Preparation method of plastic woven bag

A technology for plastic woven bags and woven bags, applied in the directions of bags, sacks, containers, etc., can solve the problems of poor tensile strength, poor bursting resistance, poor tearing degree, etc., and achieve the improvement of melt flow rate and peeling strength. , The effect of preventing high temperature creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

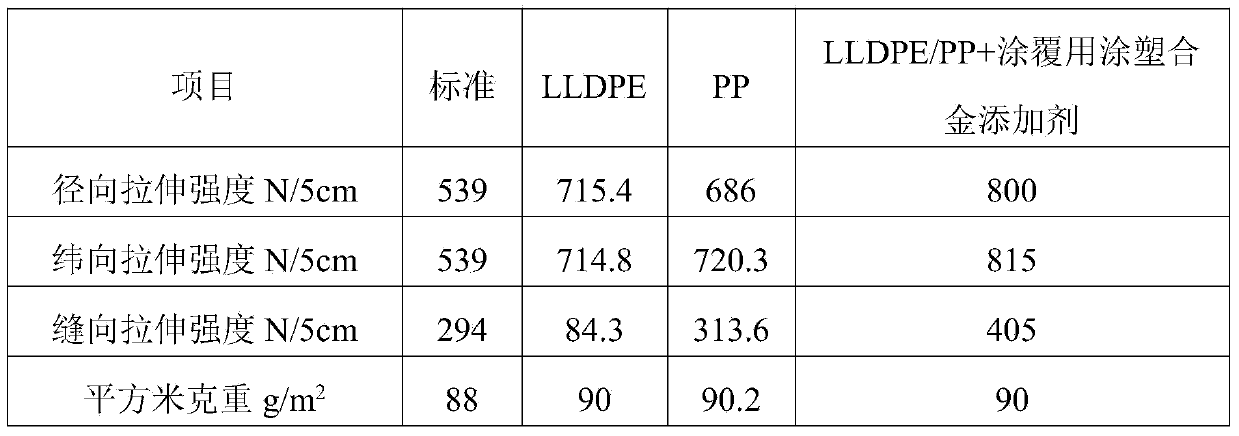

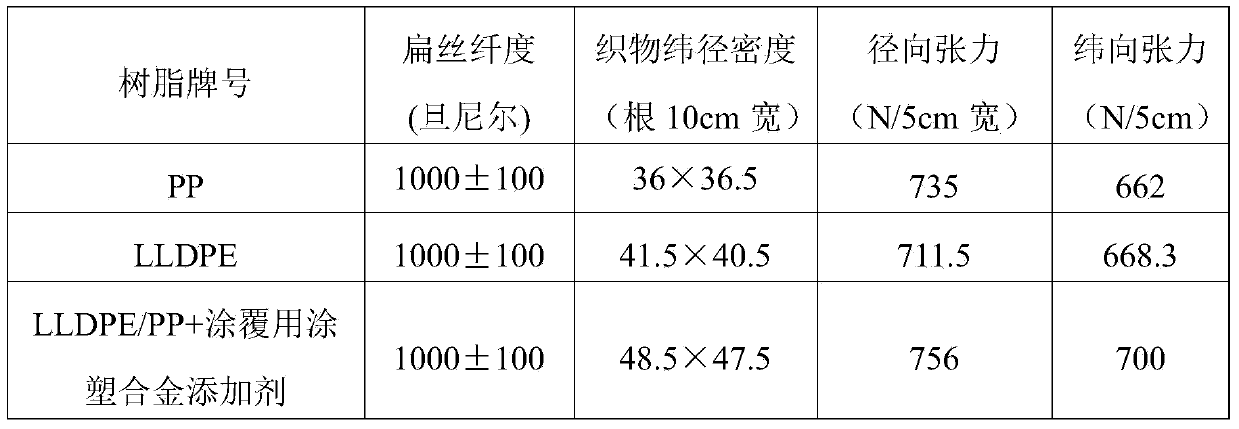

[0020] Specific implementation mode one: this implementation mode is a kind of preparation method of plastic woven bag, specifically is finished according to the following steps:

[0021] 1: Add plastic-coating alloy additives for coating, LLDPE resin, PP resin antioxidant and ultraviolet absorber into the mixer in sequence, and mix evenly at a temperature of 60-100°C to obtain a mixture; the coating described in step 1 The mass ratio of plastic coating alloy additive and LLDPE resin is 100:(2~3); the mass ratio of coating plastic coating additive described in step 1 and PP resin antioxidant is 100:(2~3) ; The mass ratio of coating plastic-coating alloy additive and ultraviolet absorber described in step 1 is 100:(0.02~0.03);

[0022] Two: Add the mixture to the extruder at a feeding speed of 125kg / min for extrusion, and then cool and form it to obtain a coated woven fabric for producing woven bags;

[0023] Three: First, preheat the temperature of the preheating roller to 60...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molecular weight of the low-density polyethylene described in step ① is 100,000 to 300,000. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the melt flow rate of the ethylene-propylene copolymer described in step ① is 120 g / 10 min. Others are the same as those in Embodiment 1 or 2.

[0042] The ethylene-propylene copolymer described in this embodiment is prepared by using ethylene monomer and propylene monomer as raw materials, using a metallocene catalyst as a catalyst, and preparing the molar ratio of ethylene monomer to propylene monomer at 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com