Patents

Literature

117results about How to "Reduce chemical pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing bamboo fibers by separating bamboo

The invention discloses a method for preparing bamboo fibers by separating bamboo, which belongs to a technical method for separating the bamboo fibers from the bamboo. The method comprises the following successive steps of: cutting and splitting the bamboo into bamboo strips, and soaking the bamboo strips into liquid with active bio-enzyme for enzymolysis; and the method is characterized in that: after the splitting of the bamboo into bamboo strips and before the enzymolysis, the bamboo strips are subjected to expanded treatment; and the expanded treatment comprises vacuumizing treatment on the bamboo strips, or temperature change treatment on the bamboo strips, or pressure change treatment on the bamboo strips; or the expanded treatment is combined expanded treatment with two or more kinds of expanded treatment. The method for preparing the bamboo fibers has the advantages of: the boiling separation after the expanded treatment, and microbe and active bio-enzyme separation on non-bamboo fiber organic matters are easier, the time is short, the available temperature and pressure are low, less microbe and active bio-enzyme are used, and the aim of separating the bamboo fibers at low cost is fulfilled. The obtained bamboo fibers are environment-friendly products.

Owner:廖大中

Preparation method of long-acting anti-microbial textile

InactiveCN106978721AImprove antibacterial propertiesReduce chemical pollutionRadio/micro wave fibre treatmentUltrasonic/sonic fibre treatmentMicrowaveRoom temperature

The invention discloses a preparation method of a long-acting anti-microbial textile. The preparation method concretely comprises the following processes: firstly a desizing or refining process is carried out for the textile, and pretreatment is carried out for the textile by using low temperature plasma; textile which is pretreated is dipped at a room temperature for 10-30 minutes in a mixed finishing solution which comprises a chitosan solution and a silver nitrate solution, the textile is taken out and superfluous finishing solution is rolled out, liquor retention is 100-150%, the textile which is dipped in the finishing solution is transferred into a piece of microwave equipment for carrying out treatment for a certain period of time, after the reaction ends, the textile is taken out and washed with water, and after drying, the anti-microbial textile is obtained. The anti-microbial textile has the advantages of excellent anti-microbial properties, washing resistance, lasting anti-microbial effects, simple preparation technology, and low chemical pollution; the method overcomes the problems of complex processes, bad stability of nanometer silver, bad anti-microbial durability and the like existed in the prior art.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Waterborne damping coating for vehicle

InactiveCN102408792ANo pollution in the processAvoid it happening againConjugated diene hydrocarbon coatingsEpoxy resin coatingsEmulsionChemical products

A waterborne damping coating for vehicles of the invention belongs to the fields of chemical product and coating preparation. The waterborne damping coating comprises an emulsion base material, an inorganic matter filler, a film forming additive, a thickening agent, a heating-expansible organic hollow filling material, an organic foaming agent, and water. The emulsion base material is compounded by 2-3 emulsions with different Tgs; the using amounts of the heating-expansible organic hollow filling material and the organic foaming agent respectively account for, on a weight basis, 0.3%-5% and 0.1%-5% of the total amount of the waterborne damping coating. The thick paste coating prepared in the invention has a damping value of 0.06-0.15 at 20-60 DEG C; the coating has a micropore structure,can prevent film defects such as chaps, cracks, needle eyes, expansion and the like caused by the coating, can form a film with a thickness of 3-6 mm by coating once, and is applicable to the coatingof vibration parts of various vehicles and motor products so as to inhibit vibration and reduce noise.

Owner:JILIN UNIV

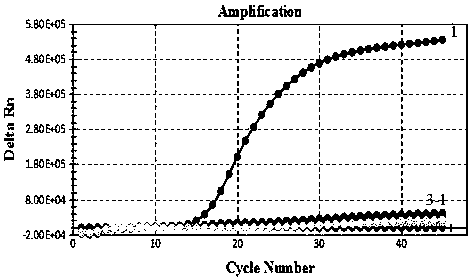

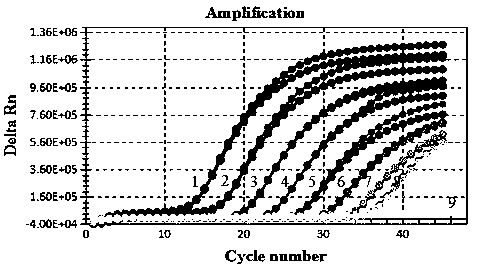

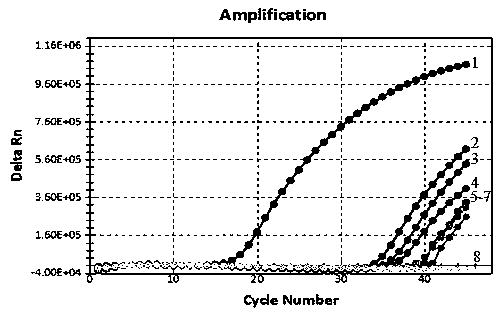

Primer and kit for real-time fluorescence quantification PCR detection of wild strain TaqMan-MGB of cattle nodular skin disease virus and detection method

InactiveCN108950069AIncreased sensitivityRapid expansionMicrobiological testing/measurementMicroorganism based processesPositive controlFluorescence

The invention discloses a primer and kit for the real-time fluorescence quantification PCR detection of a wild strain TaqMan-MGB of a cattle nodular skin disease virus and a detection method. According to the method, two primers and a specific MGB probe are designed and respectively have the DNA sequences of SEQ ID NOs.1-3. The kit contains amplification reaction liquid, a positive control, a negative control and sterilized deionized water. A target sequence can be rapidly, efficiently, specifically and sensitively detected by virtue of a two-step amplification method, the operation is simpleand convenient, expensive instruments and reagents are not used, the technical requirements on operators are not required, the detection cost is low, the flux is high, and the detection period is short.

Owner:INSPECTION & QUARANTINE TECH CENT OF CHONGQING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Activity-enhanced algae microorganism fertilizer and preparation method thereof

The invention discloses an activity-enhanced algae microorganism fertilizer and a preparation method thereof. The microorganism fertilizer breaks through the structure of a conventional fertilizer, algae fermentation liquor is taken as a synergistic ingredient, and microorganisms are added, and the microorganism fertilizer is finally processed in a scientific manner. The algae fermentation liquor not only can be used as a synergist to promote nutrient absorption of plants, but also can play roles of controlled release and coating on nutrients, provides a safer growth environment for crops, and promotes stable yield, high yield and high quality of the crops. Microbial flora can degrade nutrients in soil, promote crop absorption, and improve the soil structure.

Owner:岳万华

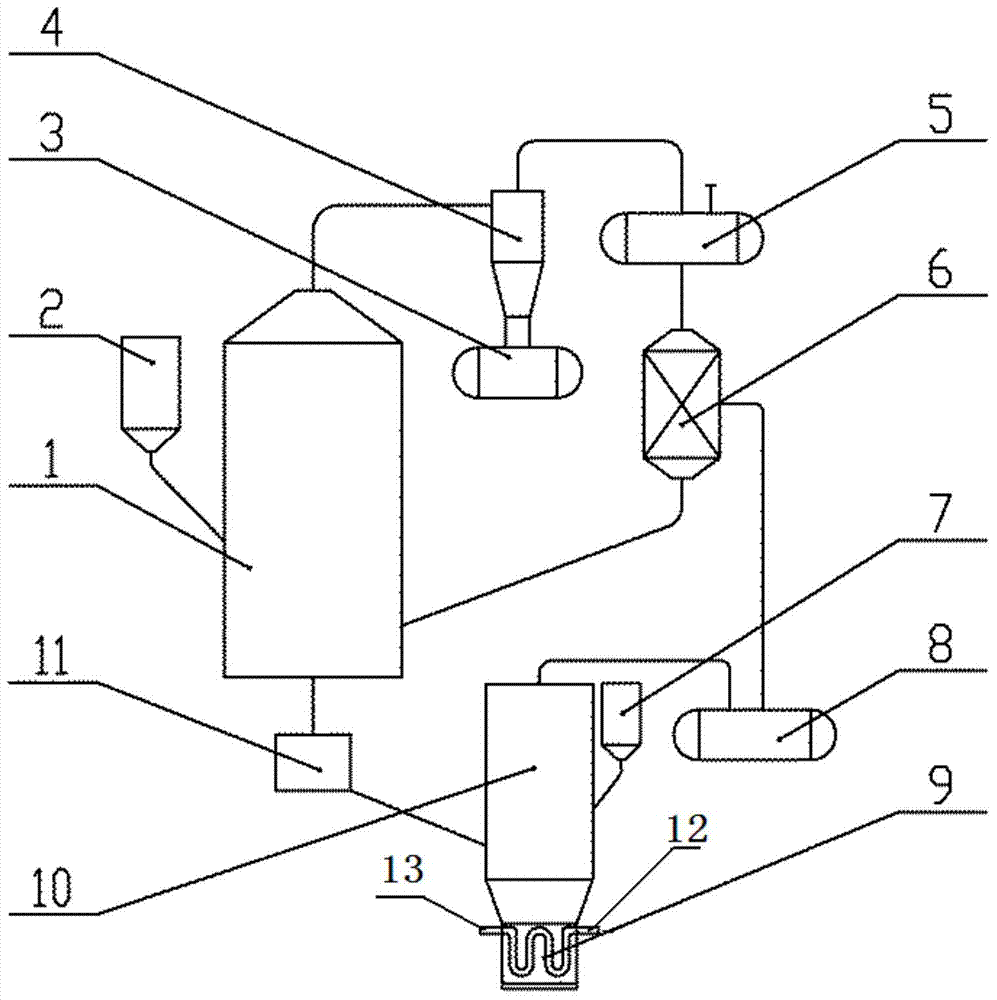

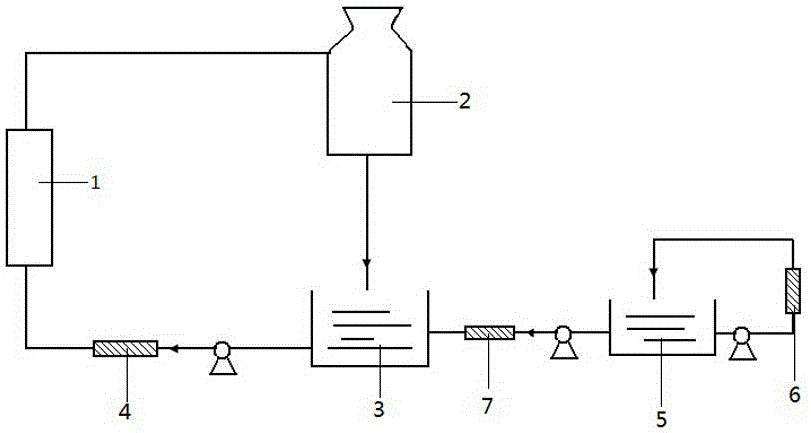

System and process for comprehensive utilization of oil shale destructive distillation and semicoke gasification

InactiveCN103923677ARealize energy utilizationReduce pollutionLiquid hydrocarbon mixture productionSpecial form destructive distillationHeat carrierWater vapor

The invention discloses a system for comprehensive utilization of oil shale destructive distillation and semicoke gasification, which comprises a destructive distillation furnace, an oil shale bin, an oil storage tank, an oil-gas separator, a gas heater, a gasification fuel bin, a combustible gas tank, a heater, a gasification furnace and a conveyer device. According to the invention, by using a process for comprehensive utilization of oil shale destructive distillation and semicoke gasification by using the system, semicoke generated by destructive distillation and powdered oil shale are subjected to gasification reaction to generate combustible gas, a part of combustible gas can be used as a fuel to be introduced into the gas heater to heat a heat carrier gas used in the destructive distillation furnace, high-temperature solid residues generated in the gasification furnace are discharged into a heat exchanger to heat cold water into hot water or vapor. According to the invention, the semicoke generated by oil shale destructive distillation is gasified to be recycled, and thus the addition benefits in an oil shale destructive distillation process is increased, heat pollution and chemical pollution of shale residues are reduced, and energy source utilization rate is improved.

Owner:SHANGHAI JIAO TONG UNIV

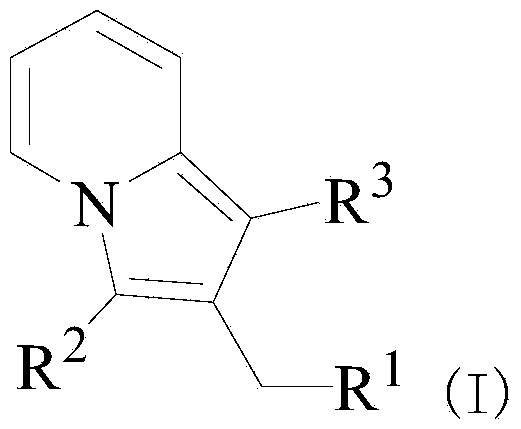

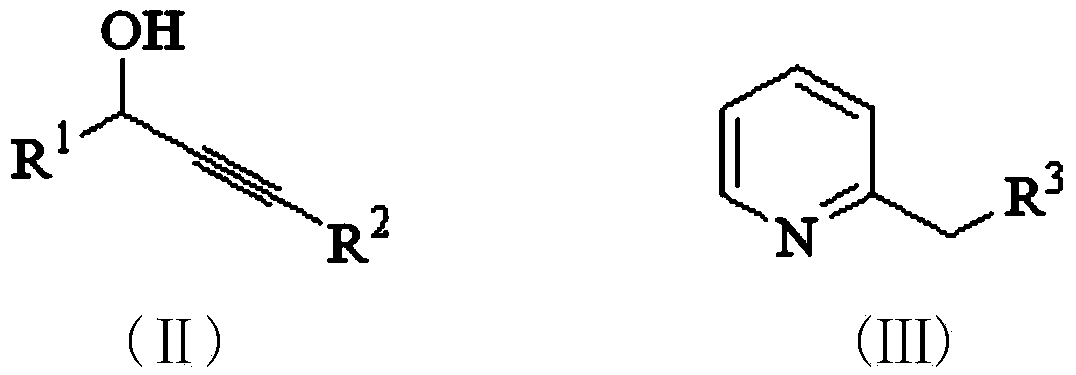

Purrocoline derivative and synthetic method and application thereof

InactiveCN103641827ANovel structureReduced responseOrganic active ingredientsOrganic chemistrySynthesis methodsTriflic acid

The invention discloses a purrocoline derivative and a synthetic method and application thereof. The purrocoline derivative with a novel structure can be prepared by reacting propargyl alcohol and a 2-alkyl pyridine compound by taking samarium trifluoromethanesulfonate as a catalyst under the condition without a solvent; the reaction consumption and the chemical contamination are reduced, the cost is reduced and the operation is simplified; the obtained purrocoline derivative has better activity on a gastric cancer cell strain MGC80-3. The structural formula of the purrocoline derivative is shown in a formula (I) in the specification, wherein R<1> is phenyl, 4-methoxyphenyl, 4-fluorophenyl and 2-chlorphenyl or thienyl, R<2> is phenyl, and R<3> is H, phenyl, methyl, a nitrile group or an ethyl acetate group.

Owner:GUANGXI NORMAL UNIV

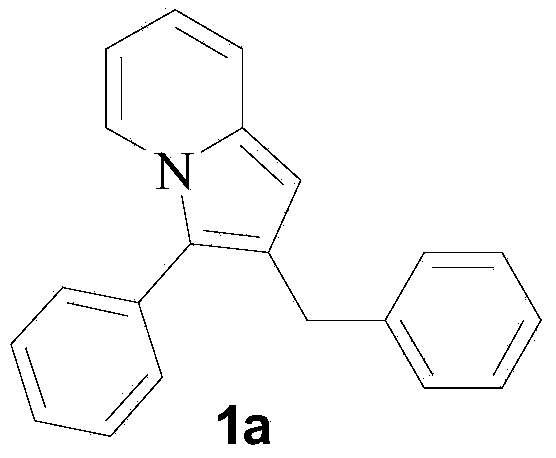

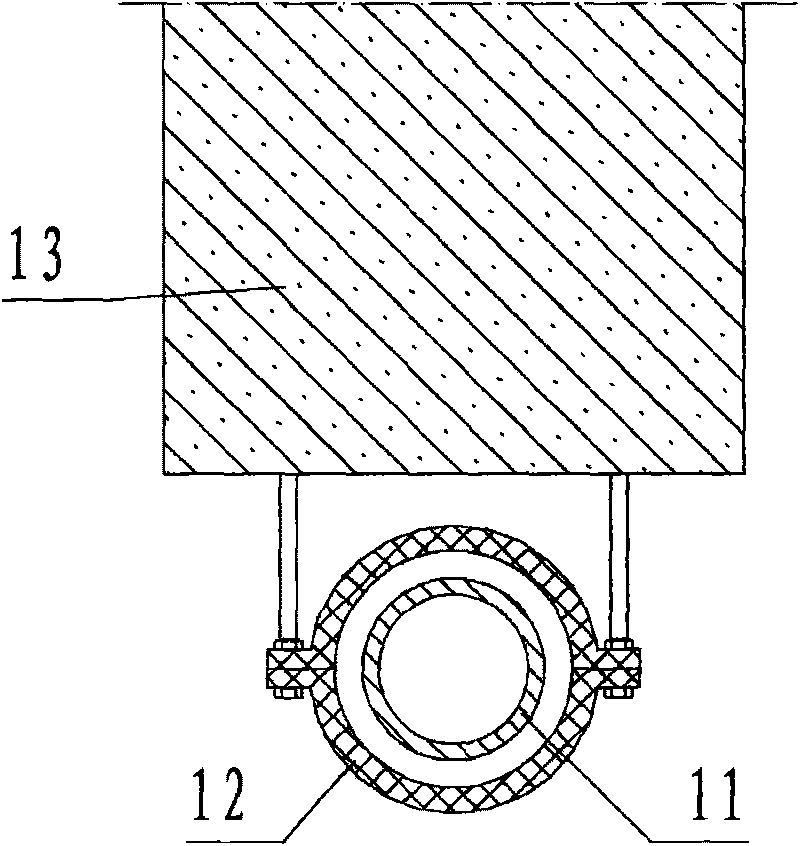

Pathogenic microorganism waste liquor treatment system

InactiveCN101691247ATimely processingThe overall collection and processing of the processing station is timelyWater/sewage treatment by heatingLiquid wastePathogenic microorganism

The invention discloses a pathogenic microorganism waste liquor treatment system, which comprises a waste liquor collecting pipeline system (1), a waste liquor sterilizing tank (2) and a sewage treatment station (3). The invention adopts a technical scheme that waste liquor is integrally collected and treated through the waste liquor collecting pipeline system, the high-temperature steam bath waste liquor sterilizing tank and the sewage treatment station special for the waste liquor so as to overcome the defects that the liquor collecting vehicle and liquor collecting bucket mode in the prior art has low waste liquor treatment capacity, occupation of on-site space of a clean area for transit storage, indefinite sterilization effect and easy chemical pollution to environment. The pathogenic microorganism waste liquor treatment system provided by the invention directly conveys the waste liquor generated by various viable bacteria and live virus areas of buildings to the waste liquor sterilizing tank for high-temperature steam sterilization, and then conveys the waste liquor to the common sewage treatment station for physicochemical treatment through a pipeline so as to achieve the aims of timely, massively, highly efficiently and reliably treating the pathogenic microorganism waste liquor with low cost, and reducing the chemical pollution.

Owner:NINGBO RONGAN BIOLOGICAL PHARMA

Coffee grounds paper tray and preparing method thereof

InactiveCN110318289AReduce dosageReduce material costsVegetable material additionPaper/cardboardPulp and paper industrySizing

The invention discloses a coffee grounds paper tray, and belongs to the technical field of paper tray products. The coffee grounds paper tray comprises, by mass, 60-70% of raw wood pulp, 10-20% of white paper edges, 5-15% of coffee grounds and 5-10% of an adsorbent. The adsorbent comprises, by mass, 40-50% of corn starch, 30-40% of tapioca flour and 10-20% of vinyl acetate. The invention further discloses a preparing method of the coffee grounds paper tray. The method includes the steps of material preparing, coffee grounds preprocessing, adsorbent preparing, pulping, mixing, pulp preparing, forming and sizing. The coffee grounds paper tray produced through the preparing method has the advantages of being low in production cost, good in deodorizing effect, high in safety, and equivalent toan existing paper tray in strength.

Owner:咖法科技(上海)有限公司

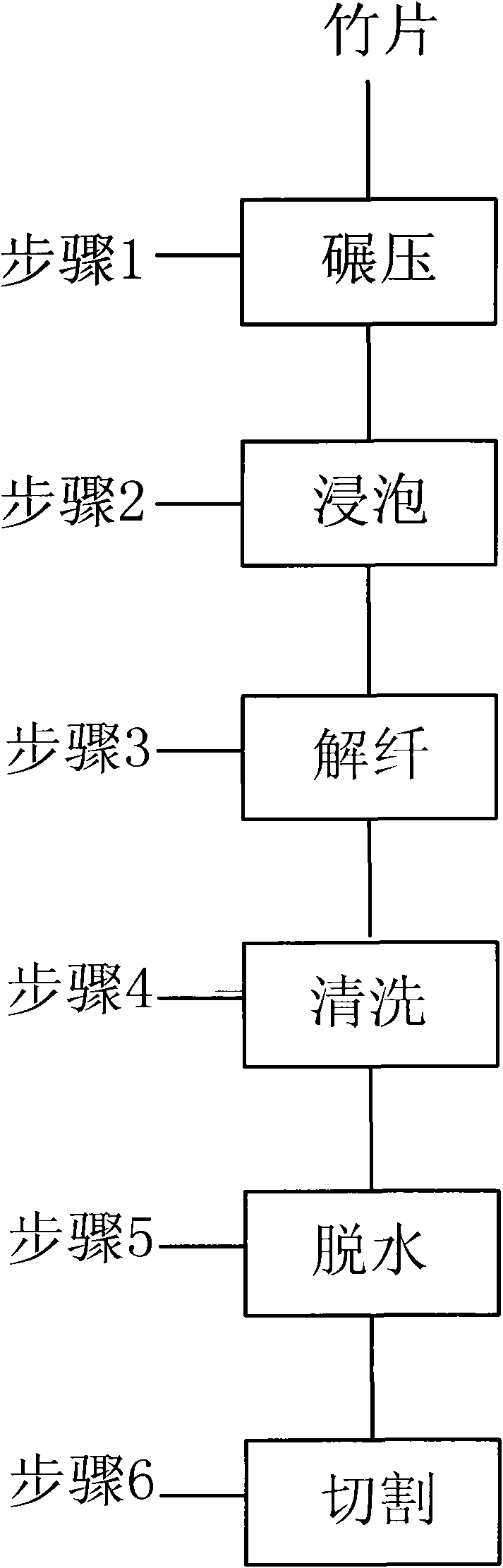

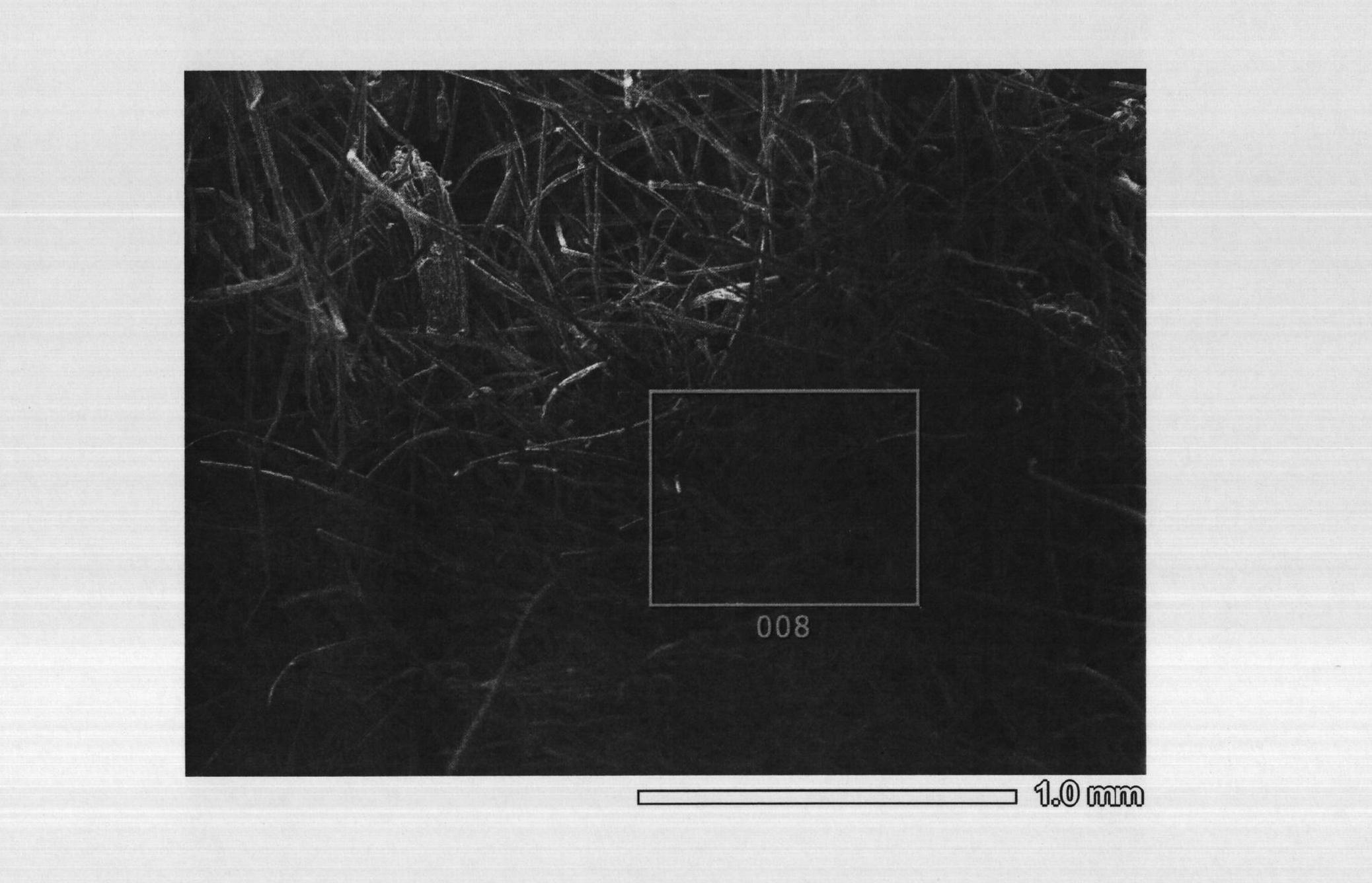

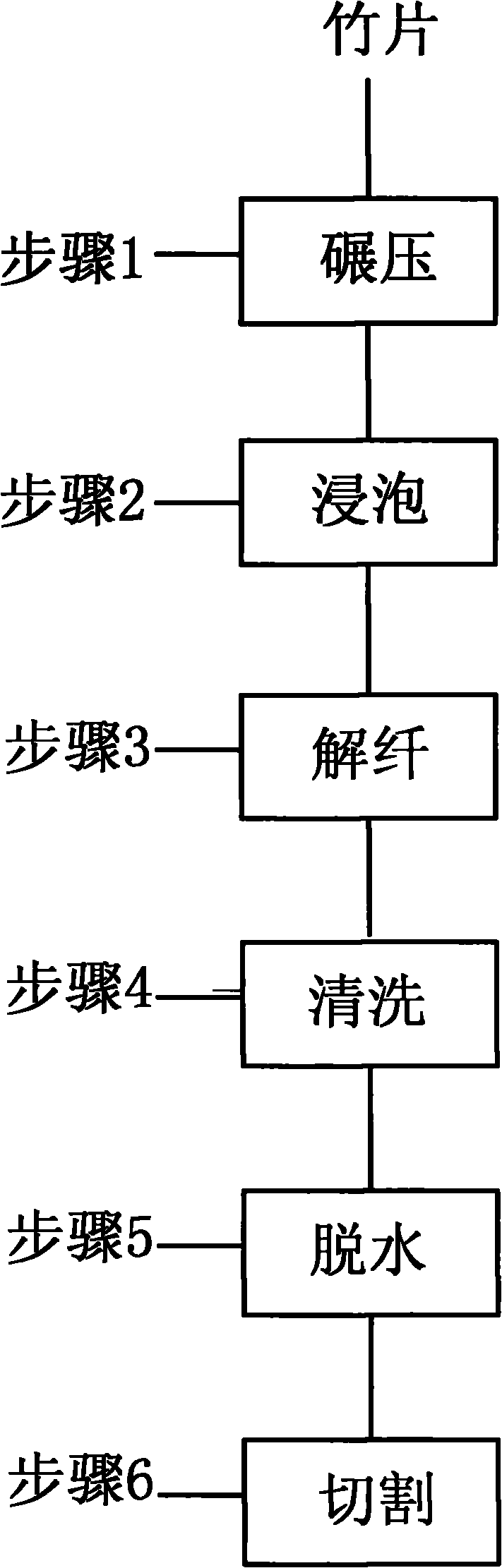

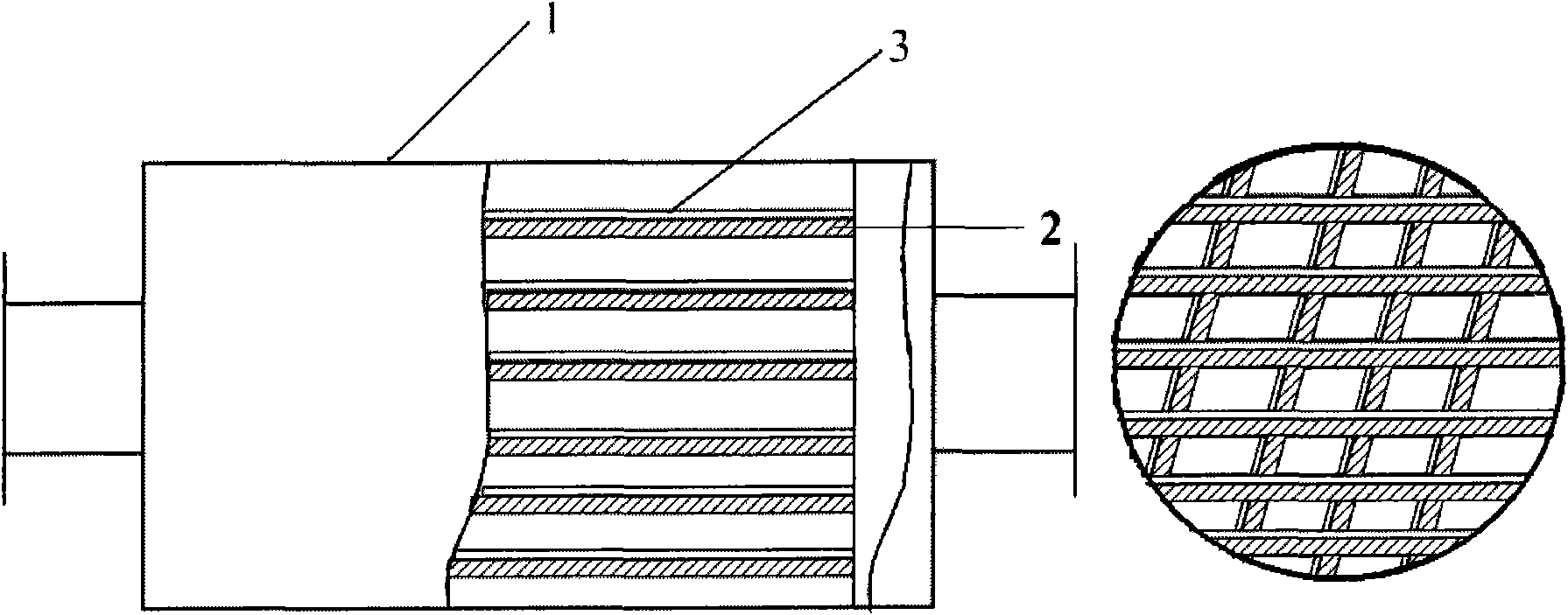

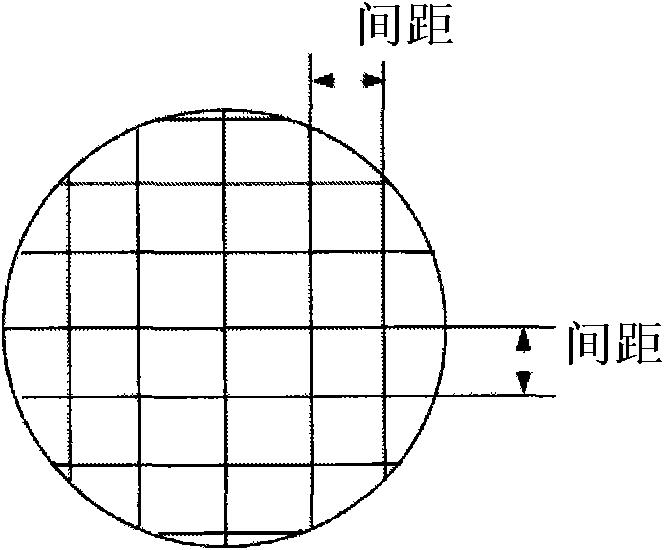

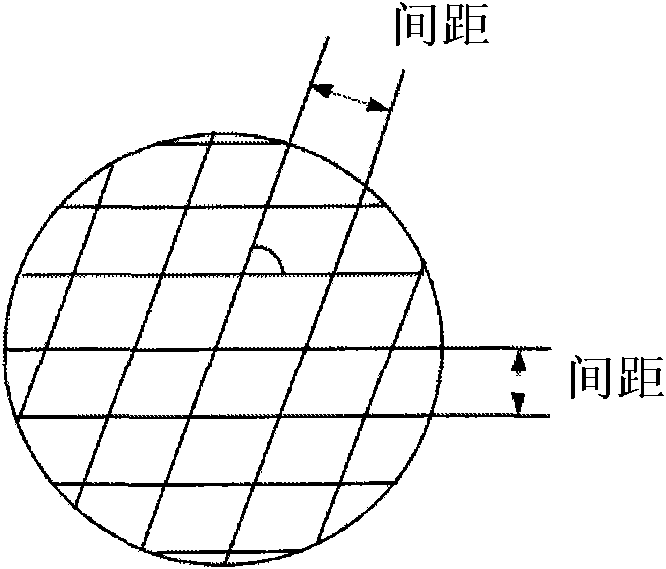

Method for manufacturing bamboo fibers

ActiveCN101934545AQuick removalReduce chemical pollutionWood working apparatusChemical reactionSingle fiber

The invention provides a method for manufacturing bamboo fibers. The method comprises the following steps of: 1) rolling: rolling to crack a bamboo chip to ensure that the bamboo fibers are possibly dispersed; 2) dipping: putting the bamboo chip into a reaction kettle, and mixing with a proper amount of reactant for 10 to 90 minutes to remove lignin, polysaccharide, colloid and protein on the surface of the bamboo fiber; 3) defibering: reducing the pressure instantaneously to standard atmospheric pressure to ensure that the bamboo chip is exploded in the reaction kettle and defibered to form a single-fiber bamboo chip; 4) cleaning: washing the bamboo fibers with hot water with the temperature of between 50 and 100 DEG C at least twice to remove byproducts from the surfaces of the bamboo fibers; 5) dewatering: drying the cleaned bamboo fibers to obtain a dry bamboo fiber finished product; and 6) cutting: cutting the bamboo fibers into bamboo fibers with a proper length. By adopting a physical instantaneous depressurized explosion mode and a chemical reaction reagent dipping mode, the bamboo chip is treated by steps, and the instantaneous depressurized explosion also accelerates thereacting speed of the chemical reagent and the bamboo chip to achieve the effect of quickly removing the lignin, the polysaccharide, the colloid and other substances from the surface of the bamboo chip.

Owner:宁波竹源新材料科技有限公司

Preparation method for freeze-dried Chinese yam superfine micro-powder

InactiveCN103859321AIncrease productivityReduce power consumptionFood shapingFood ingredient functionsWater contentEnzyme

The invention provides a preparation method for freeze-dried Chinese yam superfine micro-powder. The preparation method comprises the following steps: selecting materials and washing; peeling off and slicing; lyophilizing; crushing to obtain superfine micro-powder and sealing and packaging; after selecting the materials and washing, pre-cooling Chinese yams; then peeling off and slicing, wherein the pre-cooling temperature of the pre-cooling step ranges from-27 DEG C to -30 DEG C and the pre-cooling time of the pre-cooling step lasts for 3h; the slicing thickness in the step of peeling off and slicing is 3-5mm; the temperature in the lyophilizing step ranges from -35 DEG C to -45 DEG C; the water content of the lyophilized materials is less than or equal to 3%; the step of crushing to obtain the superfine micro-powder adopts a vibration type superfine micro-powder crusher to crush the materials; the temperature of the materials is controlled to -10 DEG C in the crushing process. According to the preparation method for the freeze-dried Chinese yam superfine micro-powder provided by the invention, immersion by adopting color-protecting solution and enzyme deactivation are not needed and the loss of heat-sensitive components of the prepared Chinese yam micro-powder is small; the loss of nutrition ingredients of the raw materials is little, the reconstitution property is good and the medical value is high.

Owner:HENAN UNIV OF SCI & TECH

Oil preparation and gas production system and technology by conducting pressurization, hydrogenation and pyrolysis on large-sized seaweeds

ActiveCN105505429AImprove qualityHigh yieldLiquid hydrocarbon mixture productionHydrocarbon oils treatmentHydrogenFiltration

The invention provides an oil preparation and gas production system and technology by conducting pressurization, hydrogenation and pyrolysis on large-sized seaweeds. The system comprises a rapid thermal cracking system and a secondary pyrolysis system; the rapid thermal cracking system comprises a pressurization feeding system, a rapid thermal cracking system, a particle separation device, a filtration device, a hydrogen material flow pipeline, a flammable gas tank, an oil-gas separator and an oil storage tank, the secondary pyrolysis system comprises a secondary pyrolysis furnace, a secondary pyrolysis fuel bin and a dreg falling opening, and the second pyrolysis furnace comprises two feed inlets. The whole system is simple in structure, the oil yield of seaweed biomass is high, the problems of solid waste semicocke losses and environmental pollution are avoided, and efficient and clean utilization of the large-sized seaweed biomass resource is finally achieved.

Owner:泰州市海创新能源研究院有限公司

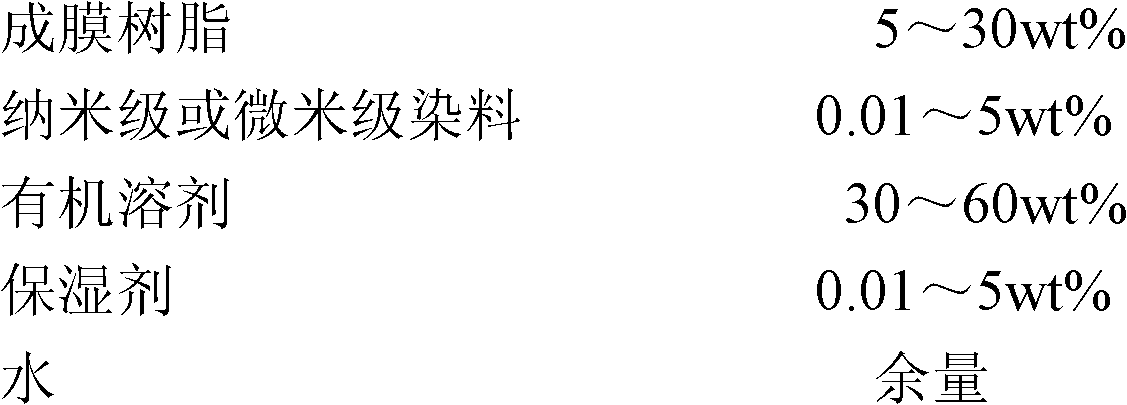

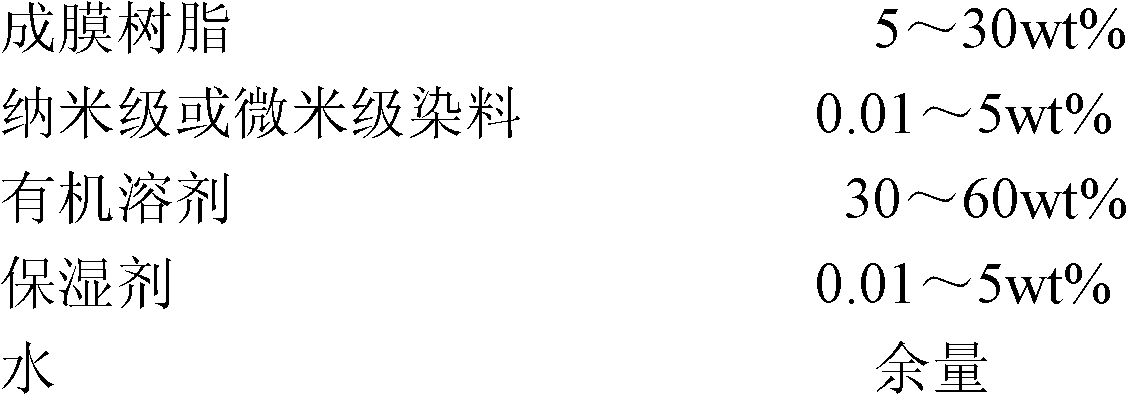

Ink for printing and directly making plate used in nanometer material and preparation method thereof

The invention belongs to ink for printing plate making, relates to a material for directly making a plate by jetting ink and printing based on a nanometer material, in particular to ink for printing and directly making a plate used in a nanometer material and a preparation method thereof. The method comprises the following steps of: uniformly stirring and mixing 5-30 percent by weight of film-forming resin, 0.01-5 percent by weight of a nano-grade or micron-grade dye, 30-60 percent by weight of an organic solvent, 0.01-5 percent by weight of a humectant and the balance of water at the room temperature on the basis of the total weight of ink; and after the film forming resin is dissolved completely, performing multi-stage filtration for removing impurities and / or undissolved substances from a mixed solution to obtain a filtrate, i.e., the ink provided by the invention. The ink is jetted onto the surface of a metal substrate through an ink jet printer for forming printing patterns, and can be directly printed after curing, so that the chemical pollution and a post-treatment process are reduced, the printing resistance of a printing plate can be up to 100,000 and the resolution is up to 175lpi.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for supporting laneway below coal pillar

ActiveCN102155248ALarge surface areaStrong watch protectionMine roof capsAnchoring boltsMetal meshCoal pillar

The invention discloses a method for supporting a laneway below a coal pillar. The method comprises the following steps of: firstly, arranging temporary supports on a top plate and two sides of the laneway, paving a metal mesh and a steel band, pressing the metal mesh with the steel band and supporting the steel band with a monomer hydraulic support post; secondly, drilling holes on the top plate through the orifice of the steel band of the top plate by using drill bits matched with the diameters of threaded steel anchor rods in combination with a drilling machine, arranging the threaded steel anchor rods into drilling holes in sequence and reaching pre-tightening force by using a nut; and lastly, drilling holes on laneway sides from the orifices of the steel bands on the laneway sides by using drill bits matched with the diameters of threaded steel anchor rods in combination with the drilling machine, arranging hydraulic expansion anchor rods into the drilling holes on the laneway sides in sequence, and injecting high-pressure water into the hydraulic expansion anchor rods to expand the hydraulic expansion anchor rods. Anchor ropes are arranged on the top plate and the two sides at specific intervals during the performance of the procedures. The procedures are repeated until the laneway below the coal pillar is supported. The hydraulic expansion anchor rods adopted in the method can realize full-length anchorage; and after the anchor ropes are used for reinforcing and supporting the laneway, the surrounding rock deformation of the laneway below the coal pillar can be effectively controlled.

Owner:CHINA UNIV OF MINING & TECH

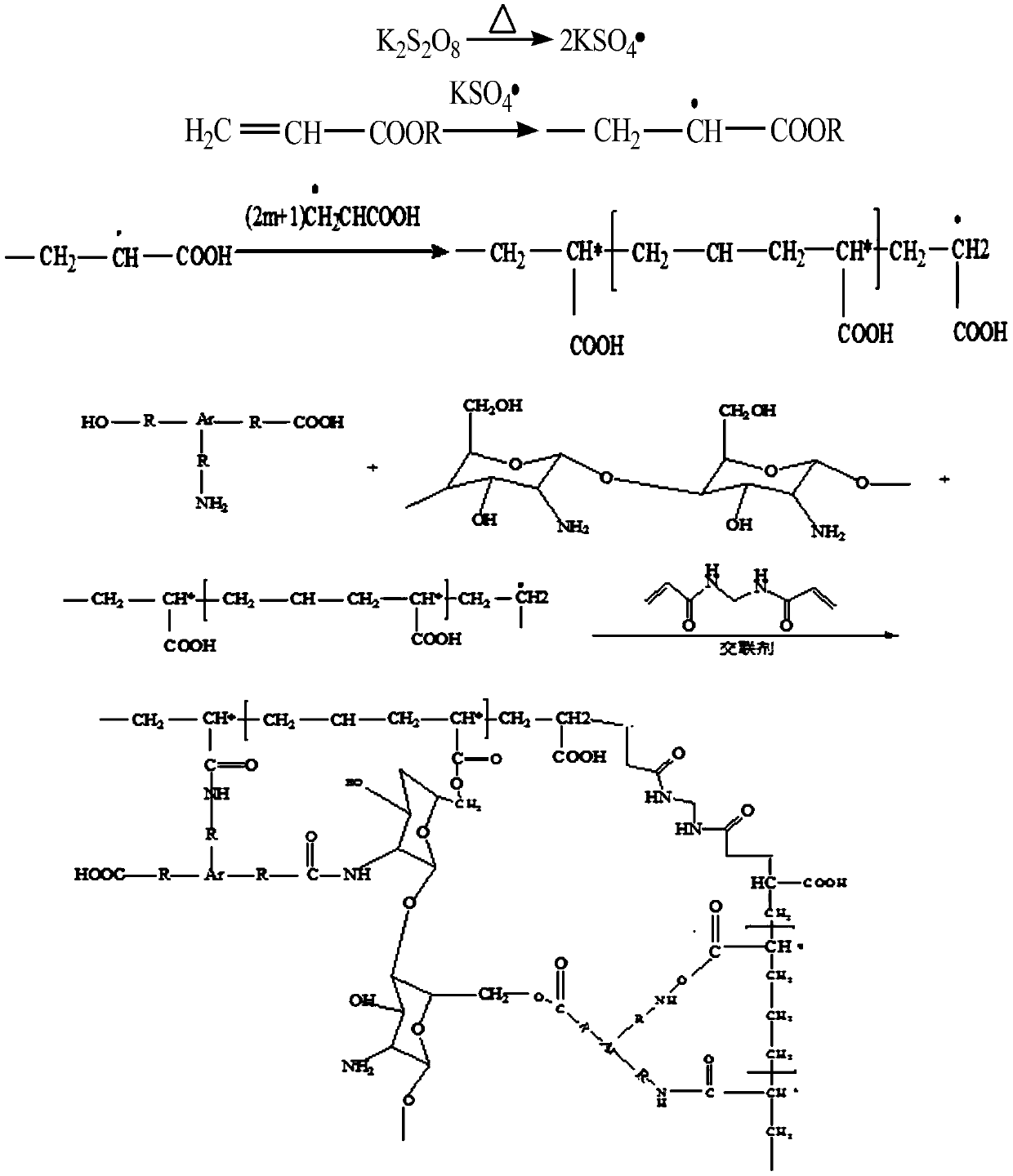

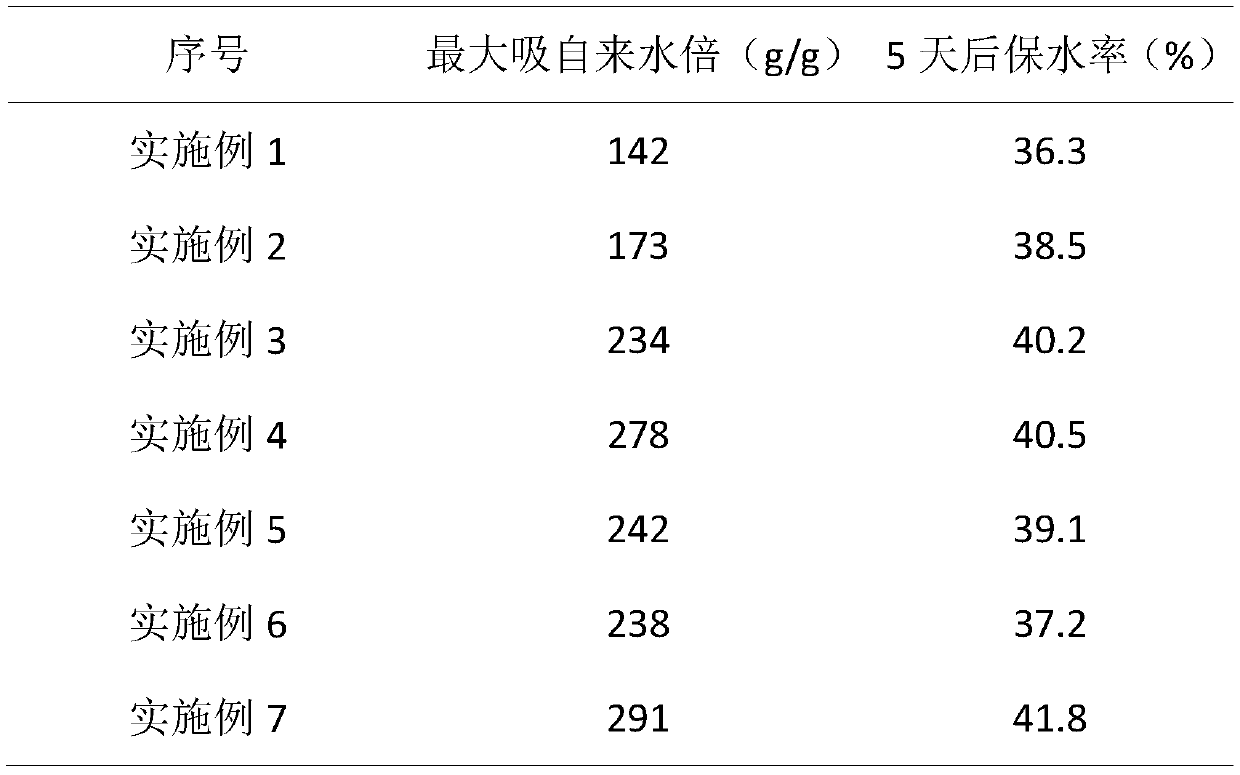

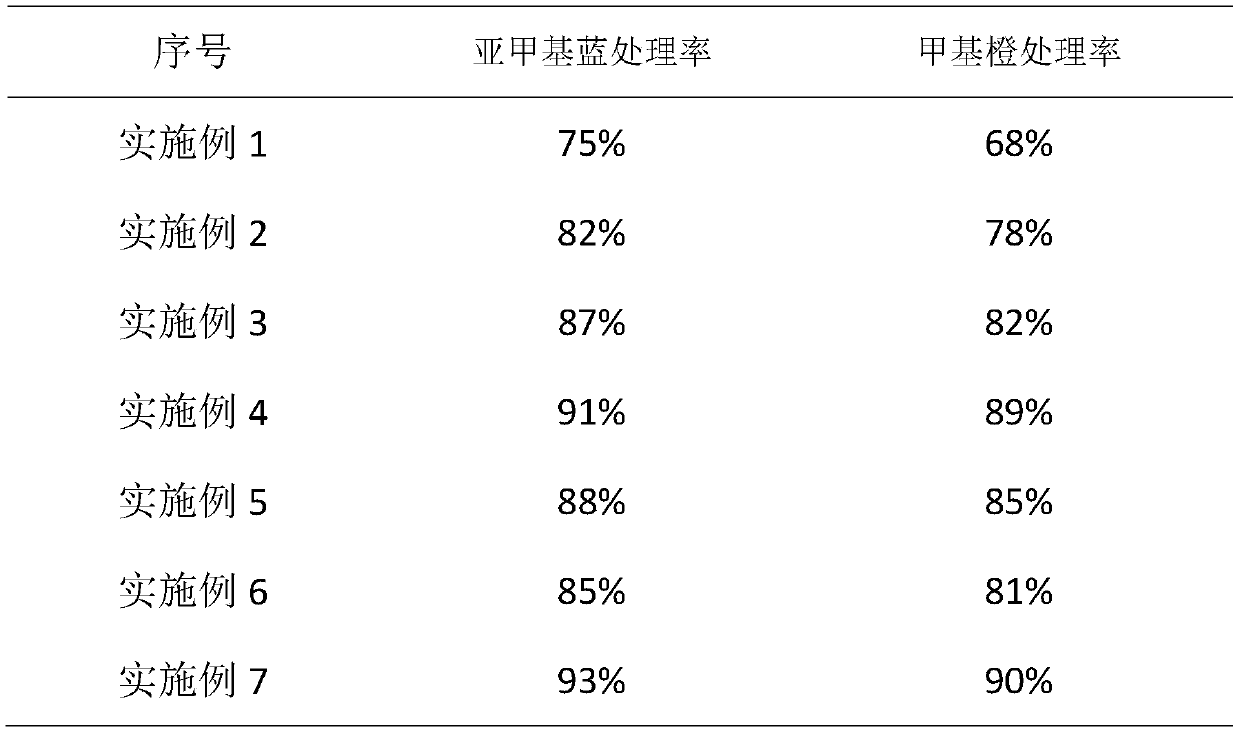

Fulvic acid type three-dimensional network composite material, and preparation method and application thereof

The invention discloses a fulvic acid type three-dimensional network composite material, and a preparation method and application thereof, and belongs to the technical field of material preparation and environment treatment. The fulvic acid type three-dimensional network composite material is prepared by dissolving fulvic acid and natural macromolecules, adding a cross-linking agent and an initiating agent, adding polyethylene glycol dropwise under the condition of heating, and stirring and drying. The fulvic acid is a high molecular organic acid which consists of aromatic groups and various functional groups thereof, is natural and degradable, and has good physiological activity and the functions of adsorbing, absorbing, complexing, exchanging and the like. The formed porous structure canenhance the adsorbing or complexing actions on heavy metal ion particulate matters. When the composite material is used for pollution treatment and ecological remediation, heavy metals in a water body and land can be adsorbed; after the adsorption is completed, the composite material can also be used as soil fertilizer to improve soil structure, restore ecological balance and reduce chemical pollution.

Owner:SHAANXI UNIV OF SCI & TECH

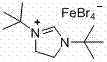

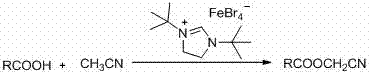

Method for synthesizing cyanomethyl carboxylate

ActiveCN107311890ARealize the esterification reactionReduce chemical pollutionCarboxylic acid nitrile preparationOrganic compound preparationDi-tert-butyl peroxideAcetonitrile

The invention discloses a method for synthesizing cyanomethyl carboxylate. According to the invention, the method employs an ionic iron (III) complex containing 1,3-di-tert-butylimidazoline cations and having a molecular formula of [(tBuNCH2CH2NtBu)CH][FeBr4] as a catalyst and di-tert-butyl peroxide as an oxidant, and synthesizes cyanomethyl carboxylate through an oxidative coupling reaction of carboxylic acid with acetonitrile. Applicative carboxylic acid substrates in the invention include aliphatic carboxylic acids, aromatic carboxylic acids and heterocyclic carboxylic acids. The method realizes synthesis of cyanomethyl carboxylate through the oxidative coupling reaction of carboxylic acid with acetonitrile under the action of an iron-based catalyst for the first time.

Owner:SUZHOU UNIV

No-tillage covering film cultivation method for paddy rice

InactiveCN107439289AReduce churnReduce the amount of applicationFertilising methodsPlant protective coveringsSoil biodiversityPlastic mulch

The invention discloses a no-tillage covering film cultivation method for paddy rice, belonging to the field of paddy rice cultivation methods. The cultivation method comprises the steps of trimming the surface of the field, weeding and ploughing stubble, applying basal fertilizer, covering film and punching holes, sowing and managing the field; water can be conserved through the covering of the mulching film on the ridge surface, soil erosion is reduced, so that soil biological development is promoted, and soil biodiversity is enriched; compared with conventional planting, the application amount of the herbicide and the chemical pollution can be reduced. The invention solves the technical problems that the production cost is high, the difficulty is large, and the working efficiency is low through the mode of no-tillage of the land and seed direct seeding during a tillage process or a seedling transplanting process, and social and economic benefits are improved.

Owner:广西那坡县翠株园林业科技有限公司

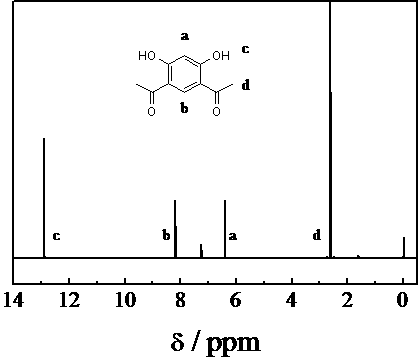

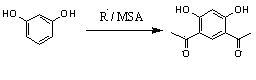

Method for preparing 4,6-diacetylresorcinol by acetylating resorcinol

ActiveCN103709024AReduce usageLow viscosityOrganic compound preparationCarbonyl compound preparation by condensationAcetic acidAcetic anhydride

The invention discloses a method for preparing 4,6-diacetylresorcinol by acetylating resorcinol under the action of methanesulfonic acid. The method mainly comprises the following step: by using methanesulfonic acid as a catalyst and acetic anhydride or acetic acid as an acylation reagent, reacting at 90-150 DEG C to convert resorcinol into the 4,6-diacetylresorcinol, wherein the methanesulfonic acid / acetic anhydride or acetic acid / resorcinol mole ratio is (0.5-5) / (1-5) / 1. Compared with the prior art, the method disclosed by the invention reduces the dependence on precursor chemicals, is more efficient, convenient and environment-friendly, and has the advantage of low cost.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

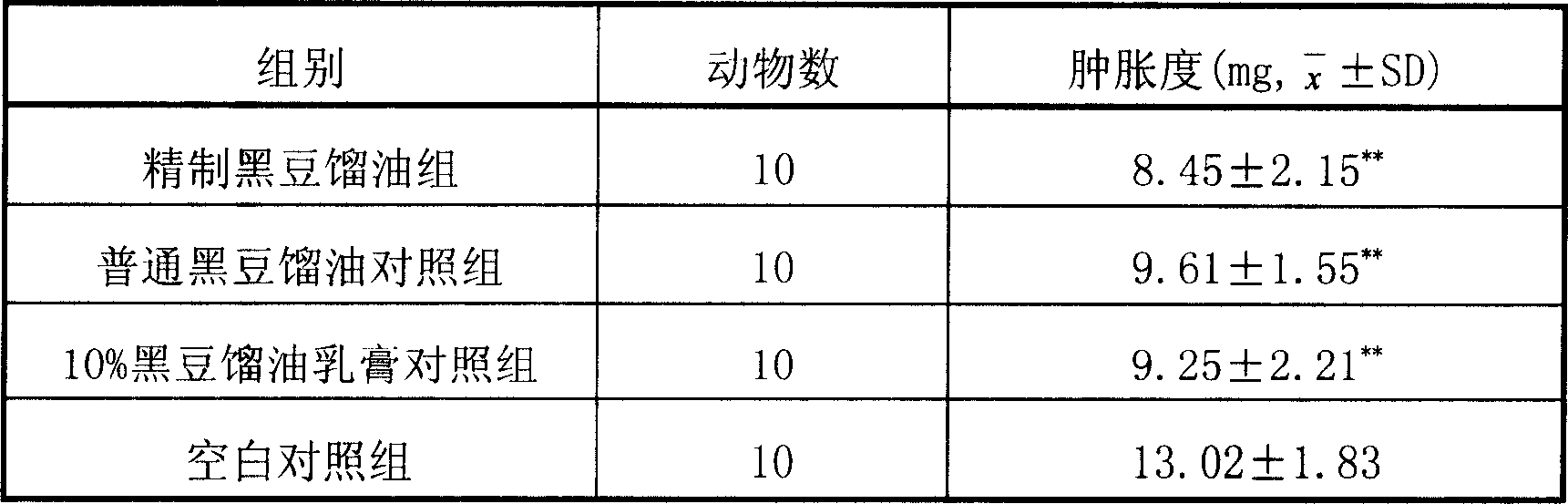

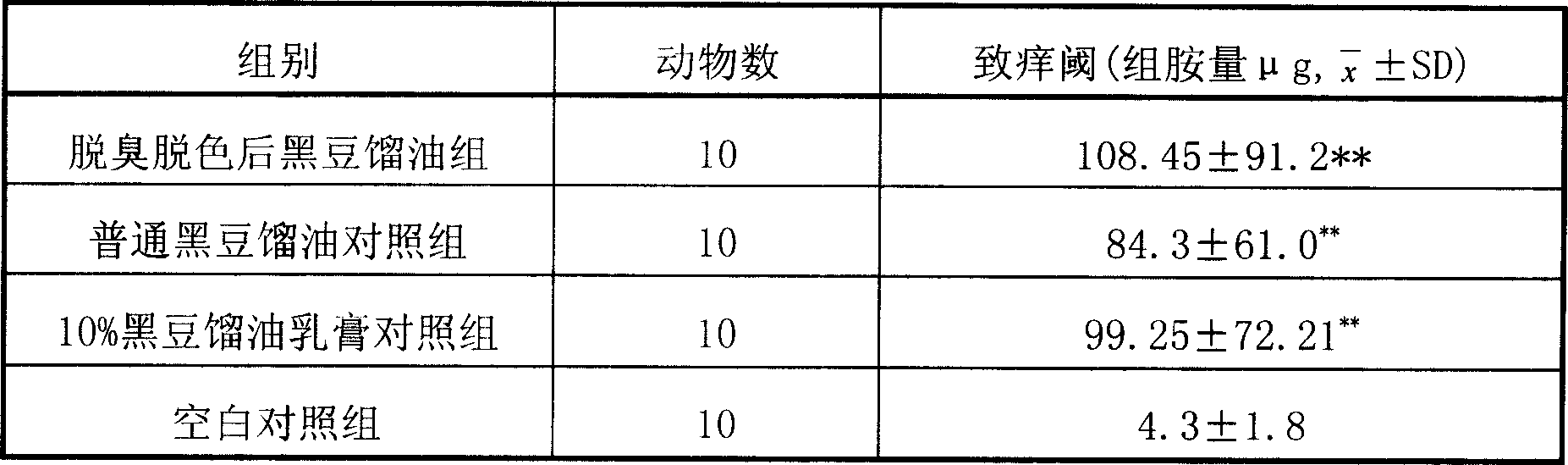

Refining method for black soya bean distillation oil

InactiveCN101015583AReduce chemical pollutionSave solventDistillation separationDermatological disorderGlycineOrganic solvent

This invention relates to a refine method for deodorizing Glycine max deflegmation oil. The invention adopts molecule short range distillation method to effectively separate component with special odour and dark brown color from Glycine max deflegmation oil, thereby obtaining light colored purified product without odour. The invention without the necessity for chemical organic solvents and specific installation has simple technology, short process time, simple operation, no enviromental pollution, and low cost; and dose not change the pharmacologic effect of processed odorless Glycine max deflegmation oil, and can improve dependance of patients.

Owner:CHONGQING HUAPONT PHARMA

Method of preparing nano ITO (Indium Tin Oxide) powder by ionic liquid

ActiveCN103803639AUniform particle sizeReduce chemical pollutionGallium/indium/thallium compoundsTin oxidesIonic liquidSodium hydroxide

The invention relates to preparation of ITO (Indium Tin Oxide) powder, and specifically relates to a method of preparing nano ITO (Indium Tin Oxide) powder by an ionic liquid. The method comprises the following steps: adding solid indium sulfate into the ionic liquid 1-butyl-3-methylimidazole trifluoromethanesulfonate, uniformly stirring, and then adding sodium hydroxide particles to obtain indium oxide powder; adding sodium hydroxide liquor into tin tetrachloride liquor, and then adding the ionic liquid 1-butyl-3-methylimidazole trifluoromethanesulfonate to obtain tin oxide powder; weighing the indium oxide powder and the tin oxide powder according to proportions, and mixing and grinding to obtain a mixture; and drying the mixture to obtain the ITO powder. Compared with mechanical grinding in the prior art, the method disclosed by the invention has the advantages that by taking indium sulfate and tin tetrachloride as raw materials, indium oxide and tin oxide powder are respectively prepared in the ionic liquid, and then the mixed power is grinded, so that the preparation process is less in chemical pollution; in addition, the prepared ITO powder is uniform in grain size, and the granularity can reach nanoscale.

Owner:广西华锡集团股份有限公司

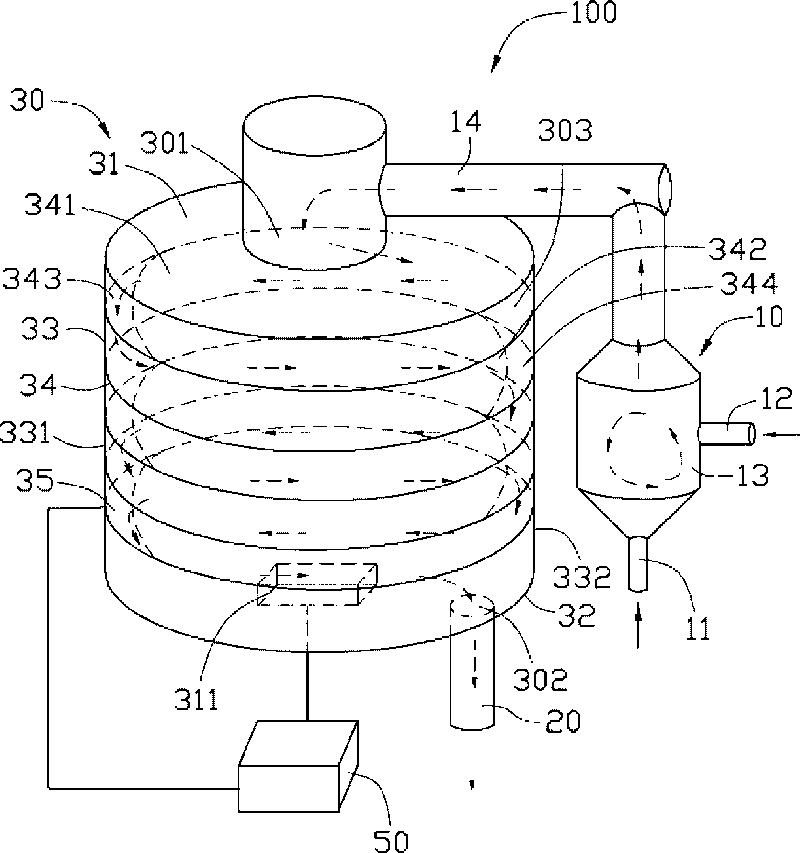

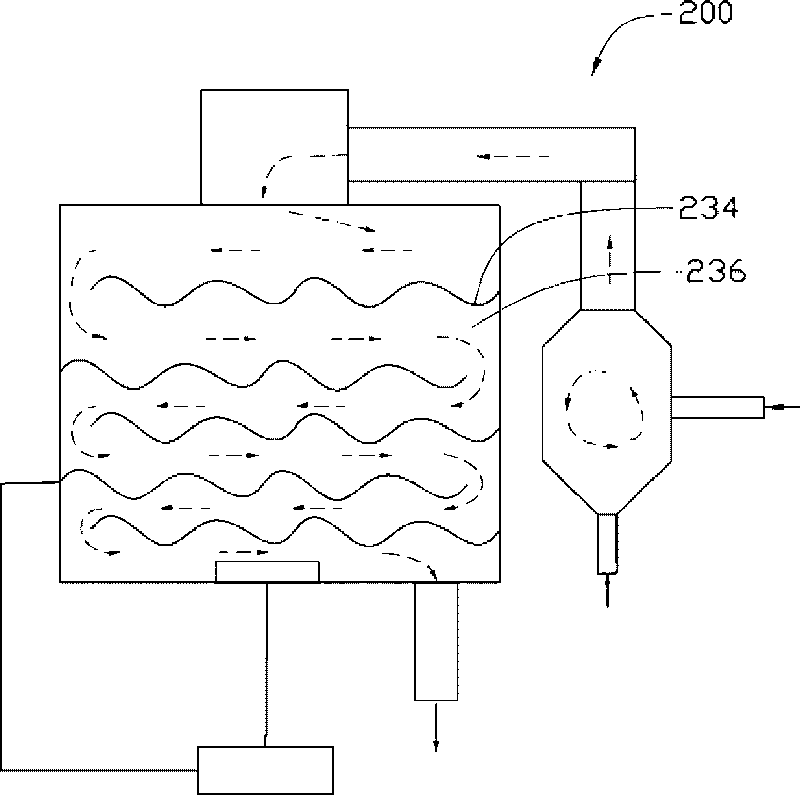

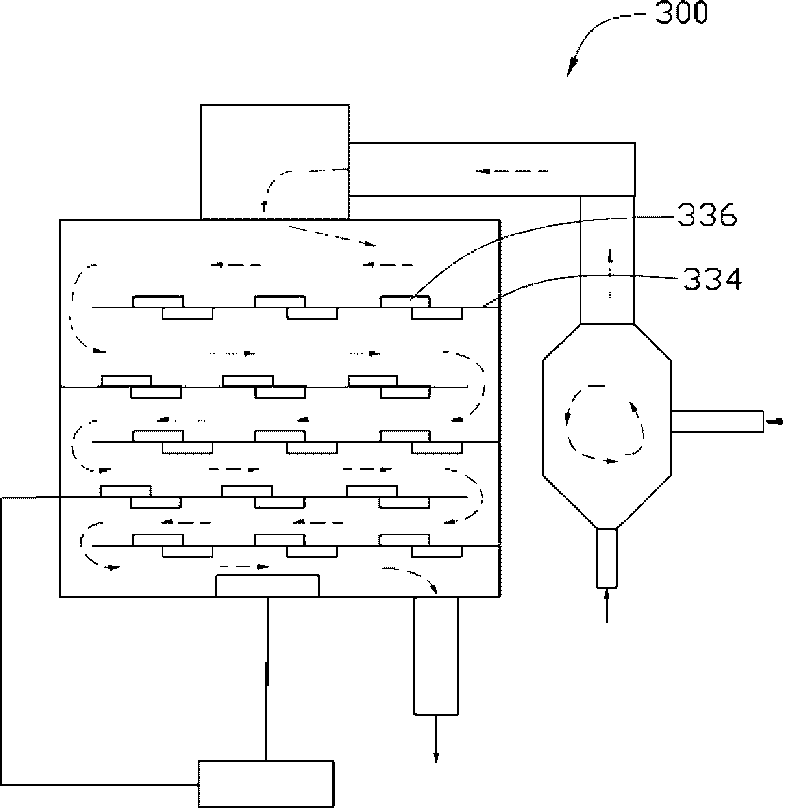

Chemical vapor deposition system

InactiveCN101760728AUniform concentrationFully lysedChemical vapor deposition coatingGas phaseAir pump

The invention provides a chemical vapor deposition system which comprises an air inlet device, an air pumping device and a reactor, wherein the reactor is connected between the air inlet device and the air pumping device; a carrier for containing a base is arranged in the reactor; a plurality of clapboards are arranged in the reactor between the air inlet device and the air pumping device; each clapboard is provided with at least one through hole; and the through holes between two adjacent clapboards are mutually staggered.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

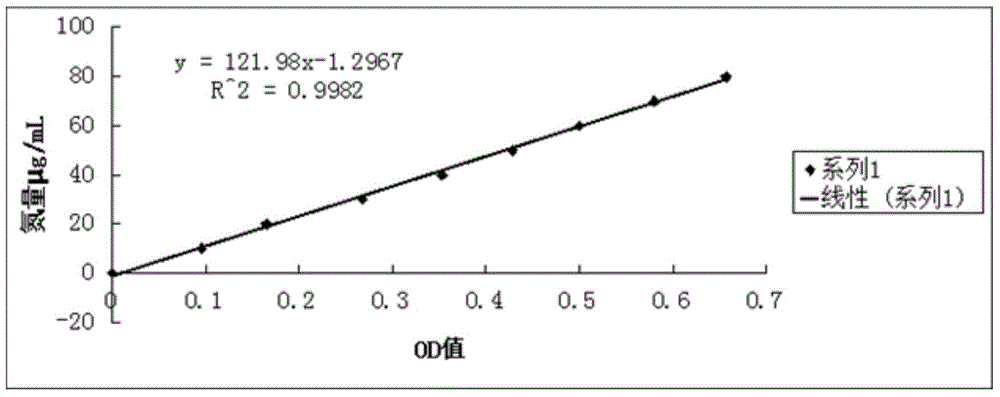

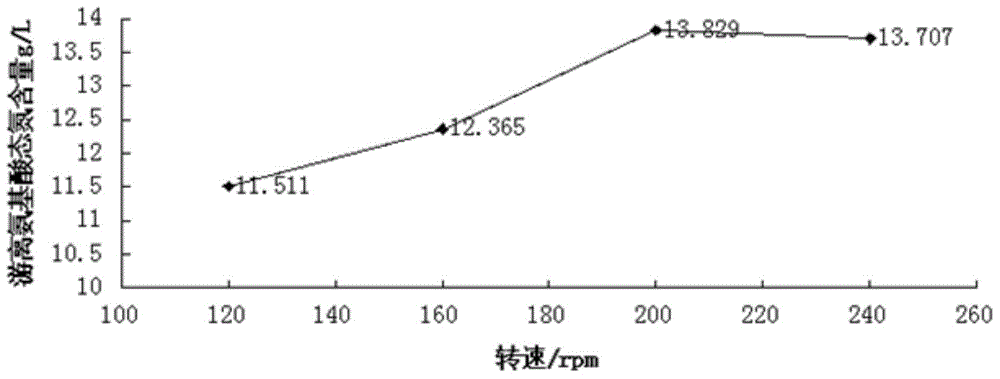

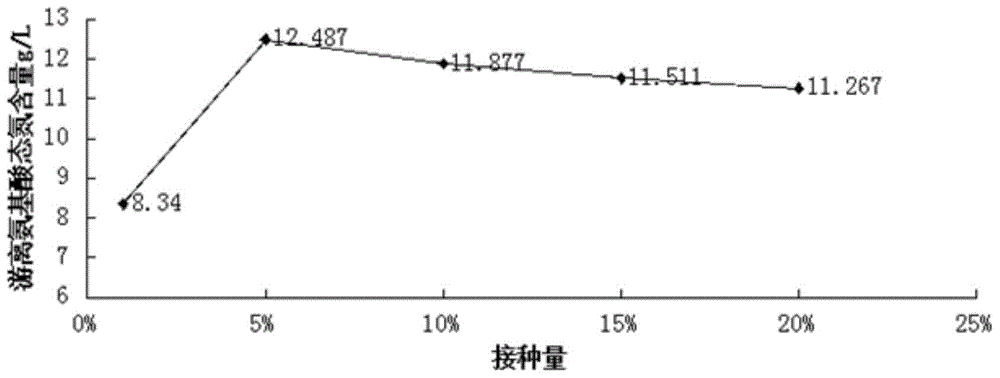

Method for fermenting aquatic product leftovers by mixed culture bacteria

InactiveCN104591808APromote growthSolve pollutionAnimal corpse fertilisersNitrogenous fertilisersBiotechnologyMixed culture

The invention discloses a method for fermenting aquatic product leftovers by mixed culture bacteria. The method is characterized by comprising the following step: fermenting the aquatic product leftovers by a combined bacterial strain, wherein the process parameters are as follows: rotation speed of 203 rpm, an inoculum size of 5% and a temperature of 30 DEG C. Under the condition, the content of nitrogen in free amino acid of the fermented liquor is up to 13.865g / L which is increased by 12.13% in comparison with the content (12.365g / L) before optimization, so that the water-soluble amino acid fertilization standards are met. The method is also suitable for preparing a microbial fertilizer.

Owner:ZHEJIANG OCEAN UNIV

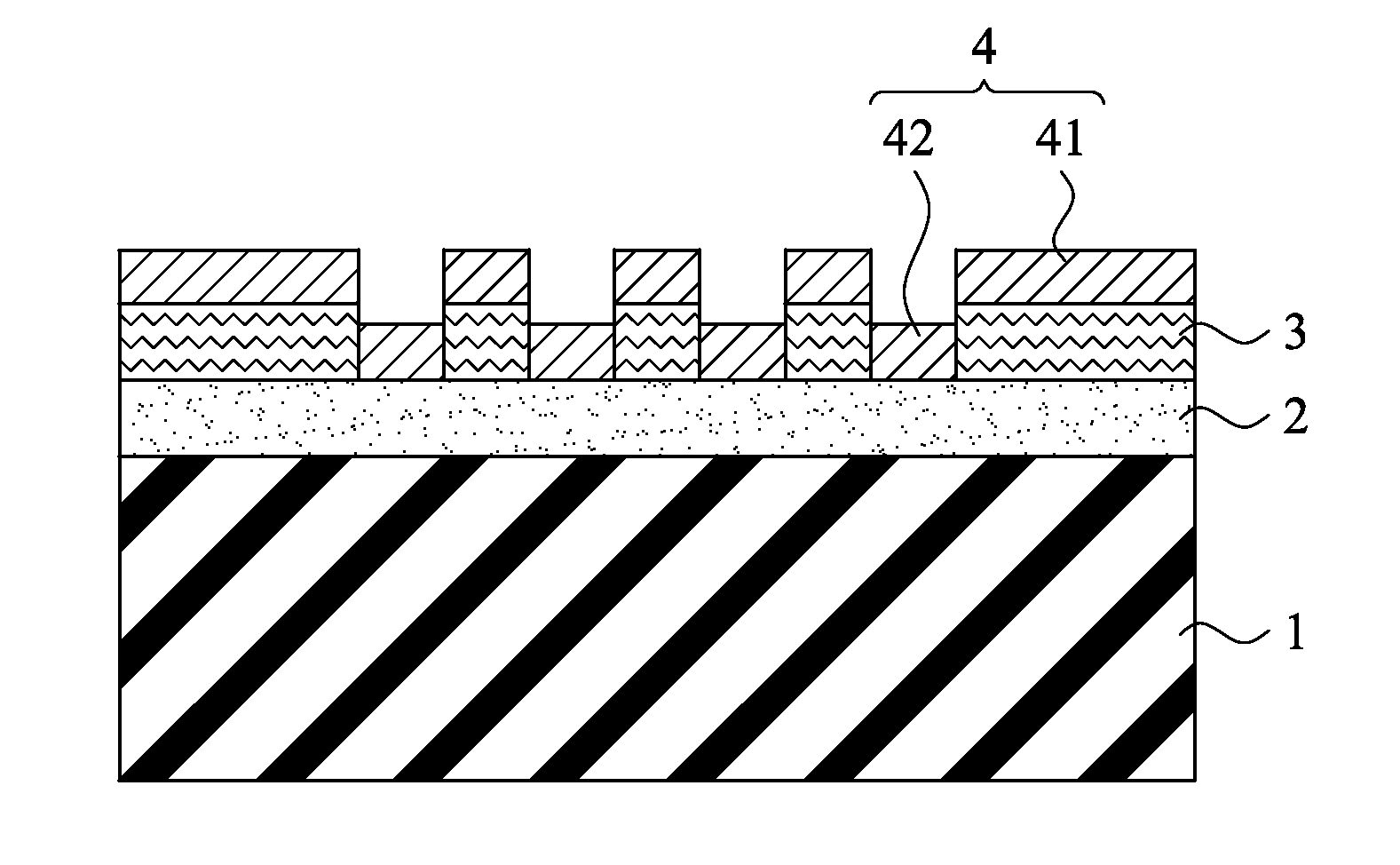

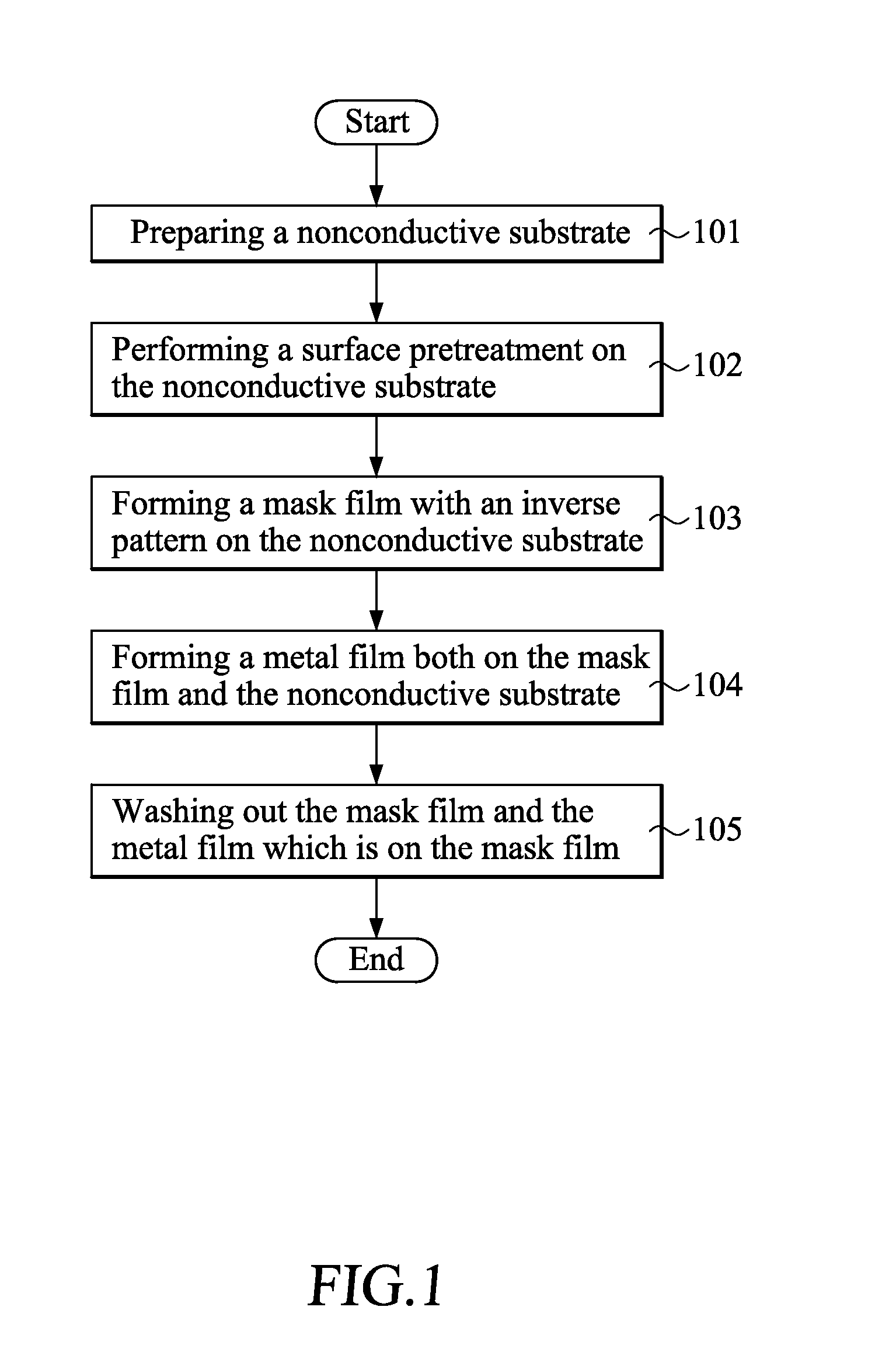

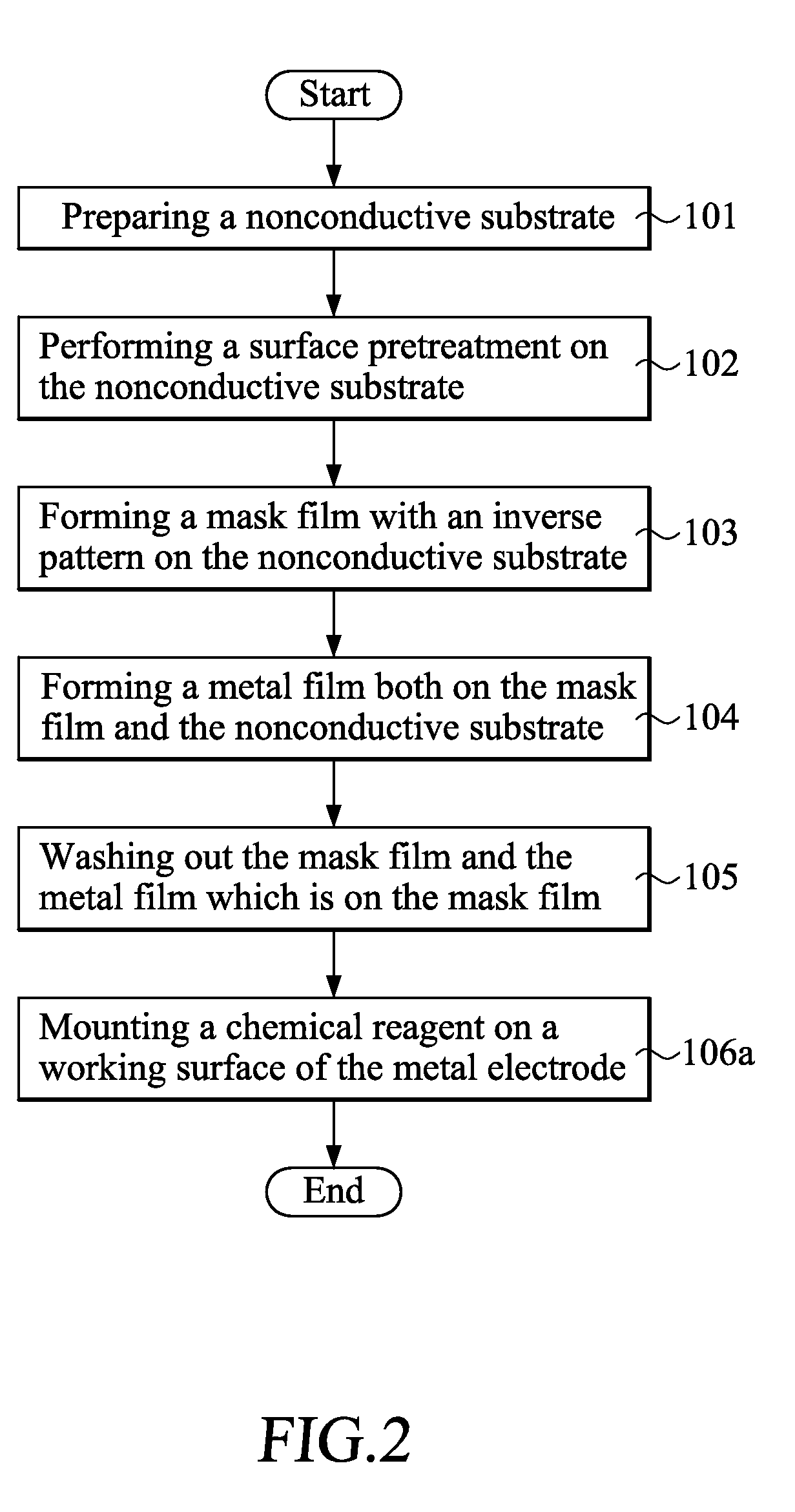

Method for manufacturing electrode pattern of disposable electrochemical sensor strip

InactiveUS20130171369A1Eliminating time in light exposingEliminating in etchingMicrobiological testing/measurementCoatingsOptoelectronicsWater soluble

Disclosed is a method for manufacturing an electrode pattern of a disposable electrochemical sensor strip. The method comprises steps of preparing a nonconductive substrate; forming a mask film with an inverse pattern on at least one side of the nonconductive substrate, said mask film is made of water soluble material or solvent soluble material; forming a metal film both on the mask film and the nonconductive substrate; and washing out, by water, solvent, or water solution, the mask film and the metal film which is on the mask film, so as to form a metal electrode with the electrode pattern on at least one side of the substrate of the disposable electrochemical sensor strip.

Owner:BRILLIANT SENSING TECH

Preparation method of microsphere accumulation type polystyrene porous material

The invention discloses a preparation method of a porous styrene thin film. The method comprises the following steps that (1) the styrene, a double bond containing comonomer, an initiating agent, a stabilizing agent and a cross-linking agent are added into a solvent prepared by absolute ethyl alcohol and deionized water; stirring is performed; the reaction is performed for 8 to 24h at the temperature of 70 to 80 DEG C; styrene copolymerized microspheres are obtained; (2) the prepared styrene copolymerized microspheres and polymers with opposite charges are mixed in an ethyl alcohol-water solvent; (3) a mixture is poured into a container; after the microspheres are settled, the solvent naturally evaporates; a polystyrene material is obtained; (4) the styrene obtained in the step (3), anhydrous ferric chloride and FDA (formaldehyde dimethyl acetal) are added into a 1,2-dichloroethane solvent; the polystyrene porous material is prepared. The preparation method has the advantages that thepreparation cost is greatly reduced; the adsorption capacity of carbon dioxide materials is improved; the chemical pollution of the materials in the preparation process is reduced; the porous materialof different sizes can be prepared; the industrial batch production and application is easy.

Owner:HUBEI UNIV

Epoxysuccinic acid polymer and preparation method thereof and system and method for treating water by combining epoxysuccinic acid polymer, magnetic field and static electricity

ActiveCN106279530AEasily biodegradableMild preparation conditionsScale removal and water softeningWater/sewage treatment by magnetic/electric fieldsPolymer scienceMeth-

The invention relates to an epoxysuccinic acid polymer and a preparation method thereof and a system and method for treating water by combining the epoxysuccinic acid polymer, a magnetic field and static electricity. The epoxysuccinic acid polymer is prepared by copolymerizing, by mass, 1 part of an epoxysuccinic acid monomer, 0.2-0.4 part of an itaconic acid monomer and 0.1-0.3 part of a 2-acrylamide-2-methanesulfonic acid monomer. The epoxysuccinic acid polymer takes epoxysuccinic acid as the main monomer, integrates a carboxylic acid group, a sulfonic acid group and an amide group into a whole and has the good scale inhibiting and dispersing performances, and the scale inhibiting rate can be effectively increased when the epoxysuccinic acid polymer is combined with the magnetic field and the static electricity to conduct water treatment.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

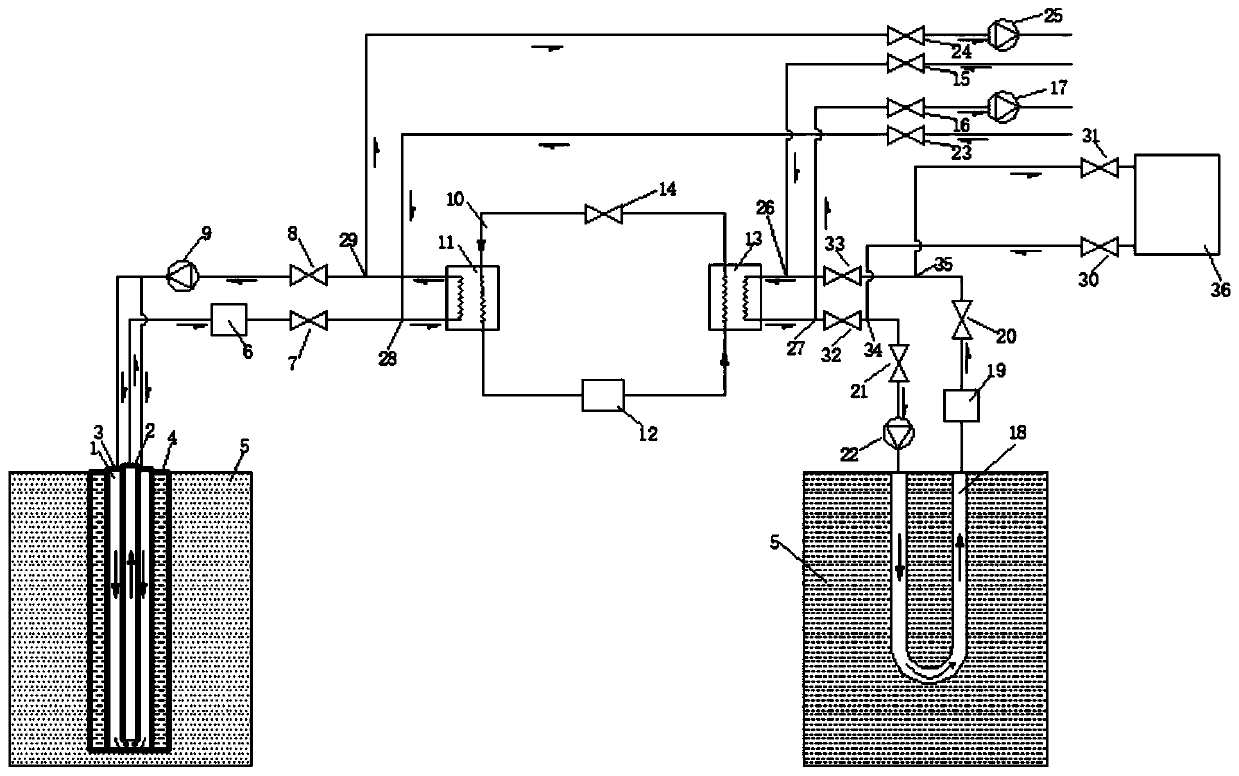

Geothermal energy combined operating system

PendingCN109869935ATemperature recoveryReduce hot and cold imbalanceLighting and heating apparatusGeothermal energy generationEngineeringThermoregulation

The invention discloses a geothermal energy combined operating system. The geothermal energy combined operating system comprises a medium deep stratum geothermal downhole heating supply system, a shallow stratum buried pipeline system, a transition season circulating pipeline, a heat pump unit, in-house circulating pipelines and a building terminal thermoregulation system. The in-house circulatingpipelines comprise the winter circulating pipeline and the summer circulating pipeline. The medium deep stratum geothermal downhole heating supply system and the shallow stratum buried pipeline system communicate with the building terminal thermoregulation system through the heat pump unit and the in-house circulating pipelines. Heating and cooling are alternately implemented by regulating valveson the corresponding pipelines to be turned on and turned off. According to the geothermal energy combined operating system, the medium deep stratum geothermal downhole heating supply system can getmedium deep stratum geothermal heat energy on the premise of only using heat and not using water and makes full use of the medium deep stratum geothermal heat energy to supply heat to a ground building in winter; the shallow stratum buried pipeline system makes full use of shallow soil to provide cold energy for the ground building in summer. Tkothermal energy combined operating system is ingenious in design, reasonable in layout, safe and environment-friendly.

Owner:HEBEI UNIV OF ENG

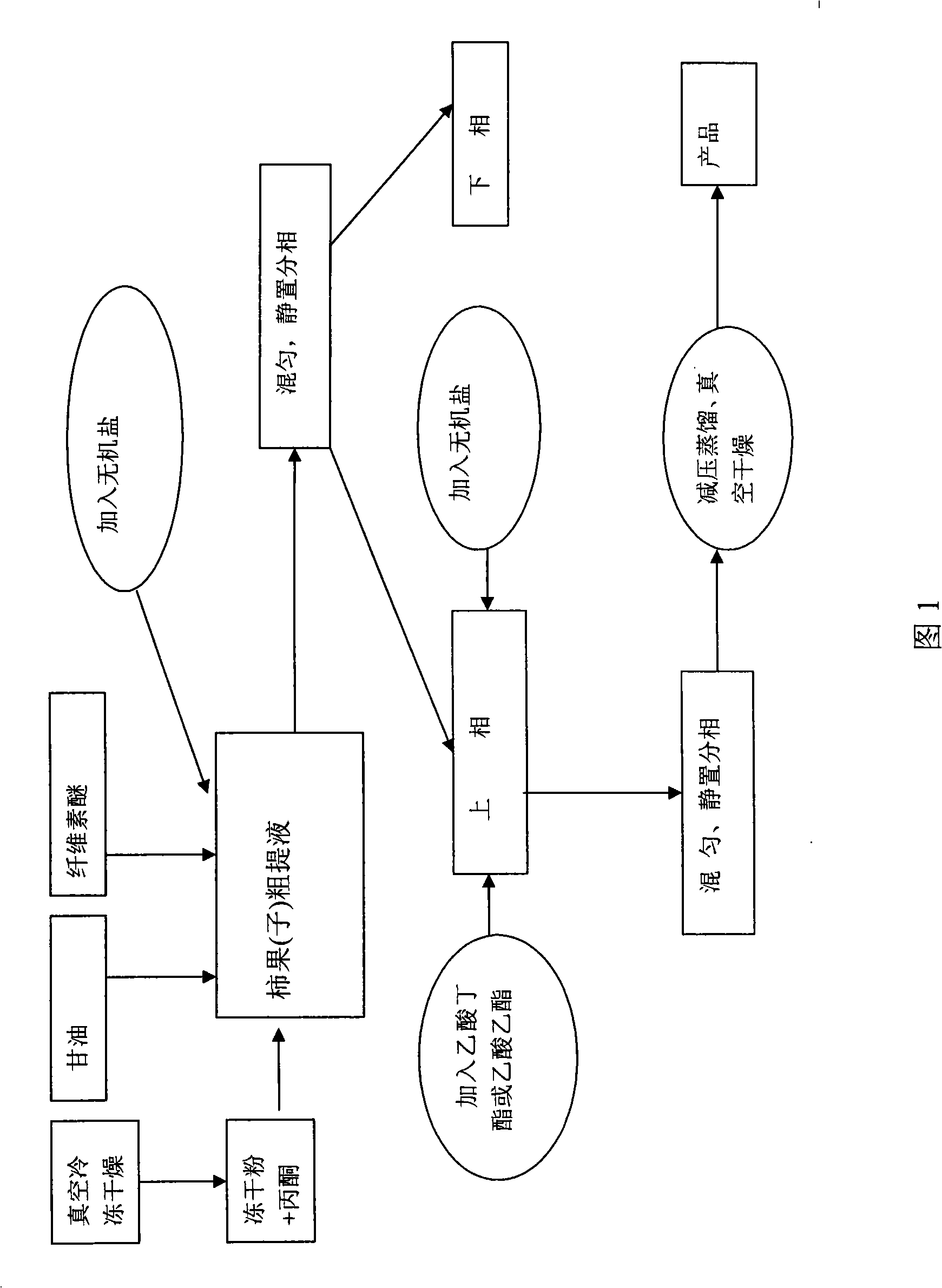

Process for double-aqueous-phase extracting and refining persimmon lycopene

InactiveCN101311148AHigh extraction rateImprove qualityExtraction purification/separationCelluloseInorganic salts

The invention relates to an aqueous two-phase extraction and refinement method for persimmon lycopene, which is technically characterized in that persimmons are washed; after rotten fruits are removed, the persimmons are diced, carry out vacuum freeze drying, and are crushed, added with acetone, and then carry out solid-liquid extraction; after filtering, lycopene crude extract is obtained. The crude extract is taken, added with cellulose ether and glycerin aqueous two-phase system, evenly mixed and divided into an upper phase and a lower phase. The phase of cellulose ether which is rich in lycopene is taken out, added with water, acetic ester and inorganic salt for evenly mixing. The phase of acetic ester which is rich in lycopene is taken out for reduced pressure distillation and solution concentration, and then the concentrated solution carries out vacuum drying to obtain lycopene solid. The invention has the advantages that the method increases the extraction yield of persimmon lycopene, obtains high-quality lycopene solid, which is economical, nontoxic, simple in operation and easy for industrial production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Digital intelligent scale-removing device

InactiveCN101555073AZero maintenance costEnergy saving and water saving effectScale removal and water softeningWater cyclingWater treatment

The invention discloses a digital intelligent scale-removing device, belonging to the technical field of scale prevention and removal of liquid flow flowing through a heated surface in water treatment. The device is connected with a water inlet end pipeline of a water circulating system by a flange, the outer part thereof adopts stainless steel pipes as a skeleton and the inner part thereof is made into a lattice by special alloy plates and is arranged in stainless steel pipe cavities; a nano generating layer is coated or melted on the special alloy plates which are connected by welding or mechanical matching and are connected with the stainless steel pipes by welding or mechanical matching. The device generates active ions, utilizes the active ions to activate scaling factors to disturb the scaling process and achieve the purposes of preventing scale and removing scale, and can be used for scale prevention and removal of devices of heat exchangers, water cooling walls, cooling and condensing equipment, hot water boilers and the like.

Owner:浙江欧可美科技股份有限公司

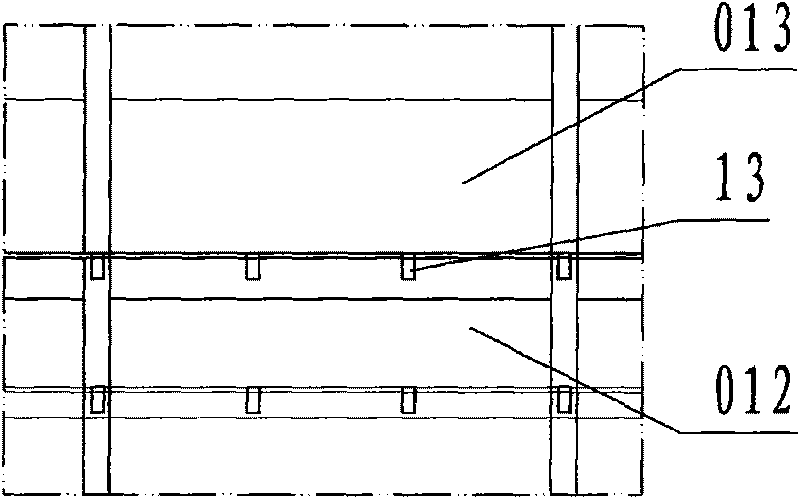

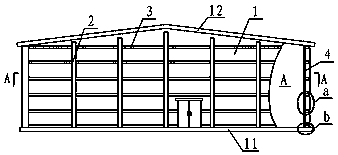

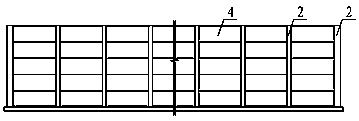

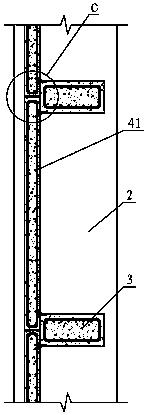

Assembled frame-type horizontal warehouse, prefabricated wallboard mould and construction method of horizontal warehouse

PendingCN110259237ALong construction periodBuild fastWallsMouldsSupporting systemReinforced concrete

The invention discloses an assembled frame-type horizontal warehouse, a prefabricated wallboard mould and a construction method of a horizontal warehouse. In recent years, steel plate silos develop rapidly due to the characteristics of the high construction speed, the short construction period, the low cost and the like, however, the fatal weakness of the steel plate silos is that the silo wall is thin, the temperature is greatly affected by the outside world, grain and other items which have strict requirements for the temperature and moisture are prone to mildewing, decaying and other phenomena in the storage process, it is difficult to store the grain for a long time, and the service life of the steel plate silos is short. The assembled frame-type horizontal warehouse comprises a frame-type warehouse body (1), the frame-type warehouse body is connected with a foundation (11) and a warehouse top (12), the frame-type warehouse body comprises a group of reinforced concrete stand columns (2) located at the four walls of a wall body, reinforced concrete connecting beams (3) are arranged between the reinforced concrete stand columns to form a supporting system of the warehouse top, and the reinforced concrete stand columns (2) and the reinforced concrete connecting beams (3) are connected with a reinforced concrete prefabricated wallboard (4). The assembled frame-type horizontal warehouse is used for horizontal warehouse construction.

Owner:刘全义

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com