Patents

Literature

33results about How to "Reduce cement consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method for solidifying sludge of sewage plant in city

This invention relates to a method for solidification treatment of sludge discharged from urban sewage treatment plant. The method utilizes solidification and stabilization techniques to treat sludge discharged from urban sewage treatment plant, and improve its landfill physicochemical properties, thus can solve the problems related to sludge landfill. The method adopts cement as the solidification agent, and one or more of lime, aluminum salt, aluminum oxide and cinder as the coagulant aid. The method comprises: adding 3-8% solidification agent and 1-8% coagulant aid into sludge, mechanically stirring uniformly, spreading onto a landfill site, covering with a waterproof film, dry-maintaining for 3-15 days, and performing following landfill. The method has such advantages as low cost, easy operation and good effect. The treated sludge has such advantages as high compressive strength, high soaking resistance and low leaching toxicity.

Owner:GUOZHONG AIHUA TIANJIN MUNICIPAL ENCIRONMENT ENG

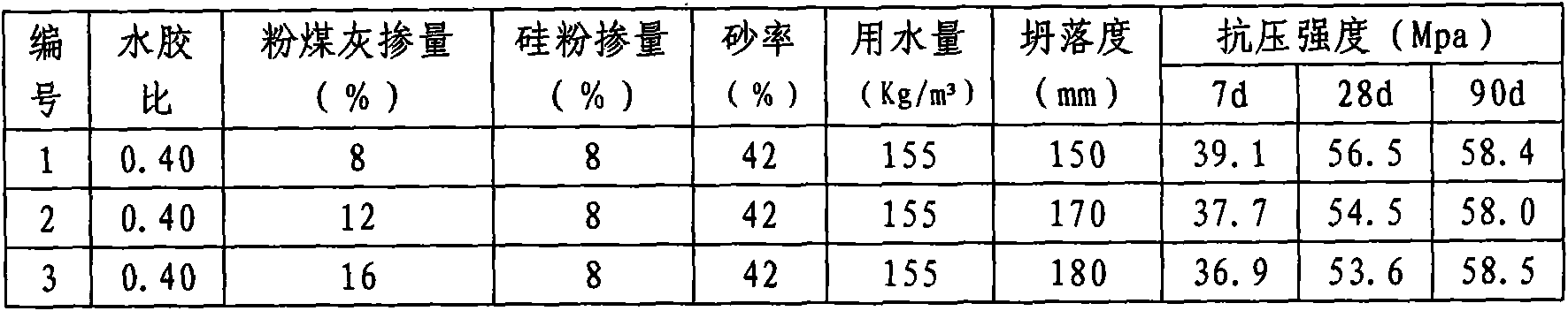

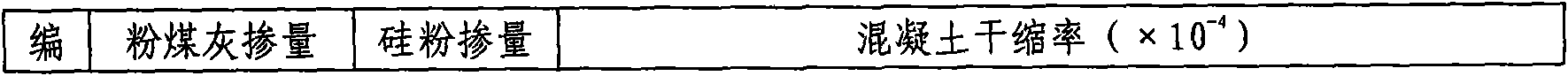

High strength silica powder concrete and construction technology

InactiveCN101538137AReduce cement consumptionReduce adiabatic temperature riseSolid waste managementSilica fumePozzolanic reaction

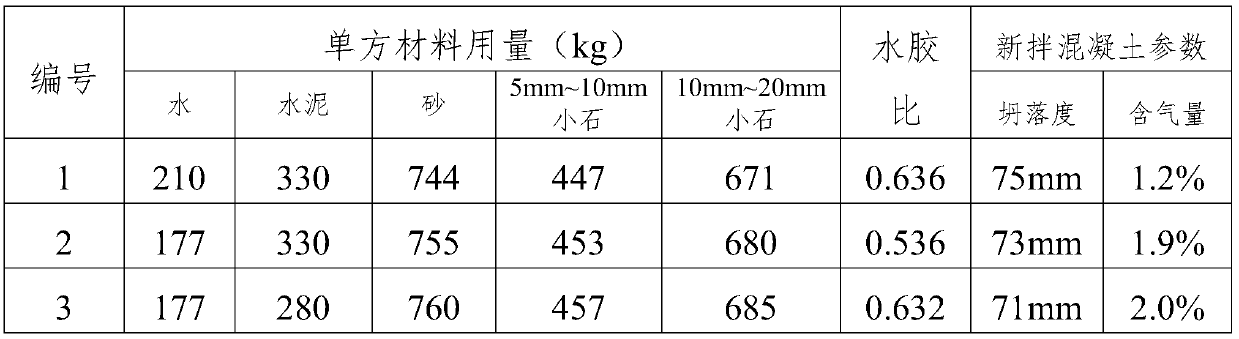

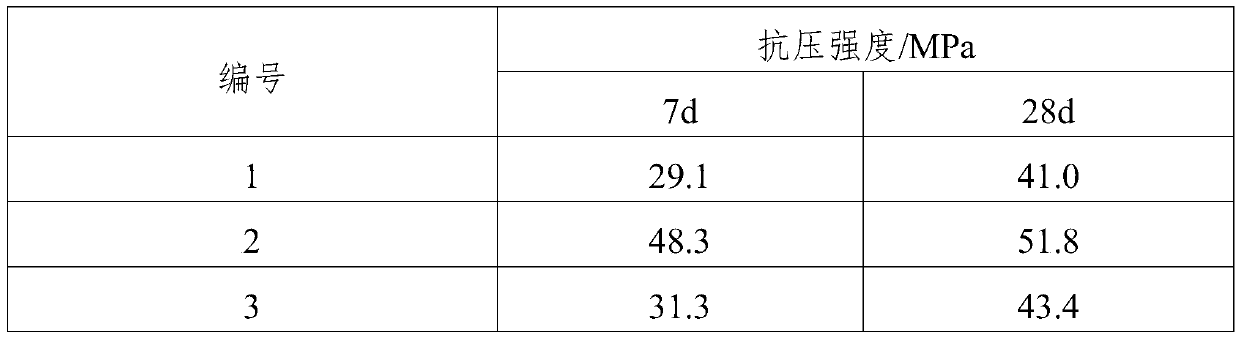

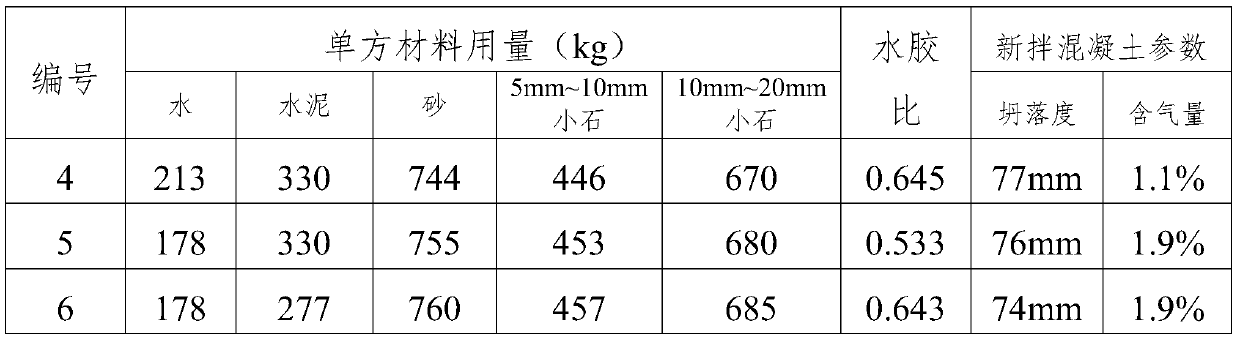

The invention discloses high strength silica powder concrete and a construction technology thereof. The optimal selection of raw materials and the optimal design of mixing proportion are used as footholds, the measure of mixing pulverized fuel ash and silica powder with selected moderate-heat or low heat cement replaces other measures of mixing composite high efficiency water reducing agent, fibers, and the like with parts of cement, so as to reduce the use level of the cement as much as possible and to reduce the adiabatic temperature rise of the cement, thereby greatly overcoming the disadvantages of the silica powder, improving the early-age cracking-resistance property of the cement, and giving full play to the gap filling efficacy and the pozzolanic reaction property of the silica powder. While strengthening the intensity of the concrete, the invention effectively avoids the technical problem of early-age cracking during the silica powder construction.

Owner:吴运华

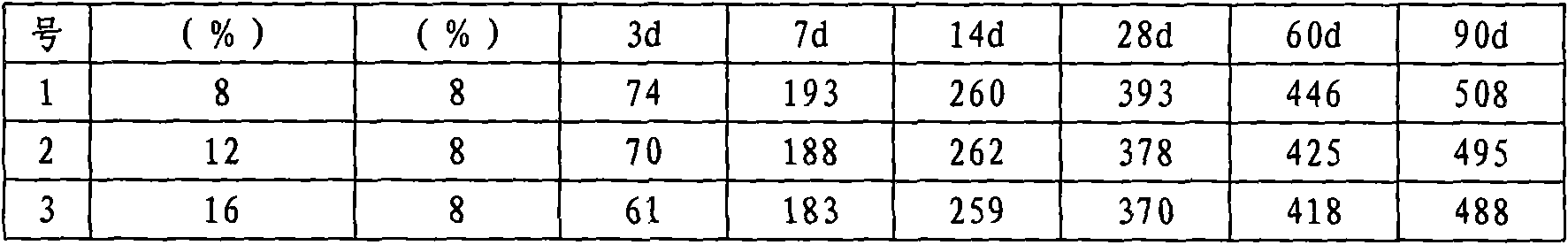

Solidification/stabilization treatment method for papermaking sludge

InactiveCN101885575AHarm reductionReduce cement consumptionSludge treatment by de-watering/drying/thickeningCinderWater content

The invention discloses a solidification / stabilization treatment method for papermaking sludge. The method comprises the following steps of: adding a solidifying agent into the papermaking sludge with water content of 70 to 80 percent according to a weight ratio of the sludge to the solidifying agent of 100:14-24, stirring the mixture to react for 10 to 15 minutes and uniformly mixing the mixture to form solidified block precursors; and laying solidified block precursors which are uniformly stirred in a sludge landfill site according to a thickness of 5 to 100cm, covering a water-proof membrane on the solidified blocks and curing the solidified blocks for 2 to 10 days by using a dry curing method to form sludge solidified blocks, wherein the compressive strength of the sludge solidified block is 160 to 320kPa, the COD concentration in solidified block leaching solution is 110 to 200mg / L, and the water content of the solidified block is 30 to 40 percent; and the solidifying agent comprises the following components in percentage by weight: 40 to 50 percent of aluminate cement, 15 to 25 percent of fly ash and 30 to 40 percent of cinder; toxic heavy metal ions are wrapped after the sludge solidification, so that the pollution of the sludge is reduced; the solidified sludge does not have foul smell of the original sludge and reduces the harm to an operator during the operation; and the method has the advantages of readily available raw material, low cost, stable effect and simple operation procedure.

Owner:GUANGDONG UNIV OF TECH

Phosphor slag power concrete mortar

InactiveCN101269942AReduce cement consumptionProlong clotting timeSolid waste managementSlagSilicate Cement

The present invention discloses phosphorous ground slag cement mortar, and comprises ordinary silicate cement, phosphorous ground slag, sand and water. On the one hand, the phosphorous ground slag used in the present invention is used as mixed material to substitute the cement in equal weight to be mixed into the pre-mixing commodity mortar, thus reducing the consumption volume of the cement; on the other hand, the retardation property of the phosphorous slag is used to obviously prolong the condensation time, thereby overcoming the weakness that the retardation agent must be added into the traditional pre-mixing commodity mortar, and can realize the effect similar to the adding of the retardation agent. Therefore, the present invention makes full use of the effect of the phosphorous to improve the workability of the mortar, thereby greatly reducing the production cost, and reducing the environmental pollution.

Owner:GUIZHOU UNIV

PVA fiber reinforced cement-based composite material

InactiveCN105906261ALow costReduce cement consumptionSolid waste managementClimate change adaptationStress concentrationNatural resource

The invention discloses a PVA fiber reinforced cement-based composite material, which is composed of the following ingredients (by weight): 11.8-26.8 parts of cement, 32.2-47.2 parts of flyash, 20.8-21.5 parts of river sand, 0.53-0.54 part of a water reducing agent, 0.03 part of an antifoaming agent, 0.03 part of a thickening agent, 1.24-1.25 parts of fiber and 17.7-17.9 parts of water. By replacing cement in the PVA fiber reinforced cement-based composite material with high volume of flyash, wastes are changed into valuable things, cost is reduced, CO2 emission is minimized, and lots of natural resources and energy are saved. In addition, crack width and natural air shrinkage of the PVA fiber reinforced cement-based composite material are reduced, long-term durability of the structure is enhanced, stress concentration degree of crack tip is weakened, fiber crack-retarding mechanism is fully performed, and flexural toughness of the fiber reinforced cement-based composite material is enhanced.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Cement mixing pile composite additive, curable material and preparation method of composite additive

The invention discloses a cement mixing pile composite additive and a preparation method thereof. The cement mixing pile composite additive is composed of the following raw materials by mass percentage: 5%-10% of nano-silica, 15%-20% of triethanolamine, 10%-15% of water glass, 10%-15% of a dispersant, 5%-8% of sodium carbonate, 1%-1.5% of an exciting agent, and the balance water. Through compound use of the cement mixing pile composite additive with cement and gypsum, under the circumstance of not changing existing construction equipment and process, cement can be saved and the material cost can be lowered; or under the condition of maintaining a same cost, the pile strength can be improved, the cement mixing pile composite additive especially has a special consolidation strengthening effect on improvement of the pile-forming performance of organic soil, peat soil, river silt and other projects.

Owner:HANGZHOU LAIBAODE NEW MATERIAL TECH CO LTD

Construction method of low-cement fully-regenerated rock-fill concrete

Owner:TSINGHUA UNIV +1

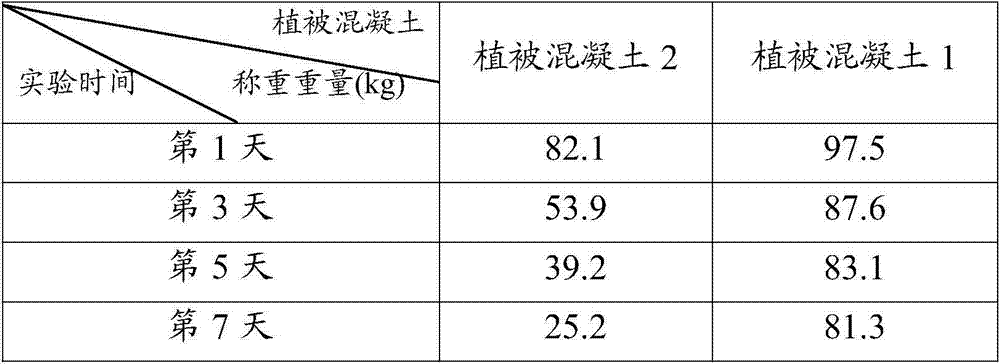

Novel vegetation concrete

The invention provides special vegetation concrete for slope protection and greening. The special vegetation concrete comprises the following raw materials: cement, soil, plant fiber, a polyacrylamide soil improver, thin steel bars, an organic compost, plant seeds, a Chinese herbal medicine nutritional agent, an alkaline neutralizing agent and water. The thin steel bars are added in the vegetation concrete provided by the invention, so that the strength after setting is increased; furthermore, the using amount of the cement is reduced, the alkalinity of the concrete is reduced, and the vegetation concrete is more suitable for the growth of plants; by adding the polyacrylamide soil improver, the germination and emergence rate of crops can be improved, the growth and the development of the crops are promoted, and water-retaining and fertilizer-saving performances are simultaneously and obviously improved; and by adding the Chinese herbal medicine nutritional agent for providing nutritional ingredients for the growth of the seeds, the growth is promoted, pores of the concrete are increased, the alkalinity is reduced, and the final survival rate of the plants can achieve above 95%.

Owner:青岛中科坤泰装配建筑科技有限公司

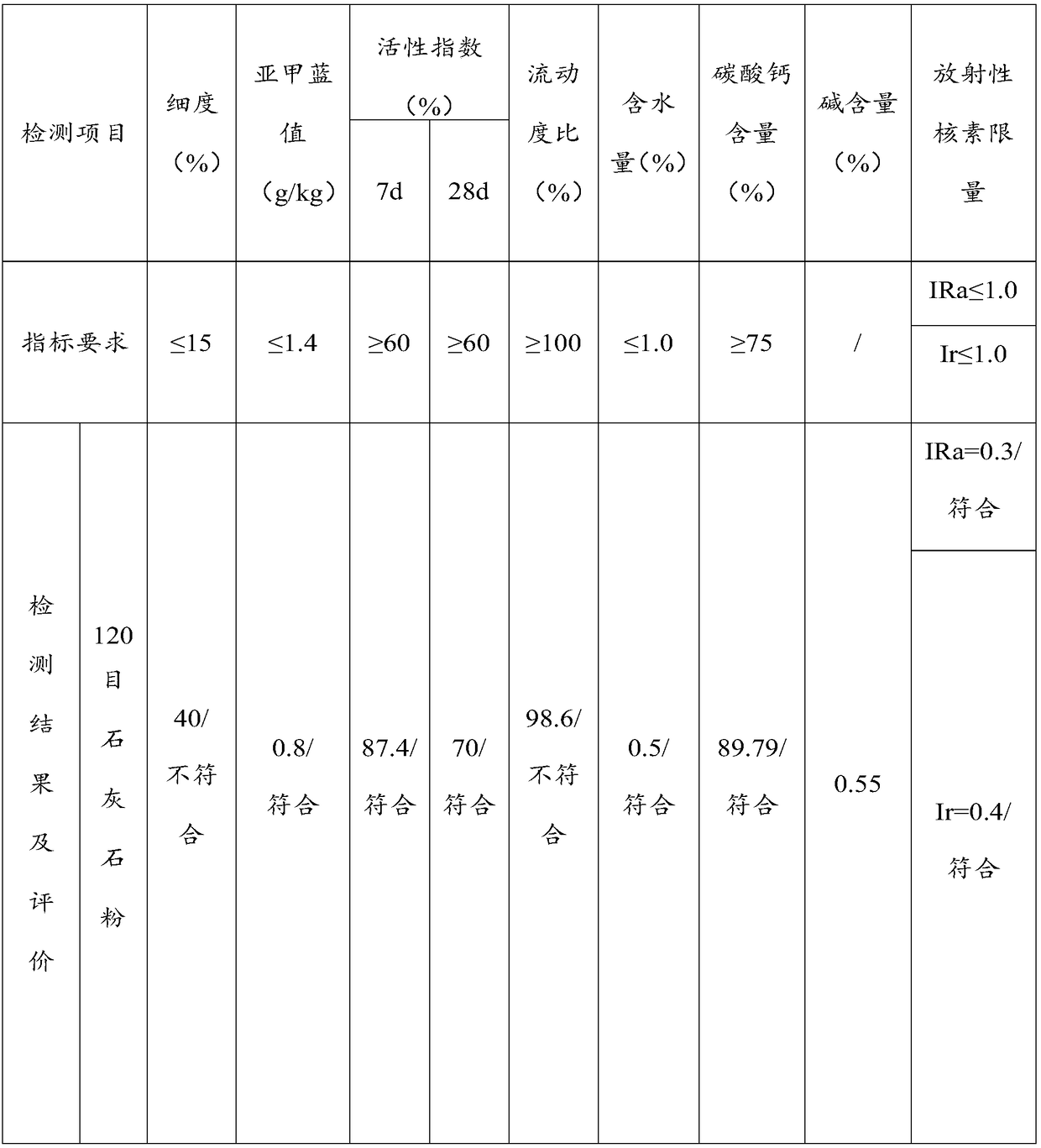

Sprayed concrete as well as preparation method and application thereof

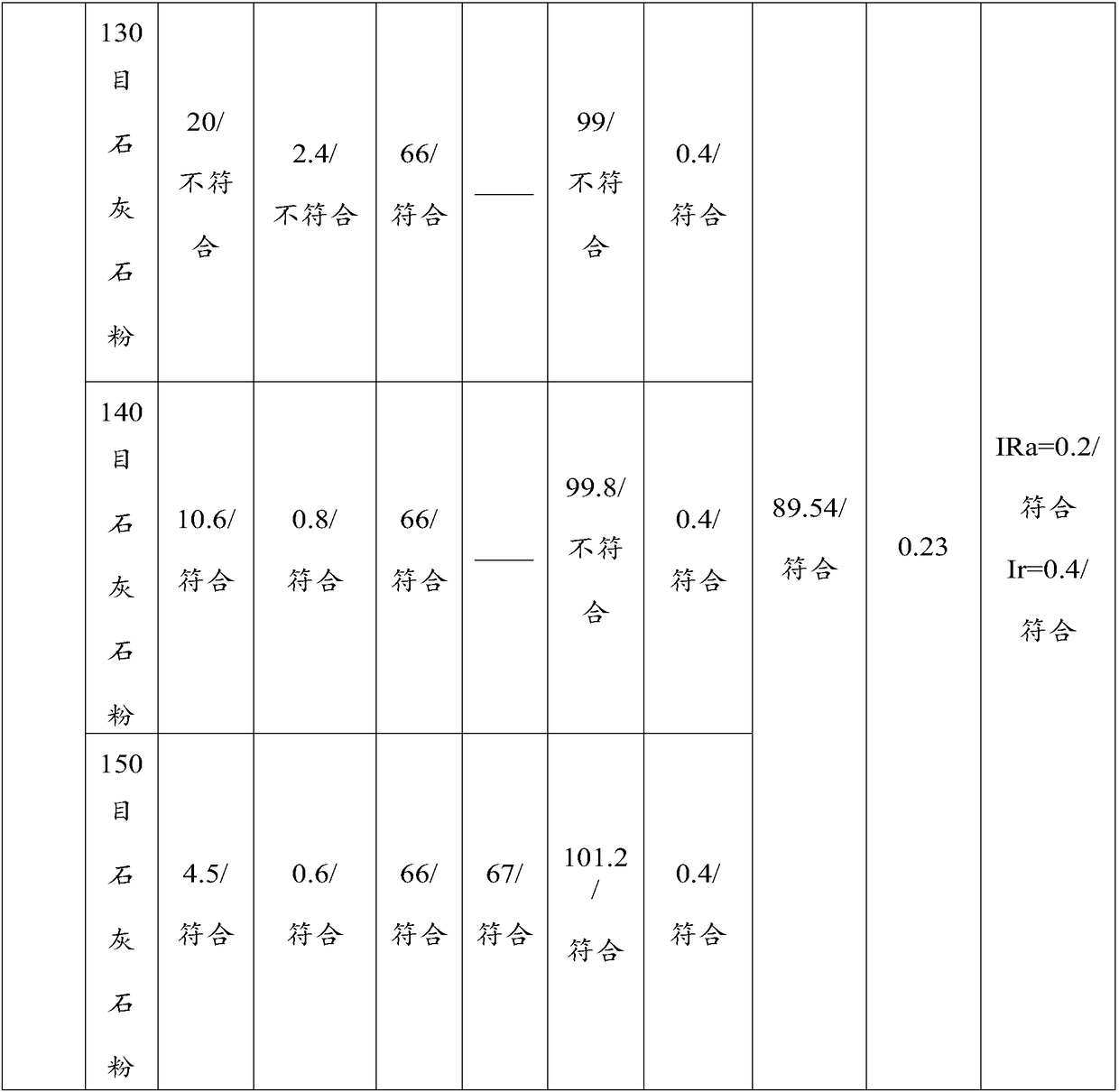

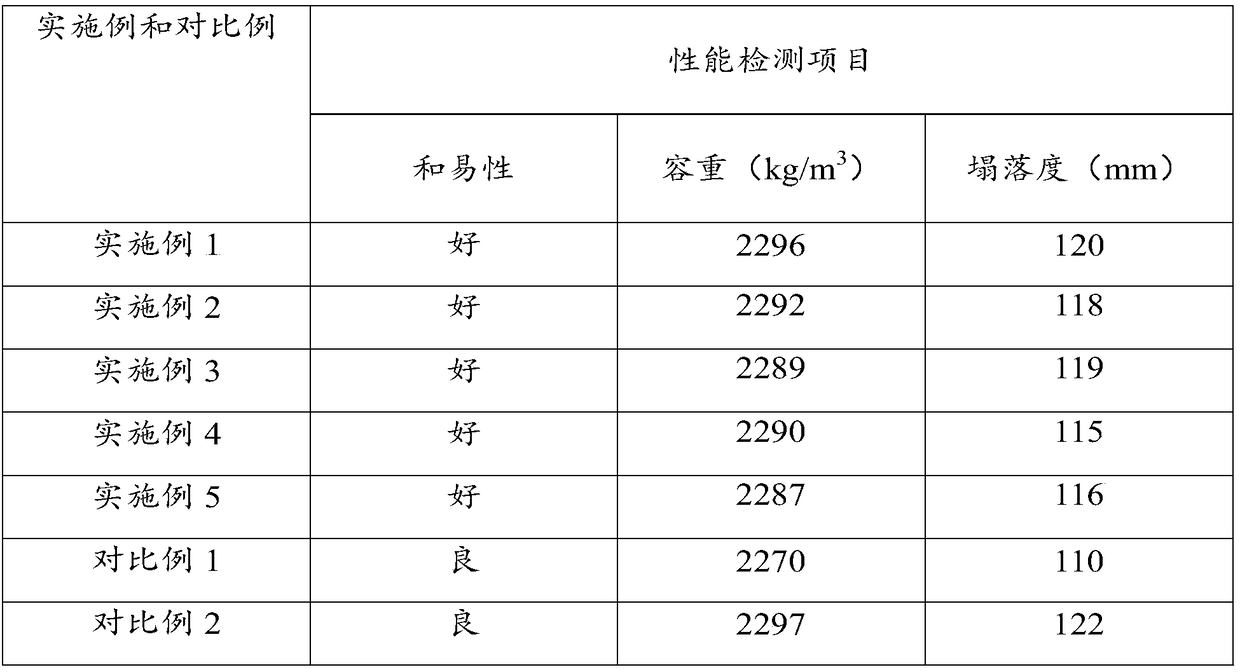

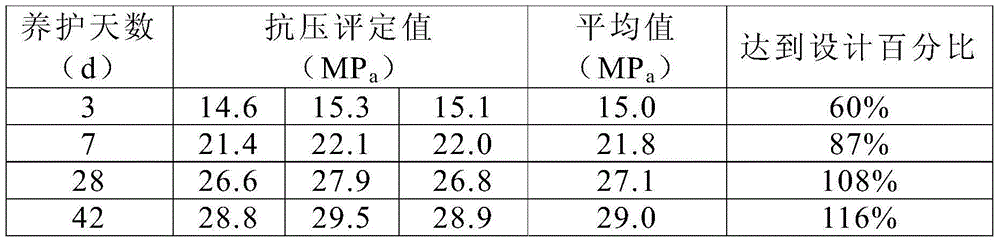

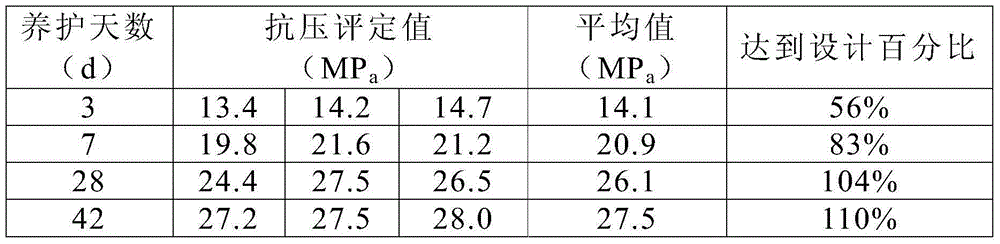

The invention belongs to the technical field of highway engineering materials and particularly relates to sprayed concrete as well as a preparation method and application thereof. The sprayed concreteis mainly prepared from the following components in parts by weight: 300-350 parts of cement, 60-100 parts of limestone powder, 740-780 parts of gravel, 945-980 parts of sand, 2-3 parts of a water reducer, 20-27 parts of a setting accelerator, 0.08-0.13 part of a tackifier and 150-190 parts of water. According to the sprayed concrete, limestone powder is used as a mineral admixture and is appliedto the sprayed concrete, so that the consumption of the cement is reduced, and the cracking risk of the concrete is reduced; a small amount of the water reducer is added; the water consumption, the total amount of a cementing material and the addition amount of the setting accelerator are reduced; the sand rate is appropriately increased; a trace amount of the tackifier is added; the limestone powder is used as a mineral admixture; a trace amount of cellulose ether is used as a novel tackifier of the sprayed concrete; the workability of the sprayed concrete is improved; the cost and the resilience rate of the limestone powder sprayed concrete are reduced.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

C25 green high-performance concrete prepared from all recycled coarse aggregate

InactiveCN104860612AReduce cement consumptionReduce water demandSolid waste managementHigh performance concreteConstruction aggregate

The invention relates to C25 green high-performance recycled concrete. The concrete is mainly prepared by crushing, cleaning and grading waste concrete and taking recycled aggregate obtained through mixing in a certain ratio as all coarse aggregate to replace pebbles. 100% of the recycled coarse aggregate is added, the waste concrete is used secondarily, and meanwhile, the strength of the concrete is guaranteed. The concrete is doped with mineral powder and fly ash, the usage amount of cement is reduced, the workability of the green high-performance concrete is higher than that of ordinary concrete, the water demand is low, the compactness is good, and various technical indexes meet production, transportation and pumping requirements of the concrete. The concrete is easy to construct, the preparation process is green, and the cost is reduced.

Owner:GUANGSHA CONSTR GROUP +1

Imitation marble brick prepared by construction waste and preparation method thereof

InactiveCN109650792AReduce cement consumptionReduce dosageSolid waste managementCeramic shaping apparatusFlexural strengthSurface layer

The invention provides an imitation marble brick prepared by the construction waste. The brick comprises a three-layer structure, which is successively a superficial layer, a surface layer material and a bottom layer material. The superficial layer is obtained by polishing after the surface layer material is coated with a curing agent; the surface layer material comprises high-quality recycled coarse aggregate; and the bottom layer material comprises general-quality recycled coarse aggregate and general-quality recycled fine aggregate. Meanwhile, the invention provides a manufacture method ofthe imitation marble brick. The recycled material produced by the construction waste accounts for more than 80% of the total materials. The flexural strength of the prepared imitation marble brick is4-6.5 MPa, and the surface marble pattern is durable in use.

Owner:深圳市绿发鹏程环保科技有限公司

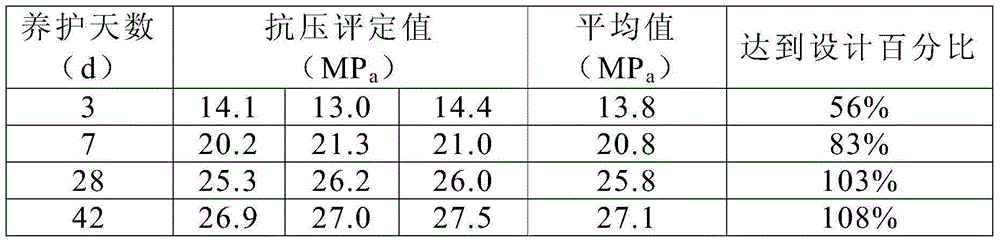

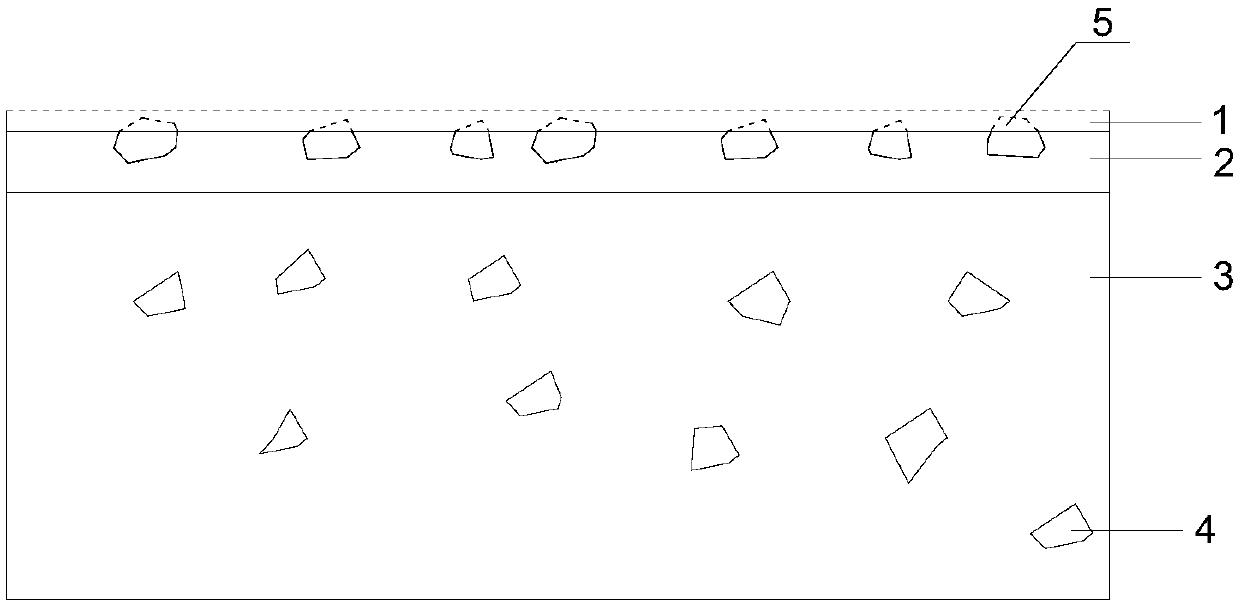

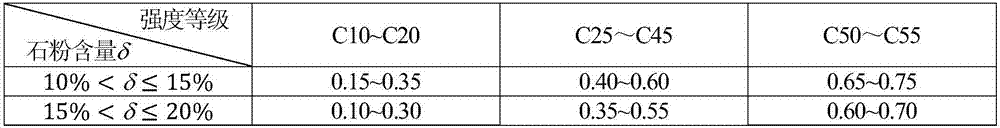

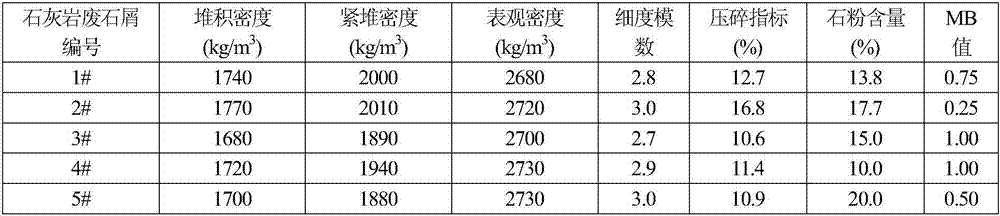

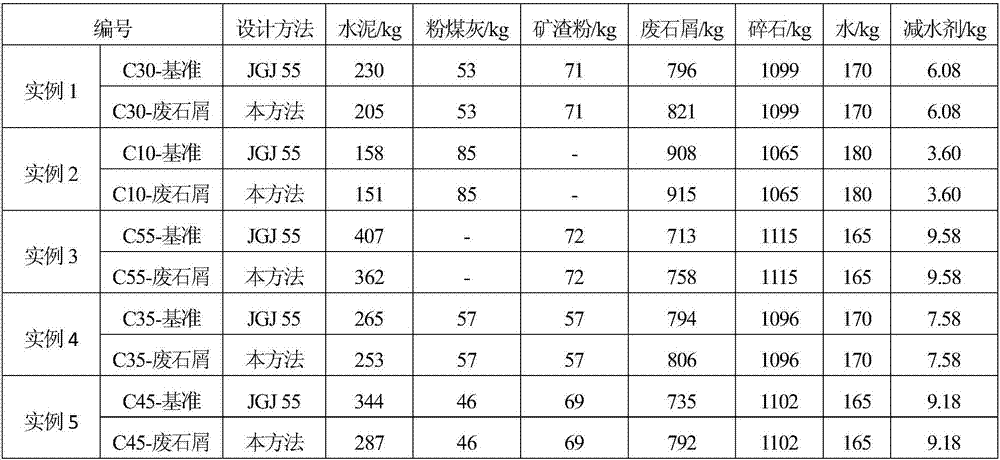

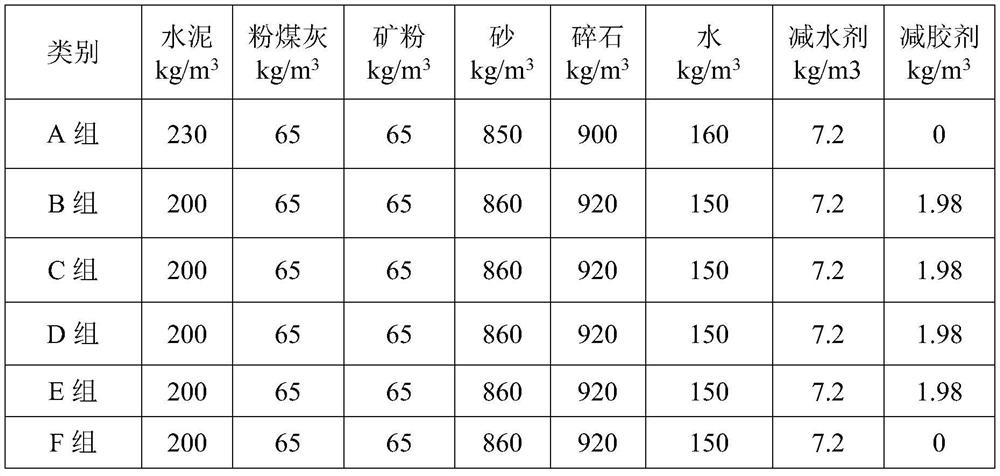

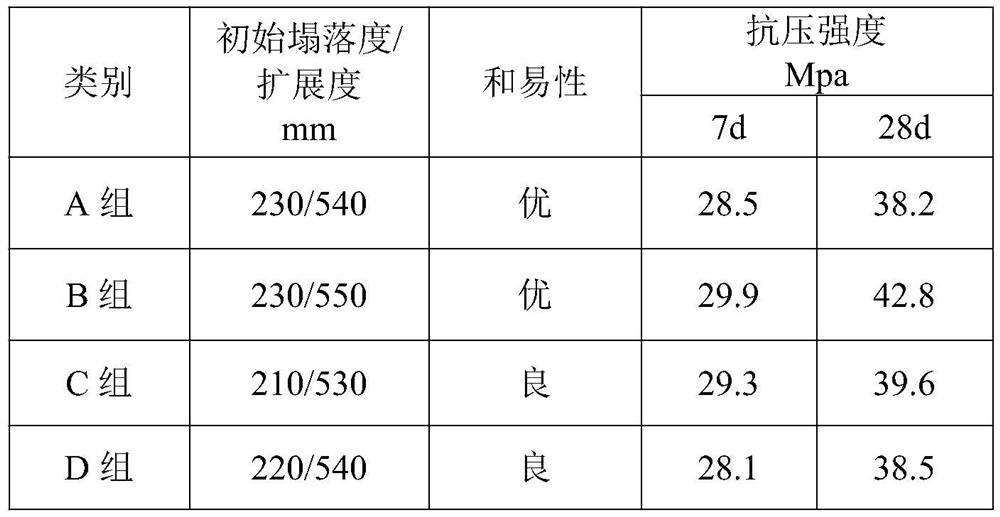

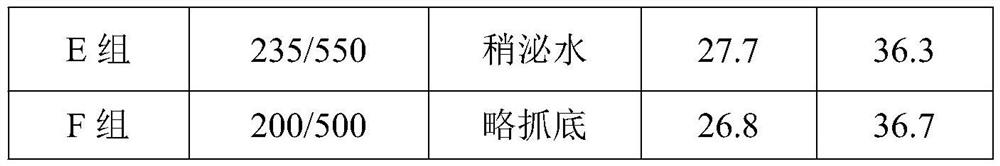

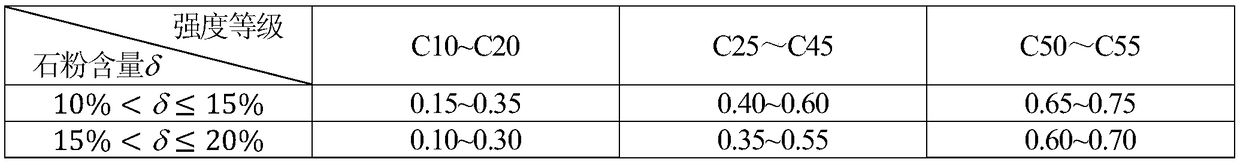

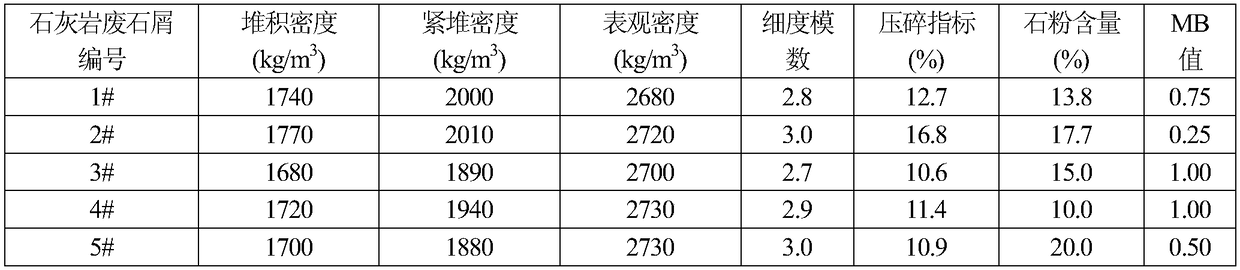

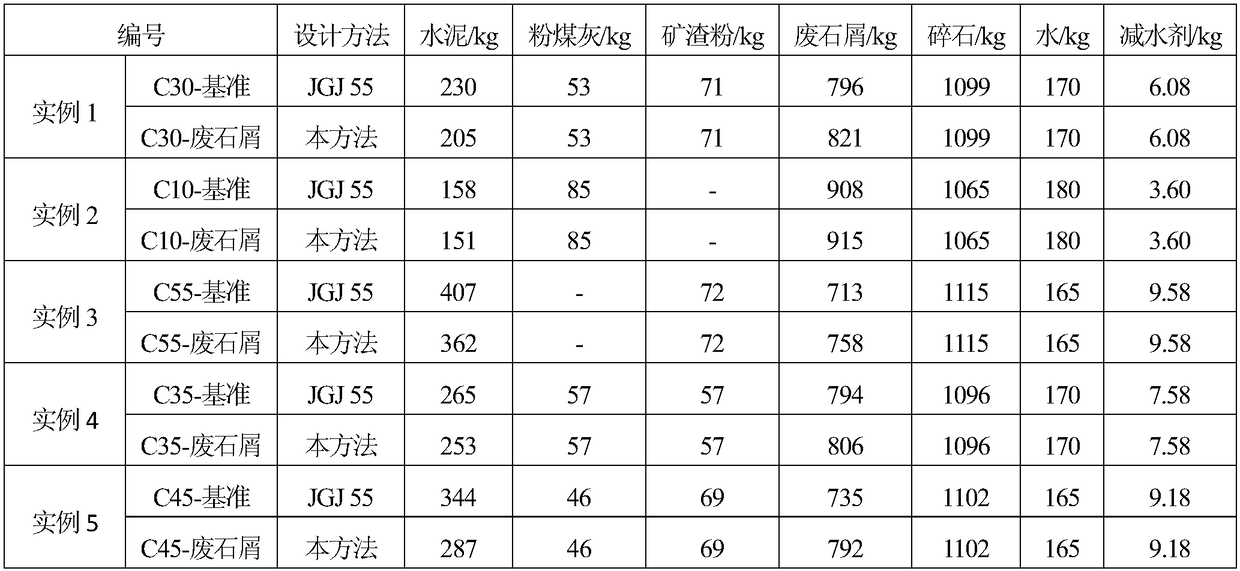

Mix proportion design method of high-stone-powder-content concrete containing waste limestone chippings

ActiveCN106892605AImprove performanceComprehensive utilization of resources is highRatio controlAbsolute volumeCrushed stone

The invention relates to a mix proportion design method of high-stone-powder-content concrete containing waste limestone chippings. The method includes: testing and determining the stone powder content delta of the waste limestone chippings actually used in a project according to the method of Standard for technical requirements and test method of sand and crushed stone (or gravel) for ordinary concrete JGJ 52, and calculating the stone powder excess value Delta delta of the waste limestone chippings according to a stone powder content limit value delta 0; using an absolute volume method to calculate and determine the mix proportion parameters of reference concrete according to the regulations of Specification for mix proportion design of ordinary concrete JGJ 55; using the stone powder of the excess part in the waste limestone chippings as inert mineral admixture, calculating and determining a substitution cement amount according to a certain substitution coefficient K, keeping unit weight unchanged, and calculating and determining the mix proportion parameters of the concrete containing the waste limestone chippings. The mix proportion design method has the advantages that under the premise that concrete performance satisfies design and construction requirements, the technical difficulty of the waste limestone chippings with stone powder content exceeding standards in the field of concrete application is solved, the cement use quantity and production cost of the concrete are lowered, and energy conservation and environmental protection are achieved.

Owner:云南建投绿色高性能混凝土股份有限公司

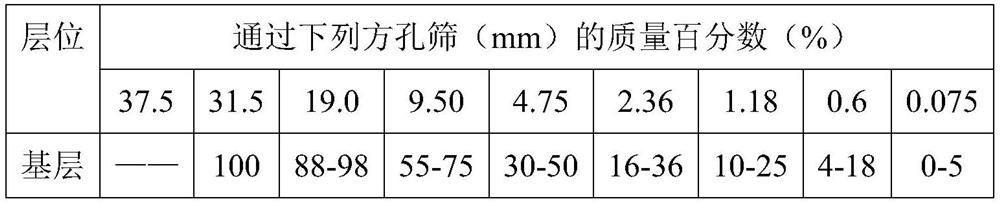

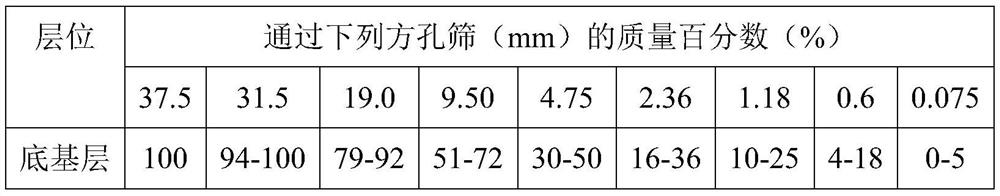

Geopolymer cementing material for pavement base based on multielement solid waste synergy and preparation method of geopolymer cementing material

The invention discloses a geopolymer cementing material for pavement base based on multielement solid waste synergy and a preparation method of the geopolymer cementing material. The geopolymer cementing material is mainly characterized in that fly ash, slag, carbide slag and desulfurized gypsum are used as main materials, the characteristics of various solid wastes are fully played, and the geopolymer cementing material is prepared on the basis of the principle of the geopolymer cementing material by utilizing the synergistic enhancement effect of the solid wastes. Through three main procedures of drying, grinding and secondary uniform mixing, the geopolymer cementing material special for the pavement base is prepared, wherein various performance indexes of the geopolymer cementing material meet the requirements of JT / T 994-2015 Cement for Highway Engineering Pavement Base Stability. Compared with the traditional cement-stabilized pavement base material, the dry shrinkage of the cement-stabilized pavement base material is greatly improved, and the crack hazard of the pavement caused by the dry shrinkage of the base is obviously reduced. Meanwhile, a large number of road building materials can be saved, waste is fully utilized, energy is saved, environmental pollution is reduced, resources are saved, the environment is protected, the road quality is improved, and the green traffic development concept is met.

Owner:INNER MONGOLIA UNIV OF TECH

Phosphogypsum base polymer iron tailing sand concrete and preparation method thereof

ActiveCN110304882AReduce cement consumptionReduce environmental pollutionConstruction aggregatePolymer

The invention relates to phosphogypsum base polymer iron tailing sand concrete and a preparation method thereof. The phosphogypsum base polymer iron tailing sand concrete is prepared from the components in parts by weight: 30 parts of phosphogypsum, 5-15 parts of waste glass powder, 5-15 parts of pulverous coal, 5 parts of quick lime, 35-55 parts of cement, 35-36 parts of water, 90-110 parts of iron tailing sand and 0.8-1 part of a water reducer. According to the phosphogypsum base polymer iron tailing sand concrete and the preparation method thereof, the formulation is reasonable, design is simple, the waste glass powder and the quick lime are used for commonly activating the activity of the phosphogypsum, a cementing material with the same action as the cement is produced, part of the cementing material replaces the cement, and the purpose of reducing cement using amount to reduce environment pollution is achieved; the iron tailing sand replaces coarse aggregate stones and natural sand, and environment-friendly construction is achieved; raw materials are mostly solid waste, the solid waste is utilized, the cost is low, and good economic benefits are achieved; and the applicationrange of products is wide, the phosphogypsum base polymer iron tailing sand concrete can be used in building structure elements and non-structural elements with the low strength requirement, and the phosphogypsum base polymer iron tailing sand concrete can further be used in crack repair materials for concrete pavements and shop-front-added layers of the concrete pavements.

Owner:上海青城绿浦环境资源发展有限公司

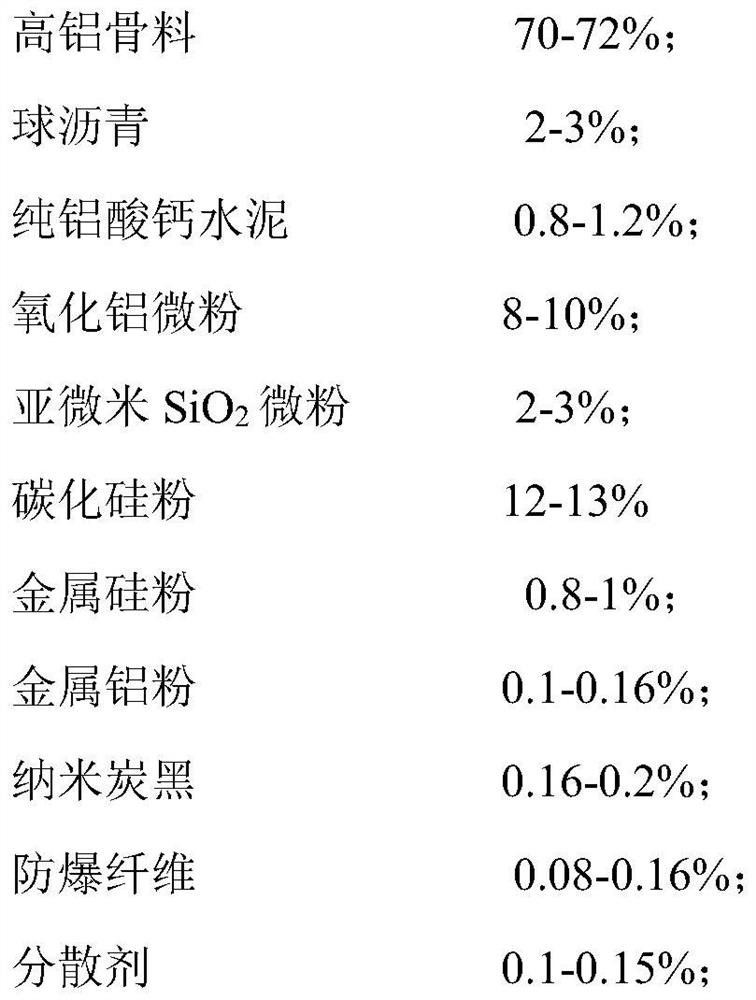

High-performance high-aluminum castable for iron runner

The invention discloses a high-performance and high-aluminum castable for an iron runner. The castable comprises the following components in percentage by mass: 70-72% of high-aluminum aggregate; 2-3% of ball pitch; 0.8%-1.2% of pure calcium aluminate cement; 8-10% of alumina micro powder; 2 to 3 percent of submicron SiO2 micro powder; 12-13% of silicon carbide powder; 0.8-1% of metal silicon powder; 0.1%-0.16% of metal aluminum powder; 0.16 to 0.2 percent of nano carbon black; 0.08 to 0.16 percent of explosion-proof fiber; and 0.1%-0.15% of a dispersing agent; and the product is prepared by adding 4.2% of water, uniformly stirring the components, and carrying out vibration molding. Through multiple technical measures, the compactness degree of the high-aluminum iron runner castable is improved to the maximum extent, meanwhile, a castable matrix generates fewer low-melting phases at high temperature, and through breakthrough enhancement of the performance of the powder matrix, the defect of the high-temperature performance of high-aluminum aggregate is counteracted, the problem that the thermal strength of the high-aluminum iron runner castable is obviously reduced compared with that of a corundum iron runner castable for a long time is solved, and the aim of completely replacing corundum aggregate with high-aluminum aggregate in a common iron runner castable is achieved.

Owner:中冶武汉冶金建筑研究院有限公司 +1

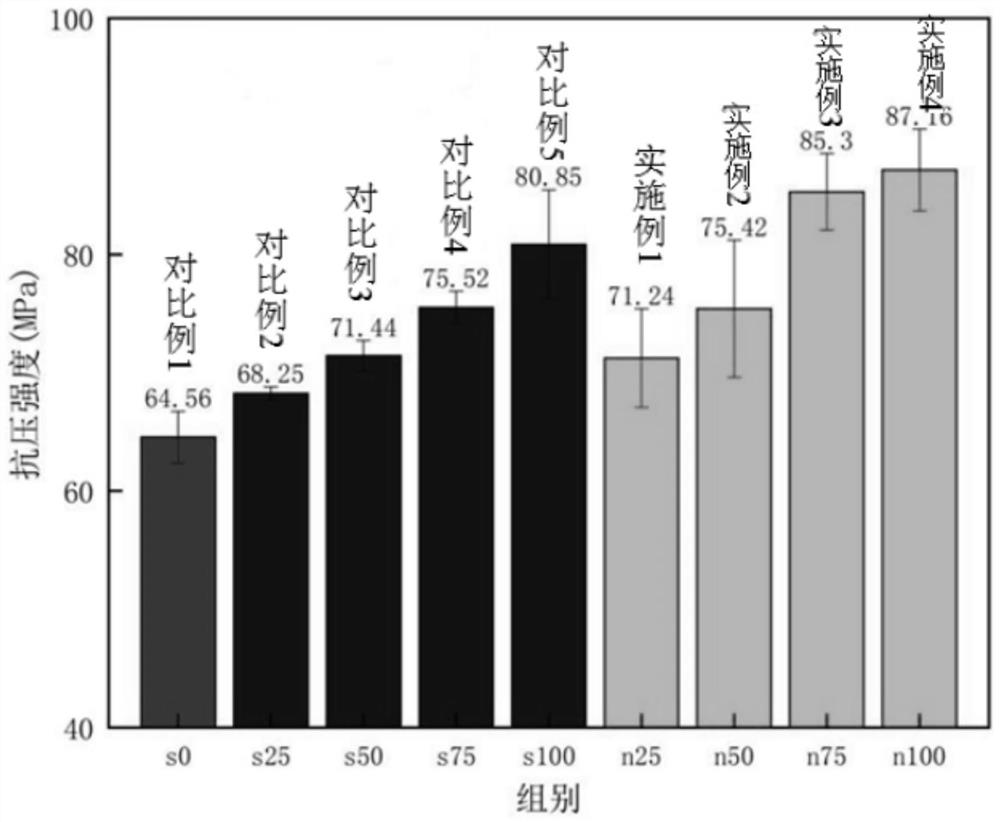

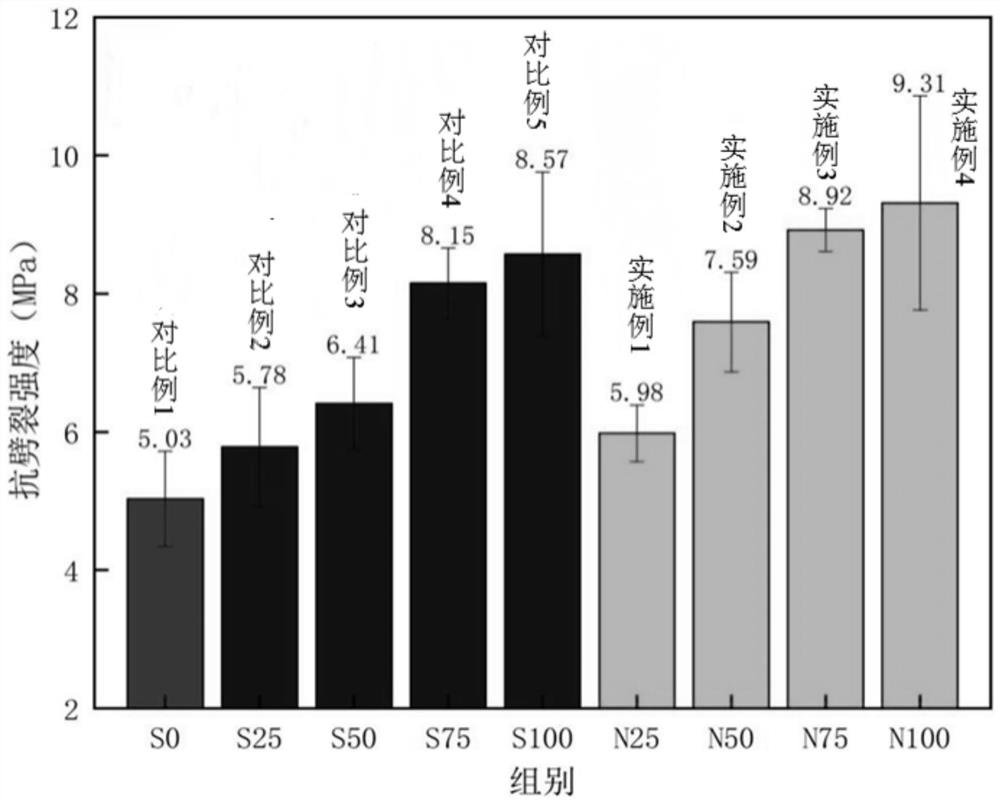

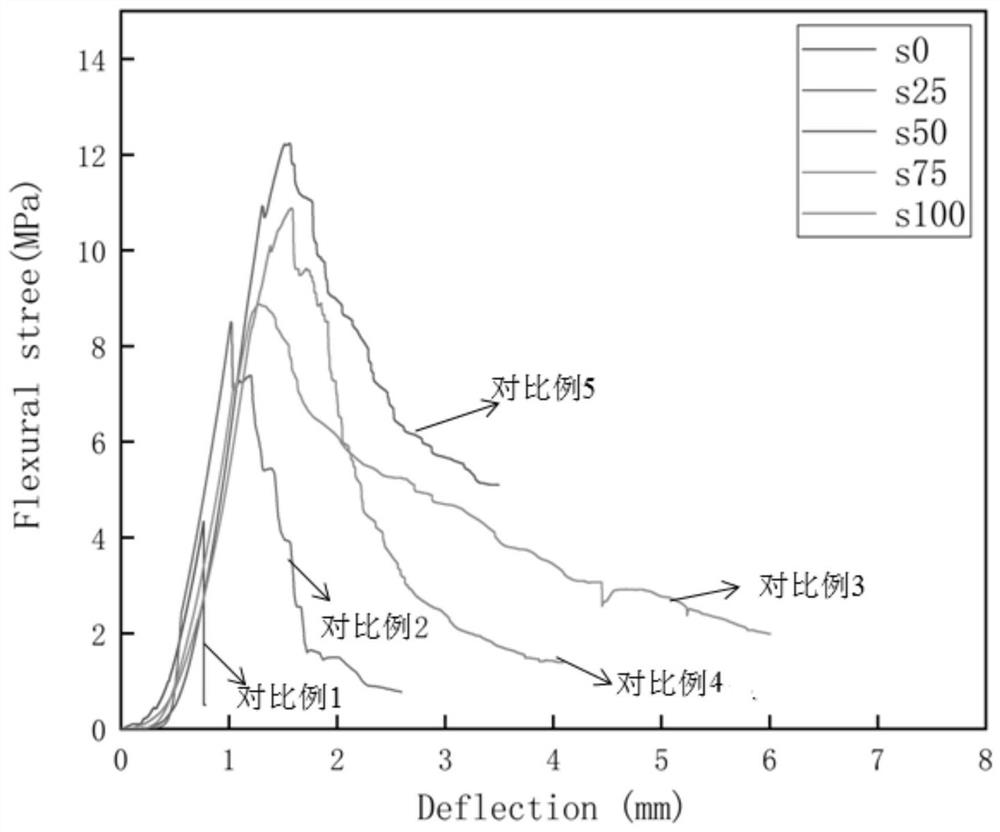

NiTi alloy fiber concrete and preparation method thereof

PendingCN114249570AReduce cement consumptionImprove mechanical propertiesSilica fumeEarthquake resistant

The invention discloses NiTi alloy fiber concrete and a preparation method thereof. The concrete comprises the following raw materials in percentage by mass: 10-15% of cement, 2-3% of fly ash, 2-2.5% of slag, 1.5-2% of silica fume, 25-30% of sand, 40-45% of gravel, 0.5-3% of NiTi alloy fiber, 5-10% of water and 0.5-1% of a water reducing agent, and the sum of the mass percentages of all the raw materials is 100%. The composite NiTi-based alloy toughened cement-based composite material has the characteristics of high strength, high toughness, high durability and the like; the anti-seismic ductility of the structure is improved, the resistance of the structure to severe environments is enhanced, generation of concrete cracks is slowed down, and the service life of the structure is prolonged. According to the invention, the unique shape memory effect and the phase change superelastic NiTi alloy fiber are adopted, the related cost of maintenance and the like of the structure in the use process is reduced, the characteristic enables the structure to still play a predetermined role well under the condition of atrocious weather environment for a long time, and even if the structure of the test piece is damaged, the test piece can still work normally. And the fibers can still bear stress, so that stress holding is realized.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

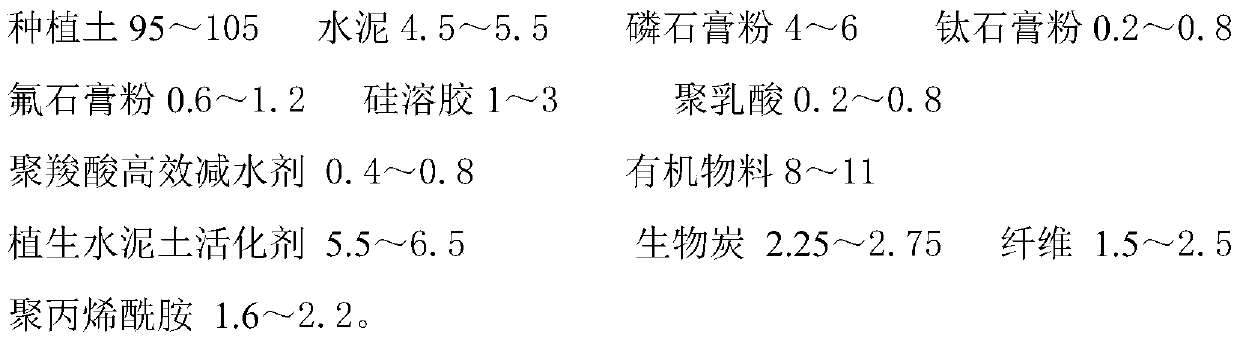

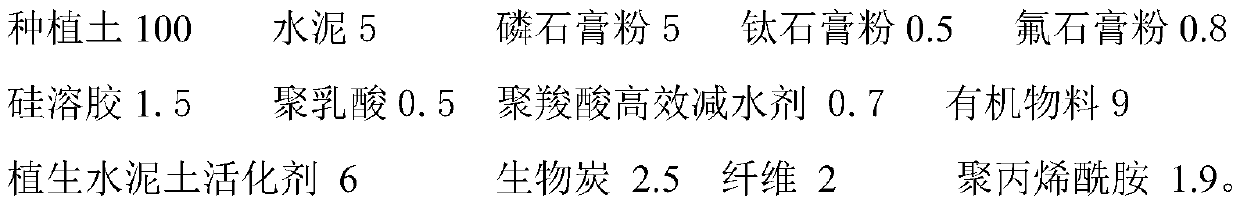

Plant-growing cement soil ecological restoration substrate and preparation method thereof

InactiveCN110372273AImproves compressive strength and frost resistanceReduce cement consumptionExcavationsIndustrial wastePolyacrylamide

The invention discloses a plant-growing cement soil ecological restoration substrate. The plant-growing cement soil ecological restoration substrate is prepared from the following components in partsby weight: 95-105 parts of planting soil, 4.5-5.5 parts of cement, 4-6 parts of phosphogypsum powder, 0.2-0.8 part of titanium gypsum powder, 0.6-1.2 parts of fluorogypsum powder, 1-3 parts of silicasol, 0.2-0.8 part of polylactic acid, 0.4-0.8 part of a polycarboxylic acid efficient water reducing agent, 8-11 parts of an organic material, 5.5-6.5 parts of a plant-growing cement soil activator, 2.25-2.75 parts of biochar, 1.5-2.5 parts of fibers and 1.6-2.2 parts of polyacrylamide. According to the plant-growing cement soil ecological restoration substrate and a preparation method thereof, the problems that the material utilization rate is low and industrial waste residue cannot be effectively utilized, the physical and chemical properties between various industrial by-products or industrial waste are utilized, a large amount of the industrial waste such as phosphogypsum can be consumed, the use amount of cement in a product can also be decreased, and the production cost is lowered.

Owner:CHINA THREE GORGES UNIV +2

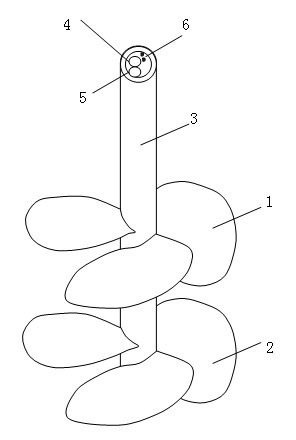

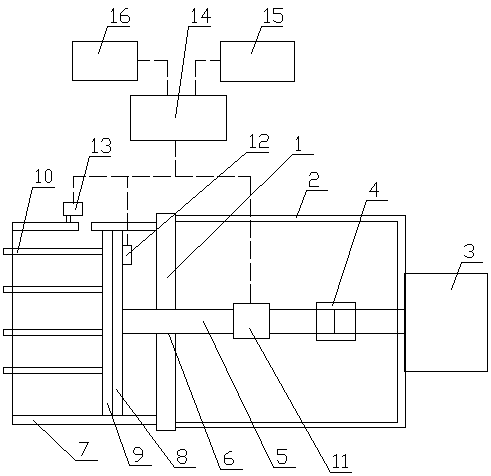

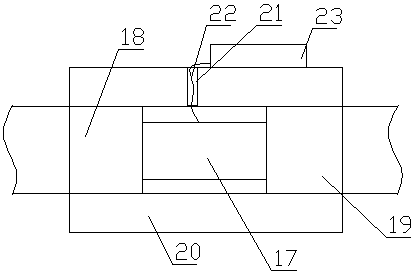

Device for reducing water ratio of sludge

InactiveCN102503070AReduce cement consumptionGood for vacuuming efficiencySludge treatment by de-watering/drying/thickeningHeavy metalsHelix

The invention discloses a device for reducing water ratio of sludge. The device for reducing the water ratio of the sludge comprises a hollow transmission shaft, wherein a water drain pipe is arranged inside the improved transmission shaft; an upper spiral blade and a lower spiral blade are arranged on the transmission shaft; an electrically-conductive plate is arranged below the upper spiral blade; the electrically-conductive plate is insulated from the upper spiral blade; a metal water filtering layer is arranged on the upper surface of the lower spiral blade; the metal water filtering layer is insulated from the lower spiral blade; a power cord is arranged inside the transmission shaft; the positive electrode of a power supply is connected to the electrically-conductive plate; and the negative electrode of the power supply is connected to the metal water filtering layer. Compared with the prior art, under the action of an electromotive force, water migrates towards the lower blade,while a vacuumizing position is rightly above the lower blade, so that the vacuumizing efficiency is improved; and along with the downward movement of the upper blade, the upper blade is always separated from dry sludge to be in contact with the sludge with relatively high water ratio, so that the water and heavy metal migrating capability of the electromotive force is improved.

Owner:HOHAI UNIV

Enhanced type cement and production method thereof

The embodiment of the invention discloses enhanced type cement and a production method thereof and belongs to the technical field of building materials. The enhanced type cement is prepared from common portland cement and a water reducing agent according to the weight ratio of 100 to (0.05 to 1.5). According to the embodiment provide by the invention, a certain amount of the water reducing agent is added into the common portland cement to obtain cement containing the water reducing agent; when the cement is used, the water reducing agent does not need to be additionally purchased, so that thewater reducing agent can be conveniently used in occasions where the water reducing agent is convenient to use when the cement is used for producing concrete or mortar and the application is simplified; meanwhile, the strength of the concrete also can be increased, the quality of the concrete is improved and the service life of a concrete structure is prolonged; the enhanced type cement has relatively good economic benefits, social benefits and environment benefits and is suitable for being popularized and applied.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

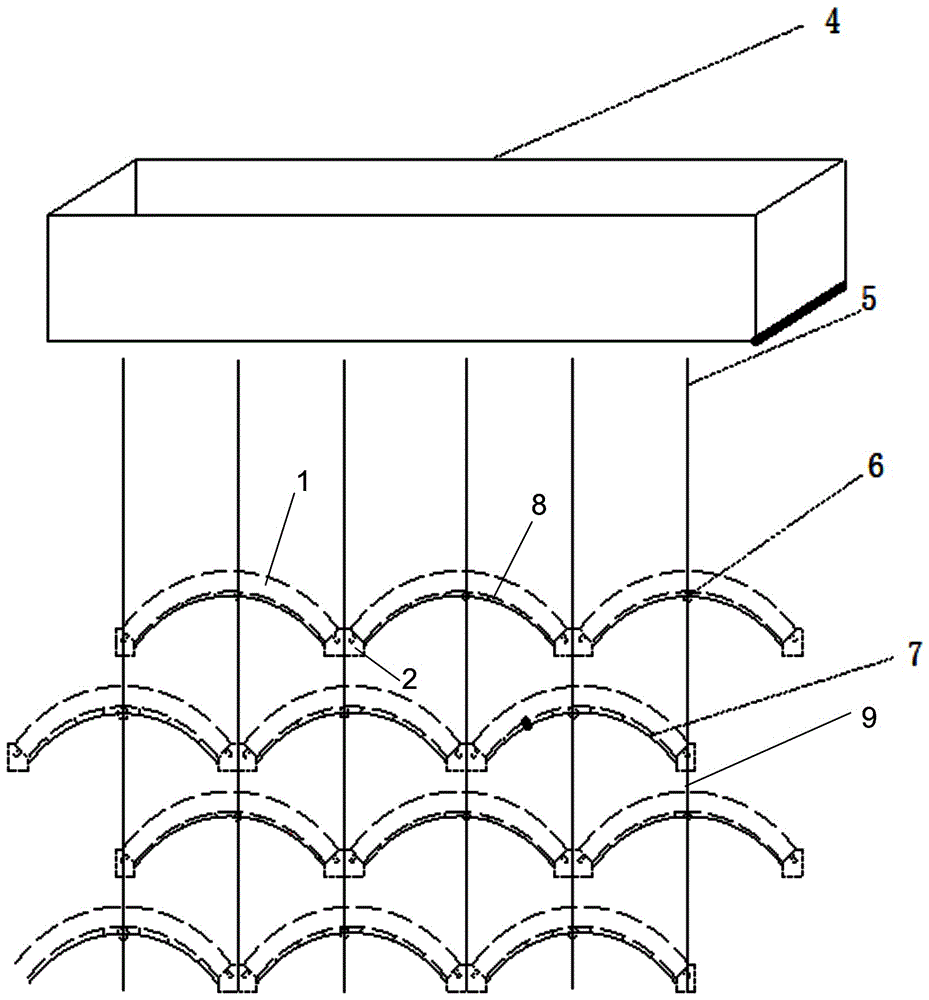

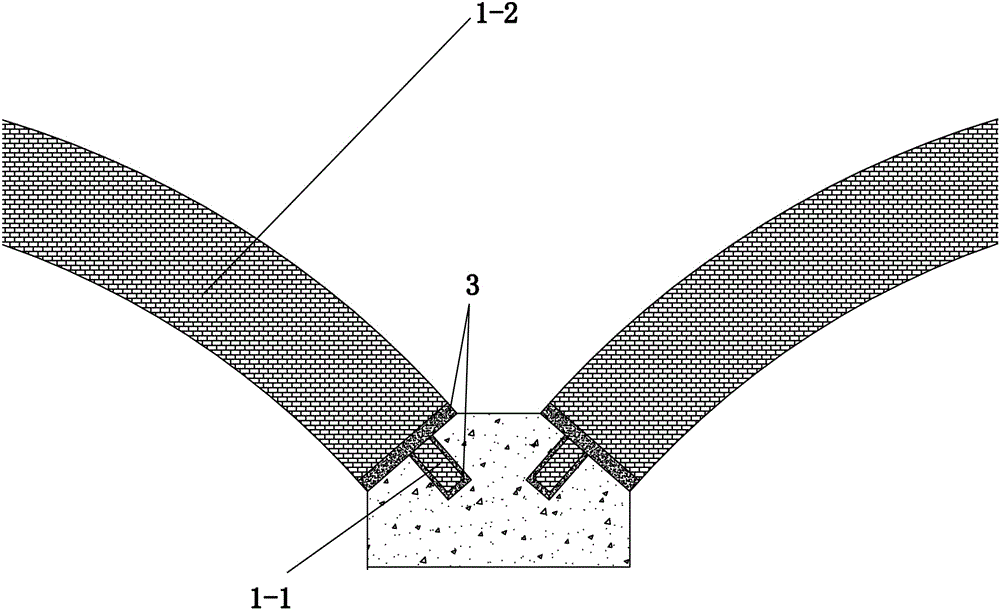

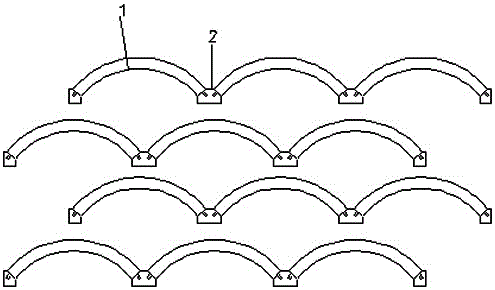

Greening system and greening method for prefabricated arch body bearing-type vegetation concrete side slope

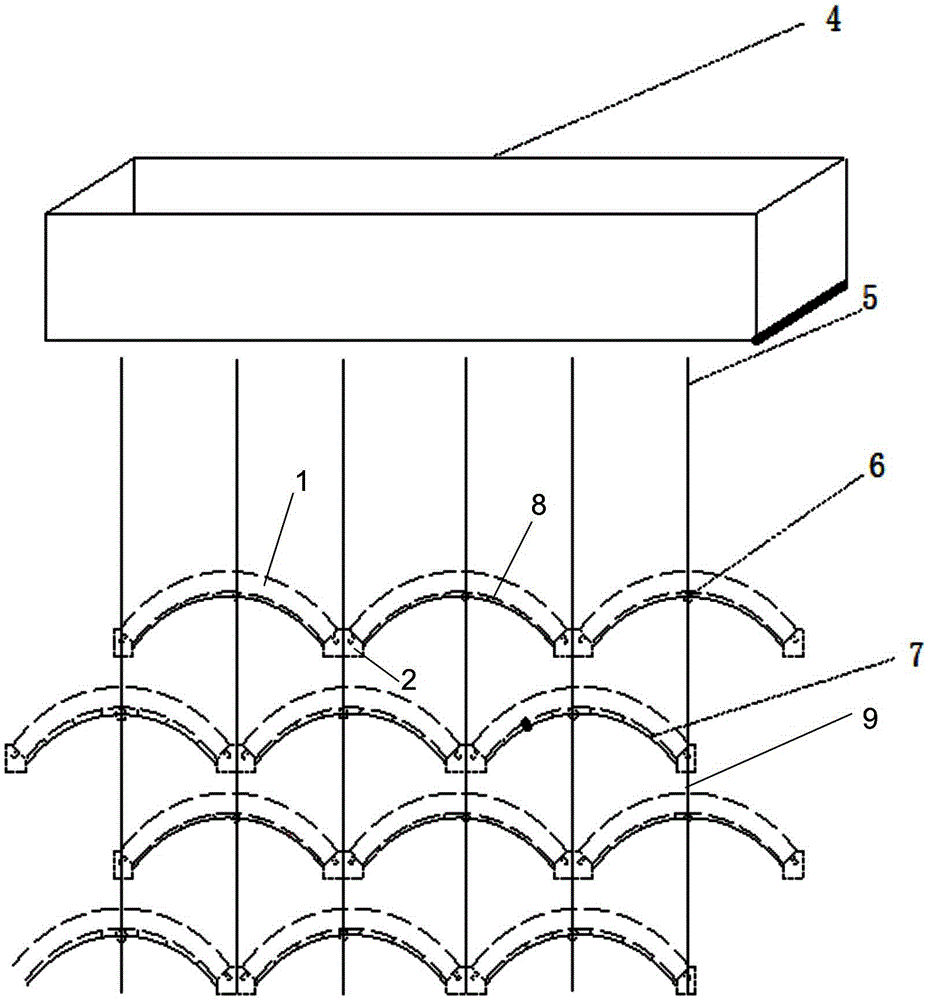

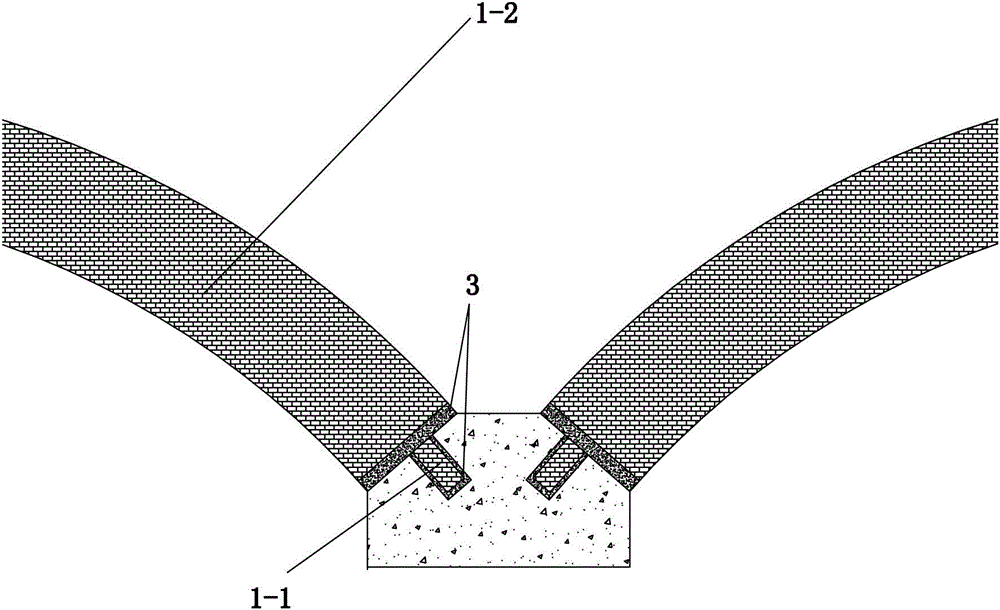

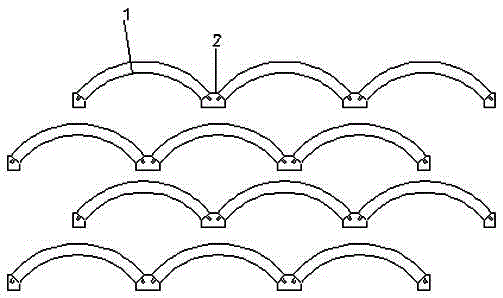

ActiveCN105297746AReduce cement consumptionImprove germination rateWatering devicesExcavationsWater reservoirGeotechnical engineering

The invention discloses a greening system for a prefabricated arch body bearing-type vegetation concrete side slope. The greening system comprises a plurality of rows of arc body bearing devices laid along the surface of the side slope. The arc body bearing devices comprise a plurality of prefabricated arc bodies. Every two prefabricated arc bodies are connected through a stressing pier, and the stressing piers are built on the side slope through bolts embedded in the side slope. A water storage pool is installed at the top of the side slope. A plurality of multistage water supplying devices which are vertically arranged and used for watering vegetation around each prefabricated arc body are communicated with the water storage pool. According to the greening system and a greening method for the prefabricated arch body bearing-type vegetation concrete side slope, the problem brought by the cement use amount can be solved, the cement use amount of vegetation concrete is decreased, the germination rate of seeds is increased, the gravity stress and later downward creeping influence of the vegetation concrete are lowered, cracking and falling of the vegetation concrete are reduced, and the downward shearing force of the terrene surface is decreased.

Owner:CHINA THREE GORGES UNIV

Stray current resistant concrete material and preparation method thereof

InactiveCN109574593AImproves impermeability and electrical resistivityReduce cement consumptionCoal gangueWater reducer

The invention discloses a stray current resistant concrete material and a preparation method thereof, and belongs to the field of civil engineering materials. The concrete material comprises, by weight per cubic meter of concrete, 240-440 parts of cement, 1000-1200 parts of coarse aggregate, 660-740 parts of fine aggregate, 15-30 parts of rubber powder, 100-150 parts of fly ash, 15-30 parts of spontaneous combustion coal gangue powder, 30-100 parts of glass powder, 180-220 parts of mixed water, and 2-4 parts of additives. The preparation method includes firstly, uniformly stirring the coarse aggregate, the fine aggregate and the rubber powder, adding the cement, the fly ash, the spontaneous combustion coal gangue powder and the glass powder, continuously stirring uniformly, adding a waterreducing agent and the water, and continuously stirring uniformly the mixture to obtain the stray current resistant concrete material; secondly, putting the material into a cube test mold, vibrating on a concrete vibrating table, and then maintaining and dismantling the mold. According to the method, the cost can be reduced; meanwhile, on the basis of ensuring the concrete strength grade, the anti-stray current has a better effect, so that the material has remarkable innovation significance and a potential engineering application prospect.

Owner:DALIAN UNIV OF TECH

Flexible putty powder

InactiveCN105384401AEnhanced gelling propertiesReduce cement consumptionHydroxypropylmethyl celluloseMaifan Stone

The invention relates to flexible putty powder. The flexible putty powder comprises the following raw materials in parts by weight and in a compounding ratio: 20-29 parts of kaolin powder, 6-16 parts of sepiolite powder, 5-29 parts of portland cement, 1-2 parts of hydroxypropyl methyl cellulose, 2-6 parts of an exciting agent, 2-6 parts of water-soluble emulsion powder, 1-3 parts of maifan stone powder, 3-9 parts of graphite and 3-9 parts of silicon carbide crystal grains. Compared with the prior art, the flexible putty powder disclosed by the invention has extremely high water resistance, after the flexible putty powder is exposed to water and affected with damp, the phenomena of hollowing, peeling, cracking and shedding are not generated, the phenomena of becoming yellow, becoming mildewed and generating black spots are not generated, and the flexible putty powder is good in artistic properties, safe, environment-friendly and long in service life.

Owner:广西兴安县桂兴矿粉厂

Light cement-based porous material and preparation method thereof

InactiveCN109133777AReduce cement consumptionHigh strengthCeramicwareSilica fumeHydrostatic pressure

The invention relates to a light cement-based porous material and a preparation method thereof, and belongs to the technical field of building materials. The light cement-based porous material comprises, by weight, 185-280 parts of cement, 20-70 parts of coal ash, 5-14 parts of silica fume, 8.3-16.8 parts of chemical foaming agents, 1-2 parts of water reducing agents, 0.3-0.45 part of foam stabilizers, 1.85-8.40 parts of fibers, 0.5-2.0 parts of water repellents and 102-168 parts of water. The compressive strength of the light cement-based porous material formed by matching is higher than or equal to 0.40MPa, the tensile strength of the light cement-based porous material is higher than or equal to 0.13MPa, by adding the coal ash and the silica fume, cement content can be decreased, cracksgenerated by stress of the light cement-based porous material can be eliminated, the later strength of the light cement-based porous material can be improved, the fibers are added into slurry to enhance the crack resistance of the light cement-based porous material, pores and filling capillary channels in the light cement-based porous material can be decreased by the water repellents, the water absorptivity or the water permeability of the light cement-based porous material under hydrostatic pressure are reduced, permeability resistance is improved, and durability is enhanced.

Owner:SOUTHEAST UNIV

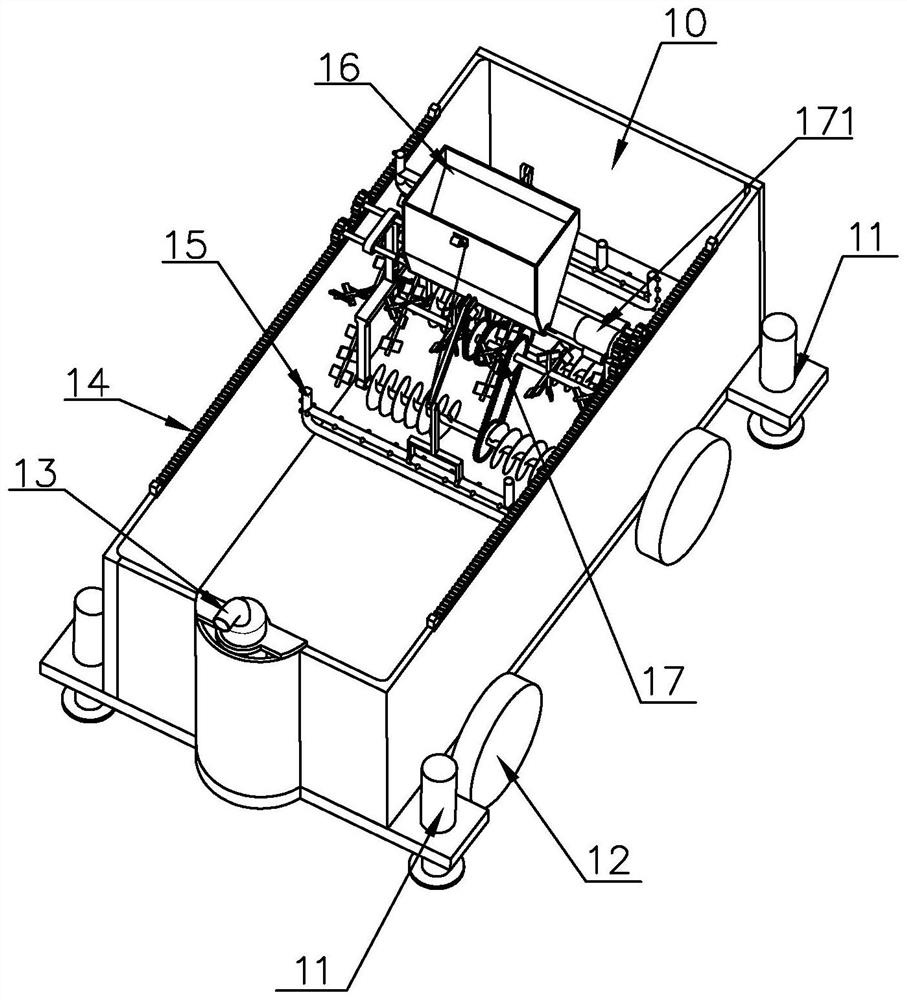

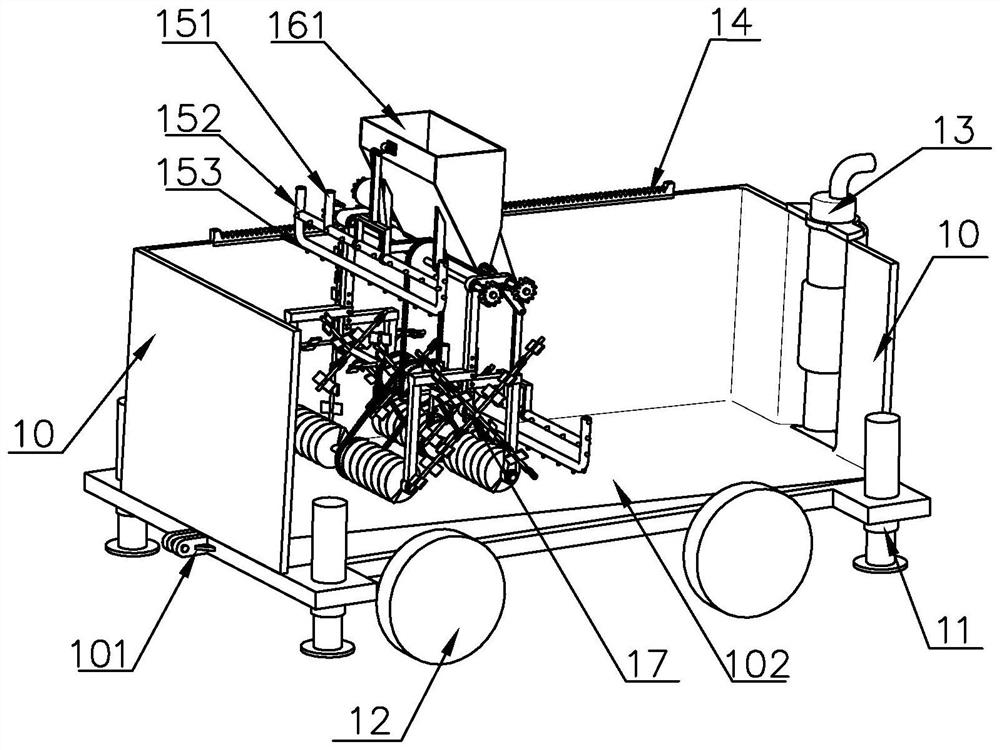

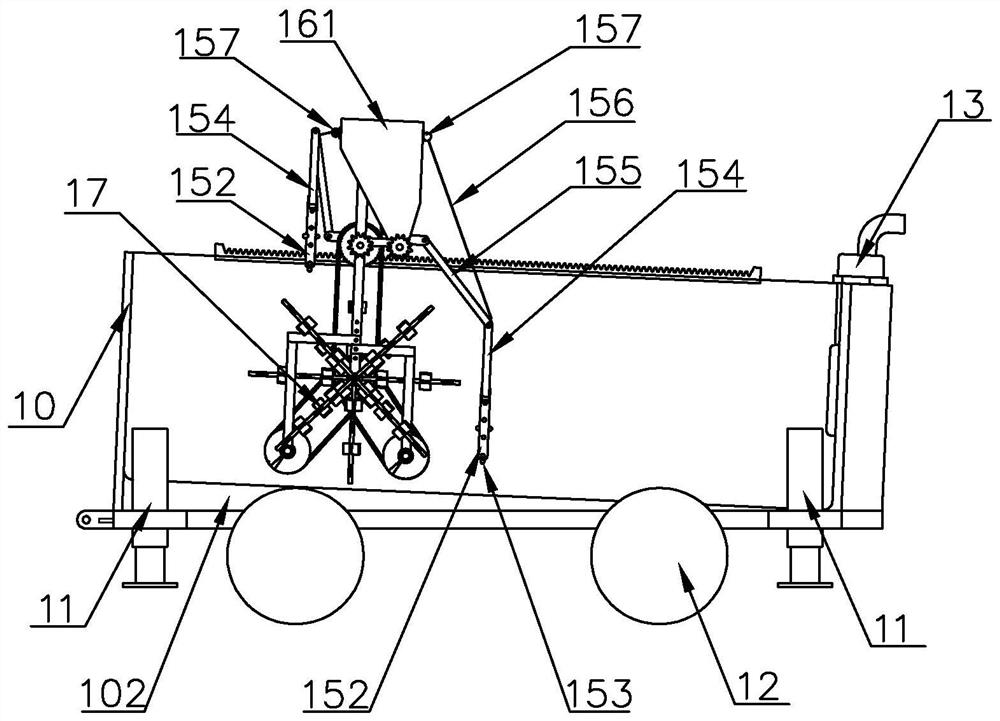

Solidified soil stirring box for municipal construction

PendingCN114311310AReduce cement consumptionImprove the strength of consolidated soilCement mixing apparatusMechanical engineeringSludge

Owner:众智机械(临沂)有限公司

A prefabricated arch load-bearing type vegetation concrete slope greening system and its greening method

ActiveCN105297746BReduce self-weight stressReduced creep effectsWatering devicesExcavationsWater storageVegetation

The invention discloses a greening system for a prefabricated arch body bearing-type vegetation concrete side slope. The greening system comprises a plurality of rows of arc body bearing devices laid along the surface of the side slope. The arc body bearing devices comprise a plurality of prefabricated arc bodies. Every two prefabricated arc bodies are connected through a stressing pier, and the stressing piers are built on the side slope through bolts embedded in the side slope. A water storage pool is installed at the top of the side slope. A plurality of multistage water supplying devices which are vertically arranged and used for watering vegetation around each prefabricated arc body are communicated with the water storage pool. According to the greening system and a greening method for the prefabricated arch body bearing-type vegetation concrete side slope, the problem brought by the cement use amount can be solved, the cement use amount of vegetation concrete is decreased, the germination rate of seeds is increased, the gravity stress and later downward creeping influence of the vegetation concrete are lowered, cracking and falling of the vegetation concrete are reduced, and the downward shearing force of the terrene surface is decreased.

Owner:CHINA THREE GORGES UNIV

A kind of jack calibration tooling

ActiveCN106113251BExact lengthAvoid quality lossMeasurement devicesShaping reinforcementsCrack resistanceEngineering

The invention discloses a checking tool for a jack. The checking tool for the jack comprises a baffle. A supporting leg is arranged on one side of the baffle, and the jack is arranged on the supporting leg. The jack is connected with a tensioning rod through a connection nut. A guide hole is formed in the middle of the baffle, and the tensioning rod penetrates through the guide hole. A steel plate ring is arranged on the other side of the baffle. A tensioning plate connected with the tensioning rod is arranged in the steel plate ring. A bar hanging plate is arranged on the tensioning plate and connected with a steel bar. The tensioning rod is provided with a tension checking mechanism. The tensioning plate is provided with a displacement checking mechanism. The steel plate ring is provided with a wire slippage monitor mechanism corresponding to the steel bar. By checking the tensioning length and tensioning force and monitoring the tensioning quality, high-quality construction in the tensioning process is ensured; and through cooperation of checking on the tensioning length and the tensioning force and monitoring on the tensioning quality, the purposes that the cement consumption of electric poles is correspondingly reduced, the weight of the electric poles is gradually reduced, and the cracking resistance, ductility and rigidity are gradually improved are achieved, and meanwhile the service life of the electric poles can be prolonged.

Owner:HENAN DINGLI POLE TOWER

Composite water-retaining thickening material for commodity mortar and using method thereof

ActiveCN100558669CImprove cohesionImprove water retentionSolid waste managementSodium BentoniteThermal insulation

Owner:上海曹杨建筑粘合剂厂

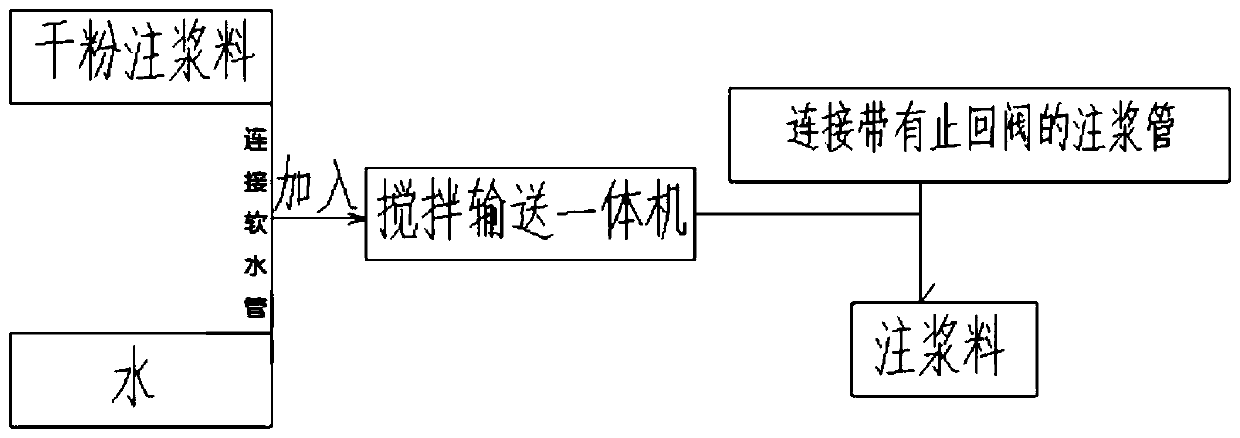

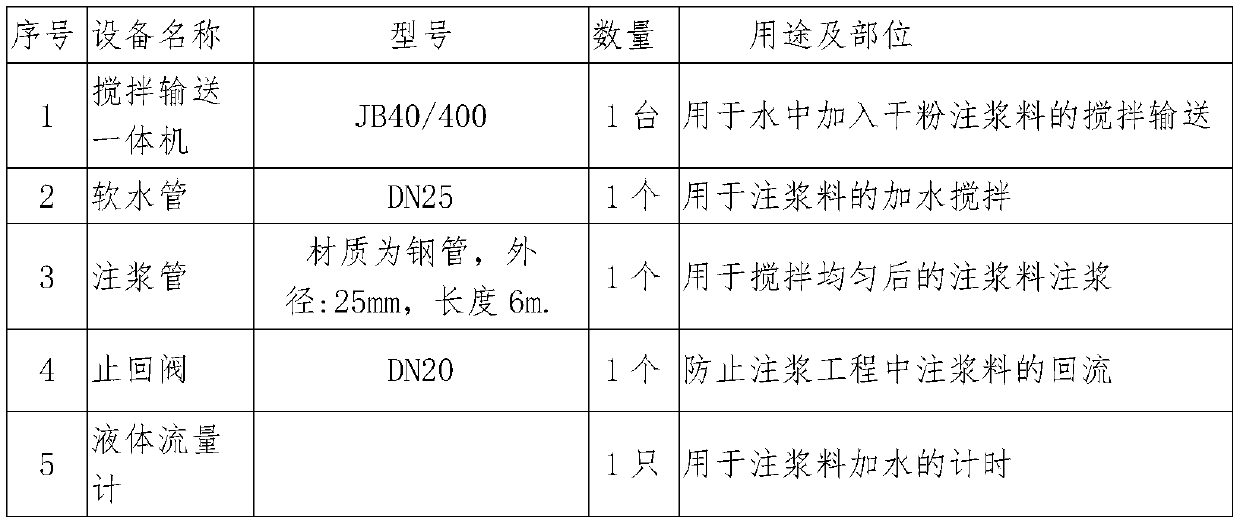

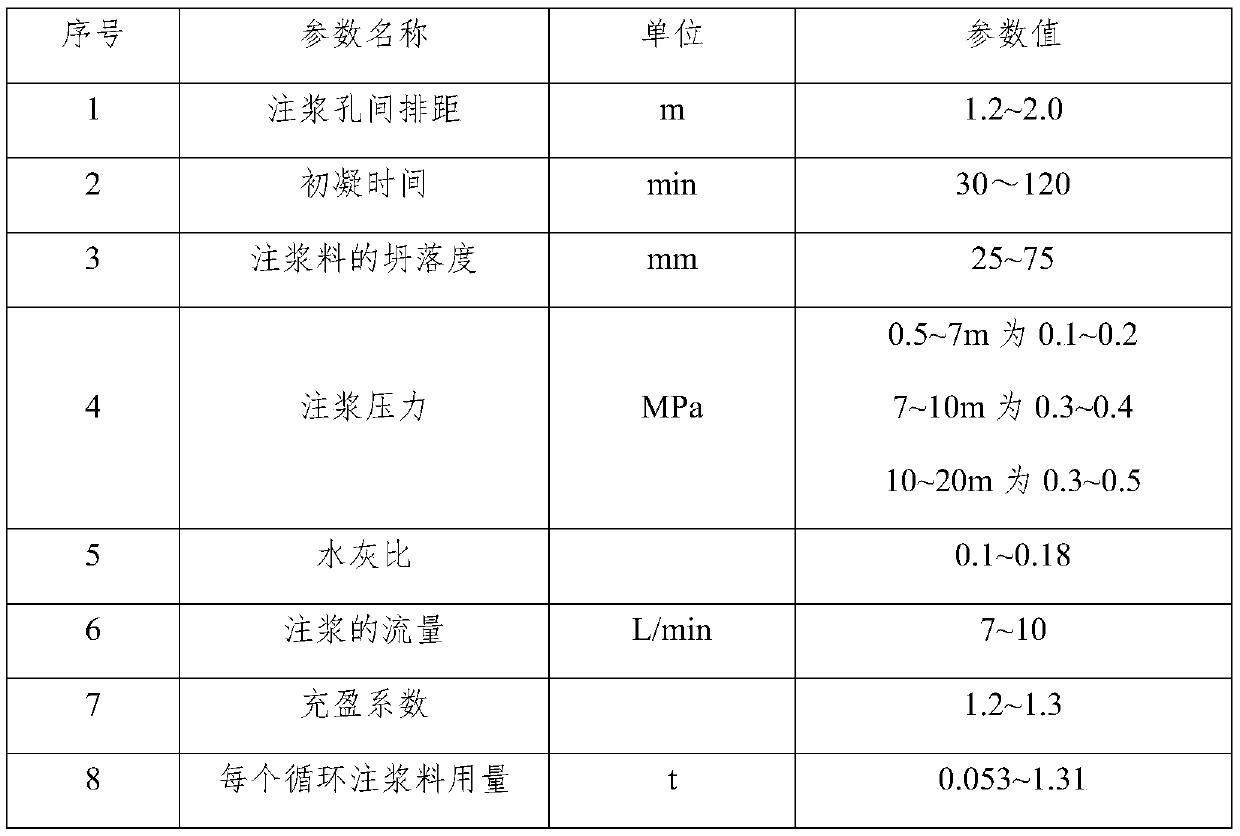

A kind of preparation method of grouting material

A preparation method for a grouting material, wherein 80-12 parts of magnesium phosphate cement, 4-15 parts of an additive, 10-15 parts of an admixture and 50-100 parts of an aggregate are used as a grouting material; by means of reasonable proportional design, the amount of magnesium phosphate cement may be effectively reduced so that the powder content in the aggregate is controlled and costs are reduced. The grouting material is suitable for geological conditions in which engineering is complex, such as tunnel engineering, slope treatment engineering, mining engineering, and urban underground spaces, and the effect of the grouting material on surrounding rock reinforcement and anti-seepage and plugging in the geological conditions in which engineering is complex is improved.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

Concrete glue reducing agent and preparation method thereof

ActiveCN112358228AIncreased hydrationReduce cement consumptionSolid waste managementActive agentEther

The invention relates to a concrete glue reducing agent and a preparation method thereof. The concrete glue reducing agent is prepared by adding a quaternary ammonium salt surfactant and silicone oilinto raw material components according to a proper proportion. During preparation, a methyl allyl polyoxyethylene ether polycarboxylic acid water reducing agent is added into water firstly, then organic amine and organic alcohol are added for a stirring reaction, cellulose ether is added, a stirring reaction is performed for certain time, a mixture of a quaternary ammonium salt surfactant and silicone oil is added, and a stirring mixing reaction is performed to finally prepare a concrete glue reducing agent. According to the invention, the concrete glue reducing agent is used for concrete, thehydration degree of the cement is enhanced, the cement consumption is lowered, the mechanical properties and compactness of the concrete are effectively enhanced, and the workability and the volume stability of the concrete are also improved; and according to the concrete glue reducing agent, the manufacturing cost can be effectively reduced, 30 kg of cement can be saved for each cubic meter of concrete with C30 or above, and the concrete glue reducing agent is compatible with a conventional additive and has no side effect.

Owner:北京富瑞勒斯科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com