Locking device with double spherical hinge bearing structure for pile legs of self-elevating drilling platform

A technology for pile legs and bearing structures of drilling platforms, which is applied to underwater structures, infrastructure engineering, hydraulic engineering, etc., can solve the problems of difficulty in unlocking, inability to effectively utilize the bearing capacity in different ways, and troublesome on-site operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

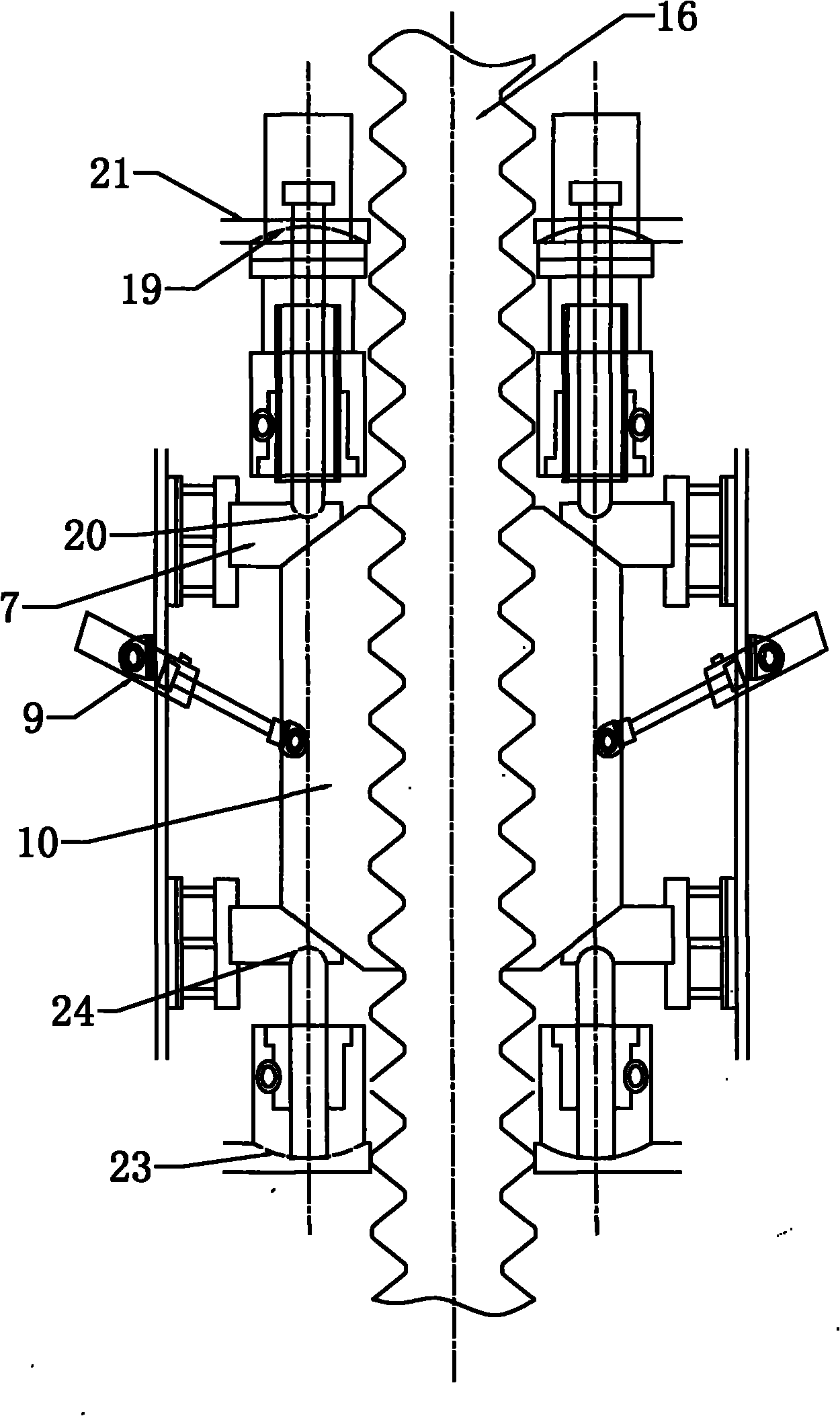

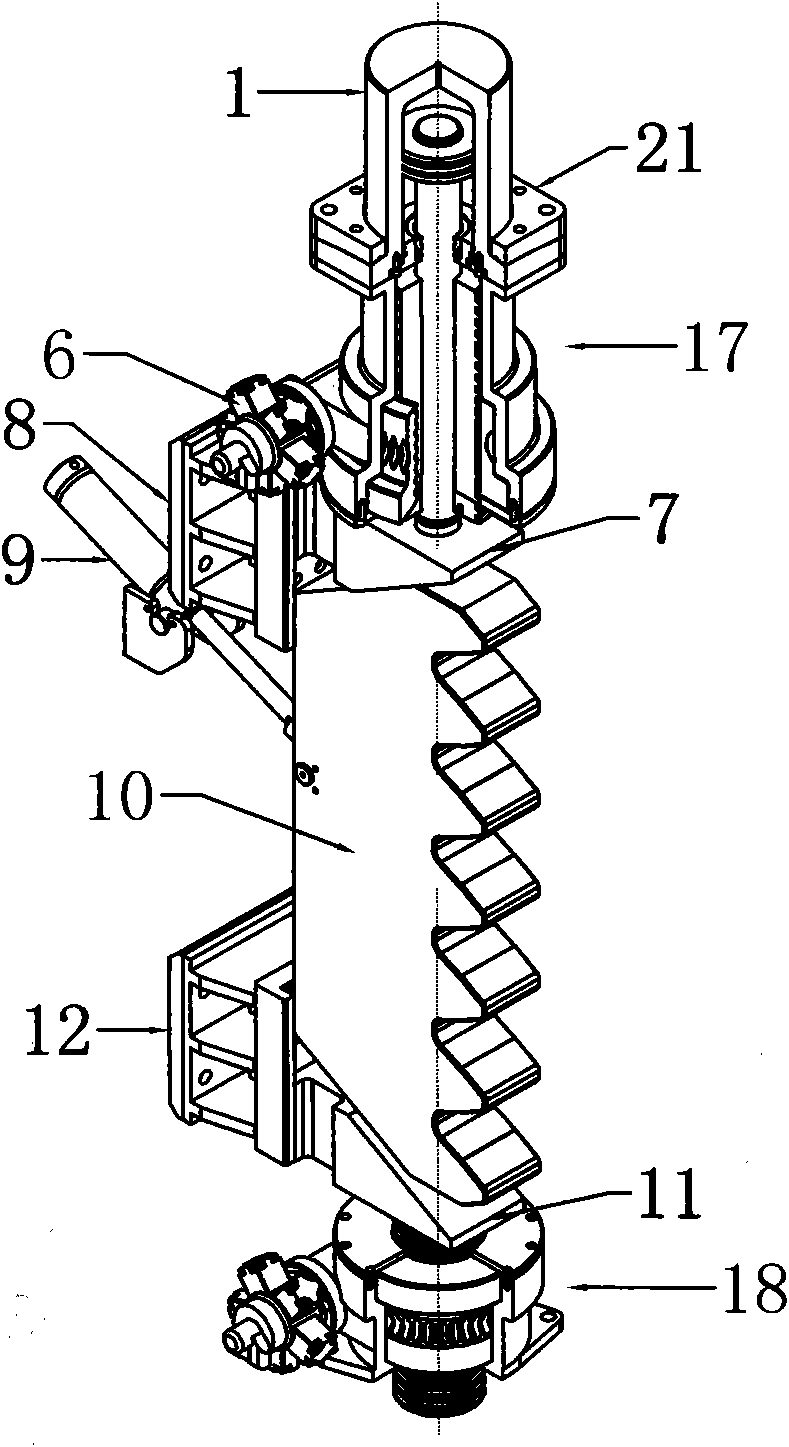

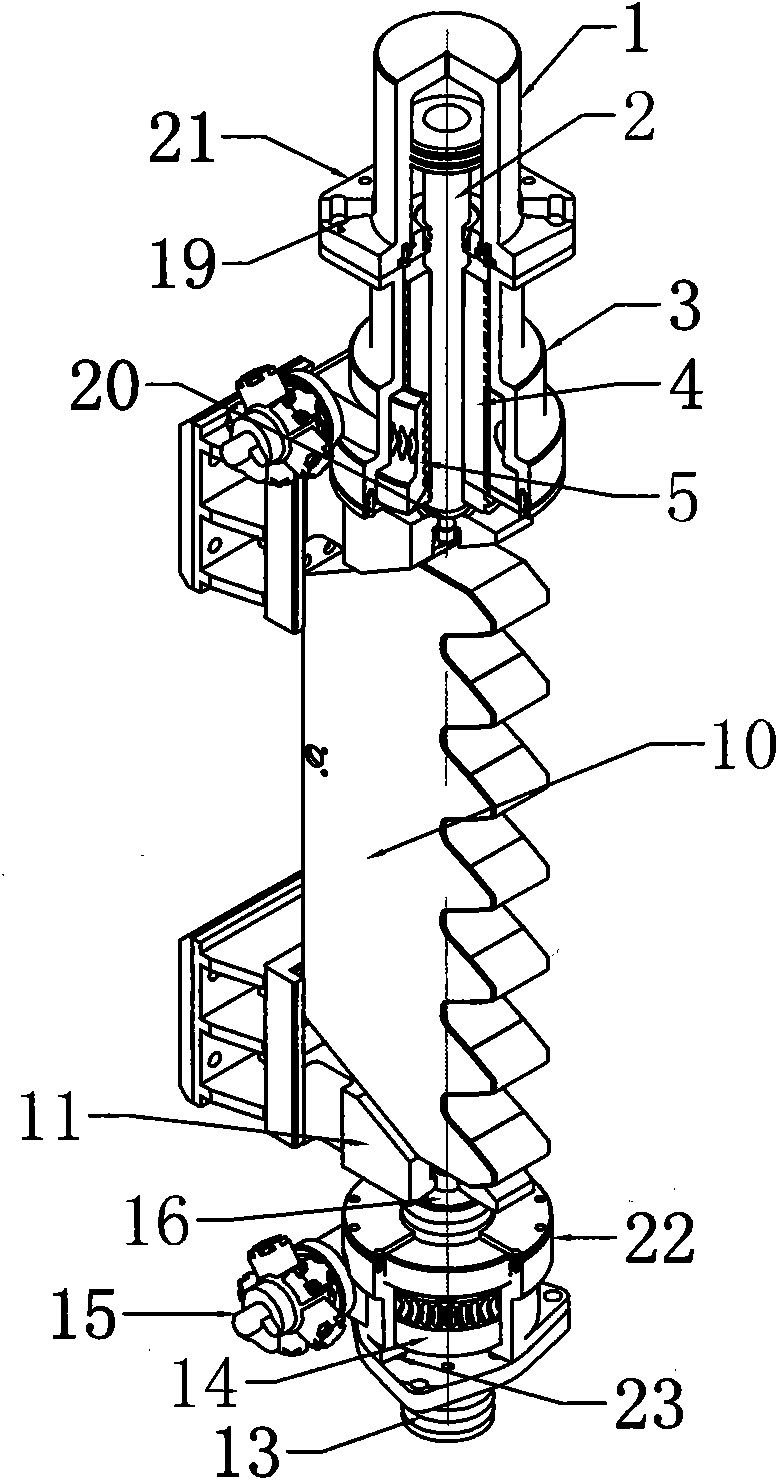

[0015] Attached below figure 1 To attach image 3To further illustrate the present invention, the preferred embodiment of the present invention is: the self-elevating drilling platform leg locking device with double spherical joint bearing structure described in this embodiment, the locking device includes a top locking device Component 17, bottom locking component 18, locking block 10, wherein the locking block 10 is fitted on the leg rack 16 through the teeth, and the carrying platform 21 is provided with a lateral tension cylinder 9, a lateral tension cylinder 9 The cylinder body is installed on the bearing platform 21, and the piston rod of the lateral tension cylinder 9 is hinged with the locking block 10. The top locking assembly 17 and the bottom locking assembly 18 are multiple groups, radially distributed on the outside of the leg rack 16, and assembled on the bearing platform 21 on the upper and lower sides of the locking block 10, and through the top wedge 7. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com