Tunnel structure monitoring system and tunnel structure monitoring method based on distributed long-gauge fiber bragg grating

A fiber grating and tunnel structure technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as short time, and achieve the effects of disaster prevention, simple layout, and low monitoring cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

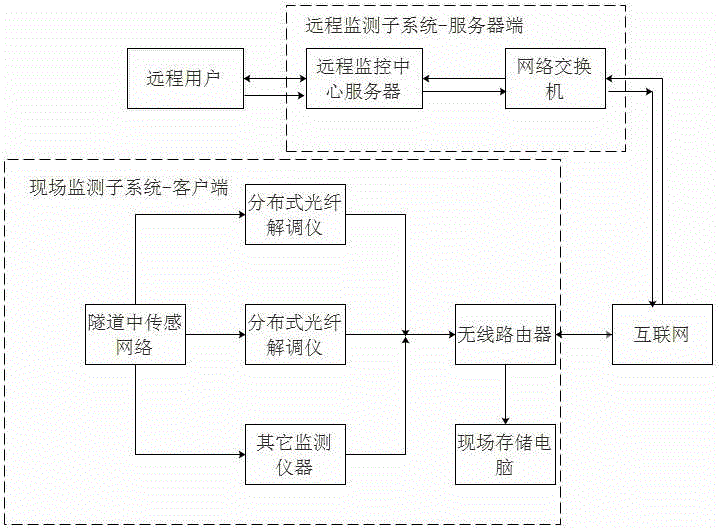

[0037] The distributed optical fiber grating sensing tunnel health monitoring system of this embodiment includes a sensing optical fiber arranged in the tunnel and a processing system for collecting and sensing optical fiber data.

[0038] Distributed long gauge fiber grating sensors or other distributed fiber grating sensors can be used in this system. Distributed sensors can be divided into two types: horizontal layout and vertical layout.

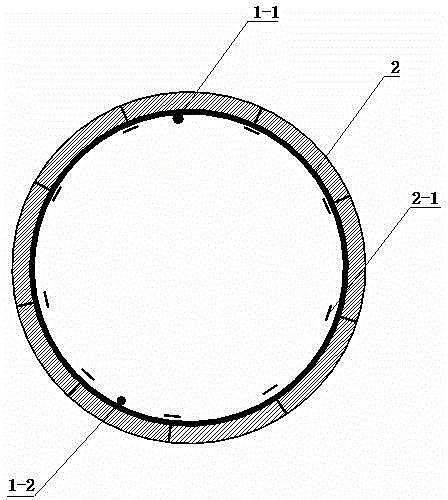

[0039] Taking the shield segment during the construction period as an example to illustrate, the schematic diagram of the sensor layout is as follows figure 1 shown.

[0040] The first sensors arranged along the entire length of the tunnel include a top sensor 1-1 at the vault of the tunnel and a bottom sensor 1-2 at the bottom of the tunnel for monitoring the settlement of the tunnel. The second sensor 2 arranged circumferentially along the inner surface of the tunnel lining structure is used to monitor the diameter change of the tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com