Graphene-metallic oxide nano-particle three-dimensional porous composite material

A nanoparticle, three-dimensional porous technology, applied in the field of nanomaterials manufacturing, can solve the problems of high equipment requirements, high energy consumption, unfavorable practical application, etc., achieve uniform concentration, simple method, and increase the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 50mg of graphene oxide and 80mg of copper nitrate as raw materials, dissolve them in 100ml of deionized water, and mix them evenly by ultrasonic;

[0021] The obtained product is frozen by a refrigeration compressor to obtain a solid, and then dried and dehydrated under low-temperature negative pressure;

[0022] The obtained product was heated to 200° C. and kept for 10 hours in the air to obtain a three-dimensional porous composite material of graphene-copper oxide nanoparticles.

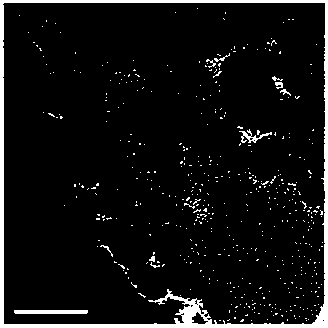

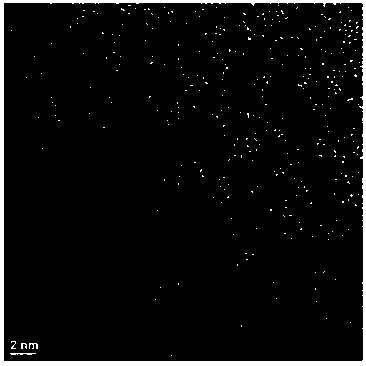

[0023] The product was characterized by transmission electron microscopy, and the results were as follows: figure 1 shown. The product was characterized by scanning electron microscopy, and the results were as follows: figure 2 It can be seen that the composite material is a porous structure.

Embodiment 2

[0025] Dissolve 20 mg of graphene oxide and 50 mg of cobalt nitrate in 20 ml of deionized water, and mix evenly by stirring;

[0026] Immerse the obtained product in liquid nitrogen and freeze it into a solid, and then carry out low-temperature negative pressure dehydration treatment in a freeze dryer;

[0027] The obtained product was heated to 800° C. in hydrogen for 30 minutes to obtain a three-dimensional porous composite material of graphene-cobalt tetraoxide nanoparticles.

[0028] The product was characterized by transmission electron microscopy, and the results were as follows: image 3 shown.

Embodiment 3

[0030] Dissolve 10mg of graphene oxide and 100mg of zinc nitrate in 50ml of deionized water, and mix them uniformly by ultrasonic;

[0031] The obtained product is subjected to refrigerating compressor freezing and drying;

[0032] The obtained product was heated to 1100° C. for 10 seconds in nitrogen to obtain a three-dimensional porous composite material of graphene-zinc oxide nanoparticles.

[0033] The obtained result is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com