Patents

Literature

180results about How to "Reduce chafing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

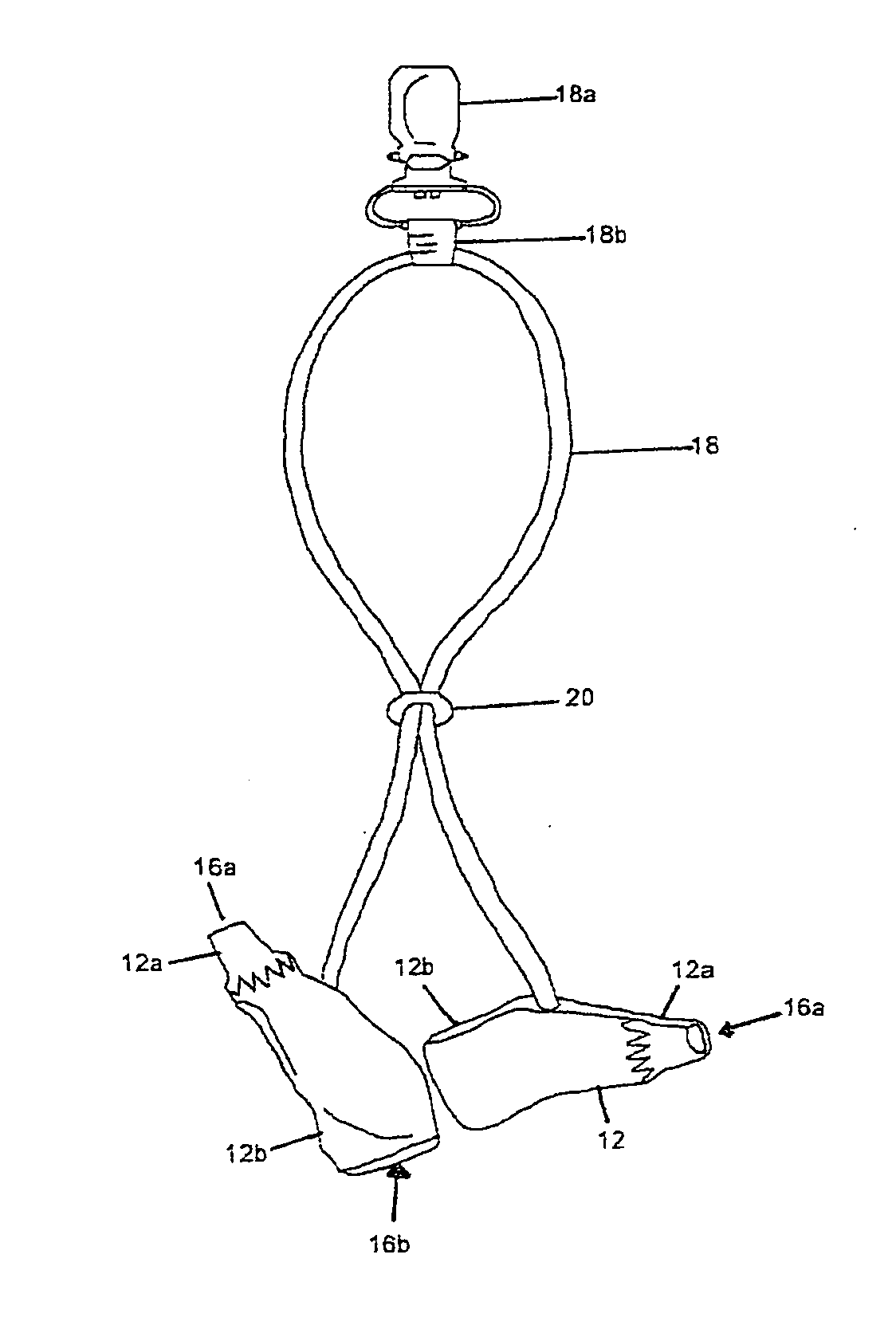

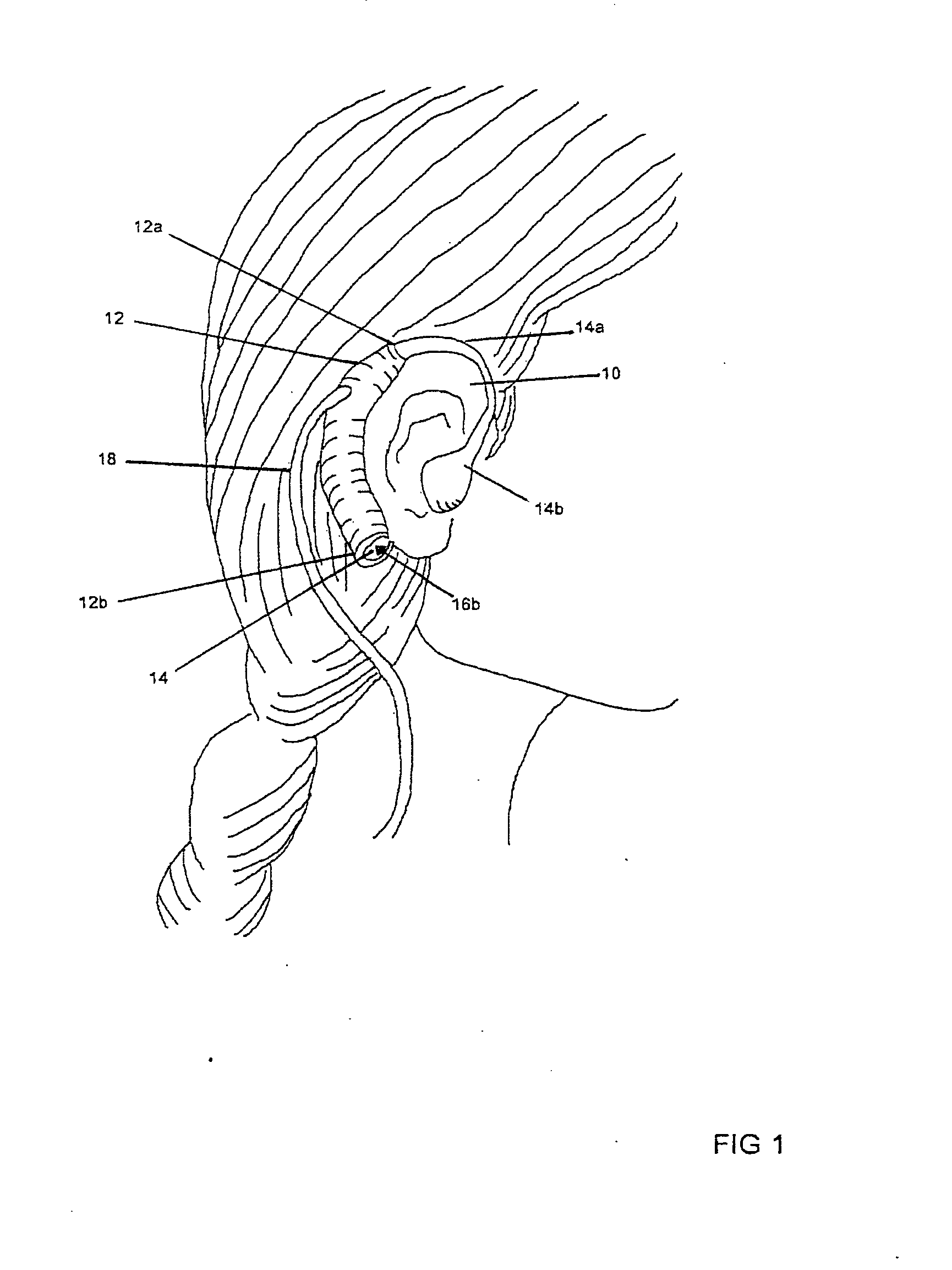

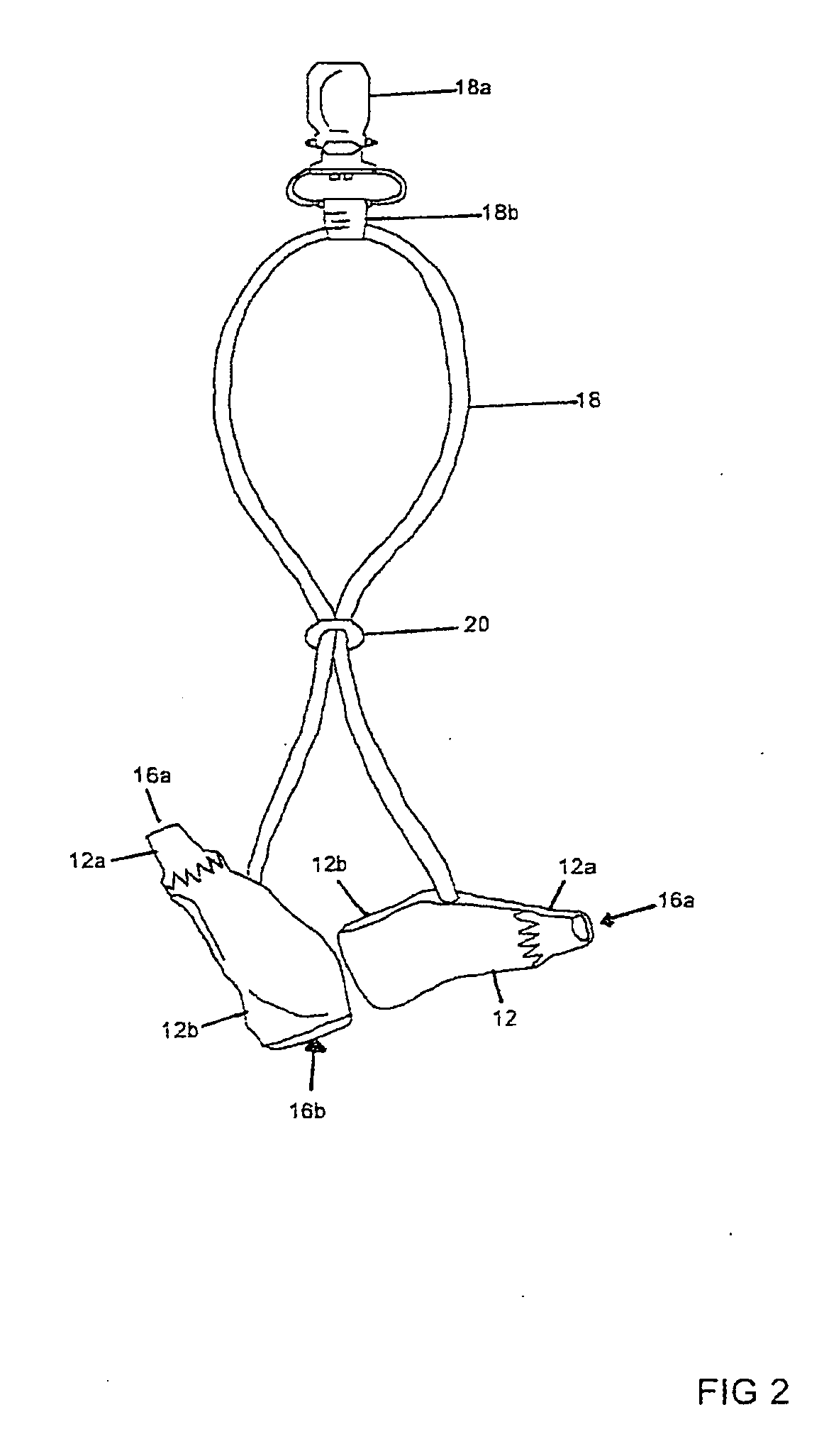

Security and protection device for an ear-mounted audio amplifier or telecommunication instrument

InactiveUS20120057740A1Comfortable to wearLight weightEarpiece/earphone attachmentsHearing aids housingAudio power amplifierEngineering

A security and protection device for an ear-mounted audio amplifier or telecommunication instrument. The device includes a resilient water-pervious hollow sleeve sized and shaped to snugly conform to the shape of an audio amplifier or telecommunication instrument having an earpiece insertable in to the ear of a user when the sleeve is slid over the instrument. The sleeve has a top opening at a top end of the sleeve and a bottom opening at an opposite bottom end of the sleeve. The bottom opening is sized to snugly receive the instrument into the hollow sleeve so as to substantially completely cover the instrument when journalled in the sleeve. The top opening is sized to snugly receive through the top opening a corresponding upper end of the instrument. The upper end of the instrument is connected to the instrument earpiece.

Owner:ROSAL MARK BRYAN

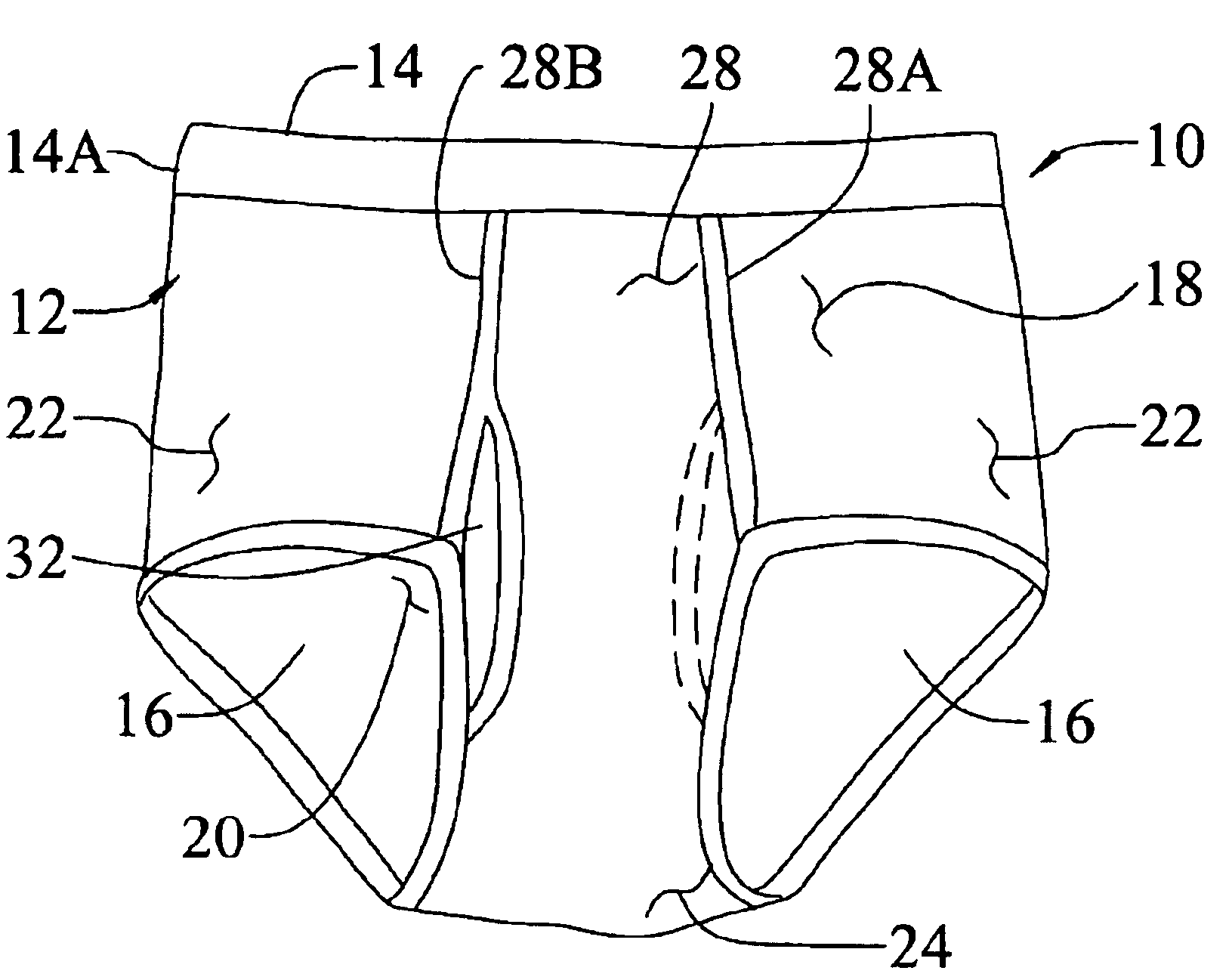

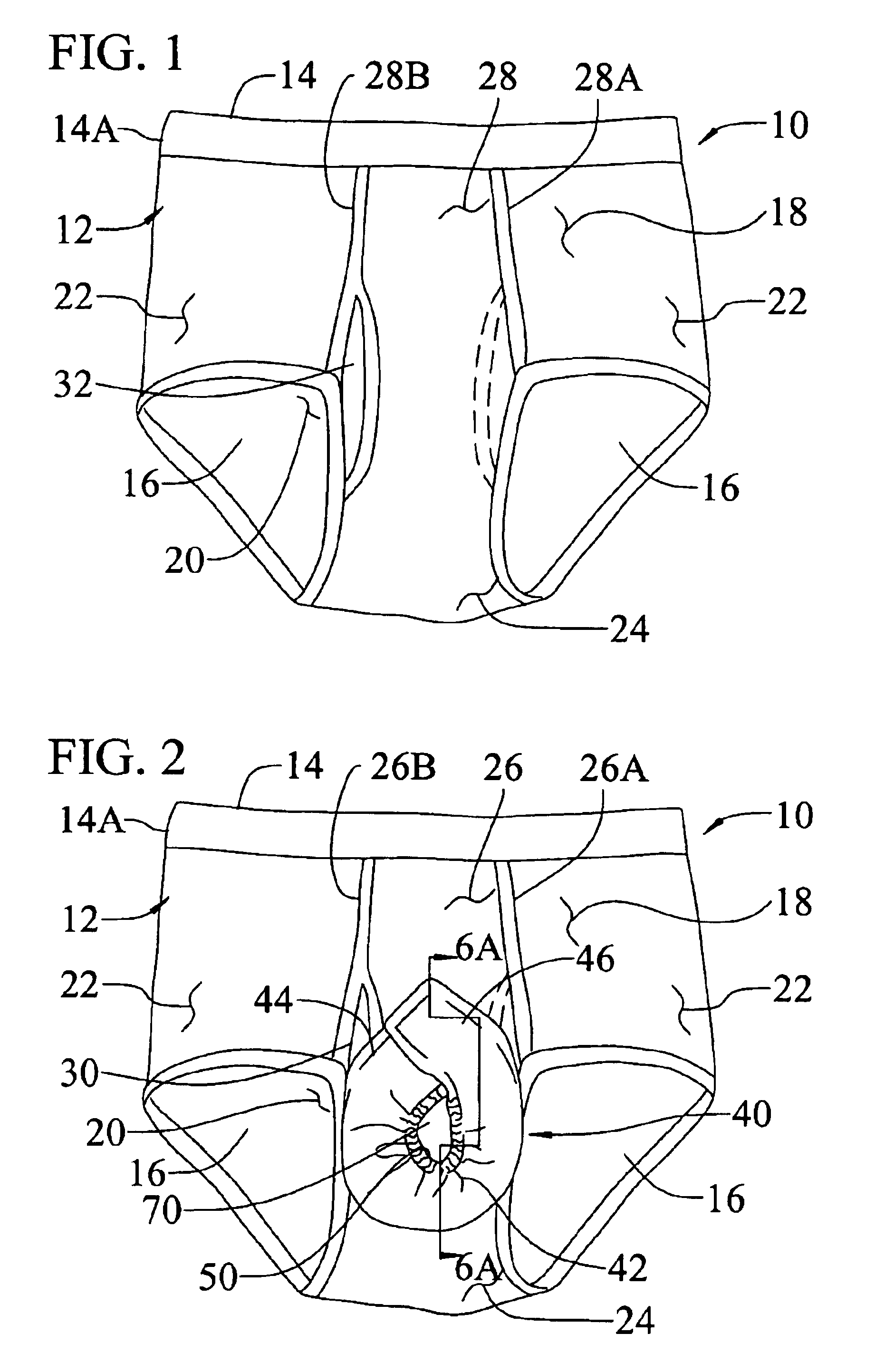

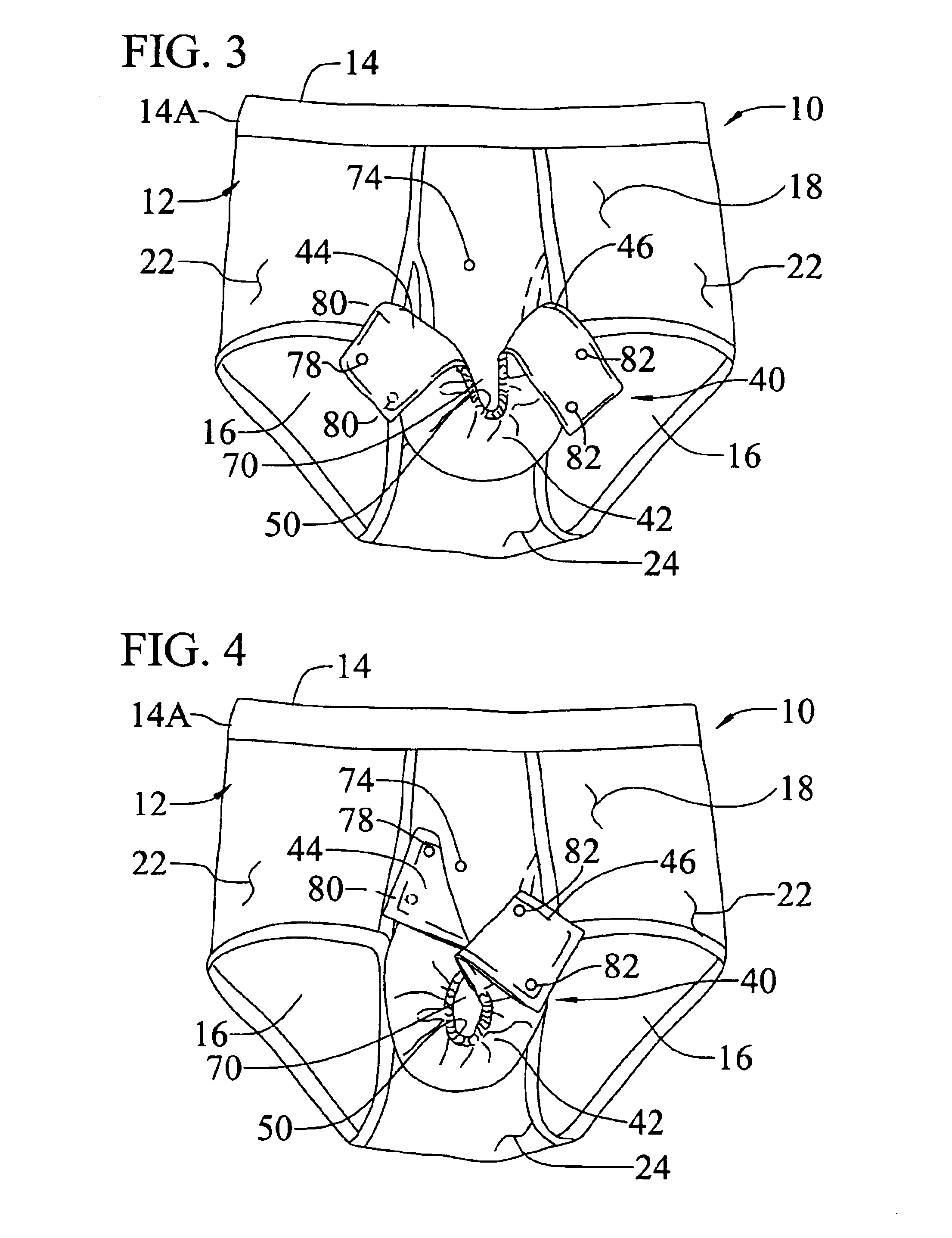

Men's brief with inner support pocket

InactiveUS6901607B1Improve comfortSimple and straightforward in design and implementation and useUndergarmentsBandagesMechanical engineeringEngineering

Owner:ELWELL JEAN D

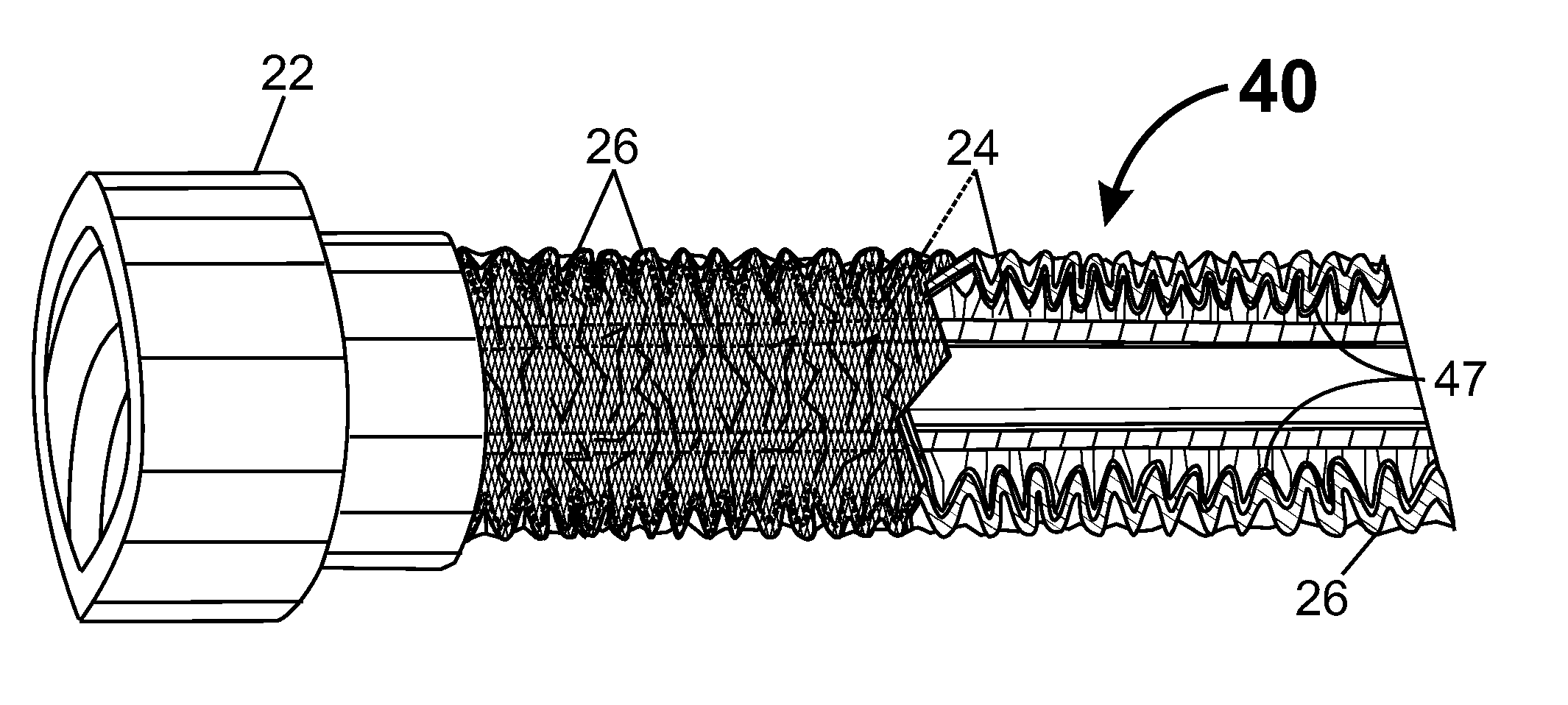

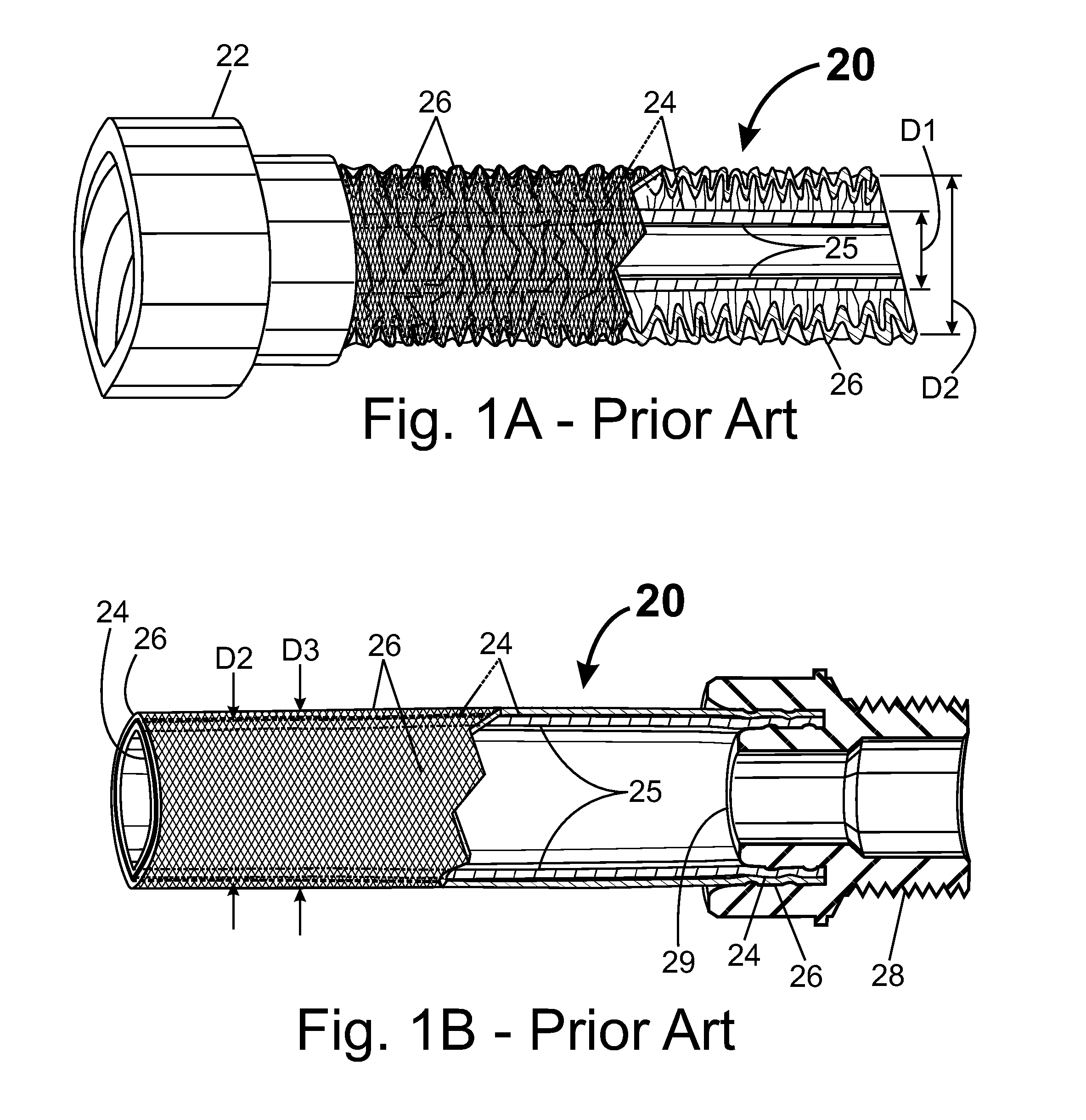

Lubricated elastically biased stretch hoses

ActiveUS20150007902A1Prevent localized over-stretchingAvoid breakingFlexible pipesWoven fabricsParaffin waxEngineering

A retractable pressure hose can be created which comprises an inlet connector, an outlet connector, an inner elastic tube, an outer cover, and a lubricant disposed to reducing chafing between the inner elastic tube and the outer cover. In such a hose, the lubricant can comprise a solid lubricant such as paraffin wax or other slippery solids, a liquid lubricant such as olive oil or other slippery liquids, or a combination of solid and / or liquid lubricants.

Owner:RAGNER TECH CORP

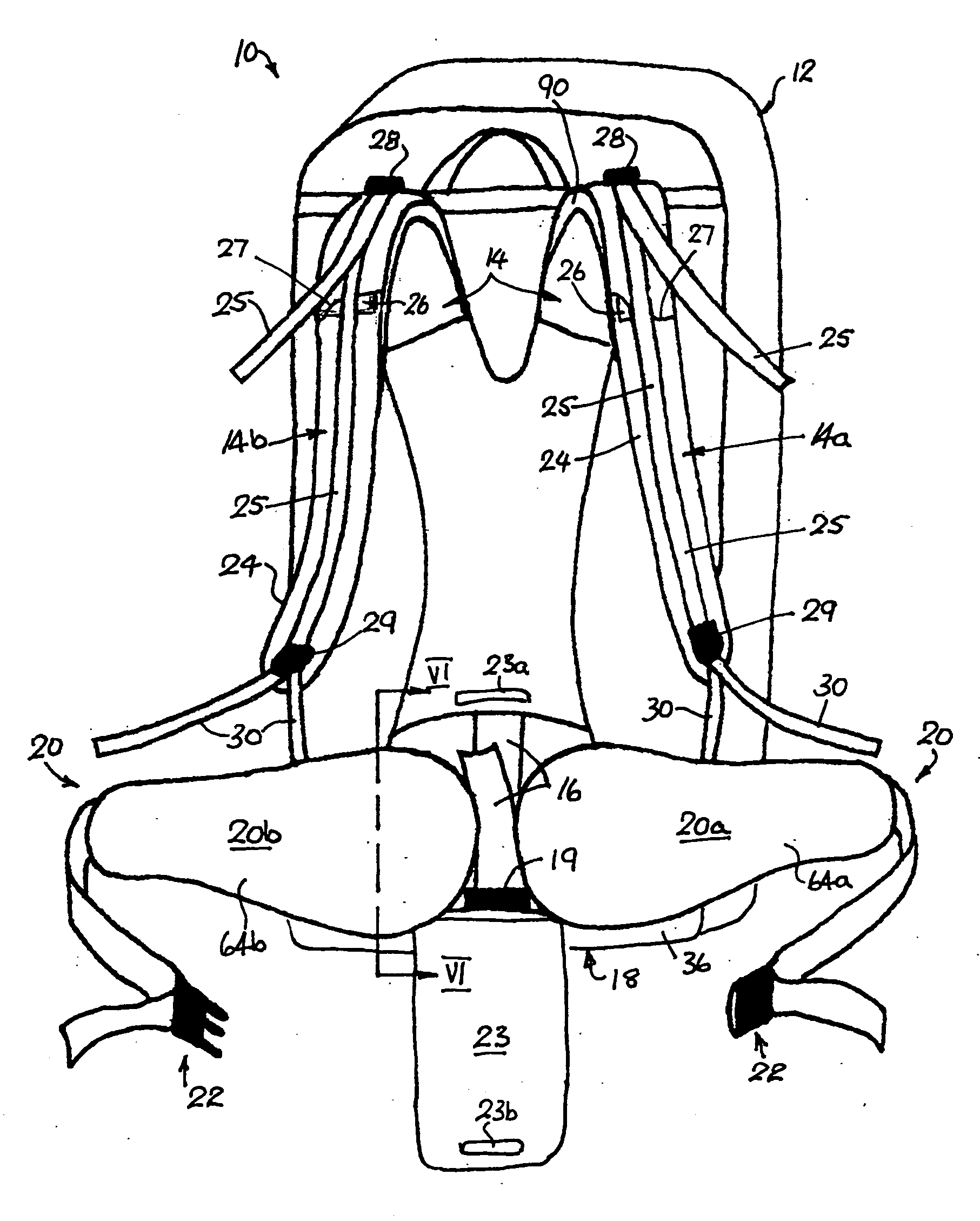

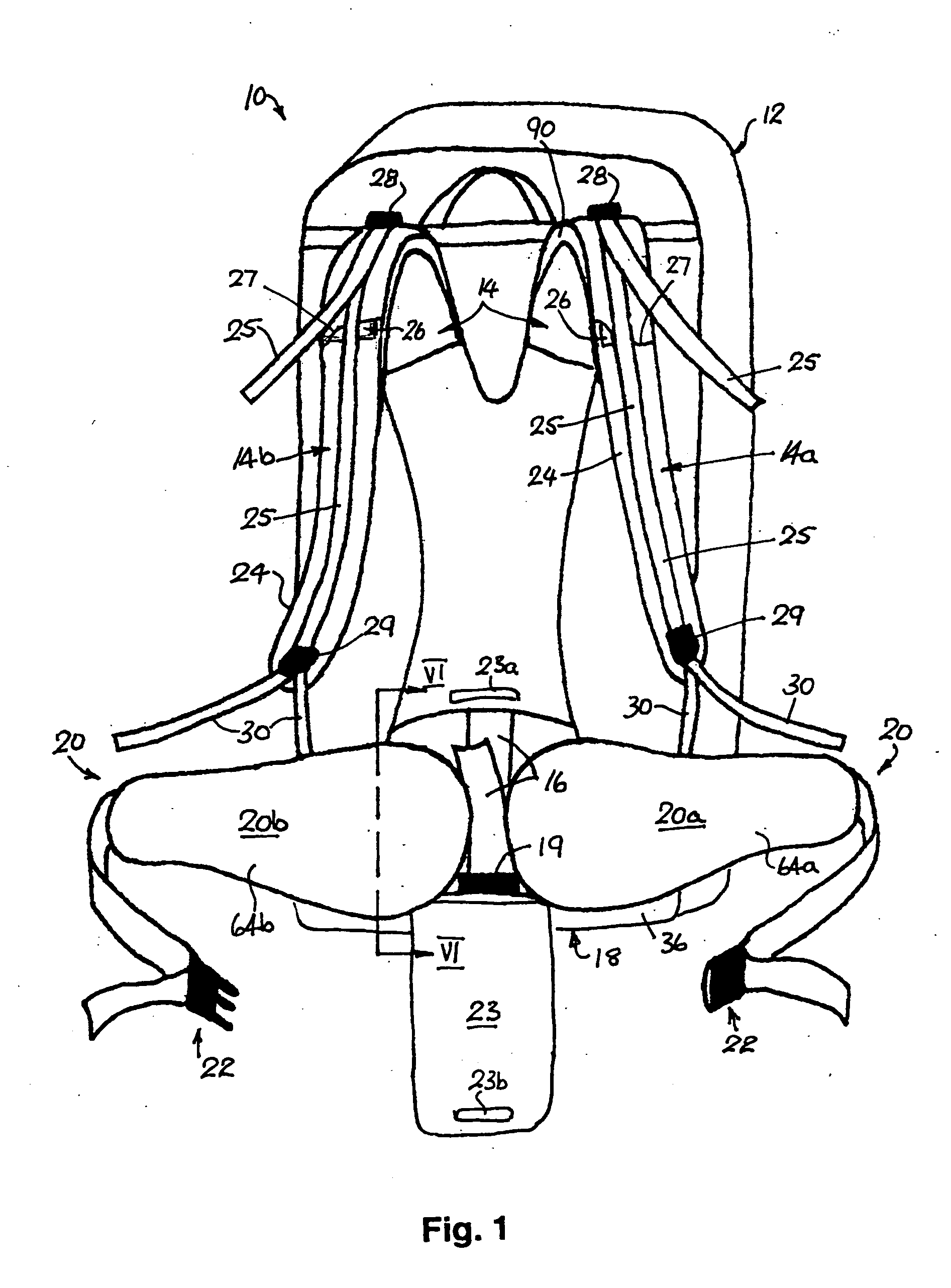

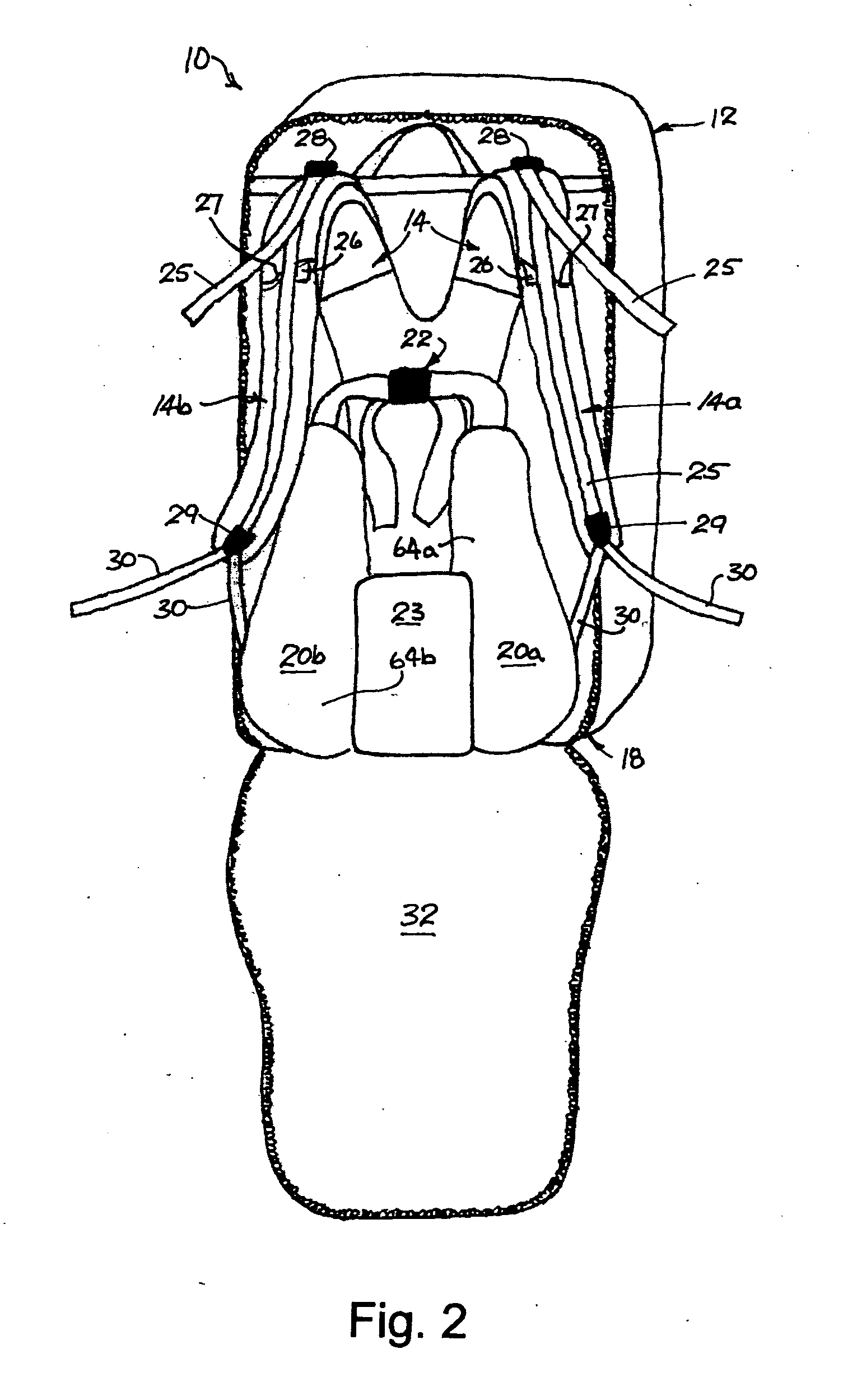

Backpack and components therefor

InactiveUS20050092802A1Mitigate bunching and edge-curlingStrongly resist coplanar flexing forceTravelling sacksEngineering

Owner:MALEY IAN JAMES

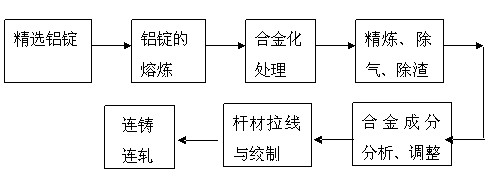

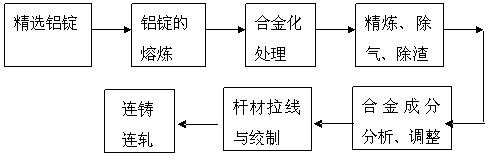

High-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and production method thereof

InactiveCN102634695ASave construction investmentImproved resistance to overloadIngotUltimate tensile strength

The invention discloses a high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and a production method of the high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire. The high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire is produced by finely selecting ingredients and contents of aluminum alloy and conducting process control. The specific steps are as follows: selecting Fe, Si, Mg, Cu and Re with different weight percents, melting aluminum ingot with the content not more than 0.03% in a vertical melting furnace, adding alloying elements in a heat insulation furnace, stirring, refining, conducting on-the-spot contents rapid analysis, carrying out content adjustment, and standing, enabling the aluminum ingot and the alloying element into a continuous casting machine for casting, rolling to be a circular aluminum alloy rod on a continuous rolling machine, pulling the circular aluminum alloy rod to be a circular aluminum alloy wire and twisting the circular aluminum alloy wire to be a conductor for aerial power transmission and distribution. According to the application of the aluminum alloy wire and the production method of the aluminum alloy wire, the aluminum alloy wire directly replaces the generally used aluminum conductor steel reinforced and is an energy-saving, environment-friendly and novel wire.

Owner:FAR EAST CABLE

Modified gear oil

A modified gear oil can be used for extreme worm oil, open industrial gear oil and closed industrial gear oil in traffic transportation, machinery, metallurgical, chemical industries. In the mineral lube-oil or synthetic lube-oil, modified nano-carbon with average grain size 2-6nm is added as extreme anti-scuff agent and oily agent, quality fraction is 2X10-5-1X10-2, nano-diamond occupies 10-99%, wear rate is decreased by 46.7%, mechanical efficiency improves by 2.84%, polishing scratch depth is decreased from 4.94 mu m to 0.07 mu m.

Owner:TIANJIN CHANYU SUPERHARD SCI TECH CO LTD

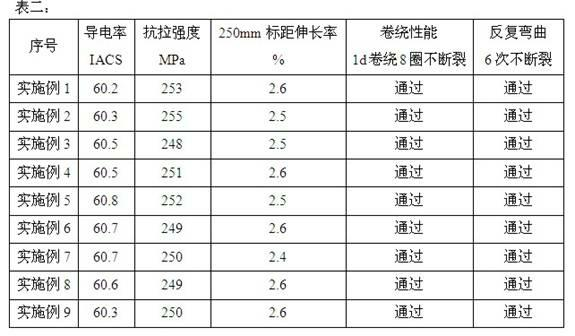

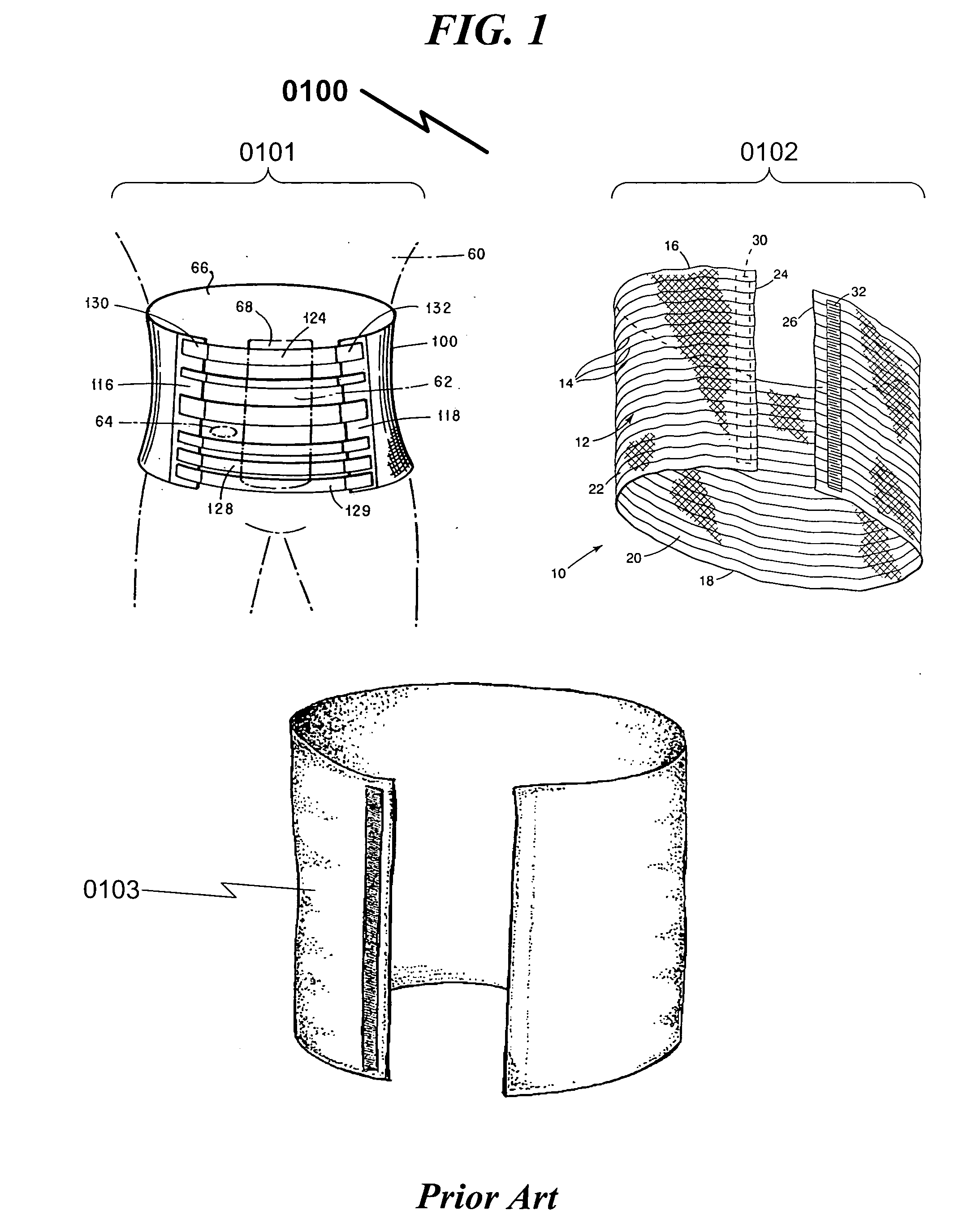

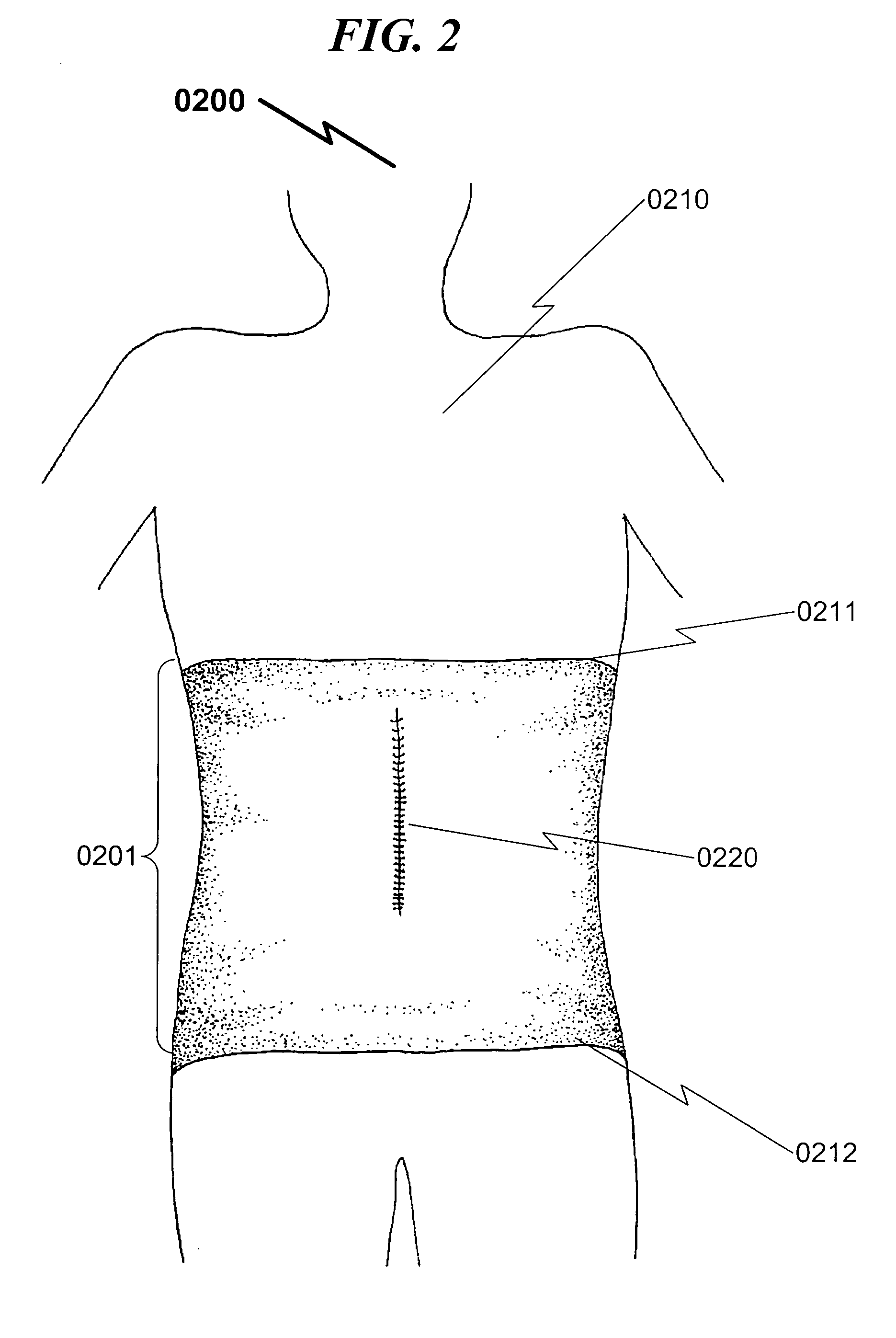

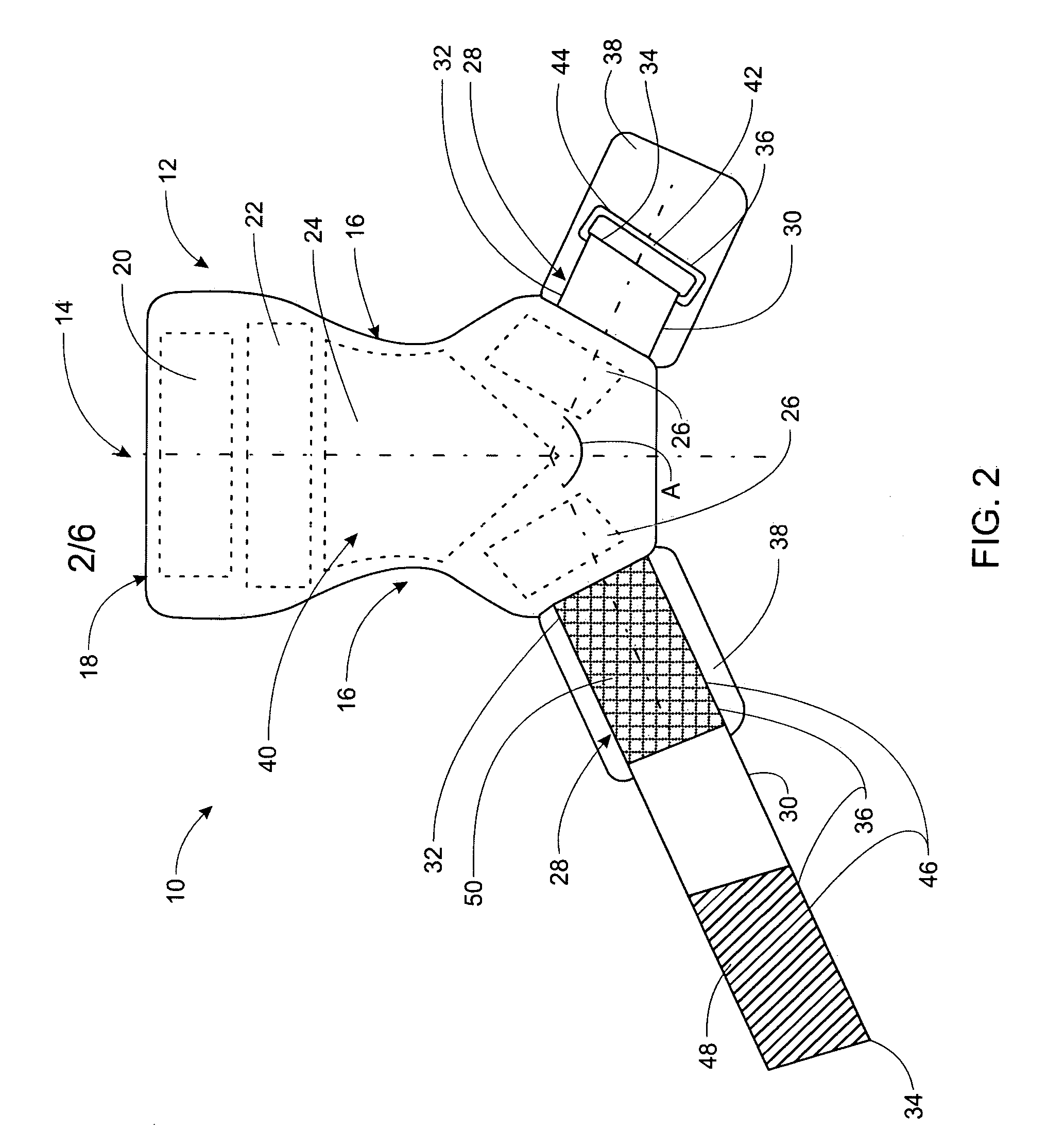

Surgical binder undergarment system and method

InactiveUS20070118062A1Reduce frictionReduce skin/binder frictionAbsorbent padsAbdomen bandagesPolyesterIrritation

A surgical binder undergarment system and method are disclosed which are designed to prevent skin chafing / irritation on patients recovering from abdominal / thoracic / back surgery and who must wear a surgical binder to prevent post-surgical injury to patient muscle and skin tissue because of incisions necessitated by the surgical procedure. The present invention is generally constructed of a seamless tubular fabric optimally comprising a fabric weave of 50% cotton and 50% polyester that is latex free and stretches over the abdomen / thorax of the patient to form a flexible protective low friction interface between the patient's skin and the surrounding surgical binder. Use of the present invention permits the surgical binder to remain clean with a corresponding reduction in incision infections and increase in overall patient comfort during post-operative recovery.

Owner:FLECK JANET FELICIA

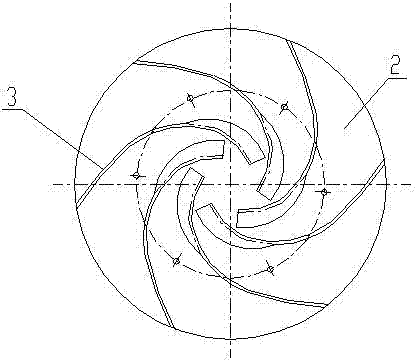

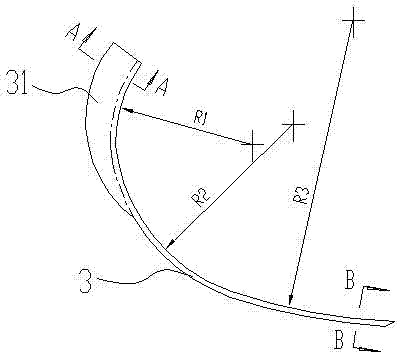

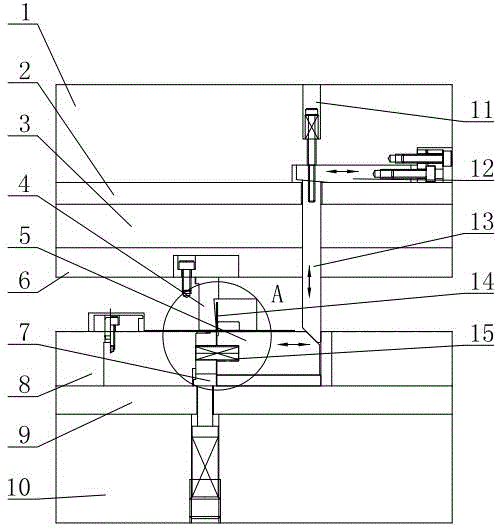

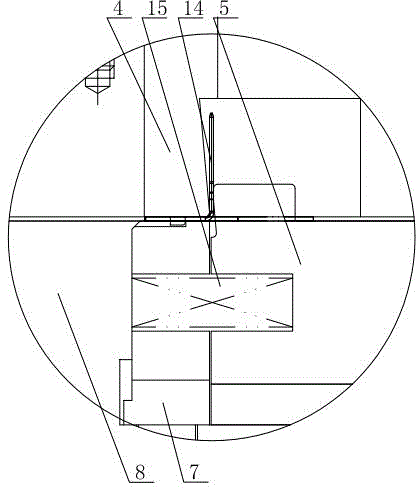

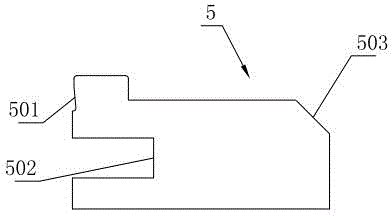

Centrifugal Acceleration Disc Structure of Pusher Centrifuge

The invention relates to the technical field of centrifuges, in particular to a centrifugal accelerating disc structure of a push-type centrifuge, and solves the problem that impact force applied to a screen by a material is high when the material is accelerated to enter a separation state by the push-type centrifuge. The structure comprises a large circular flat plate and a small circular flat plate which are parallel to each other, and is characterized in that: a plurality of blades are arranged between the two flat plates and are uniformly and radially distributed; the tail ends of the plurality of blades are positioned on the same circumference; the curve of each blade is a turbine centrifugal line; each blade consists of a plurality of sections of circular arcs; the radii of the plurality of sections of circular arcs of each blade are gradually increased from the head to the tail end; and a section of part on the head of each blade is provided with a radial arc surface which inclines to the rotation direction of each blade. The structure greatly reduces the scratch, wear and defect of crystal grains in the material, ensures that the material is fed smoothly and uniformly, canreduce the residual moisture content of the separated material, and can effectively separate a material which is difficult to separate.

Owner:ZHEJIANG QINGJI CENTRIFUGE MFG

Lubricating oil for rotary kiln wheel belts and method for preparing same

The invention discloses lubricating oil for rotary kiln wheel belts and a method for preparing the same. The lubricating oil can be used to solve the problem that the lubricating performance of the rotary kiln wheel belts is undesirable in severe environments, has high wear resistance and high temperature resistance. The maximum use temperature of the lubricating oil can reach 600 DEG C, and therefore the lubricating oil can form a high-strength high-temperature protective lubricating firm to prevent vibration, distortion and deformation of rotary kilns and falling of flame-retarding bricks and to prolong the service life of the rotary kilns. The easy method for preparing the lubricating oil can improve working efficiency and product quality obviously and save lots of energy, and is convenient to promote. The lubricating oil for rotary kiln wheel belts comprises the following components in percentage by mass: 49 to 69 percent of poly-alpha-olefin, 10 to 30 percent of composite calcium-base grease, 10 to 40 percent of composite metal soap, 2 to 5 percent of nano colloidal molybdenum disulfide powder, 2 to 4 percent of colloidal graphite powder, 1.5 to 3 percent nano soft metal powder and 5 to 6 percent of flame retarder, wherein the total percentage of the components is 100 percent. The kinematic viscosity of poly-alpha-olefin synthetic oil at 100 DEG C is 40 to 80 centistokes, and the open flash point of the poly-alpha-olefin synthetic oil is not less than 320 DEG C.

Owner:洛阳正本润滑材料有限公司

Anti-static corrugated carton

InactiveCN105542593AHigh glossHigh transparencyEpoxy resin coatingsElectrically-conductive paintsEpoxyFiber

The invention discloses an anti-static corrugated carton which comprises a box body made from a corrugated board, wherein the surface of the corrugated board is coated with a layer of anti-static coating with thickness of 1-3mm; and the anti-static coating is prepared from the following raw materials in parts by weight: 100 parts of waterborne acrylic resin, 35-45 parts of epoxy resin, 20-30 parts of alkyd resin, 1-5 parts of carbon nanotube, 3-9 parts of carbon fiber, 10-15 parts of nano calcium carbonate, 1-2 parts of conductive carbon black, 2-8 parts of conductive graphite, 1-2 parts of antifoaming agent, 0.8-1.5 parts of thickening agent, 0.1-0.3 part of modifier, 0.2-0.5 part of dispersing agent, 1-3 parts of silane coupling agent and 50-80 parts of water. According to the invention, since the anti-static coating is added with the carbon nanotube and carbon fiber, the corrugated carton has high strength, the surface is delicate and smooth, the static effect is greatly reduced, thus the surface of the corrugated carton does not adsorb dust, the scratch caused by friction is reduced, and the printing speed and printing effect are improved; and moreover, due to the addition of nano calcium carbonate, the coating has good gloss, transparency and stability.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

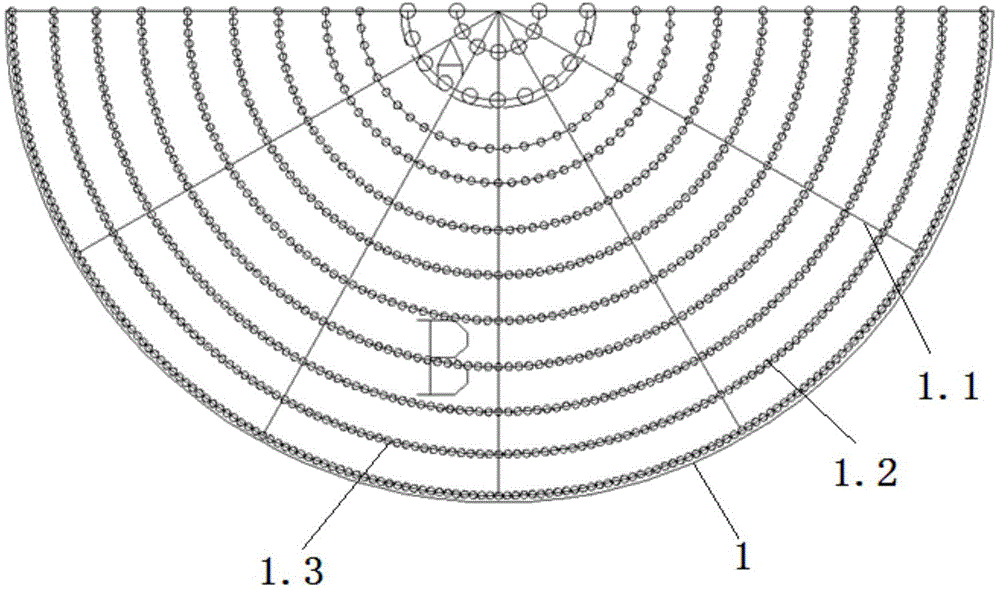

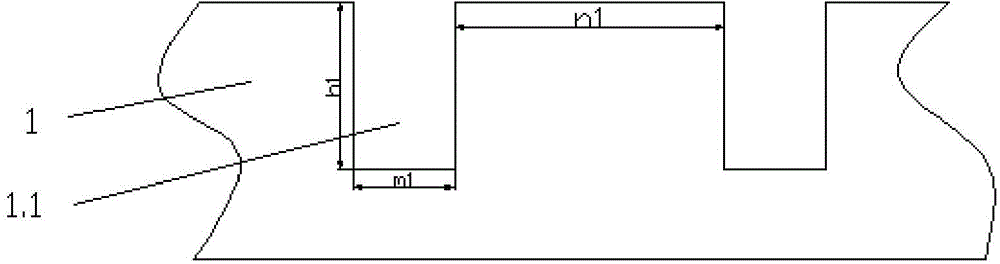

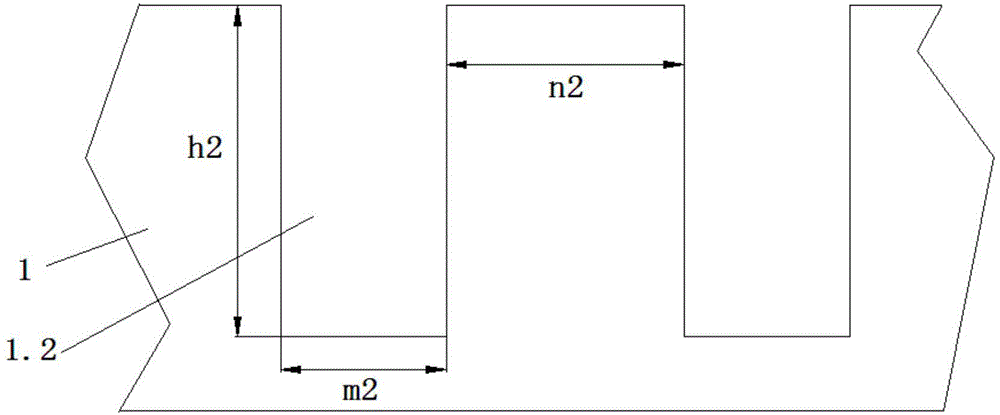

Chemical-mechanical polishing pad

The invention discloses a chemical-mechanical polishing pad and solves the problem that an existing polishing pad is scratched easily and low in polishing efficiency. According to the technical scheme, the chemical-mechanical polishing pad comprises a polishing layer, a plurality of holes are formed in the polishing surface of the polishing layer, the center of the polishing surface is a circle center, and the holes are arranged into multiple rows of concentric rings different in diameter. The center of the polishing surface is an end point, and a plurality of grooves extending to the edge of the polishing surface are evenly radiated from the end point. The surface roughness of the polishing surface is below 15 micrometers. The polishing pad is simple in structure, capable of increased polishing removing efficiency and inhibiting scratches, and long in service life.

Owner:HUBEI DINGLONG CO LTD

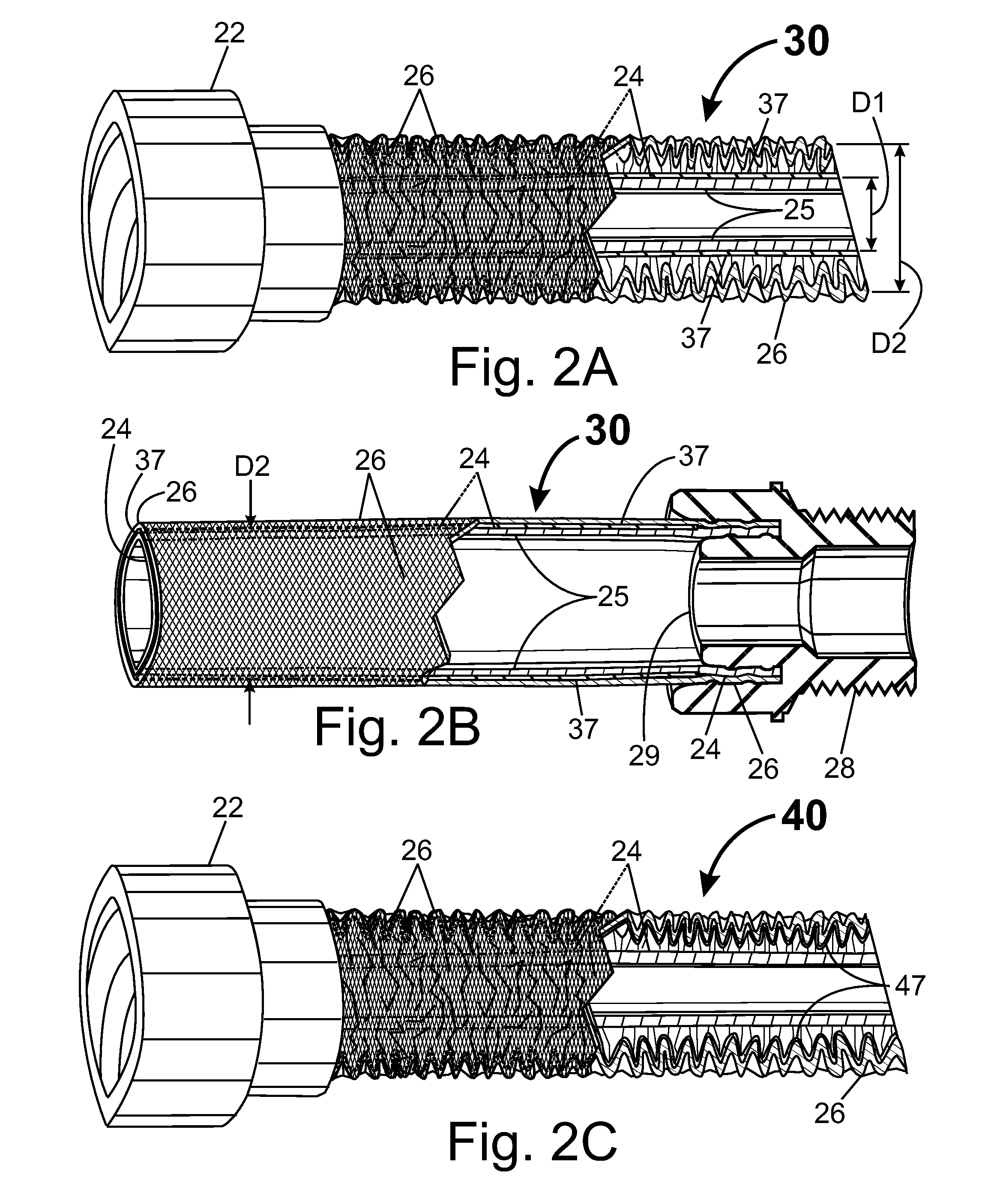

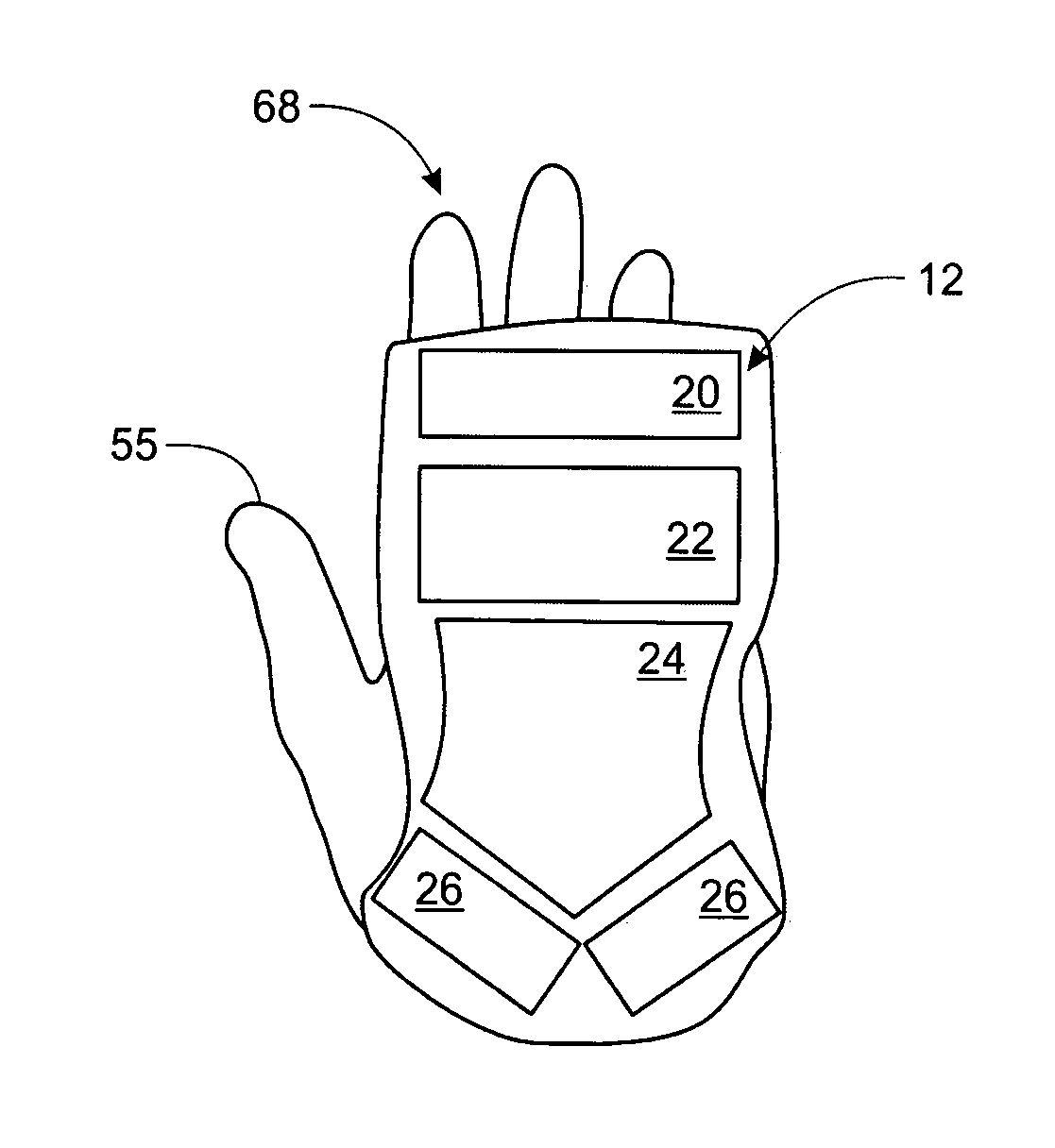

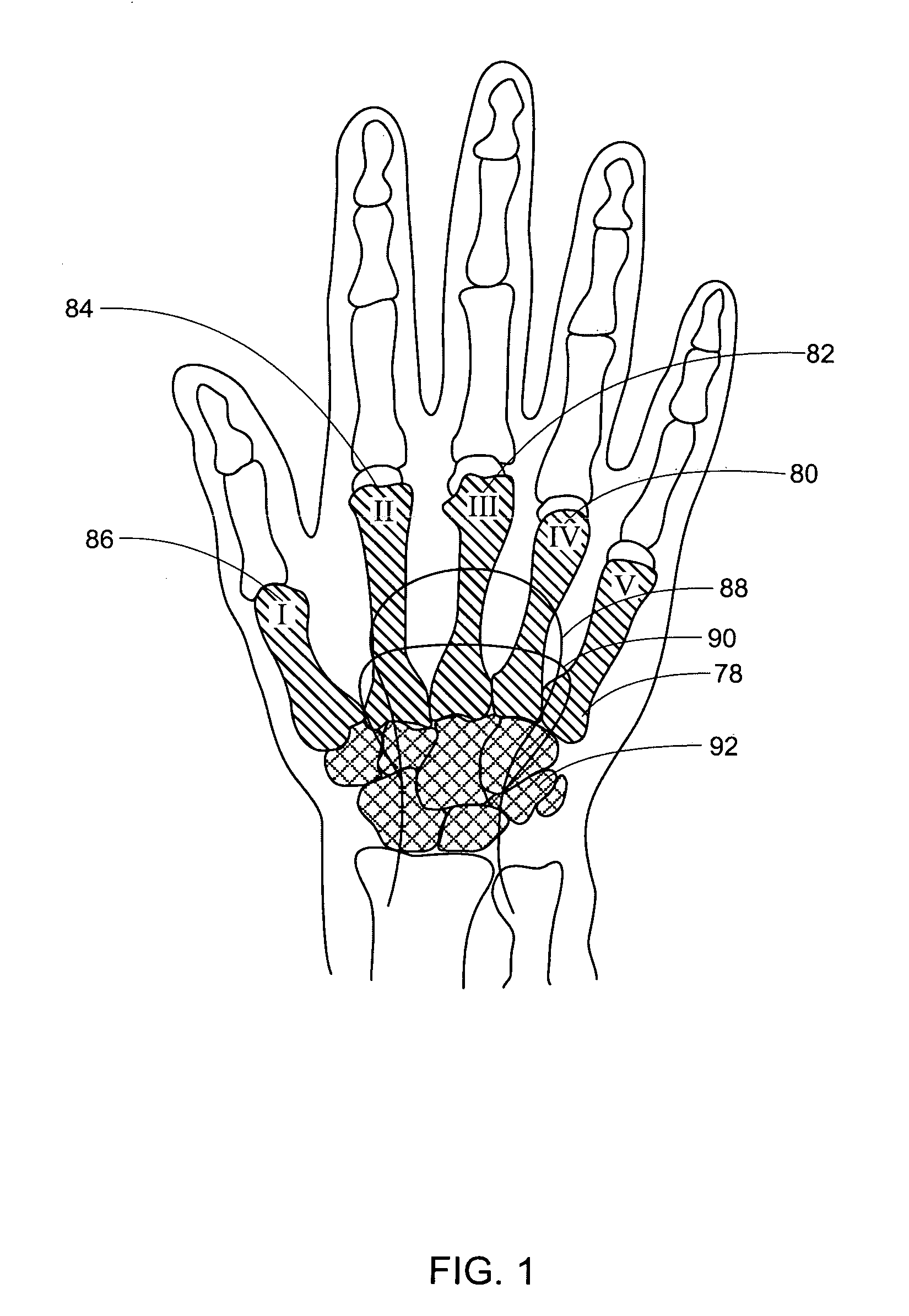

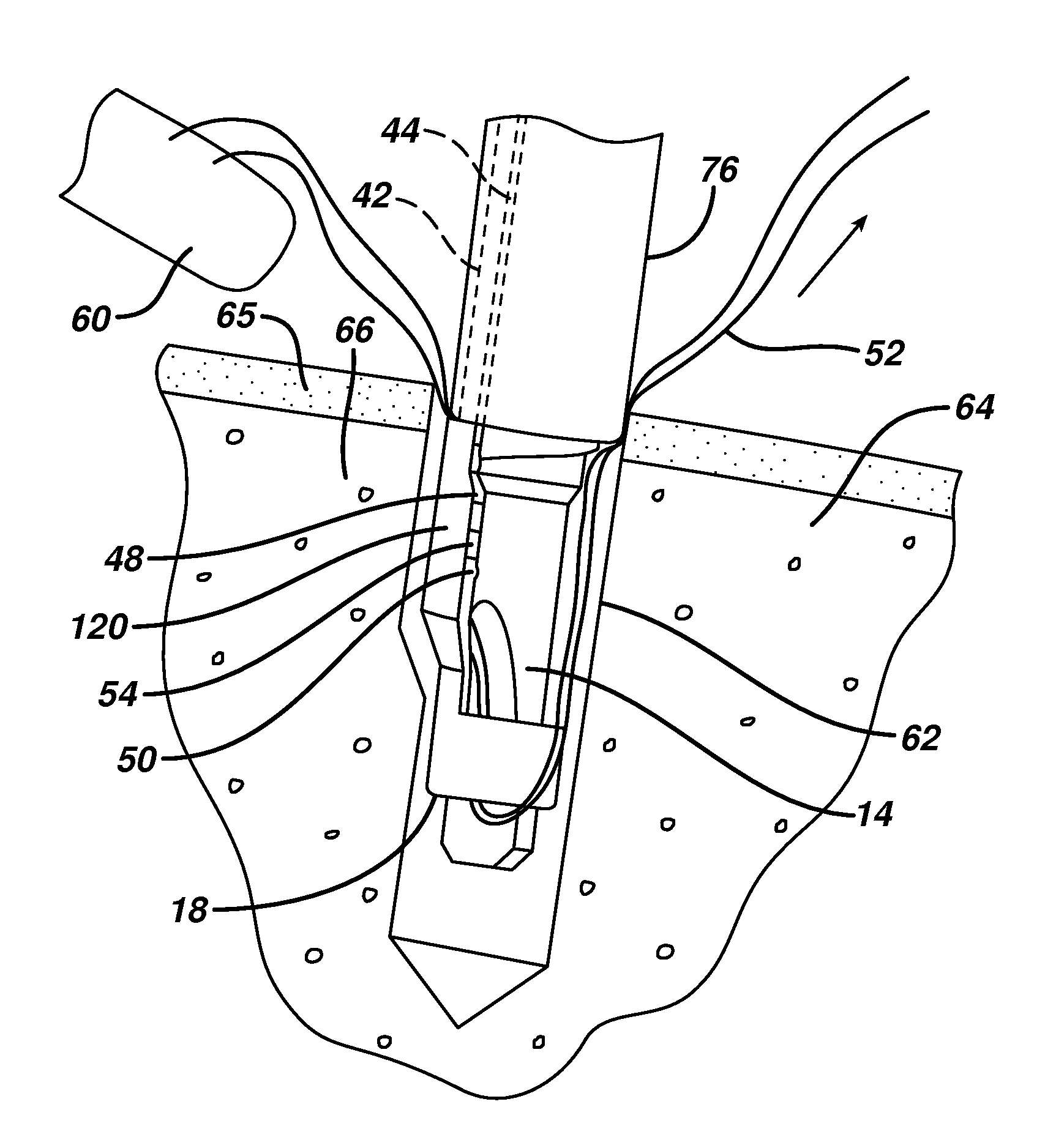

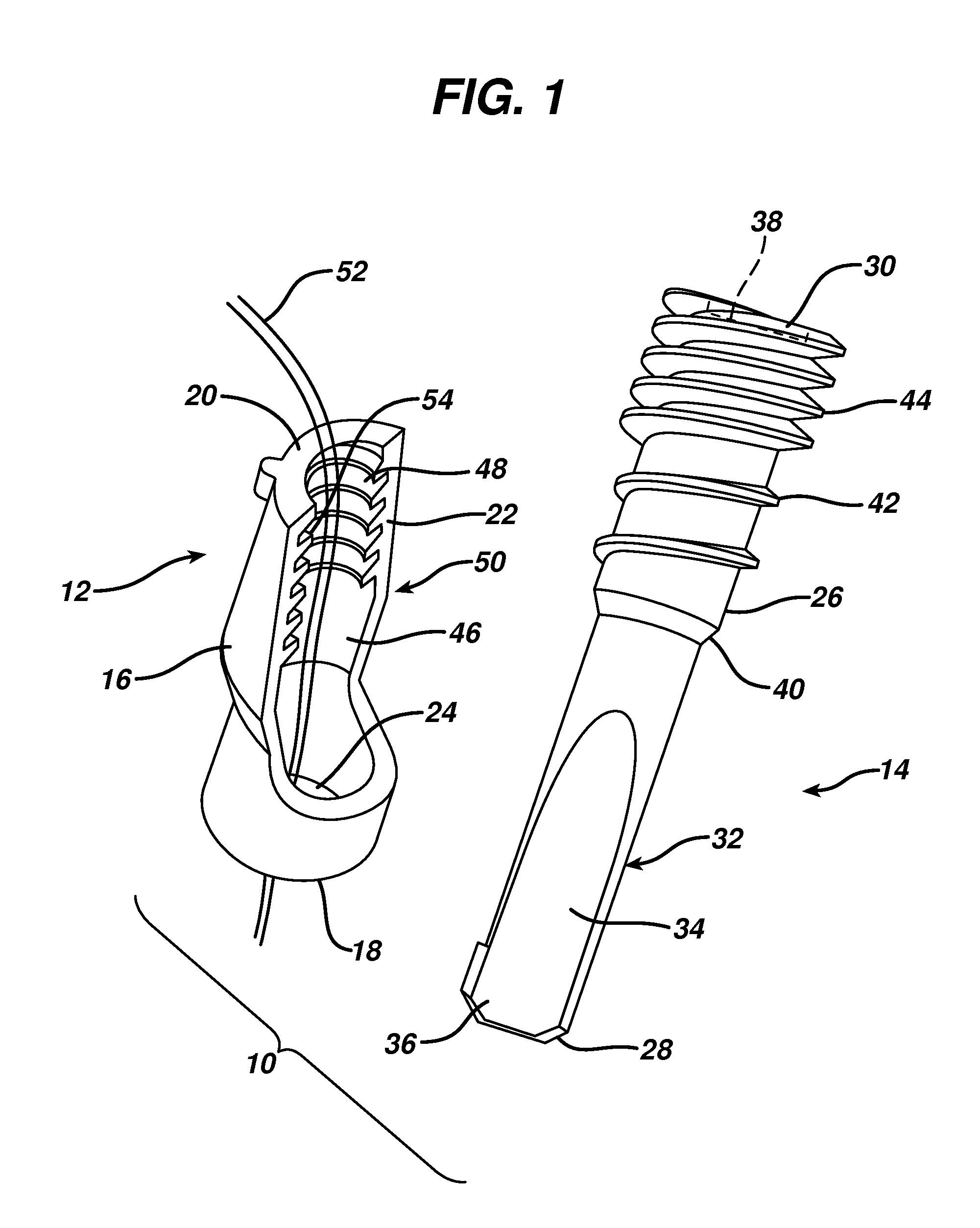

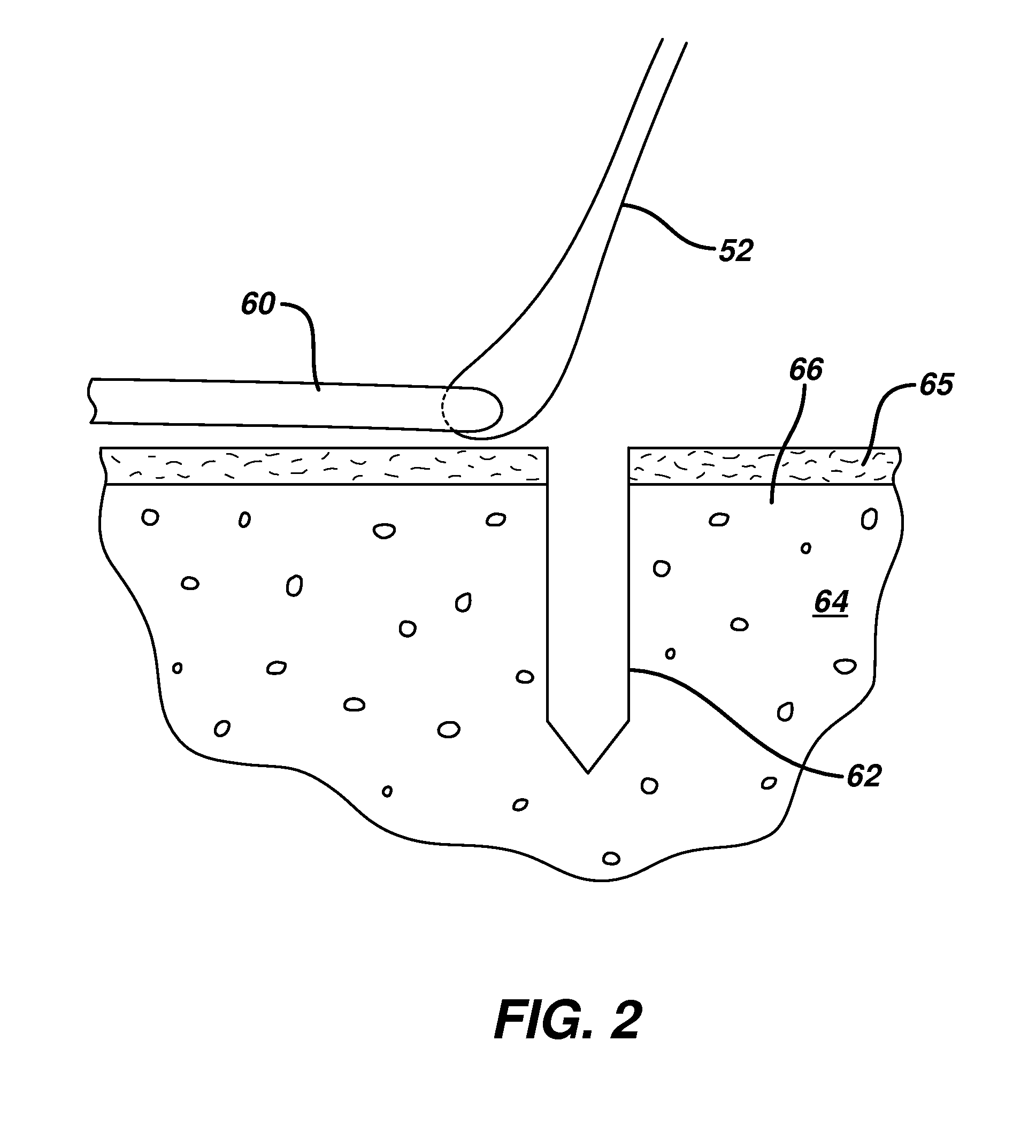

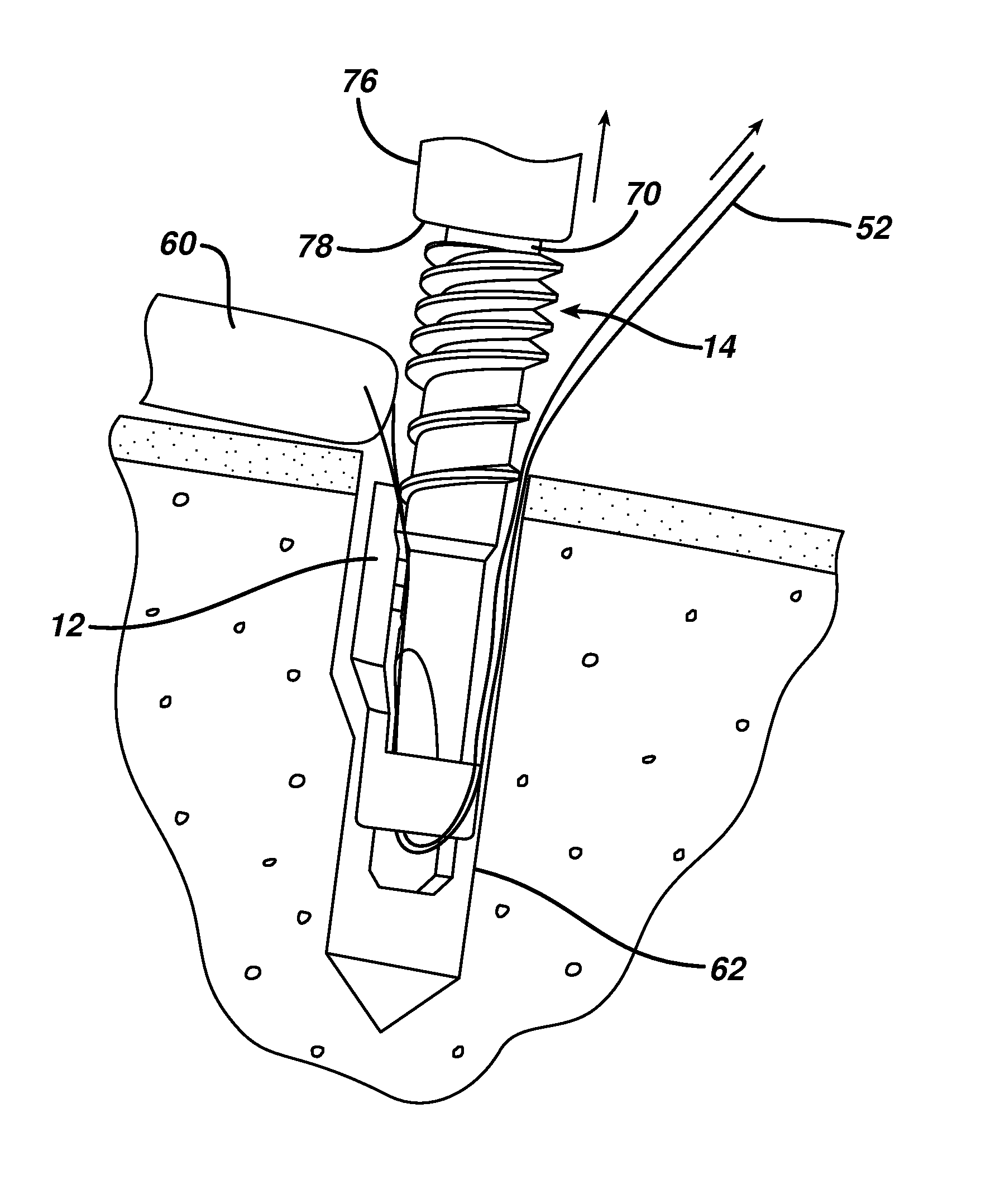

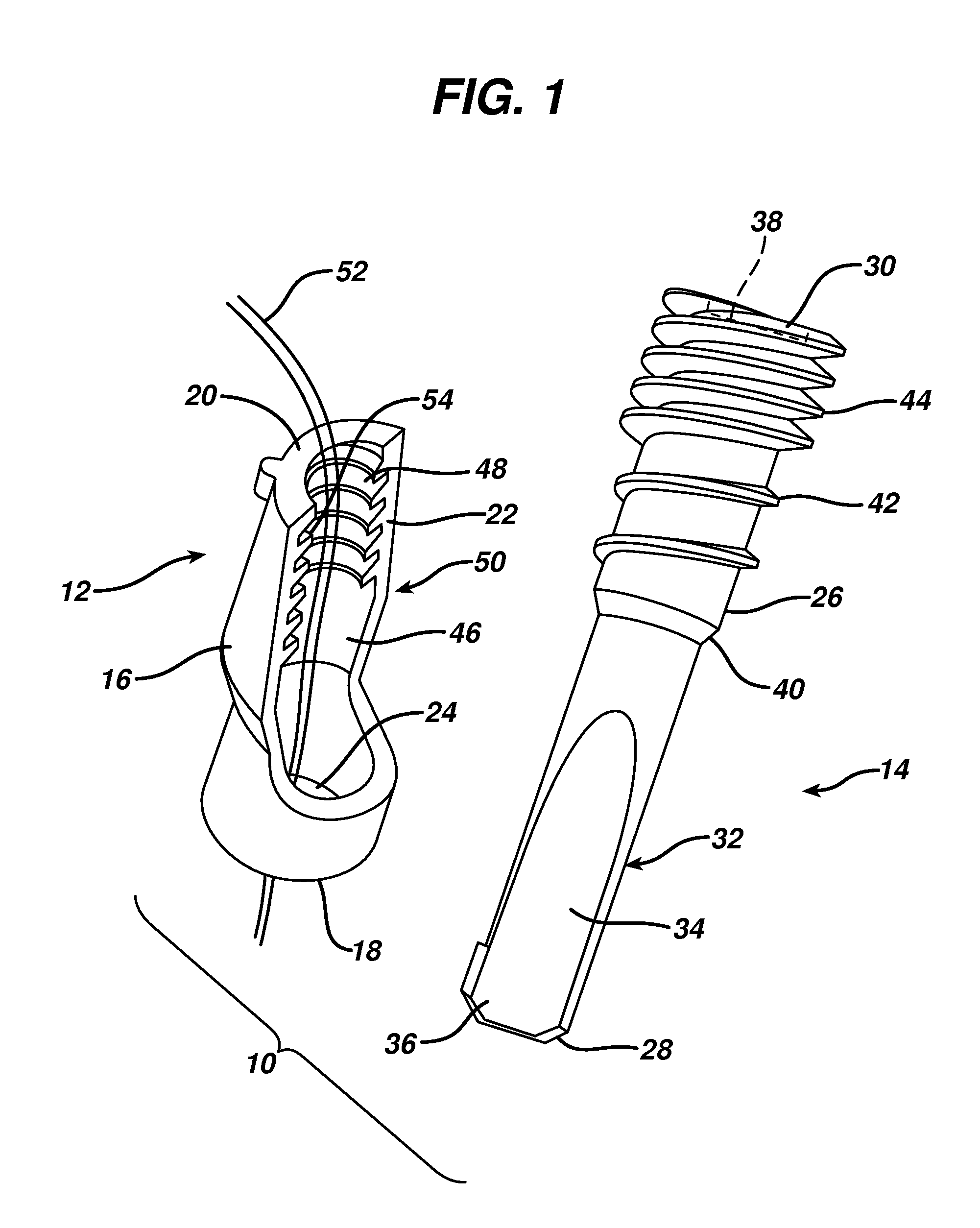

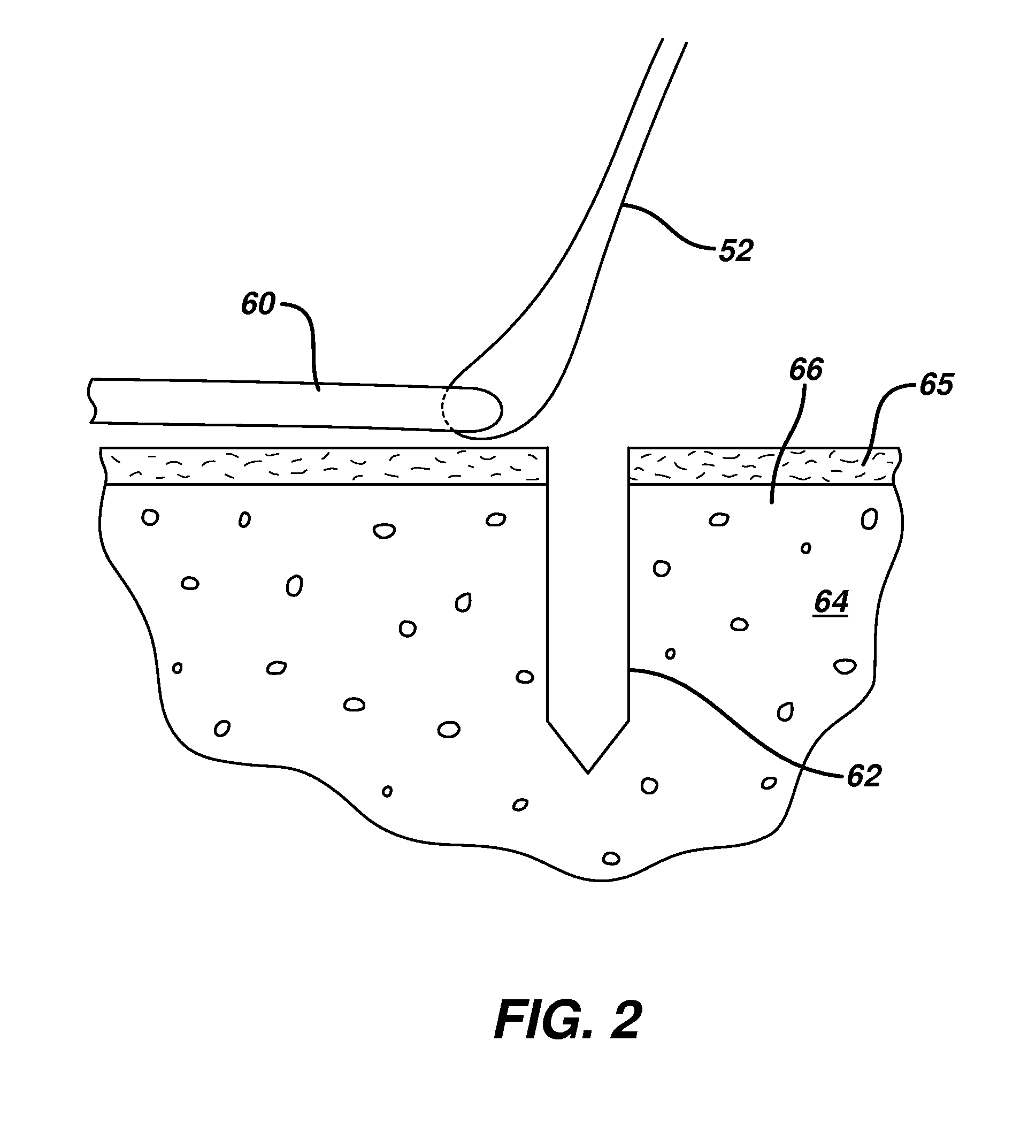

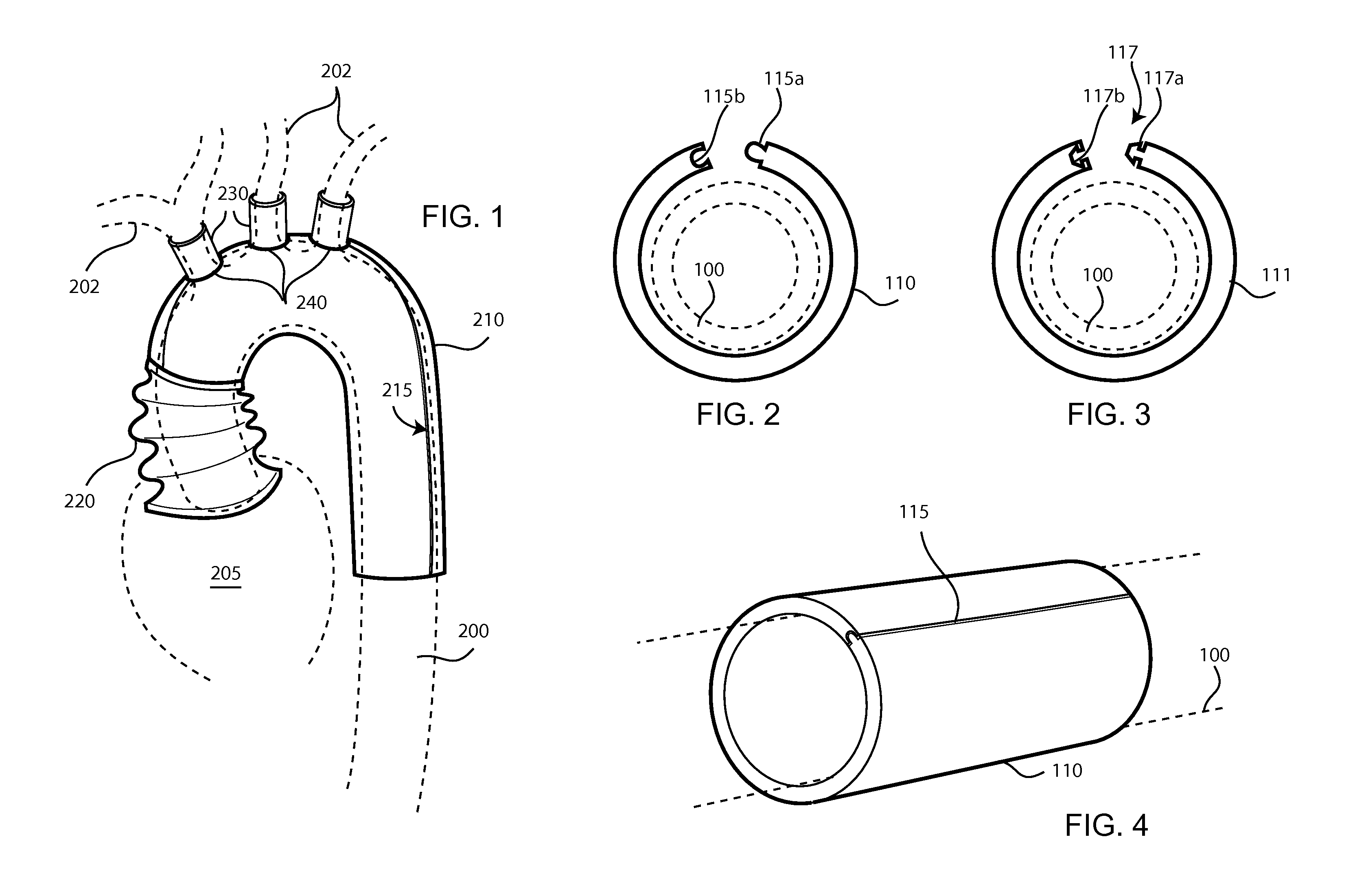

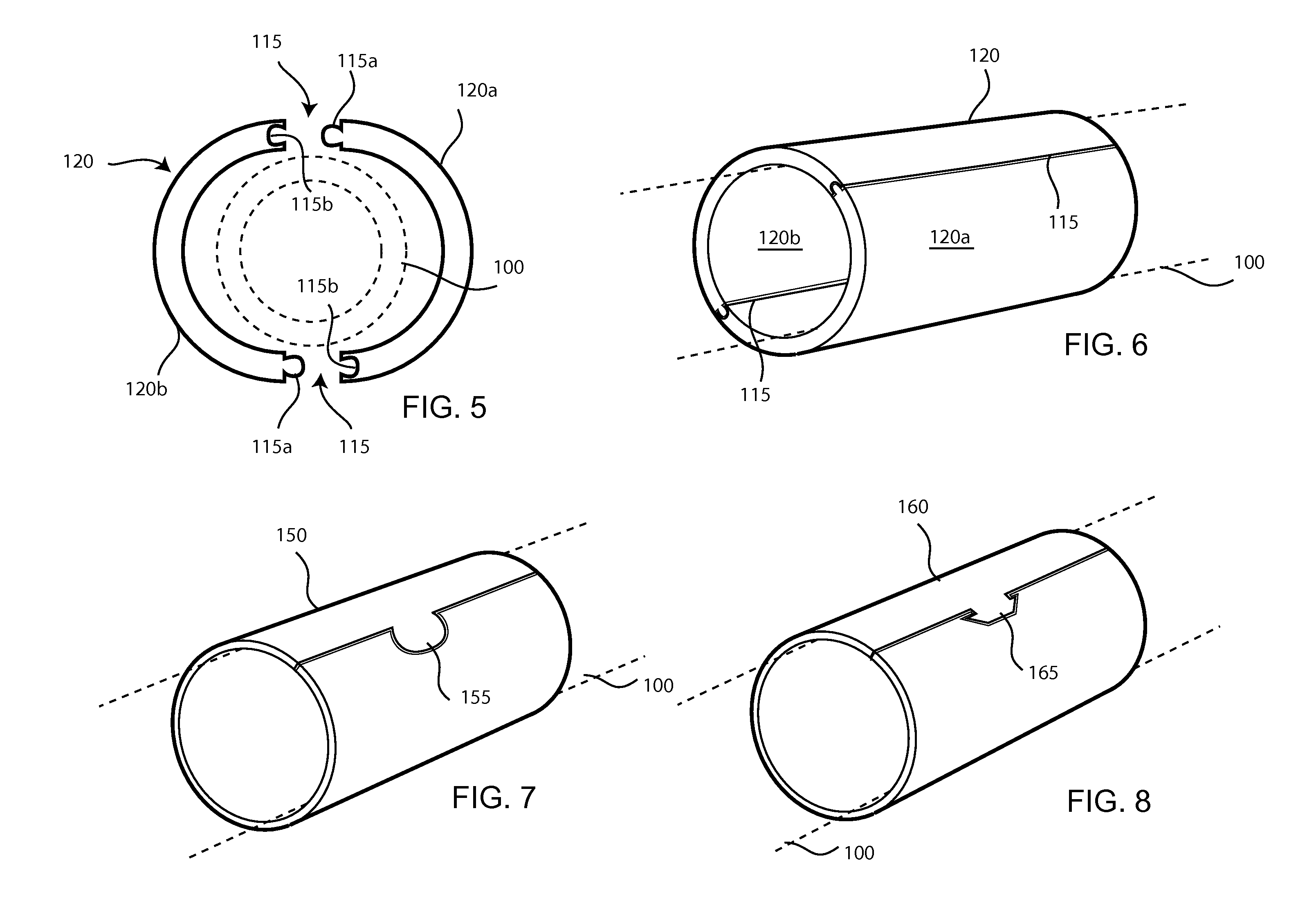

Knotless suture anchor

ActiveUS20130079818A1Simple and elegantOvercome limitationsSuture equipmentsBone tunnelSuture anchors

A suture anchor comprises a shell and an anchor member. The shell comprises a body having a distal end, a proximal end and sidewalls therebetween defining an axial cannulation therethrough. The anchor member comprises a body having a distal end and a proximal end which is sized to fit within the cannulation. The sidewalls define a lateral cut-out such that with the anchor member received within the cannulation a first lateral portion of the anchor member is exposed laterally and a second, laterally opposite, lateral portion of the anchor member is enclosed by the sidewalls. A friction enhancement on the first lateral portion frictionally engages a bone surface when the suture anchor is disposed within a bone tunnel defined by the bone surface. Suture is trapped between the shell and the anchor and also between the anchor and the bone surface.

Owner:MEDOS INT SARL

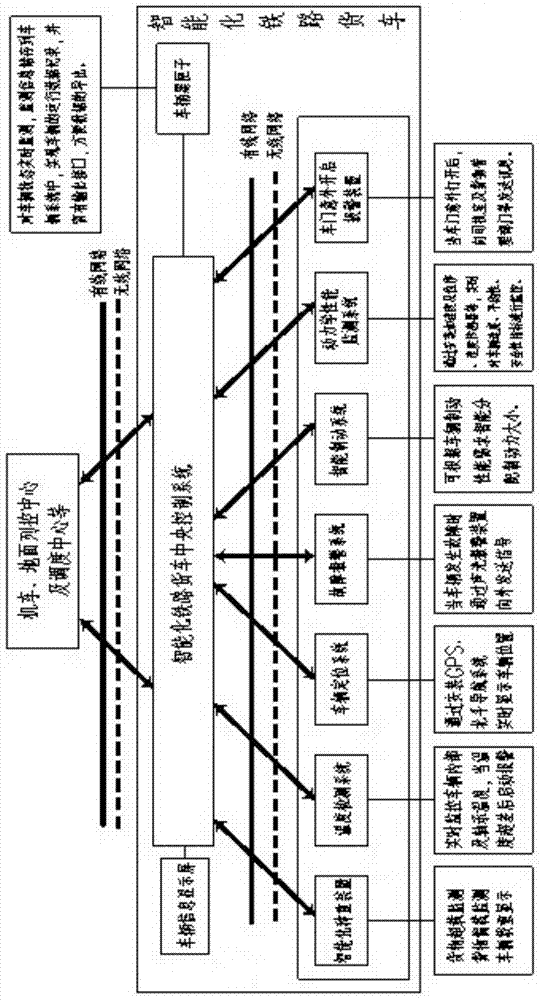

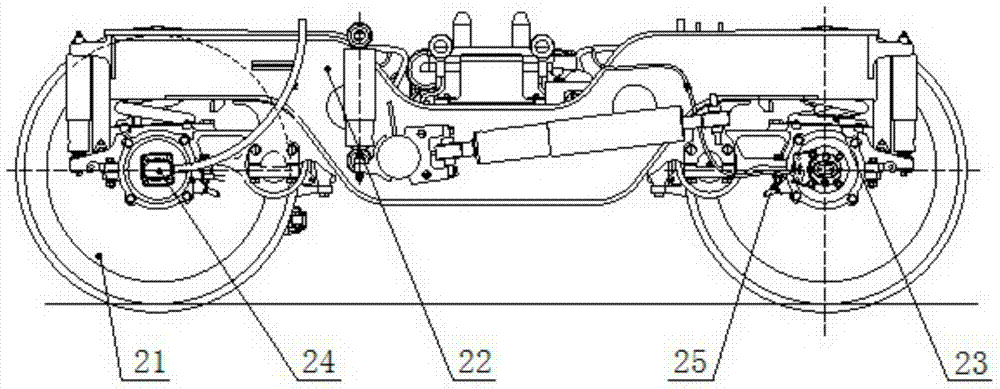

Intelligent rail wagon

InactiveCN104742936AHas exportReal-time load displayRailway signalling and safetyRailway auxillary equipmentDevice formControl system

The invention discloses an intelligent rail wagon. The intelligent rail wagon comprises a wagon body and a bogie; central control systems, intelligent weighting devices, temperature detecting systems, vehicle positioning systems, fault alarming systems, intelligent braking systems, dynamic performance detecting systems, accident door opening alarming devices, black boxes and vehicle information display screens are mounted on the wagon body and the bogie, wherein the intelligent weighting devices, the temperature detecting systems, the vehicle positioning systems, the fault alarming systems, the intelligent braking systems, the dynamic performance detecting systems and the accident door opening alarming devices form an intelligent terminal; the central control systems are used for transmitting and concentrating to process and analyze intelligent terminal data through wired network or wireless network by using a transmission medium and exchanging and transmitting vehicle information on real time with a locomotive, a ground train control center and a dispatching center through the wired network or the wireless network. With the adoption of the intelligent rail wagon, the load weight of the wagon can be displayed on real time; the positioning can be performed on real time; a user can conveniently know the goods state information on real time.

Owner:CRRC SHANDONG CO LTD +1

Lead wire etching technology with gold fingers with three surfaces wrapped by gold

InactiveCN105282983AReduce chafingImprove pass rateConductive material chemical/electrolytical removalCopperContamination

The invention belongs to the field of circuit board processing and specifically relates to a lead wire etching technology with gold fingers with three surfaces wrapped by gold. The technology comprises successive steps of inner layer, laminating, drilling, copper sinking, whole-plate electroplating, outer-layer pattern (1), pattern plating, etching (1), resistance welding, outer-layer pattern (2), nickel and gold plating, stripping, outer-layer pattern (3), etching (2), stripping, tape pasting, surface processing, and post-operations. The technology optimizes the process of gold fingers with three surfaces wrapped by gold, improves the quality, solves the problem of gold diffusion, reduces finger gold surface scratches, avoids the phenomena that a coating film cannot be attached to a plate surface completely and etching solution seeps into an etching line, reduces the risk of contamination, and has great market prospect and application value.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

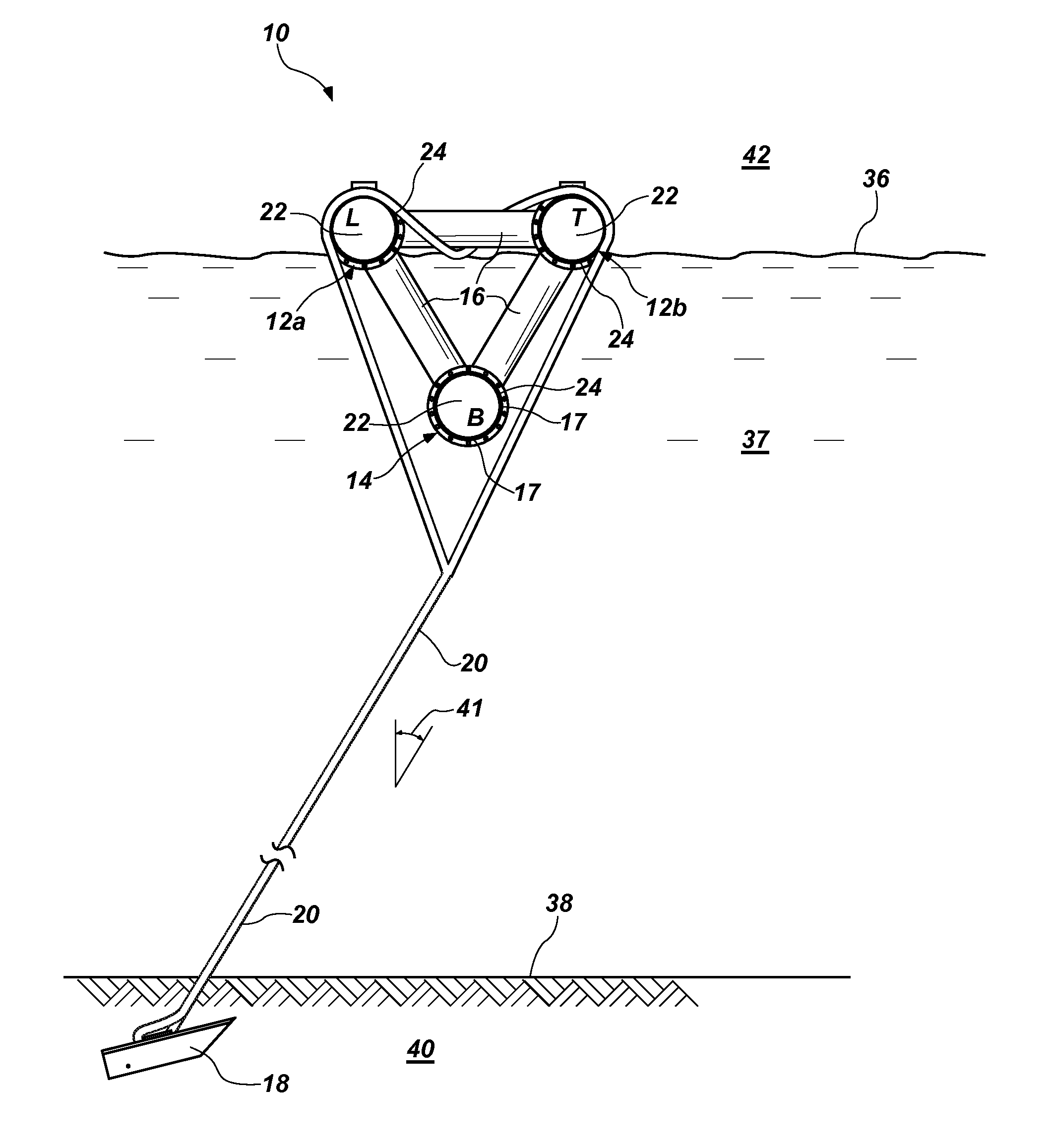

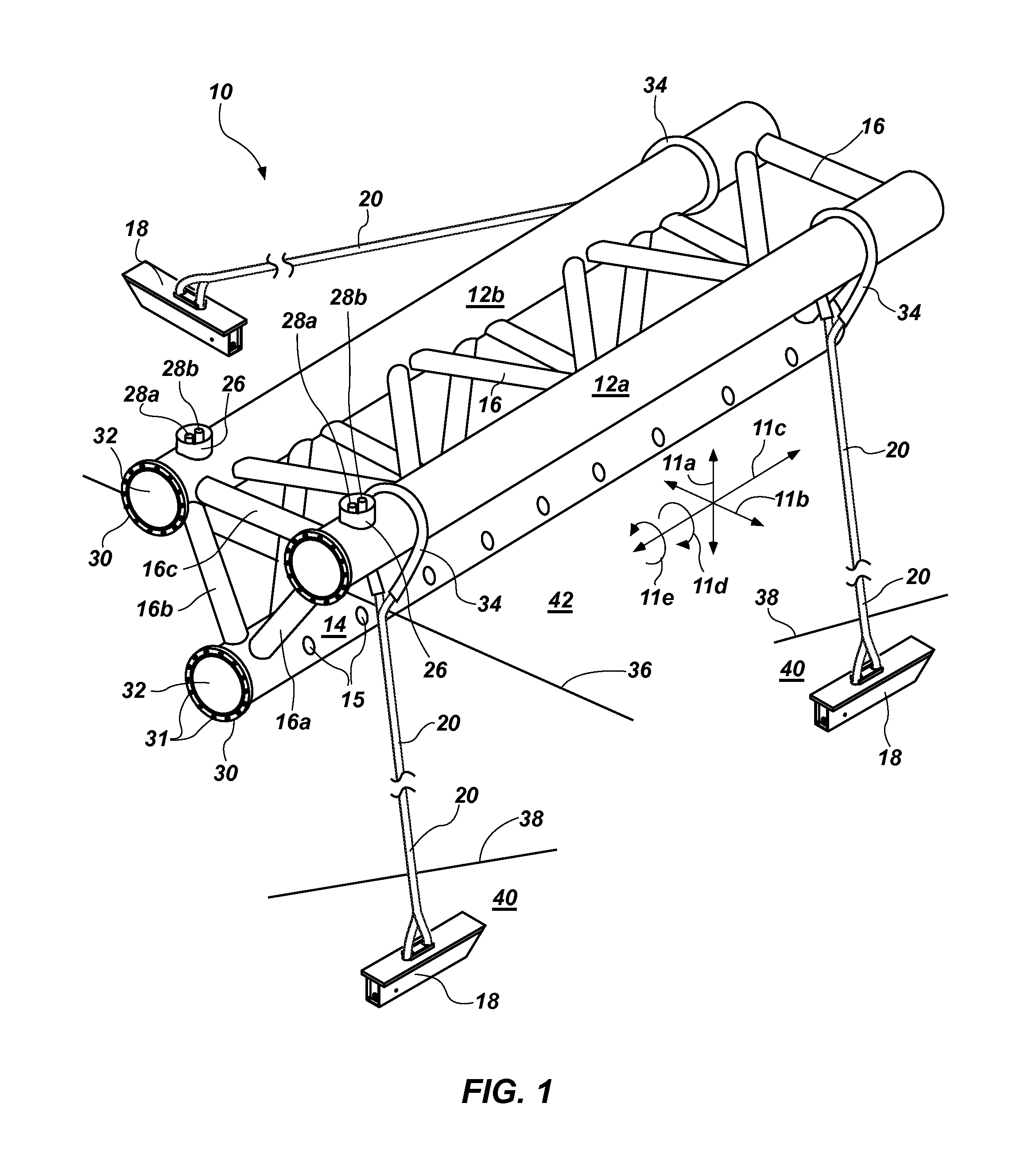

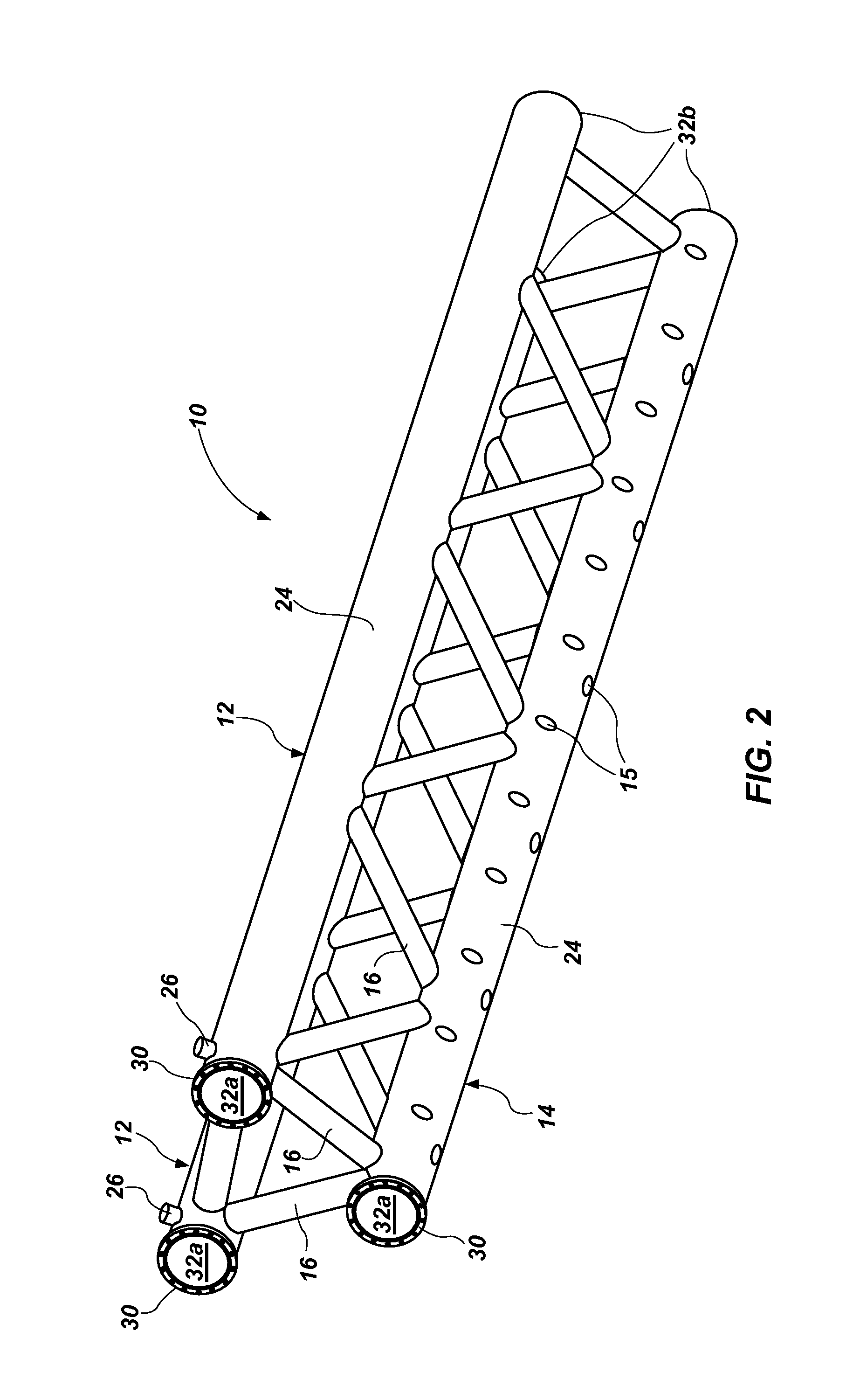

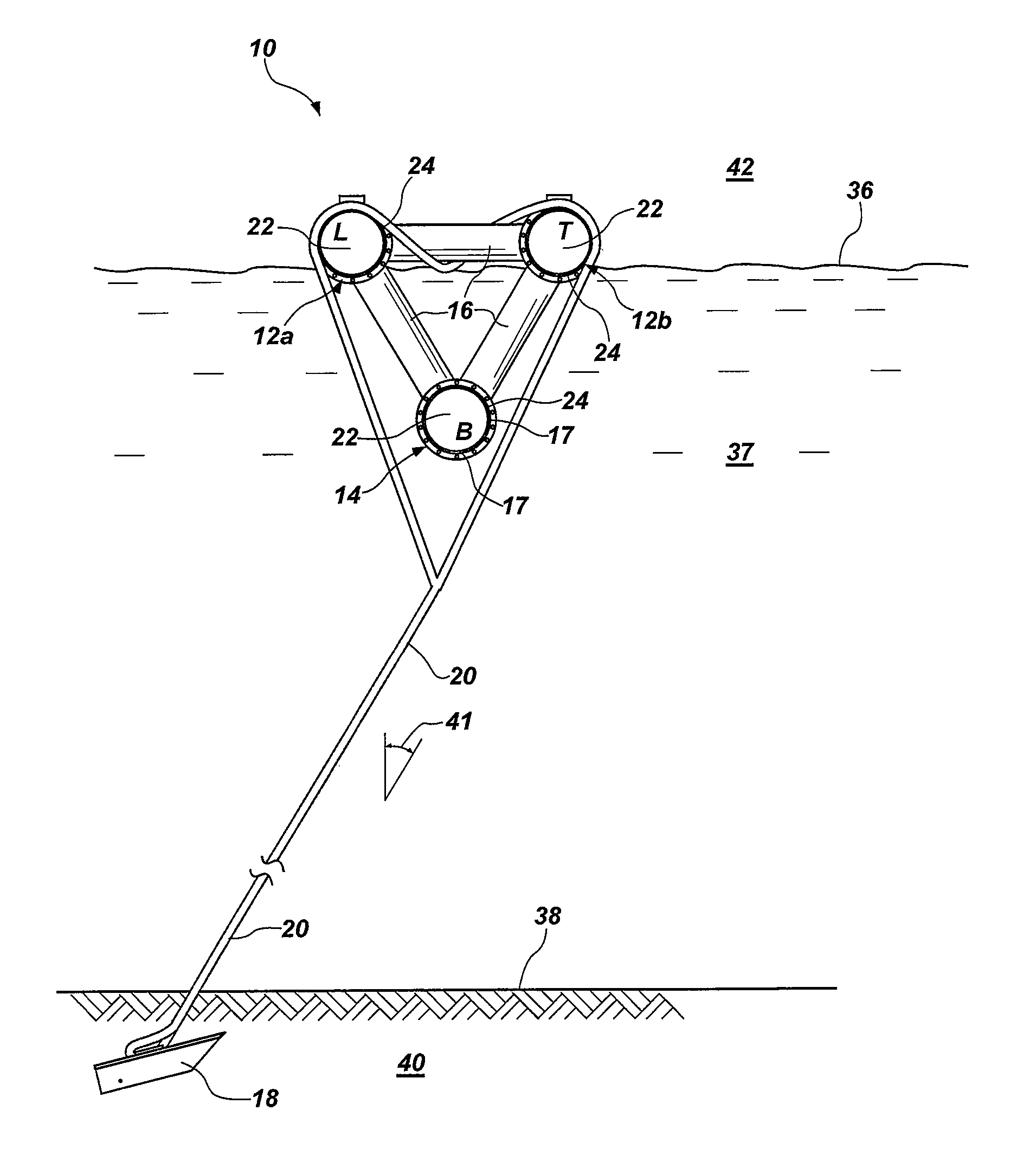

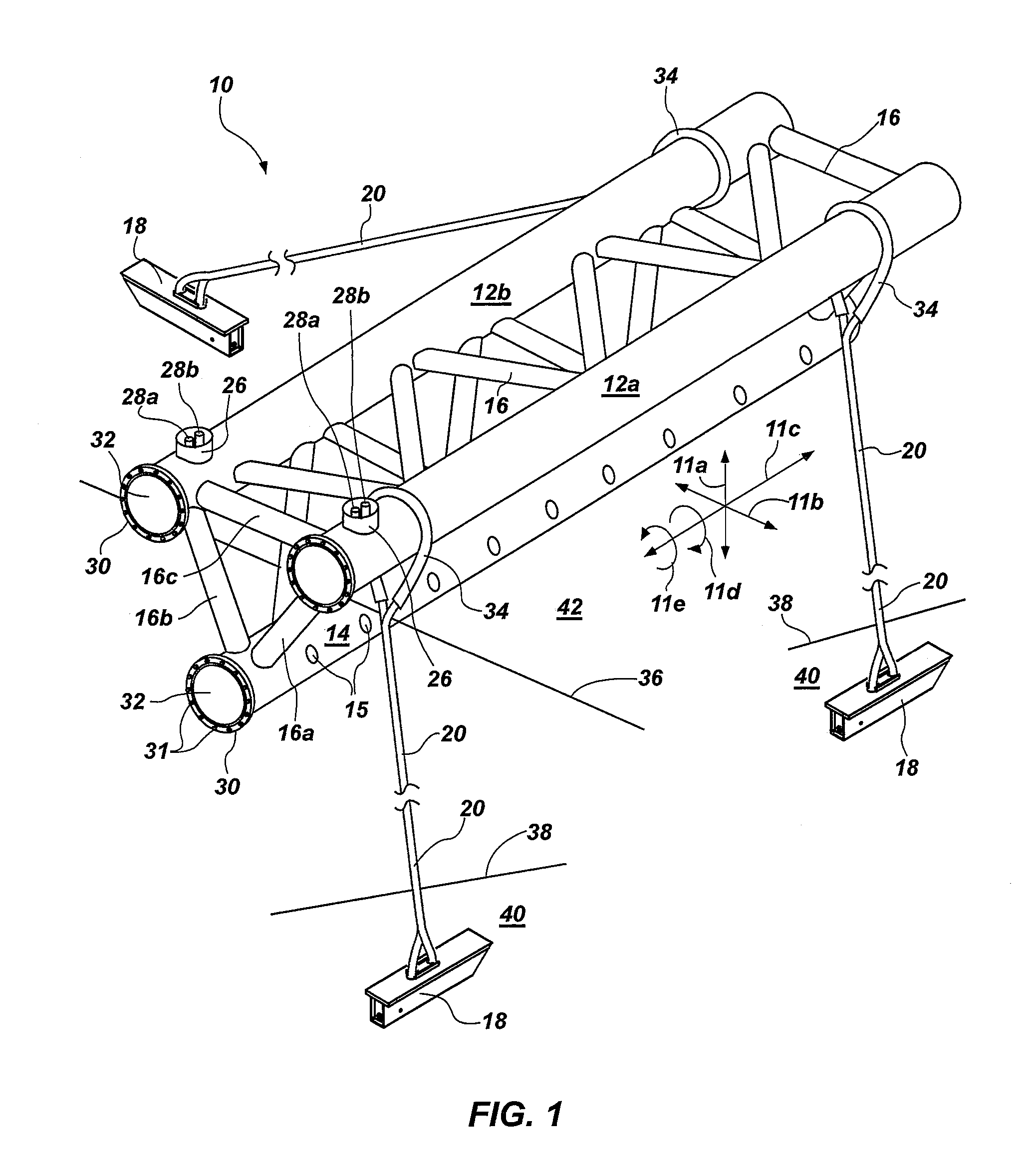

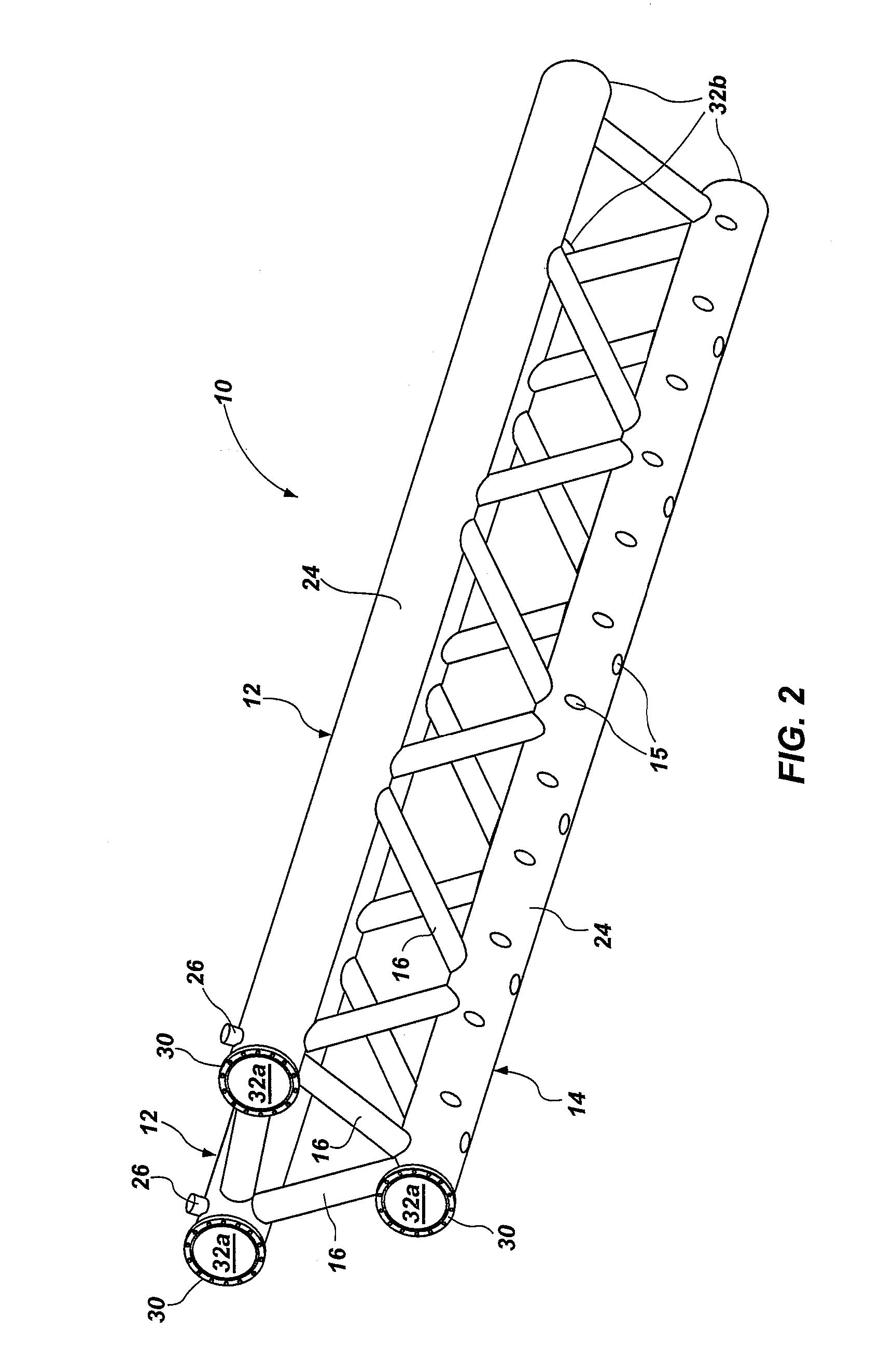

Wave attenuation system and method

A breakwater (wave attenuation system) includes two horizontal tubes as buoyant members connected to one another, their cross-sections representing vertices of a triangle, whose legs are interconnecting struts. A perforated, submerged, ballast tube forms the third vertex. Wave motion is perpendicular to the length of the float tubes tethered to an anchor at the sea floor. A lead float tube rises in response to an approaching wave, often cutting off the wave crest, while a trailing float tube rises less and later as the wave passes. Asynchronous rising and falling of the leading and trailing, floating, top tubes rocks the breakwater, redirecting and dissipating wave momentum, energy, and water volume by rotating the assembly, thrashing the water.

Owner:BETCHER CHRISTOPHER FRED

Wave attenuation system and method

A breakwater (wave attenuation system) includes two horizontal tubes as buoyant members connected to one another, their cross-sections representing vertices of a triangle, whose legs are interconnecting struts. A perforated, submerged, ballast tube forms the third vertex. Wave motion is perpendicular to the length of the float tubes tethered to an anchor at the sea floor. A lead float tube rises in response to an approaching wave, often cutting off the wave crest, while a trailing float tube rises less and later as the wave passes. Asynchronous rising and falling of the leading and trailing, floating, top tubes rocks the breakwater, redirecting and dissipating wave momentum, energy, and water volume by rotating the assembly, thrashing the water.

Owner:BETCHER CHRISTOPHER FRED

Knotless suture anchor

A suture anchor comprises a shell and an anchor member. The shell comprises a body having a distal end, a proximal end and sidewalls therebetween defining an axial cannulation therethrough. The anchor member comprises a body having a distal end and a proximal end which is sized to fit within the cannulation. The sidewalls define a lateral cut-out such that with the anchor member received within the cannulation a first lateral portion of the anchor member is exposed laterally and a second, laterally opposite, lateral portion of the anchor member is enclosed by the sidewalls. A friction enhancement on the first lateral portion frictionally engages a bone surface when the suture anchor is disposed within a bone tunnel defined by the bone surface. Suture is trapped between the shell and the anchor and also between the anchor and the bone surface.

Owner:MEDOS INT SARL

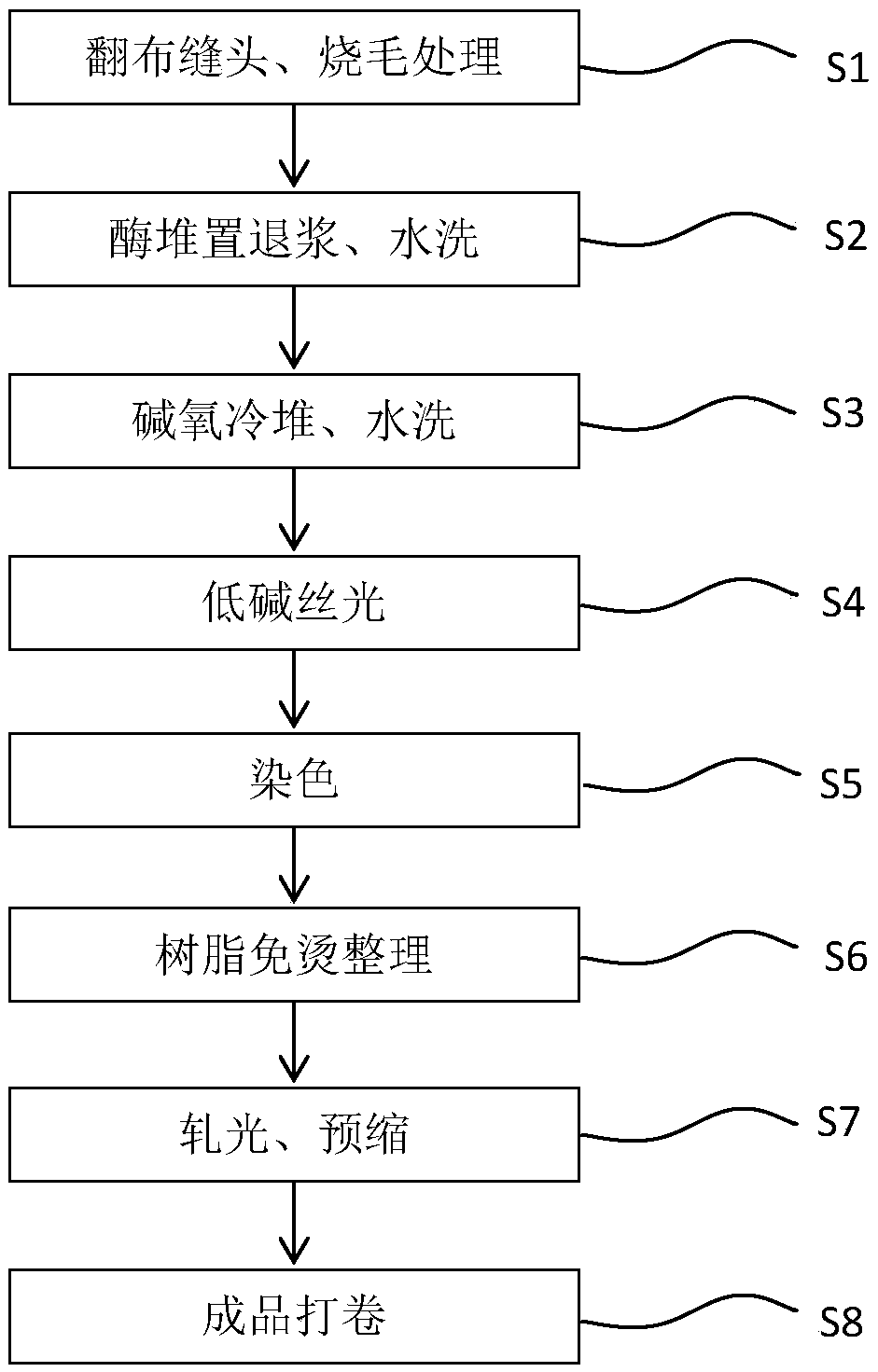

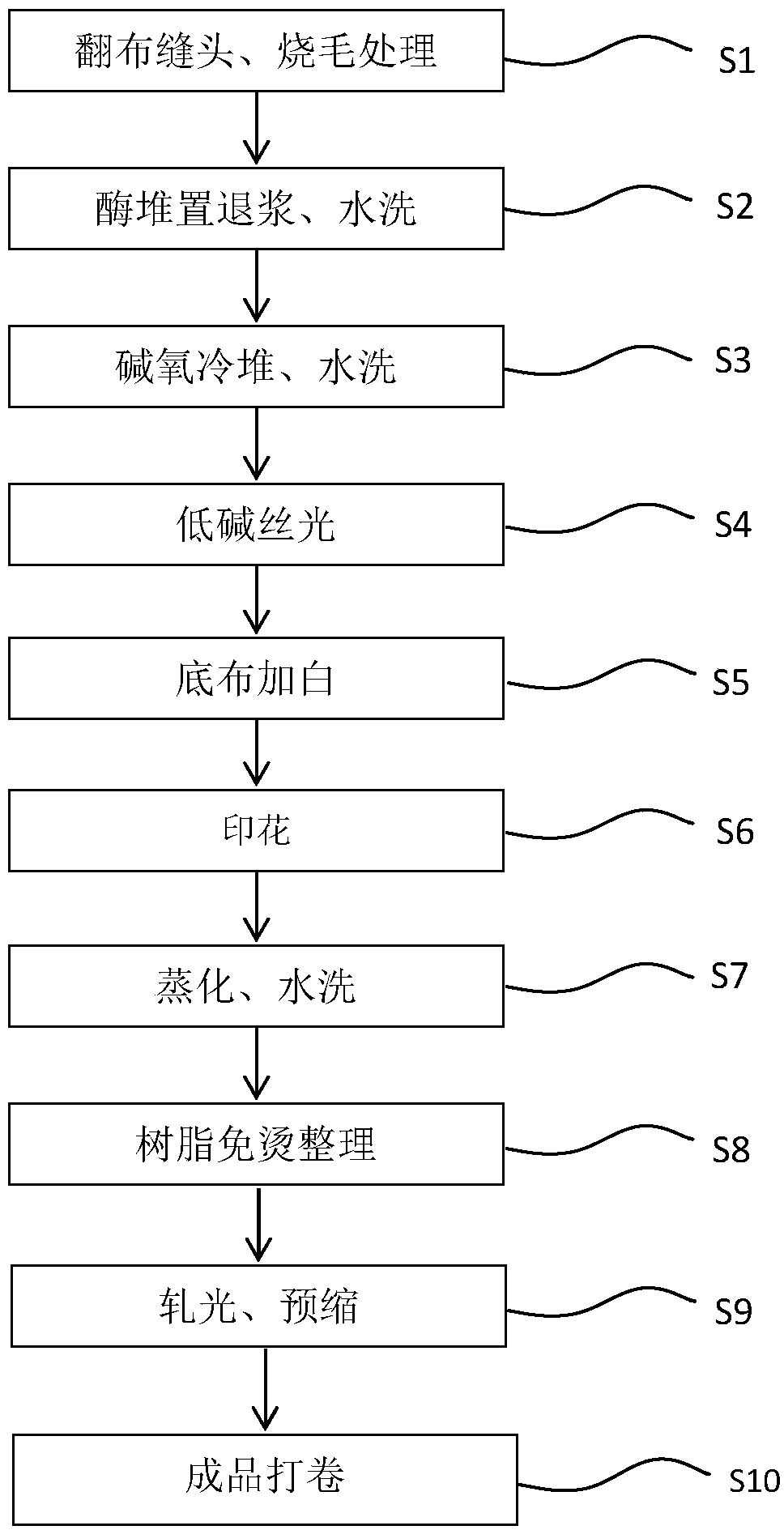

Processing method for improving washability of lyocell standard fiber fabric

InactiveCN109853218AImprove washing resistanceHigh glossMercerising of indefinite length fabricsSucessive textile treatmentsFiberEngineering

The invention relates to a processing method for improving the washability of a lyocell standard fiber fabric. The technological process comprises the following steps of cloth turning for end stitching, singeing treatment, enzyme stacking desizing, washing, alkali-oxygen cold stacking, washing, low-alkali mercerizing, dyeing or printing, ironing-free resin finishing, calendering, pre-shrinking andfinished product rolling; by controlling the whole processing technology and adding the steps of low-alkali mercerizing and ironing-free resin finishing, the water resistance of the lyocell standardfabric is improved. According to the processing method, the defects are overcome that existing lyocell standard fiber fabrics in the prior art are low in washability, the smoothness of fabric surfacesis poor after the fabrics are normally washed by machines several times, fluff is likely to be generated, and the hand feeling is hard. According to the processing method, the washability of the lyocell standard fiber fabric is improved, correspondingly the lyocell standard fiber fabric can be normally washed by a machine, the washing requirement of the lyocell standard fiber fabric is lowered, the high smoothness of the fabric surface of the lyocell standard fiber fabric can still be maintained after the lyocell standard fiber fabric is washed by the machine several times, and the lyocell standard fiber fabric has good luster and a great hand feeling.

Owner:江苏豪申家纺布艺科技有限公司

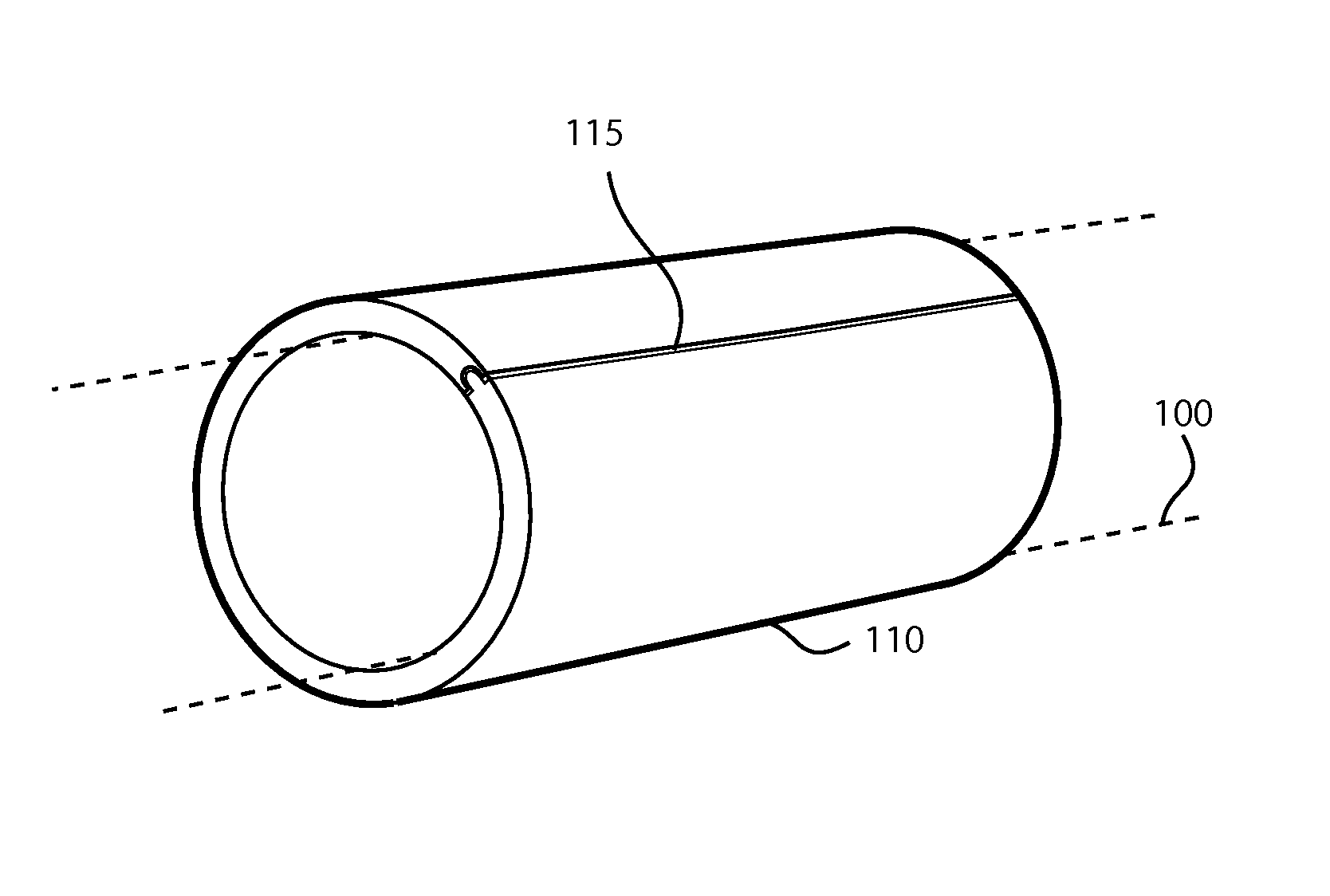

Method for deploying a sleeve and tubing device for restricting and constricting aneurysms and a sleeve and tubing device and system

InactiveUS20130218191A1Preventing from growing and expandingRestricting and constrictingStentsDilatorsCannula deviceBiomedical engineering

A sleeve device, system and method are provided for restricting and / or constricting aneurysms. More particularly, a sleeve and / or a double-walled sleeve is located in or on a vessel in the location of an aneurysm. When placed around the outside of a vessel, is used to restrict and / or constrict the aneurysm containing portion of the vessel. If desired, the sleeve may be constructed as a double-walled sleeve that can be inflated to apply pressure to and / or in the vessel.

Owner:HELTAI PAUL

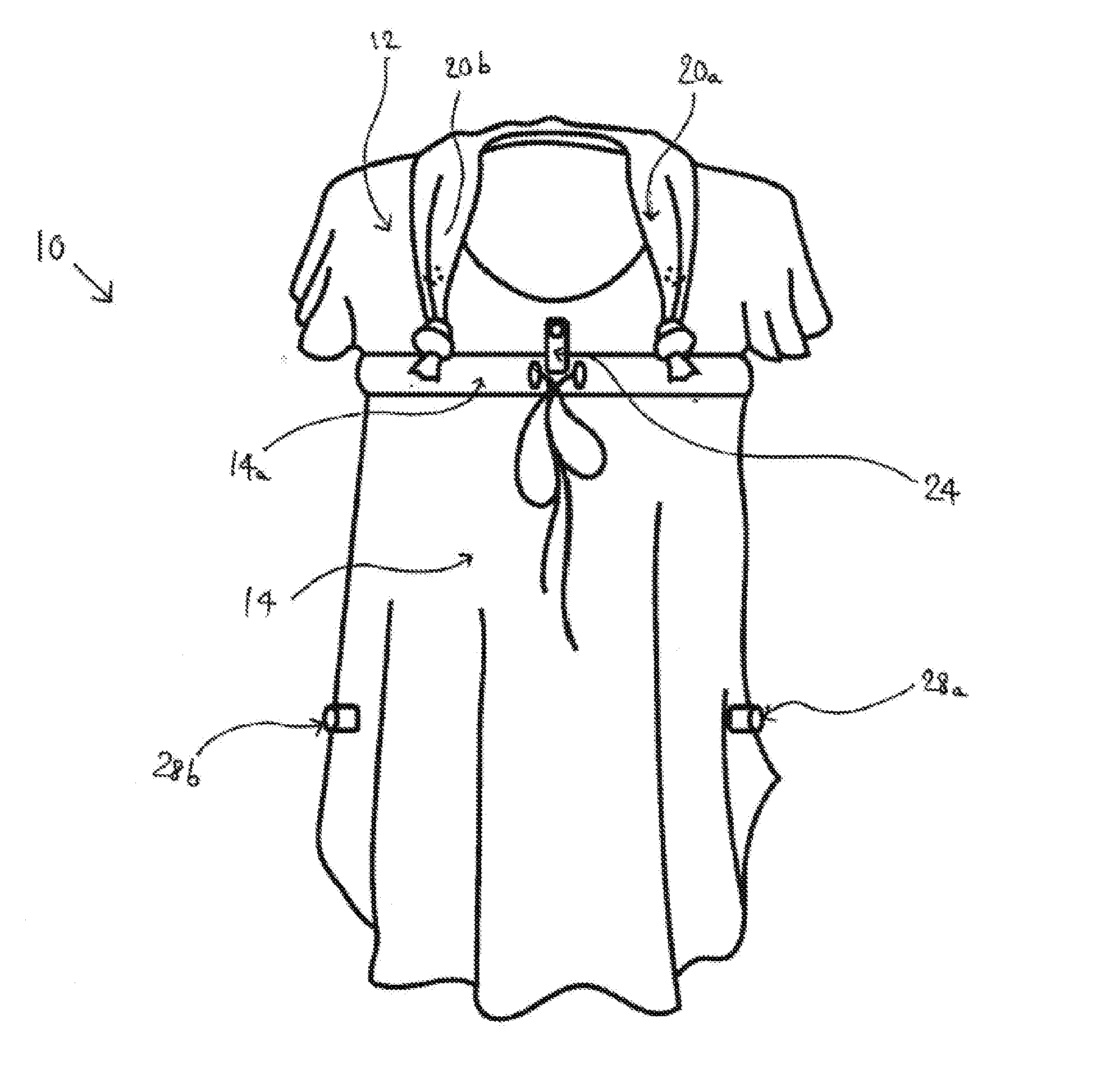

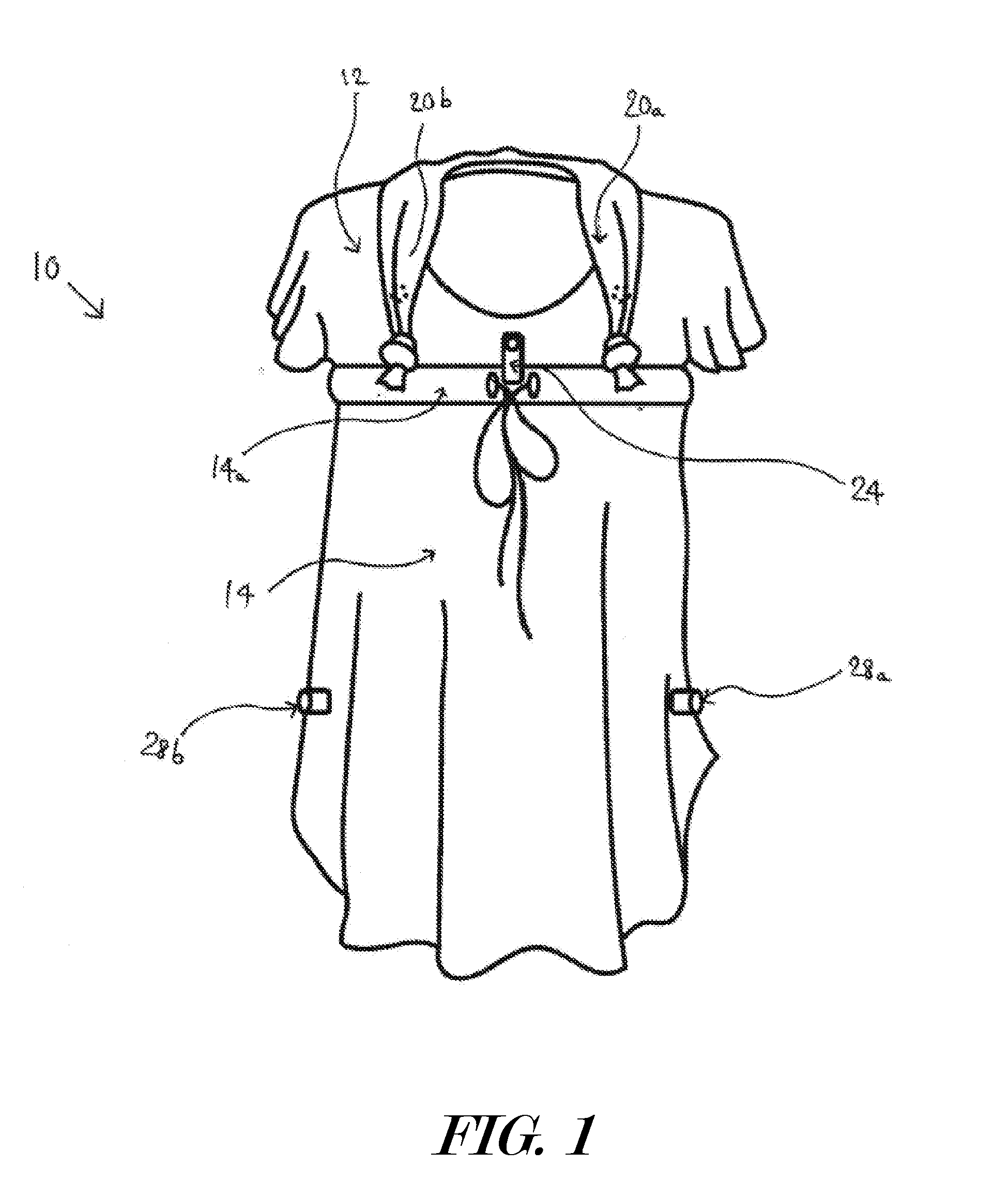

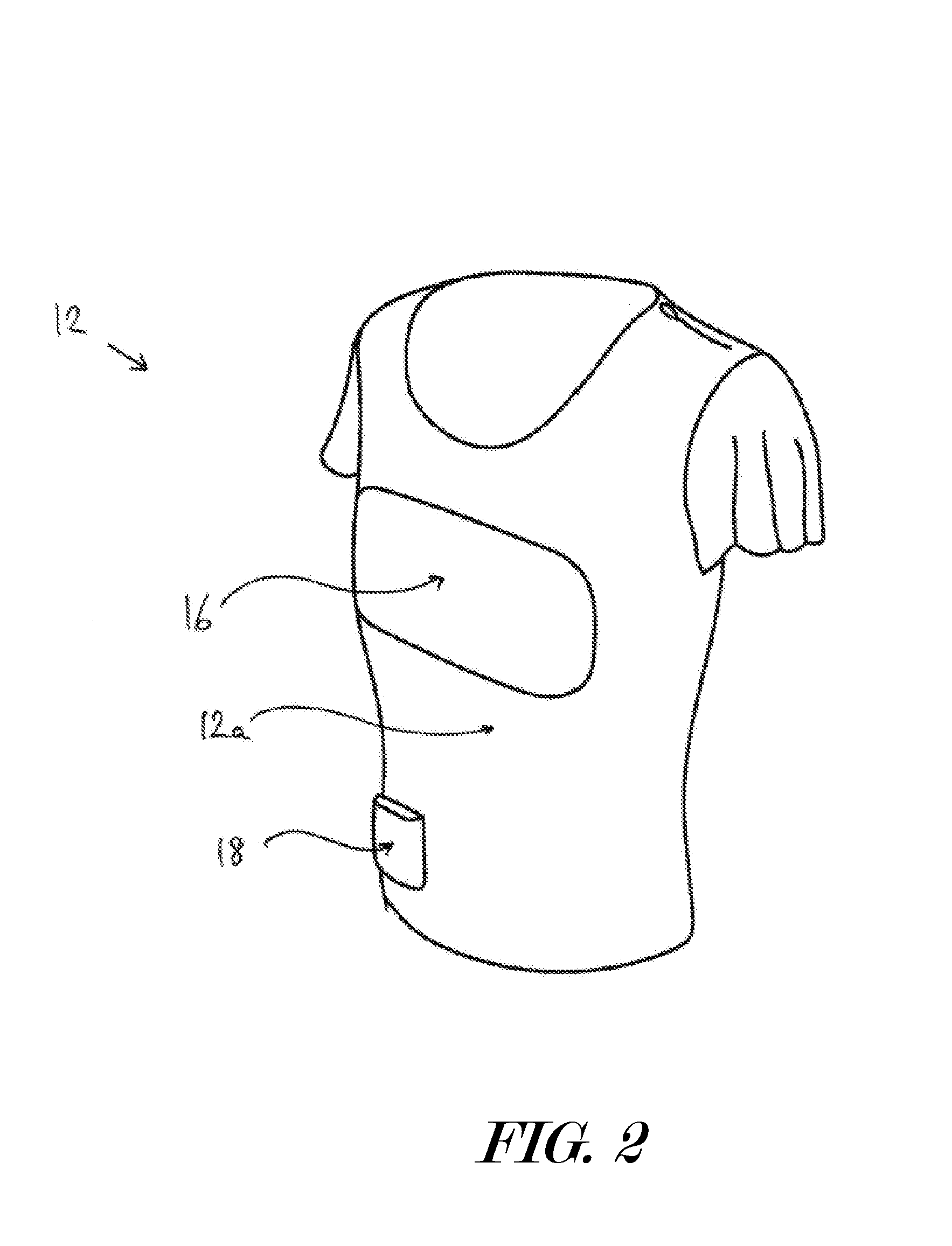

Nursing garment

InactiveUS20160295932A1Prevent saggingLess irritatingBrassieresMaternity clothingBreastfeedingBiomedical engineering

A nursing garment for wearing when breastfeeding an infant, the garment comprising a first garment layer having a front surface that leaves breasts uncovered when worn, a second garment layer connected to the first garment layer, the second garment layer overlying at least a portion of the first garment layer and covering breasts when worn, and at least one support member moveable between a non-breastfeeding position and a breastfeeding position.

Owner:HAYWARD ROPHIN +1

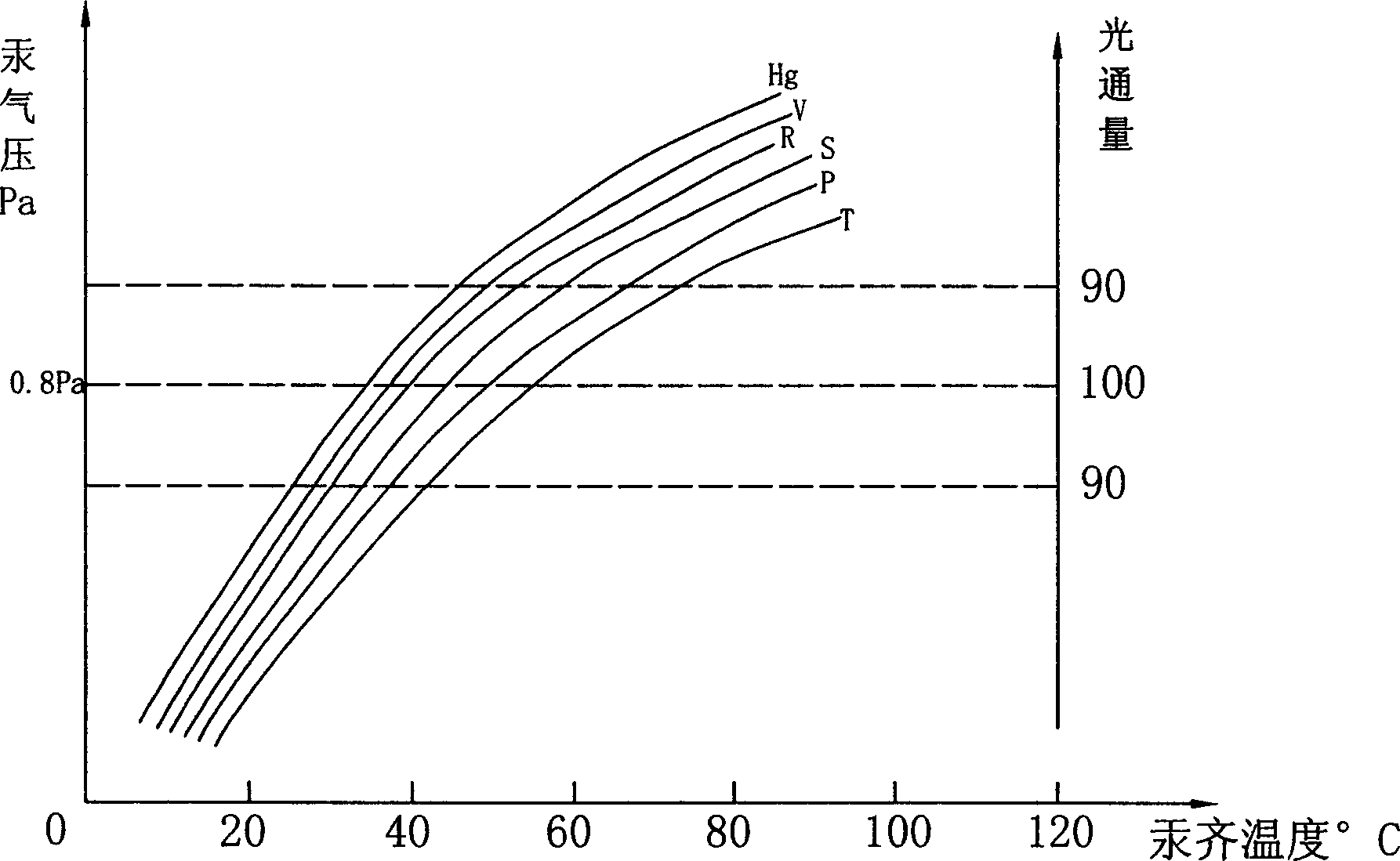

Solid mercury with high content

InactiveCN1818107AMercury range is wideGood low temperature characteristicsFluorescenceRoom temperature

The invention opened solid hydrargyrum belong to amalgam field. The weight content is: Hg 20%-65%, Sn 5%-74.5%, Zn 5%-35%, Ag 0.5%-10%, Ga 0%-10%, In 0%-10%. The solid Hg has the wide range of the Hg%, even it includes 60% Hg, it keeps the solid in the room temperature. It can be used to make the fluorescent lamp. The strip lamp has the good low-temperature characteristics and has the high brightness. Also it can use the light Hg grain, so it can decrease the damage to the fluorescent layer. The fluorescent lamp includes power saving fluorescent lamps, bactericidal lamp.

Owner:GAOYOU GAO HE PHOTOELECTRIC EQUIP

PCB appearance on-line maintenance device and maintenance method

InactiveCN108174523AAvoid multiple handlingReduce chafingPrinted circuit secondary treatmentConveyor partsScratchingReliability engineering

The invention discloses a PCB appearance on-line maintenance device. The PCB appearance on-line maintenance device includes an on-line AOI machine, an annular maintenance unit and a browning line, wherein the on-line AOI machine, the annular maintenance unit and the browning line are successively connected; and the annular maintenance unit includes an annular conveyer belt and an automatic maintenance machine which is connected with the annular conveyer belt. The PCB appearance on-line maintenance device has the advantages of implementing on-line maintenance of PCB appearance, avoiding carrying PCBs for multiple times, improving the processing efficiency, reducing the labor intensity, reducing the probability of scratching of the surfaces of the PCBs because the PCBs are carried manually.A maintenance method is also disclosed. After the on-line AOI machine detects the appearance of the PCBs, qualified PCBs can be directly conveyed to the browning line for browning processing, and PCBwith defective appearance are conveyed to the automatic maintenance machine for maintenance and then are conveyed to the browning line for subsequent browning processing after being qualified throughmaintenance. The maintenance method has the advantages of being high in level of mechanization, greatly reducing the number of carrying boards manually, improving the processing efficiency and qualityof products, and being suitable for industrial mass maintenance of PCBs.

Owner:江西景旺精密电路有限公司

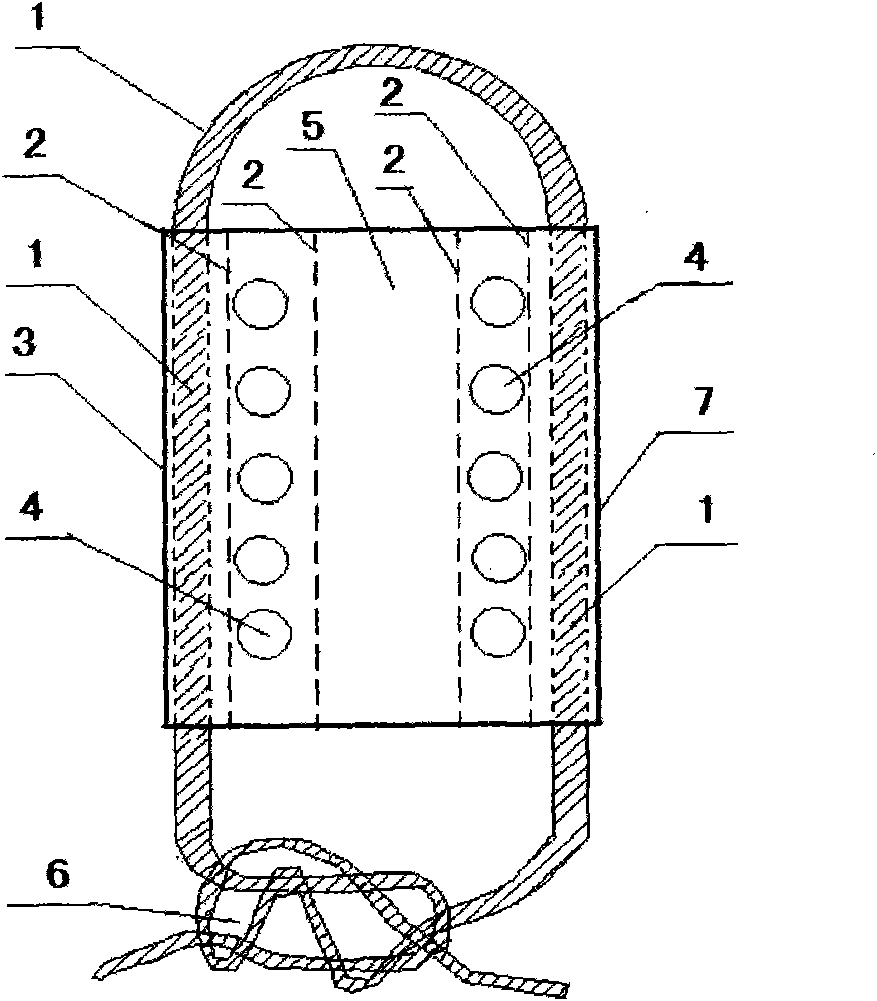

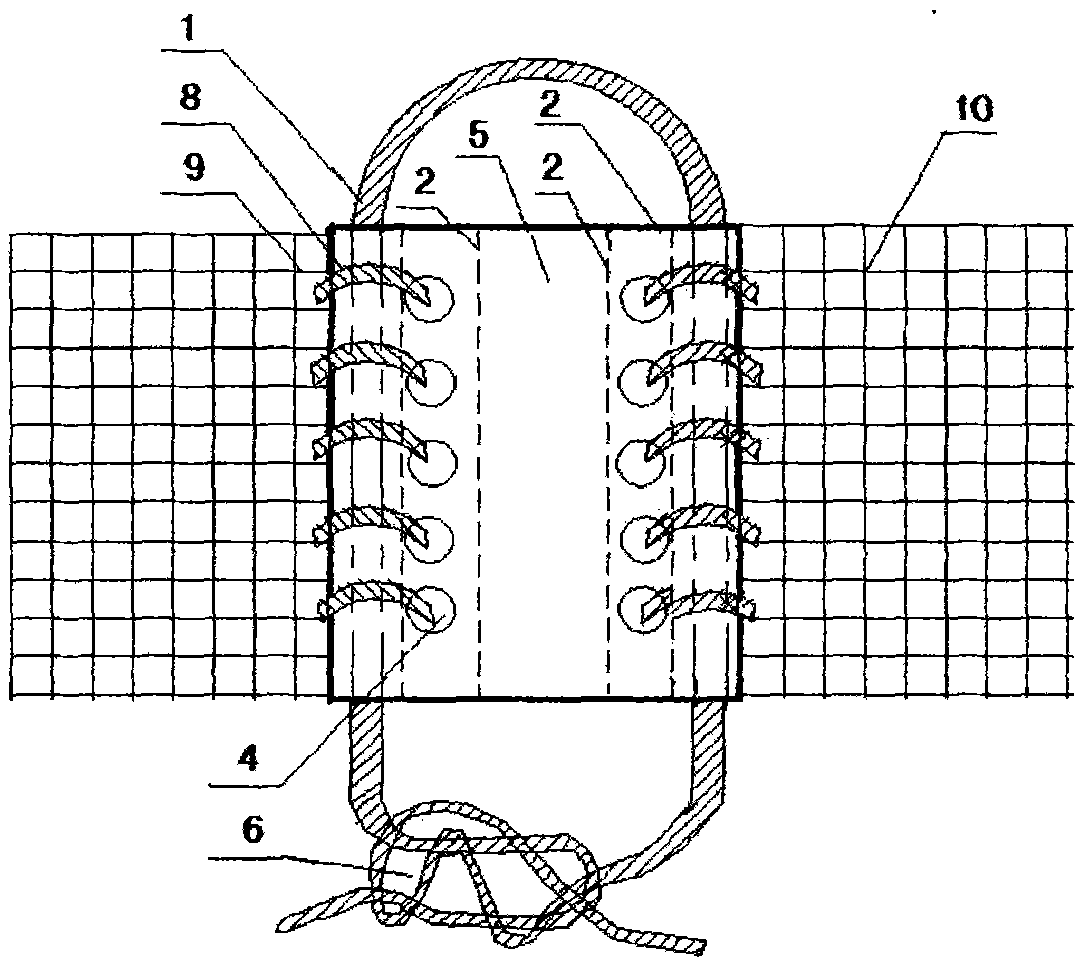

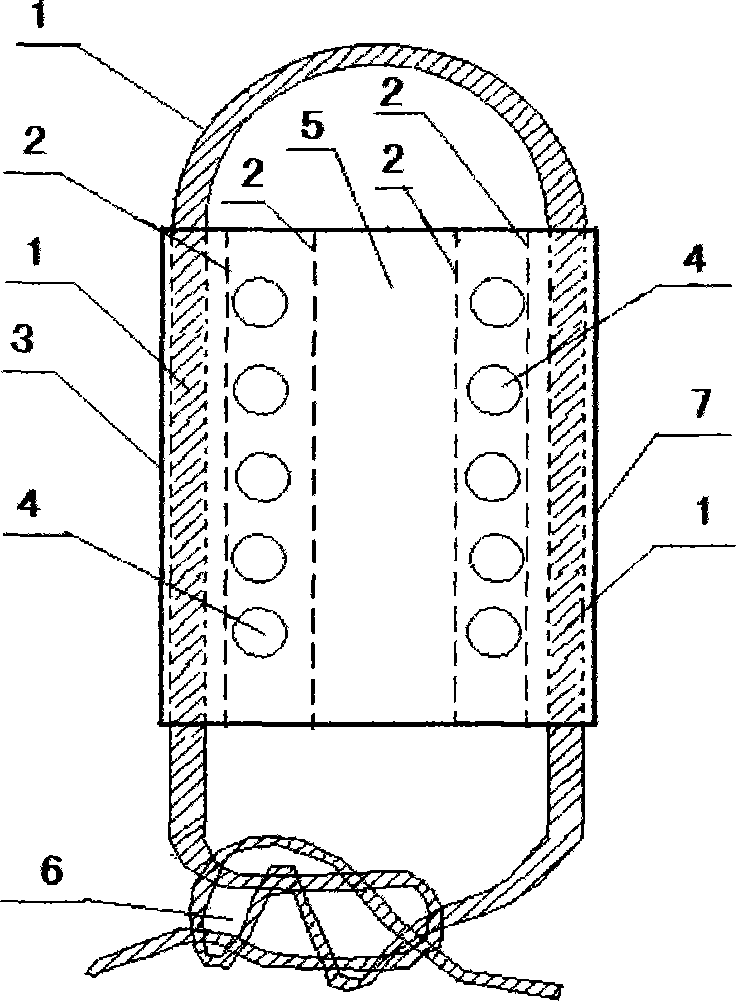

Half-soft state connecting method between copper alloy woven meshes for cage

InactiveCN102084830AQuality improvementImprove mechanical propertiesClimate change adaptationPisciculture and aquariaMetallurgyCopper alloy

The invention discloses a half-soft state connecting method between copper alloy woven meshes for a cage, relates to connection of copper alloy woven meshes for the cage, and provides a method for splicing the copper alloy woven meshes for the cage. In the method, sea anchoring cloth, ropes, suture lines and tarpaulin rings are adopted, and the method is characterized in that: the sea anchoring cloth, the ropes, the suture lines and the tarpaulin rings are assembled into half-soft state connecting pieces; the half-soft state connecting pieces are arranged between two copper alloy woven meshes; one end of a high-strength polyethylene rope is fixed at a net joint which is 3 meshes away from the splicing edge of the copper alloy woven meshes; the other end of the high-strength polyethylene rope passes through ring plates of the half-soft state connecting pieces and meshes of the woven meshes in turn; the other end of the high-strength polyethylene rope is fixed at a net joint which is 4 meshes away from the splicing edge of the copper alloy woven meshes; and the half-soft state connecting pieces are spliced with the other copper alloy woven mesh in the adjacent two copper alloy woven meshes together. The method is used for splicing the adjacent two copper alloy woven meshes in the cage.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Upward bending correction mechanism

Owner:WUXI MICRO RES

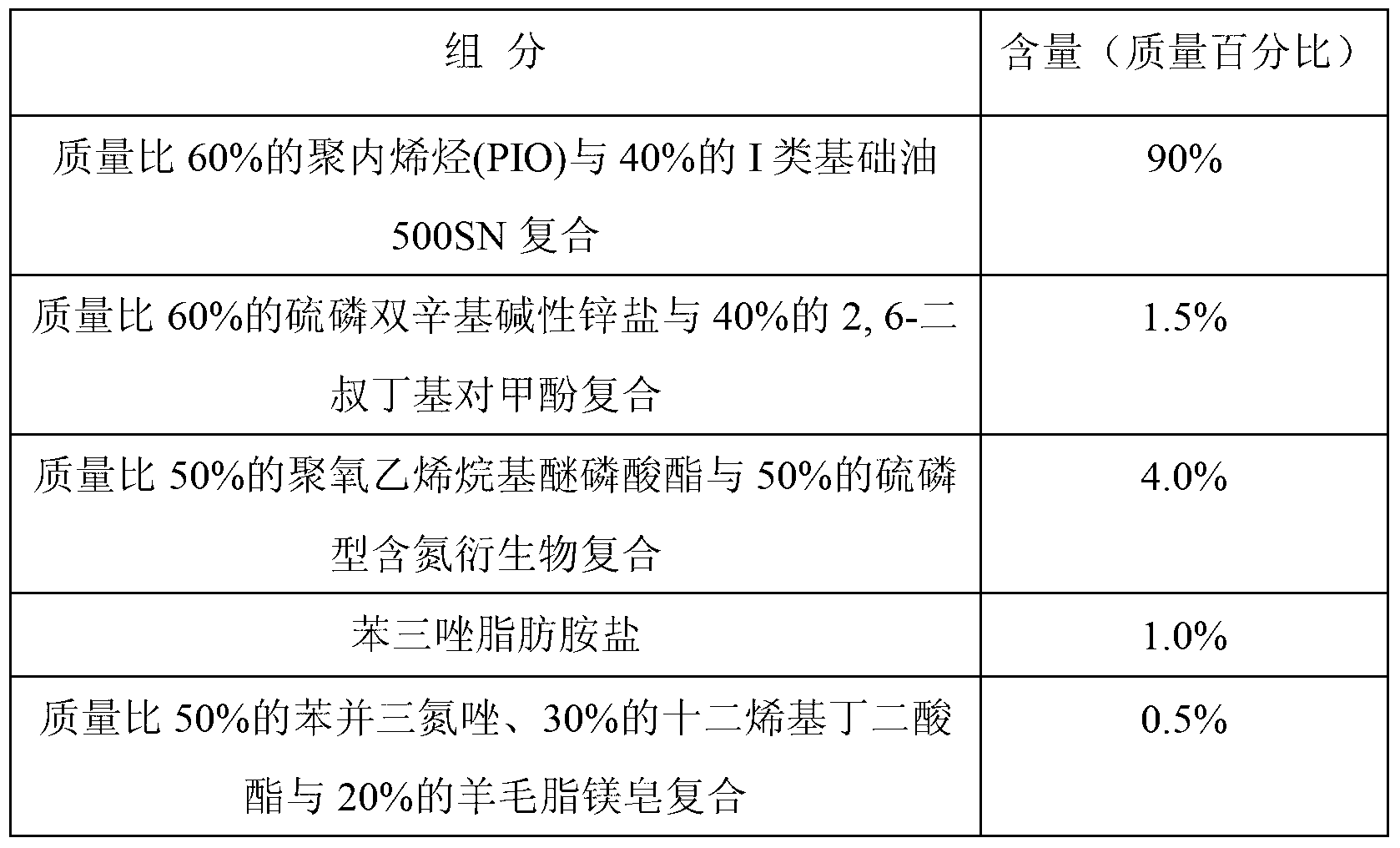

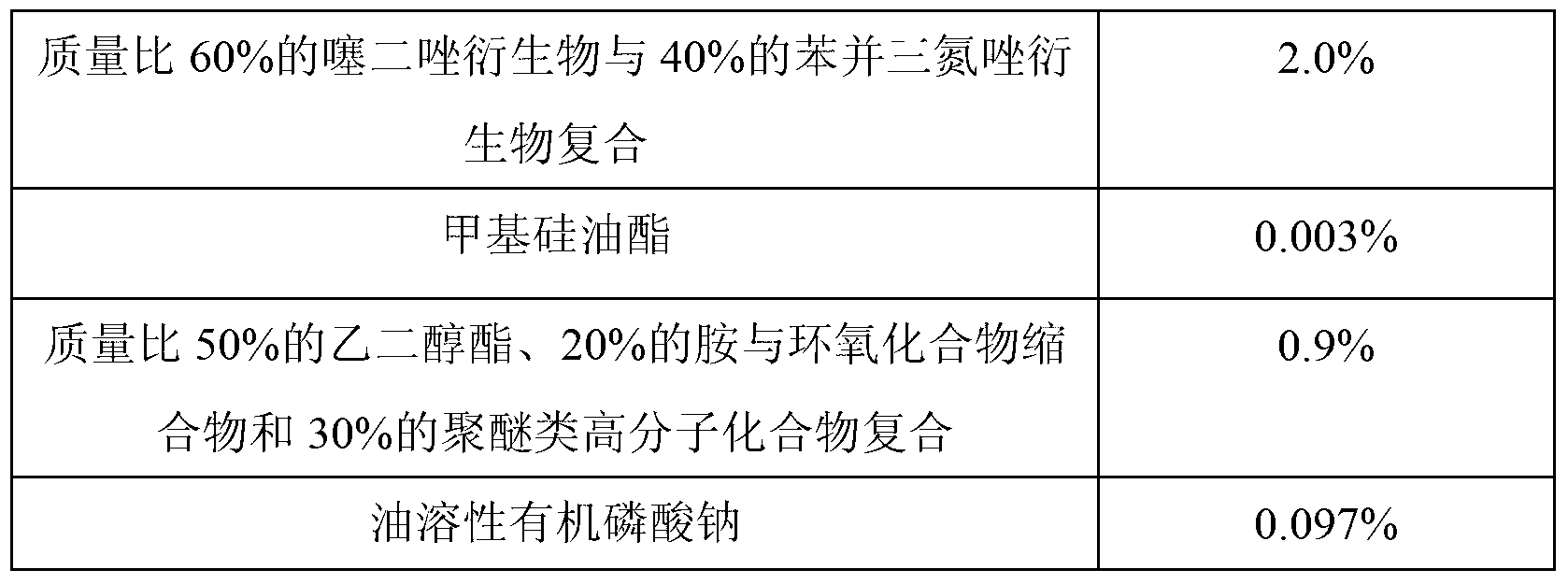

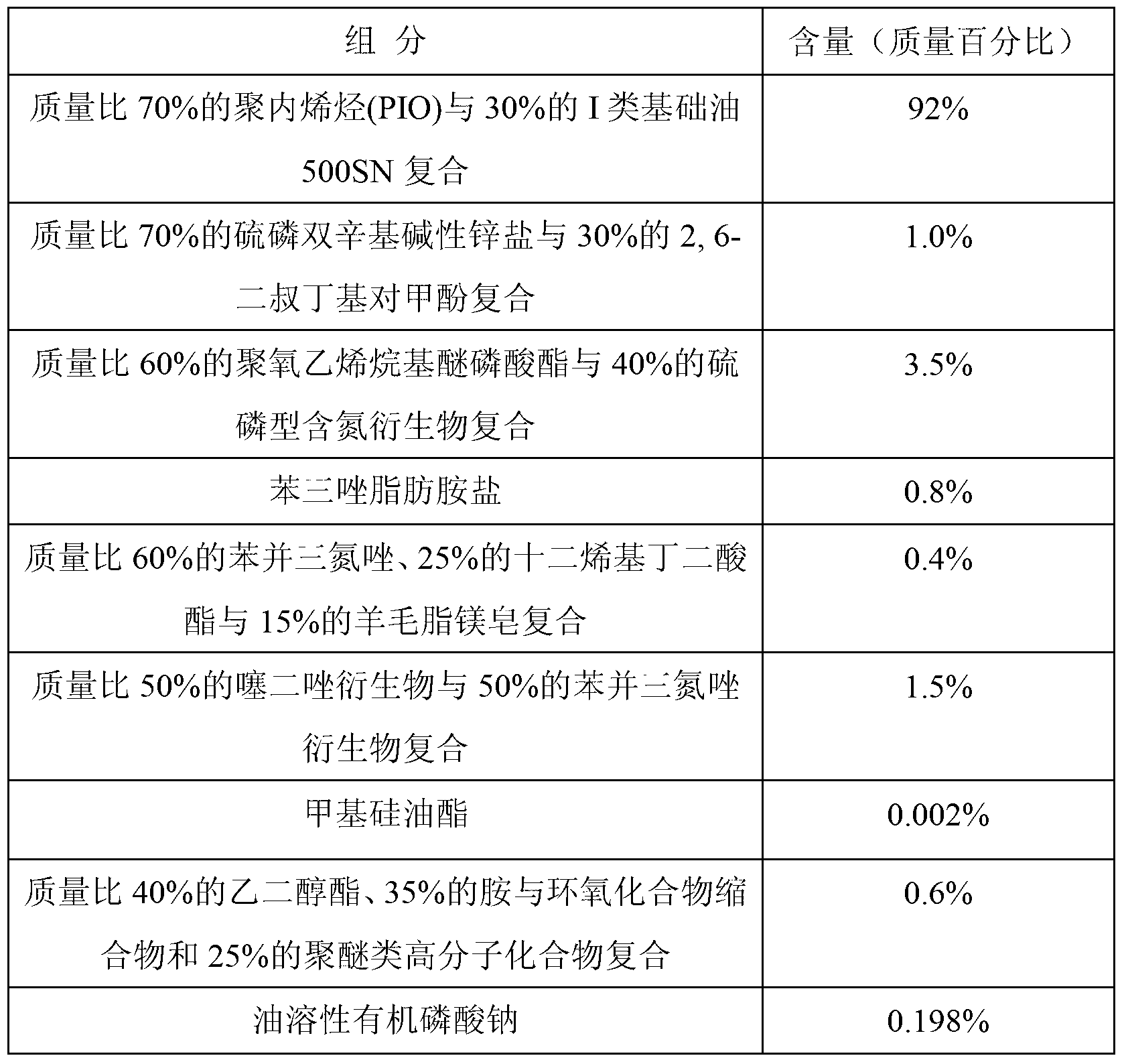

High water resistance type heavy load industrial gear oil

The invention discloses a high water resistance type heavy load industrial gear oil, which comprises the following ingredients in percentage by mass: 90-94% of base oil and 10-6% of other additives. PIO (Poly Internal Olefin) and I-type base oil 500SN are combined to serve as the base oil. The high water resistance type heavy load industrial gear oil has the remarkable advantages that the comprehensive property is good, and the use requirements on various performance indexes are met. The gear oil has good thermal oxidation stability, extreme pressure property, abrasion resistance, anti-rust resistance, foam resistance and outstanding high-temperature demulsibility; the gear face abrasion and scratching or even sintering are effectively reduced, the gear transmission efficiency is improved, and the use requirements of industrial gears in extreme severe rugged environments such as high temperature, high humidity, dust, impact load and strong vibration are met. Products of the industrial gear oil can meet the performance requirements on the viscosity grades N150, N220 and N320 of the GB5903-2011 heavy load industrial gear oil.

Owner:GUANGXI UNIV

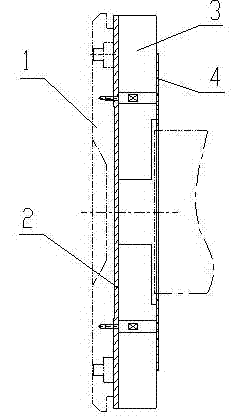

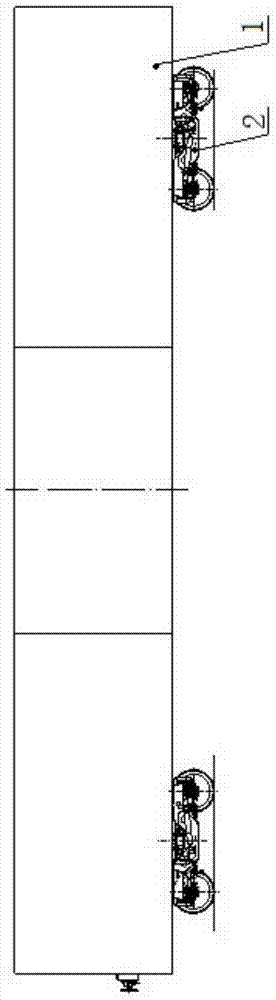

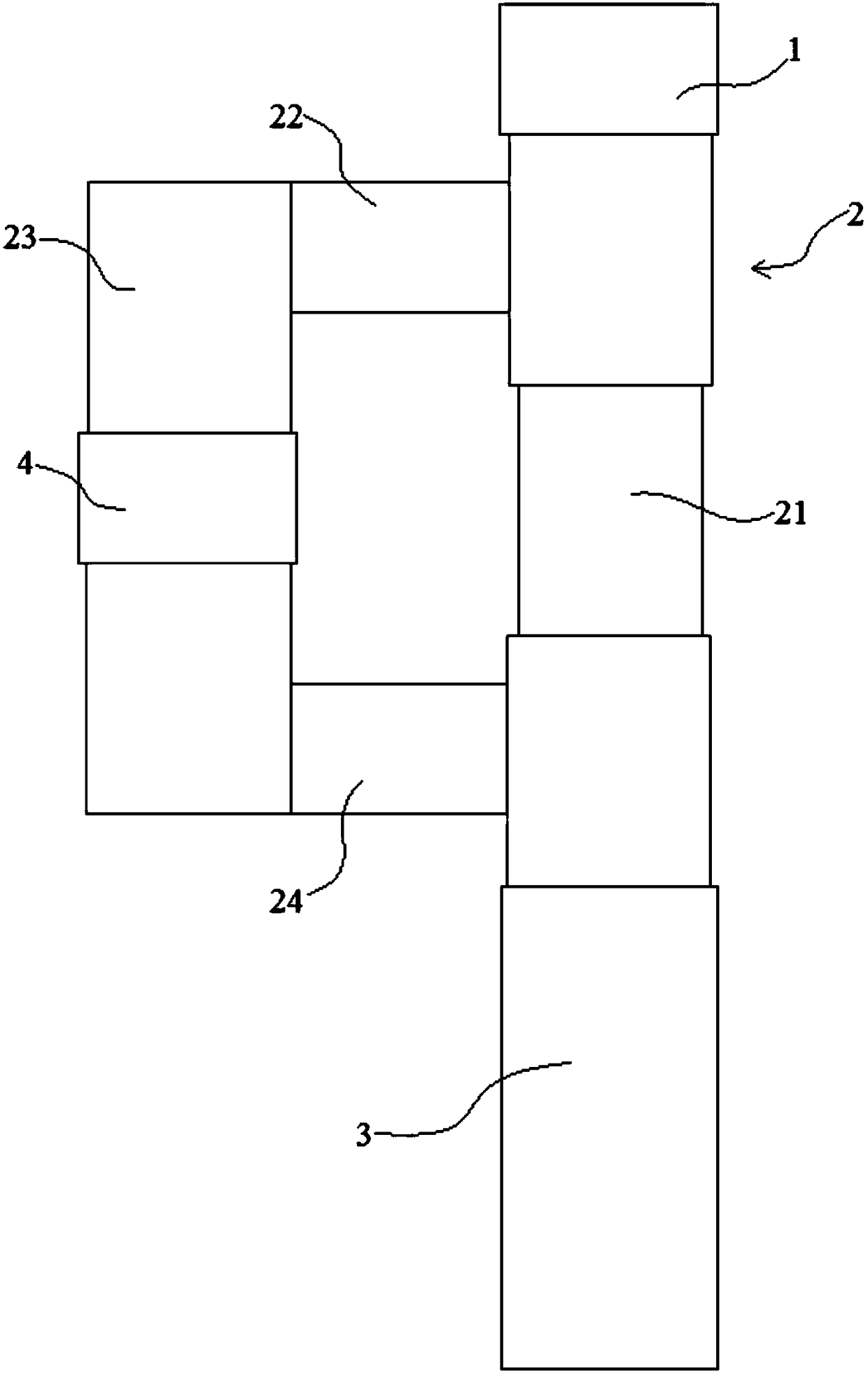

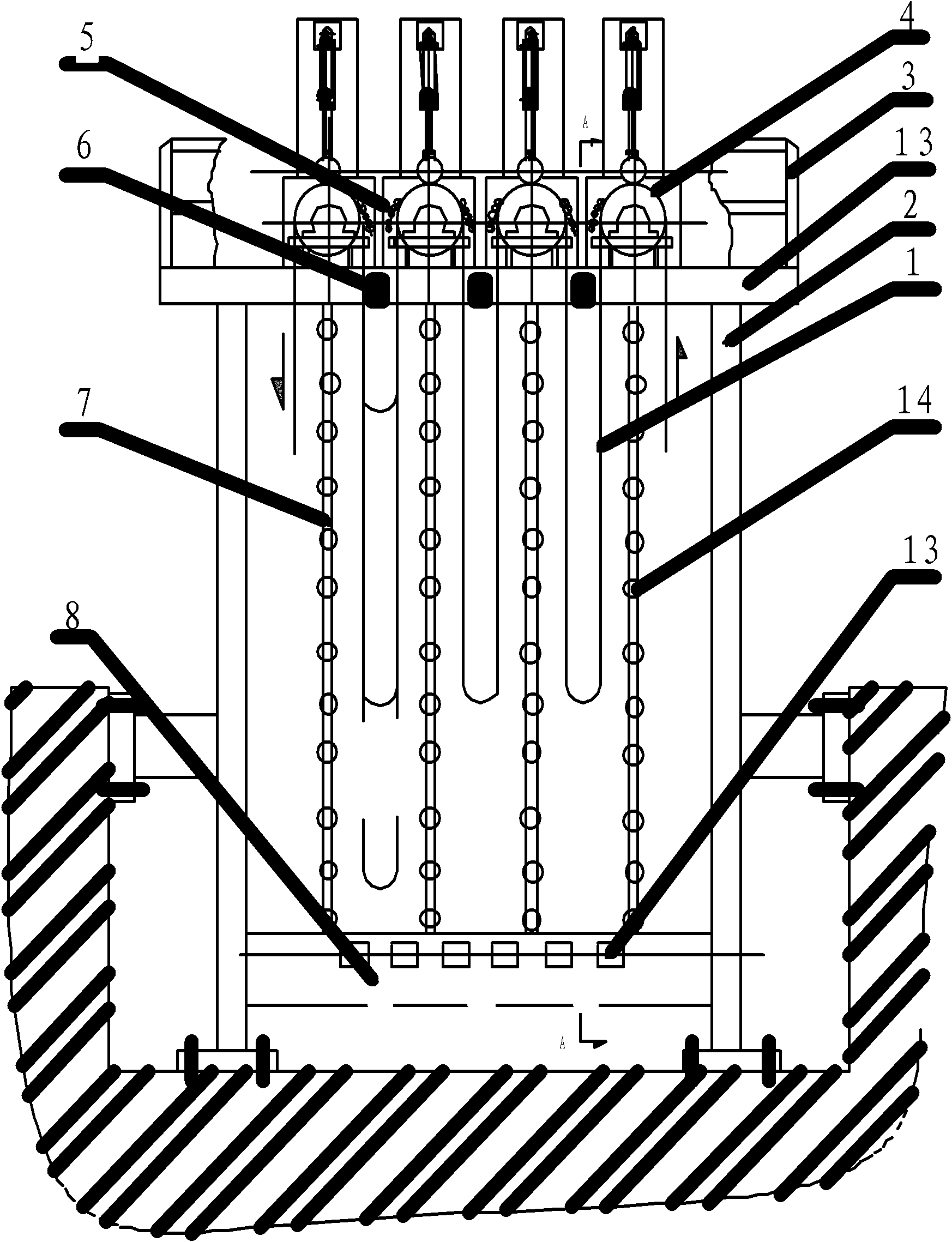

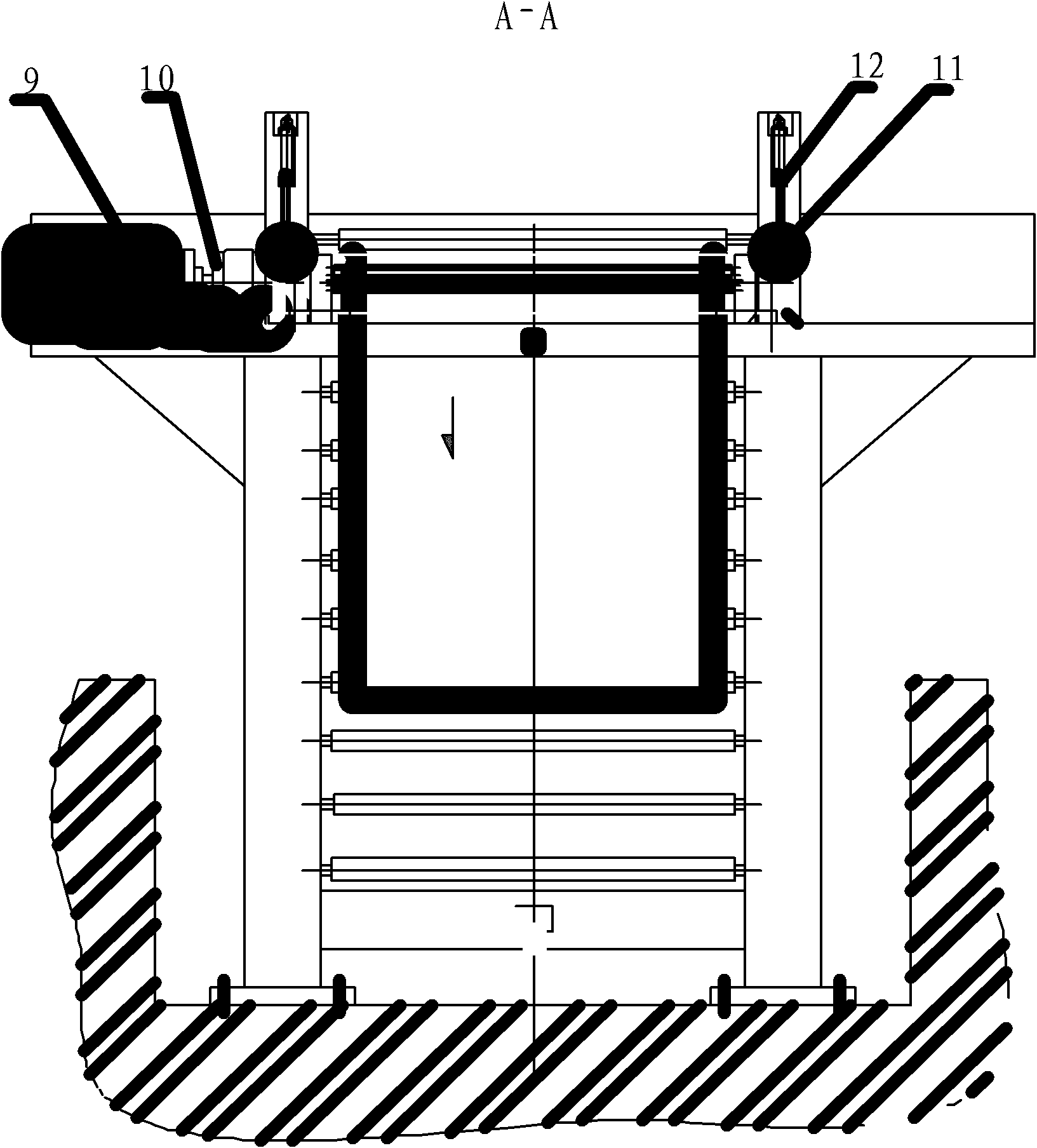

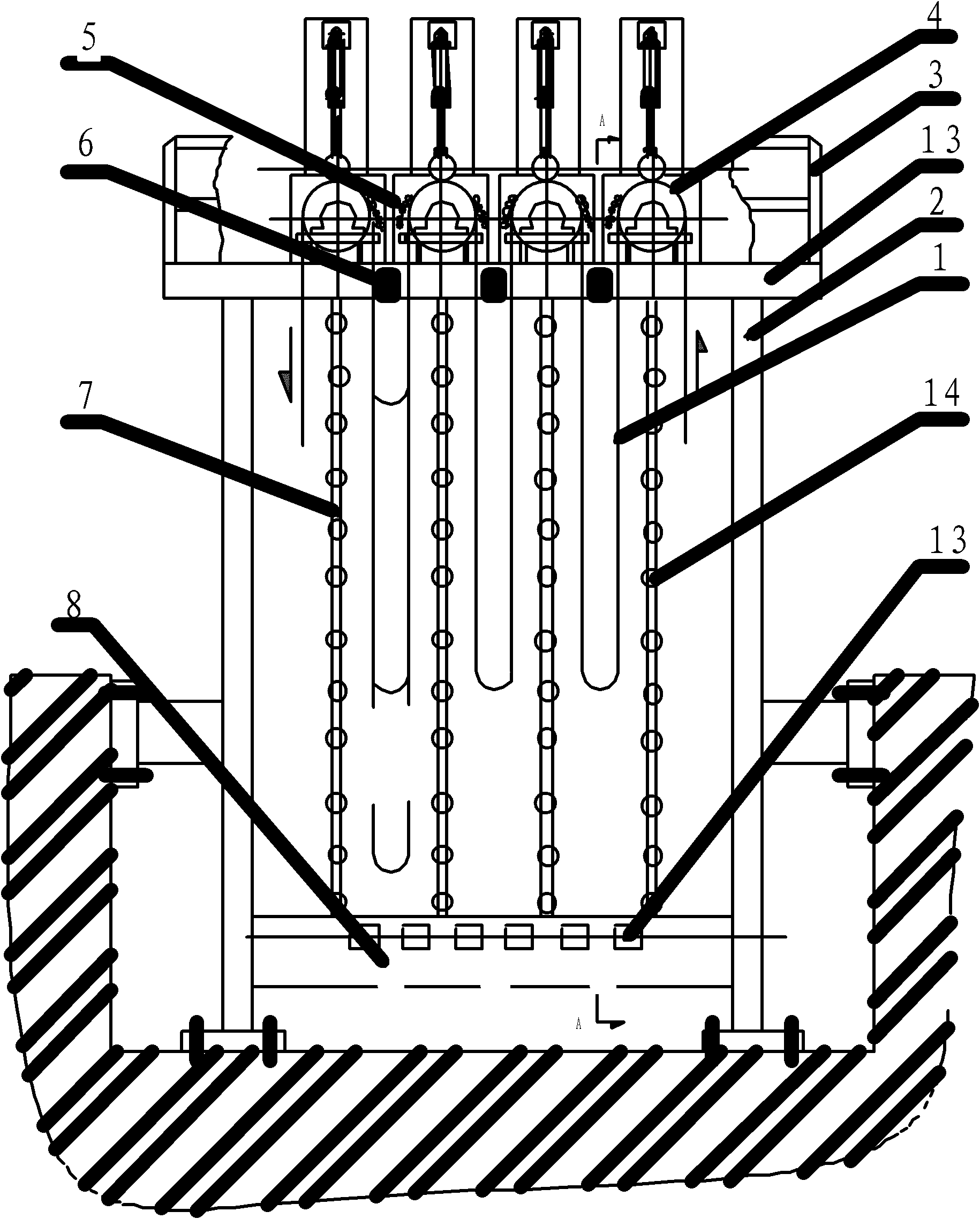

Vertical tension-free movable sleeve

InactiveCN102172729AReduce power consumptionLow costMetal-working feeding devicesFlexible work arrangmentsProduction lineEngineering

The invention provides a vertical tension-free movable sleeve, which solves the problems of large power consumption of a storage mechanism, serious energy waste, high production cost, low plate shape protection capacity, application limitation to occasion when surface protection requirements are low, and low safety of the production line in the prior art. The invention adopts a new technical scheme that the vertical tension-free movable sleeve comprises a machine frame (2), a guardrail (3), pinch rolls (4), an upper position detection device (6), an isolating device (7) and a lower position detection device (8), wherein the pinch rolls (4) are positioned on the top of the machine frame (2); the isolating device (7) is arranged between the top and bottom of the machine frame; and the position detection devices for detecting the position of a steel strip are arranged on cross beams (13) arranged on the top and bottom of the machine frame. When the technique is adopted, power consumption is small, energy is saved, the storage capacity is high, the plate shape protection performance is high, damage to the steel strips is avoided, and the safety is high.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

Screw acid pickling processing method

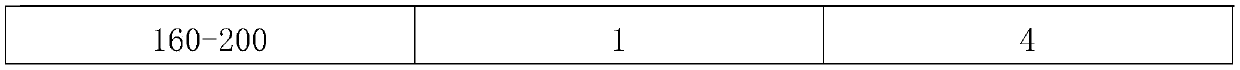

The invention discloses a screw acid pickling processing method. The screw acid pickling processing method comprises the steps of (1) feeding materials, wherein products needing treatment are lifted and placed in an annealing furnace, the annealing furnace is tightly covered with a furnace cover; (2) raising temperature, wherein the temperature in the annealing furnace is slowly raised to 680-760 DEG C from the normal temperature within 3-4 hours; (3) keeping the temperature, wherein if the materials are 1018 wires or 1022 wires, the temperature is kept for 4-6 hours at 680-715 DEG C, and if the materials are 10B21 wires or 1039 wires or CH38F wires, the temperature is kept for 5.5-7.5 hours at 740-760 DEG C; and (4) conducting cooling treatment, wherein the temperature in the annealing furnace is slowly lowered to 550 DEG C or below within 3-4 hours, and then the temperature of the products is lowered to the normal temperature through furnace cooling. According to the screw acid pickling processing method, the wires are heated to an appropriate temperature, the temperature is kept for a certain time, and then slow cooling is conducted; and in this way, the crystalline structure is adjusted, the hardness is lowered, and the normal temperature machining performance of the wires is improved.

Owner:明光市久鼎五金制品有限公司

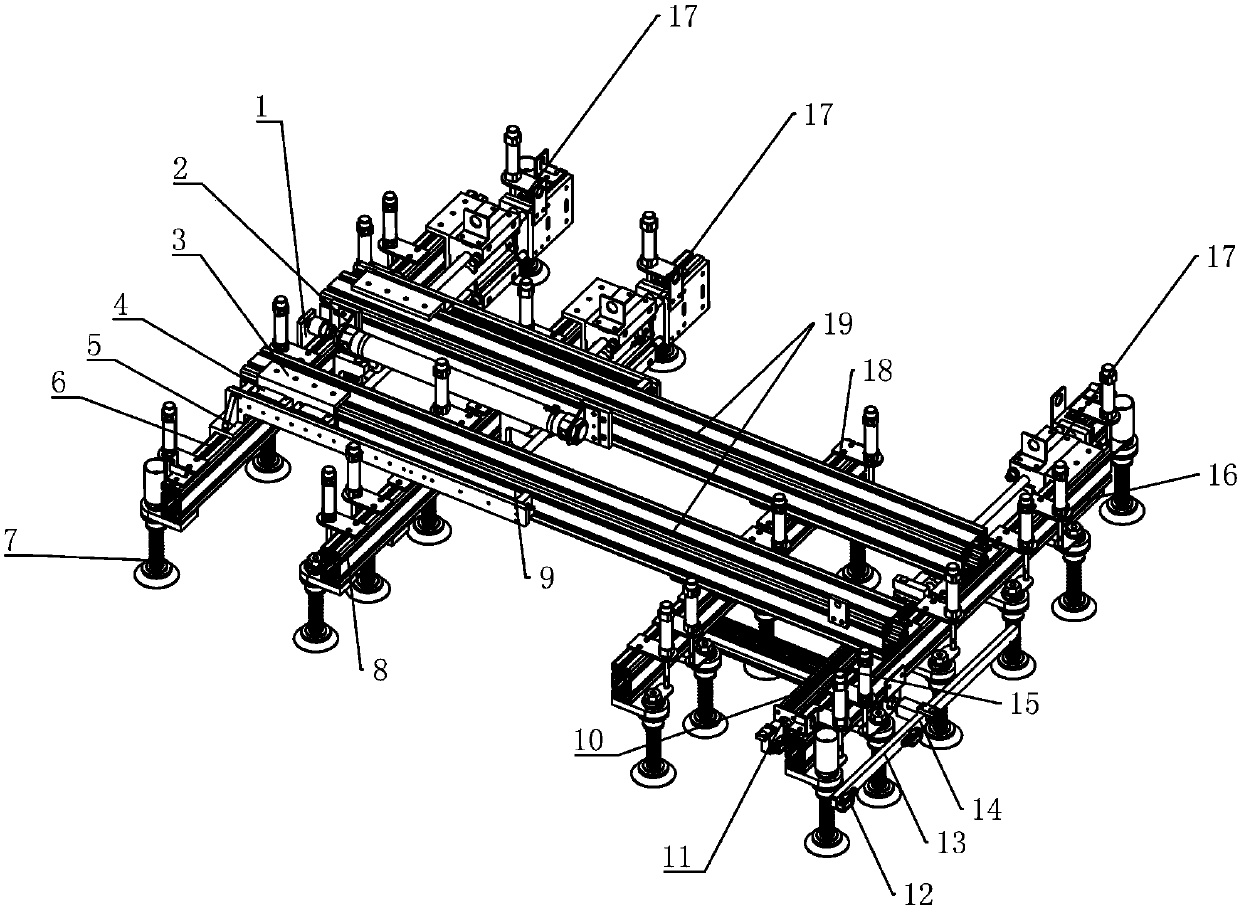

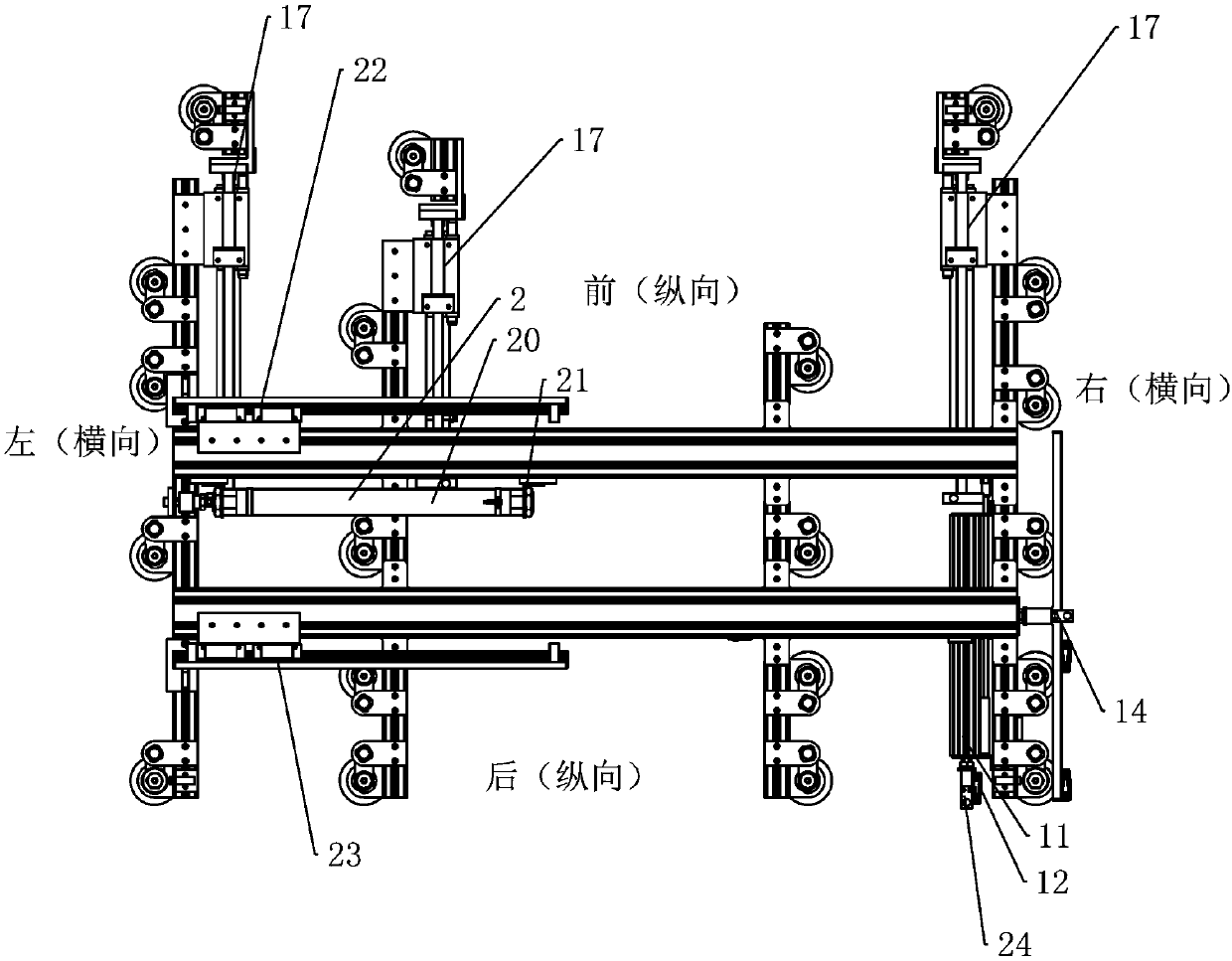

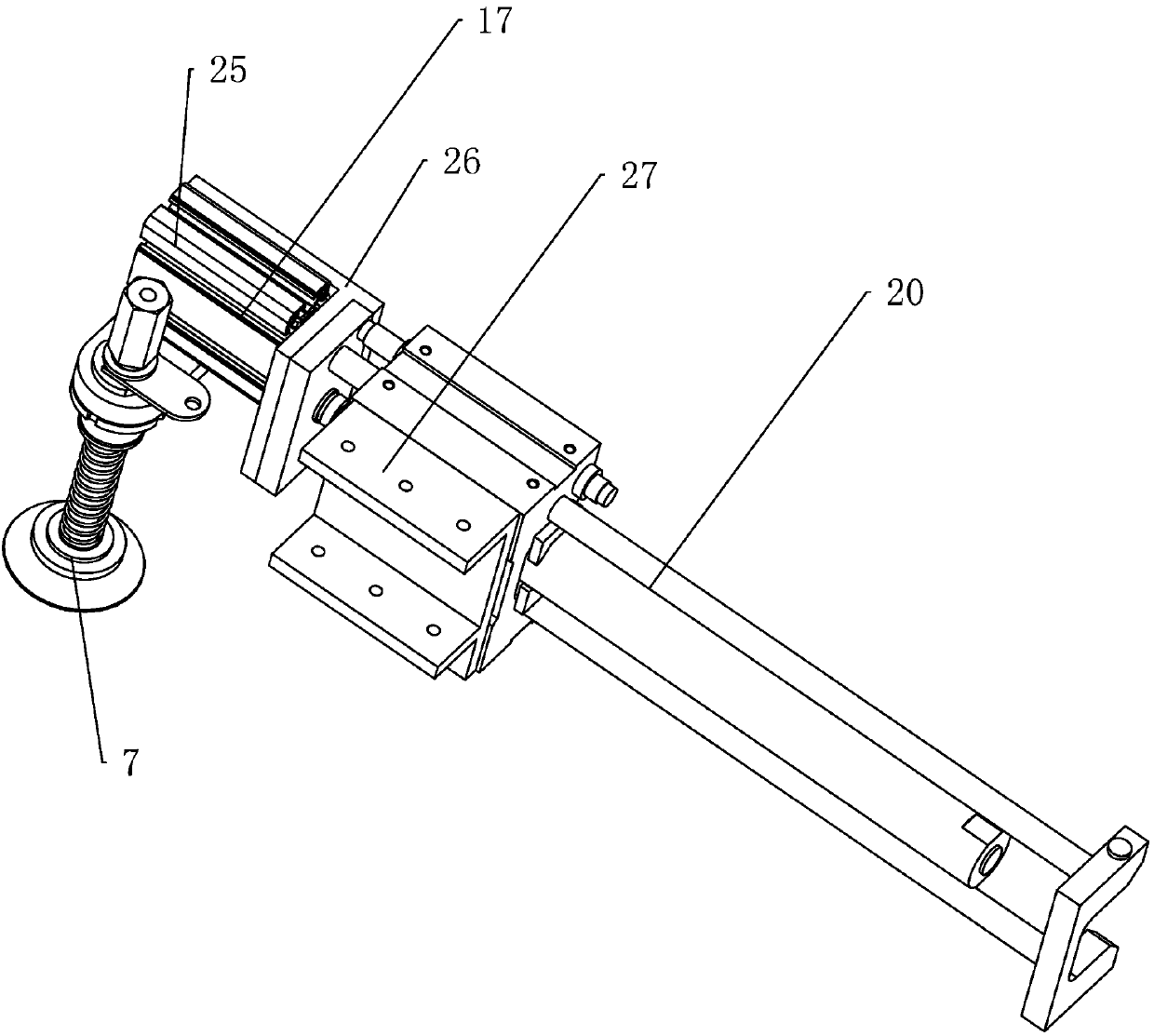

Dynamic measurement gripper with space two-freedom-degree telescopic function and method of dynamic measurement gripper

PendingCN107651449AShorten takt timeImprove efficiencyCharge manipulationConveyor partsMechanical engineeringClassical mechanics

The invention relates to a dynamic measurement gripper with a space two-freedom-degree telescopic function and a method of the dynamic measurement gripper. The dynamic measurement gripper comprises abody and a measurement system. The body comprises main beams, fixed auxiliary beams, a telescopic auxiliary beam, a first sliding rail telescopic mechanism, a second sliding rail telescopic mechanism,an air cylinder transverse telescopic mechanism, air cylinder longitudinal telescopic mechanisms and a suction cup structure. The measurement system comprises a transverse measurement mechanism and alongitudinal measurement mechanism. The structure of the gripper has the two-freedom-degree telescopic function in space, that is, telescopic action is achieved in the transverse direction and the longitudinal direction. Movement, in the transverse direction, of the telescopic auxiliary beam can be achieved through the air cylinder transverse telescopic mechanism, then a suction cup mechanism onthe telescopic auxiliary beam and suction cup mechanisms on other fixed auxiliary beams act together, and grabbing work of glass of larger dimensions is achieved; and in a similar way, glass of largerdimensions can be grabbed in the longitudinal direction through the action of the air cylinder longitudinal telescopic mechanisms.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

Ultralow-friction composite brake shoe for European freight train

ActiveCN109737157AReduce pollutionIncrease vibrationOther chemical processesBraking membersVulcanizationFreight trains

The invention aims to provide a composite brake shoe with the ultralow friction coefficient. The composite brake shoe can replace a cast iron brake shoe. The composite brake shoe comprises a frictionbody and a steel back. The friction body sequentially comprises, by mass percentage, 4%-8% of butadiene rubber, 4%-10% of steel fibers, 1.5%-3% of acrylic fibers, 1.5%-3% of aramid fibers, 4%-8% of liquid butadiene rubber, 18%-25% of modified phenolic resin, 20%-30% of graphite, 2%-6% of mica powder, 2%-5% of barium sulfate, 0.5%-2% of aluminum oxide, 1%-3% of iron powder, 3%-6% of calcium carbonate, 1%-2% of vulcanization accelerators and 5%-15% of other filling materials. The composite brake shoe has the ultralow friction coefficient, can fulfill the braking function instead of the cast ironbrake shoe under the condition that a braking unit is not changed, and reduces the pollution, caused by chemical components in the wear debris, to the environment.

Owner:北京浦然轨道交通科技股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com