Observation system for saturation line of dam body of tailing reservoir

An observation system and wetting line technology, which is applied in liquid/fluid solid measurement, measuring devices, lubricating parts, etc., can solve the problem of harsh working environment, distortion of dam soaking line observation data, and large error of dam soaking line observation data and other issues, to achieve the effect of easy observation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

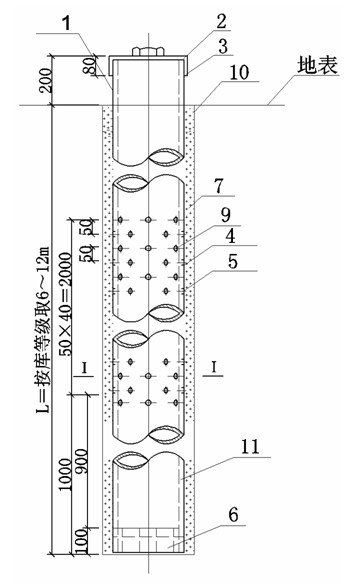

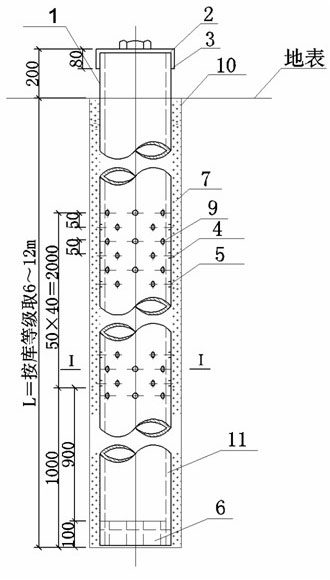

[0025] In order to further describe the present invention, the structure of an observation system for the seepage line of the tailings pond dam body of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

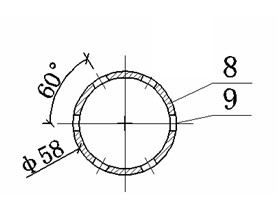

[0026] Depend on figure 1 As shown in the present invention, a kind of observation system for the infiltration line of the tailings dam body is shown in the longitudinal section structure schematic diagram, and a kind of observation system for the infiltration line of the dam body of the tailings dam of the present invention is made of steel pipe 1, steel Plug 2, screw thread 3, geotextile 4, hemp silk 5, oil-soaked cork 6 are combined to form. The steel pipe 1 is wrapped with a geotextile 4 and bound firmly with hemp silk 5 . The bottom of the steel pipe 1 is sealed firmly with an oil-soaked wood plug 6 . The steel pipe 1 is arranged in the body of the tailings dam. The lower part of the steel pipe 1 is a 0.9m-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com