Dynamic measurement gripper with space two-freedom-degree telescopic function and method of dynamic measurement gripper

A technology of dynamic measurement and degrees of freedom, which is applied to conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problem of insufficient ability to grasp various specifications of glass, save takt time, improve efficiency, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

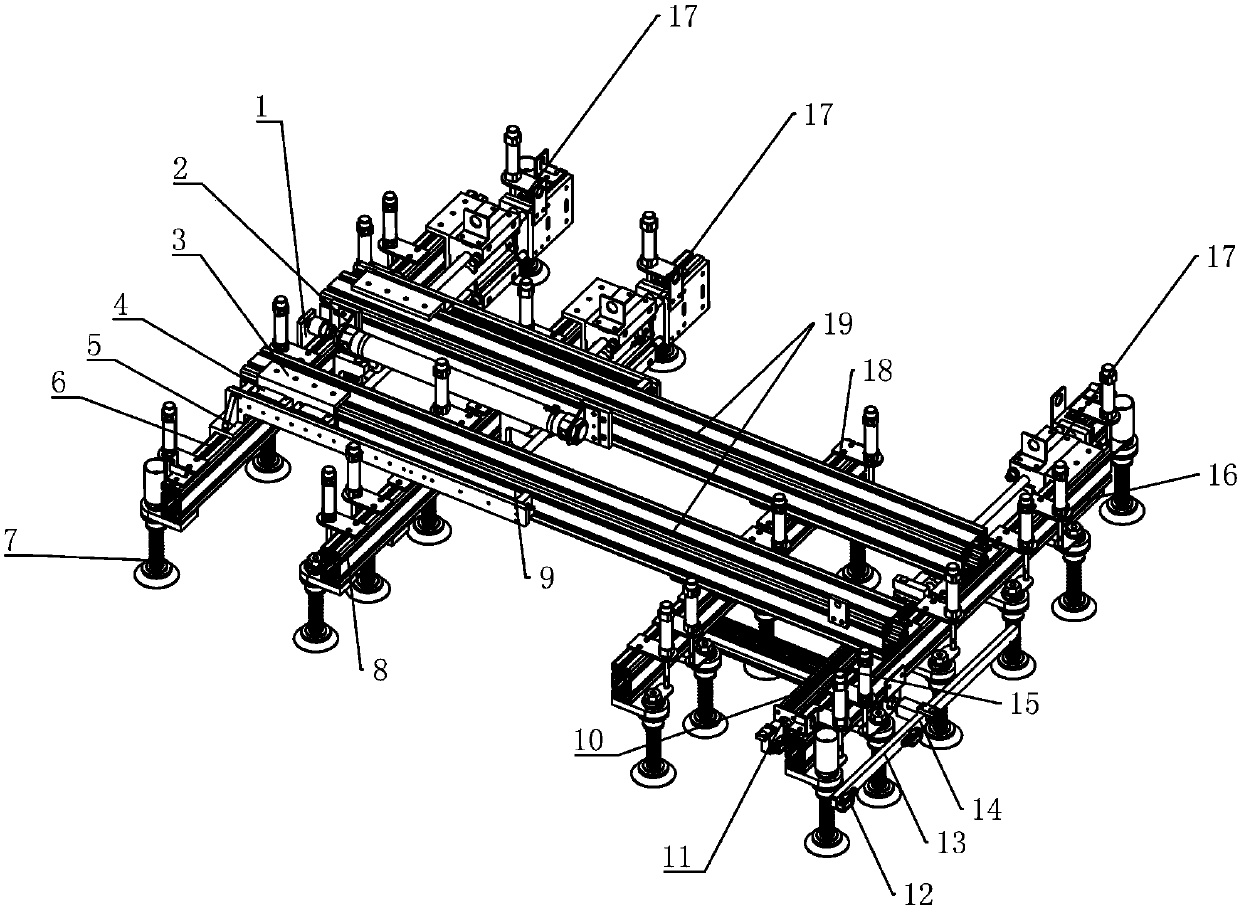

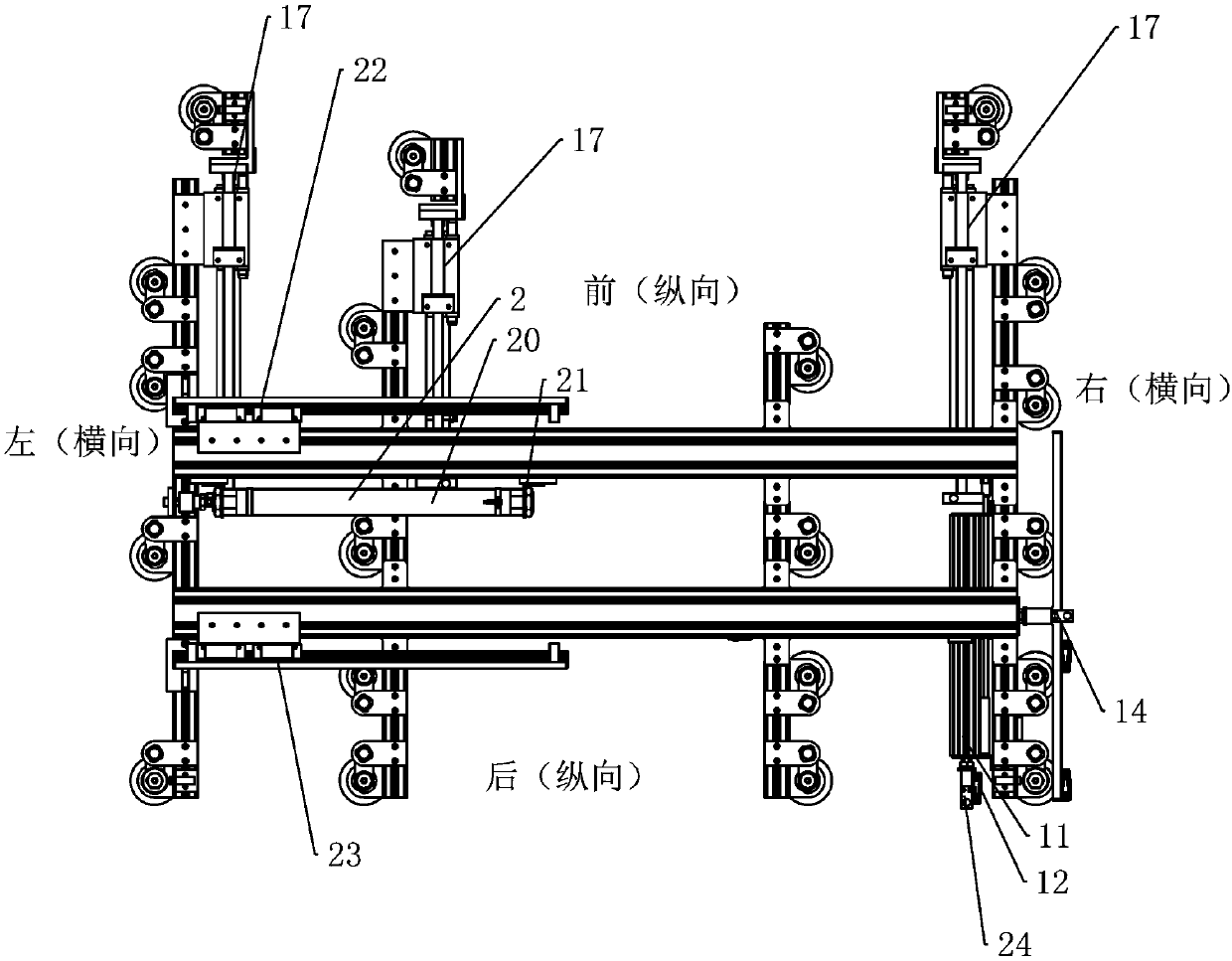

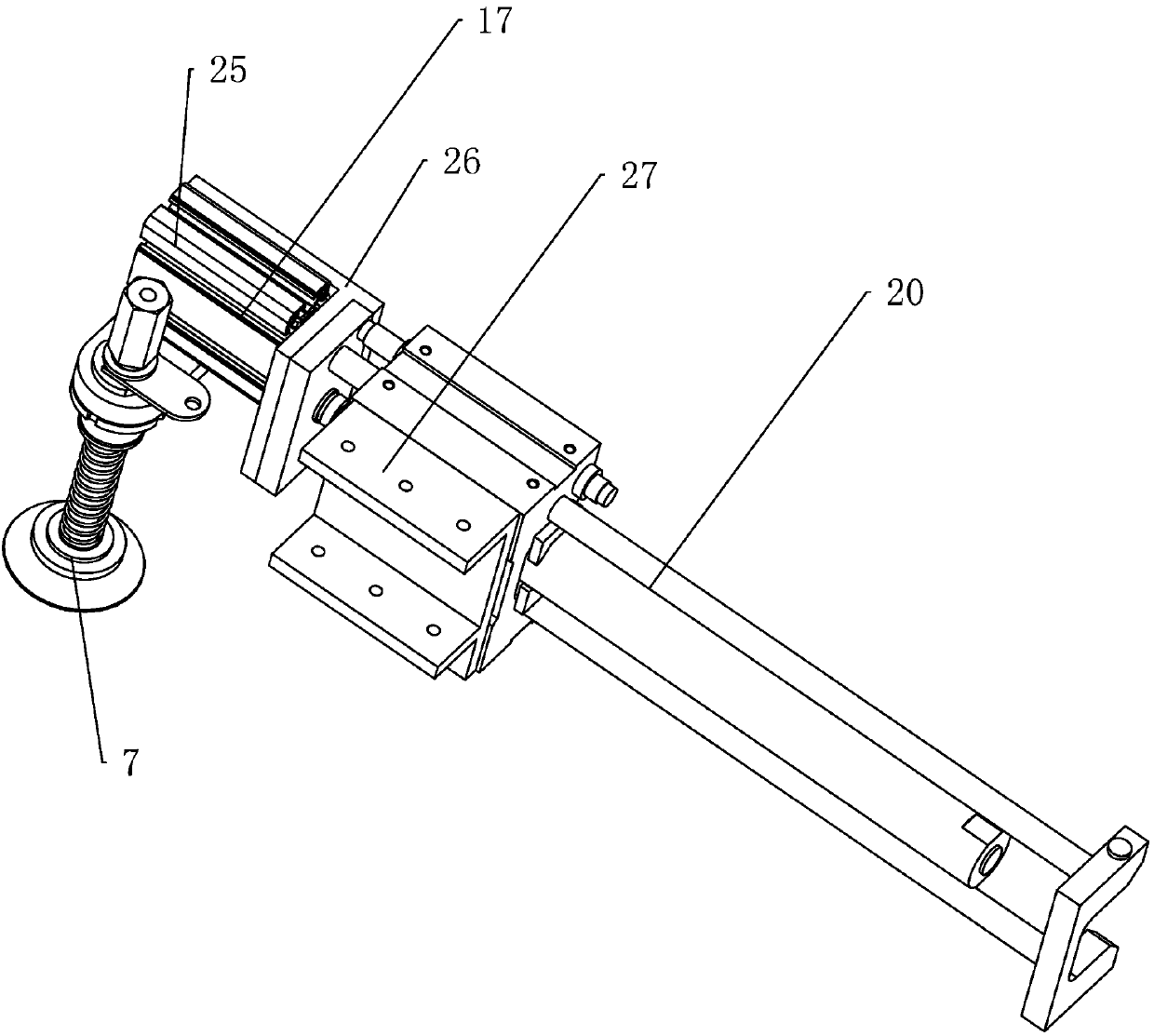

[0062] The dynamic measurement gripper with space two-degree-of-freedom telescopic function is used for heavy-duty robots. Its main feature is that it includes a body and a measurement system. The body is a structural frame with telescopic functions in two directions, and A gripping device is arranged on the body, and the measurement system is arranged on the body to measure the expansion and contraction in two directions to determine the position of the object grasped by the dynamic measurement gripper.

[0063] In a preferred embodiment, the main body includes a main beam 19, a fixed auxiliary beam, a telescopic auxiliary beam 6 and a telescopic mechanism, and the fixed auxiliary beam includes first fixed auxiliary beams 16 arranged parallel to each other , the second fixed auxiliary beam and the third fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com