Municipal sludge drying tail gas treatment device and method

A technology for tail gas treatment and municipal sludge, applied in dehydration/drying/concentrated sludge treatment, chemical instruments and methods, separation methods, etc., can solve the problem of increasing sewage treatment devices, large amount of water chemical reagents, and increasing equipment investment cost and other issues, to save water resources, reduce water consumption, and achieve obvious energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

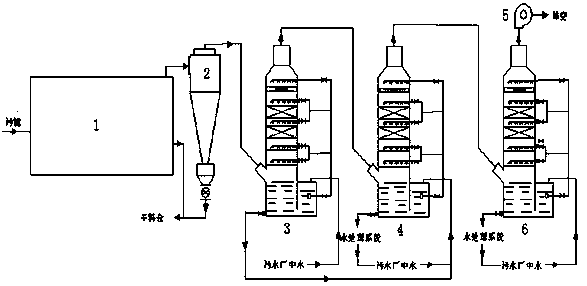

[0032] An urban sludge drying tail gas treatment device, the device comprises a drying device 1, a cyclone dust collector 2, a water washing tower 3, an alkali washing tower 4, a biological filter 6 and an induced draft fan 5, the air outlet of the drying device 1 and the cyclone dust removal The air inlet of the device 2 is connected, and the air outlet of the cyclone dust collector 2 is connected with the inlet of the water washing tower absorbing ammonia in the tail gas, the outlet of the water washing tower 3, the inlet of the alkali washing tower 4, the outlet of the alkali washing tower 4, and the biological filter The entrance of pond 6 is connected successively, and the air outlet of biofilter 6 links to each other with induced draft fan 5, and the bottom of alkali washing tower 4, biofilter 6 is respectively with its top respectively and is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com