Mix proportion design method of high-stone-powder-content concrete containing waste limestone chippings

A technology of mixing ratio design and stone powder content, applied in the direction of ratio control, non-electric variable control, instruments, etc., can solve the problems of low comprehensive utilization rate of waste rock chip resources, loss of stone powder, secondary pollution, etc., and achieve significant social benefits and Economic benefits, improving concrete performance, and avoiding environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

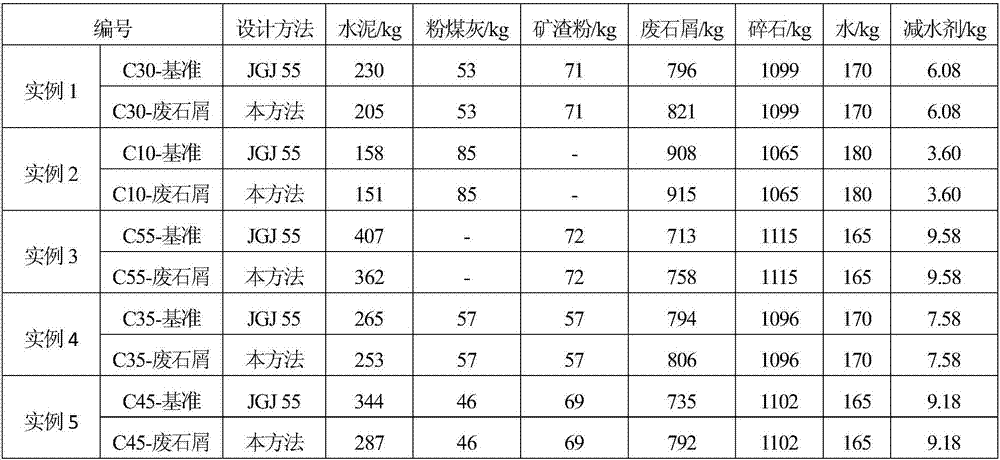

example 1

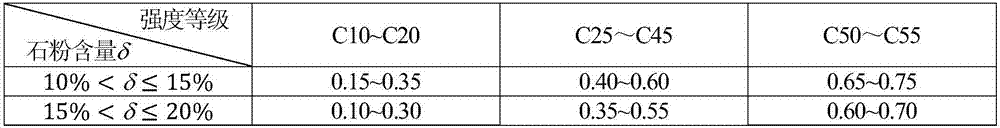

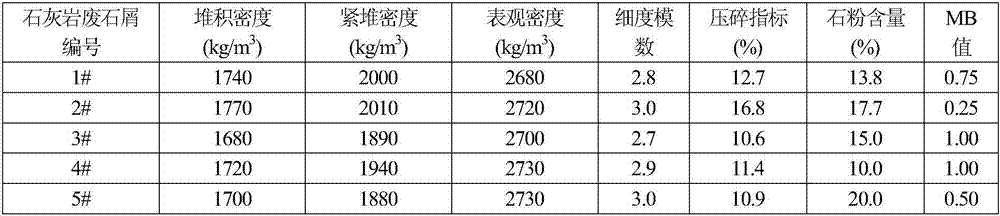

[0029] Taking the limestone waste rock concrete with strength grade C30 as an example, the concrete mix design is carried out according to the following steps:

[0030] ⑴According to the method stipulated in JGJ 52 of "Sand and Stone Quality and Inspection Method Standards for Ordinary Concrete", the stone powder content δ of 1# limestone waste rock chips is tested to be 13.8%, and the stone powder content limit δ 0 is 7.0%, calculate the stone powder excess value Δδ of 1# limestone waste rock chips, Δδ=δ-δ 0 = 13.8% - 7.0% = 6.8%;

[0031] ⑵According to the provisions of JGJ 55 in the "Ordinary Concrete Mix Proportion Design Regulations", the absolute volume method is used to calculate and determine the mix ratio parameters of C30 benchmark concrete, in which the fly ash and slag powder are respectively 15% and 20% of the total amount of cementitious materials %. The mix ratio parameters of the C30 reference concrete determined by the mix ratio calculation are as follows: c...

example 2

[0034] Taking C10 limestone waste rock concrete as an example, follow the steps of this design method to design the concrete mix ratio, and follow the steps below to design the concrete mix ratio:

[0035] ⑴According to the method stipulated in JGJ 52 of "Sand and Stone Quality and Inspection Method Standards for Ordinary Concrete", the stone powder content δ of 2# limestone waste rock chips was determined to be 17.7%, and the stone powder content limit δ 0 is 10.0%, calculate the stone powder excess value Δδ of 2# limestone waste rock chips, Δδ=δ-δ 0 = 17.7% - 10.0% = 7.7%.

[0036] ⑵According to the provisions of JGJ 55 in the "Ordinary Concrete Mix Proportion Design Regulations", the absolute volume method is used to calculate and determine the mix ratio parameters of C10 benchmark concrete, in which fly ash is 35% of the total amount of cementitious materials. The mix ratio parameters of the C10 reference concrete determined by the mix ratio calculation are as follows: ce...

example 3

[0039] Taking C55 limestone waste rock concrete as an example, follow the steps of this design method to design the concrete mix ratio, and follow the steps below to design the concrete mix ratio:

[0040] ⑴According to the method stipulated in JGJ 52 of "Sand and Stone Quality and Inspection Method Standards for Ordinary Concrete", the stone powder content δ of 3# limestone waste rock chips is tested to be 15.0%, and the stone powder content limit δ 0 is 7.0%, calculate the stone powder excess value Δδ of 3# limestone waste rock chips, Δδ=δ-δ 0 = 15.0% - 7.0% = 8.0%.

[0041] ⑵According to the provisions of JGJ 55 in the "Ordinary Concrete Mix Proportion Design Regulations", the absolute volume method is used to calculate and determine the mix ratio parameters of C55 benchmark concrete, and the amount of slag powder is 15% of the total amount of cementitious materials. The mix ratio parameters of the C55 reference concrete determined by the mix ratio calculation are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com