Patents

Literature

30results about How to "Comprehensive utilization of resources is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Attapulgite activated carbon haydite filter board

ActiveCN102430290AComprehensive utilization of resources is highReduce land occupationOther chemical processesFiltration separationEnvironmental geologyWater treatment

The invention discloses an attapulgite activated carbon haydite filter board; and the key point of the technical scheme of the attapulgite activated carbon haydite filter board is that the attapulgite activated carbon haydite filter board comprises a high viscosity attapulgite clay powder, attapulgite clay tailings powder, coal ash, anthracite culm, acidified sawdust powder and kaoline tailing powder. The components of the attapulgite activated carbon haydite filter board are mixed, formed in a pressing manner, maintained, roasted and cooled and then are packed into the attapulgite activated carbon haydite filter board. The attapulgite activated carbon haydite filter board has rough surfaces with multiple micropores, internally contains plenty of high-quality activated carbon and fine air holes and has a large specific surface area, light weight, high abrasive resistance strength, large adsorption capacity, good filtration effect, little water consumption of back washing and long service life. The coal ash and the tailings are comprehensively used for producing the attapulgite activated carbon haydite filter board, thereby being beneficial to the increasing of the comprehensive utilization rate of resources, making waste profitable and protecting environments; and the attapulgite activated carbon haydite filter board is suitable for water treatment engineering.

Owner:江苏点金石凹土矿业有限公司

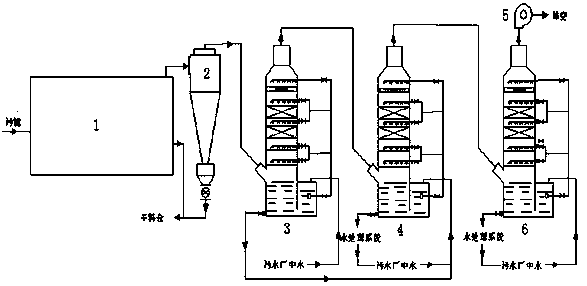

Municipal sludge drying tail gas treatment device and method

ActiveCN103920378AReduce usageAvoid excessive heatSludge treatment by de-watering/drying/thickeningDispersed particle separationComing outWater source

The invention discloses a municipal sludge drying tail gas treatment device and method. The device comprises a drying device, wherein an air outlet of the drying device is connected with a cyclone dust collector, the tail gas generated after dedusting sequentially passes a bath tower, an alkaline tower and a biological filter and is sucked and exhausted through an induced draft fan, the air outlet of the drying device is connected with an air inlet of the cyclone dust collector, an air outlet of the cyclone dust collector is communicated with an inlet of the bath tower, an outlet of the bath tower, an inlet of the alkaline tower, an outlet of the alkaline tower and an inlet of the biological filter are sequentially communicated, an air outlet of the biological filter is connected with the induced draft fan, the bottom of the alkaline tower and the bottom of the biological filter are directly communicated with the top of the alkaline tower and the top of the biological filter respectively and communicated with a sewage disposal system used for carrying out secondary treatment on waste liquid produced by the alkaline tower and the biological filter. External water in a water replacement system in a sewage plant serves as absorbing solvents, the waste liquid coming out from the bottoms of the towers is treated through the sewage disposal system and then is returned to an absorbing tower, the use amount of water is greatly reduced, and operating expenses are reduced.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

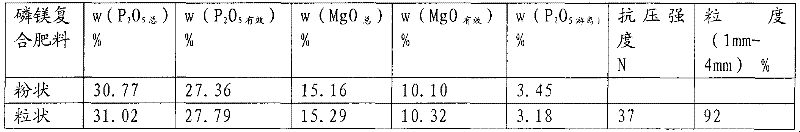

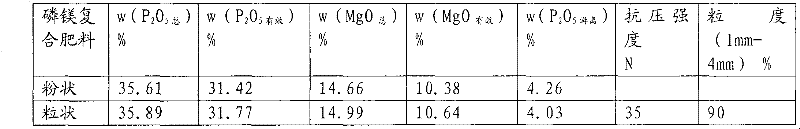

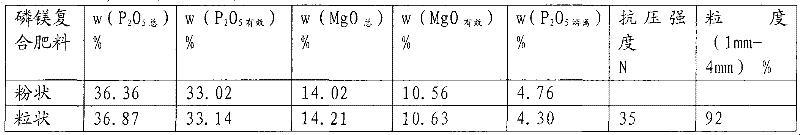

Method for preparing phosphorus-magnesium compound fertilizer by utilizing raffinate and phosphate tailings with high magnesium content

ActiveCN102161602AImprove decomposition rateEradicate pollutionSolid waste disposalFertilizer mixturesHigh magnesiumReaction temperature

Owner:WENGFU (GRP) CO LTD

Method for preparing alloy iron and glass ceramics

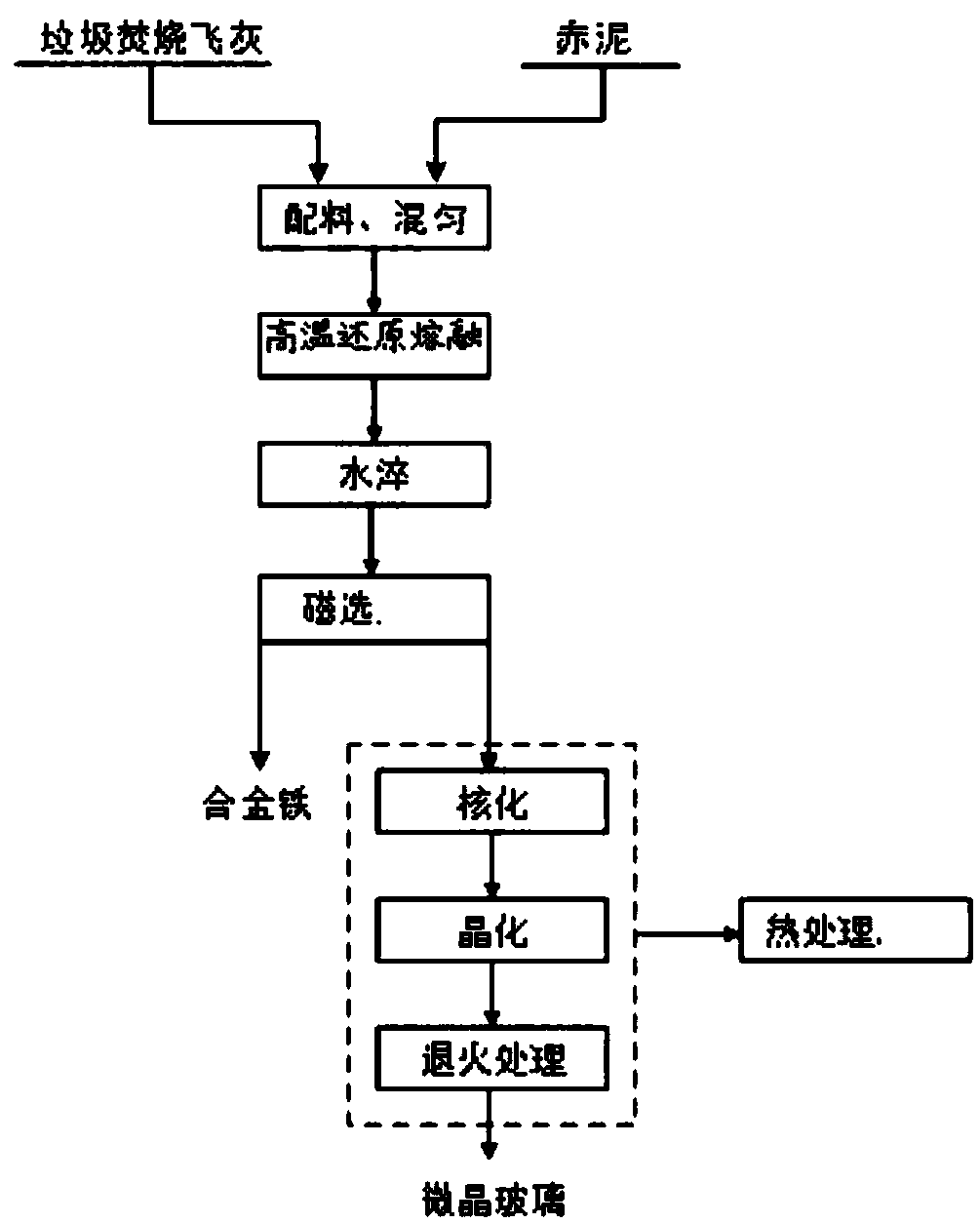

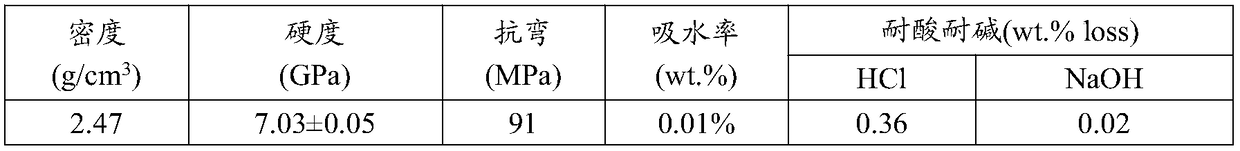

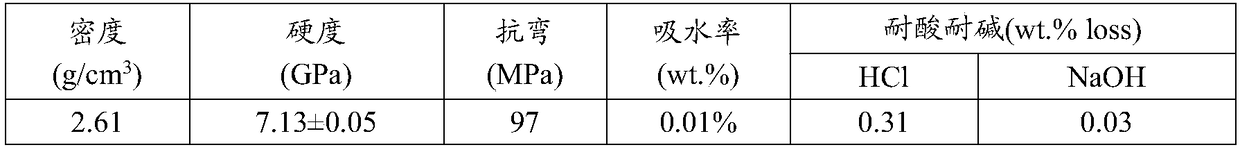

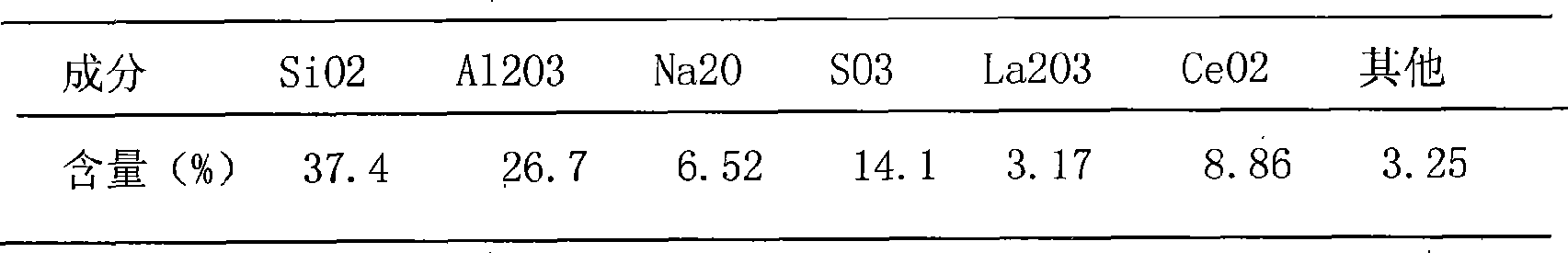

The invention provides a method for preparing alloy iron and glass ceramics, and belongs to the field of solid waste recycling. The method is characterized in that a syneryistic effect between carbon,calcium and heavy metal components in waste incineration fly ash, and iron, aluminum, silicon and titanium main components in red mud is efficiently utilized, so that alloy iron and glass ceramics can be finally obtained, and therefore, waste is treated with waste, to-be-treated important hazardous wastes of waste incineration fly ash and red mud, and bulk industrial solid waste are recycled andcomprehensively utilized, a resource comprehensive utilization rate is increased, resource-saving type society is favorably established, a higher economic value can be realized, an alloy iron productis obtained through high-temperature reductive smelting and thermal treatment, and the alloy iron product is higher than iron concentrate in price; the alloy iron product contains trace elements suchas Ni and Cu, and has a higher value than that of a directly reduced iron product; and the obtained glass ceramic is better and more excellent in comprehensive performance as a small amount of titanium oxide and heavy metal is contained.

Owner:TSINGHUA UNIV

Oxygen-sulfur paragenesis zinc mine flotation method

An oxygen sulfur symbiosis zinc mine flotation method uses sodium hexametaphosphate as a dispersant, sodium sulfide as an activator, octadecyl acetic acid amine and kerosene as collectors and No.2 oil as foaming agent. During the flotation, ores are grinded into mineral monomers for dissociation. Then, the sodium hexametaphosphate is added in a stirring barrel firstly, the sodium sulfide is added for activation and octadecyl acetic acid amine, the kerosene and the No.2 oil are added for collection. With the present invention adopted, the flotation and the recovery of oxide zinc and sulfide zinc can be realized at the same time. The process is shortened. The equipment investment is saved and the production cost is lowered. The total recovery rate of the zinc can reach to 85-90 percentage, and the zinc concentrate grade can reach to 39-52 percentage.

Owner:GUANGXI UNIV

Rubber fender produced by using automobile tyre leftovers and method for producing same

InactiveCN101591900AComprehensive utilization of resources is highEnergy savingClimate change adaptationShipping equipmentPlasticizerAntioxidant

The invention discloses a rubber fender produced by using automobile tyre leftovers and a method for producing same. The rubber fender is produced by using the auto tyre leftovers as a main material and adding auxiliary materials of synthetic rubber, a heat stabilizer, an antioxidant, a plasticizer DOP, an internal lubricant, a filling reinforcing agent, polyester short fiber and the like. The rubber fender is produced by using the leftovers of automobile rubber tyre production as the main raw material, waste rubber is modified and is recycled directly, renewable resources are recycled for comprehensive utilization, and a large number of waste rubber resources after production and consumption are recycled and changed into valuable, thus the three principles of 'minimization, reusing and recycling' is met, the resource comprehensive utilization rate is improved and energy resources are saved. The rubber fender has simple production process and low production cost, and is advantageous for market promotion.

Owner:ZHEJIANG SANMEN TINAHUA RUBBER

Method for producing rare-earth poly-ferric aluminum silicate sulfate from rare earth-containing sludge and iron-containing dust sludge

InactiveCN101481161AReduce acidolysisShorten the timeWater/sewage treatment by flocculation/precipitationSludgeRare earth

The invention belongs to the technical field of preparing macromolecule flocculating agent for sewage processing, and in particular relates to a method of producing poly-silicate rare-earth aluminum ferric sulfate by using mud containing rare earth and ferric dust, which comprises the steps of material mixing, acid hydrolysis and oxidization, hydrolysis and polymerization. The invention provides a novel technology of using main raw materials, such as sewage and mud containing rare earth and generated in pertrification catalyst production enterprises and mud containing ferric dust generated in metallurgy steel-smelting enterprises for preparing macromolecule flocculating agent. The invention simplifies the technical process for producing poly-silicate rare-earth aluminum ferric sulfate, shortens the production time, has good product stability and performance, provides a new way for utilizing the mud containing rare earth and ferric dust, increases resource integrated utilization rate, lowers the production cost of the poly-silicate rare-earth aluminum ferric sulfate flocculating agent and the cost for sewage processing, and has high economic benefit, environmental protection benefit and social benefit.

Owner:杨祺

Thermal mortar and preparation method thereof

InactiveCN108002775AEasy constructionNot easy to produce surface hollowingCeramicwarePortland cementCoal

The invention discloses thermal mortar and a preparation method thereof and relates to the technical field of thermal mortar. The thermal mortar comprises the following raw materials in parts: 65-75 parts of portland cement, 45-55 parts of modified coal ash, 40-45 parts of modified fiber reinforced particles, 25-35 parts of modified glass beads, 20-25 parts of glutinous rice glue, 15-20 parts of modified nanocarbon, 15-20 parts of an additive and 120-150 parts of water. The thermal mortar preserves heat, is toughened, has good workability, has low probability arousing such problems as surfacehollowing, cracking and falling, and is prolonged in service life.

Owner:明光市泰丰新材料有限公司

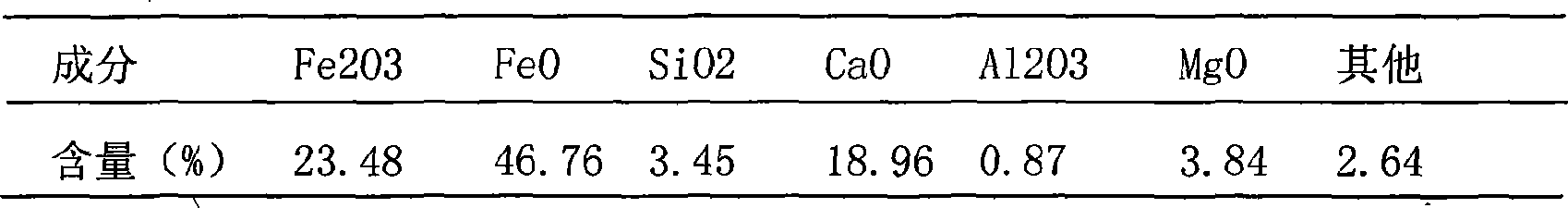

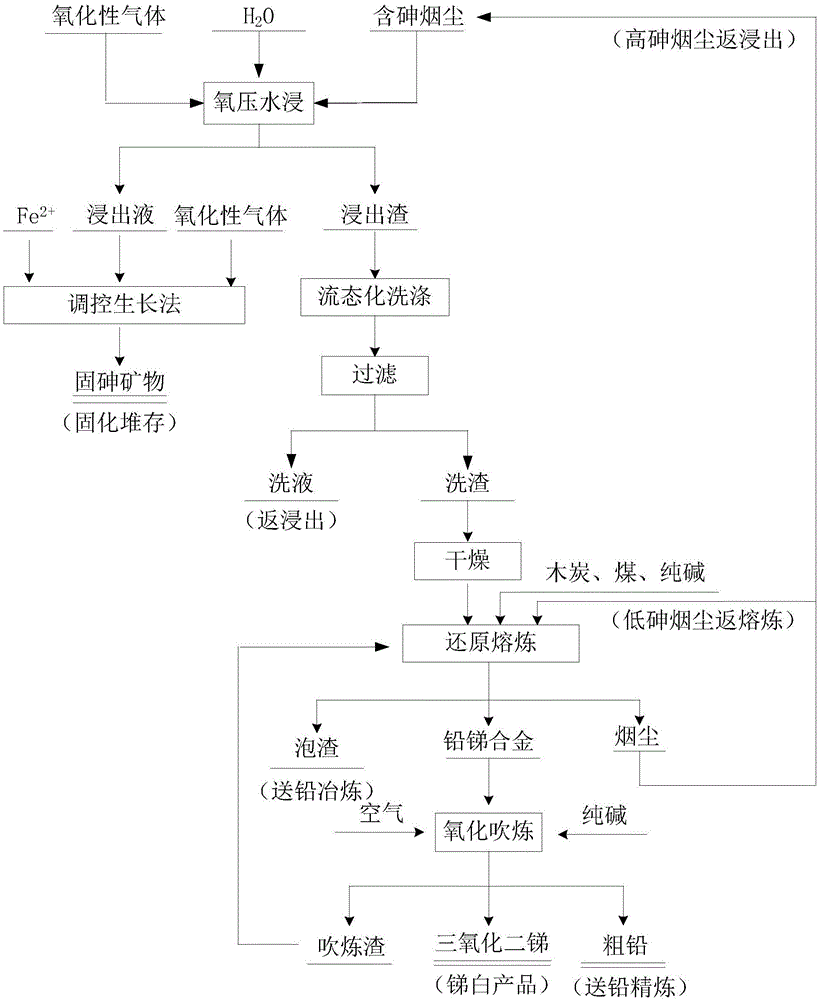

Method for comprehensively treating arsenic-contained smoke and synthesizing arsenic fixing minerals by control growth method

ActiveCN106834720AComprehensive utilization of resources is highRaw material adapts to a wide rangeProcess efficiency improvementSmelting processBismuth

The invention belongs to the technical field of metallurgy, and in particular, relates to a method for comprehensively treating arsenic-contained smoke and synthesizing arsenic fixing minerals by a control growth method. The method comprises four steps of oxygen pressure water leaching, leaching liquid arsenic fixation, leaching slag washing and recovery of valuable metal from washing slag in sequence; the method uses the oxygen pressure water leaching for removing solvable arsenic in the smoke; arsenic in leaching liquid is synthesized as high-stability arsenic fixing minerals by the control growth method; and then, the arsenic fixing minerals are cured by a stockpiling mode. All valuable elements are recycled from leaching slag to the greatest extent by such procedures as washing, reduction smelting and oxidation blowing. The method removes arsenic from the smoke and synthesizes the stable arsenic fixing minerals, but retains antimony, lead, bismuth and the like in the leaching slag as far as possible, and realizes separation of arsenic from the valuable metal and harmlessness. The method is high in resource comprehensive utilization rate and wide in raw material application range, solves the pollution problem in the traditional extracting process, in particular the smoke generated in the lead-zinc smelting process, and is more obvious in advantages.

Owner:CENT SOUTH UNIV

Closed cycle preparation new process of zinc sulfate and zinc oxide

ActiveCN106745195AImprove abilitiesComprehensive utilization of resources is highZinc sulatesZinc oxides/hydroxidesWaste treatmentSodium sulfate

The invention discloses a closed cycle preparation new process of zinc sulfate and zinc oxide, and belongs to the field of chemical engineering. The new process comprise a liquid preparing system procedure, a product preparation system procedure and a waste liquid treatment system procedure, wherein the liquid preparing system procedure is composed of the procedures of medium-acid leaching, oxidation for iron removal and oxidation for manganese removal of leaching agent, and replacement for impurity removal; the product preparation system procedure is composed of a preparation subsystem of zinc sulfate and a preparation subsystem of zinc oxide; the waste liquid treatment system procedure is composed of treatment procedures of generated waste liquid such as zinc sulfate separated mother liquid produced in the preparation sub-system of the zinc sulfate, an ammonium sulfate or sodium sulfate solution and basic zinc carbonate cleaning liquid produced in the preparation sub-system of the zinc oxide. The original production lines of singly producing the zinc sulfate and the zinc oxide are integrated and transformed into a closed cycle production system, the wastewater zero discharge is realized, the vicious circle of pollution-treatment-secondary pollution is avoided; the production of three-waste is controlled from the source so as to prevent the environment pollution, and the production cost is lowered, and the economic benefit is improved.

Owner:宁夏京成天宝科技有限公司

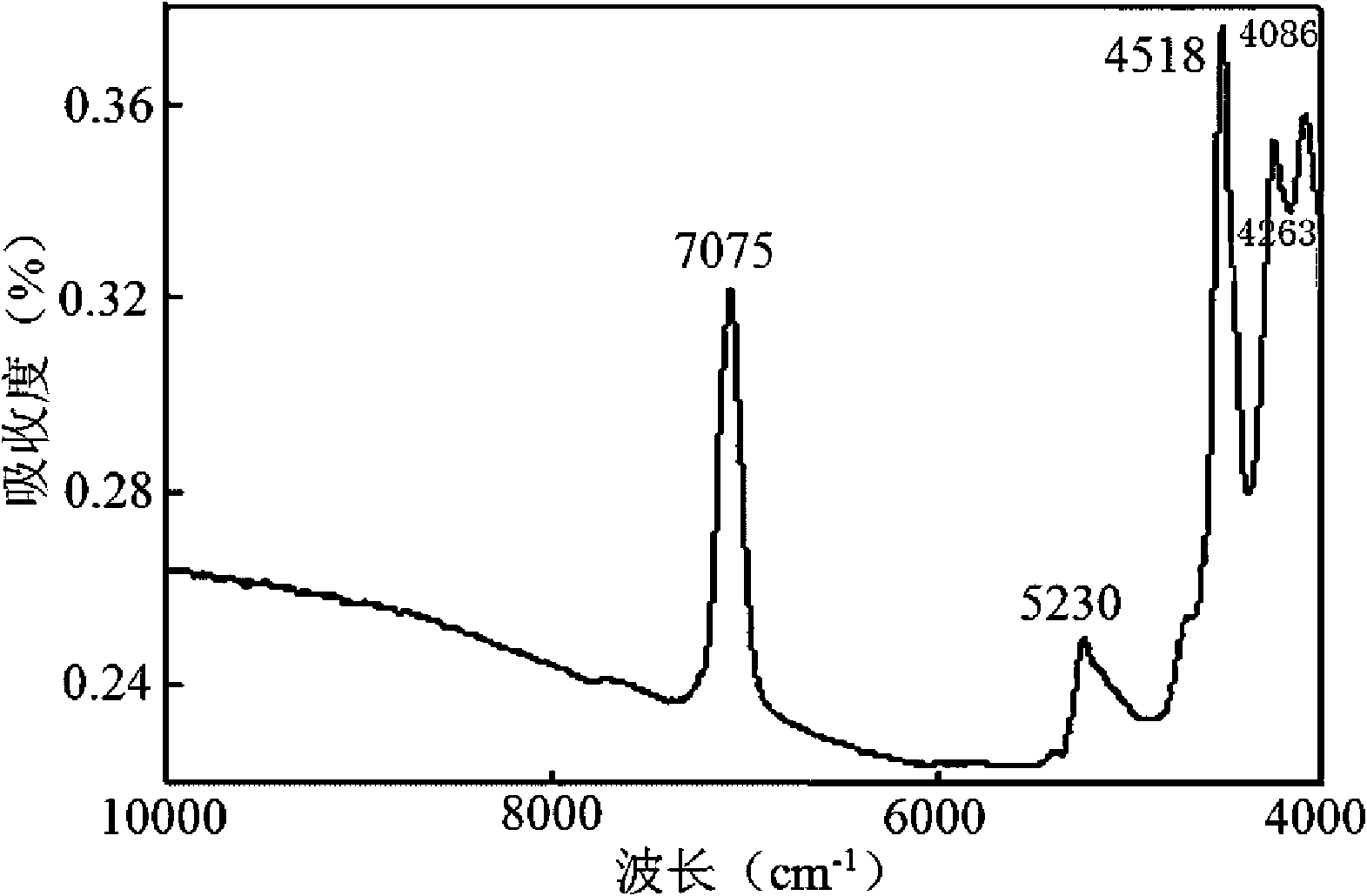

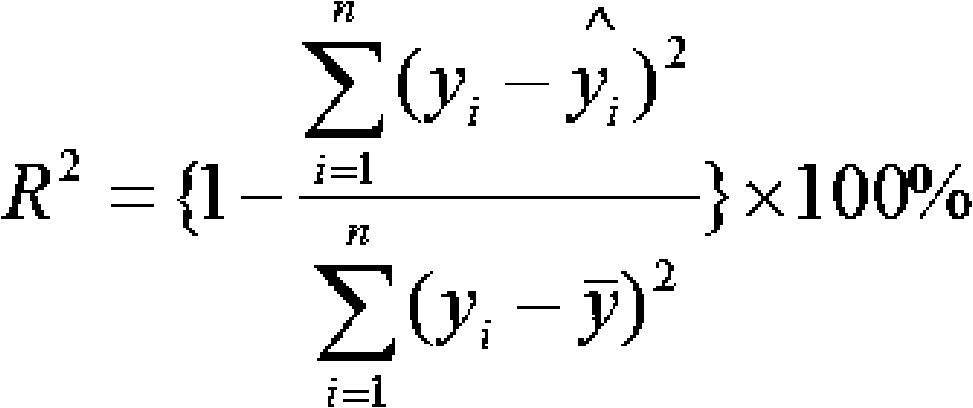

Method for quickly testing and analyzing quality of sericite

InactiveCN101650306ABroaden applicationIncrease salesColor/spectral properties measurementsMicroscopic observationFourier transform on finite groups

The invention relates to a method for quickly testing and analyzing the quality of sericite, which solves the problems that a microscope viewing method or chemical analysis method used in the prior art for testing the quality of sericite wastes time and labor and has low production efficiency. The method comprises the following steps: acquiring spectral information of the sericite sample to be tested by using a Fourier transform near-infrared spectroanalysis instrument, and analyzing the spectral information by using an optimal calibration model to obtain analysis result; the optimal calibration model is obtained by the following method: establishing a spectral library according to the spectral information of the sample, selecting representative spectral information to establish a calibration sample set, and gradually optimizing the quantitative analysis model of the spectral information of the sample by using a cross validation method according to the calibration sample set until obtaining the optimal calibration model. The method is suitable for quickly testing the purity analysis on the sericite in the green ore exploration and the tailing recycle.

Owner:HARBIN INST OF TECH

Hill wind power plant maintenance task intelligent scheduling method

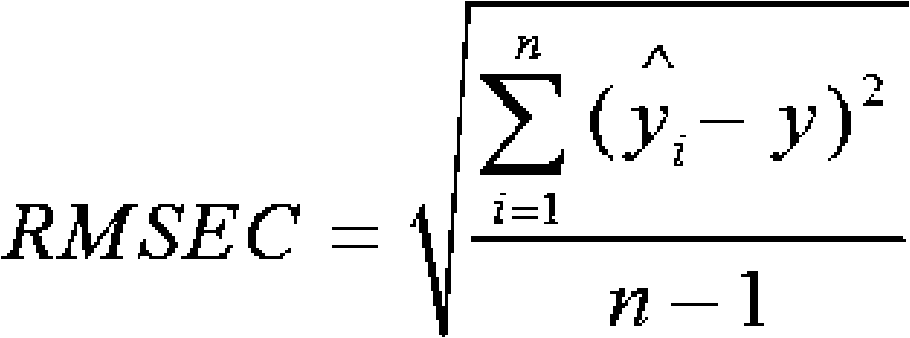

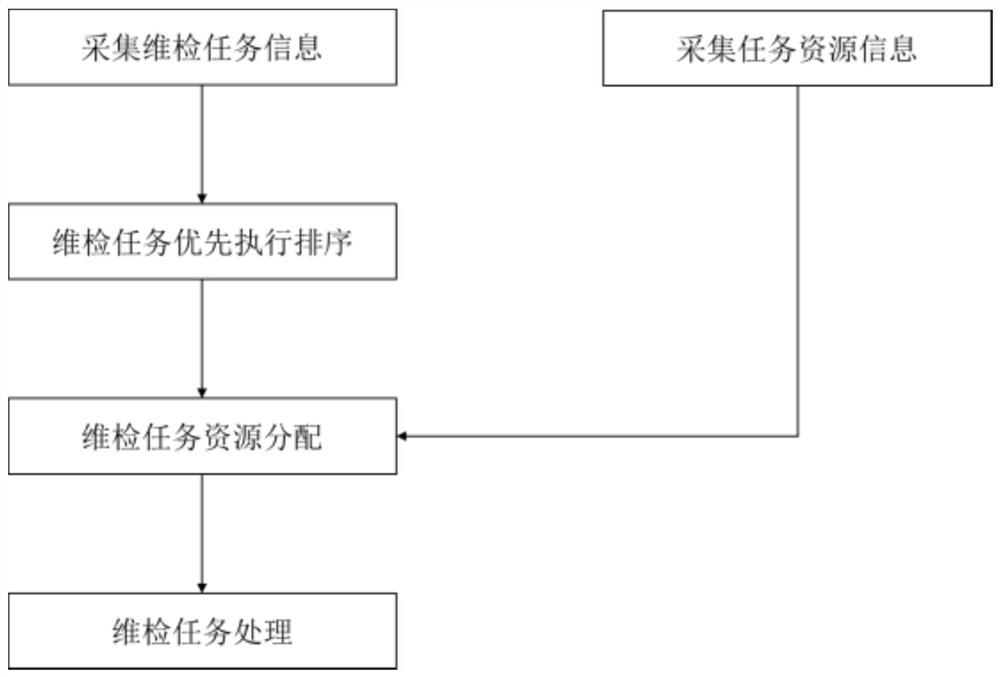

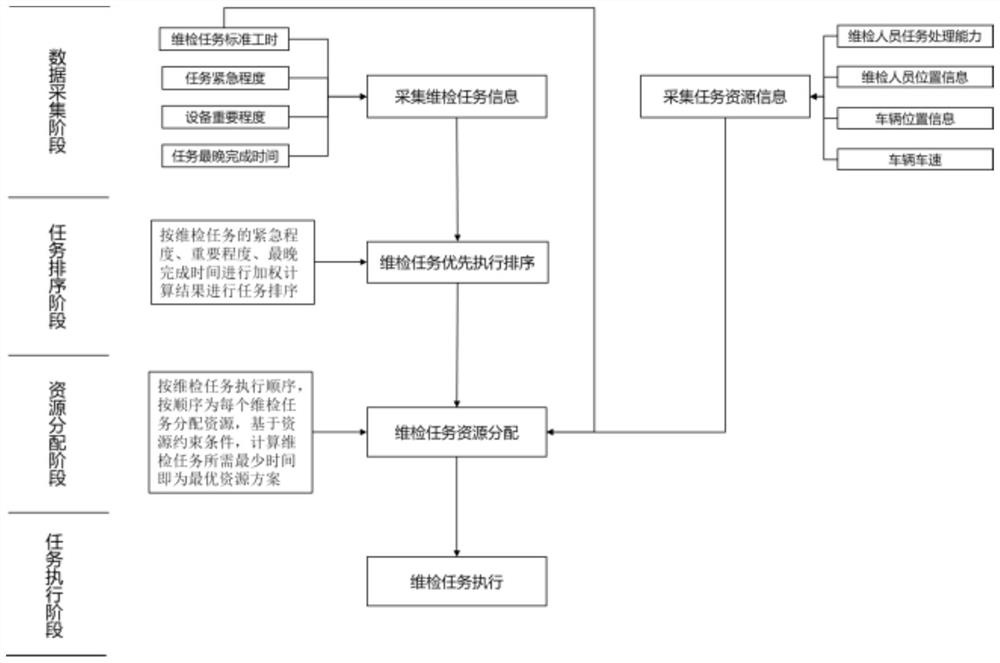

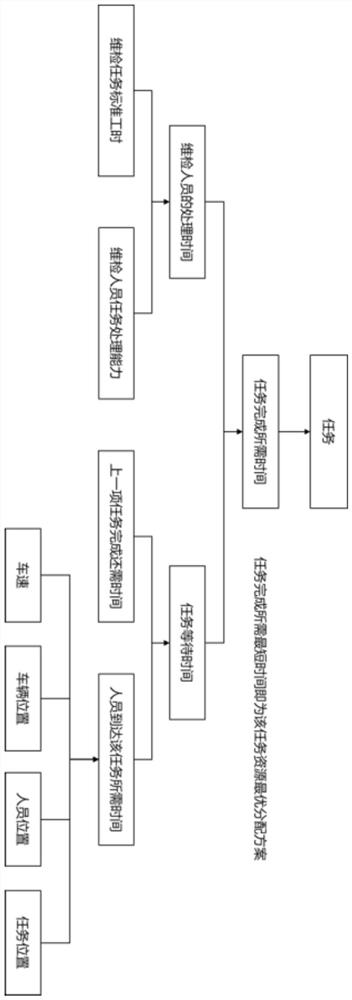

PendingCN112465353ALow failure rateComprehensive utilization of resources is highResourcesInformation technology support systemCompletion timeProgram planning

The invention relates to the technical field of power plant maintenance task scheduling, in particular to a hill wind power plant maintenance task intelligent scheduling method, which comprises the following steps of S1, collecting maintenance task information and states; S2, collecting task resource information; S3, sorting the execution priorities of the maintenance tasks, and sorting the execution priorities of the maintenance tasks according to comprehensive calculation of the emergency degree of the tasks, the importance degree of maintenance equipment and the latest maintenance completion time factor; S4, performing a maintenance task resource allocation scheme; and S5, processing the tasks according to the task execution sequence and the resource allocation scheme. According to thehill wind power plant task scheduling method based on various resource constraint conditions, priority maintenance and execution of important equipment and important maintenance plans of a wind powerplant can be ensured, and through distribution of various task resources, the utilization rate of maintenance resources can be increased, the maintenance period of the equipment can be shortened, andthe effective utilization rate of the equipment for wind power generation can be increased.

Owner:HUANENG HUAJIALING WIND POWER CO LTD +1

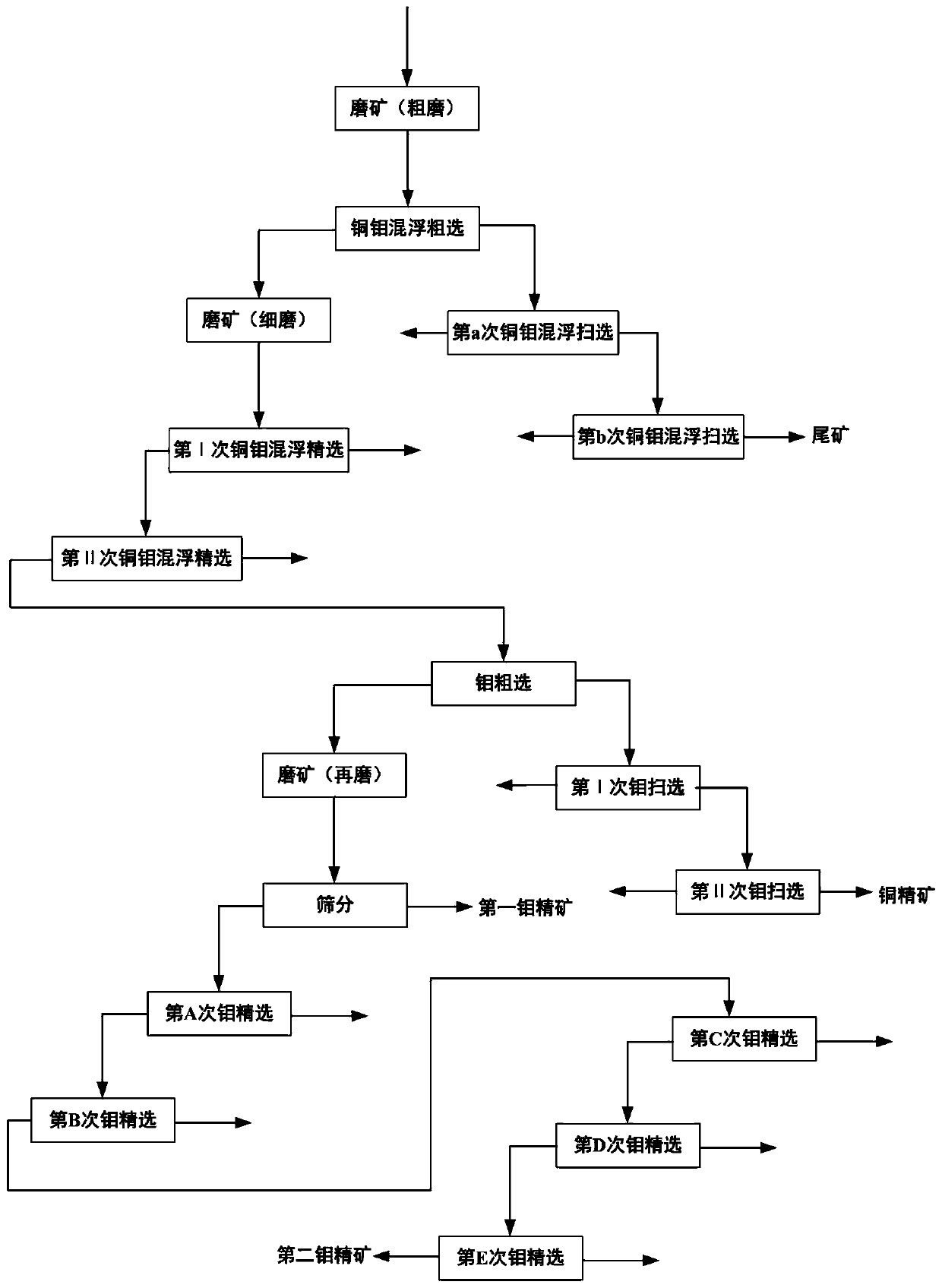

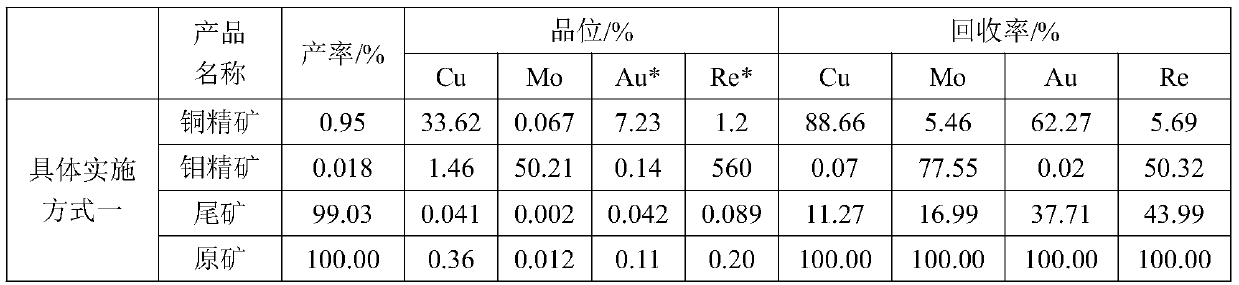

Beneficiation method for efficiently recovering copper and molybdenum associated with gold and rhenium from porphyry type copper-molybdenum deposit

The invention discloses a beneficiation method for efficiently recovering copper and molybdenum associated with gold and rhenium from porphyry type copper-molybdenum deposit and belongs to the technical field of mineral processing. The method comprises the following steps: roughly grinding raw ore under the condition of low alkalinity, and carrying out primary mixed flotation roughing, secondary mixed flotation scavenging and tailing discarding to obtain mixed flotation roughing concentrate; finely grinding the mixed flotation roughing concentrate and then carrying out secondary mixed flotation concentrating, primary molybdenum roughing and secondary molybdenum scavenging to obtain copper concentrate with 30 percent or above of copper and molybdenum roughing concentrate; regrinding and sieving the molybdenum roughing concentrate to obtain first molybdenum concentrate; and carrying out molybdenum concentrating for five times on sieved tailings, and alternatively using an inhibitor and partially combining and returning ore in molybdenum to obtain second molybdenum concentrate, wherein the content of molybdenum in comprehensive molybdenum concentrate is 50 percent or above. The beneficiation method disclosed by the invention adopts a technical solution of rough grinding mixed flotation of raw ore, fine grinding recleaning of mixed flotation rough concentrate, regrinding and sieving graded ore grinding sorting of molybdenum concentrate and has the characteristics of simple reagent system, convenient operation and management, good separating effect, stable indexes, good reproducibility and the like.

Owner:HEILONGJIANG DUOBAOSHAN COPPER LTD +1

Smelting process for efficient and energy-saving regenerated lead

InactiveCN110551899AResolve recovery rateReduce lossesProcess efficiency improvementLead smeltingSmelting process

The invention discloses a smelting process for efficient and energy-saving regenerated lead. The smelting process for the efficient and energy-saving regenerated lead is characterized by comprising the following steps: step S1, preparation for a lead raw material for smelting; step S2, treatment for a lead paste; step S3, forming for the lead smelting raw material; step S4, smelting treatment; andstep S5, by-product aftertreatment. The invention further discloses the efficient and energy-saving regenerated lead prepared according to the smelting process for the efficient and energy-saving regenerated lead. The smelting process for the efficient and energy-saving regenerated lead is capable of efficiently, rapidly and safely smelting lead scraps and wastes into the regenerated lead, so that resource recycling is realized, waste is turned into wealth, and the problems of low metal recovery rate and high lead content of slag in an existing smelting process for regenerated lead, and environment pollution caused by the generation of lots of smoke containing lead, sulfur dioxide and acid mist, are solved; and the smelting process for the efficient and energy-saving regenerated lead hasthe advantages of being high in lead direct-recovery rate, comprehensive recovery rate and labor productivity, low in precious metal loss, and high in economic value, ecological value and social value.

Owner:骆驼集团(安徽)再生资源有限公司

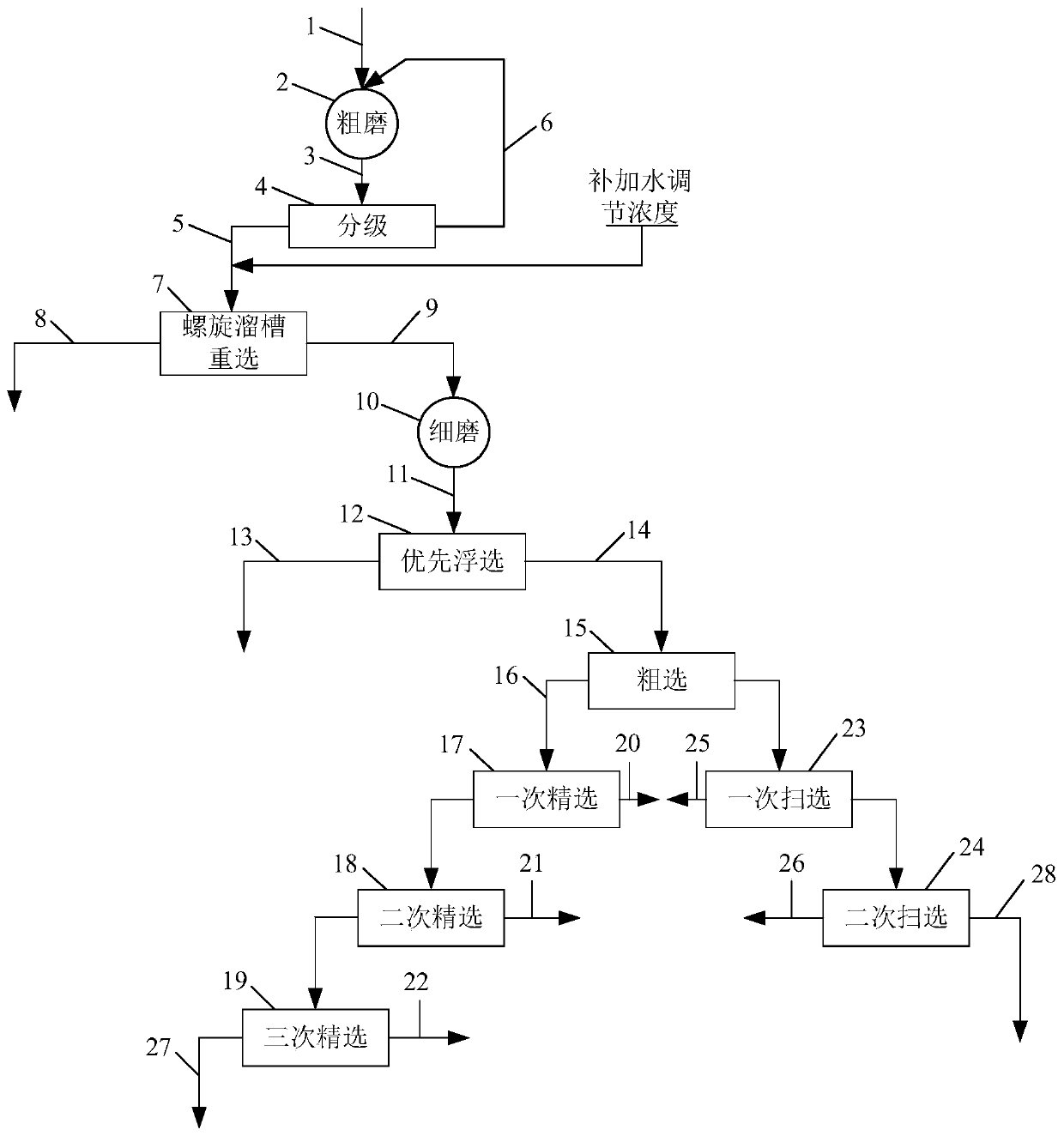

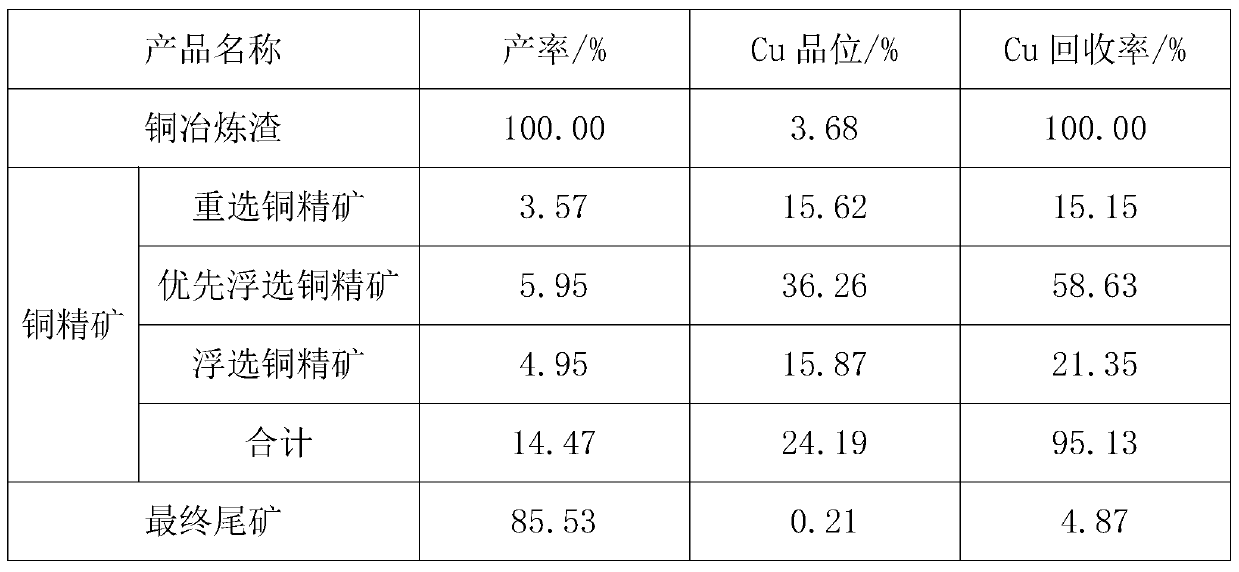

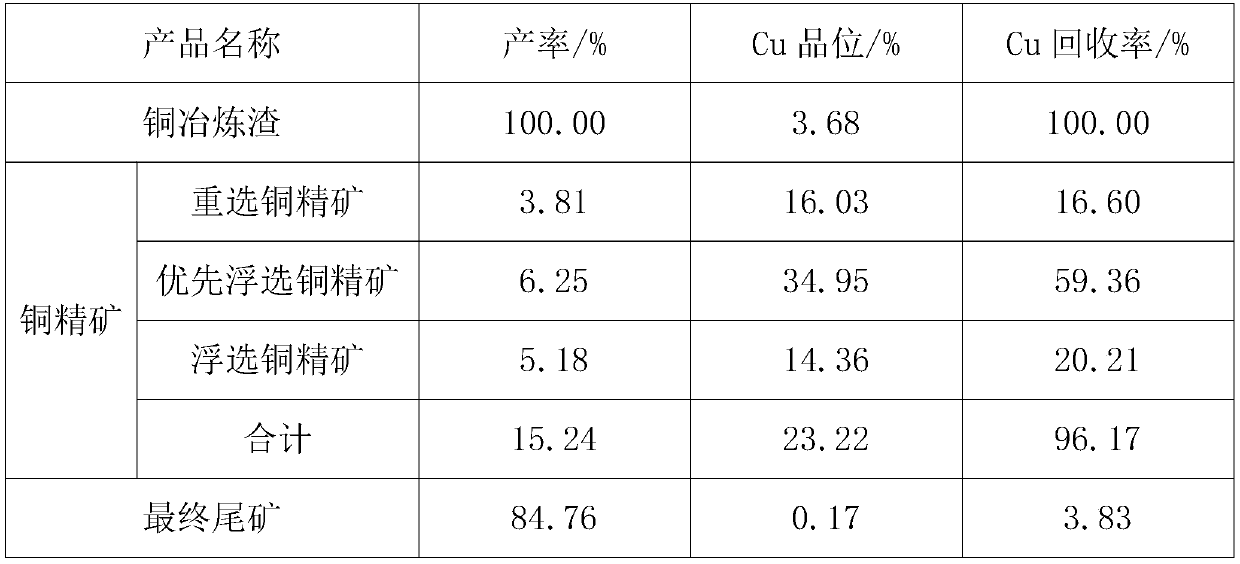

Beneficiation method for efficiently recovering copper from copper smelting slags

InactiveCN110882834AHigh copper recoveryComprehensive utilization of resources is highSolid separationGrindingBeneficiation

The invention relates to a beneficiation method for efficiently recovering copper from copper smelting slags. The beneficiation method is particularly suitable for further copper recovering from the copper smelting slags generated through carrying out copper pyrometallurgy processing on copper concentrate. In the invention, rough grinding and grading are adopted for obtaining selected raw materials reselected by a spiral chute, reselected copper concentrate is obtained through reselection operation, and then preferential flotation copper concentrate, flotation copper concentrate and final tailings are obtained through fine grinding, preferential flotation, one-time roughing, two-time scavenging and three-time concentration. In the preferential flotation, roughing and scavenging processes,a combined collecting agent is used in cooperation, middlings successively return to a last operation section, and finally qualified copper concentrate is obtained. The method is advanced in process,high in treatment capacity, good in separation effect, and stable in operation, copper in the copper smelting slags can be effectively recycled, a Cu grade of the copper concentrate is greater than orequal to 23.22%, and a Cu recycling rate of the copper concentrate is greater than or equal to 95.13%. And valuable resource recovery efficiency of the smelting slags is improved, and economic benefits are brought to enterprises.

Owner:COLLEGE OF APPLIED SCI JIANGXI UNIV OF SCI & TECH

Nickel-based target and production process

InactiveCN101660123AReduce thicknessChange direction of growthVacuum evaporation coatingSputtering coatingAcid washingMechanical property

The invention discloses a nickel-based target and a production process. The production process comprises working procedures of cold rolling, high-temperature vacuum heat treatment, ammonia atmosphere protective heat treatment, primary rolling, welding, precision rolling, annealing and the like. The production process has no high-temperature processes of smelting, hot rolling and the like, and also has no high-pollution processes of acid washing, alkali washing and the like. Therefore, compared with the conventional process, the production process reduces the energy consumption by 30 percent and the metal loss by 50 percent, improves the one-time yield by over 10 percent, has high comprehensive utilization rate of resources, and is environmentally-friendly; and the process is simple and convenient to operate, can effectively guarantee the purity of a electrolytic nickel thin plate, improve the comprehensive mechanical property and physical property of the electrolytic nickel thin plateand replace the prior production process for smelting and hot-rolling the nickel target, and is suitable for industrialized production.

Owner:HUNAN XIANDENG INTELLIGENT TECH CO LTD

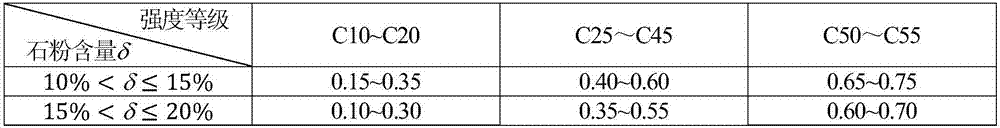

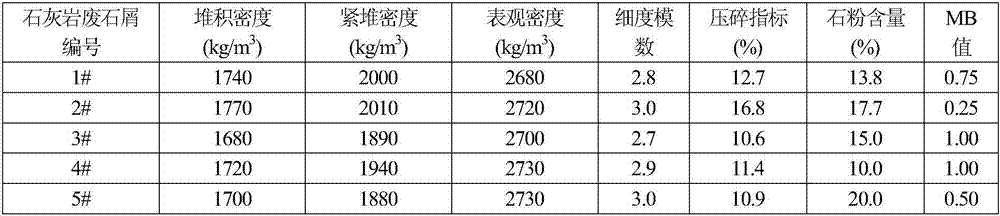

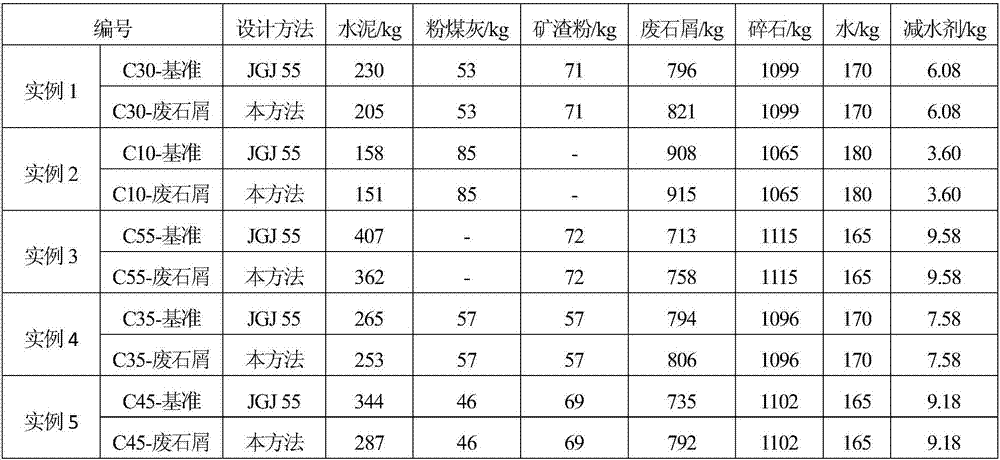

Mix proportion design method of high-stone-powder-content concrete containing waste limestone chippings

ActiveCN106892605AImprove performanceComprehensive utilization of resources is highRatio controlAbsolute volumeCrushed stone

The invention relates to a mix proportion design method of high-stone-powder-content concrete containing waste limestone chippings. The method includes: testing and determining the stone powder content delta of the waste limestone chippings actually used in a project according to the method of Standard for technical requirements and test method of sand and crushed stone (or gravel) for ordinary concrete JGJ 52, and calculating the stone powder excess value Delta delta of the waste limestone chippings according to a stone powder content limit value delta 0; using an absolute volume method to calculate and determine the mix proportion parameters of reference concrete according to the regulations of Specification for mix proportion design of ordinary concrete JGJ 55; using the stone powder of the excess part in the waste limestone chippings as inert mineral admixture, calculating and determining a substitution cement amount according to a certain substitution coefficient K, keeping unit weight unchanged, and calculating and determining the mix proportion parameters of the concrete containing the waste limestone chippings. The mix proportion design method has the advantages that under the premise that concrete performance satisfies design and construction requirements, the technical difficulty of the waste limestone chippings with stone powder content exceeding standards in the field of concrete application is solved, the cement use quantity and production cost of the concrete are lowered, and energy conservation and environmental protection are achieved.

Owner:云南建投绿色高性能混凝土股份有限公司

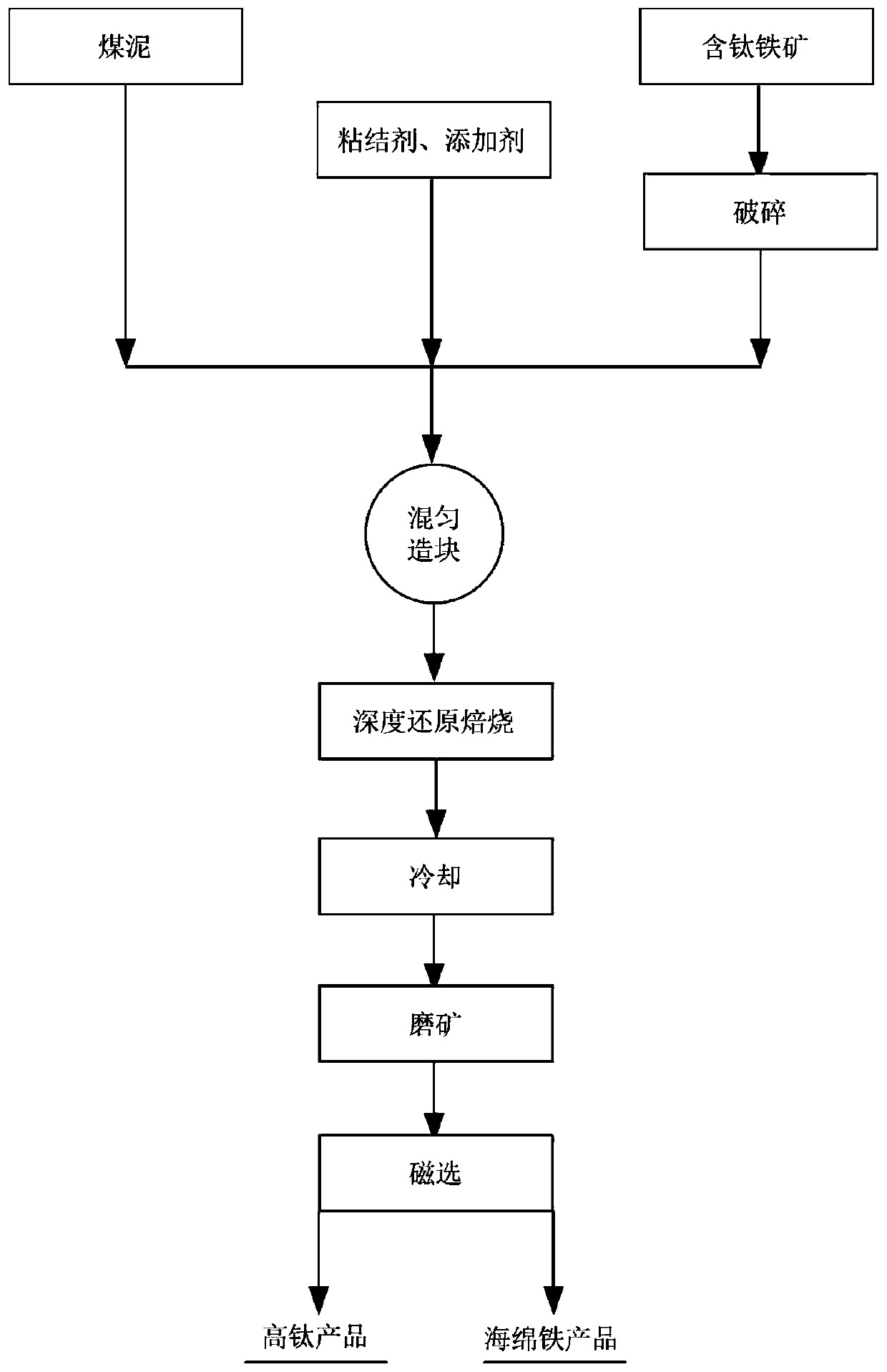

Method of producing high-titanium products and sponge iron using arentilla and coal slime as raw materials

InactiveCN109825698AAvoid secondary pollutionEasy constructionFluidised-bed furnacesSodium BentoniteTitanium

The invention belongs to the field category of resource comprehensive utilization, and relates to a method of producing high-titanium products and sponge iron using coal slime and arentilla as raw materials. The method comprises the following steps that the solid waste coal slime is used as a reducing agent, bentonite is used as a bonding agent, and sodium carbonate and calcium carbonate are usedas an additive, and the reducing agent, the bonding agent and the additive are uniformly mixed with the arentilla to be pressed into blocks; then deep reducing roasting is performed to obtain roastedproducts; and ore grinding-magnetic separation is performed for two times, so that the high-titanium products and sponge iron products can be obtained. The method disclosed by the invention is simplein technique method, not only resource recycling of the solid waste coal slime is realized, but also using of coal powder which is high in cost is avoided; besides, through the effect of the additive,the ferrotitanium high-efficiency separation of the arentilla is difficult to sort, and finally, the high-titanium products of which the content of titanium dioxide is greater than 25% and the spongeiron products of which the content of the iron is greater than 92% can be obtained; and through the adoption of the method, the recovery rate of the titanium dioxide is generally greater than 91%, and the recovery rate of the iron is generally greater than 86%, so that the purpose of comprehensively utilizing resources is achieved.

Owner:鄂尔多斯市昊华红庆梁矿业有限公司

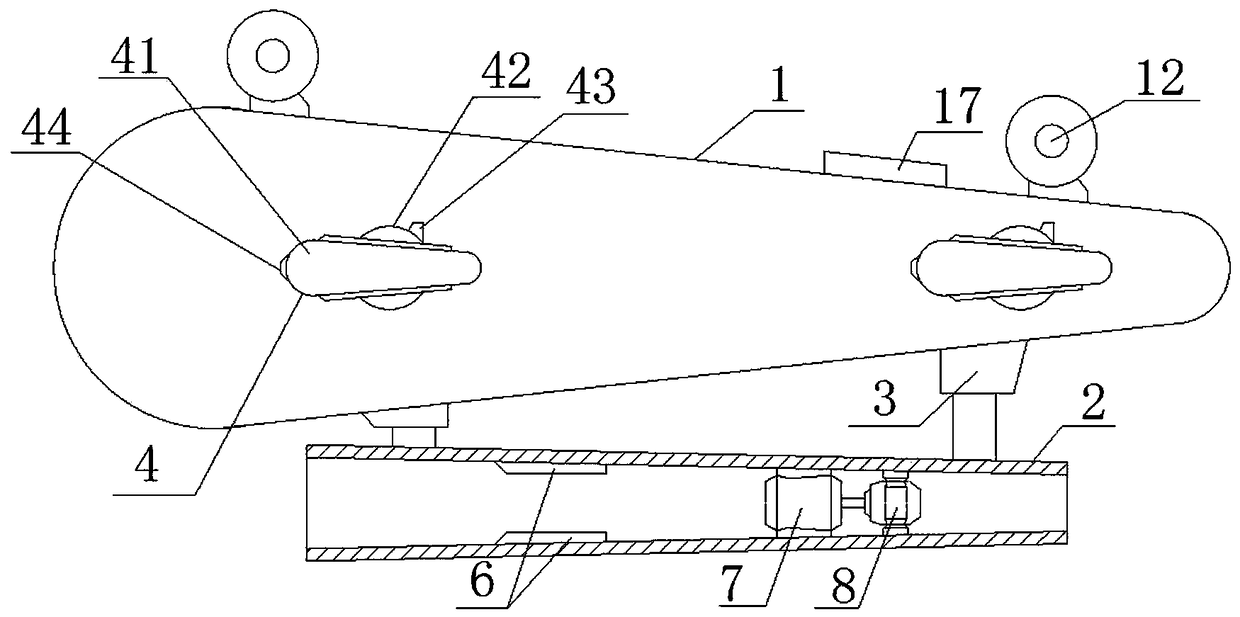

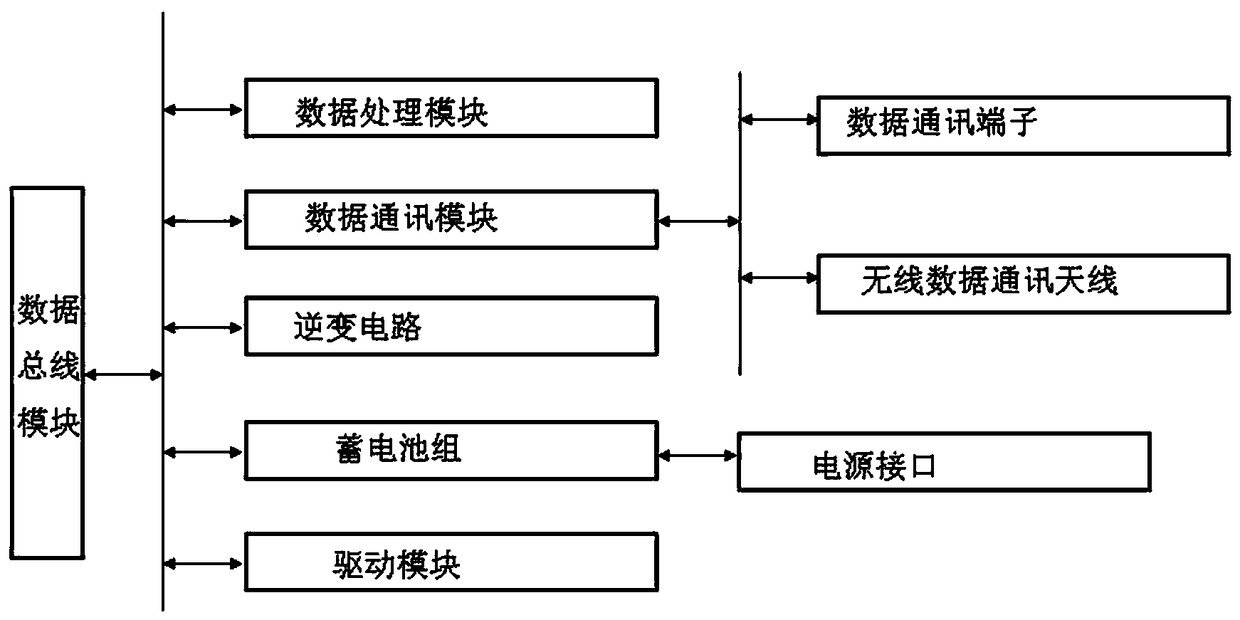

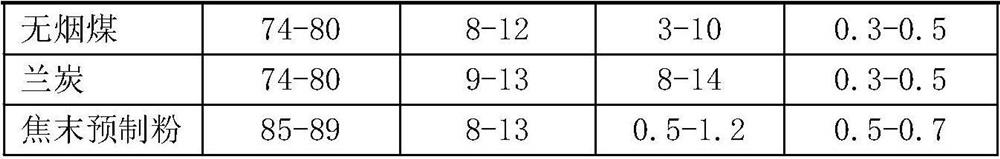

Novel automatic water body detection device

The invention relates to a novel automatic water body detection device. The novel automatic water body detection device comprises a bearing base body, a flow guide pipe, a hoisting driving mechanism,an adjusting plate, an adjusting motor, a detection sensor, a driving impeller, a driving motor and a control circuit, wherein the bearing base body comprises a bearing keel, a sealing protection layer and a bearing liner; the control circuit and the adjusting motor are embedded into a bearing cavity; the control circuit is electrically connected with the hoisting driving mechanism, the adjustingplate, the adjusting motor, the detection sensor and the driving motor respectively; the adjusting plate comprises a flow guide plate, a rotary platform mechanism, an angle sensor and a pressure sensor; the flow guide pipe is mounted on the outer surface of the bearing base body through the hoisting driving mechanism; the detection sensor, the driving impeller and the driving motor are embedded into the flow guide pipe. According to the novel automatic water body detection device provided by the invention, on one hand, the requirements of automatically carrying out water body detection work under water for a long time can be effectively met, the operation energy consumption is low and the comprehensive utilization rate of resources can be effectively improved; on the other hand, an operation state and a position in a water body can be flexibly and automatically adjusted.

Owner:JIAOZUO UNIV

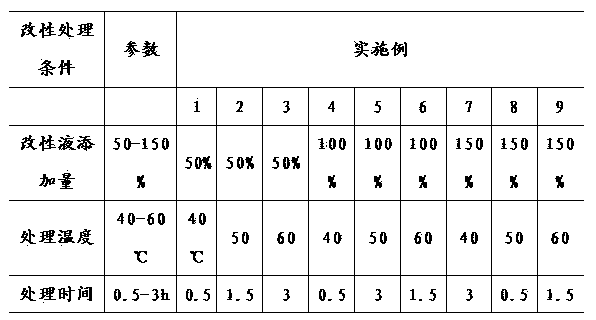

Method for manufacturing bamboo particleboards through modification of hickory nut epicarp

ActiveCN104029269ANo releaseSimple processFlat articlesDomestic articlesPulp and paper industryHickory nut

A method for manufacturing bamboo particleboards through modification of hickory nut epicarp includes the steps: after dried, crushed and screened, the hickory nut epicarp is added into bamboo shavings and mixed well, and an environment-friendly bamboo particleboard is made by the conventional bamboo particleboard production process. Mass lignin in the hickory nut epicarp is modified via laccase and is used as substitute for glue; during hot-pressing, the modified hickory nut epicarp engages in a series of chemical reactions with the bamboo shavings; accordingly, the glue is produced and used for manufacturing of the environment-friendly bamboo particleboards. The method has the advantages that the glue can be all or partially replaced with the modified hickory nut epicarp added, the cost is low, the process is simple, the particleboards are excellent in performance, no free formaldehyde is released, products are environment friendly, energy consumption is low, and the method has industrial production prospect.

Owner:ZHEJIANG FORESTRY ACAD

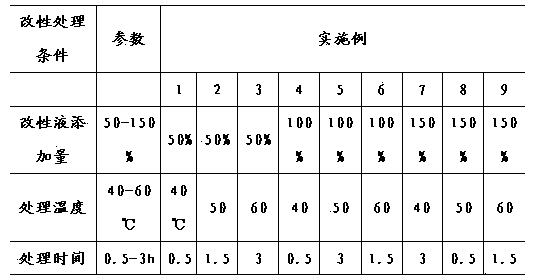

Method for preparing functional oil by segmented solid state fermentation of mixed fungus

ActiveCN109536268AAdd flavorIncrease contentFatty substance preservation using additivesFatty-oils/fats refiningPyrazineFractionation

The invention discloses a method for preparing functional oil by segmented solid state fermentation of mixed fungus, and belongs to the field of processing of edible oil. According to the invention, soybeans are utilized as main fermentation substrates, and are collocated with other oil seeds according to the demand for different functional nutrients, and the segmented solid state fermentation ofthe fungus is utilized and combined with a supercritical extraction fractionation technology, so that the aims of improving the aftertaste of soybean oil and producing different flavors are achieved,and the nutritional value of the oil is improved at the same time. According to the segmented solid state fermentation of the fungus disclosed by the invention, the oil extraction rate is increased; the composition of fatty acids of the oil is improved; the contents of the main flavor substances such as pyrazines, alcohols and phenols are increased; and the sensory functions such as flavor and color of the oil are more in line with the demand of consumers for innovative products. The fermented oil seed meal can be further processed for producing by-products such as functional peptides, and sustainable green development is realized.

Owner:JIANGNAN UNIV +1

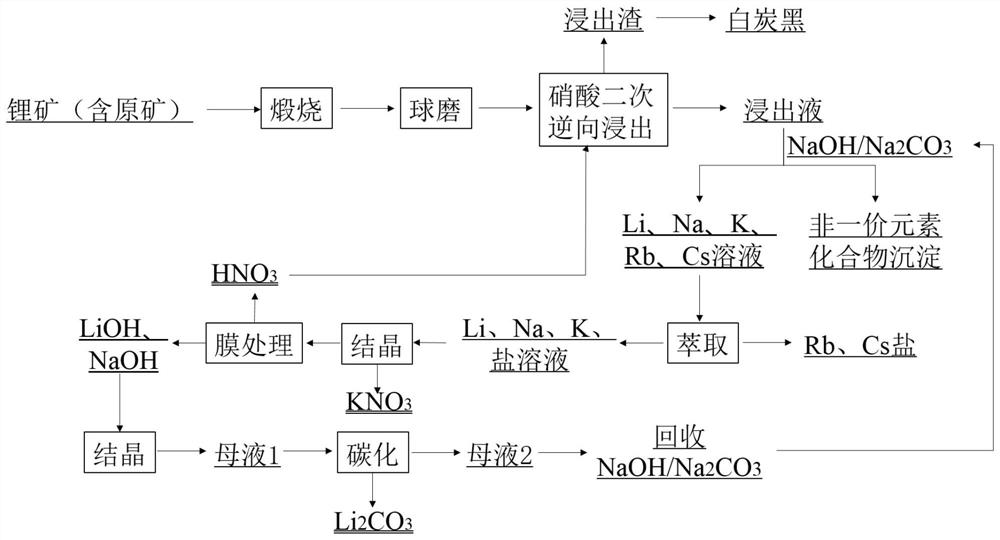

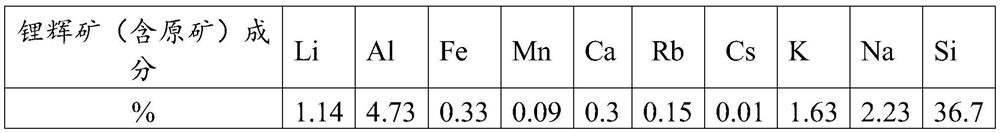

Method for producing lithium carbonate by leaching spodumene with nitric acid

PendingCN114854986AComprehensive utilization of resources is highIncrease profitProcess efficiency improvementLithium carbonates/bicarbonatesLithium carbonatePhysical chemistry

The invention discloses a method for producing lithium carbonate by leaching lepidolite with nitric acid. The method comprises the following steps: calcining and ball-milling spodumene; water is added for pulping, nitric acid is added into the pulp for nitric acid secondary reverse leaching, and leaching liquid and leaching residues are obtained; adjusting the pH value of the leachate; monovalent ionic liquid and non-monovalent element compound precipitates are obtained; extracting rubidium and cesium salts and a solution after the rubidium and cesium salts are extracted from the monovalent ionic liquid by adopting an extracting agent and a diluting agent; crystallizing and separating the solution from which the rubidium salt and the cesium salt are extracted, and performing membrane treatment on the crystallized solution to obtain a mixture of HNO3, LiOH and NaOH; and crystallizing the LiOH and NaOH mixture to separate out a LiOH product, carbonizing the crystallized mother liquor 1 to generate a Li2CO3 product, and recycling the carbonized mother liquor 2. According to the method, potassium, rubidium, cesium, sodium and leaching residues are recycled while lithium is extracted, the comprehensive utilization rate of lithium ore is increased, complexity of a traditional production process is simplified, the process production cost is reduced, the added value of products is increased, and maximum resource utilization is achieved.

Owner:四川顺应锂材料科技有限公司

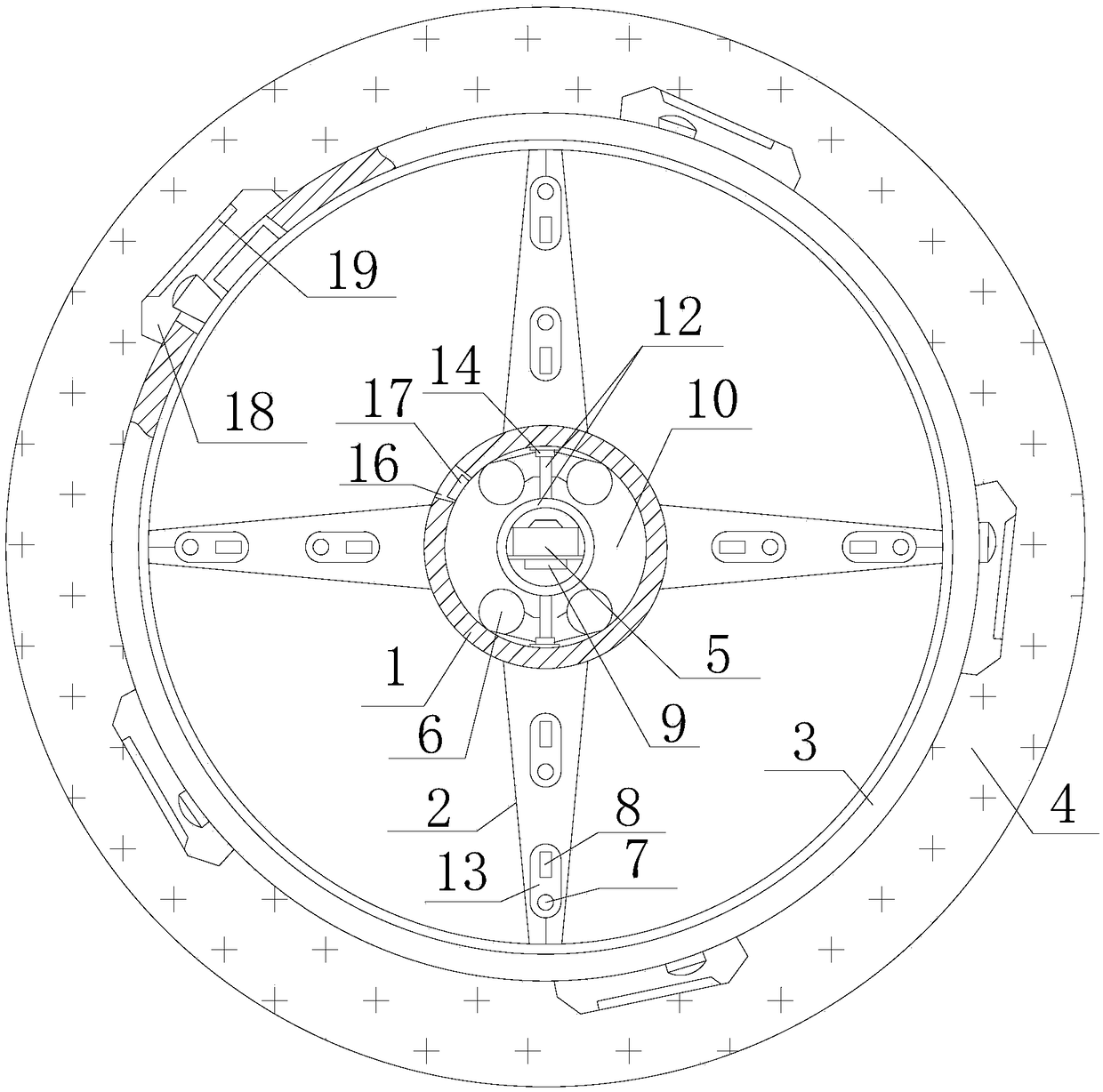

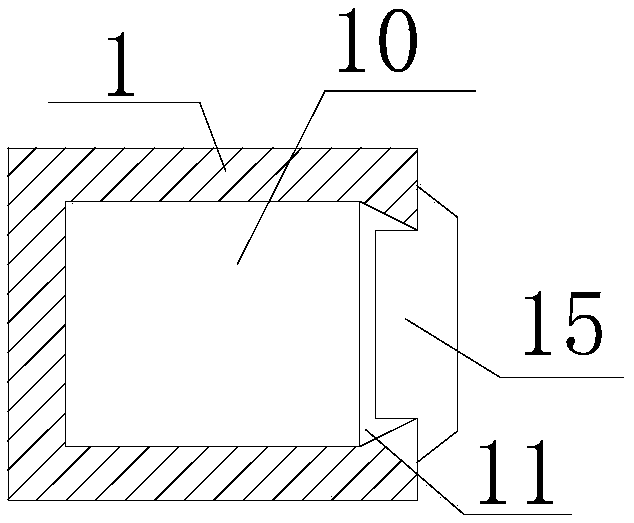

Novel colored lamp wheel

InactiveCN108621684AImprove continuityImprove stabilityAcoustic signal devicesOptical signallingOperating energyColored

The invention relates to a novel colored lamp wheel comprising a hub, spokes, a rim, a transparent tire, a rotor power generator, rolling power generators, colored lamps, loudspeakers and a control circuit; the hub is mutually connected with the rim through the three or more spokes, the outer surface of the rim is mutually connected with the transparent tire, the hub is provided with a bearing cavity, and the rotor power generator, the rolling power generators and the control circuit are embedded in the bearing cavity; a plurality of positioning grooves are evenly distributed in the side surfaces of the spokes and the upper surface of the rim; and the colored lamps and the loudspeakers are mounted in the spokes and the rim through the positioning grooves. According to the novel colored lamp wheel, on the one hand, the reliable positioning and bearing space can be effectively provided for the colored lamps and the loudspeakers, on the other hand, the ability of providing power supplement for vehicle operation is achieved while the power loss of a vehicle is reduced, thus the continuity and stability of vehicle operation are greatly improved, operating energy consumption is reduced,and the comprehensive utilization rate of resources is increased.

Owner:WUHU BAOYI AMUSEMENT EQUIP

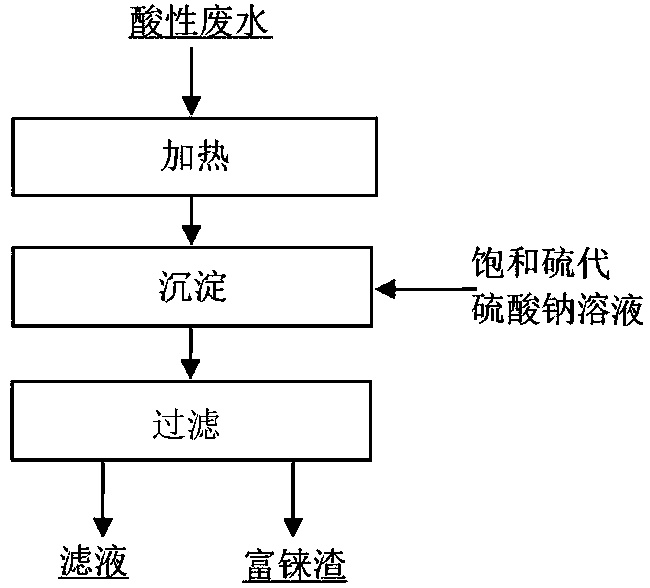

Enrichment method for rhenium in acid wastewater of copper smelting smoke purification system

InactiveCN109518014AHigh enrichment rateHigh recovery rateTreatment involving filtrationWaste water treatment from gaseous effluentsRheniumAcid water

The invention discloses an enrichment method for rhenium in acid wastewater of a copper smelting smoke purification system. The temperature of the acid wastewater is 30 DEG C-50 DEG C through heating.saturated sodium thiosulfate solution is added into a reaction vessel, the quantity of the saturated sodium thiosulfate solution added into per liter of acid wastewater is calculated with the sodiumthiosulfate molar content, the sodium thiosulfate molar content in the added saturated sodium thiosulfate solution is 1.1-1.3 times of the copper molar content in the acid waste liquid, stirring is conducted in the adding process of the saturated sodium thiosulfate solution, and thermal reaction is conducted for 2-4 h. After the reaction, reaction liquid is aged, filtrated and dried to obtain rhenium-containing enrichment slag. The enrichment method has the beneficial effects that the enrichment rate of rhenium in the acid water is high, a precipitation enrichment process for rhenium in the acid wastewater is built, the recovery rate of valuable metal is increased, production cost is lowered, resources are saved, and environmental pollution is reduced.

Owner:JINCHUAN GROUP LIMITED

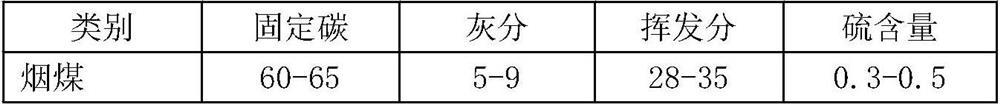

Coke breeze-containing mixed fuel for blast furnace coal injection and preparation method thereof

PendingCN112063781AReduce usageLow costBlast furnace detailsBlast furnace smeltingProcess engineering

The invention discloses coke breeze-containing mixed fuel for blast furnace coal injection and a preparation method thereof, and the technical problem of high cost of mixed fuel for blast furnace coalinjection in the prior art is mainly solved. The coke breeze-containing mixed fuel for blast furnace coal injection comprises the following raw material components of, by weight, 5%-20% of coke breeze prefabricated powder, 25%-50% of bituminous coal, 5%-45% of anthracite and 10%-25% of semi-coke, and the sum of the weight percentages of all the raw material components is 100%. The coke breeze prefabricated powder comprises the following components of, by weight, 85%-89% of fixed carbon, 9%-13% of ash and 1.0%-1.5% of volatile components. The Hastelloy grindability index of the coke breeze prefabricated powder is 25-45. Under the condition that the mixed fuel meets the blast furnace smelting production requirements, the consumption of the anthracite is greatly reduced, and the cost of themixed fuel for blast furnace coal injection is reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for preparing sunscreen cream from calcined coal gangue powder

InactiveCN106236615AImprove physical propertiesReduce pollutionCosmetic preparationsToilet preparationsSocial benefitsDistilled water

Owner:大同市金源高岭土有限责任公司

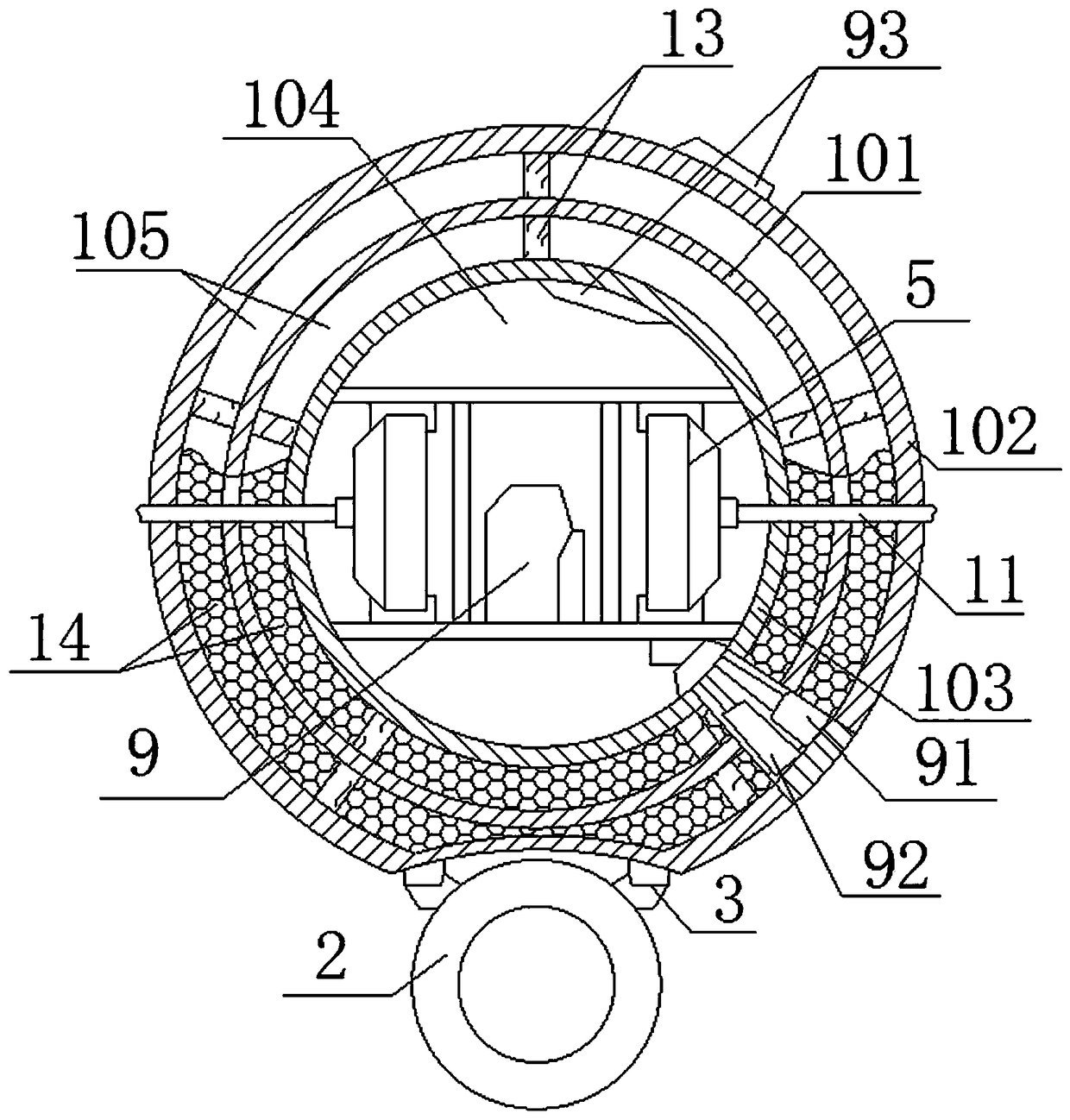

A battery bearing device for an electric vehicle

InactiveCN108987637AEffective bearer positioningEffectively meet the bearing positioningSecondary cellsCell component detailsAutomotive batteryEngineering

The invention relates to a battery bearing device for an electric vehicle. The device includes a bearing base, heat exchange tubes, plates, thermoelectric generator, semiconductor refrigerator, electric heating wire, ventilating fan, Temperature sensor and control circuit, A low end face setting position mechanism of a bearing base An upper end face set position groove, A heat exchange plate is uniformly distributed around the axis of the positioning groove, A low end face is slidably connected with an upper end face of a load-bearing base through a guide rail, A heat exchange tube is embeddedin the rear end face of the heat exchange plate, the air inlet and the air outlet of the heat exchange tube are respectively communicated with the ventilation fan, the thermoelectric power generationdevice and the semiconductor refrigeration device are installed on the side surface of the bearing base, the electric heating wire is embedded on the inner surface of the sidewall of the positioninggroove, and the control circuit is installed on the lower end face of the bearing base. On the one hand, the invention can effectively satisfy the effective bearing positioning of the battery equipment for the electric vehicle; on the other hand, the invention can greatly improve the capacity and efficiency of regulating the temperature of the battery when the battery is running, and can effectively realize the recovery and utilization rate of the heat energy.

Owner:安利平 +2

Treatment process suitable for spinning plant waste gas

InactiveCN110898616AComprehensive utilization of resources is highReduce energy consumptionCombination devicesGas treatmentPolyamideOligoester

Belonging to the field of environmental protection, the invention particularly discloses a treatment process suitable for spinning plant waste gas. According to the treatment process suitable for spinning plant waste gas, mainly spinning plant waste gas is introduced into a water spraying tower and flows from the bottom up the water spraying tower, and a water spraying device at the upper part ofthe water spraying tower sprays atomized water vapor to flush the waste gas from top to bottom. The treatment process suitable for spinning plant waste gas can effectively remove polyamide oligomer, oil mist and smoke dust from spinning long waste, and has the characteristics of high comprehensive utilization rate of resources, low energy consumption, convenient operation, stable running, and lowcost.

Owner:徐州申恒环境科技有限公司

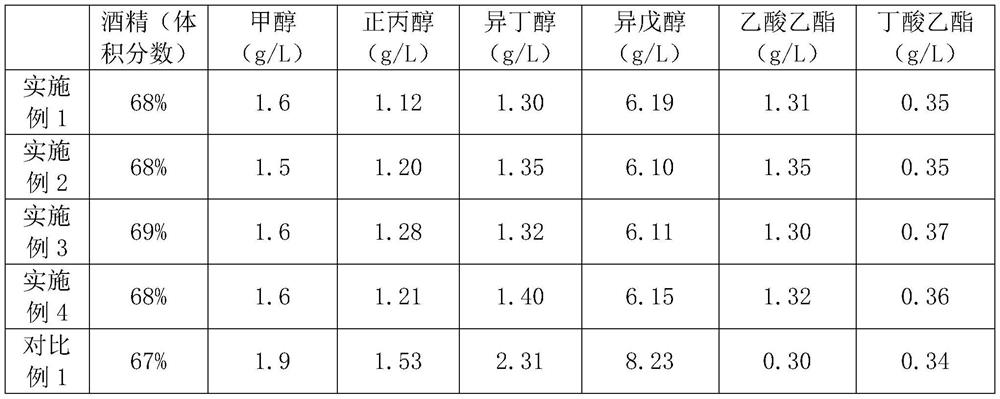

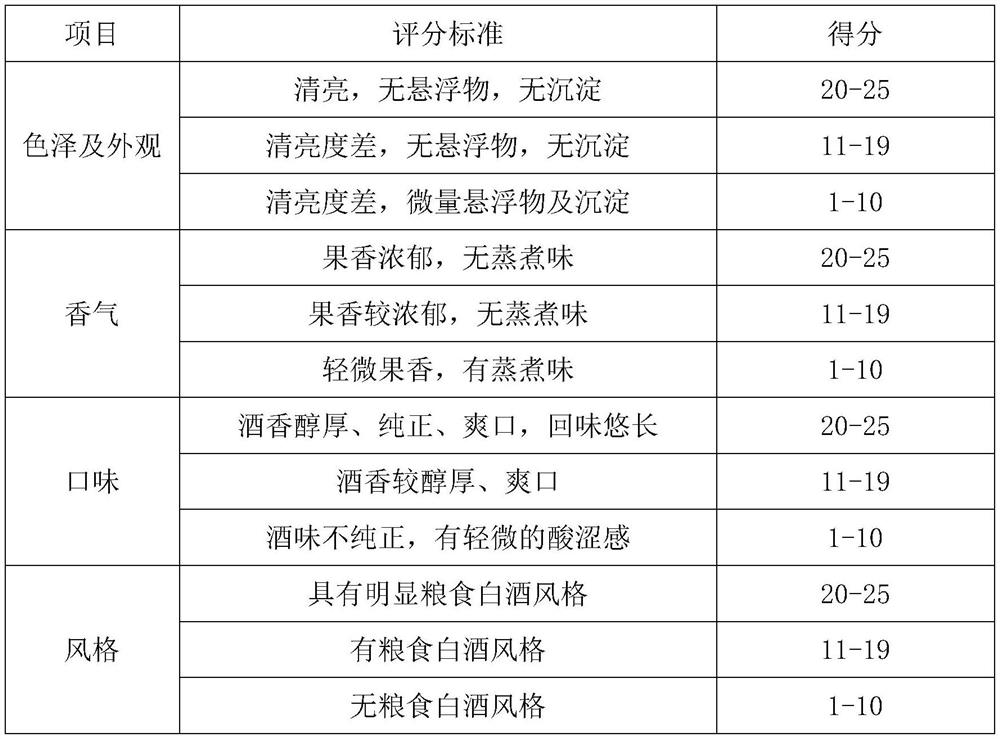

Method for preparing grape distilled liquor through solid-liquid cross steaming and product thereof

PendingCN114657045AObvious cooking smellComprehensive utilization of resources is highAlcoholic beverage preparationBiotechnologyOrganic chemistry

The invention discloses a method for preparing grape distilled liquor through solid-liquid cross steaming, and relates to the technical field of grape distilled liquor brewing. The method specifically comprises the steps that a sieve plate is additionally arranged in a distillation container, dry red wine is added into the distillation container, the liquid level of the dry red wine is lower than the lower surface of the sieve plate, meanwhile, grape skin residues are placed on the sieve plate, and the grape distilled wine is obtained through two times of distillation. The grape distilled liquor prepared by the method is rich and complex in aroma and strong in fruity flavor, and overcomes the defects of insufficient aroma of aged dry red as distilled base liquor and obvious cooking taste of peel pomace distilled liquor.

Owner:NINGXIA UNIVERSITY

Co-production preparation method of ceramide and glucoside (lipoyl) sphingosine

PendingCN113788864AComprehensive utilization of resources is highGood economic and environmental benefitsSugar derivativesCarboxylic acid amide separation/purificationMolecular biologySphingosine

The invention provides a co-production preparation method of ceramide and glucoside (lipoyl) sphingosine, which comprises the following steps: taking konjak flying powder or rice bran residue as a raw material, and sequentially extracting, adjusting the pH value, filtering, adjusting the pH value, concentrating, extracting, recrystallizing and the like to obtain high-purity free ceramide and glucoside (lipoyl) sphingosine. According to the co-production preparation method of ceramide and glucoside (lipoyl) sphingosine, the konjac flying powder and the rice bran residues are turned into wealth for resource reutilization to produce ceramide and glucoside (lipoyl) sphingosine with high economic values, so that the comprehensive utilization rate of resources is improved, and the method has huge economic benefits and environmental benefits.

Owner:绵阳膳意生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com