Chemical vapor deposition system

A technology of chemical vapor deposition and air intake device, which is applied in the field of chemical vapor deposition system, can solve the problems of chemical pollution and particle pollution, complex reaction mechanism, difficult to control, etc., and achieve the effect of fast reaction rate, reduced gas phase reaction and uniform concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The chemical vapor deposition system of the technical solution will be further described in detail below in conjunction with the accompanying drawings and multiple embodiments.

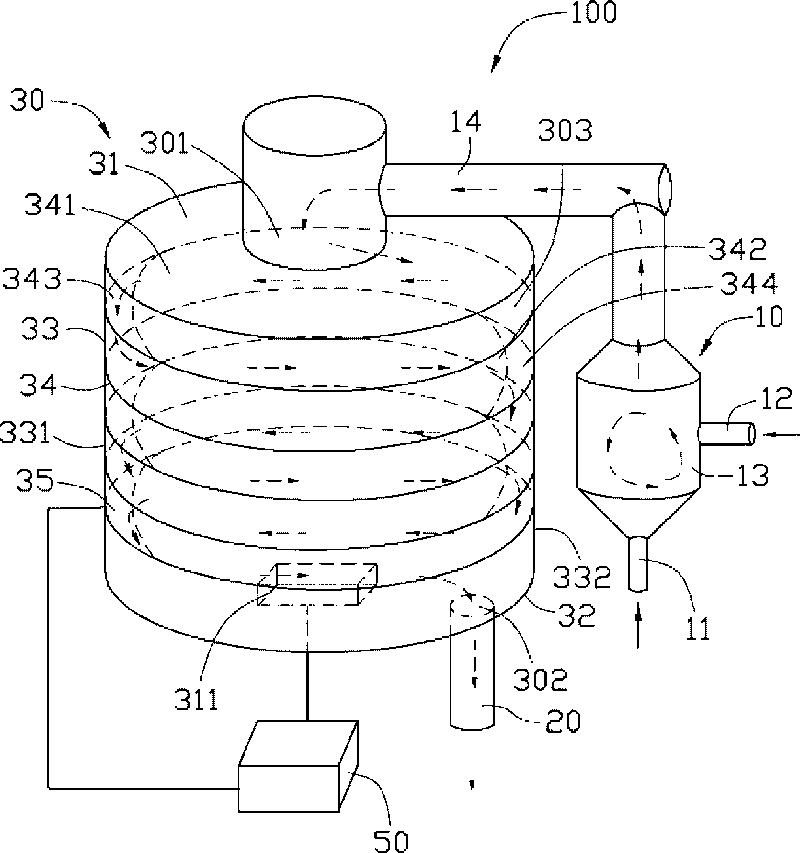

[0018] see figure 1 The chemical vapor deposition system 100 provided in the first embodiment of the technical solution includes an air inlet device 10 , an air extraction device 20 and a reactor 30 connected between the air inlet device 10 and the air extraction device 20 .

[0019] The gas inlet device 10 is connected to one end of the reactor 30 to provide reaction gas to the reactor 30 . The intake device 10 includes a first intake duct 11 , a second intake duct 12 , a gas mixing chamber 13 and a main intake duct 14 .

[0020] The first gas inlet pipe 11 communicates with the gas mixing chamber 13 and is used for transporting the vaporized precursor to the gas mixing chamber 13 . The second gas inlet pipe 12 is also in communication with the gas mixing chamber 13 for delivering auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com