Processing apparatus, method for detecting ACF sticking state or display substrate assembly line

A technology for displaying substrates and assembly lines, applied in measuring devices, nonlinear optics, optics, etc., can solve problems such as device width growth, and achieve the effects of short assembly line length, shortened processing width, and shortened takt time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

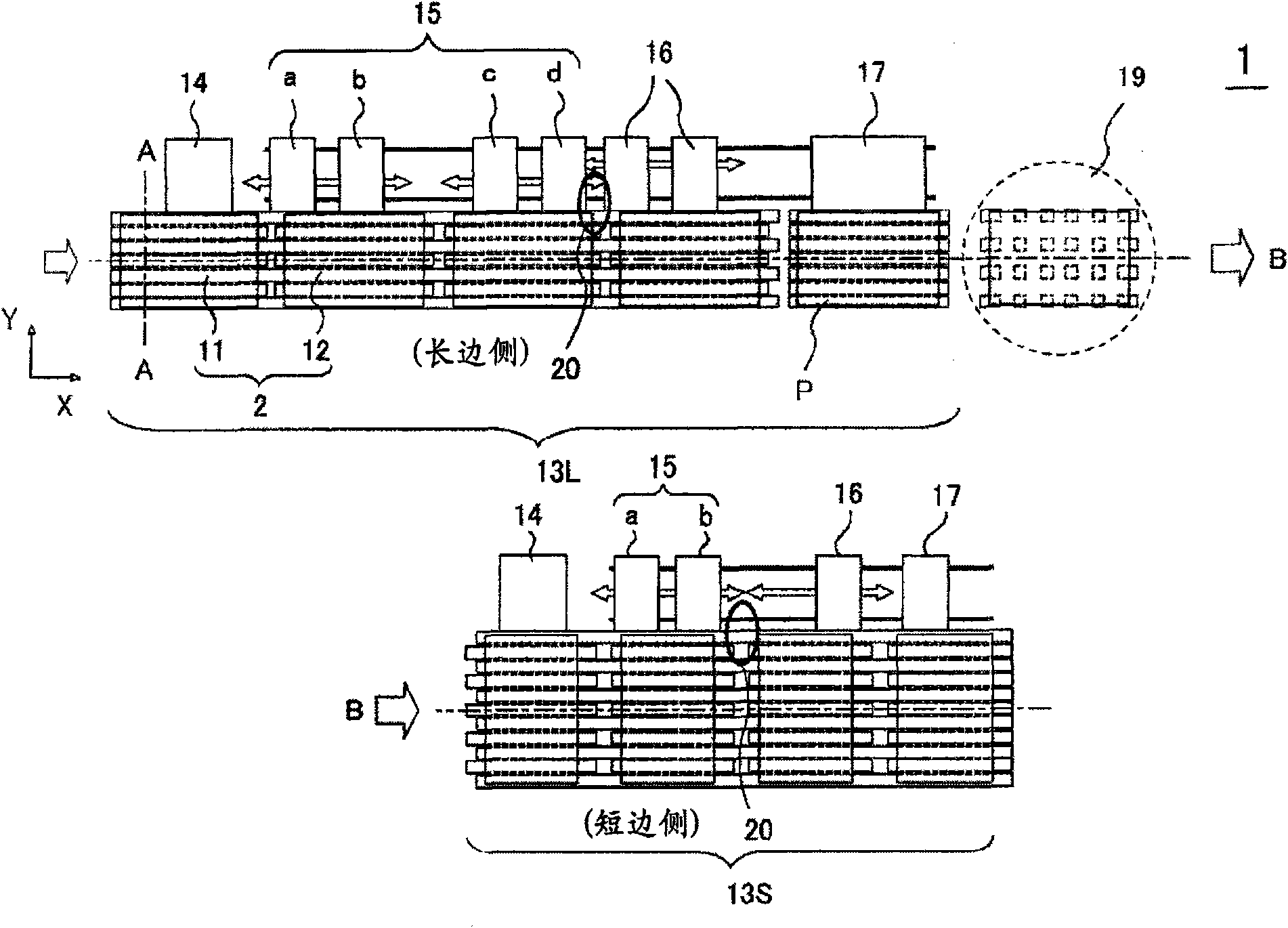

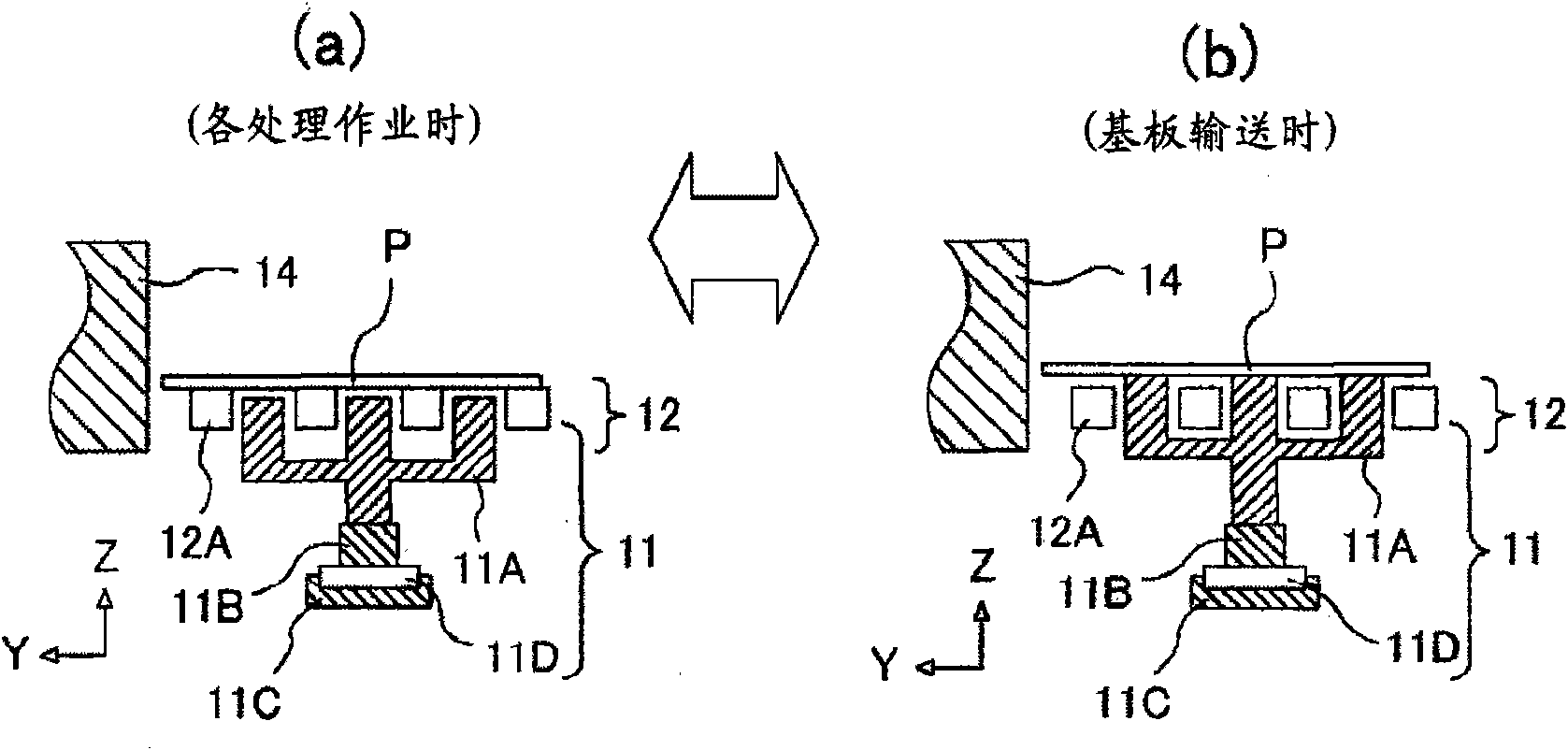

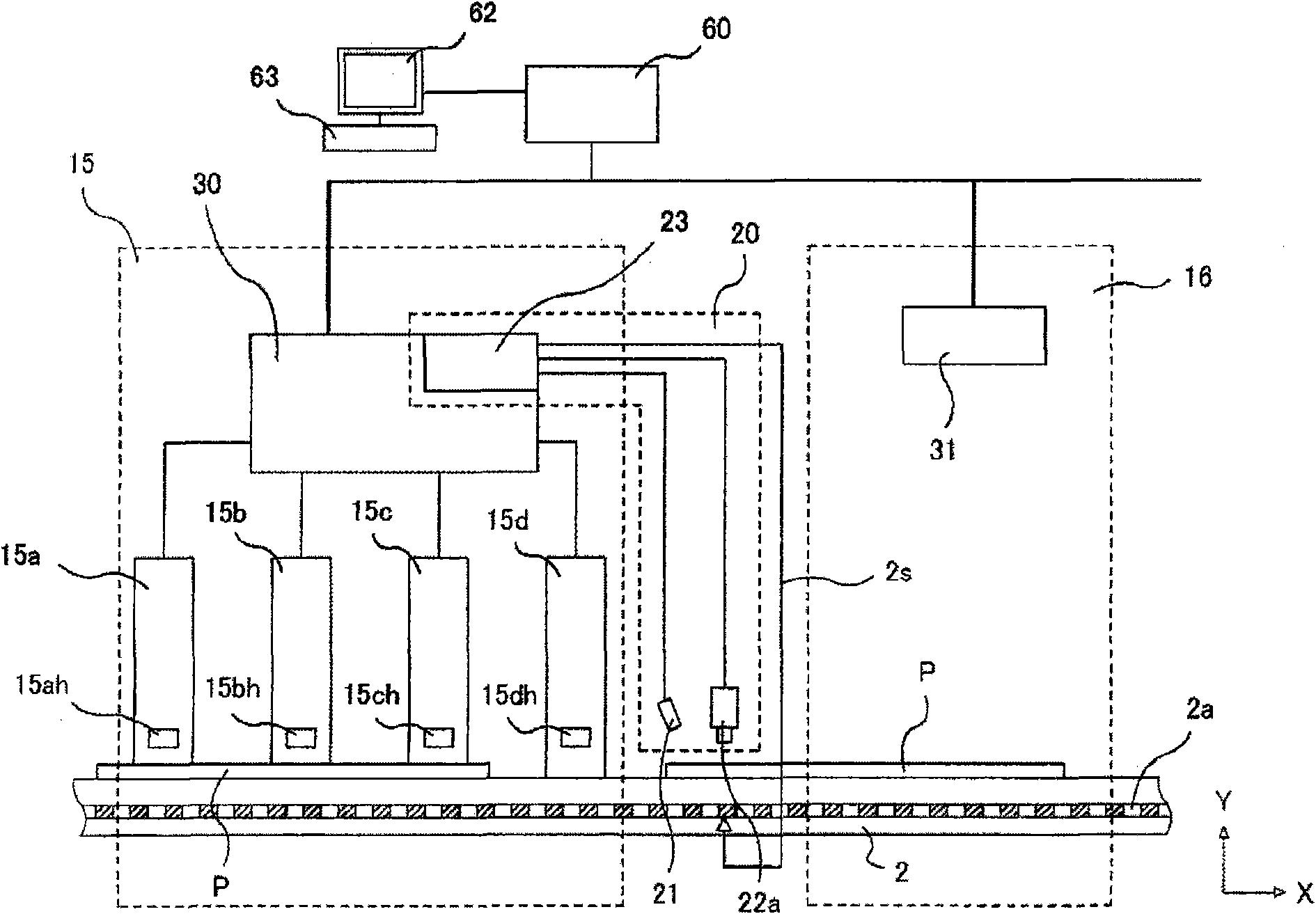

[0034] figure 1 A display substrate module assembly line 1 showing one embodiment of the present invention, figure 2 The basic structure of this substrate transfer device 2 is shown.

[0035] figure 1 is a device that is viewed from the left side in the figure by a conveying device composed of a substrate holding unit 12 holding a substrate P and a substrate conveying unit 11 for conveying the substrate to the position of an adjacent processing operation device. On the right side, substrates are conveyed sequentially, and at the same time, various processing operations are performed on the periphery of the substrates, and mounting and assembly operations such as ICs and TABs are performed. figure 1, firstly, the substrate long side is processed by the processing unit group 13L on the left side of the substrate long side, and after the substrate long side is processed, the substrate is rotated by the substrate rotation unit 19. The processing operation device group 13S on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com