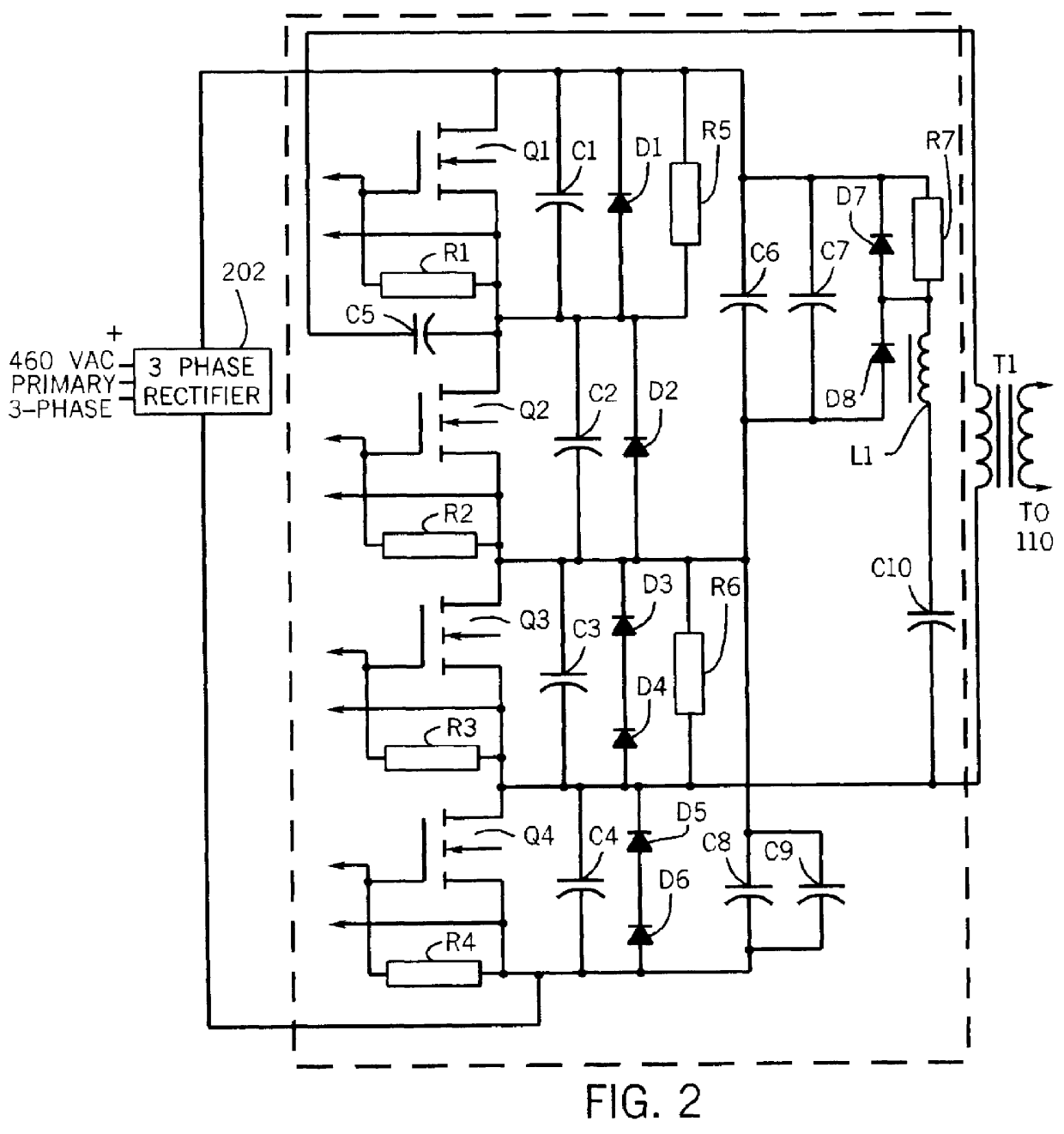

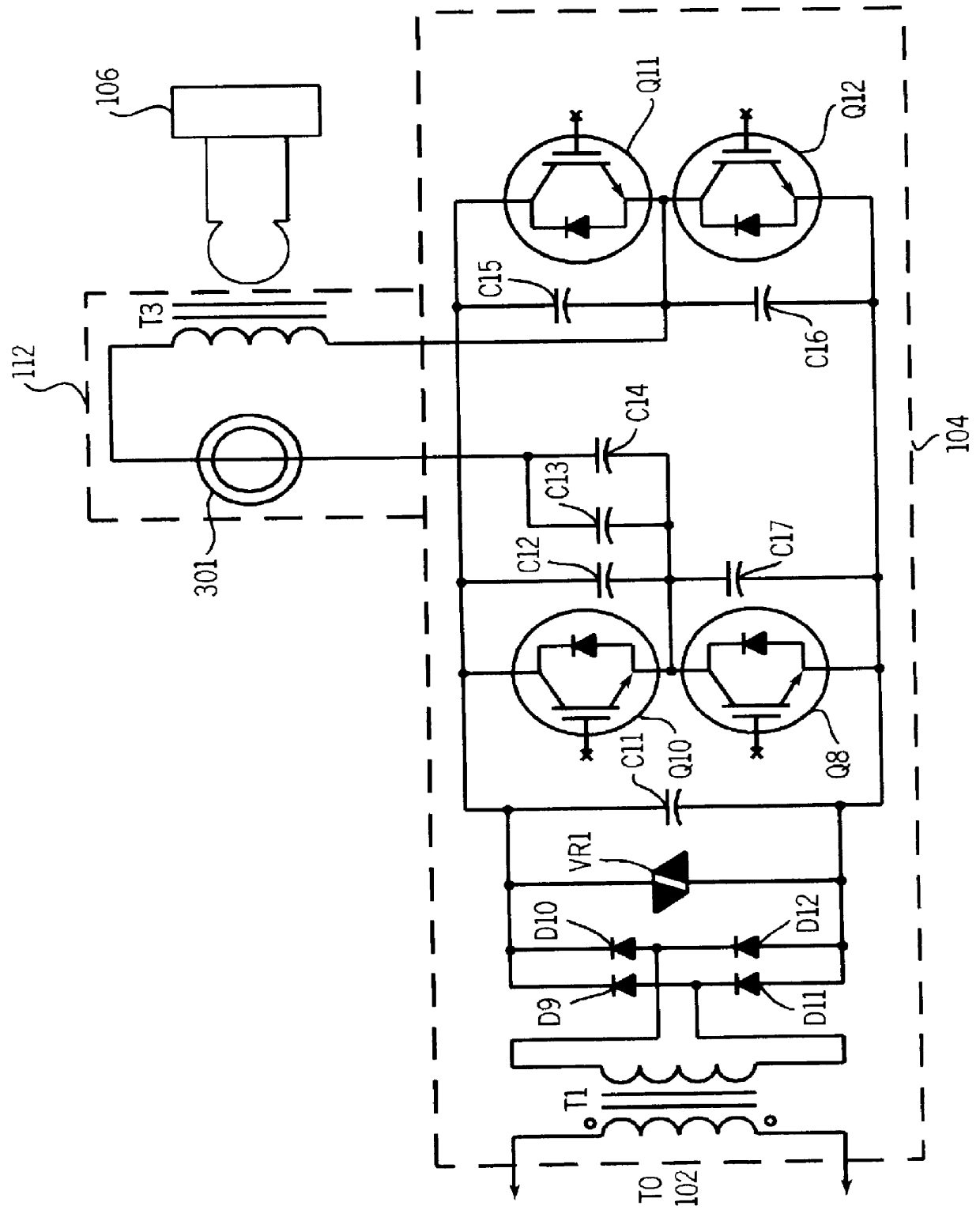

Multiple head inductive heating system

InactiveUS6043471ACoil arrangementsInduction current sourcesHeating systemElectrical and Electronics engineering

A system and method for inductively heating a workpiece includes a controller and a plurality of power supplies that receive and send signals to the controller. Induction heads receive power from the power supplies. The induction heads may be aligned with adjacent segments of the workpiece, and can span the perimeter of the workpiece. The gap between adjacent induction heads is less than one half the size of the adjacent induction heads, and preferably the induction heads abut or substantially abut. Each of the power supplies include feedback for controlling the power delivered to the segments of the workpiece. In alternative embodiments the feedback may be based on the current or power provided to the induction heads, or the power provided to the workpiece.

Owner:ILLINOIS TOOL WORKS INC

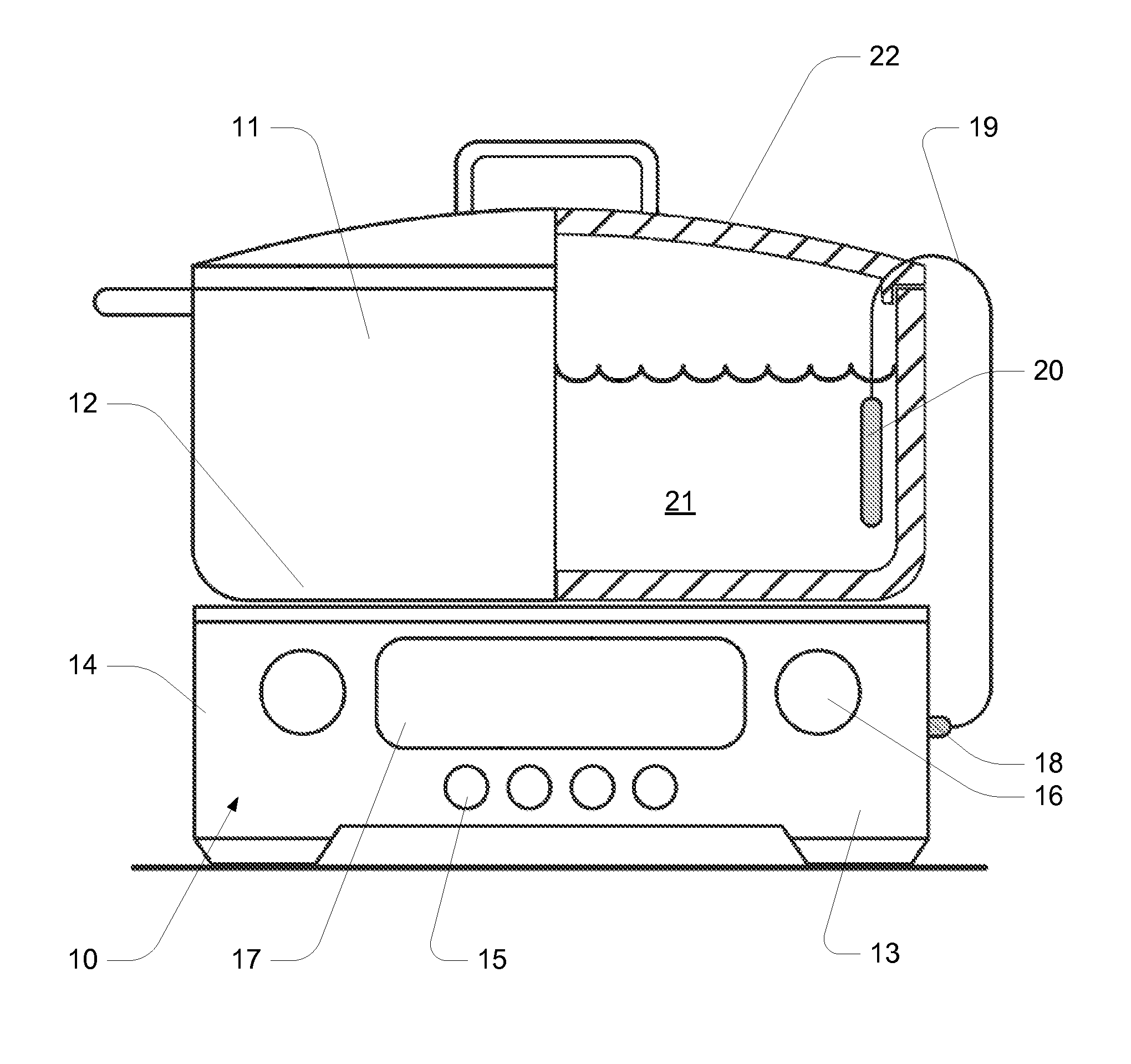

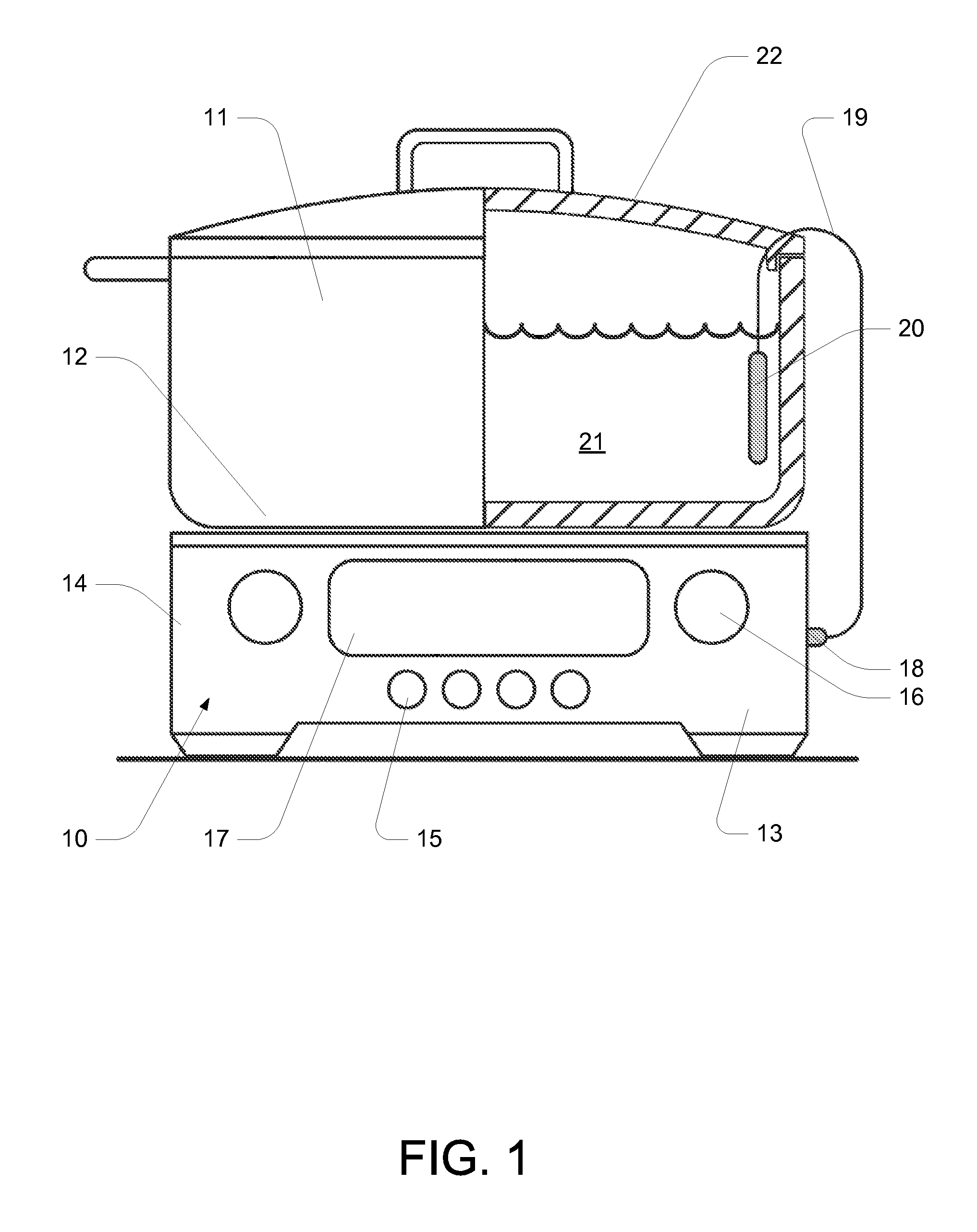

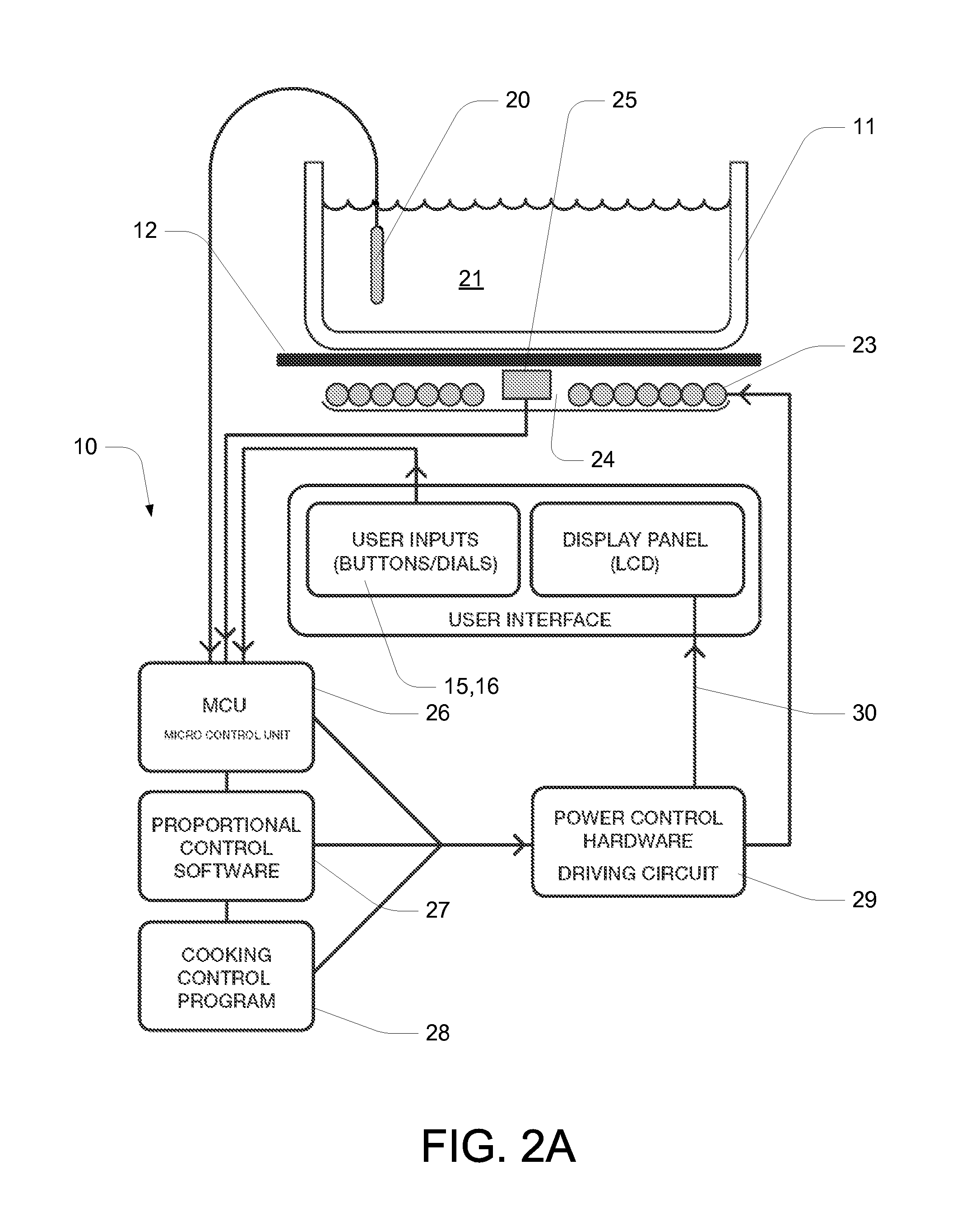

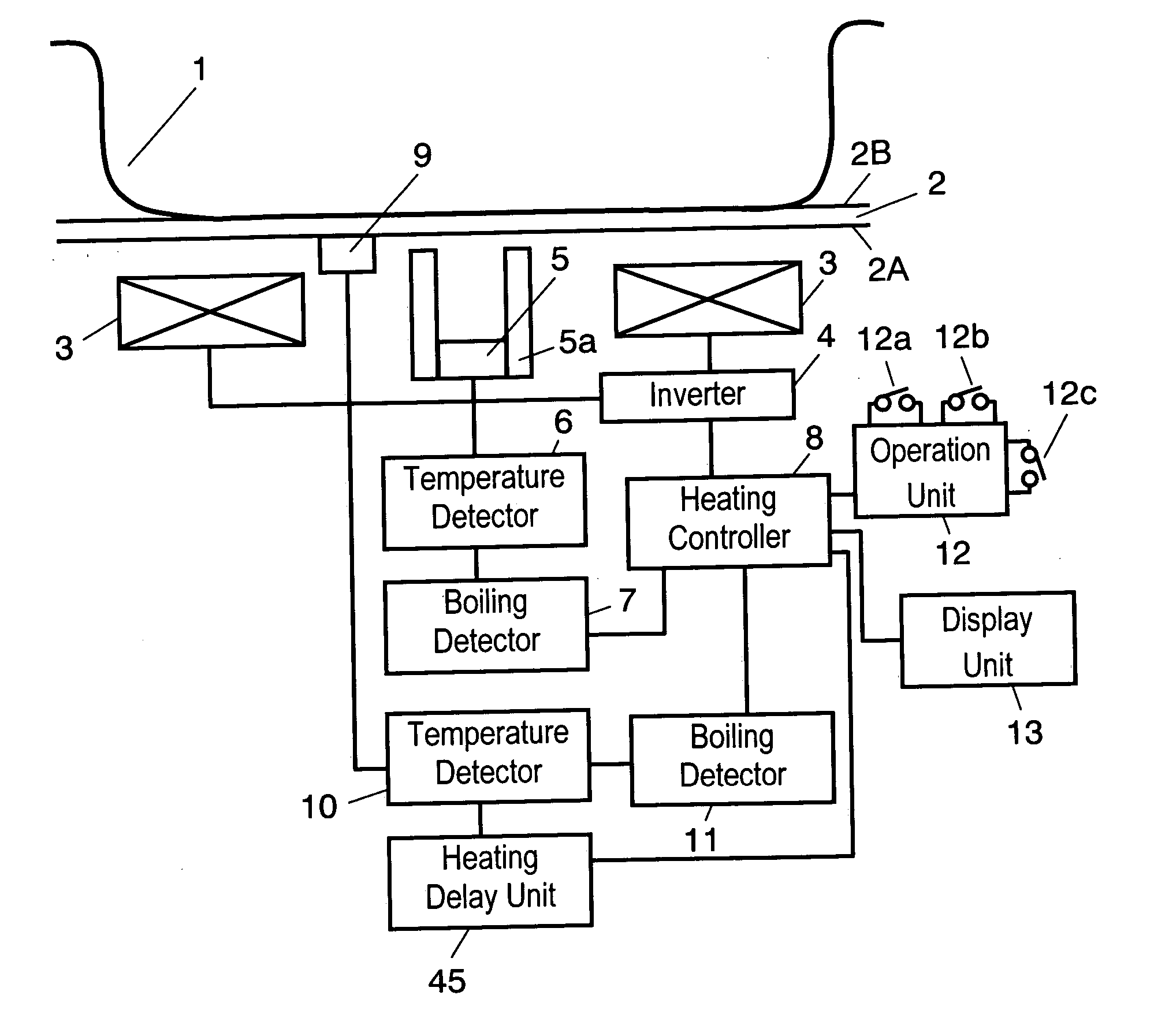

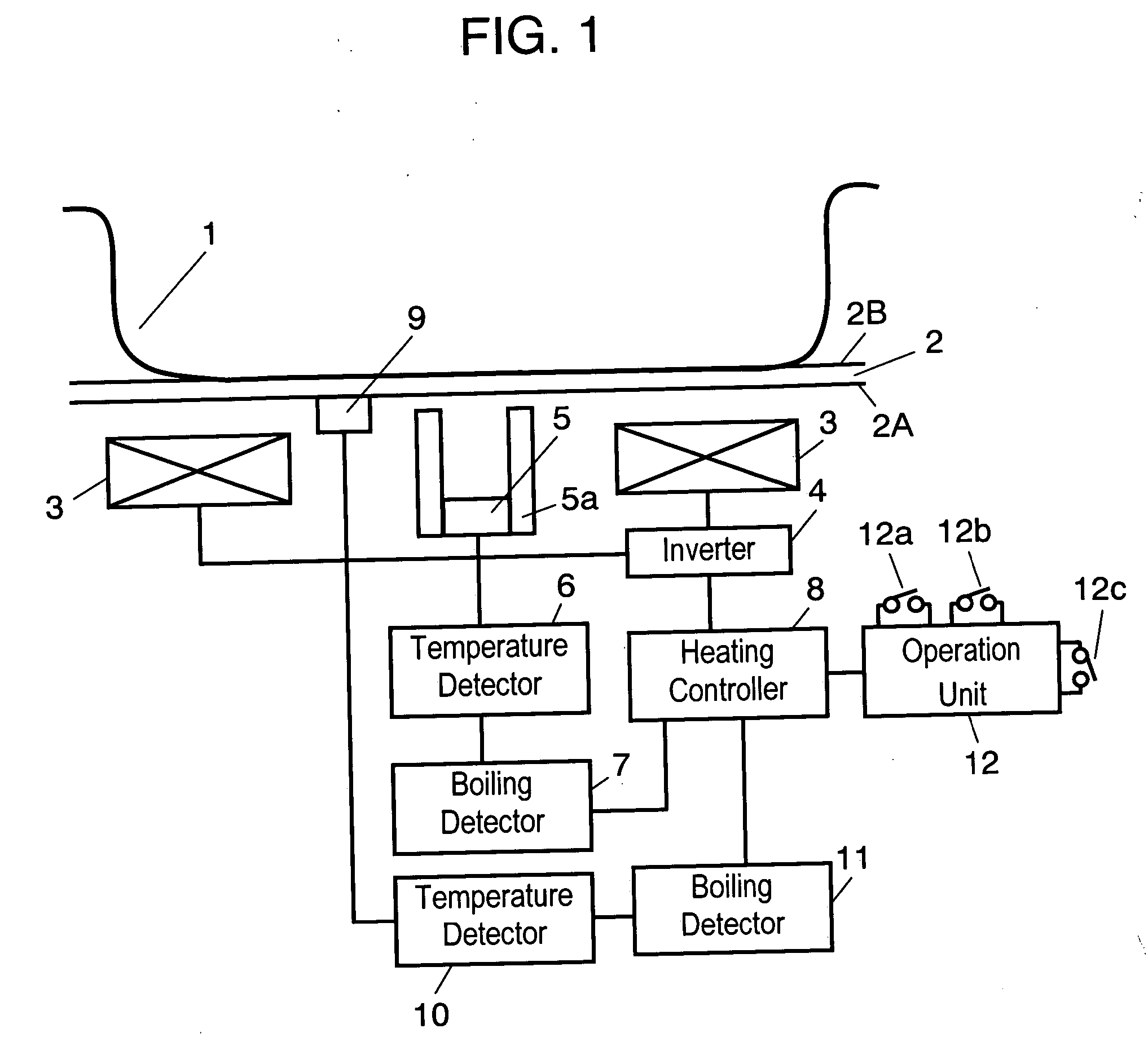

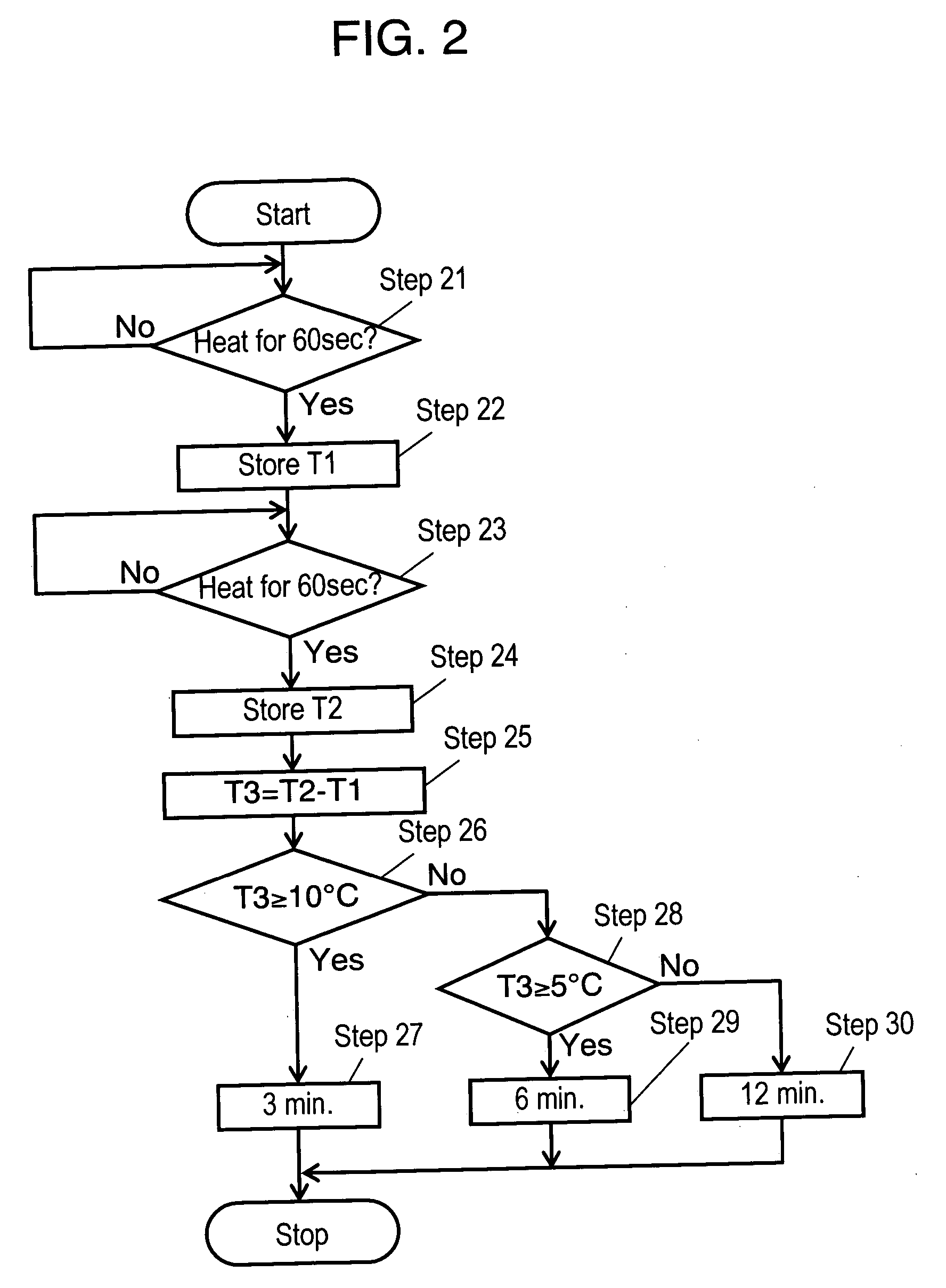

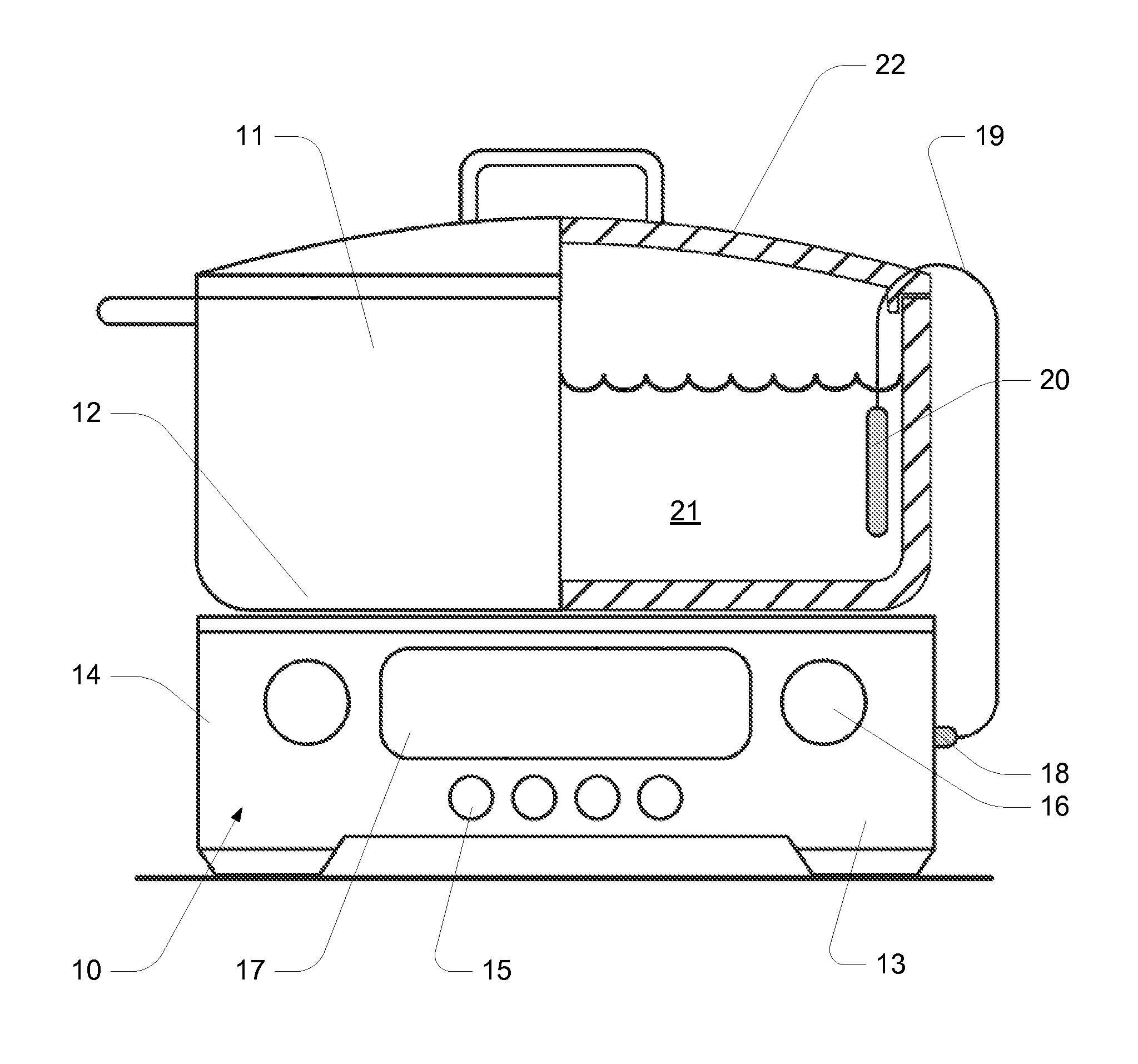

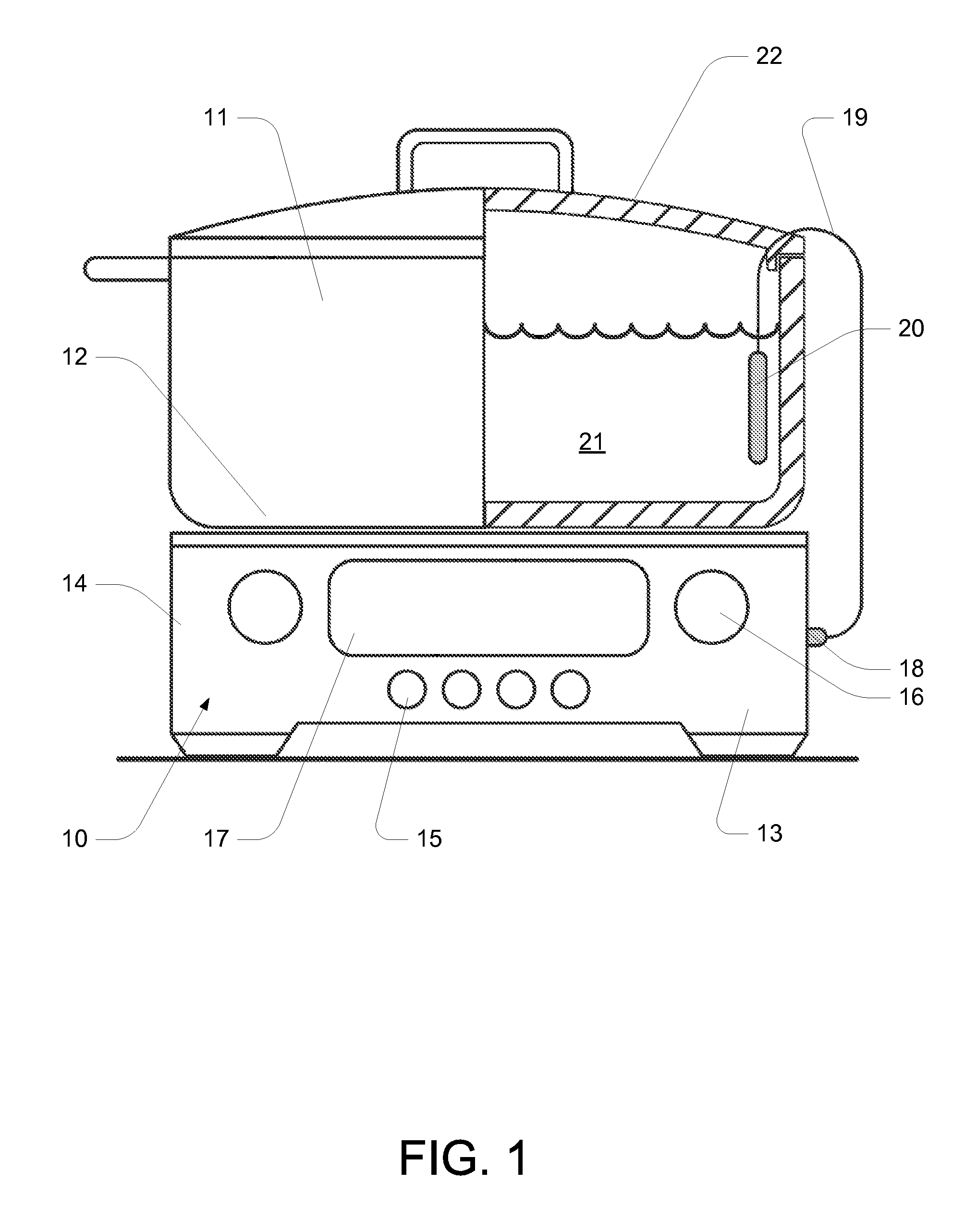

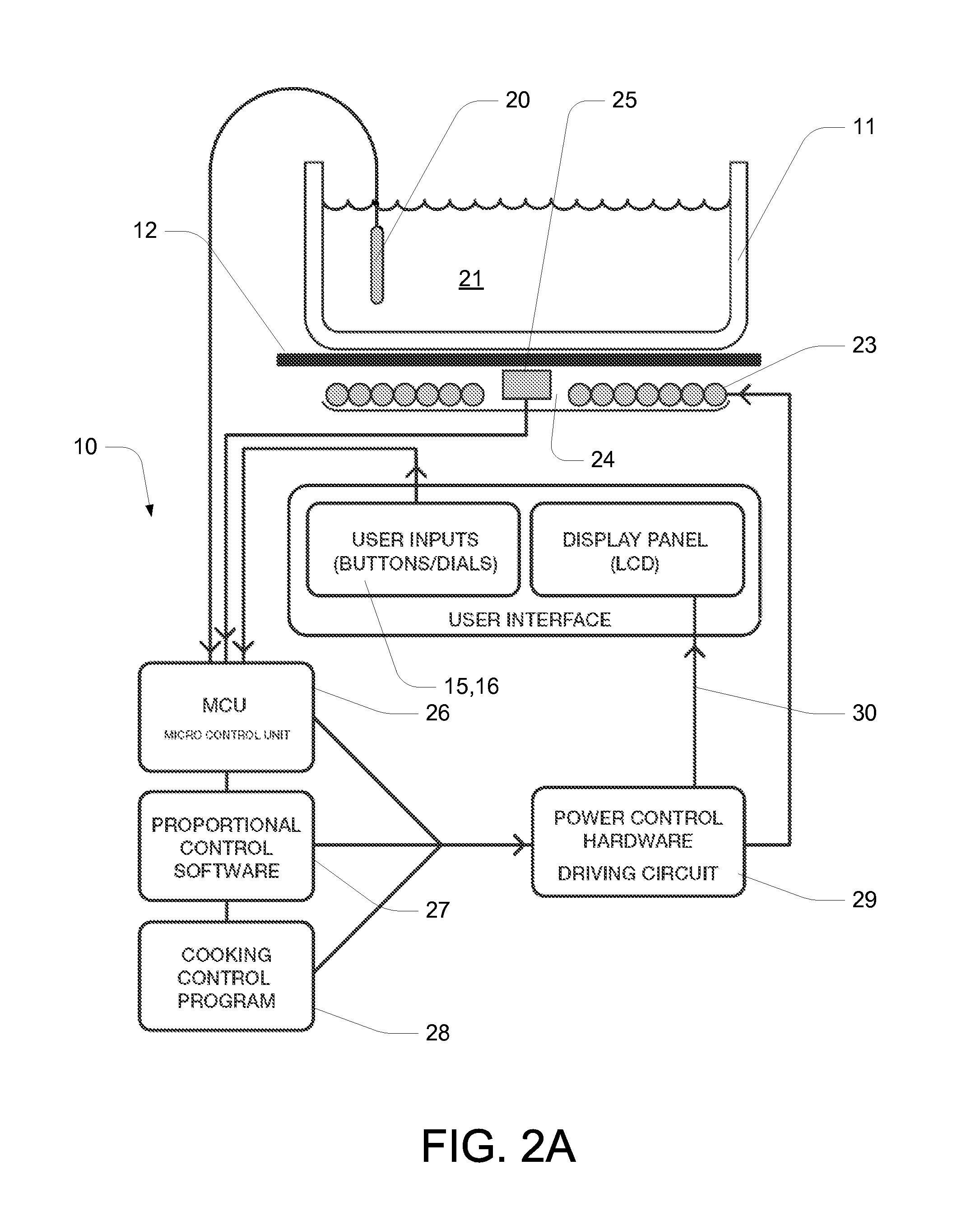

Multi cooker

ActiveUS9191998B2Automation easeEase predictabilityBoiling over preventionWater-bath cooking vesselsTemperature controlEngineering

Owner:BREVILLE HLDG PTY LTD

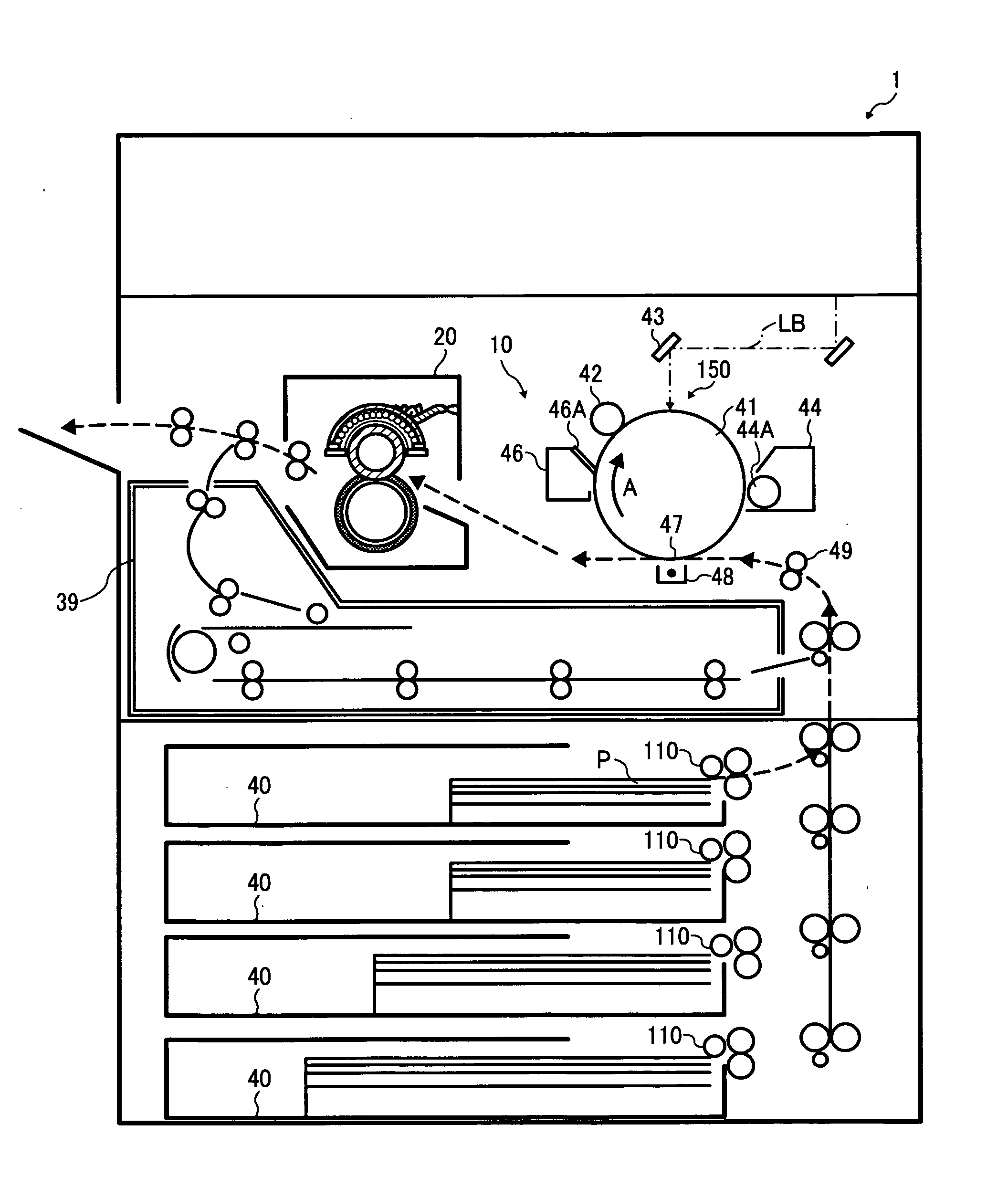

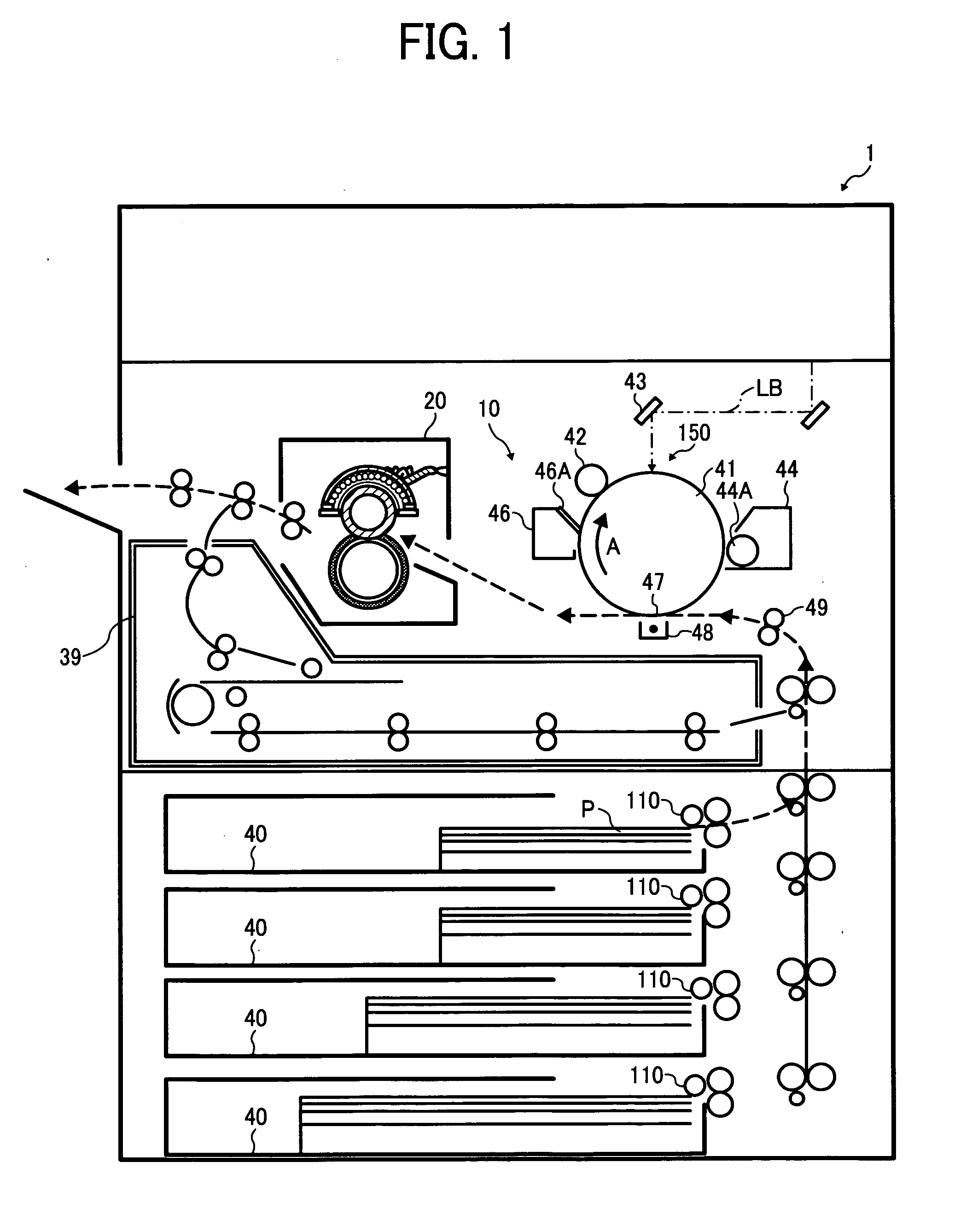

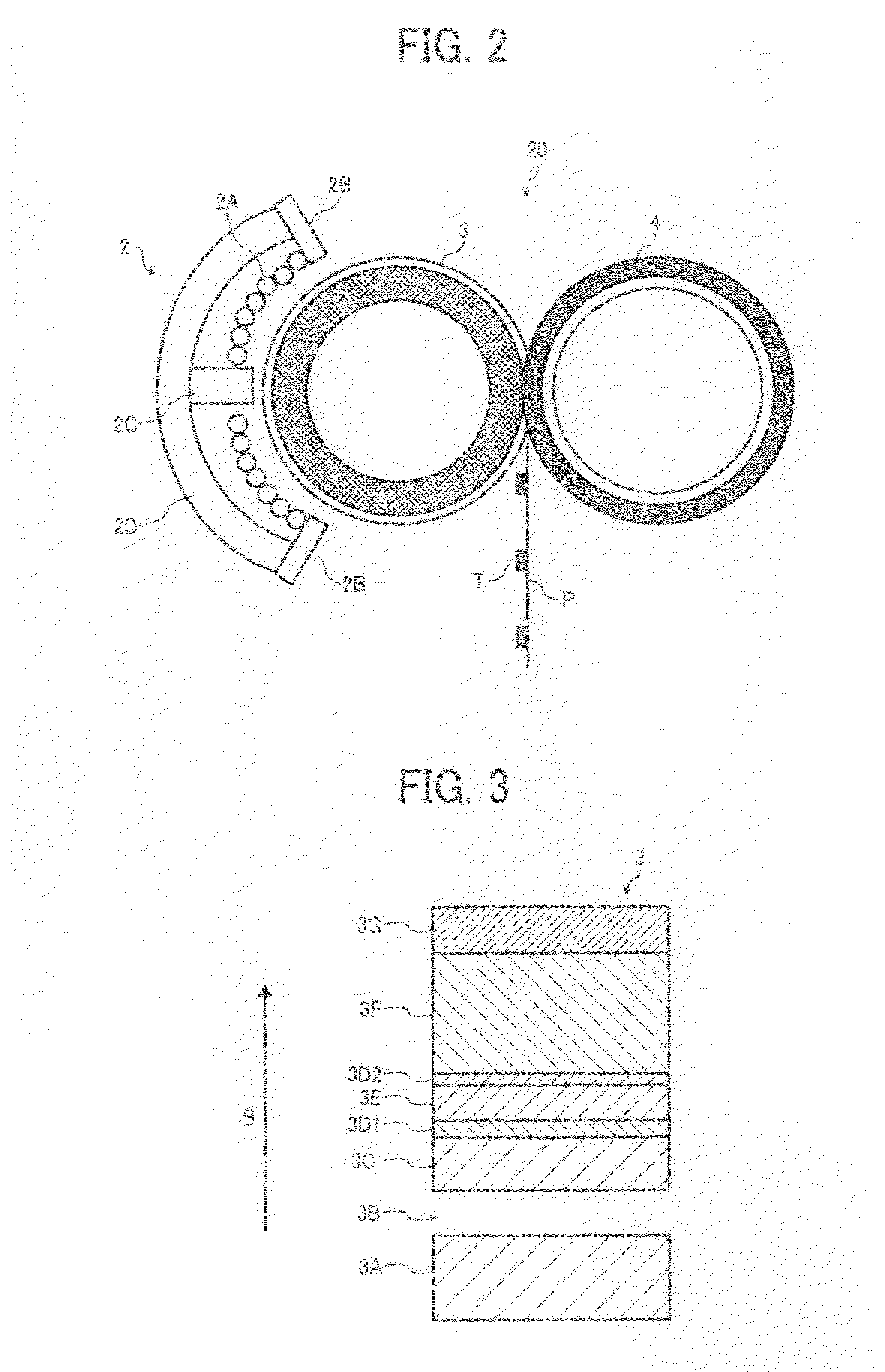

Fixing device, image forming apparatus including the fixing device, and fixing method

InactiveUS20080226326A1Ohmic-resistance heatingElectrographic process apparatusTemperature controlImage formation

A fixing device includes an excitation coil, a heat-generating layer, a magnetic shunt layer, and a degaussing member. The excitation coil generates a magnetic flux. The heat-generating layer generates heat using the magnetic flux generated by the excitation coil. The magnetic shunt layer transmits heat generated by the heat-generating layer. The degaussing member sandwiches the magnetic shunt layer together with the excitation coil, and selectively performs degaussing by generating a repelling magnetic flux for canceling the magnetic flux generated by the excitation coil so as to activate a self-temperature-control function. The degaussing member selectively refrains from degaussing so as to deactivate the self-temperature-control function.

Owner:RICOH KK

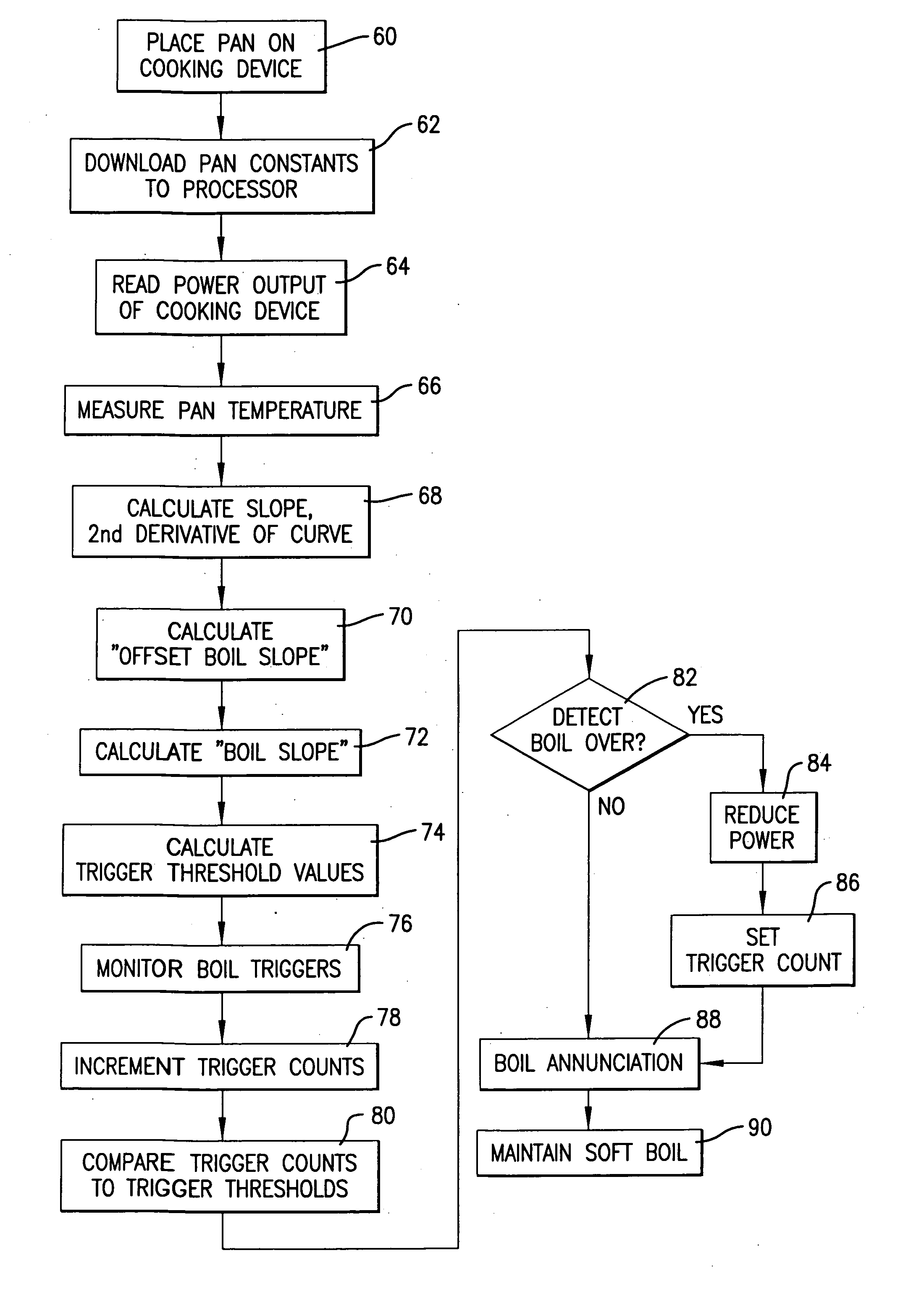

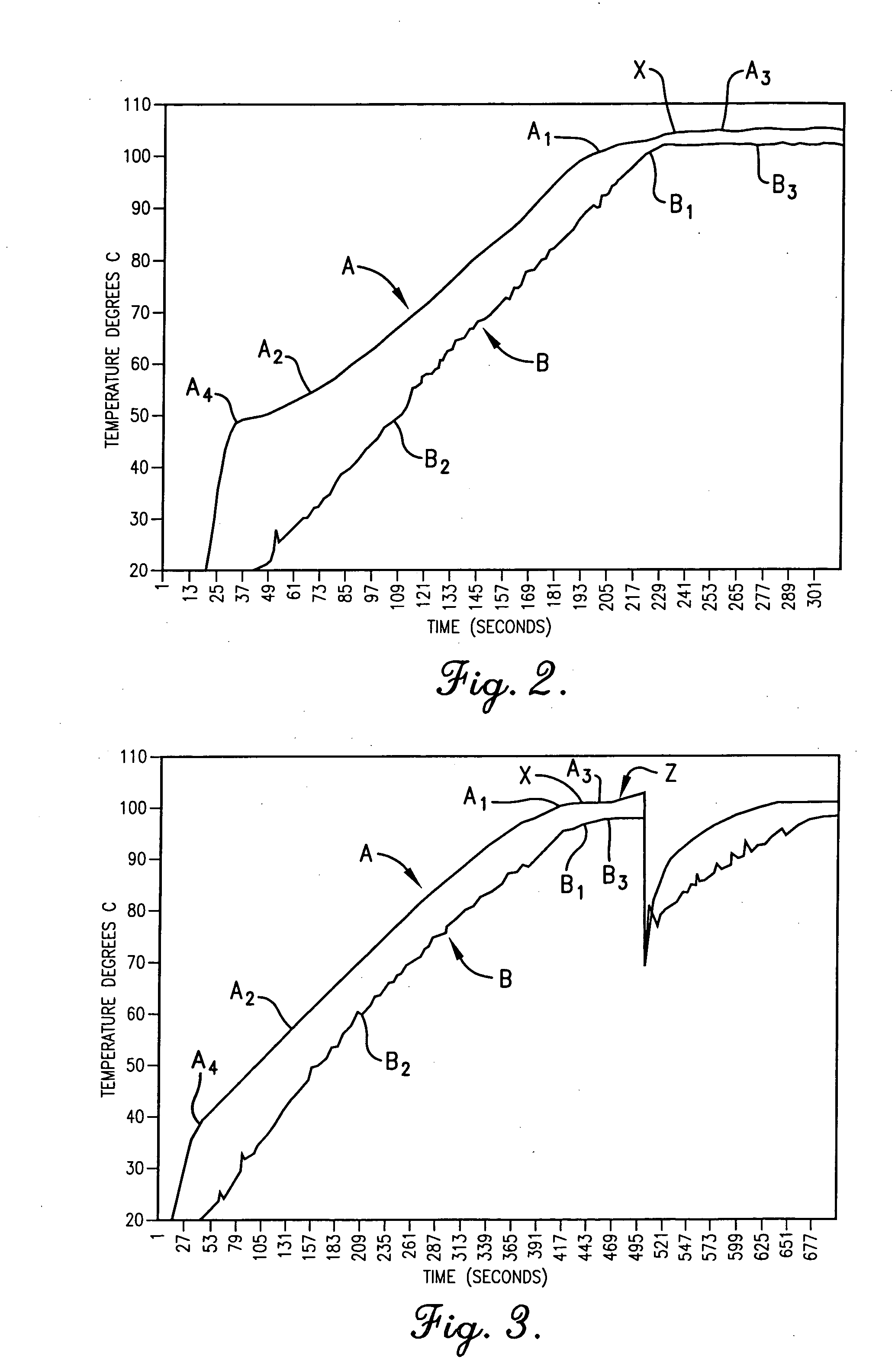

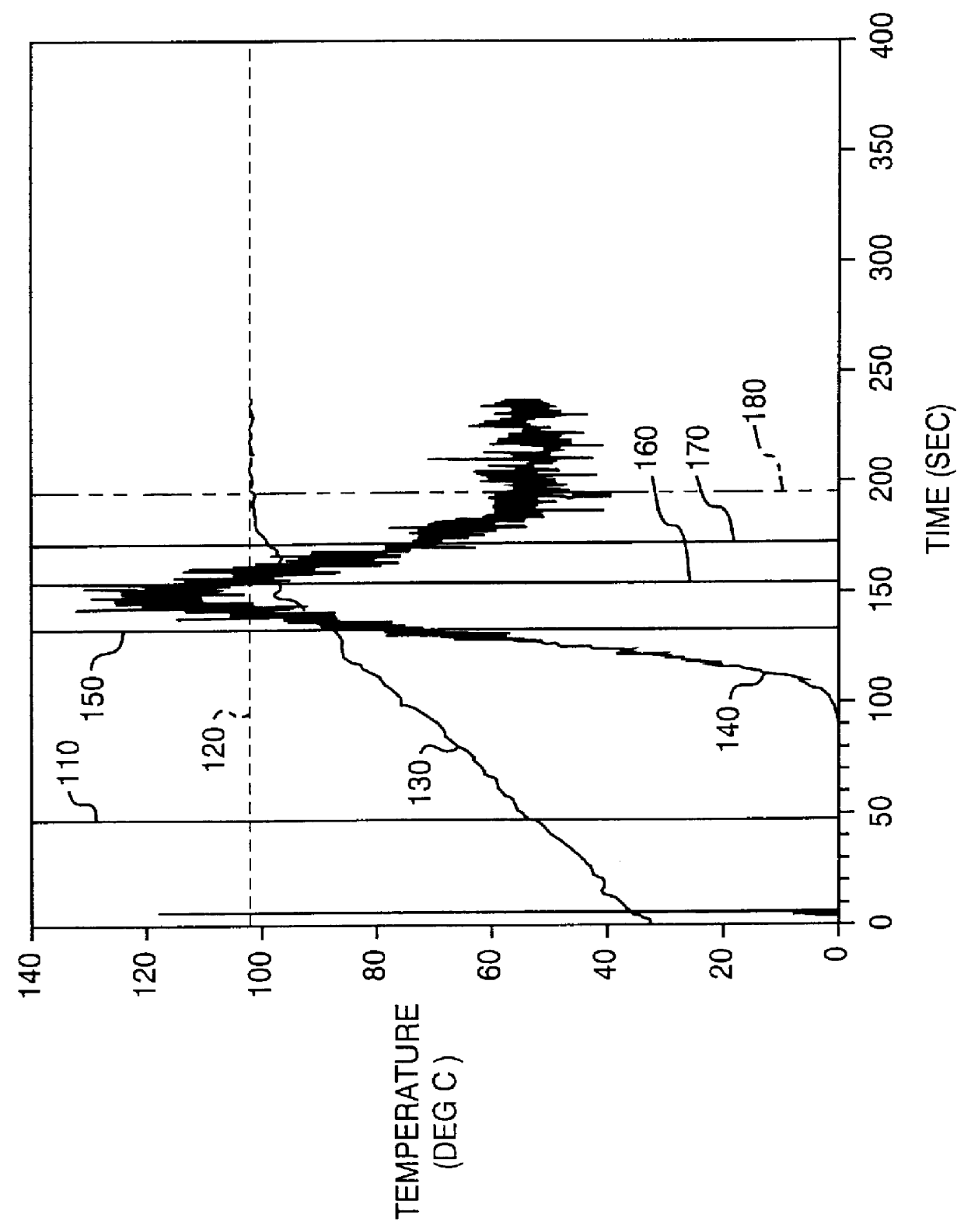

Boil detection method and computer program

A method, computer program, and cooking device for detecting boiling of liquids. The invention is implemented with a computer program executed by a processor or other computing device of a cooking unit such as an induction range. The computer program comprises a code segment for receiving an indication of successive temperatures of the vessel and for calculating a slope of a curve representing the successive temperatures versus time; a code segment for detecting boiling of the liquid based on the slope of the curve; and a code segment for providing an output which may be used to indicate the boiling. The computer program may also include a code segment for receiving variables relating to parameters and / or characteristics of the cooking vessel to refine the boiling detection.

Owner:TSI TECH

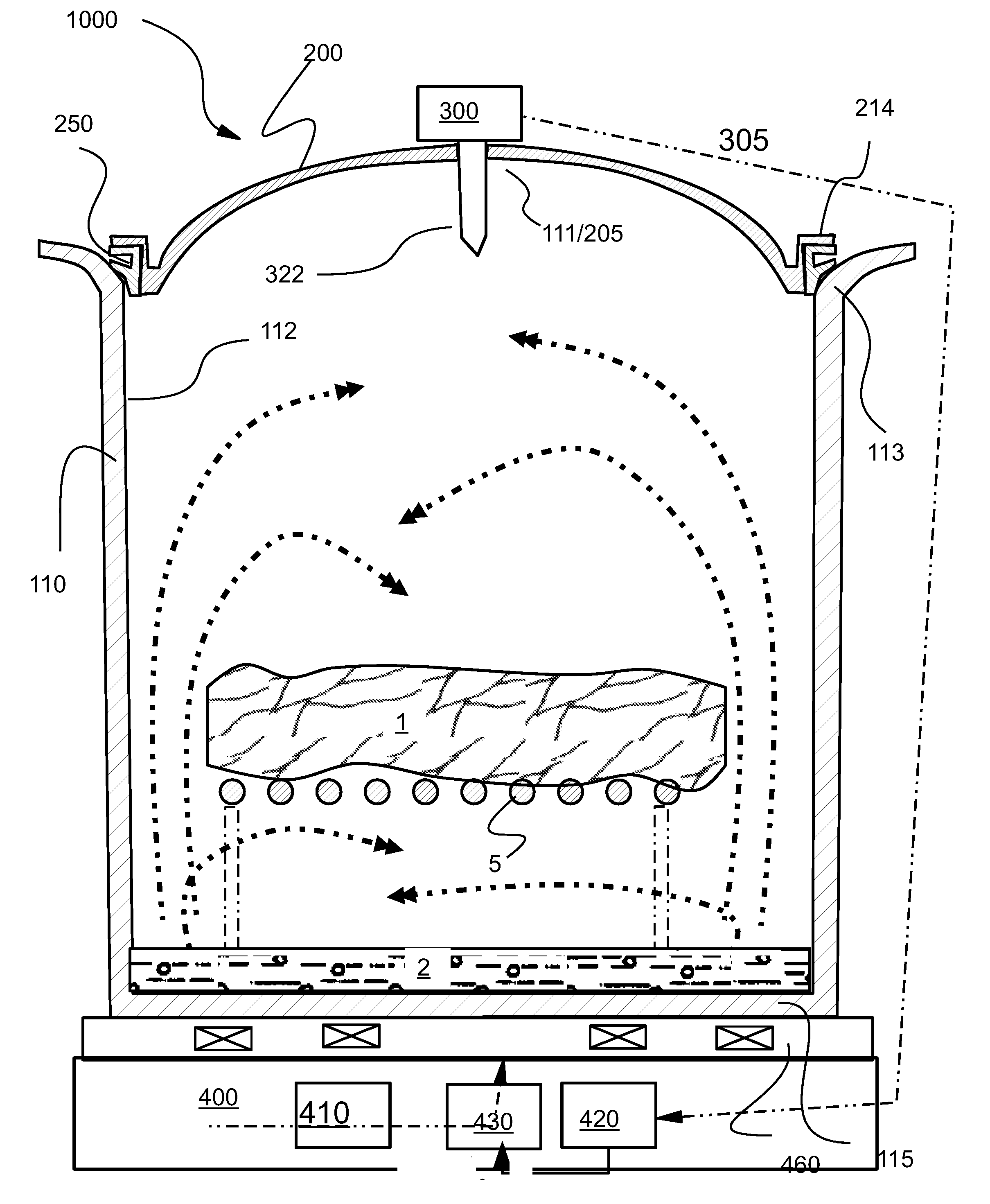

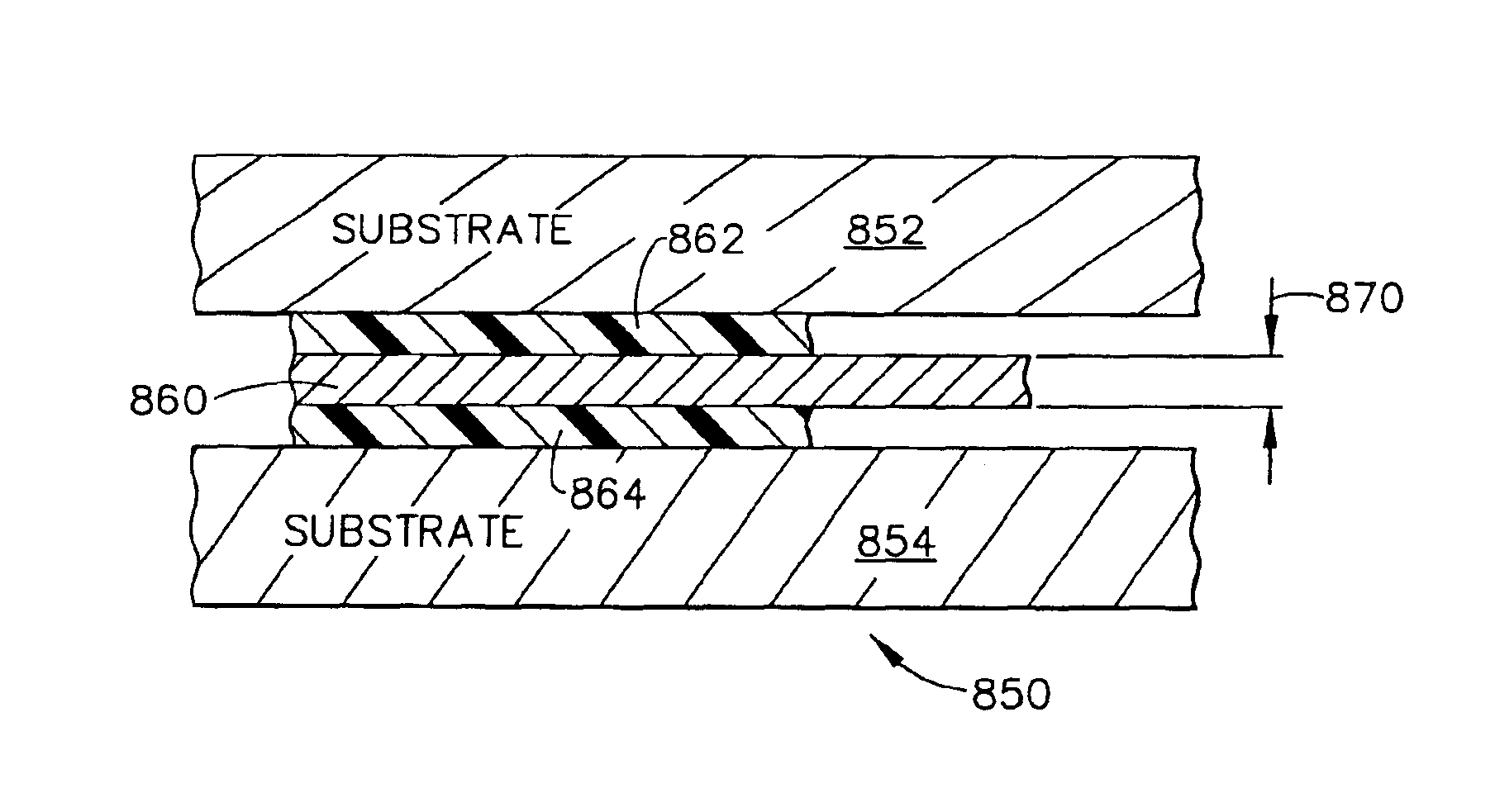

Curing Composites Out-Of-Autoclave Using Induction Heating with Smart Susceptors

ActiveUS20120145703A1Precise and uniform temperature controlSimple and relatively inexpensive to fabricateCoil arrangementsOhmic-resistance heatingSusceptorMaterials science

A composite part is cured out-of-autoclave using an inductively heated, stand-alone tooling. The part in placed on a tool and is covered by a heating blanket. One side of the part is heated by inductive coil circuits in the tool, and the other side of the part is heated by inductive coil circuits in the blanket.

Owner:THE BOEING CO

Induction cooking heater

ActiveUS20060081607A1Accurate temperature changeAvoid heatCooking vesselsDeep fat fryersEngineeringInduction cooking

An induction heating cooker includes a surface, a heating coil for inductionally-heating a load pan, an inverter for supplying a high-frequency current to the heating coil, an infrared detector which detects infrared radiation emitted from the load pan and is located under a top plate, a first temperature detector for detecting a temperature of the load pan based on an output of the infrared detector, a heating controller for controlling a power output from the inverter, a thermo-sensitive element for receiving heat from the top plate, and a second temperature detector for detecting a temperature of the load pan based on an output of the first thermo-sensitive element. This induction heating cooker detects a temperature change of the load pan accurately by detecting an infrared radiation from the load pan, and detects the temperature of the load pan by the heat conduction from the pan even if ambient light enters.

Owner:PANASONIC CORP

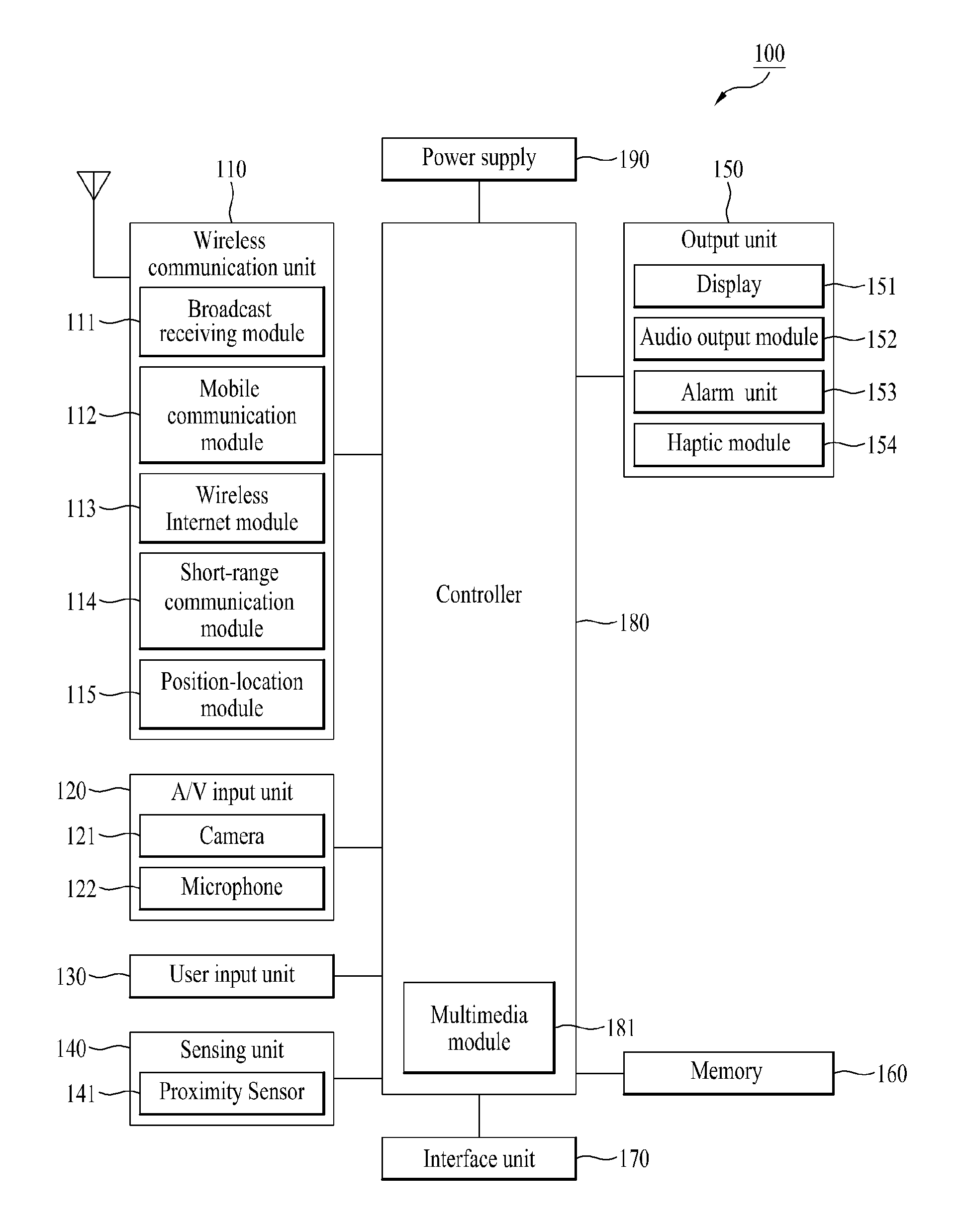

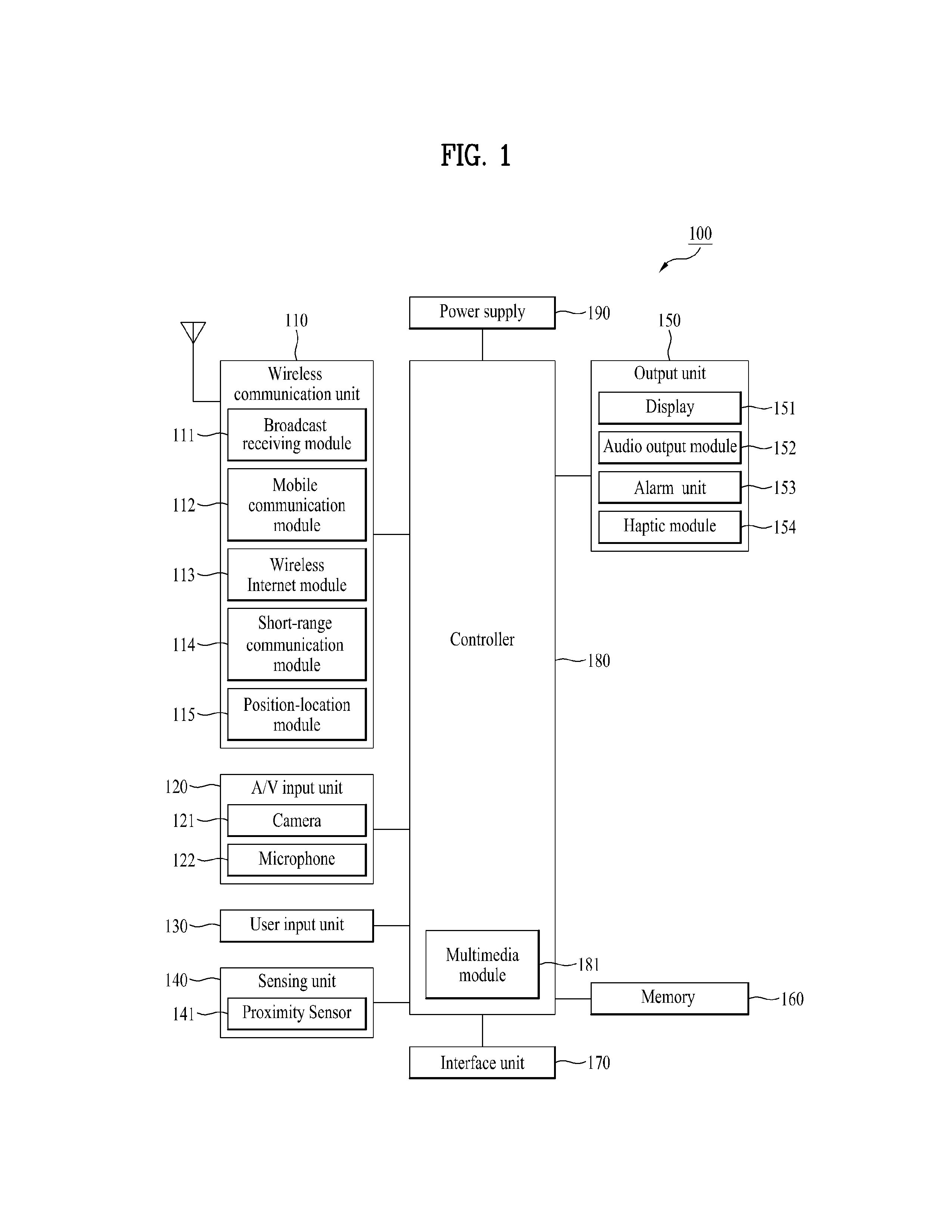

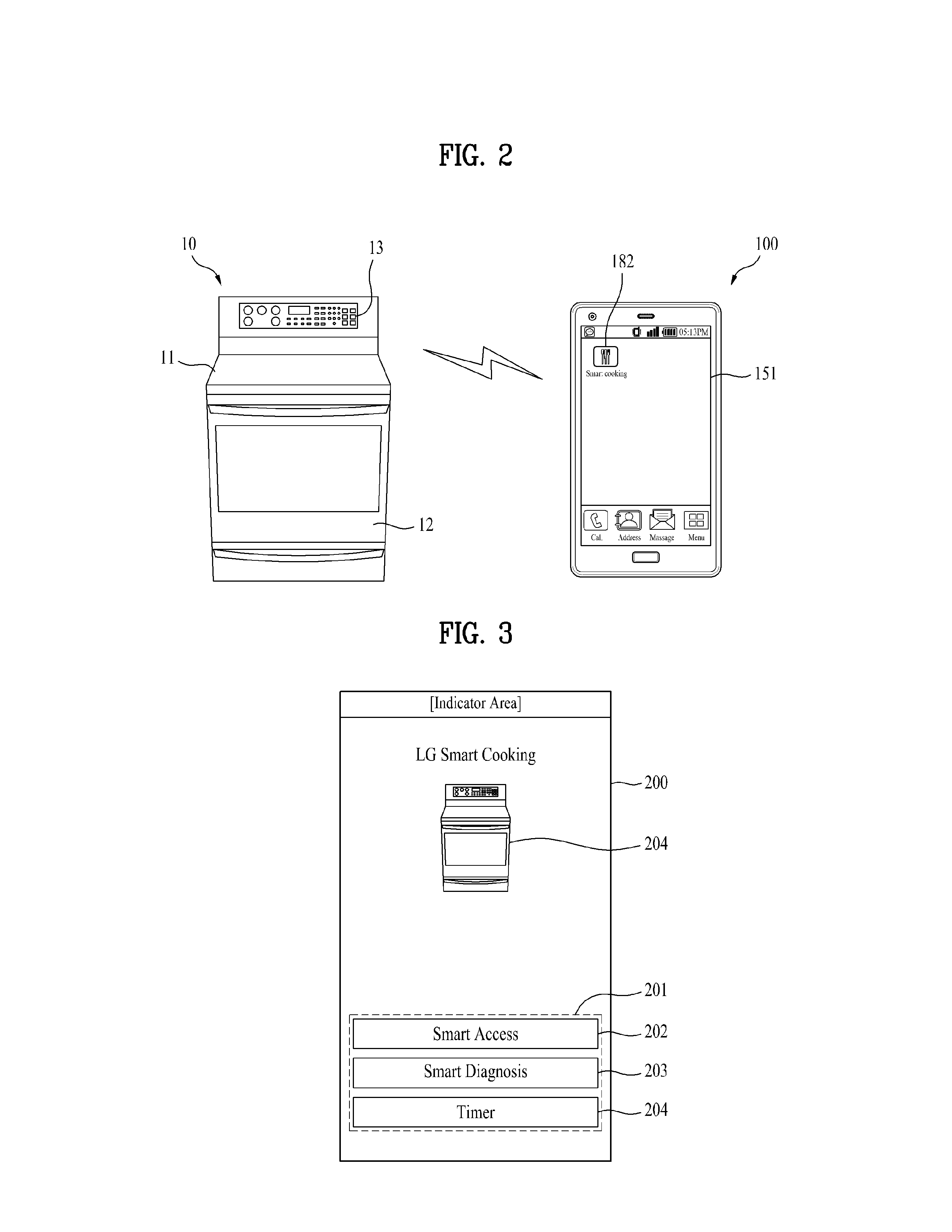

Mobile terminal

ActiveUS20130176116A1Improve user convenienceEfficiently display informationElectric signal transmission systemsElectric controllersTelecommunicationsRemote monitoring and control

A mobile terminal is disclosed. The mobile terminal can transmit / receive information or a signal to / from a cooking apparatus, improve user convenience, remotely monitor a state of the cooking apparatus, and receive a control command with respect to the cooking apparatus.

Owner:LG ELECTRONICS INC

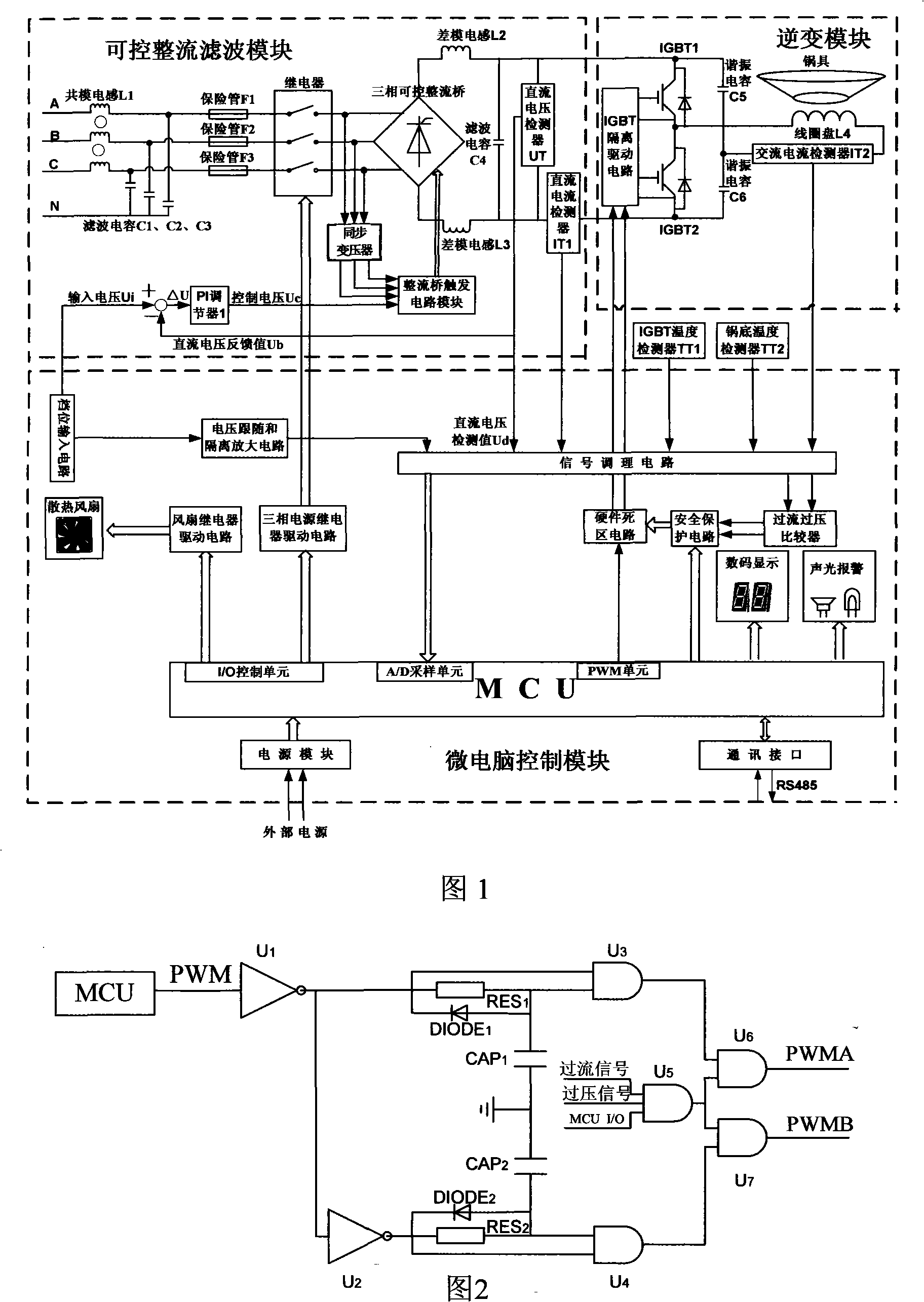

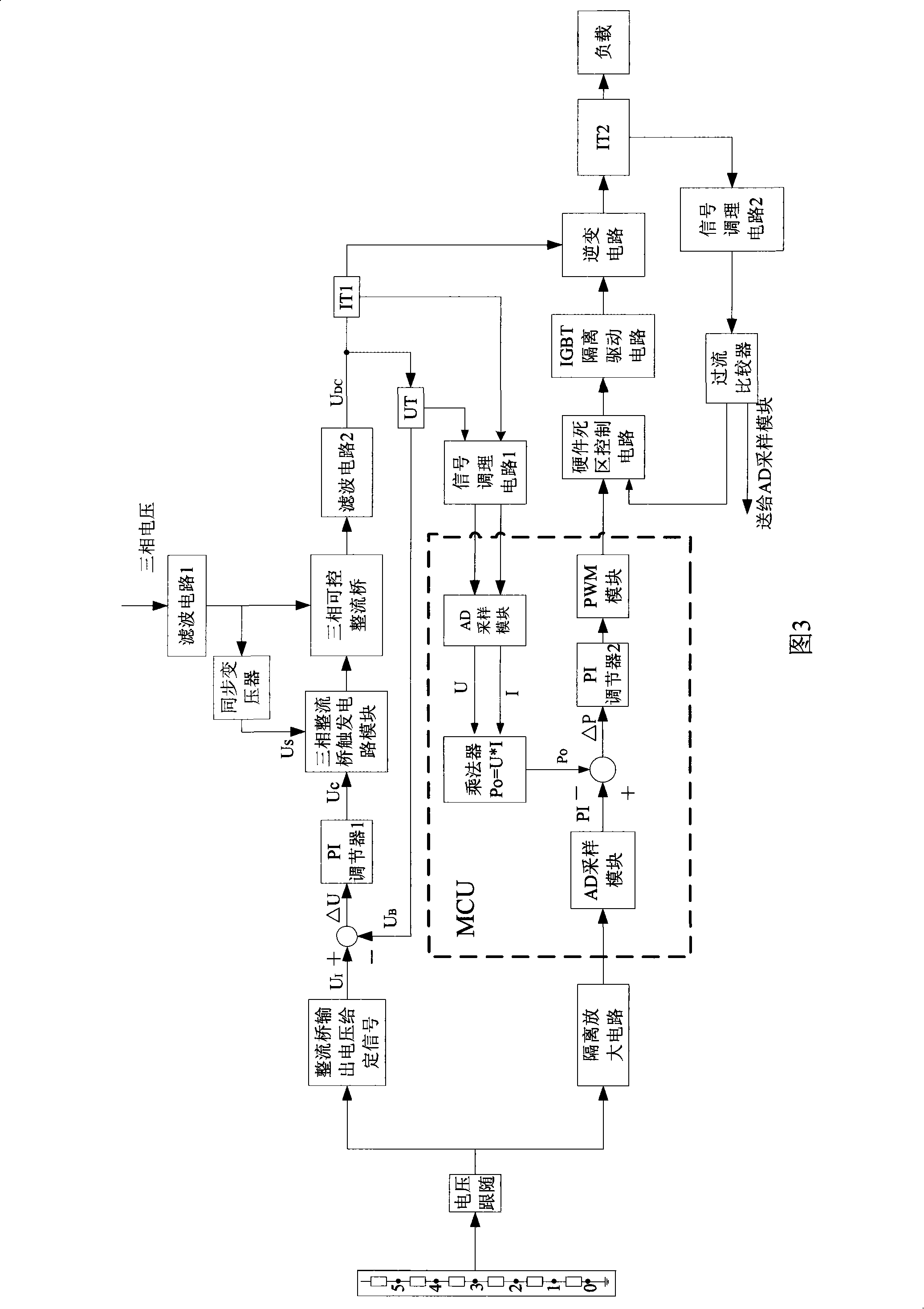

Intelligent control apparatus and method for high-power energy saving electromagnetic stove

InactiveCN101309529ASuppressor mutationProtection securityAc-dc conversionInduction heating controlConstant powerElectric network

The invention relates to an intelligent control device of a high power energy saving electromagnetic stove, and the method thereof, The intelligent control device comprises a controllable rectifying and filtering module, a contravariant module and a microcomputer controlling module, which is characterized in that a three-phase alternating current power supply is rectified into an adjustable direct current power supply through the controllable rectifying and filtering module ; the direct current power supply is inverted into a high frequency alternating current power supply through the contravariant module, and then the electric energy is converted into electromagnetic energy to be radiated to the bottom of a cookware, and vortex flow is generated, and the cookware can be heated because of the thermal effect of the vortex flow; the microcomputer controlling module is the core of the entire system, which is used for collecting data and transmitting control information to each module; the device adopts a series of advanced control policies, such as the trigger control of the rectifier bridge of an PI regulator, the intelligent self-adaptive constant power control, the intelligent soft-start control, the intelligent cookware detection control, etc., and thereby the working stability and the security of the electromagnetic stove are enhanced. The harmonic pollution of the equipment to the electric network can be reduced to the utmost extent when the electric energy of the electromagnetic stove is saved, and the electromagnetic stove is suitable for various kitchens and dining rooms.

Owner:WUHAN UNIV OF TECH

Multi Cooker

ActiveUS20130112683A1Automation easeEase predictabilityBoiling over preventionWater-bath cooking vesselsTemperature controlEngineering

A cooking appliance and method, the appliance including: at least one temperature controlled heating element; a user interface for enabling a user to select a predefined subject for cooking; and a processor module that maintains a cooking data for cooking the selected predefined subject, and provides prompts to the user during cooking. The cooking data can be indicative of a cooking sequence or procedure. A cookware sensor can automatically identifying cookware being used.

Owner:BREVILLE HLDG PTY LTD

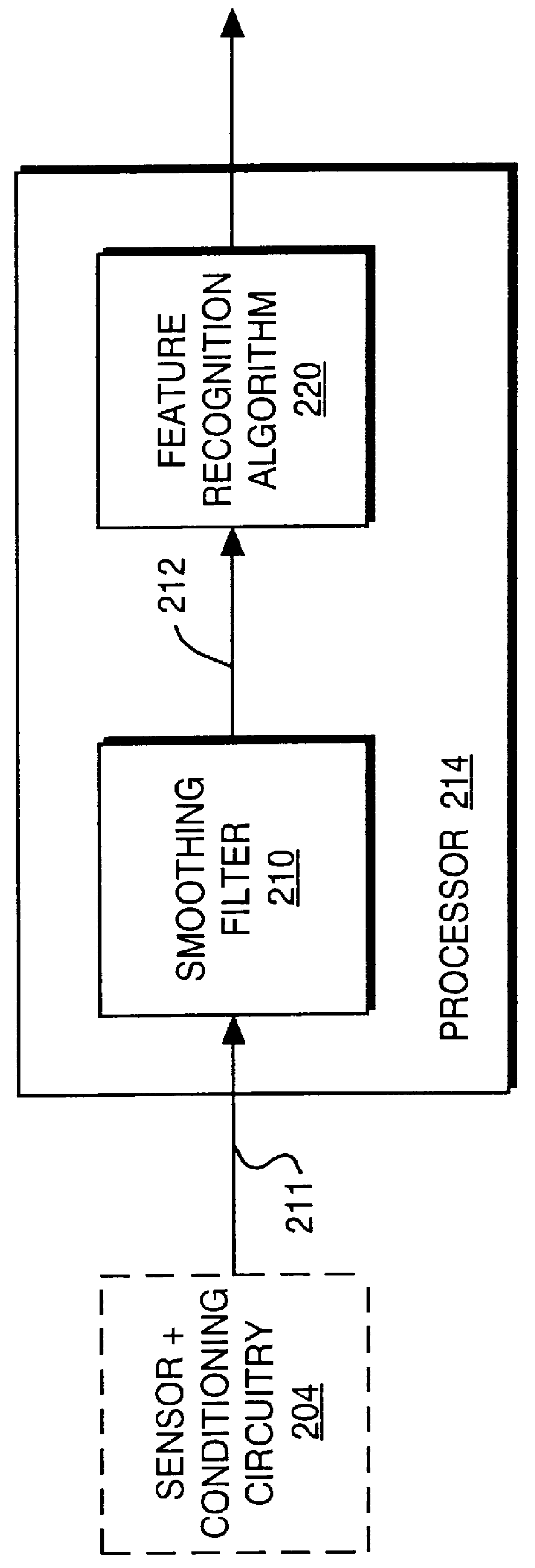

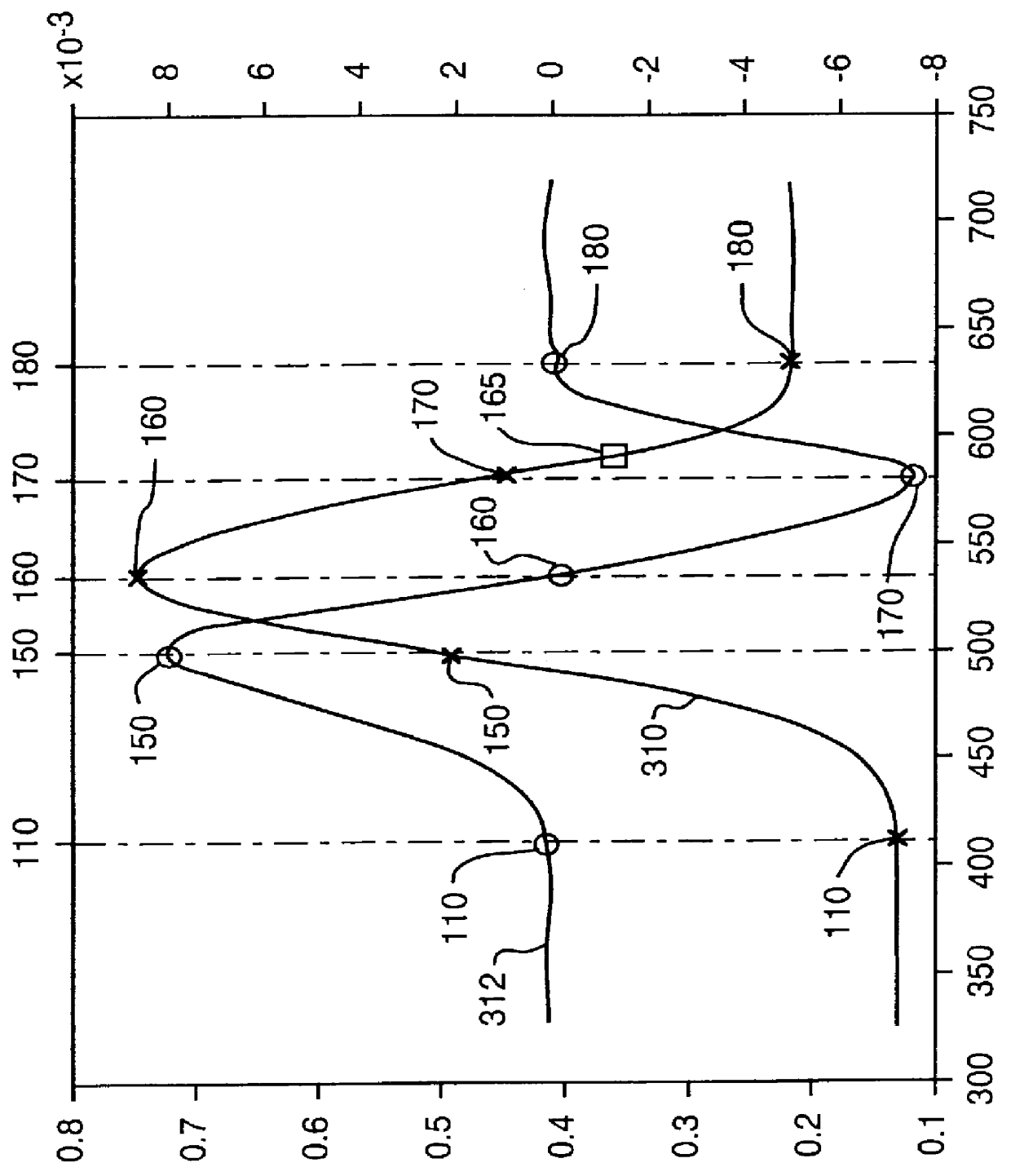

Method and apparatus for boil state detection based on acoustic signal features

InactiveUS6118104AEffective controlReliably determinedVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic sensorSignal frequency

The present invention provides a method of determining the boil states of a liquid as measured by an acoustic sensor which measures the acoustic signal generated by the liquid as it is heated. The acoustic signal is smoothed and a first derivative of the acoustic signal is calculated. Also the frequency of the acoustic signal is measured. Derivative inflection points, zero slope points, and acoustic signal frequencies are utilized to determine the pre-simmer, simmer, pre-boil, boil, boil dry, and boil over states of the liquid.

Owner:GENERAL ELECTRIC CO

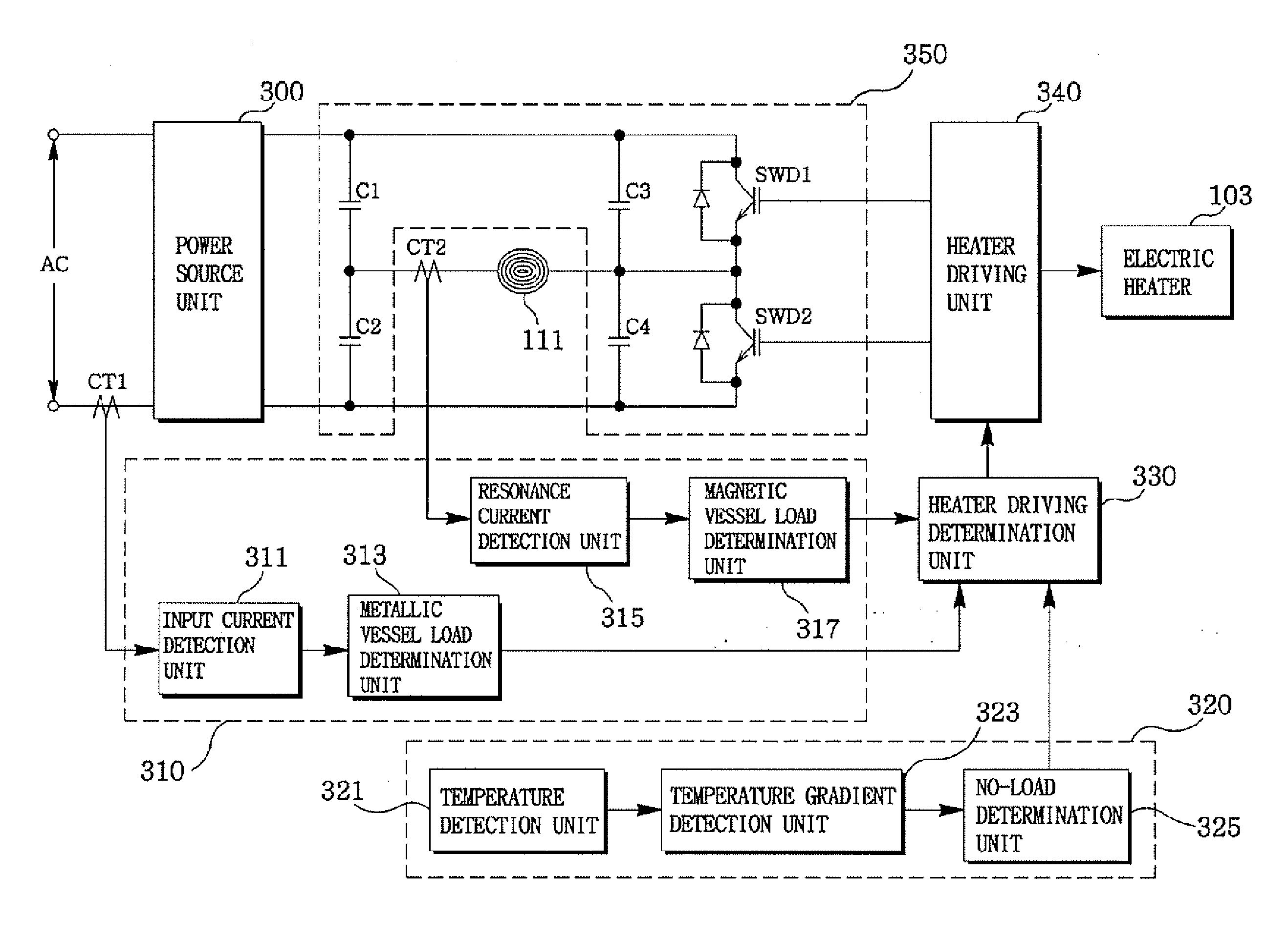

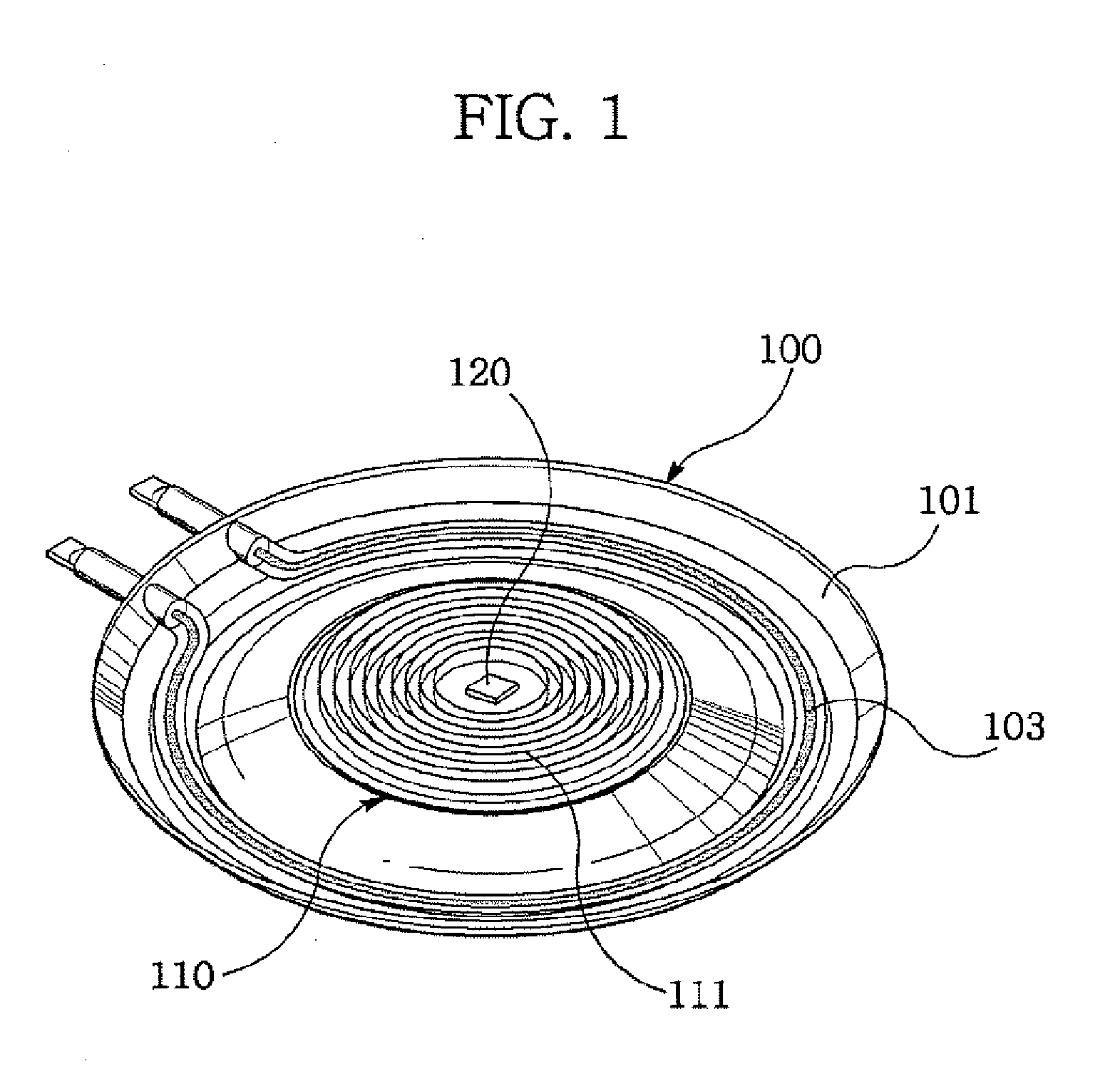

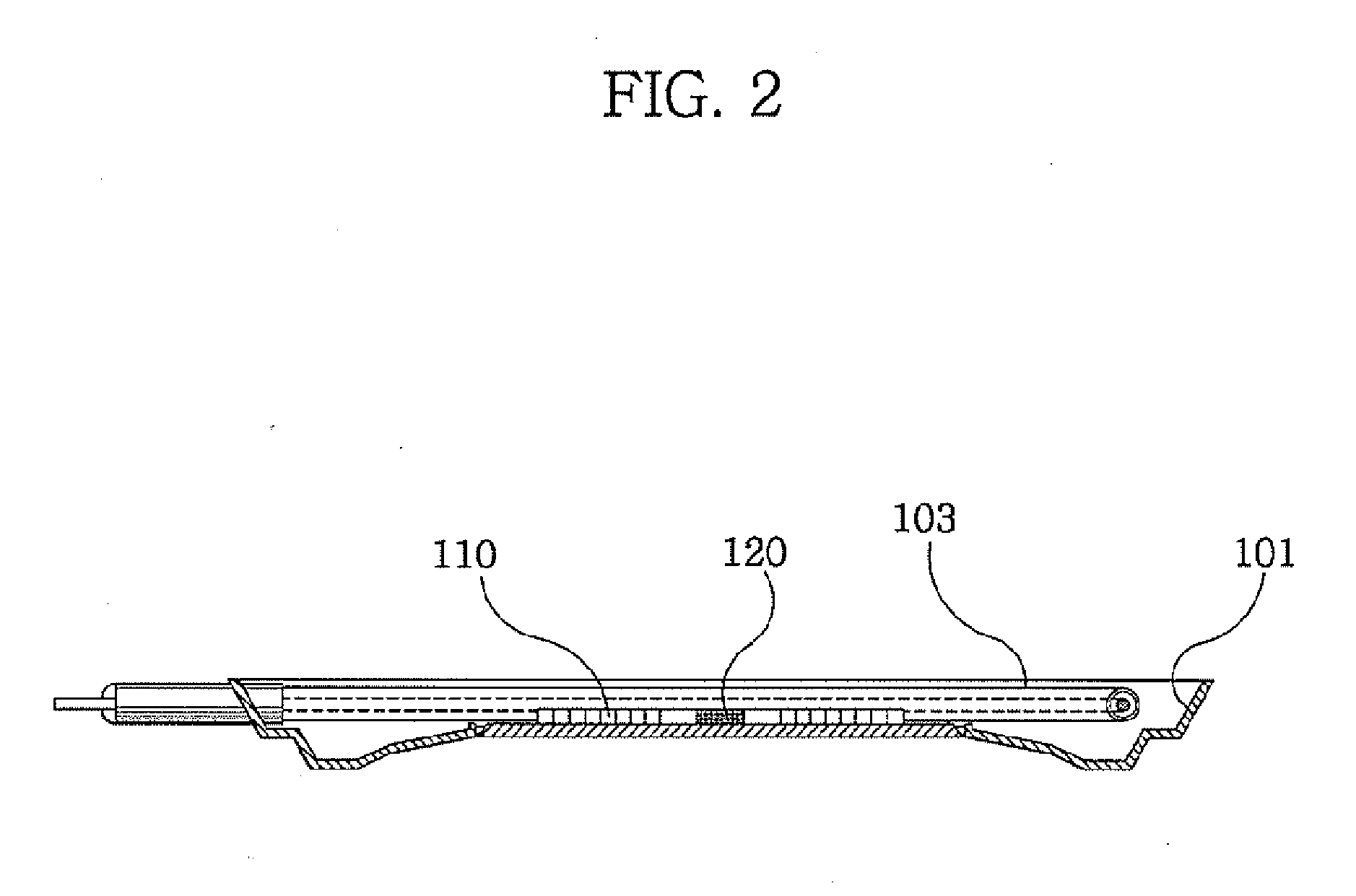

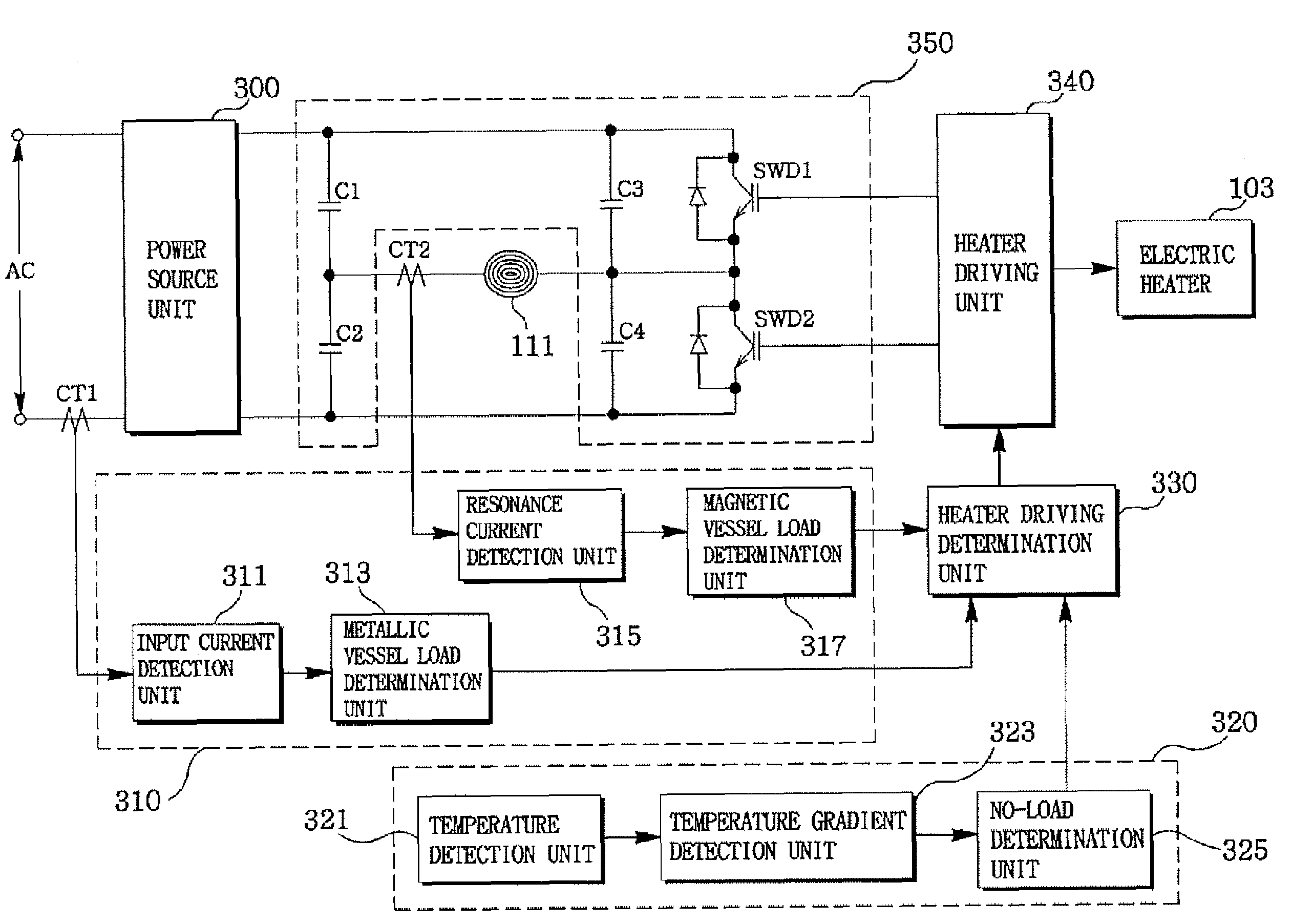

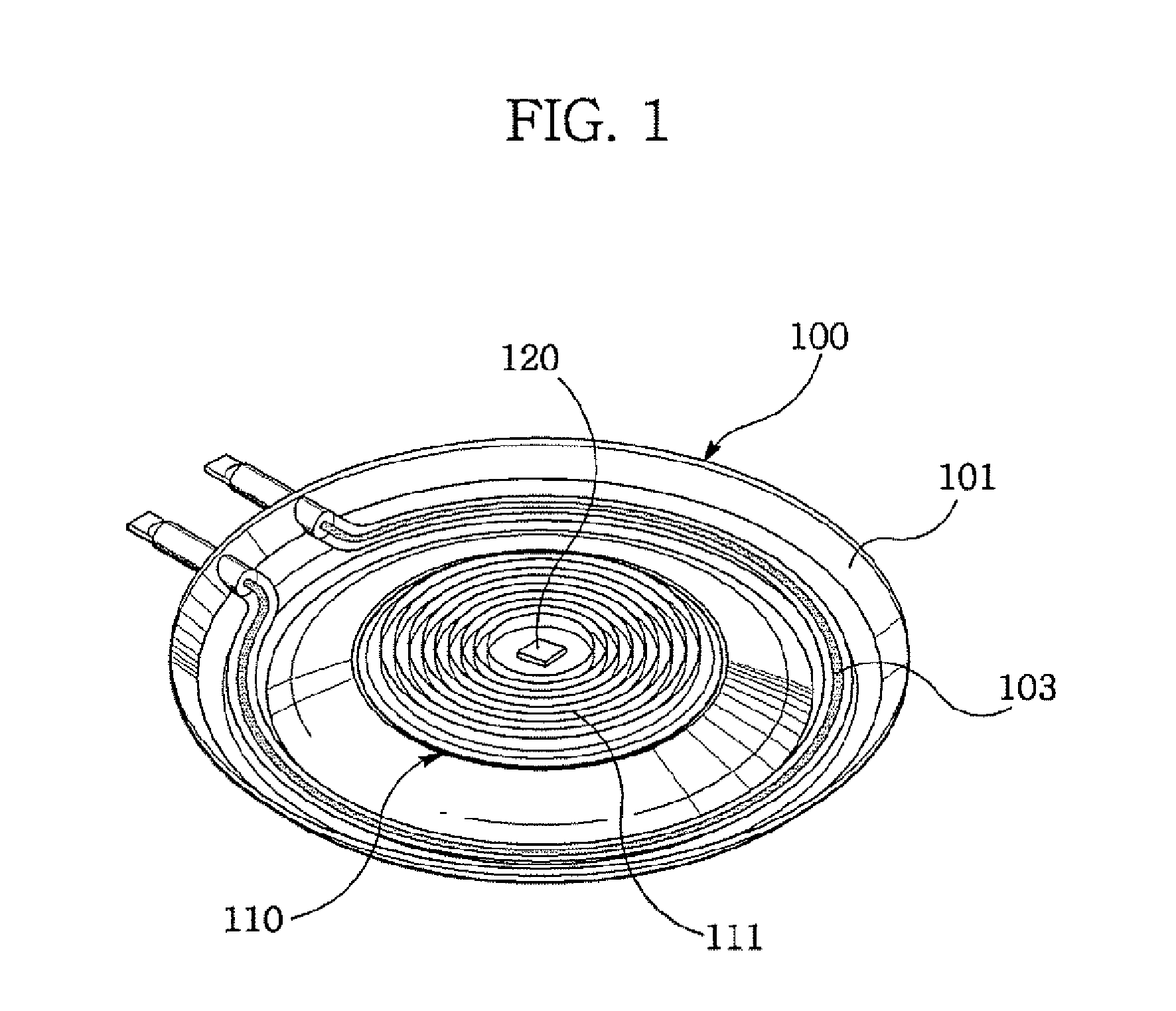

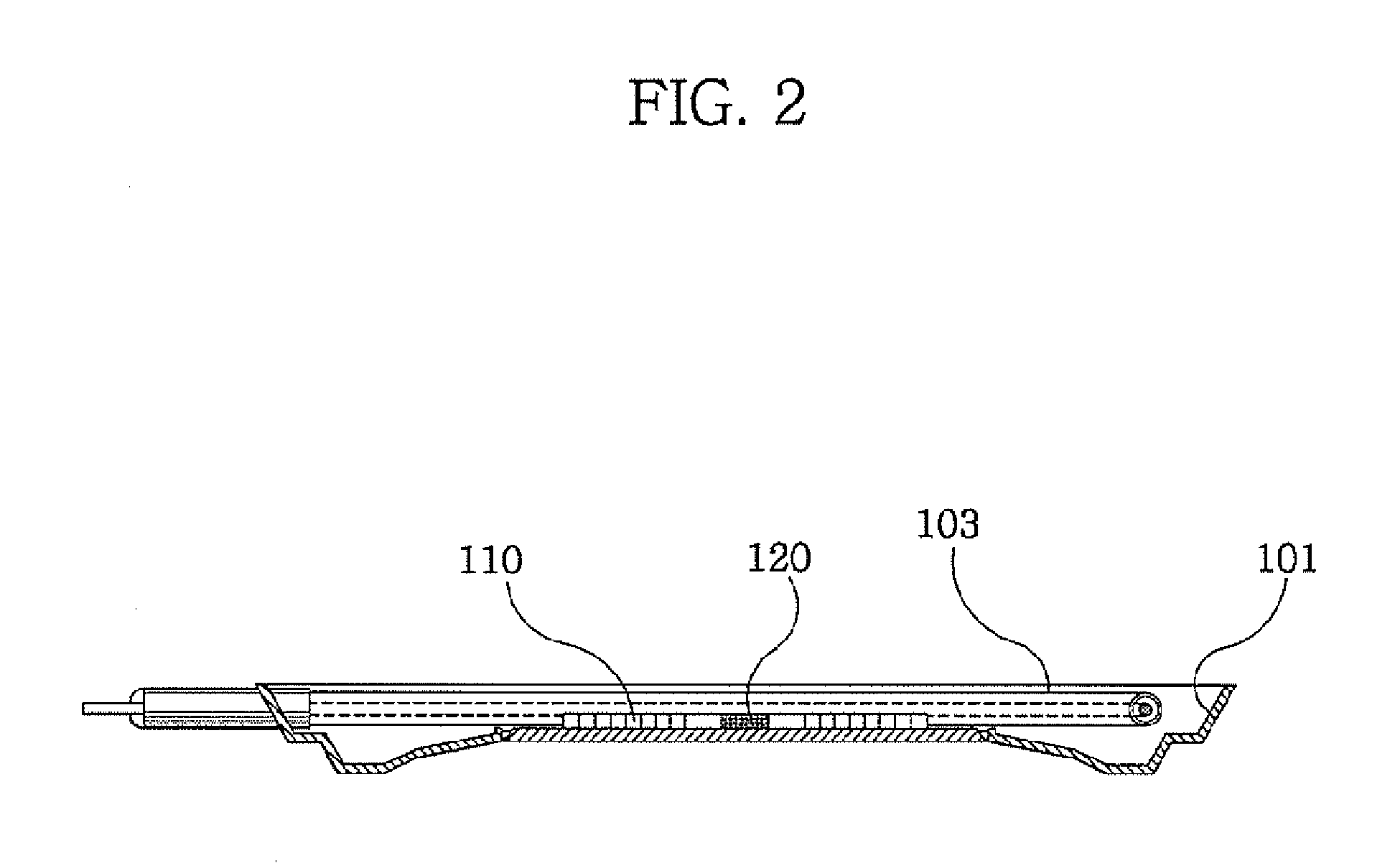

Apparatus and method for sensing load of electric cooker

ActiveUS20070125768A1Heating fastAccurate detectionMilk preservationFood preservationUser needsResonance

A heater unit is provided, the heater unit equipped with an induction heating coil and an electric heater selectively operated based on kind and state of a load of a cooking vessel placed on the heater unit. The kind is determined by an input current inputted when a load-type determination unit causes the induction heating coil to be operated and a resonance current flowing into the induction heating coil. The state is determined by a temperature change of the heater unit when a load-state determination unit allows the electric heater to generate heat, and the induction heating coil and the electric heater are selectively operated based on the determined kind and state of the load. Accordingly, a user needs not to scrupulously determine the kind of the cooking vessel and the electric cooker is not operated under a no-load state to prevent occurrence of safety accidents.

Owner:LG ELECTRONICS INC

Apparatus and method for sensing load of electric cooker

ActiveUS7368688B2Accurate detectionHeating fastMilk preservationFood preservationUser needsElectricity

Owner:LG ELECTRONICS INC

Electronic Vapour Inhalers

ActiveUS20170311648A1Gradual releaseReduce the possibilityTobacco treatmentTobacco devicesEngineeringInhaler

Owner:JT INT SA

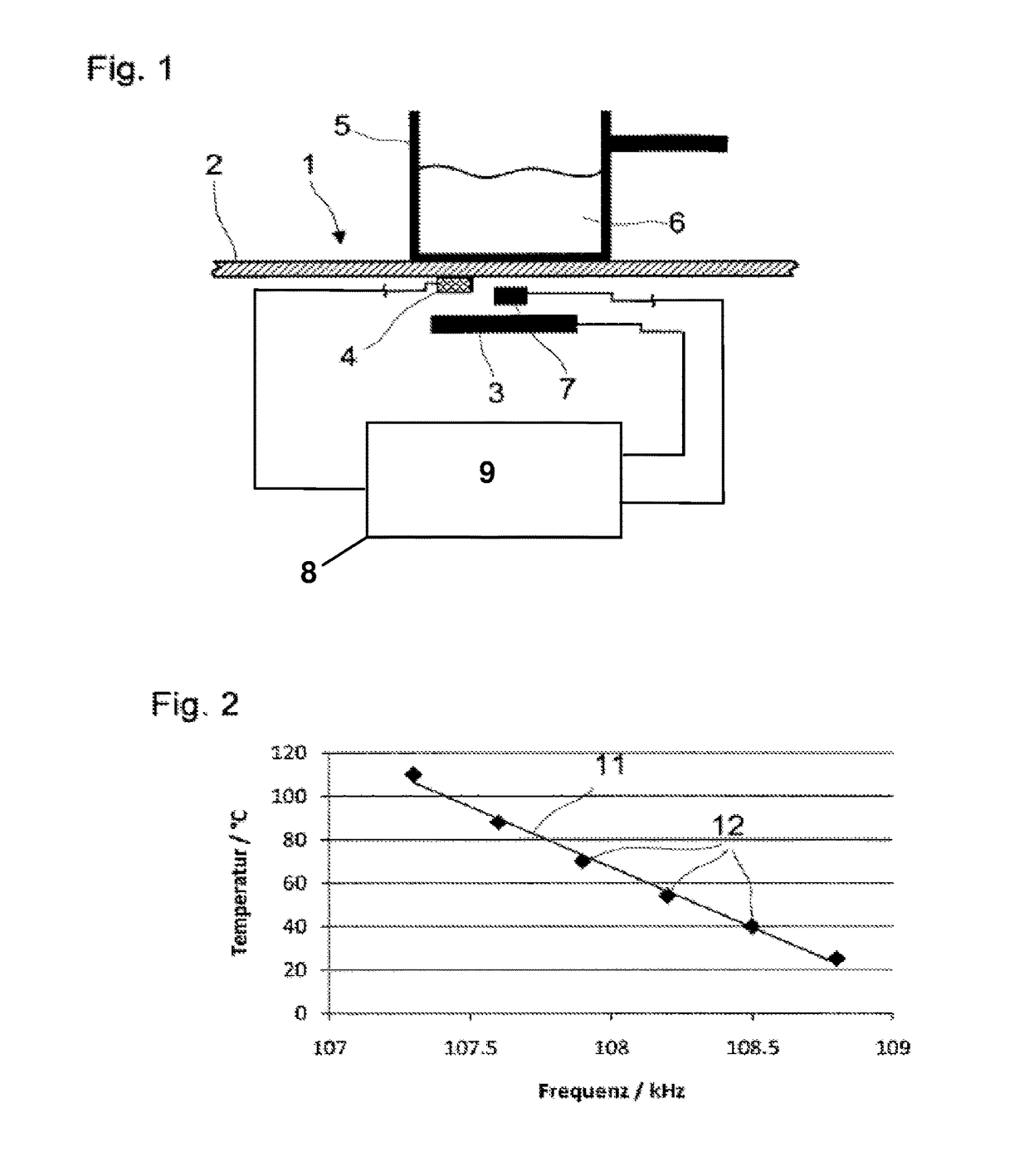

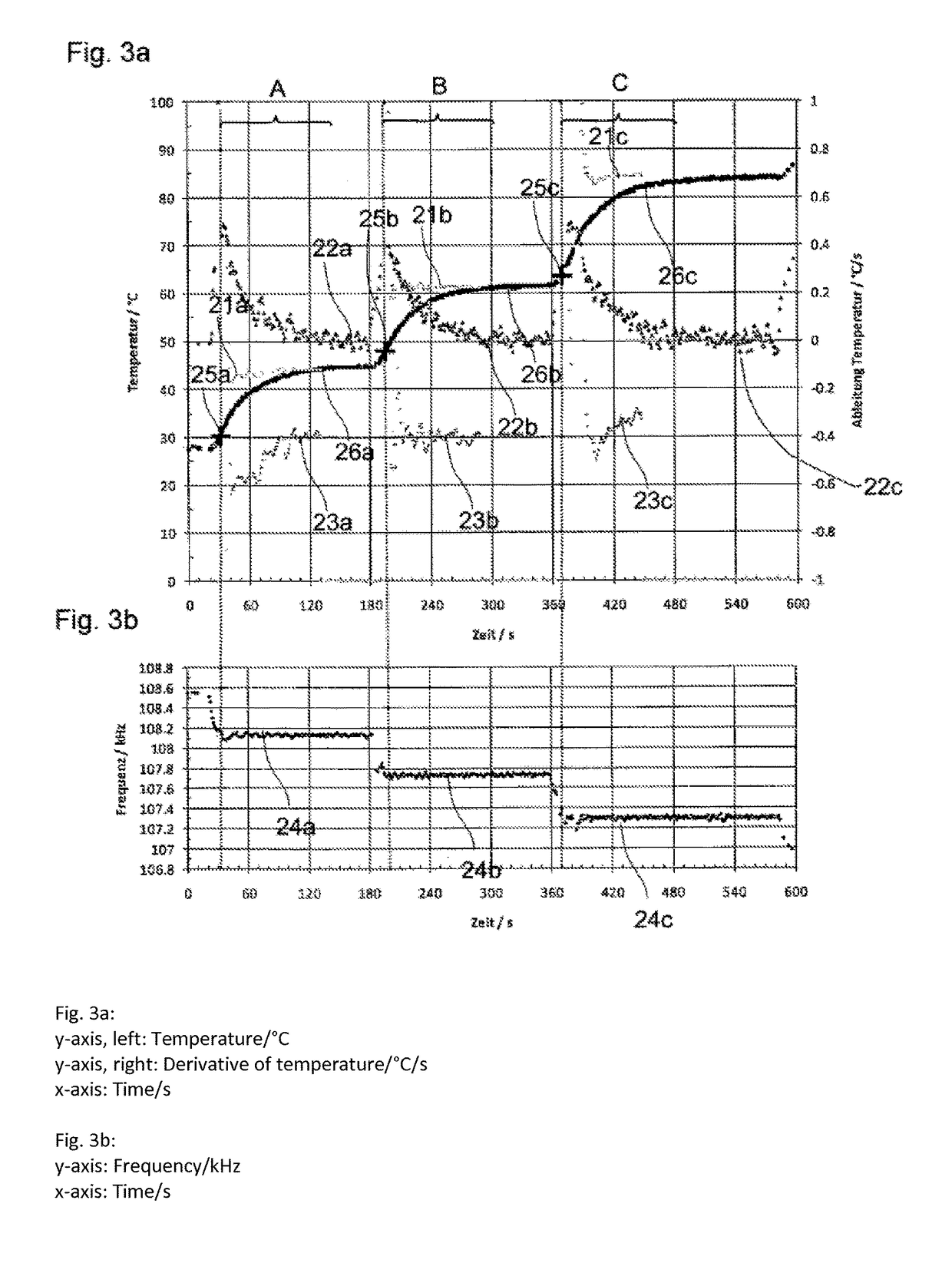

Induction cooking device for temperature-controlled cooking

ActiveUS9867234B2Temperature measurement in household appliancesTemperatue controlTemperature controlEngineering

The invention relates to a method for determining and regulating the temperature of an article with inductive properties which is heated inductively by means of an induction device, wherein the induction device contains an induction coil, means for producing an induction resonant circuit and a support element arranged above the induction coil and having a first side, which acts as support face for the article, and a second side, which is directed towards the inductive coil. At least one temperature sensor is fitted to the second side. The resonant frequency of the induction resonant circuit is measured via detection means and the temperature of the article is calculated from the measured resonant frequency, wherein the resonant frequency is related to the temperature of the article by virtue of a mathematical function, and the function is determined by determining at least two absolute temperature calibration values of the article at respectively different resonant frequencies. The temperature calibration values are calculated from temperature measured values of the sensor.

Owner:GARLAND COMML IND INC

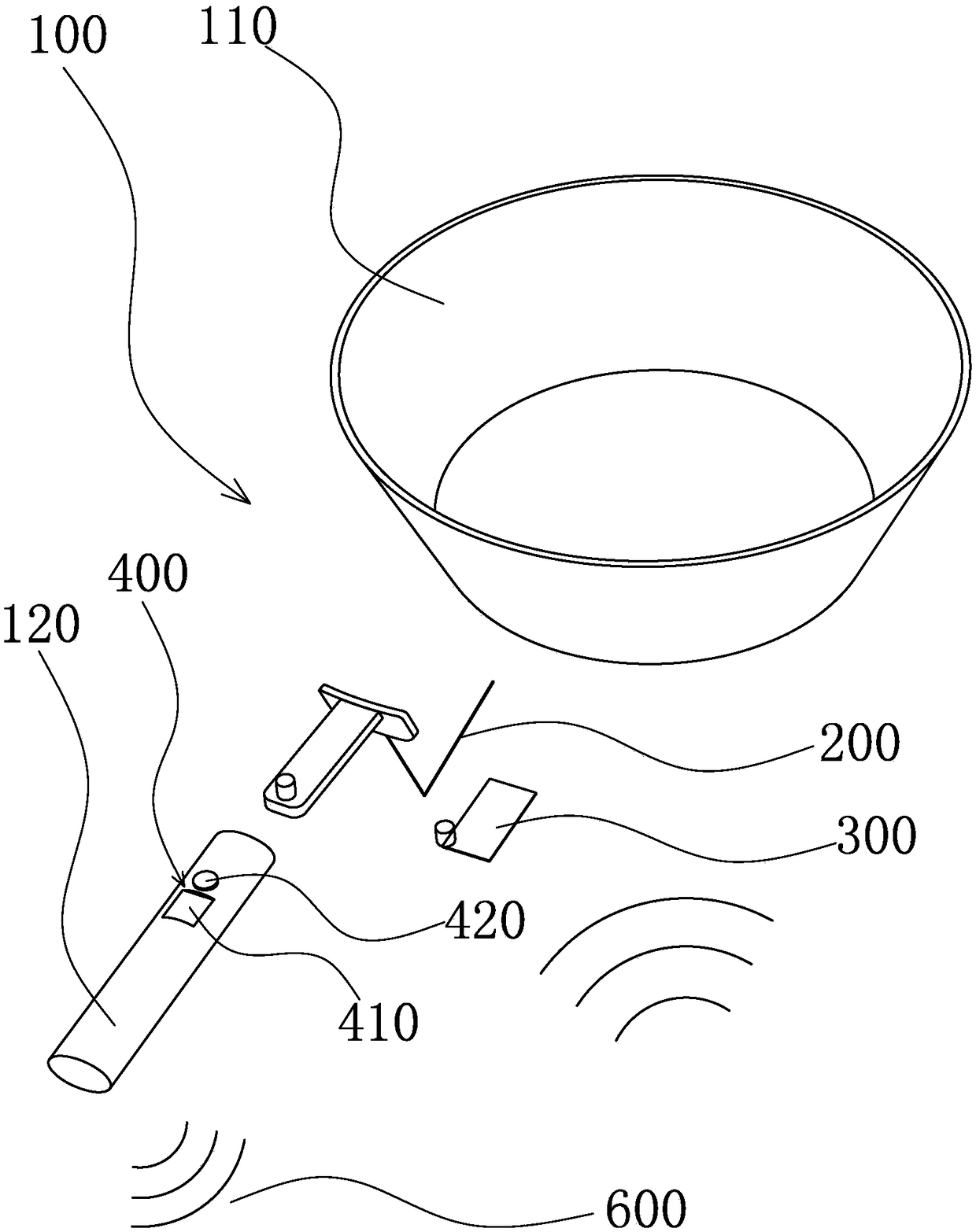

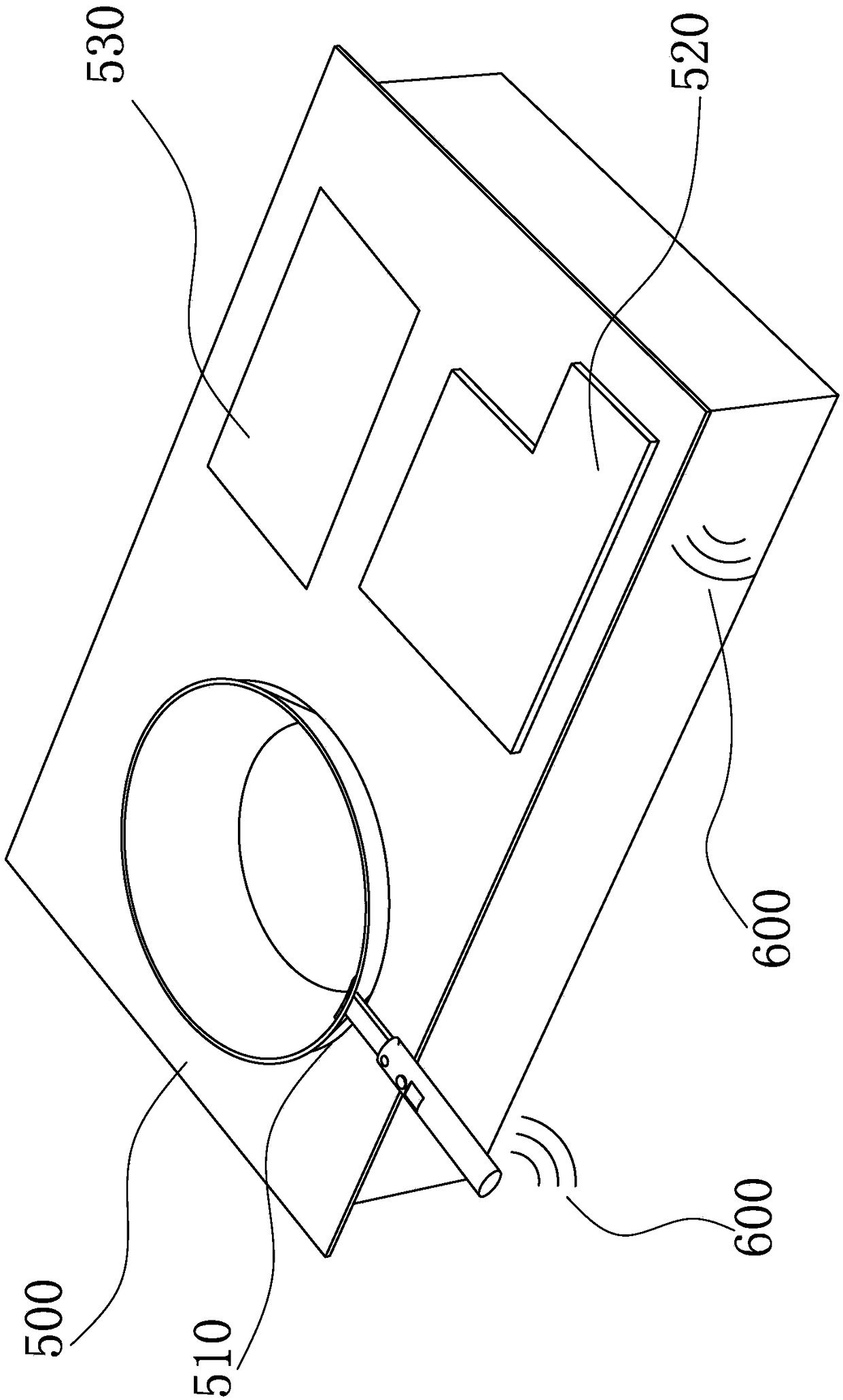

Intelligent cookware and intelligent cooker

PendingCN108552989AKeep healthyEnsure safetyKitchen equipmentInduction heating controlTemperature controlContinuous use

The invention provides intelligent cookware and an intelligent cooker. The intelligent cooker comprises a cooker body, wherein one side of the cooker body is sunken downward to form a cavity as a placement position of the intelligent cooker, wherein a heating source of the intelligent cooker comes from an electromagnetic wave in the cooker body, and it is achieved that a power supply in the intelligent cooker can be charged through the electromagnetic wave. The provided intelligent cooker has the advantages that the power supply in the intelligent cooker is charged through the electromagneticwave in the cooker body, so that the power supply does not need additional charging equipment, the continuous use of a temperature control induction module and display module in the intelligent cookeris ensured, and the reliability of the use of the intelligent cooker is improved.

Owner:NINGBO OULIN KITCHEN UTENSILS

Method of adhesive bonding by induction heating

InactiveUS6849837B2High frequency current welding apparatusInduction heating controlSusceptorElectronic controller

A method for using magnetic fields to heat magnetically susceptible materials within and / or adjacent to adhesives, so as to bond, bind, or fasten solid materials to one another. The system uses alternating magnetic fields that induce eddy currents and generate heat within susceptors. An induction heating tool is used to emit the magnetic field at its work coil, and an electronic controller measures the energy being used by a power converter that generates the alternating current driving the work coil which creates the magnetic field. The heating tool is used in a method of adhesive bonding in which the thickness of the conductive layer of the susceptor is in the range of 0.01-3.0 mils, or the heating event time interval is in the range of 0.05-10.0 seconds, or the average power density of the magnetic field at the susceptor is in the range of 10-5000 Watts per square inch.

Owner:OMG INC

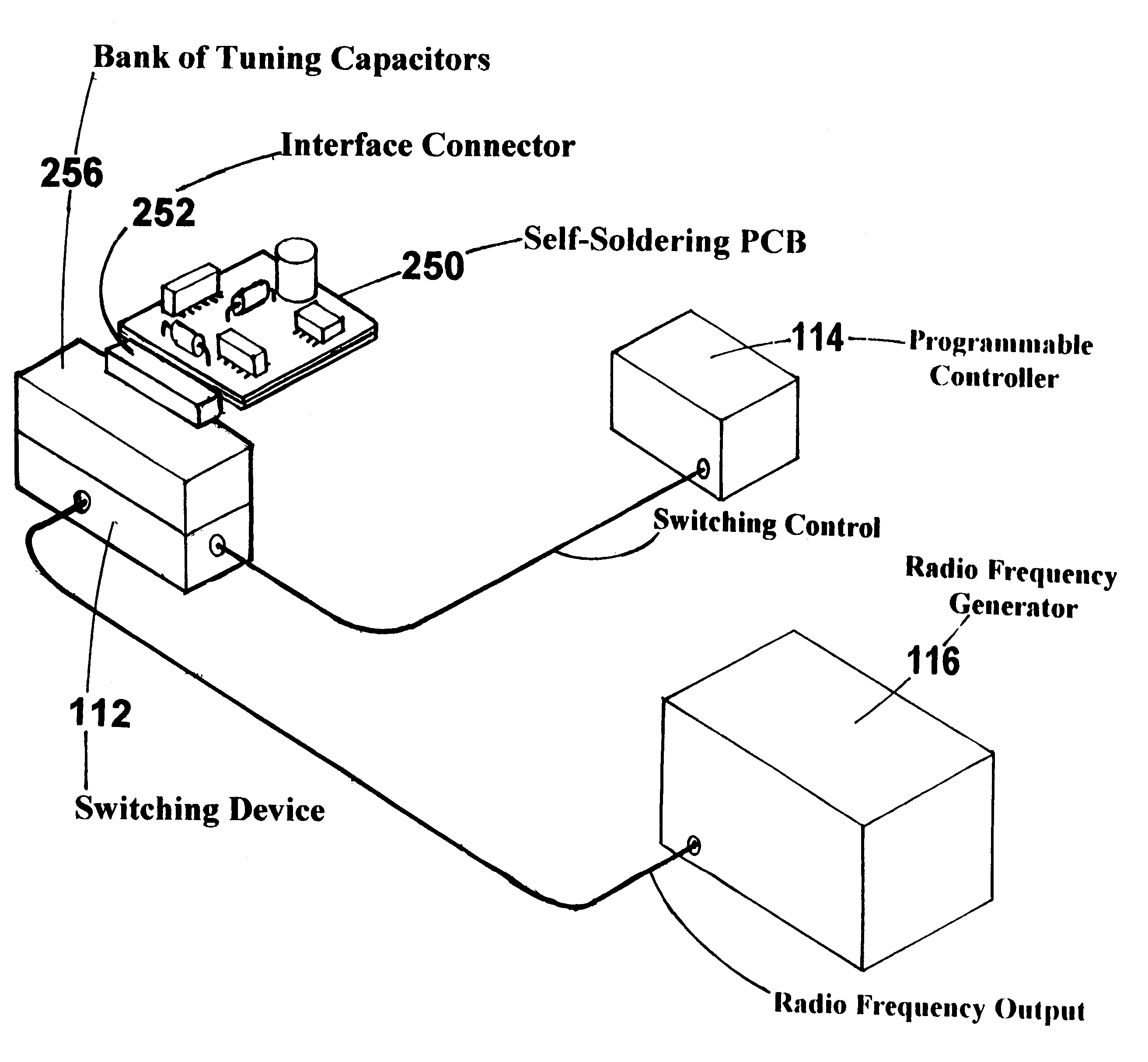

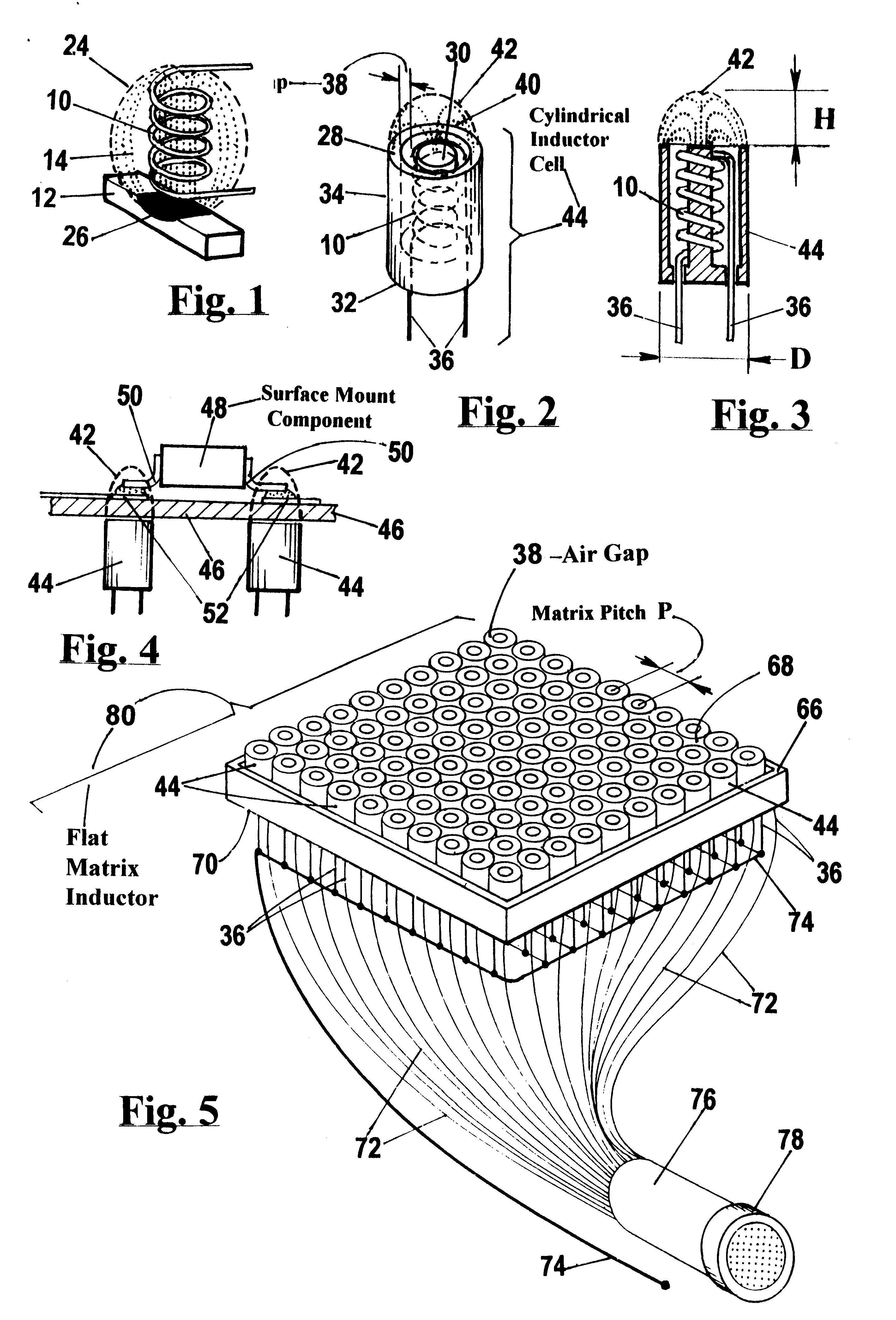

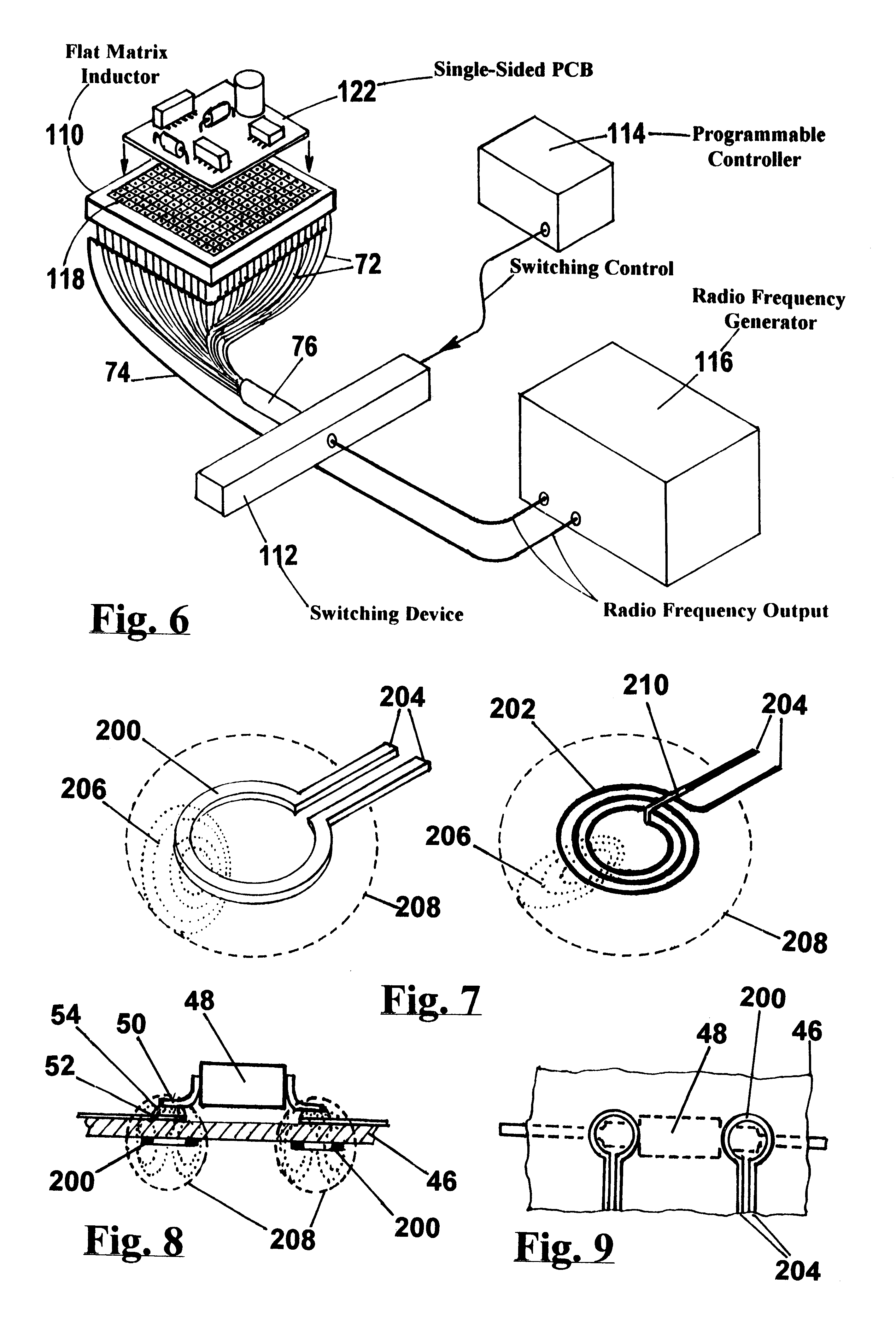

Inductive self-soldering printed circuit board

InactiveUS6229124B1Improve quality and reliabilityReduce formationPrinted circuit assemblingCoil arrangementsManufacturing technologyHeat sensitive

A new apparatus for inductively soldering surface-mount, straddle-mount and through-hole type electronic components into a self-soldering PCB (printed circuit board) in an automated fashion utilizing localized Electromagnetic Induction Heating (E.I.H.). Current manufacture technology for packaging electronic components depends on the reflow and wave soldering processes. Both processes heat up to relatively high temperatures the entire assembly, namely its PCB and all the electronic components being soldered into it. Such harsh high-temperature environment frequently causes components damage resulting in rejects and / or demanding rework. With this invention reflow oven and / or wave soldering equipment is not required. During a soldering operation only the leads and pads being soldered are heated but neither the body of said electronic components nor the dielectric material forming said self-soldering PCB and its interconnecting traces are heated. Because of this selectively localized inductive heating, the invention permits to reduce cost and improve the quality and reliability of manufactured products. The invention consumes about 200 times less energy than the reflow and wave soldering processes. This invention can readily be utilized to complement and / or supplement the reflow and wave soldering processes by providing selective inductive self-soldering of odd-form and / or heat-sensitive components. The invention also allows in-process, and in-situ, testing of soldered joints quality thus permitting rework before final assembly of a self-soldering PCB is completed. This invention also provides for a useful inductive de-soldering apparatus.

Owner:TRUCCO HORACIO ANDRES

Production/injection line and methods relating to same

A production / injection line including a production / injection tube and heating apparatus for heating of the production / injection tube. The line also includes insulation and heat conductive material to control the heat transfer from the heating apparatus towards the production / injection tube. A method is also described for supplying heat to a production / injection line in which cooling fluid from a process on an installation is supplied to transport channels extending along a production / injection tube. Methods are also described for manufacturing a production / injection line.

Owner:AKER SOLUTIONS AS

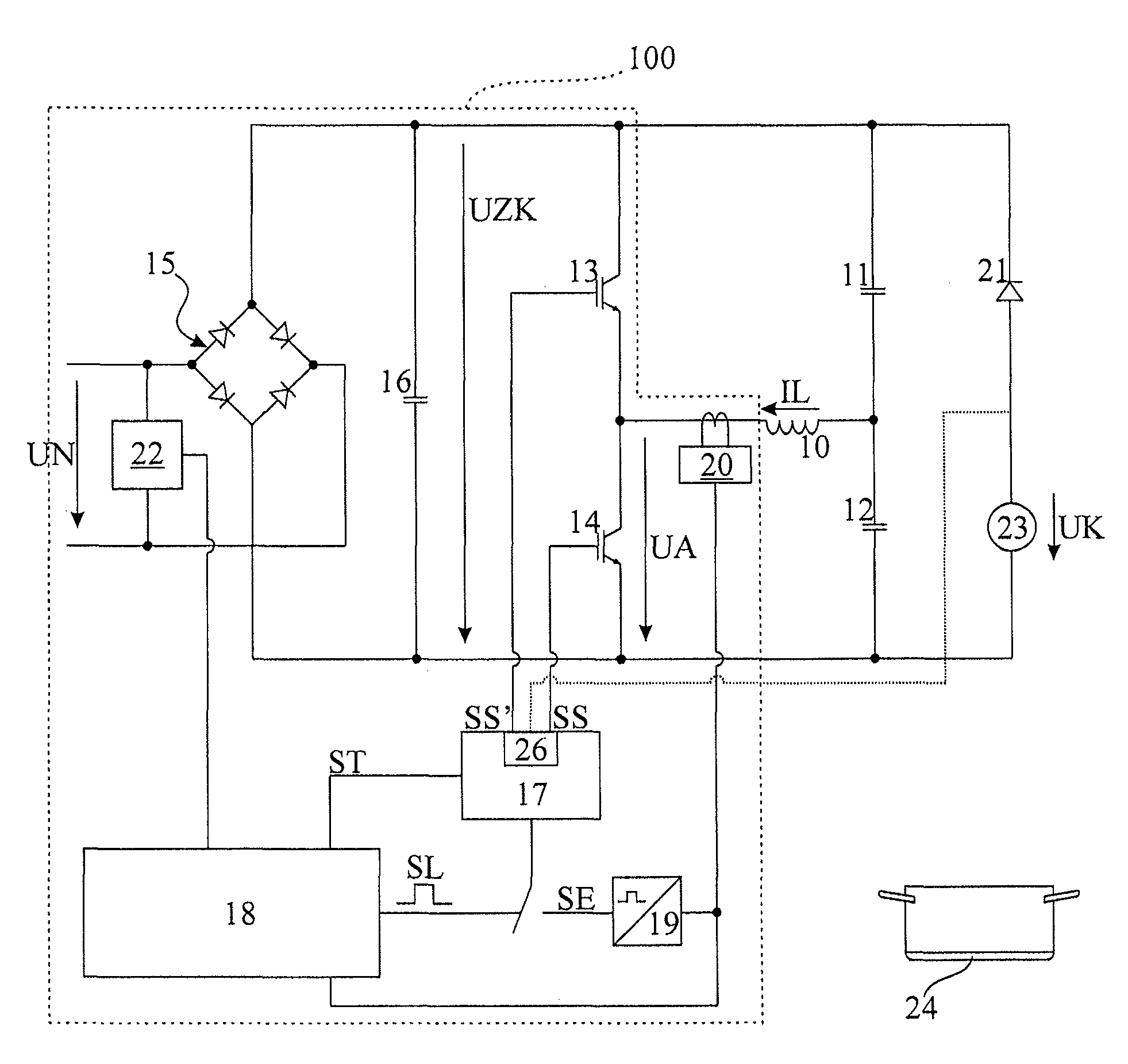

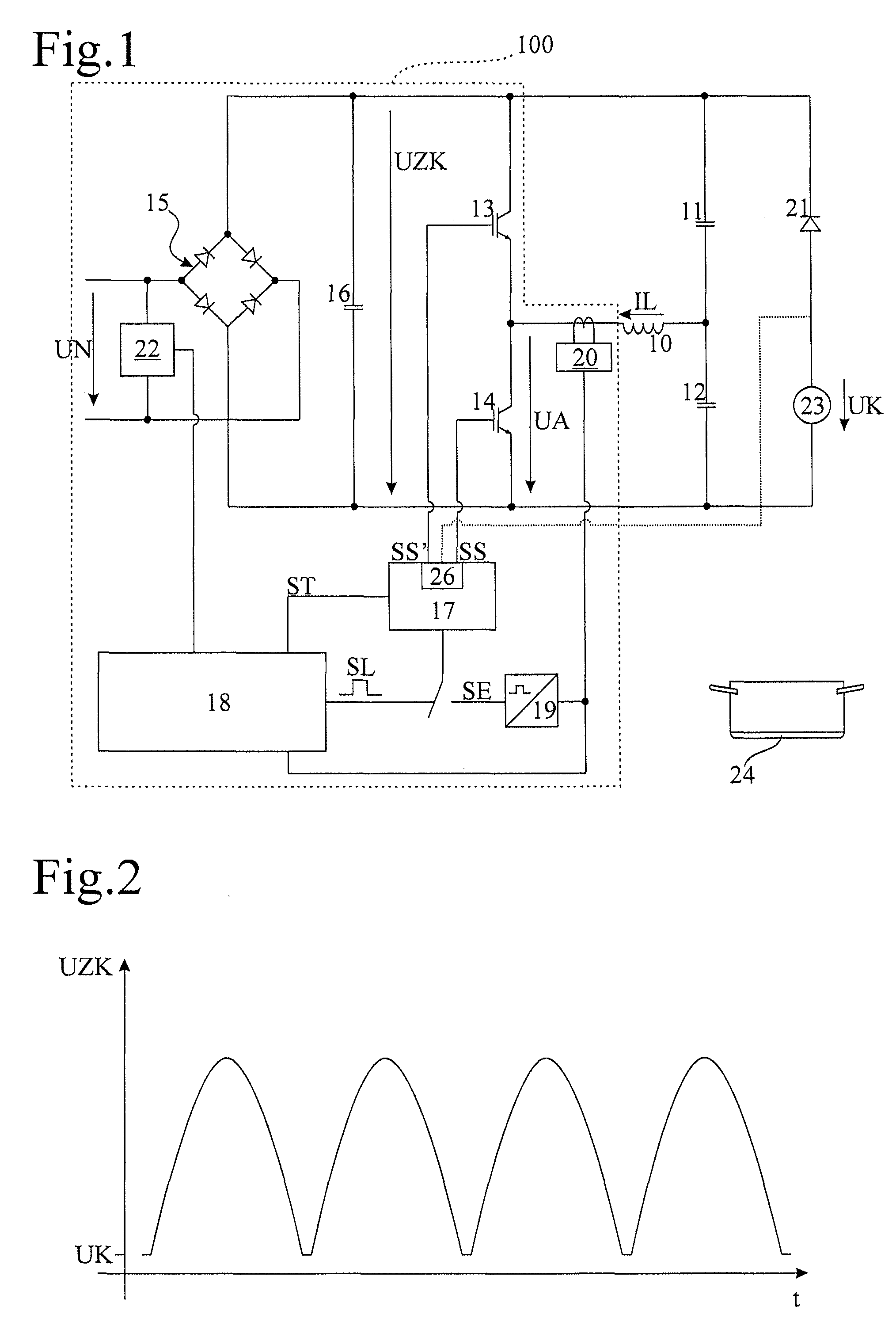

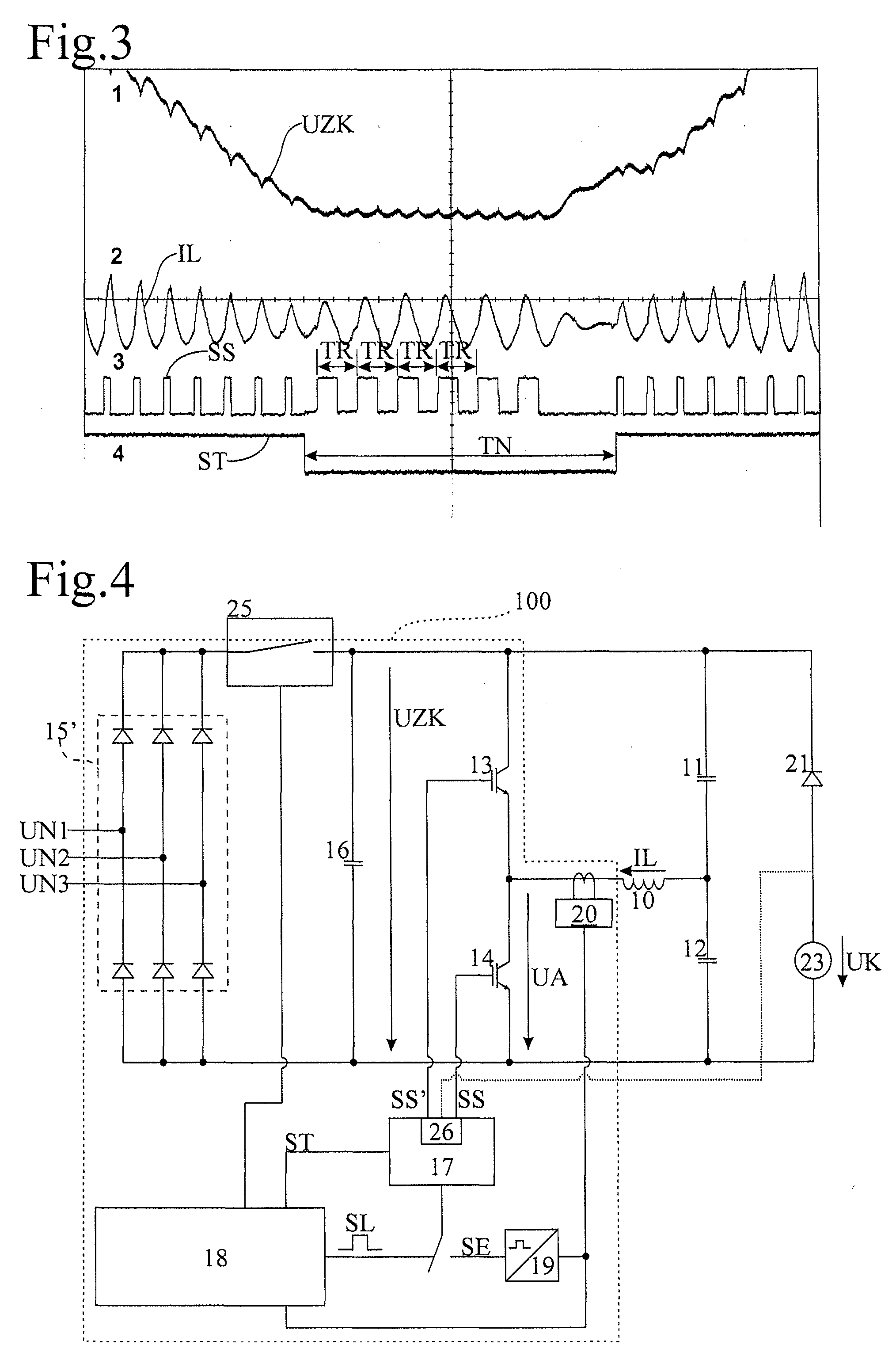

Method and induction heating device for determining a temperature of a cooking vessel base which is heated by means of an induction heating coil

ActiveUS20110120989A1Avoid switchingAvoid noiseThermometers using physical/chemical changesInduction current sourcesEngineeringFrequency oscillation

An induction heating device comprises a frequency converter that generates a high-frequency drive voltage from an intermediate circuit voltage generated at least temporarily as a function of an AC mains voltage, a resonant circuit having an induction heating coil, with the drive voltage applied to the resonant circuit, and a temperature detection device that determines a temperature of a cooking vessel base which is heated by means of the induction heating coil. An auxiliary voltage source generated the intermediate circuit voltage over predefined time periods at a constant level. The frequency converter generates the drive voltage over time periods such that the resonant circuit oscillates at a natural resonant frequency in a substantially de-attenuated manner, and the temperature detection device further measuring at least one oscillation parameter over the time periods, and to evaluate the at least one measured oscillation parameter in order to determine the temperature.

Owner:E G O ELEKTRO GERAETEBAU GMBH

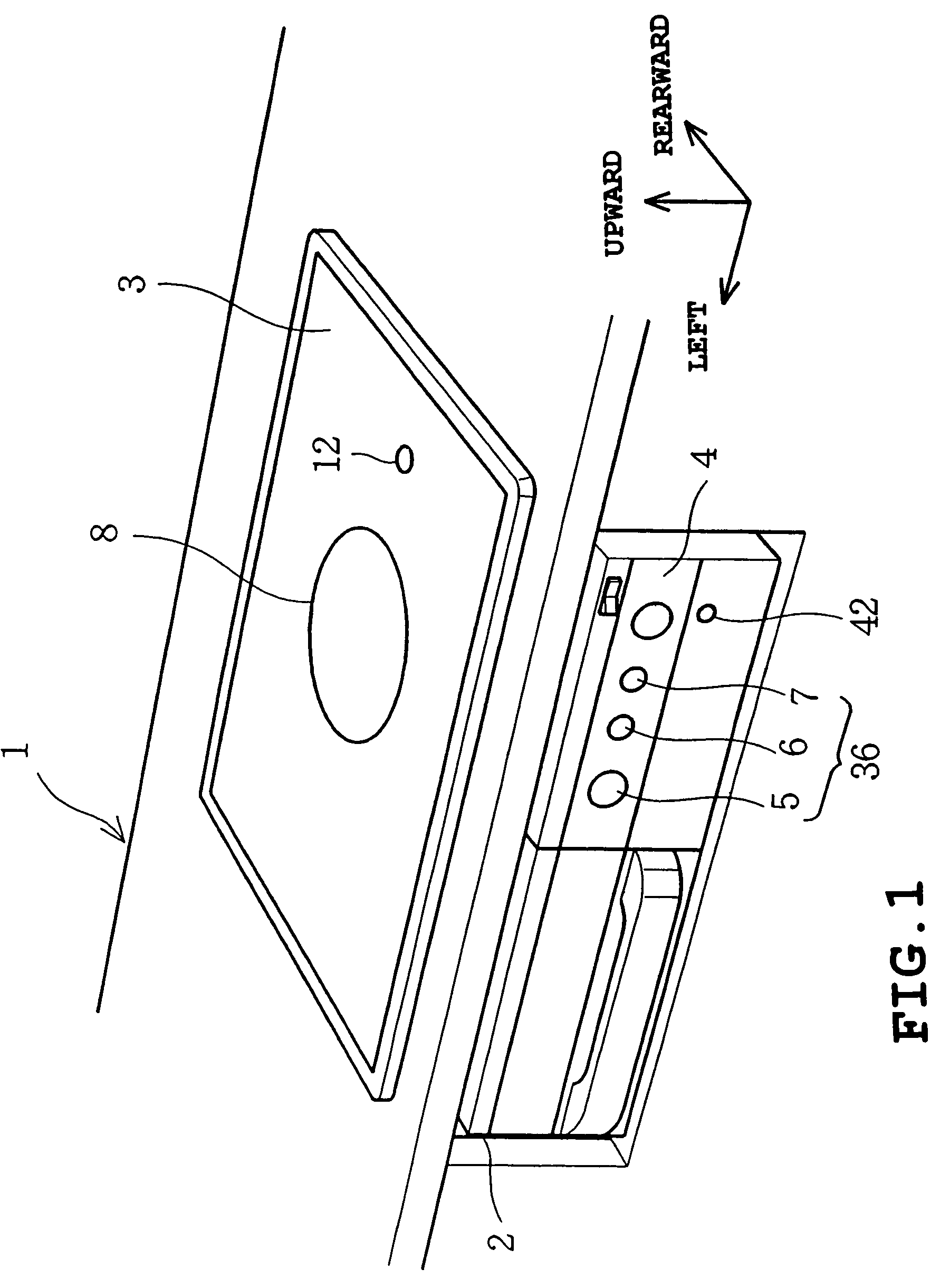

Heat cooking apparatus, cooking tool and heat cooking system

InactiveUS20070080158A1Reduce heatImprove accuracyCooking vesselsInduction heating controlInfraredProcess engineering

A heat cooking apparatus includes a supporting unit for supporting a cooking tool, a heating unit for heating the cooking tool, a receiving unit capable of receiving temperature data of the cooking tool transmitted in the form of infrared rays from the exterior, and a controlling unit for controlling the heating unit on the basis of temperature data received by the receiving unit.

Owner:IRIS OHYAMA

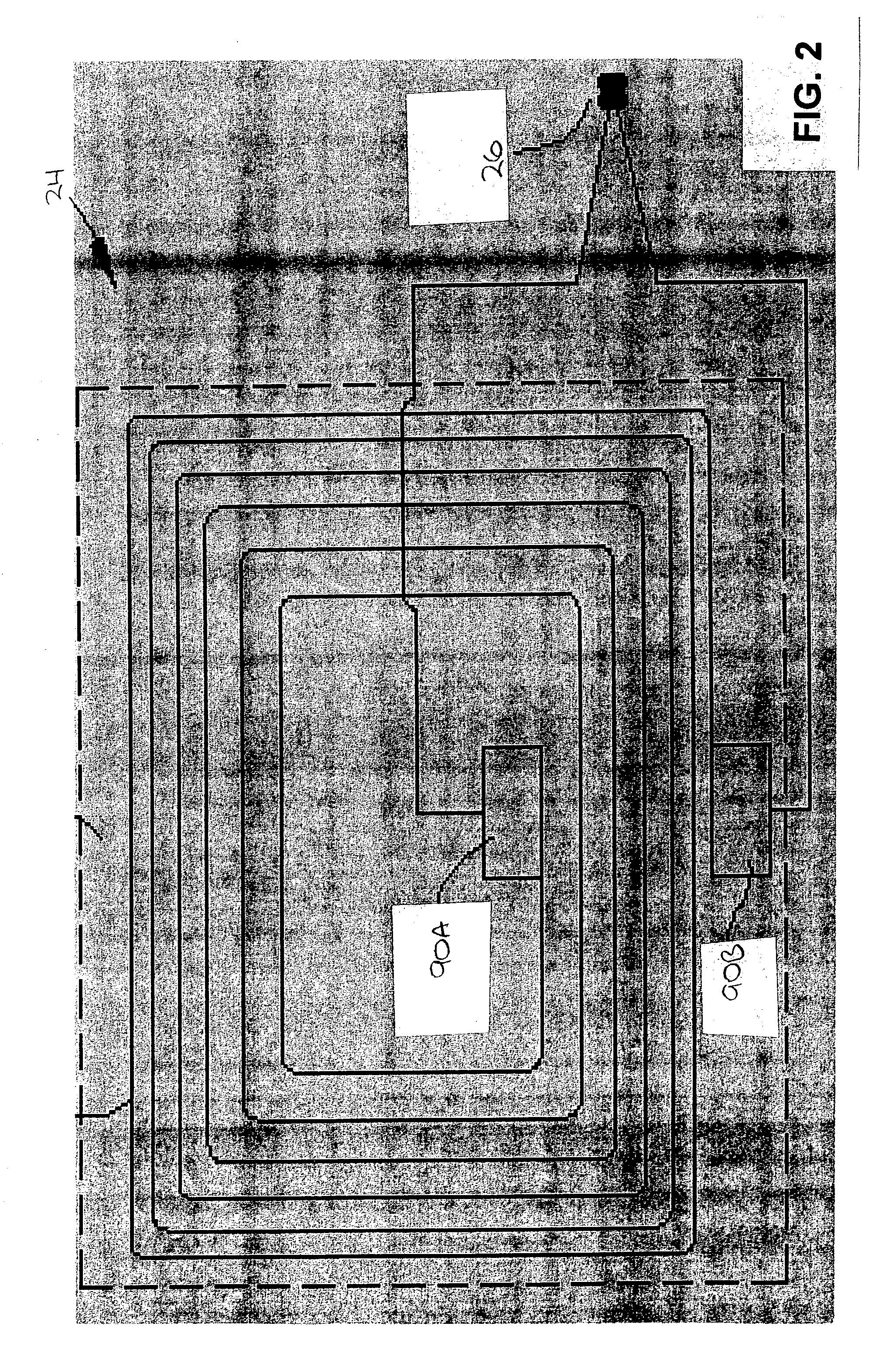

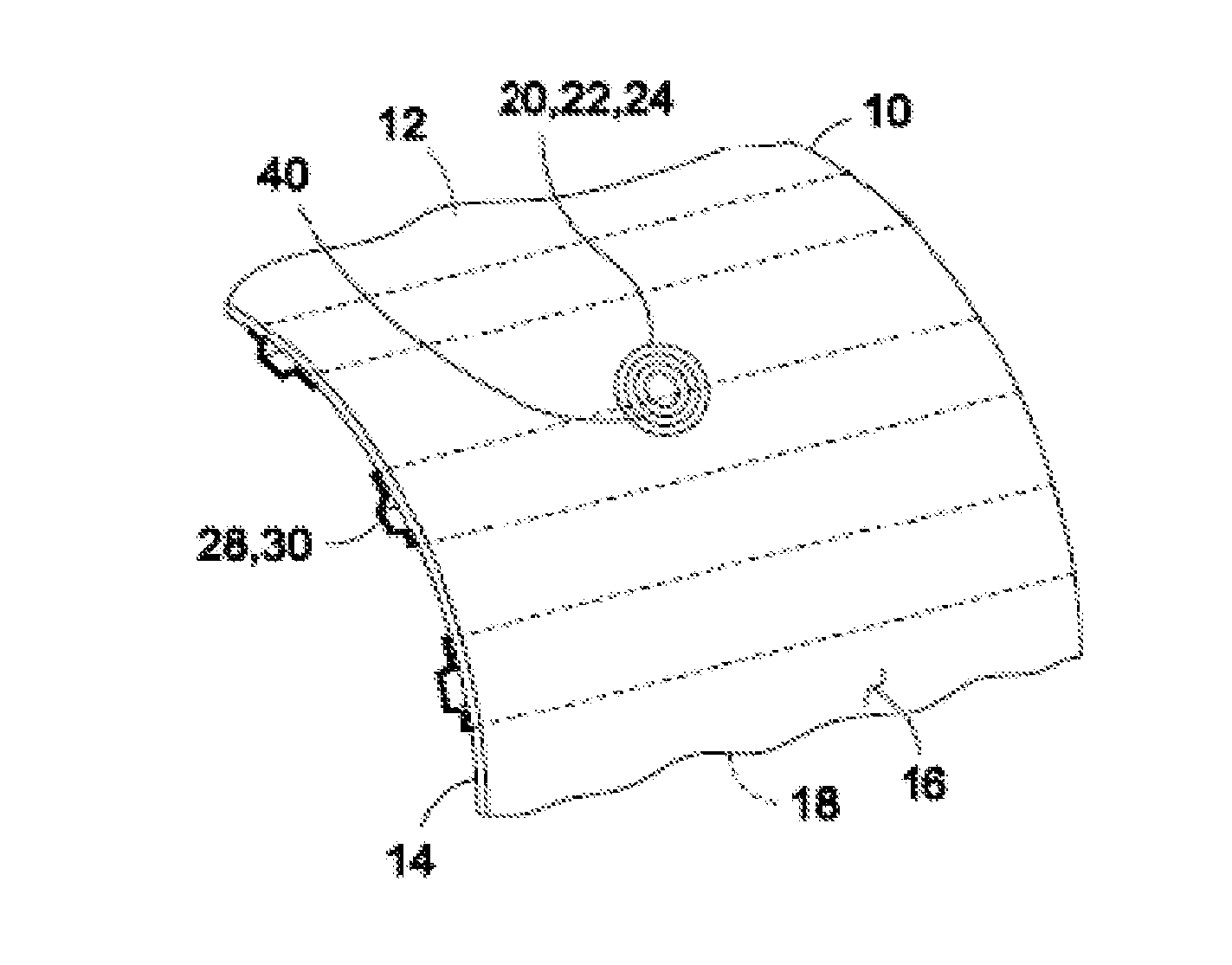

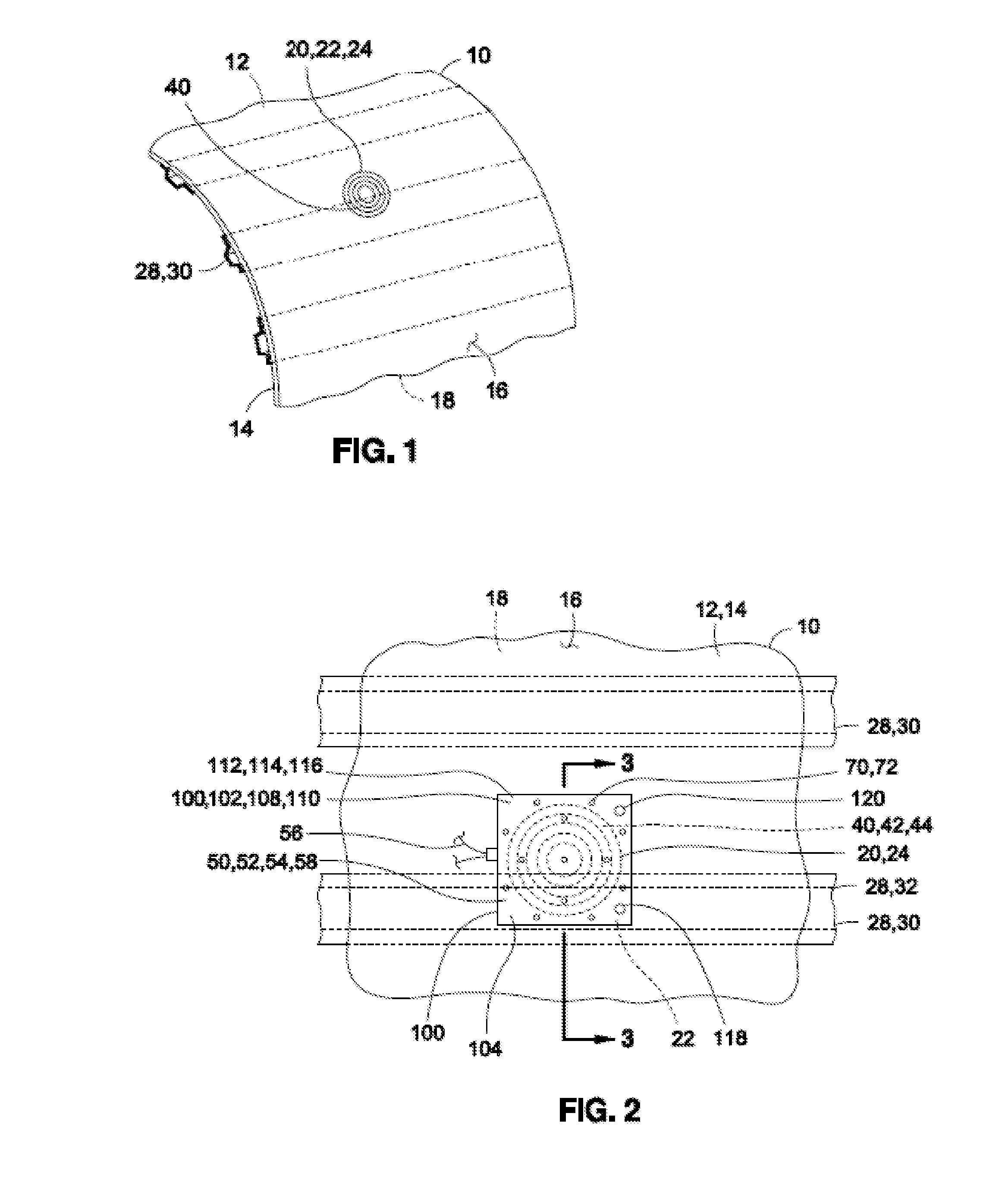

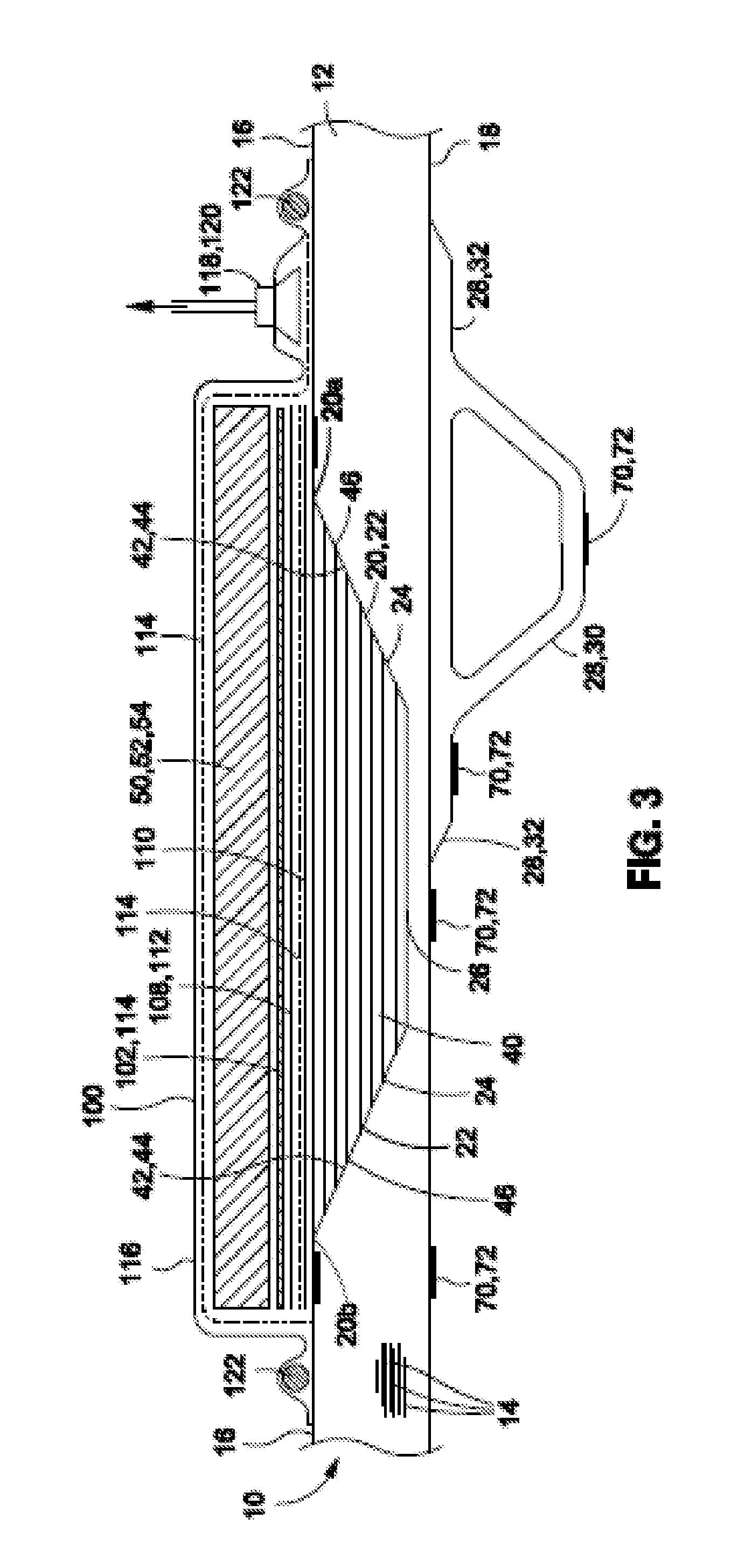

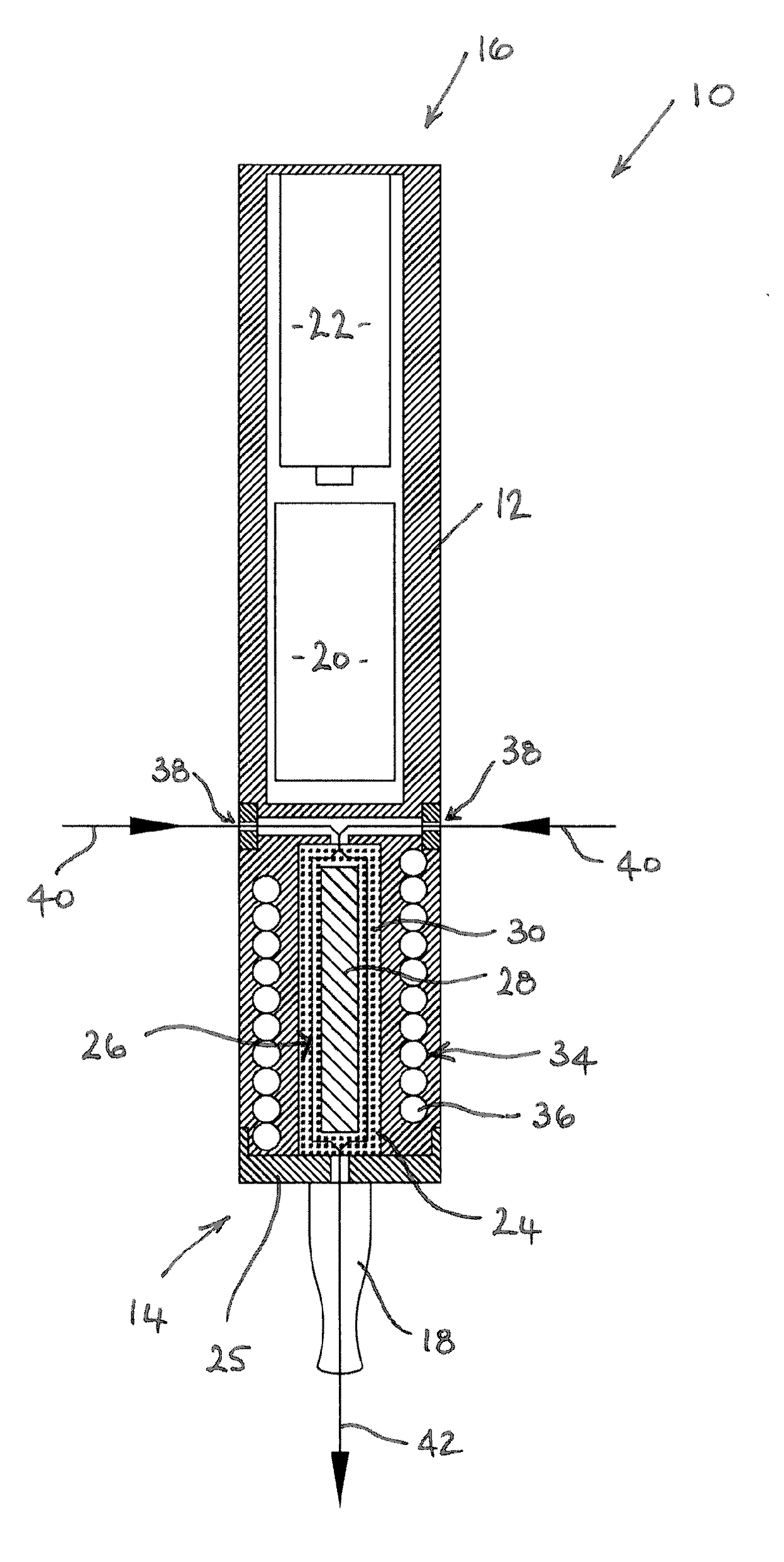

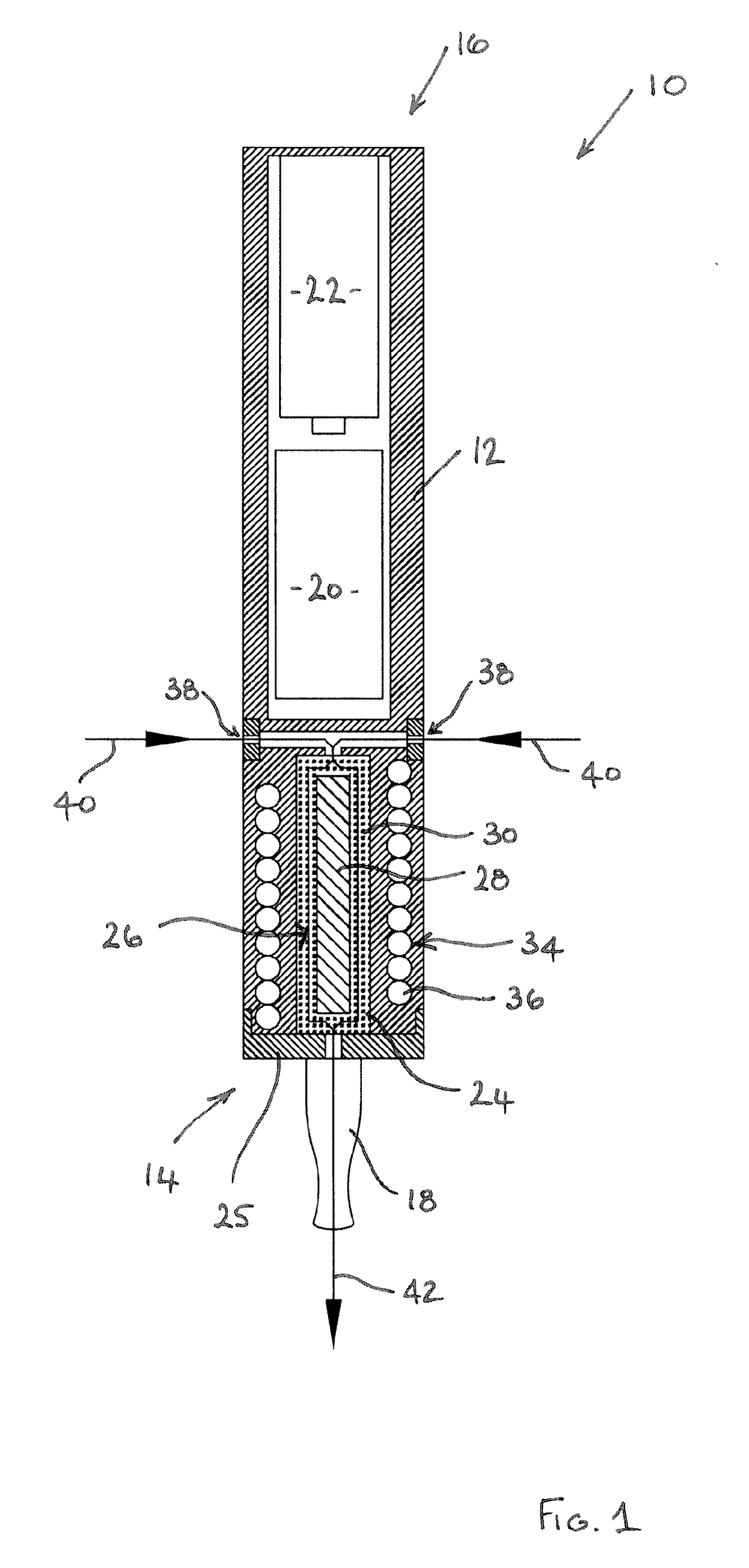

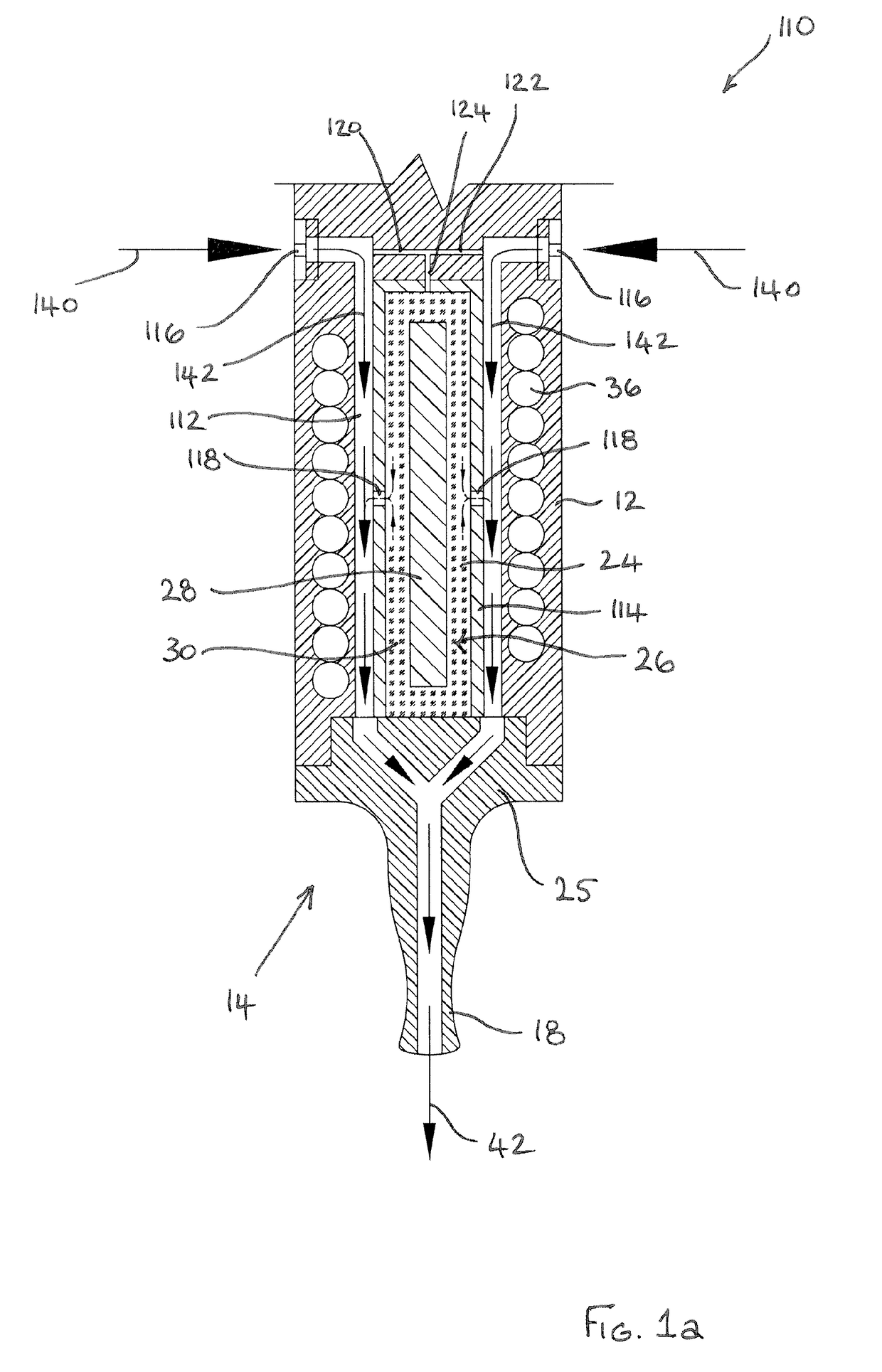

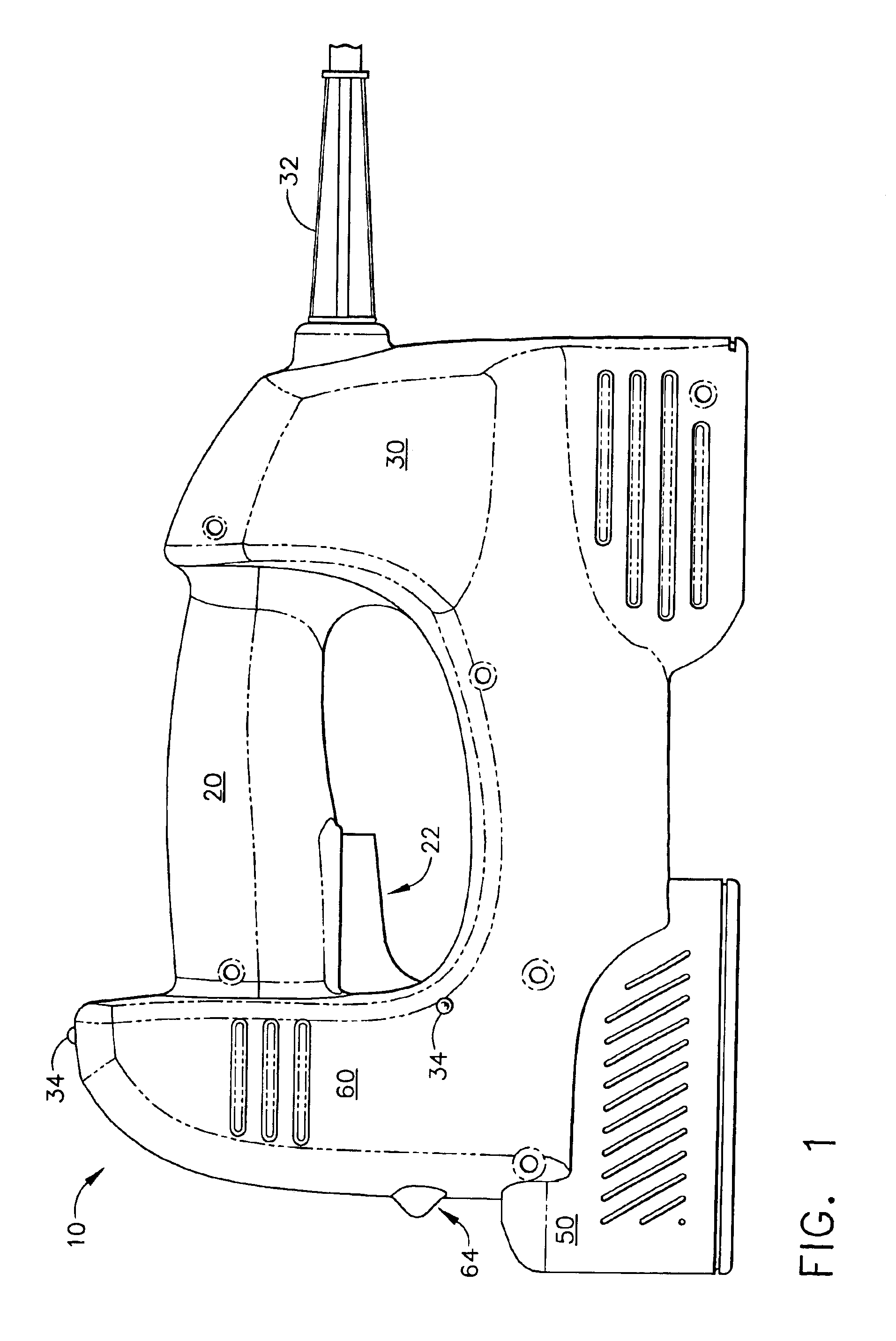

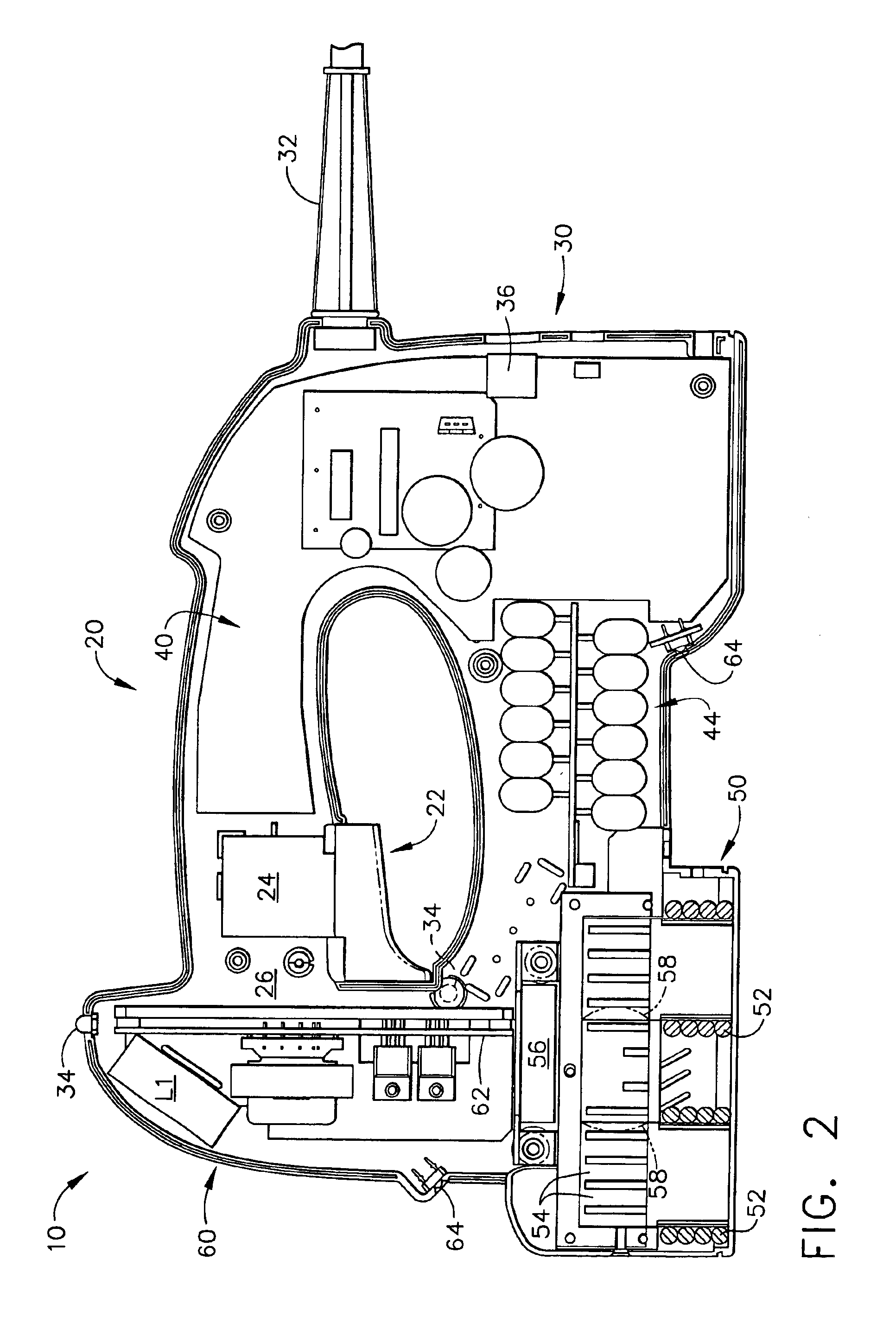

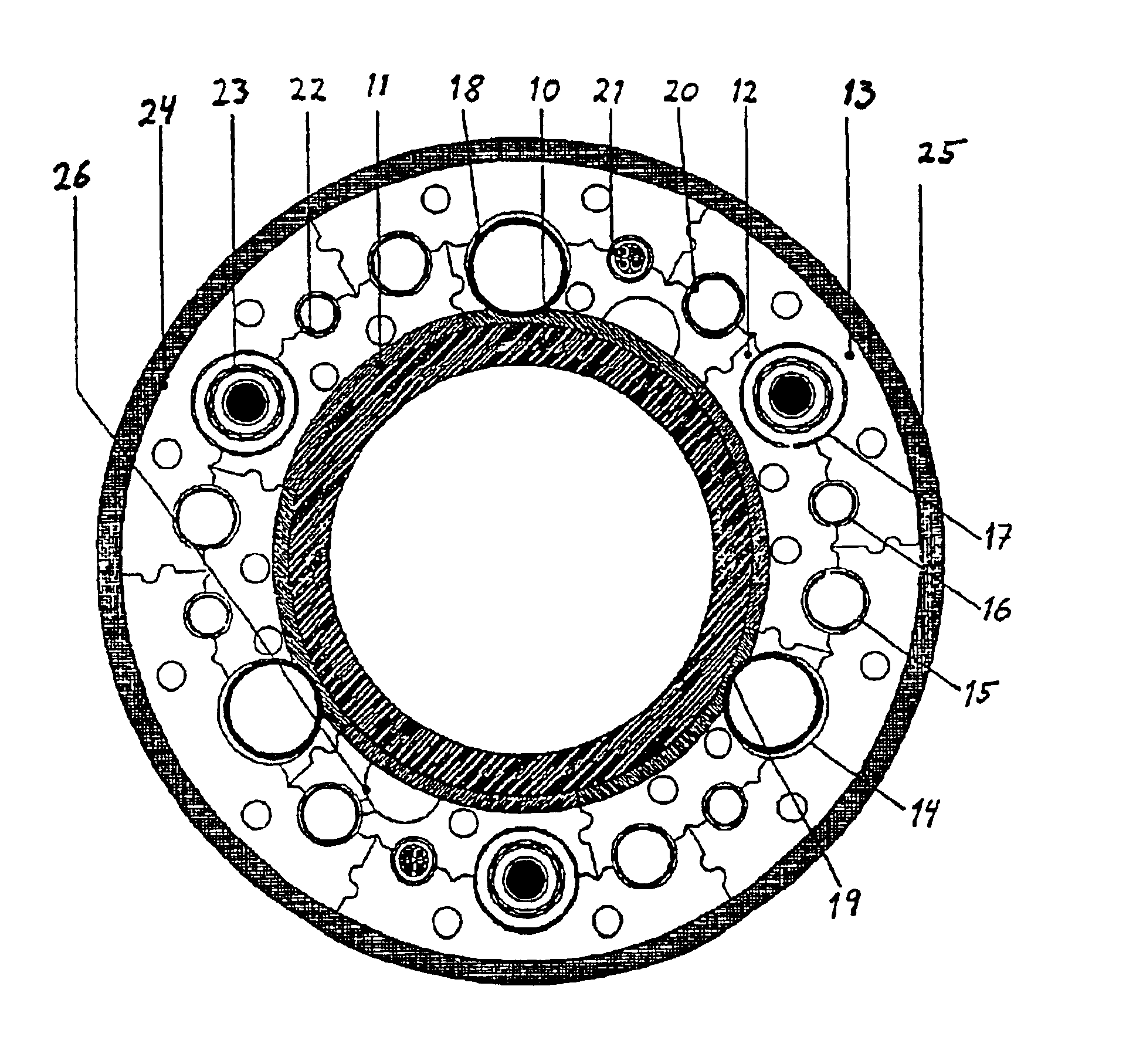

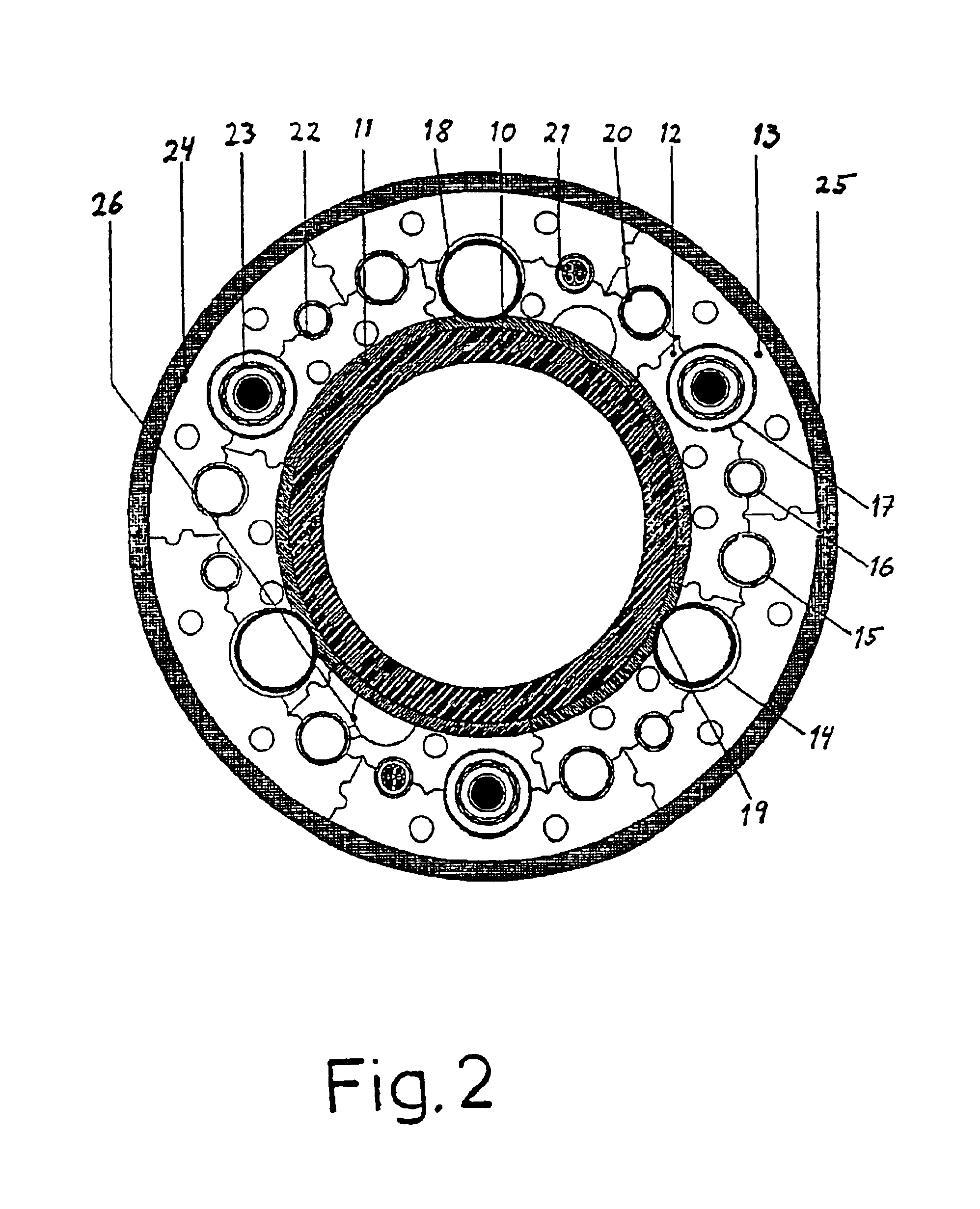

Radio frequency antenna for heating devices

ActiveUS20090194526A1Little induced voltage (noise)Reduce areaElectric signalling detailsInduction heating controlInduction heaterEngineering

The present invention provides an improved antenna assembly (66) designed to maintain RF communication between an object (22, 64, 148) to be heated, and a heating assembly (20, 60) such as an induction heater having a hob (34) equipped with an induction work coil (36). The antenna assembly (66) provides substantially continuous RF communication about the entirety of the hob (34), so that the object (22, 64, 148) can be rotated through substantially 360E, or displaced radially, without loss of RF communication. The preferred antenna assembly (66) includes an antenna (67) mounted upon a substrate (68) and presenting a plurality of continuous, conductive antenna loops (70, 72) oriented to cooperatively and substantially around the hob (34). Each of the loops (70, 72) has an inner section (82, 84) proximal to the hob (34) and defines a respective, enclosed RF communication zone (94,96) outboard of and disposed about the hob (34); the zones (94,96) cooperatively define a substantially continuous RF communication zone outboard of and disposed about the hob (34). The antenna assembly (66) also includes antenna circuitry 97 including tuning assemblies (98, 100) and a terminal network (102). In alternative forms, radiant, resistant heating, or other types of heating hobs can be used.

Owner:TSI TECH

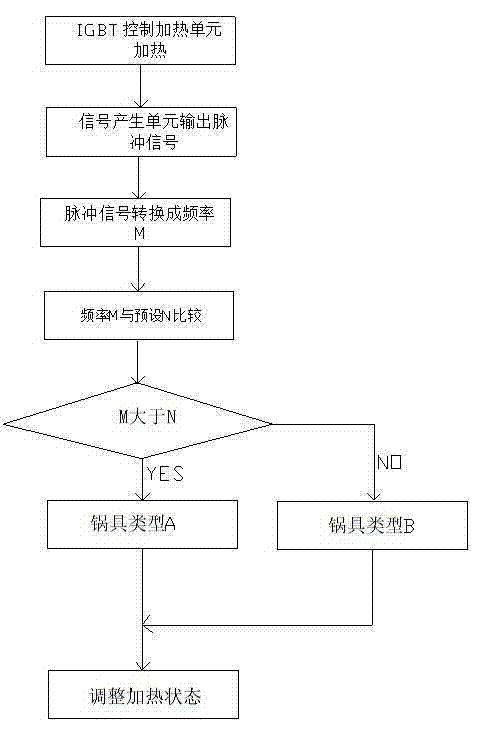

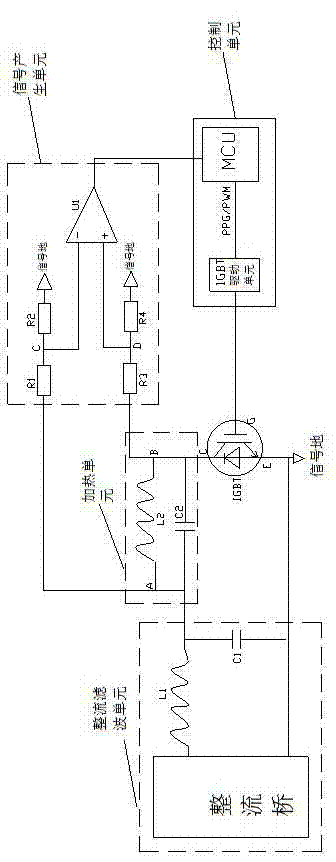

Control circuit for cookware material judgment and method thereof

ActiveCN102905411AAdjust heating statusImprove heating efficiencyInduction heating controlInduction heating apparatusError checkElectromagnetic heating

The invention discloses a control circuit for cookware material judgment and a method thereof. The method comprises the following steps: when an electromagnetic heating device works, a control unit controls an IGBT (Insulated Gate Bipolar Transistor) so as to enable a heating unit to heat; a signal generating unit outputs pulse signals to an MCU (Micro Controller Unit) of the control unit correspondingly according to the on / off state of the IGBT; the MCU records the input pulse signals and converts the pulse signals into frequency M; the frequency M is compared with preset frequency threshold N, and the type of cookware is determined to be A when the frequency M is higher than the preset frequency threshold N; the type of the cookware is determined to be B when the frequency M is less than or equal to the preset frequency threshold N; and the MCU adjusts related heating parameters according to the determined type of the cookware, so as to enable the electromagnetic heating device to adjust a heating state. The control circuit and the method have the advantages that an electromagnetic oven can be adjusted into a working state corresponding to the material of the cookware, the material of the cookware is judged in good time so as to carry out error check, and the like; and the material of the cookware is accurately updated so as to adjust the heating state and increase the heating efficiency.

Owner:MIDEA GRP CO LTD

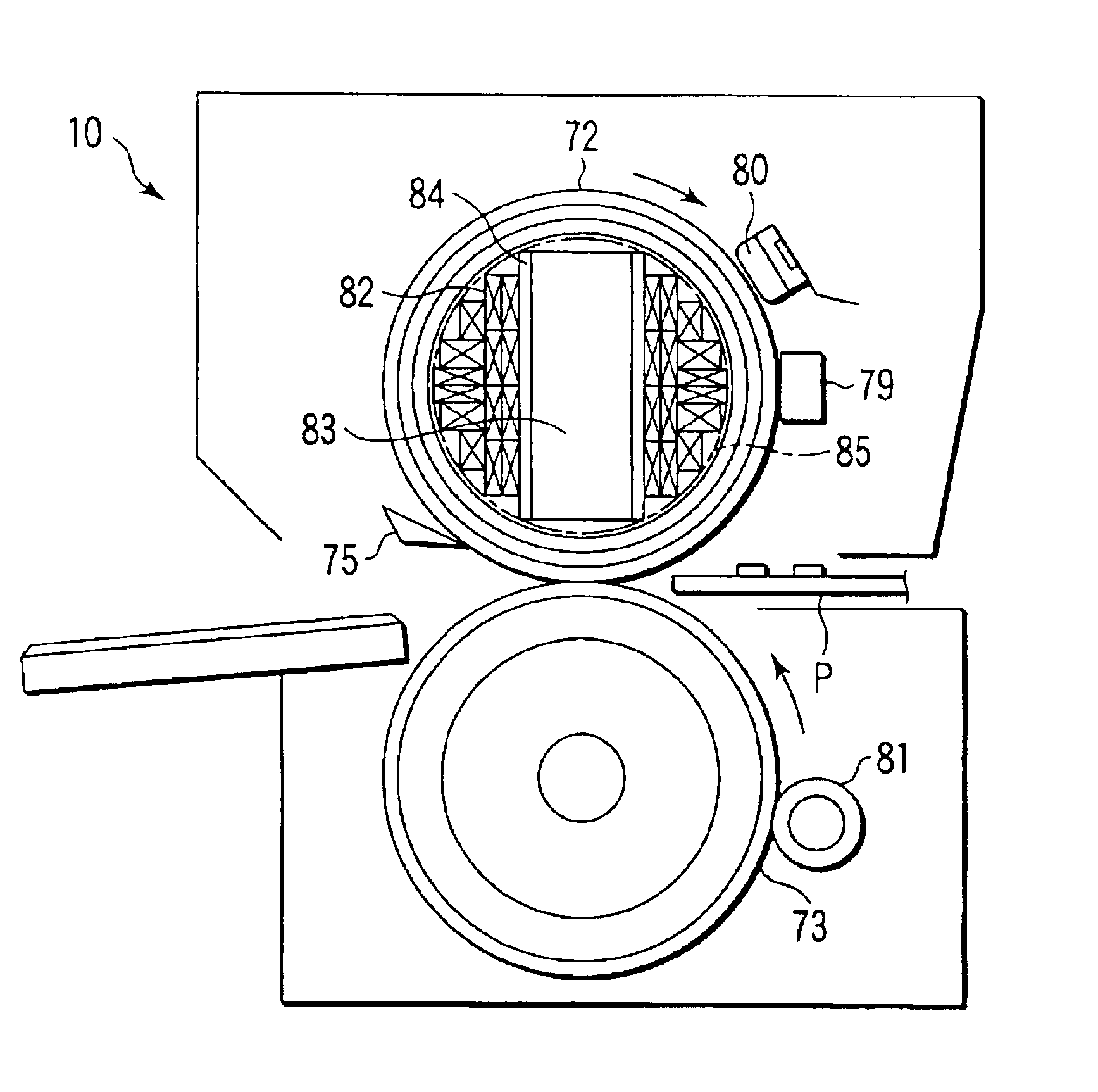

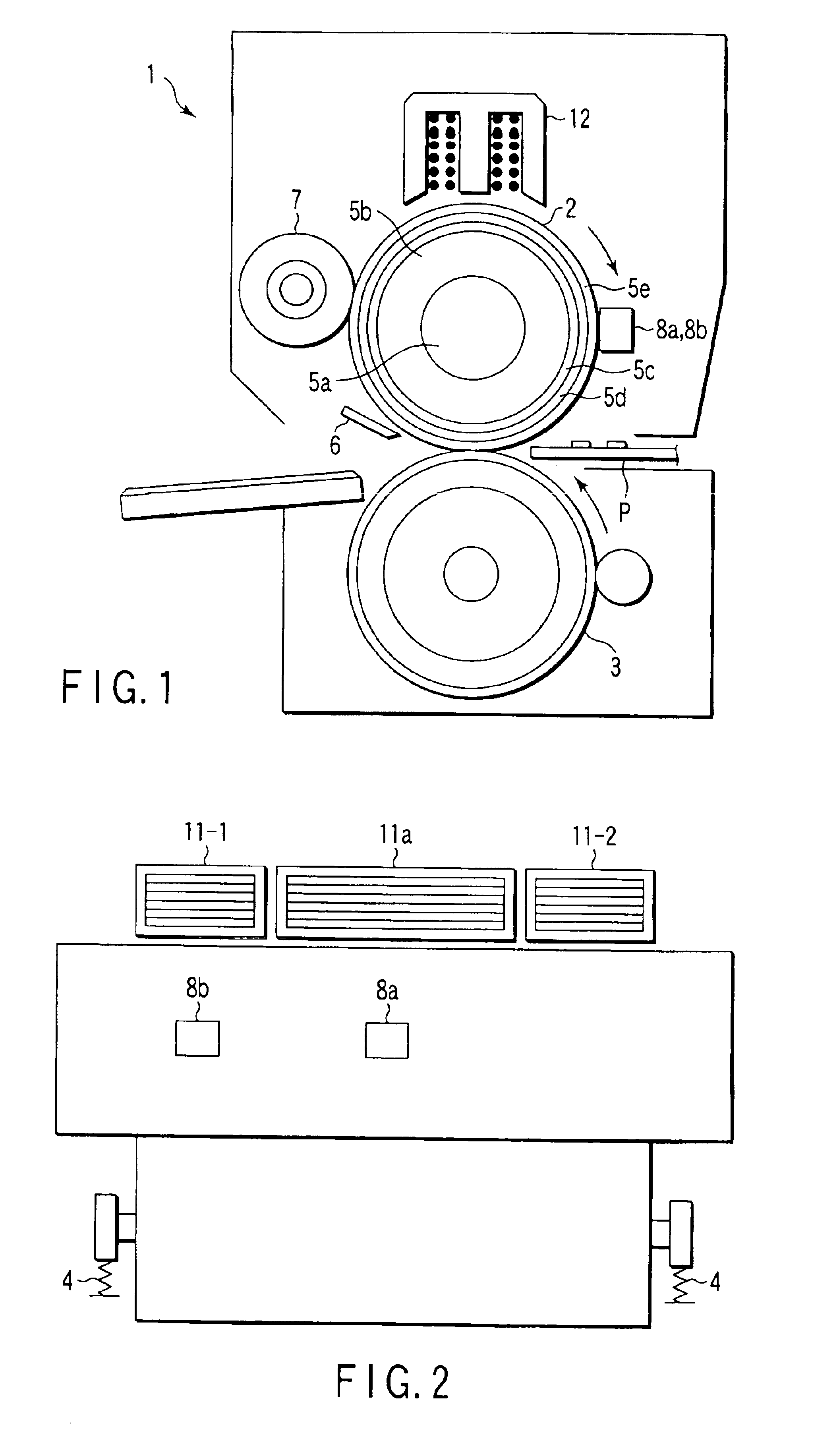

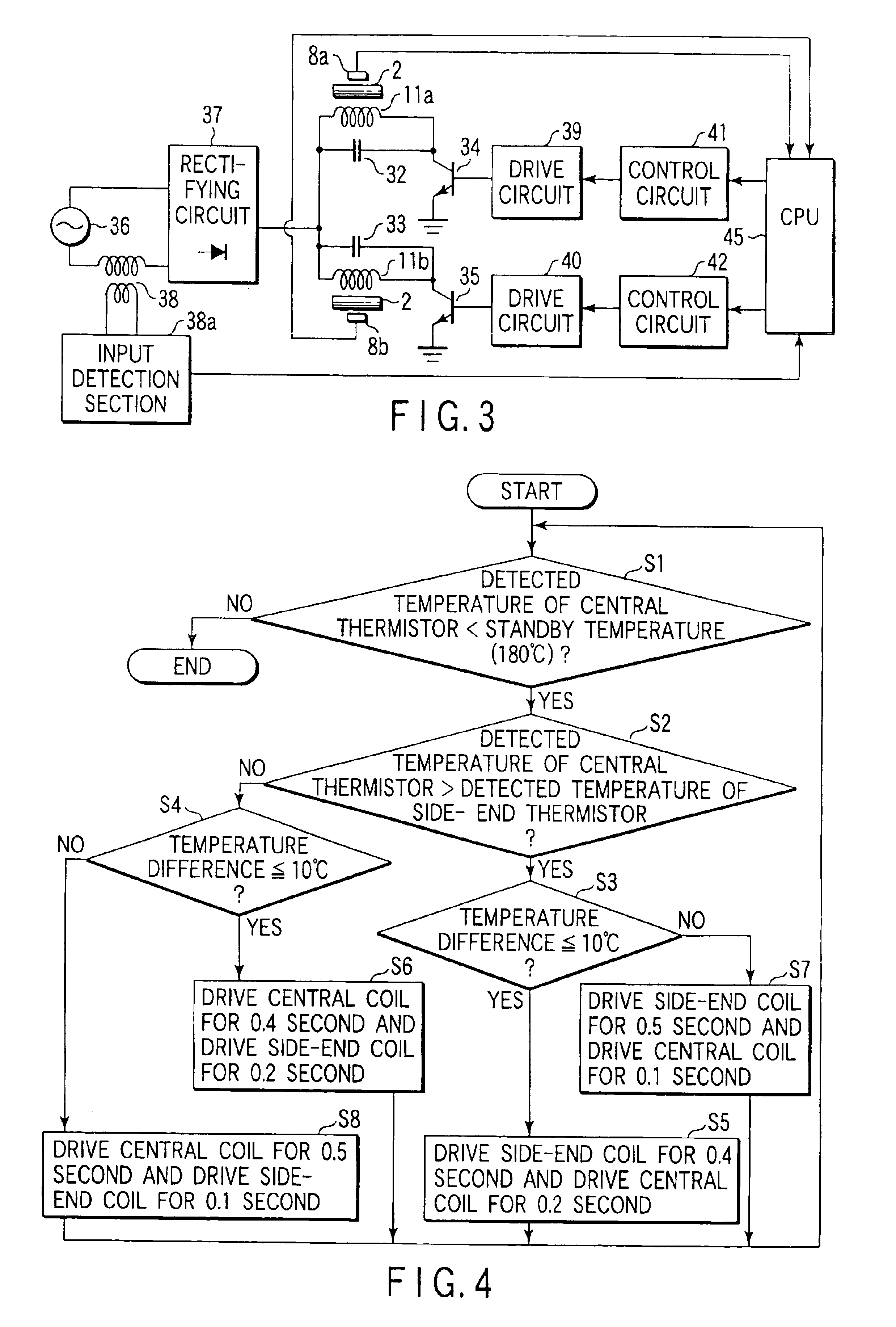

Heating device and fixing device

InactiveUS6861630B2High densityCoil arrangementsElectrographic process apparatusTemperature differenceEngineering

A CPU detects a temperature of a central part of a heating roller. If the detected temperature does not exceed 180° C., the CPU drives a central coil or a side-end coil for 0.4 second in accordance with a temperature difference between the central part of the heating roller and a side-end part of the heating roller. Then, the CPU drives the side-end coil or central coil for 0.2 second. Thereafter, the CPU detects the temperature of the central part and repeats the driving control until the detected temperature reaches 180° C.

Owner:KK TOSHIBA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com