Novel vegetation concrete

A technology of vegetation concrete and soil, applied in fertilizer mixture, agriculture, fertilization device, etc., can solve problems such as damage to the ecological environment, and achieve the effect of reducing cement consumption, increasing strength, and suitable for plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

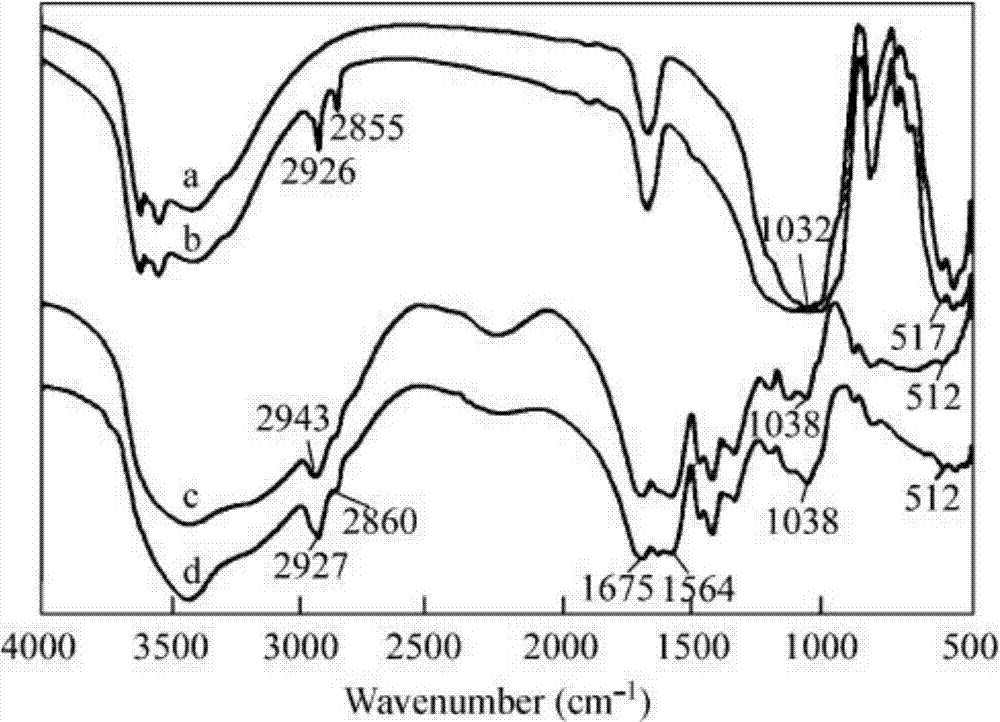

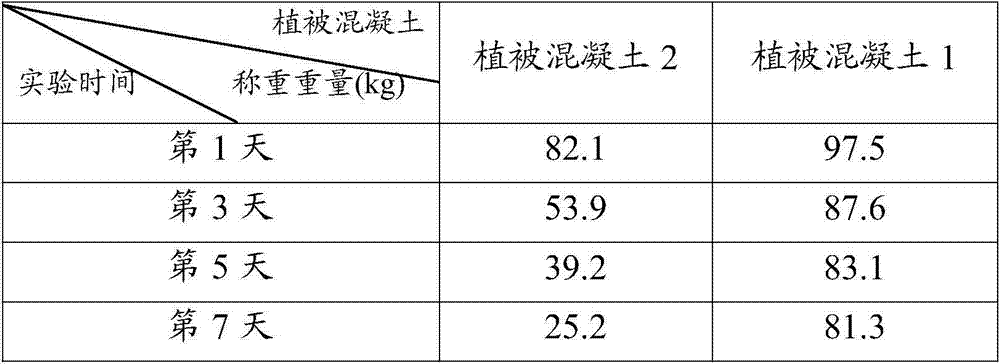

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of described soil conditioner is specifically:

[0033] The first step is organic modification of attapulgite, take 400g of attapulgite and suspend in 4L with a concentration of 0.01g / ml -1 In the dehydrated ethanol solution of cetyltrimethylammonium bromide, stir at a constant temperature of 70°C for 8h and then filter with suction, then wash the free quaternary ammonium salt with a large amount of ethanol, and the solid isolate is vacuumed at 40°C drying and grinding to obtain organic attapulgite;

[0034] In the second step, add 700g of acrylamide to the reaction container, add 2L of water to dissolve, add 70g of the organic attapulgite prepared in the first step and 25g of N,N'-methylenebisacrylamide after the dissolution is complete, Raise the temperature to 40°C and add 30g of ammonium persulfate to react for 3h, then add 2L of NaOH solution with a molar concentration of 1mol / L, raise the temperature to 95°C and react for 1h, after the reac...

Embodiment 1

[0068] The preparation of embodiment 1 organic compost

[0069] Fully mix 60kg of urban domestic sludge, 40g of waste plants and 50g of livestock and poultry manure, adjust the water content of the mixture to 45% to 50%, control the C / N ratio at 20:1 to 30:1, and put the mixture into a closed space The first fermentation is carried out in the room, the fermentation time is 14h~20h, and then the ventilation is started in stages, the ventilation time is 15min~20min per hour, and the air flow rate is 0.1m 3 / min·m 3 , lasted for 10d-15d, then placed the obtained product outdoors, turned the pile once a day, and piled it for 18d-20d to obtain organic compost.

Embodiment 2

[0070] The preparation of embodiment 2 Chinese herbal medicine nutrient

[0071] 55g of Astragalus, 40g of Atractylodes macrocephala, 25g of Caulis Spatholobus, 30g of Dendrobium, 40g of Fructus Cnidii, 30g of Acanthopanax, 20g of saponins, 20g of tangerine peel, 25g of honeysuckle, 35g of Coptis chinensis, 15g of Baibu, 20g of Baijiucao, 15g of mulberry parasites, Mix 25g of turmeric and 15g of Herba sativa, add 1.3kg of ethanol with an alcohol concentration of 95%, heat and reflux for extraction for 3 hours, filter, add 3 times the mass of ethanol with an alcohol concentration of 95% to the filter residue, and heat and reflux for extraction After 3 hours, filter, combine the filtrates, concentrate to remove ethanol, and dry to obtain Chinese herbal medicine nutrient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com