Method for preparing functional oil by segmented solid state fermentation of mixed fungus

A solid-state fermentation, segmented technology, applied in the direction of edible oil/fat, fat oil/fat production, fat production, etc., can solve the problems of fatty acid composition and beneficial accompaniment of blended oil, fuzzy concept of blended oil, etc., to improve oil Effects of flavor, energy consumption reduction, and microbial contamination reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

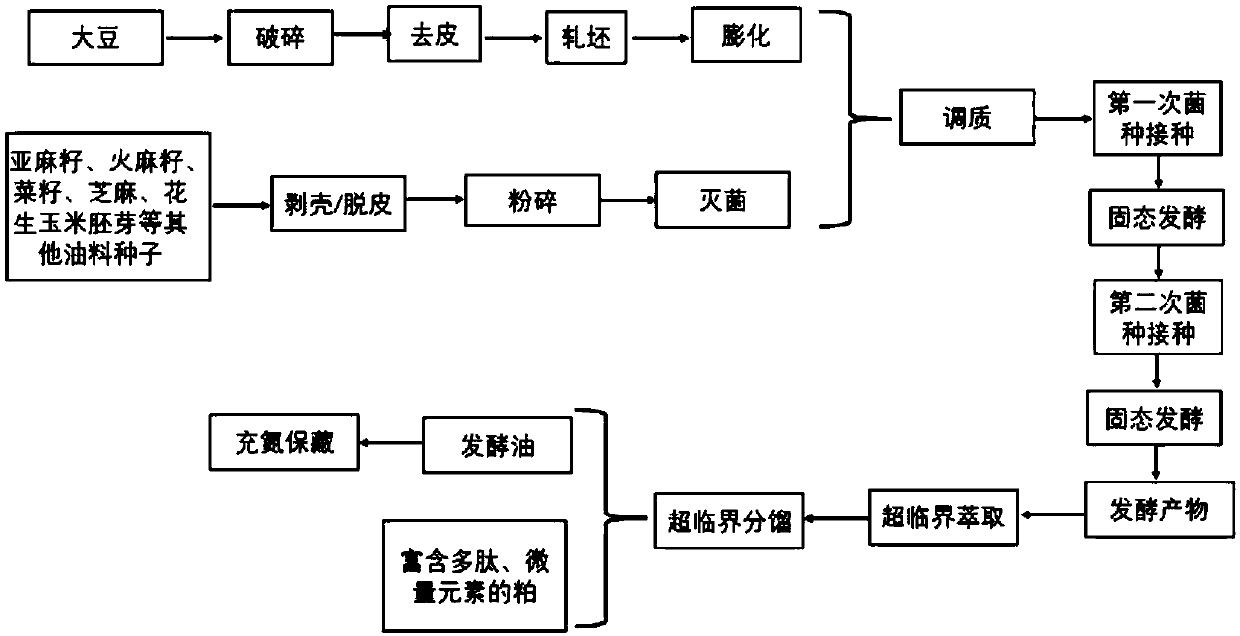

Method used

Image

Examples

Embodiment 1

[0038] (1) Powder preparation

[0039] After crushing, peeling and rolling the soybeans, use the hydraulic conical plug extruder to puff the powder. The puffing temperature is 150°C, the puffing time is 2min, and cooled to 35°C; Bacteria for 15min, cooled to 28°C;

[0040] (2) Mixed fungal fermentation

[0041] Mix the expanded soybean powder and the autoclaved linseed powder according to 8:2 (W / W), transfer to the fermenter, adjust the water content to 20wt%, add 1wt% glucose, and add 0.05wt% NaCl , adjust the pH to be about 5.0, and the dissolved oxygen amount is 30% of the total material volume; add Aspergillus oryzae in the fermenter, the inoculum size is 10% (W, the same below), the fermentation temperature is 35 ° C, and the fermentation time is 2d; 2d Finally, the temperature in the fermenter was lowered to 28°C, and 0.5wt% of glucose was supplemented. Aspergillus niger: Mortierella flavinum was mixed at a ratio of 1:1, and the total inoculum was 10%. The pH was natural...

Embodiment 2

[0046] (1) Powder preparation

[0047] After soybeans are broken, peeled and billeted, the powder is expanded using a hydraulic conical plug extruder, with an expansion temperature of 160°C, an expansion time of 2 minutes, and cooling to 30°C. Crush linseed to 100 mesh, sterilize by autoclaving at 121°C for 15 minutes, and cool to 30°C;

[0048] (2) Mixed fungal fermentation

[0049] Mix the extruded soybean powder and the autoclaved linseed powder according to the ratio of 8:2 (W / W), transfer them into the fermenter, adjust the water content to 20wt%, add glucose to 5wt%, and add NaCl to 0.1%. Adjust the pH to 6.2, the amount of dissolved oxygen to be 30% of the total material volume, inoculate Candida albicans: Rhodosporidium toruloides at a ratio of 1:1 (W / W), and the inoculum size is 10% in the fermenter, and ferment The temperature is 30°C, ferment for 3 days; after 3 days, lower the fermentation temperature to 28°C, add 2wt% glucose, adjust the dissolved oxygen to 15% ...

Embodiment 3

[0054] (1) Powder preparation

[0055] After soybeans are crushed, peeled and billeted, the powder is expanded using a hydraulic conical plug extruder at an expansion temperature of 160°C, an expansion time of 1 min, and cooled to 35°C. Crack the hemp seeds and crush them to 100 mesh, sterilize by autoclaving at 121°C for 15 minutes, and cool to 35°C;

[0056] (2) Mixed fungal fermentation

[0057] Mix the extruded soybean powder and the autoclaved hemp seed powder according to 9:1 (W / W), transfer to the fermenter, adjust the water content to 25wt%, add 5wt% glucose, and add 0.05wt% NaCl, Regulating pH is about 5.0, and the dissolved oxygen amount is 40% of total material volume; Aspergillus oryzae is added in the fermenter, inoculum size is 8% (W), and fermentation temperature is 35 ℃, and fermentation time is 2d; After 2d, fermentor The temperature in the medium was lowered to 28°C, and 0.1wt% of glucose was added, and Aspergillus niger:Mertierella flavinum was mixed at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com