Patents

Literature

290results about How to "Fully lysed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

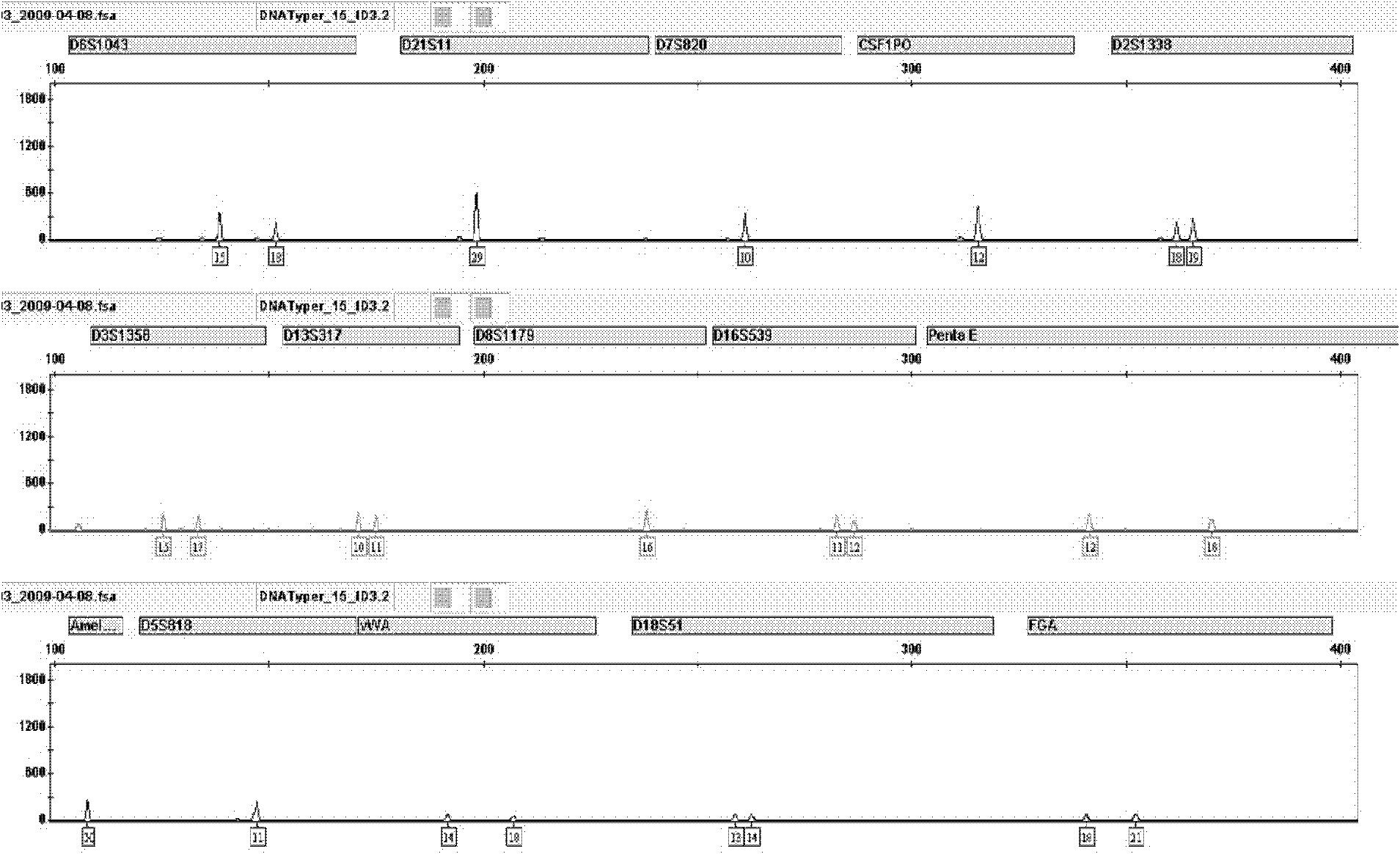

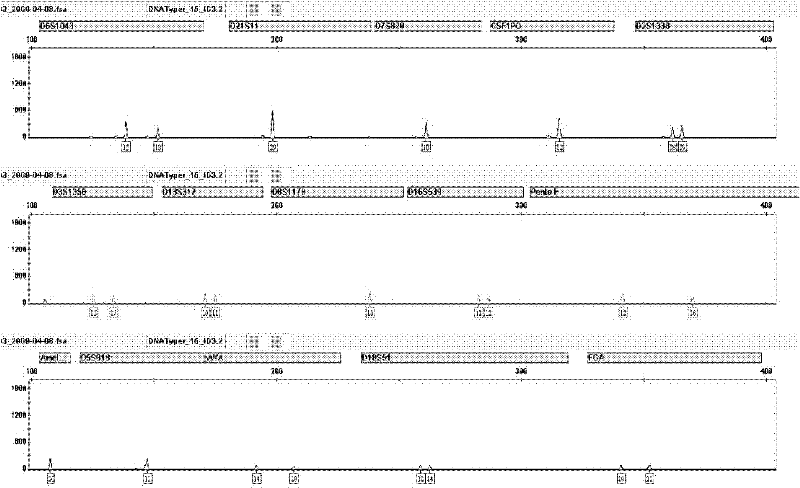

Method for extracting and purifying DNA

InactiveCN101613697AEasy to operateImplement extractionSugar derivativesDNA preparationBiological cellLysis

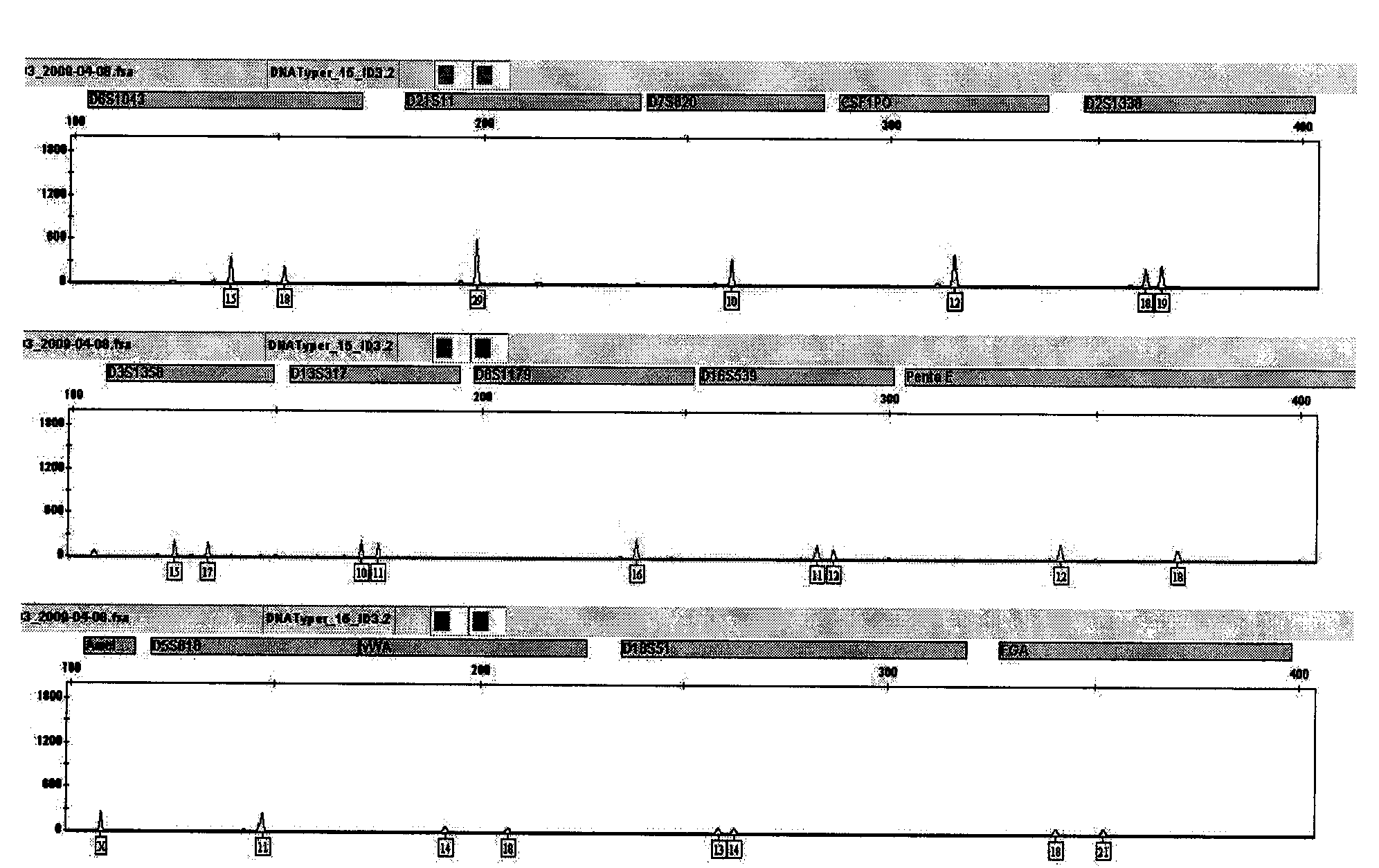

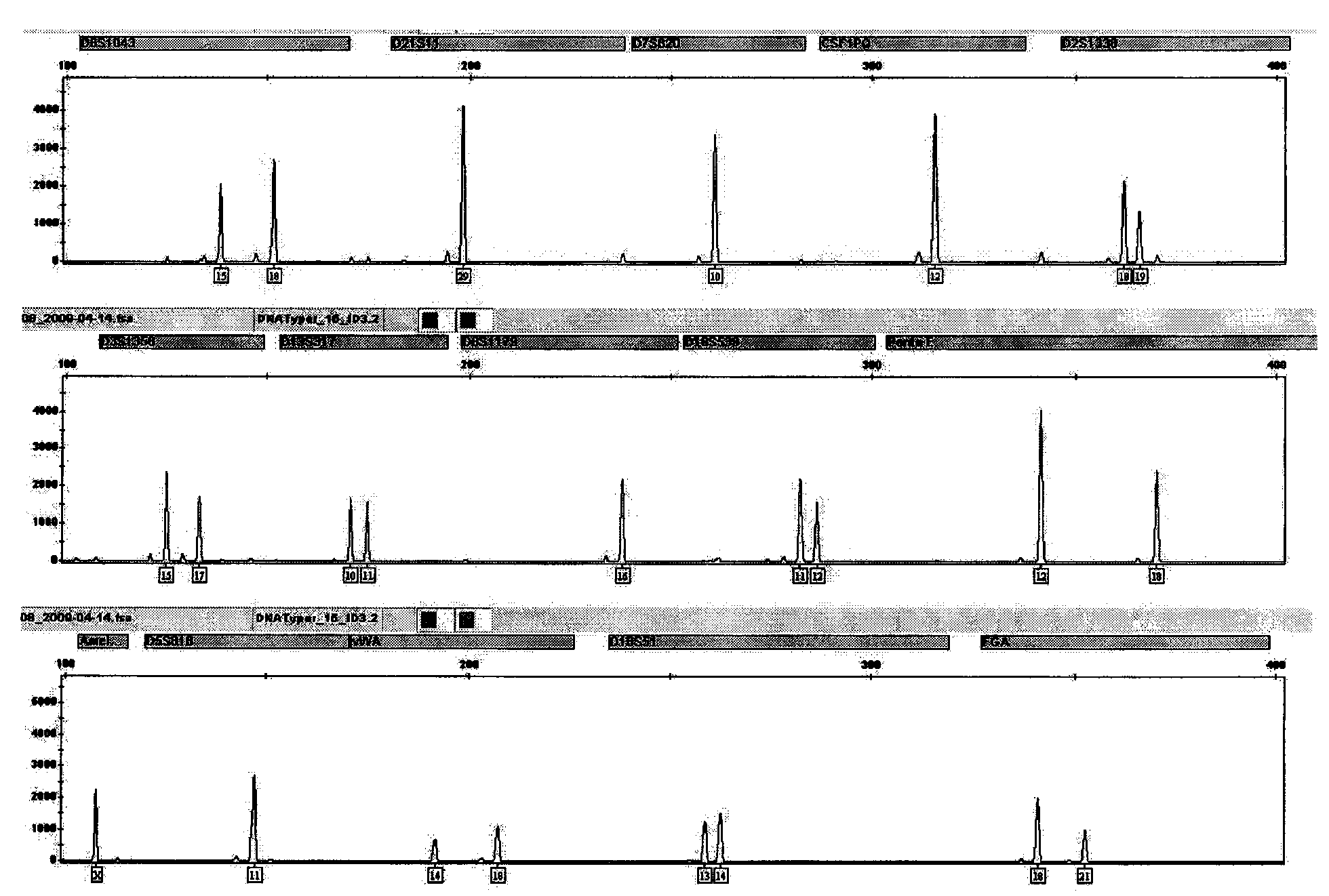

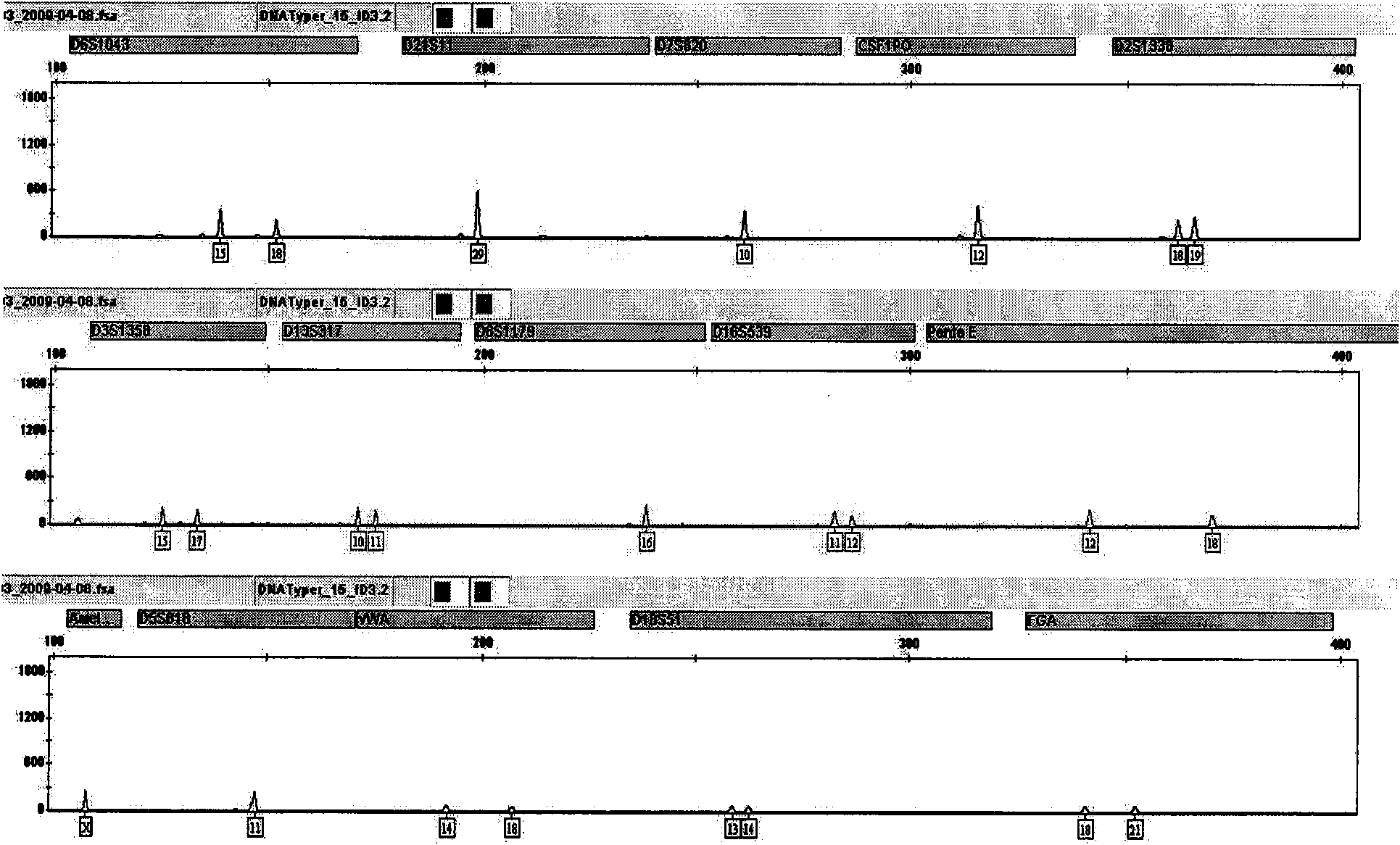

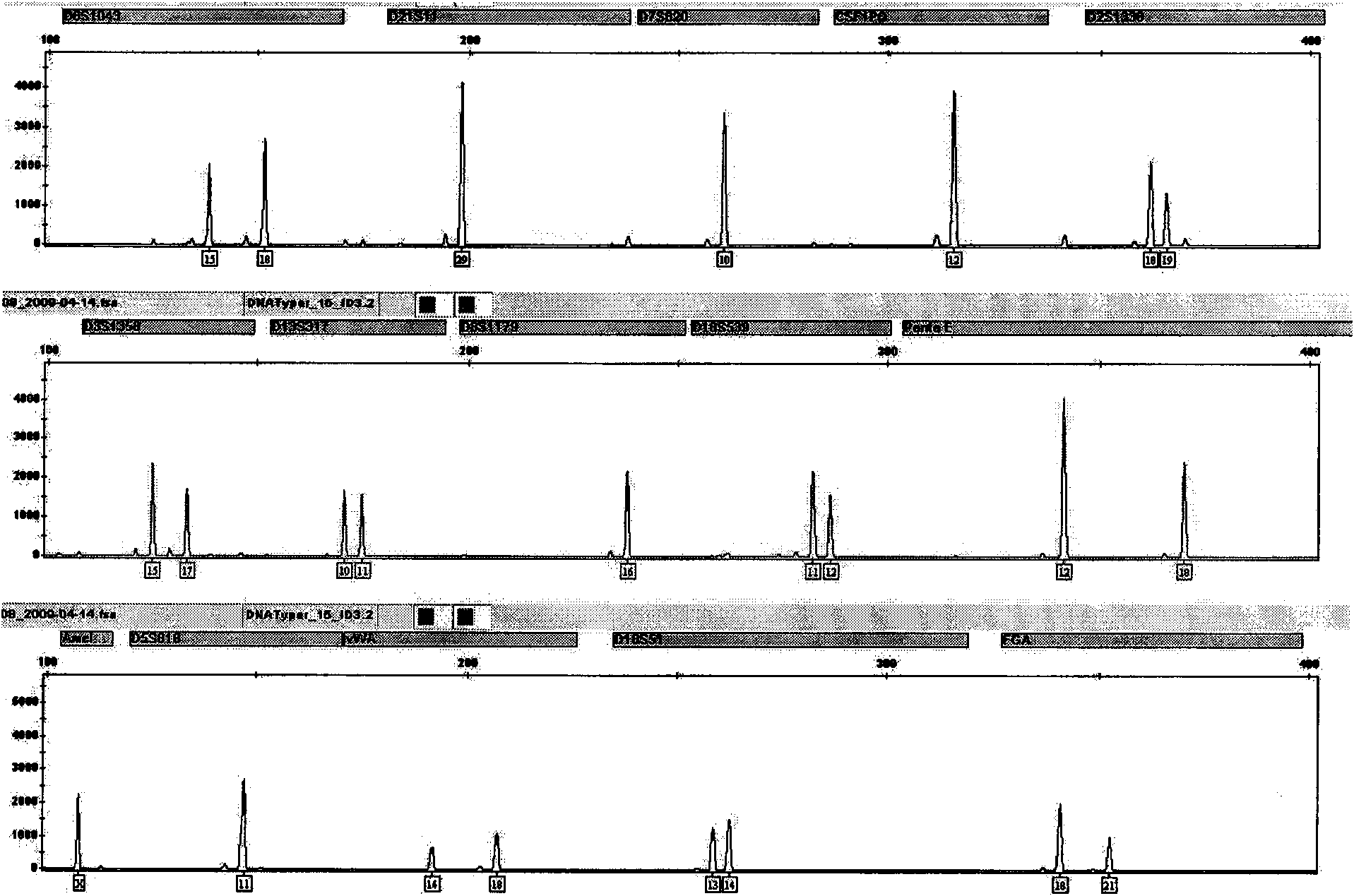

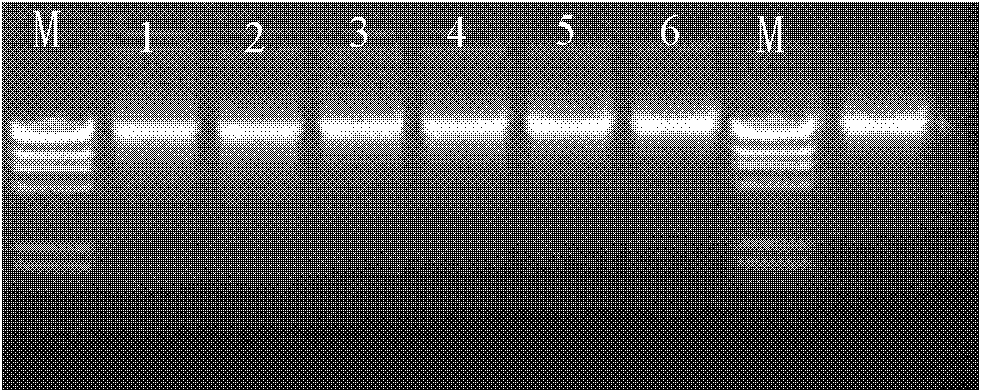

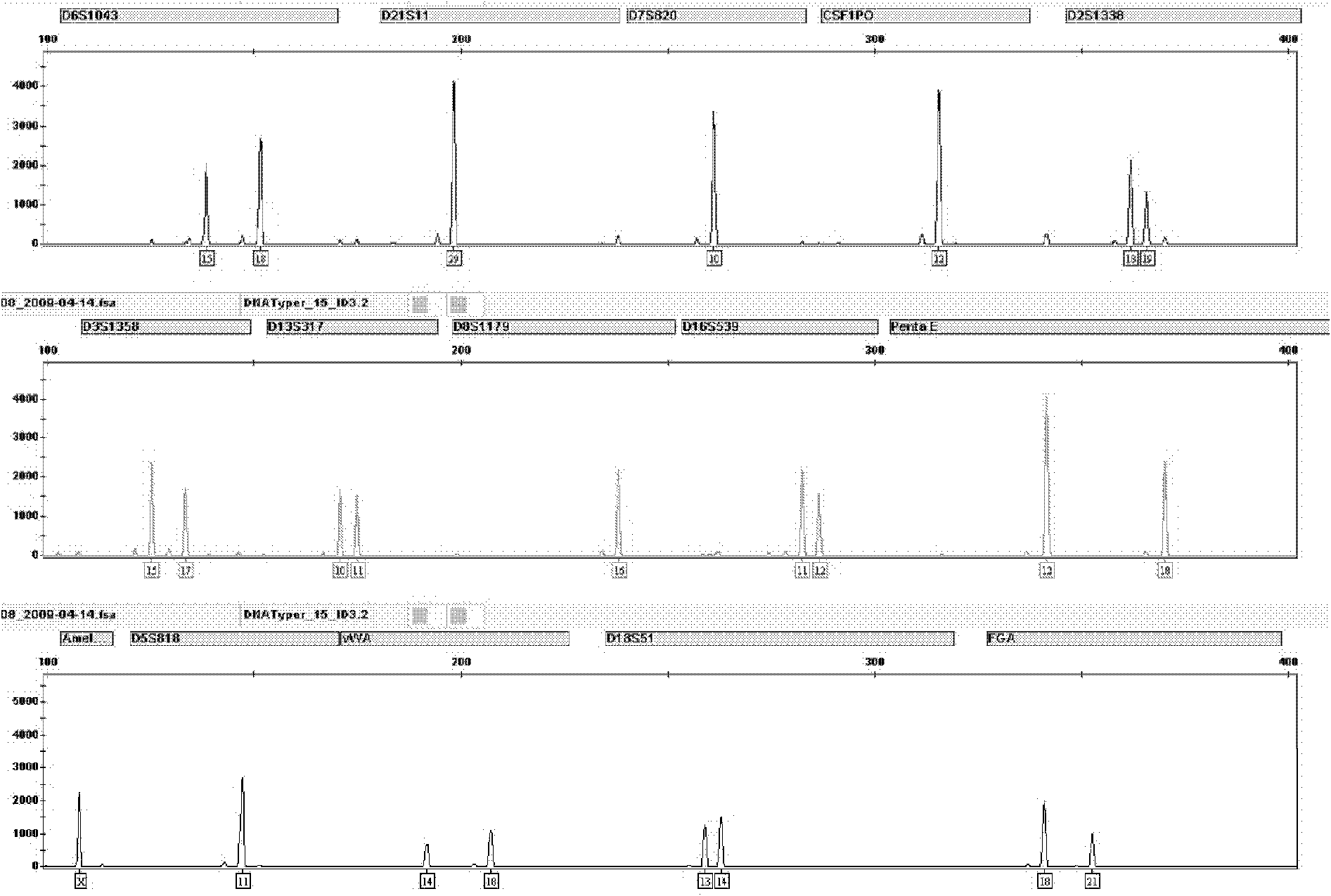

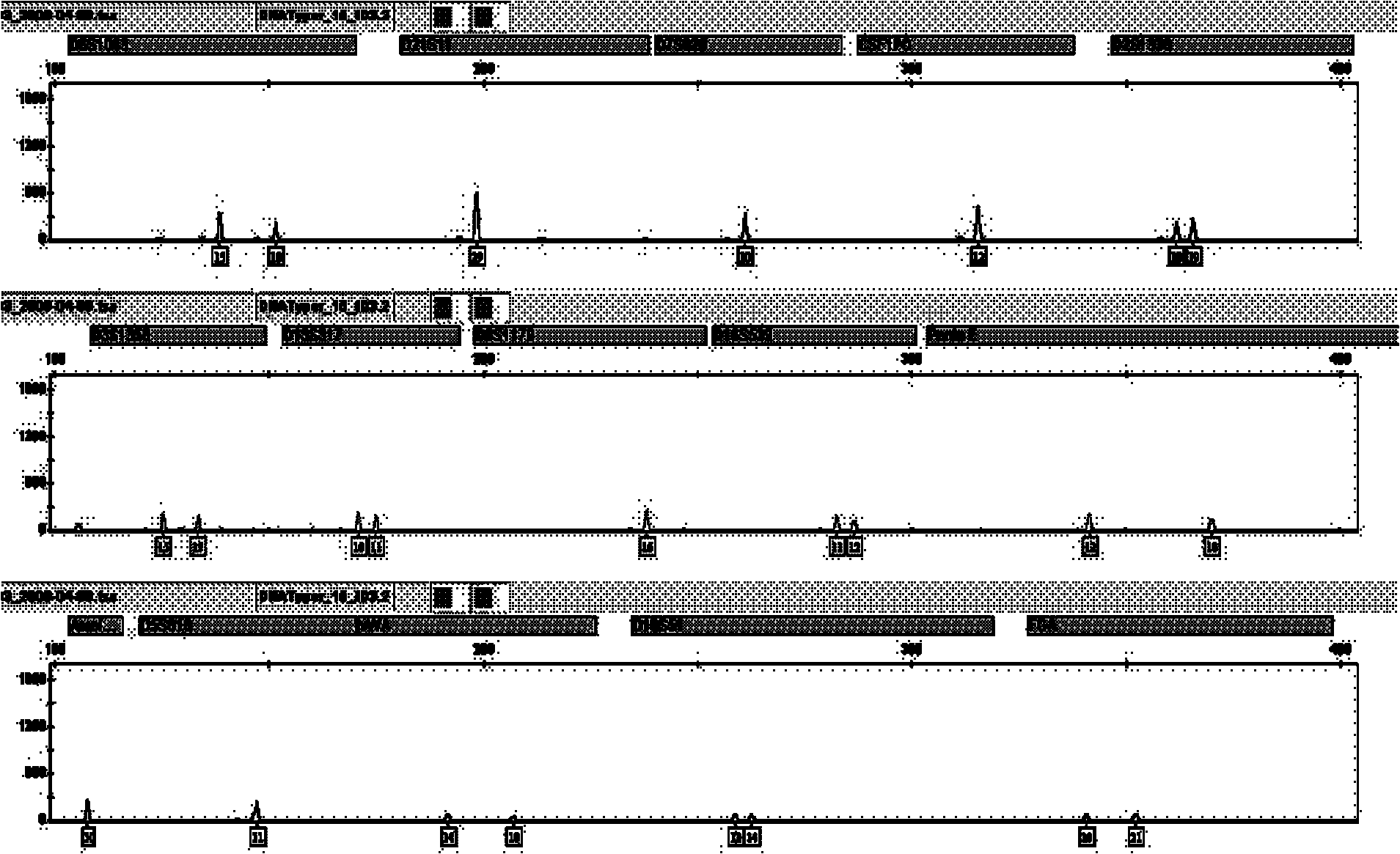

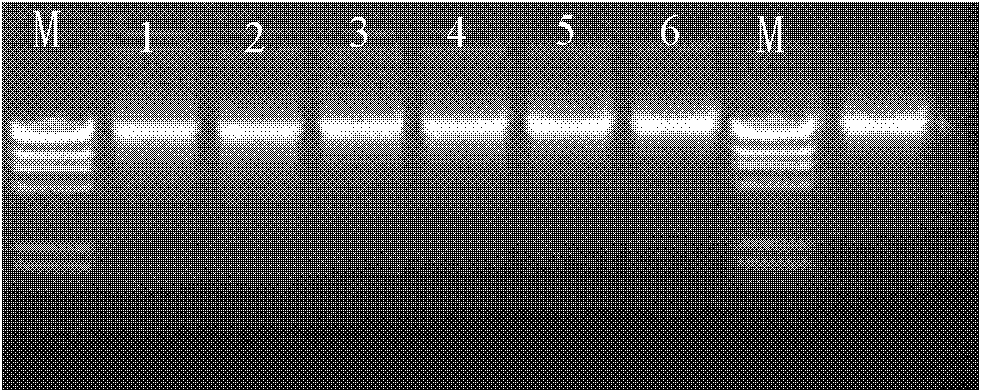

The invention discloses a method for extracting and purifying DNA, comprising the following steps: 1) pre-treatment: a biological sample is in contact with pre-treated lysis solution, and solid substance adhering to biological cells is removed to obtain rude lysis solution; 2) nucleic acid adsorption: the rude lysis solution obtained in step 1 is mixed with lyse combined liquid and magnetic bead suspension to form a solution system containing magnetic nanosphere-DNA composite body, and the magnetic nanosphere-DNA composite body in the solution system is collected; 3) washing: the magnetic nanosphere-DNA composite body obtained in step 2 is successively washed with a cleaning solution I and a cleaning solution II, and then DNA is dissolved out by spent regenerant. The method provided by the invention has 90% of the DNA extracting efficiency, the extracted DNA can be used in down stream analysis operation, such as STR multiplex amplification, DNA sequencing, DNA quantitation and the like.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

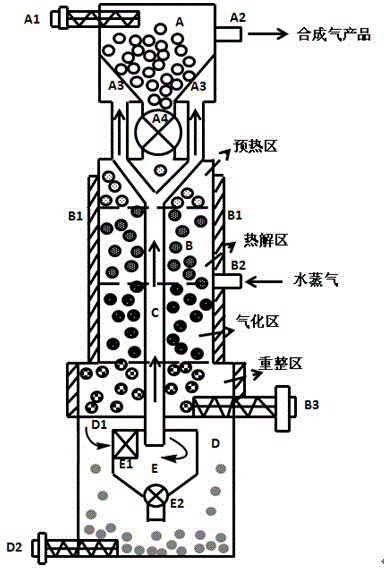

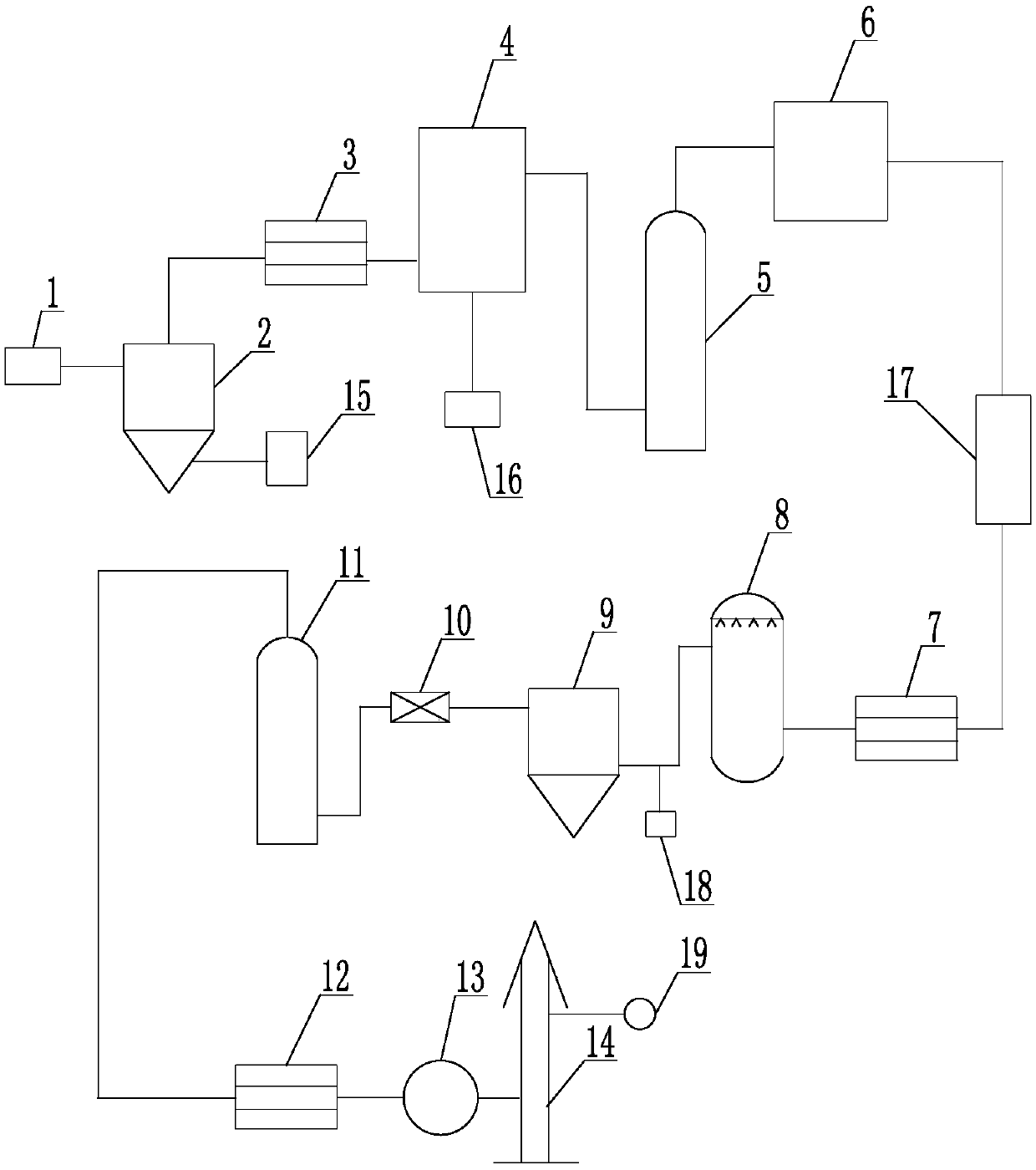

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Reagent for extracting and purifying DNA

ActiveCN101613696AMeet the extraction requirementsEasy to operateSugar derivativesDNA preparationMicrosphereMagnetic bead

The invention discloses a reagent for extracting and purifying DNA, comprising the following substances: preprocessing lysis solution with pH of 7.4-8.5: water serves as solvent, and solute comprises the substances with the following final concentration: 10-100mM of buffer salt, 0.5%-5% of surface active agent, 1-100mM of chelating agent, 50-150mM of soluble salt, and 0.2-4mg / ml of protease K; pyrolysis combined liquid with pH of 6.4-7.4: water serves as solvent, and solute comprises the substances with the following final concentration: 20-150mM of buffer salt, 3-8 of MChaotropic salt, 1-10% of surface active agent, 0.5-4% of amphoteric ion detergent, 10-100mM of chelating agent and 15-30% of alcohol; cleaning solution I: water serves as solvent, and solute comprises the substances with the following final concentration: 4-6 of MChaotropic salt, 25-50% of alcohol and 10-100mM of chelating agent; cleaning solution II is 75% of ethanol water solution; spent regenerant is TE (10mM Tris-HCl, 1mMEDTA, and pH is 8.0); magnetic bead suspension is nanoscale silicone coated magnetic microsphere (50-100mg / ml).The DNA extracting efficiency is as high as 93.67% by adopting the reagent.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

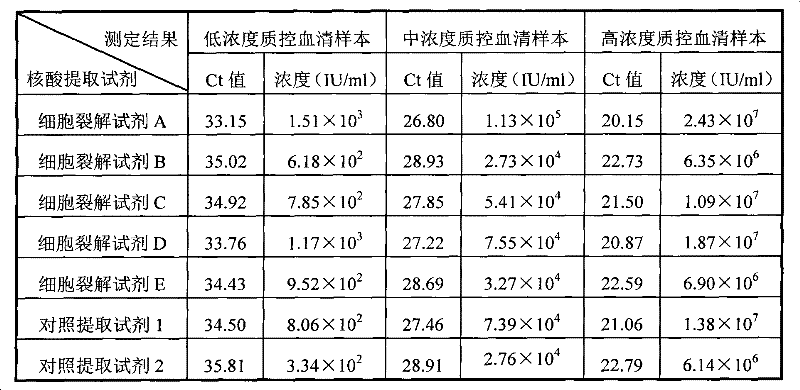

Cell lysis reagent for extracting and purifying nucleic acids in biological samples

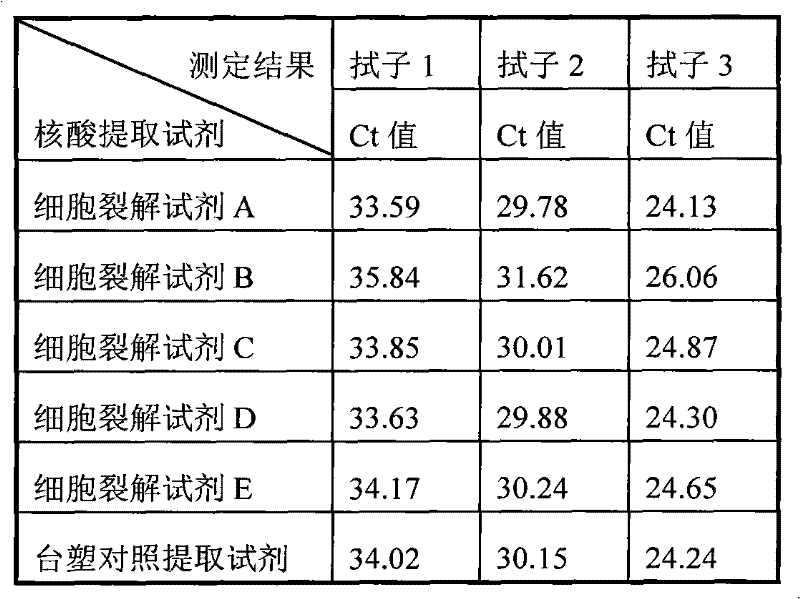

The invention discloses a cell lysis reagent for extracting and purifying nucleic acids in biological samples. The solution of the reagent is alkaline and contains the following components: guanidinium, ammonium ions and a surface active agent, thereby, cells in the biological samples can be more fully cracked in an alkali solution-phase environment, and nucleic acids [deoxyribonucleic acid / ribonucleic acid (DNA / RNA)] released out of the cells can be promoted to be combined and absorbed with a solid material, and finally, is separated from the solid material through an elution step. The cell lysis reagent disclosed by the invention has the advantages of simplness and convenience in operation and high extraction yield of the nucleic acids, and can be used for extracting and purifying the nucleic acids in the biological samples with various types, such as whole blood, serum, blood plasma, saliva, urine, cerebrospinal fluid, cell and tissue culture solution or human nasopharynx and urogenital canal swabs and the like.

Owner:SHANGHAI XINGYAO MED TECH DEV CO LTD +1

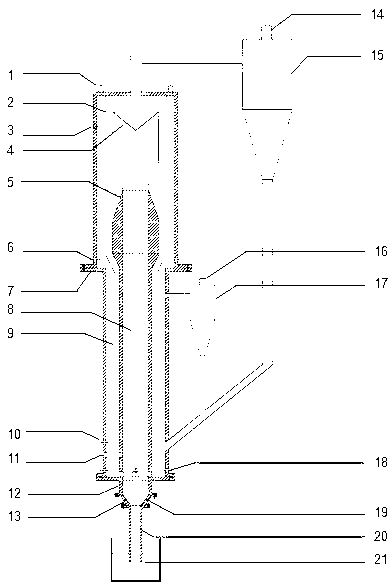

Small efficient medicinal rubbish pyrolysis incinerator

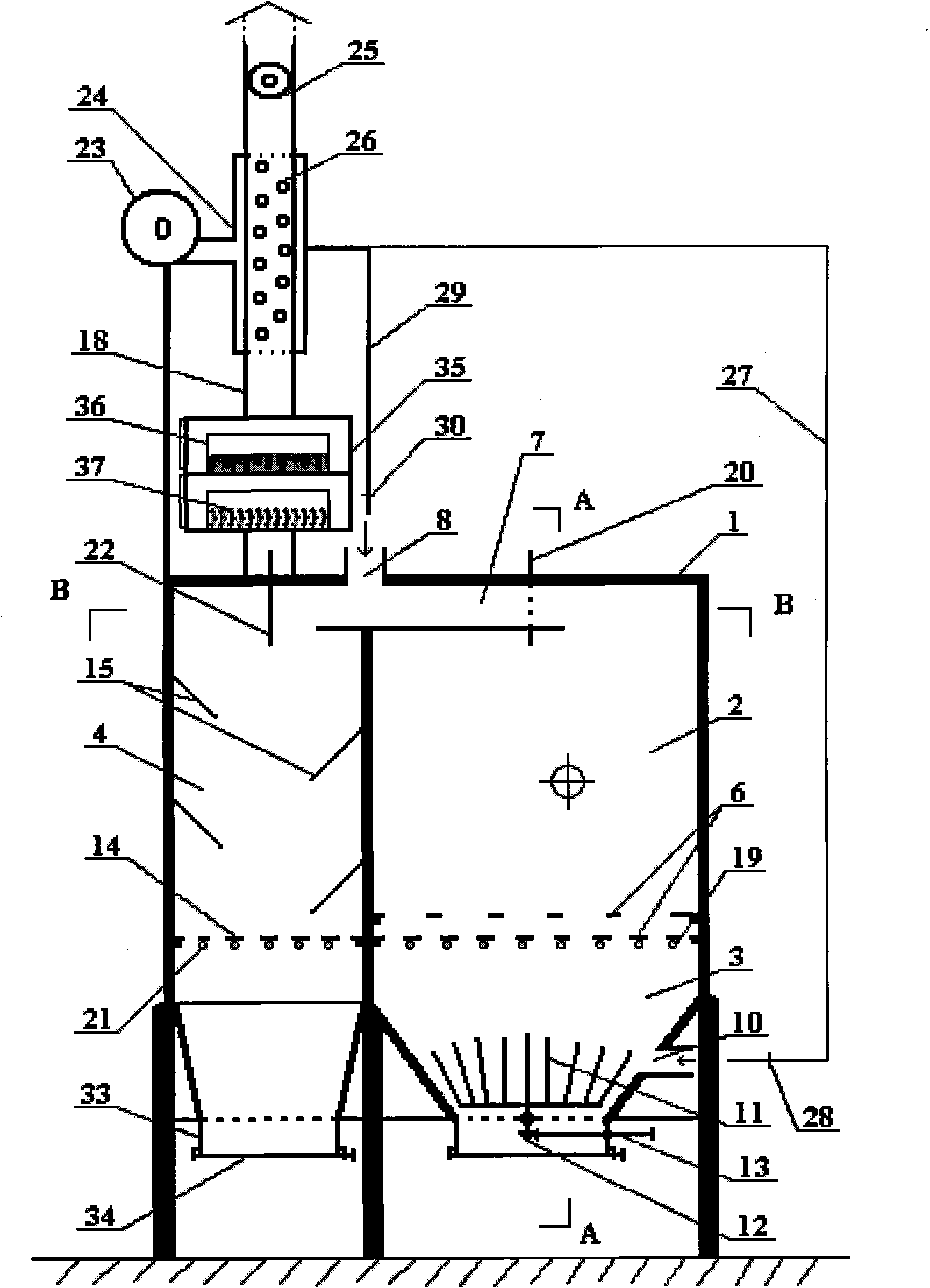

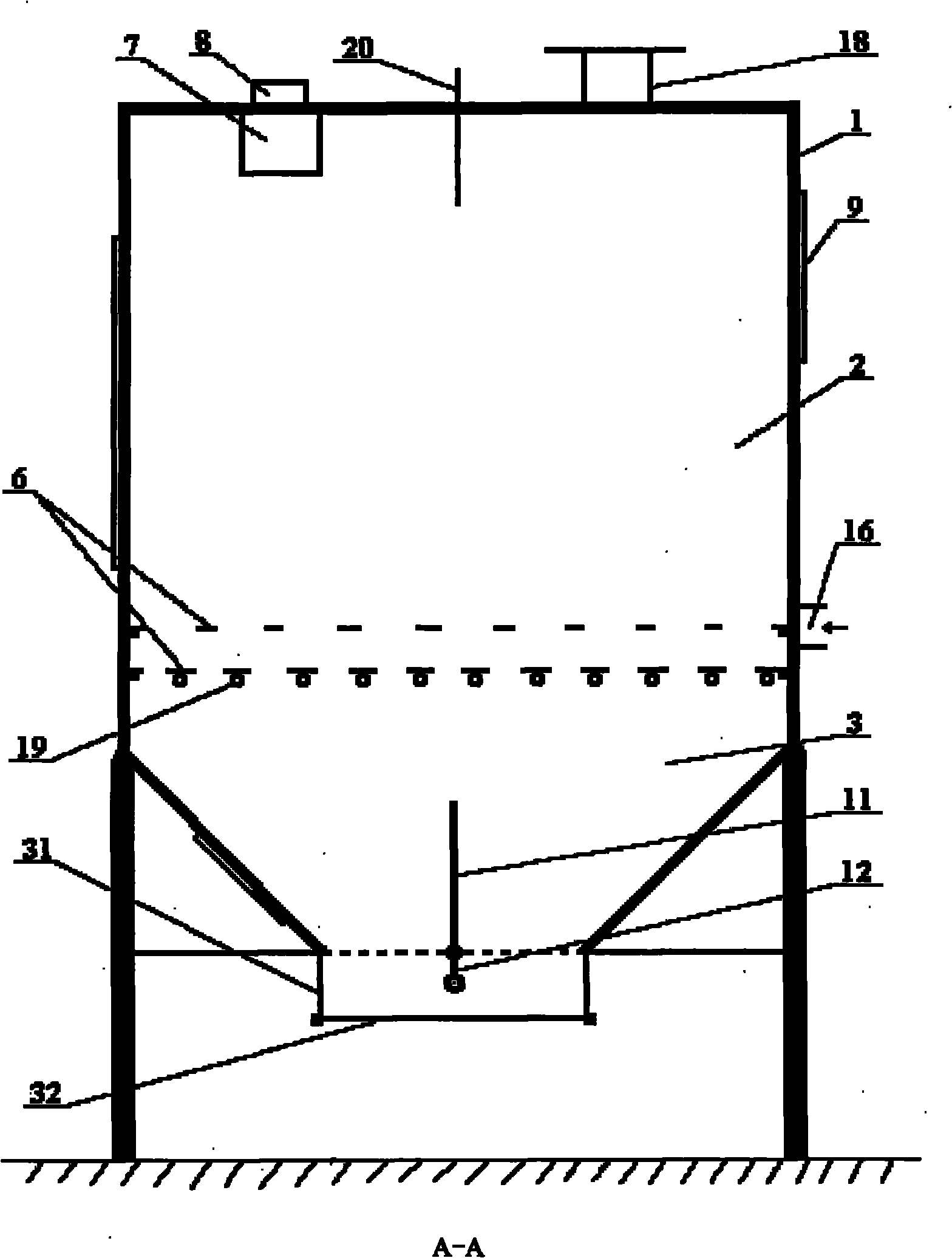

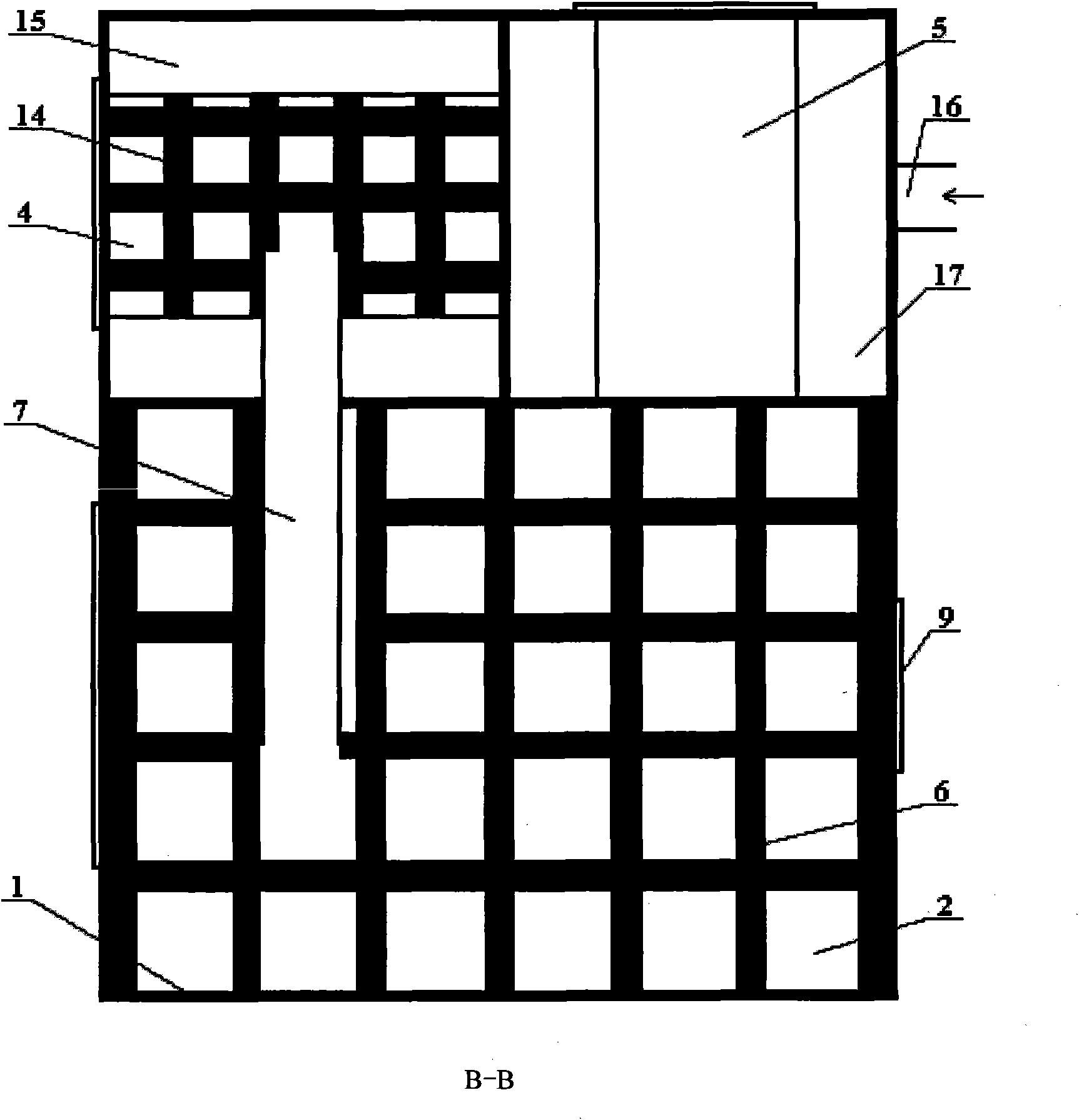

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

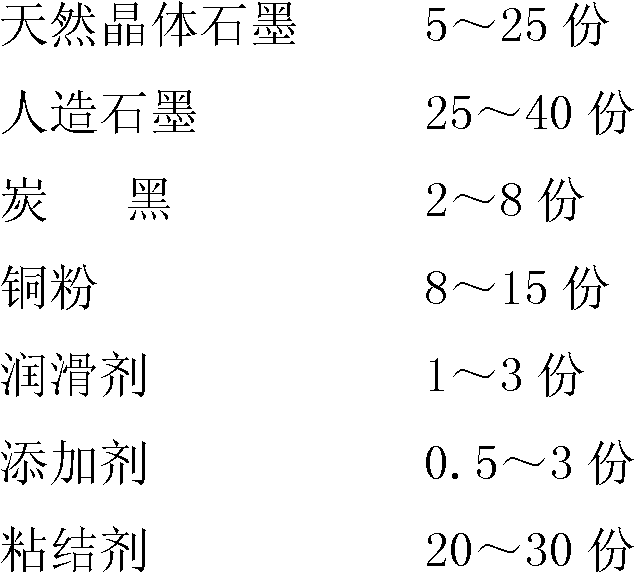

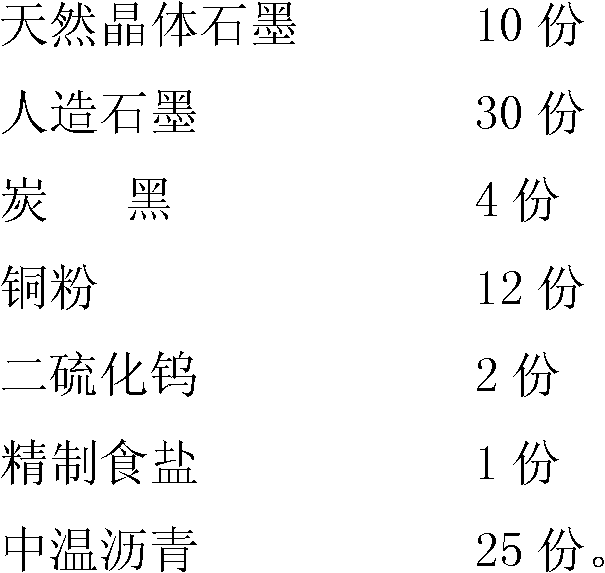

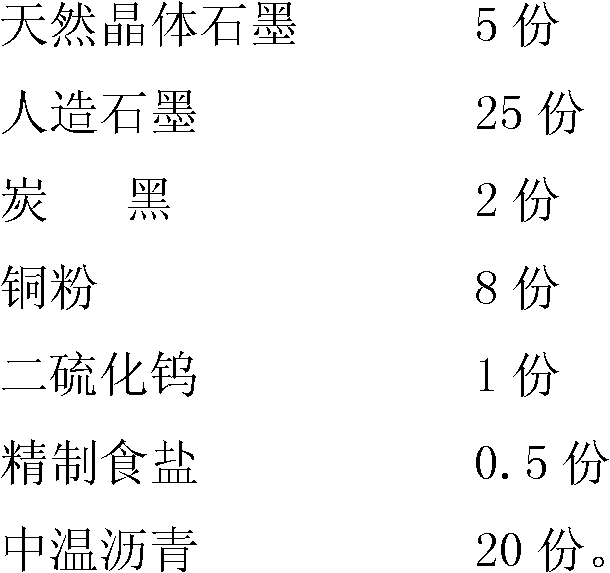

Motor brush for small household appliances and manufacturing method thereof

InactiveCN102280790AConductiveImprove conductivityRotary current collectorBrushes manufactureLow noiseAgricultural engineering

The invention discloses a motor brush for small household appliances and a preparation method thereof. The brush uses natural crystal graphite, artificial graphite, copper powder and carbon black as the main material of the brush, and is equipped with lubricants, additives, adhesives, etc. The agent is made by mixing, molding and roasting. The invention is suitable for small household electrical appliances such as soybean milk machines, juicers, shavers, hair dryers, and small irons. The motor brush for small household electrical appliances of the present invention adopts special raw materials and proportions, and has the advantages of low resistivity, good commutation performance, low running noise, excellent wear resistance, long service life, and environmental protection. Its manufacturing process is simple, Easy to implement, stable product performance and high yield.

Owner:SUZHOU DONON CARBON PRODS

Method for extracting and purifying spittle DNA

InactiveCN102220310AMeet the extraction requirementsEasy to operateDNA preparationBiological cellLysis

The invention discloses a method for extracting and purifying spittle DNA, which comprises the following: 1) a step of pre-treatment, which is to contact the spittle with pretreatment lysis solution, remove solid matters adhered onto cells and obtain coarse lysis solution; 2) a step of nucleic acid absorption, which is to mix the coarse lysis solution obtained by the step 1) with lysis binding solution and magnetic bead suspension to form a solution system containing magnetic nano microsphere and DNA composite and is to collect the magnetic nano microsphere and DNA composite from the solutionsystem; and 3) a step of washing, which is to wash the magnetic nano microsphere and DNA composite obtained by the step 2) with washing liquid I and washing liquid II in turn, and dissolve out DNA byusing eluent. When the method provided by the invention is used, the DNA extraction efficiency may reach 90 percent, the extracted DNA can be used in short tandem repeat (STR) composite amplification, DNA sequencing, DNA quantification and other downstream analysis and operation.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

Method for extracting purified DNA from human exfoliative cells

InactiveCN102181434AMeet the extraction requirementsEasy to operateDNA preparationBiological cellLysis

The invention discloses a method for extracting purified DNA from human exfoliative cells. The method comprises the following steps: 1) pretreating: contacting the human exfoliative cells with pretreating lysate to remove the solid matters adhering to the biological cells to obtain coarse lysate; 2) nucleic acid adsorbing: mixing the coarse lysate obtained in the step 1) with lysis integrated liquid and magnetic bead suspension to form a solution system containing a magnetic nano microsphere-DNA compound and collecting the magnetic nano microsphere-DNA compound in the solution system; and 3) washing: washing the magnetic nano microsphere-DNA compound obtained in the step 2) with washing liquid I and washing liquid II respectively and then dissolving out the DNA with eluent. The efficiency of extracting DNA by the method can reach 90% and the extracted DNA can be applied to such downstream analysis operations as STR (short tandem repeat) multiplex amplification, DNA sequencing, DNA quantifying and the like.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

Method and apparatus for catalytic preparation of hydrogen by biomass down-draft gasifying stove

InactiveCN1528656AImprove conversion rateImprove energy efficiencySolid waste disposalHydrocarbon oil crackingWater vaporFixed bed

The invention discloses a raw matter down absorbing gasification furnace catalysis hydrogen producing method, including the steps: raw matter is added in from the top of the gasification furnace, and after dried and pyrolyzed, makes an incomplete combustion reaction with the rich oxygen fed from the gasification furnace, to give out heat, during descending, the produced gas makes a water vapor reforming reaction and a tar fission reaction with the water vapor fed from the reducing region, the gas coming from the bottom of the gasification furnace again passes through the fixed bed catalytic reactor to make a further tar fission reaction, to produce a hydrogen-rich gas, which is made into high-purity hydrogen by variable pressure absorption. It also discloses a device to implement the above method. It has high conversion and energy utilization ratio, without discharging waste water and residue; the needed raw matter is rich.

Owner:广州中科环能科技有限公司

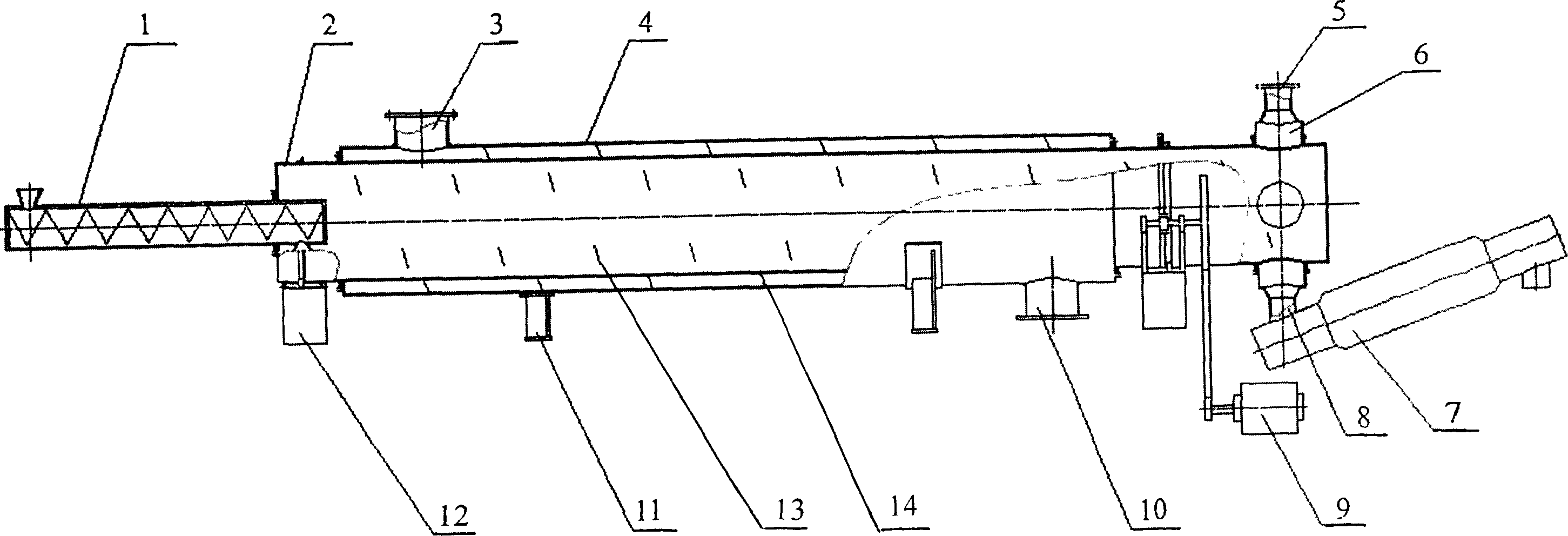

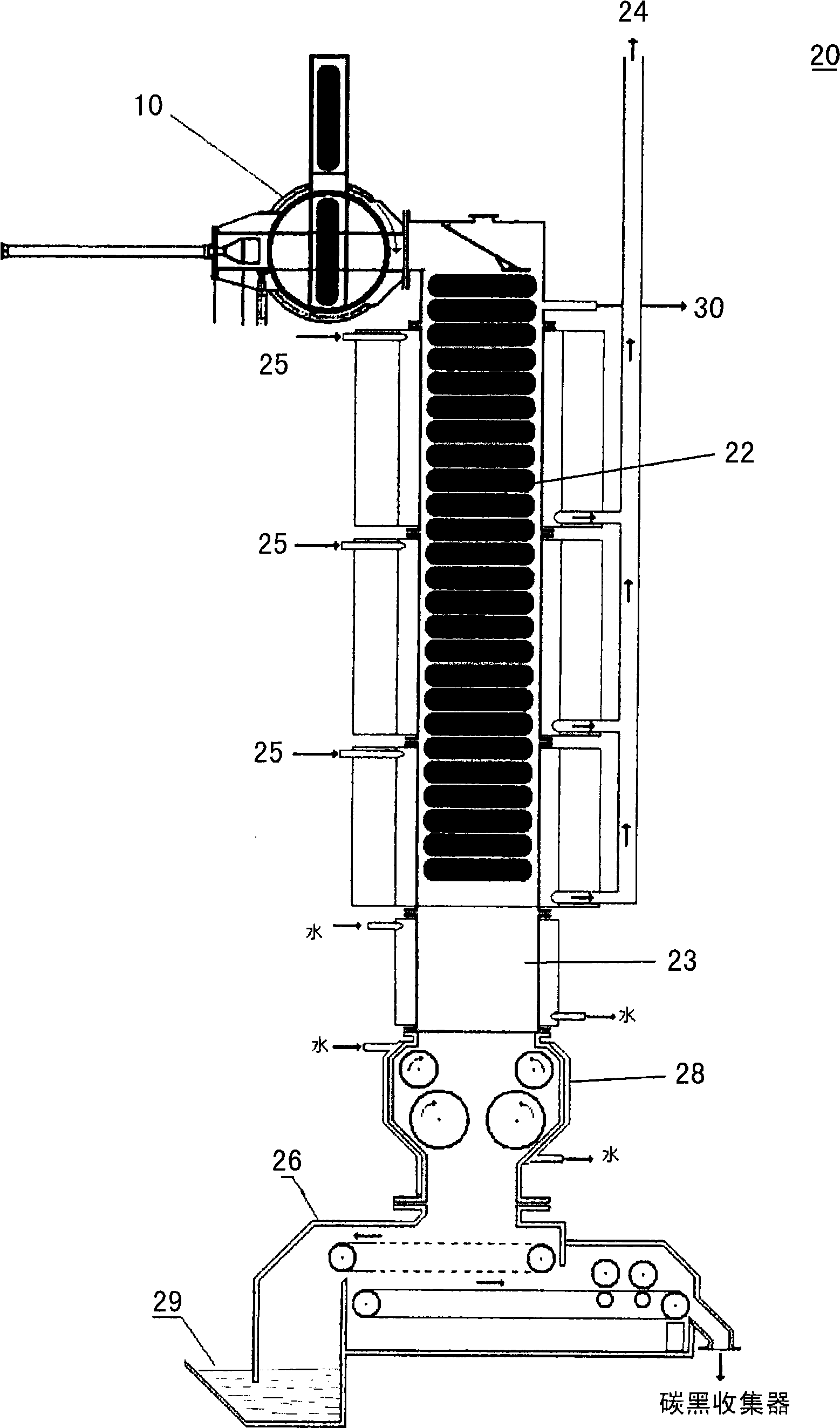

Horizontal type slew cylinder structure cracking furnace for waste steel wire blank continuous thermal cracking

InactiveCN1952045AAchieve self-sufficiencyThe cleavage reaction is fast and sufficientPigmenting treatmentLiquid hydrocarbon mixture productionEngineeringFlue

The invention disclosed a lying posture turnover cylinder cracking furnace which is used in the successive thermal cracking of a waste steel-wire tyre material. There's a below stack gas inlet and a top stack gas outlets on the outside tube of the cylinder; inside being positioned inner turning-over tube drived by transmission system; one side of the inner tube connects the tyre spiral feeder which can change the pitch, and the other side connects the static split product gathering trunk; on the top of the gathering trunk is the outlet of the gas hydrocracking product, while below the gathering trunk is outlet of the solid hydrocracking product, the gathering trunk also connects the spiral discharging device. The waste tyre material which is transferred by the spiral feeder is repeatedly grabbed by the grabbing plank located on the inner wall and pushed to the outlet. The high temperature stack gas counterflows in the passage between the outside and the inside tubes, during the process of the material's axial direction translation and circular direction rotation, the material absorbs the conducted calory from the tube wall to finish the splitting process. The gas product is pulped away by the blower while the solid product is discharged by the spiral discharging device through the bottom canal orifice.

Owner:ZHEJIANG UNIV

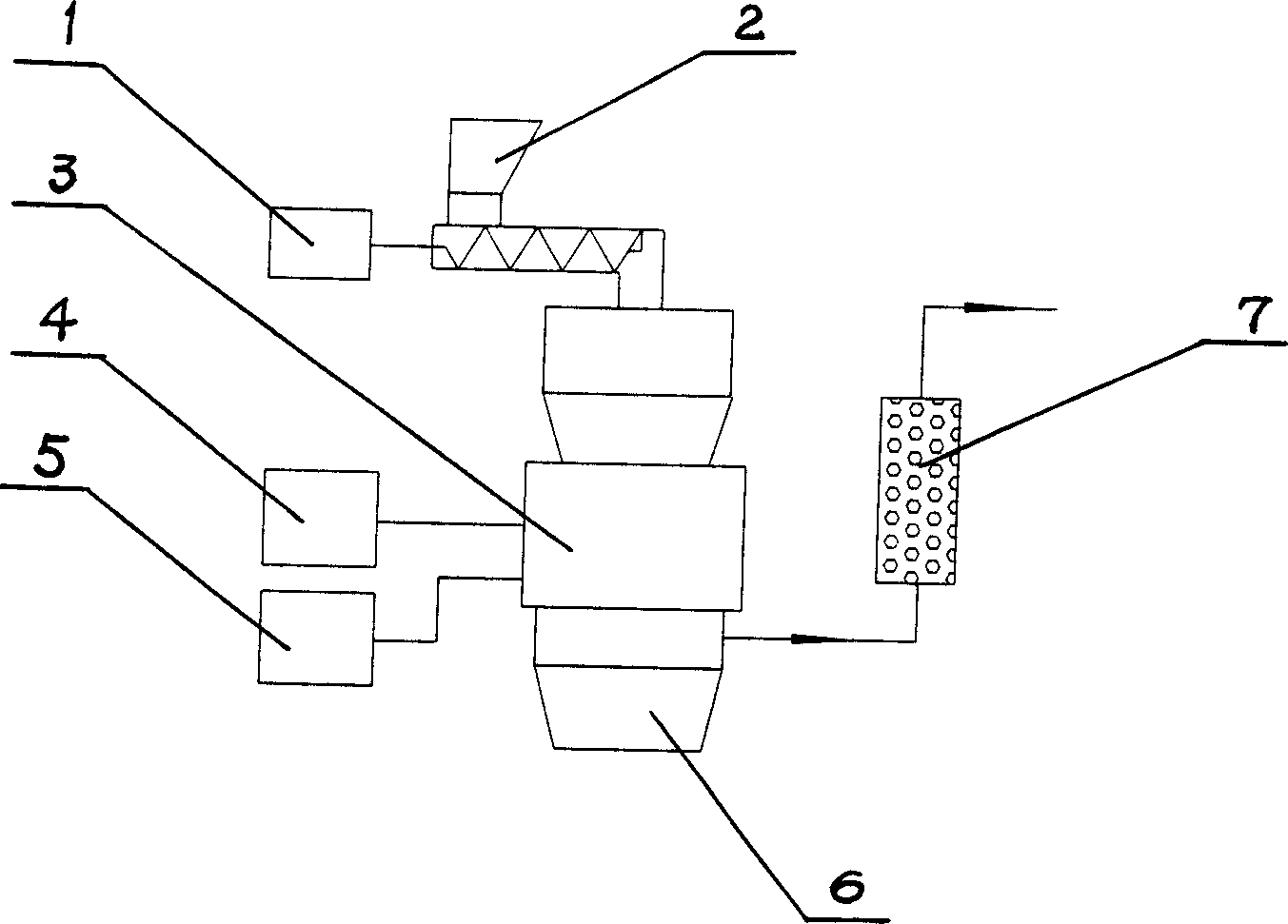

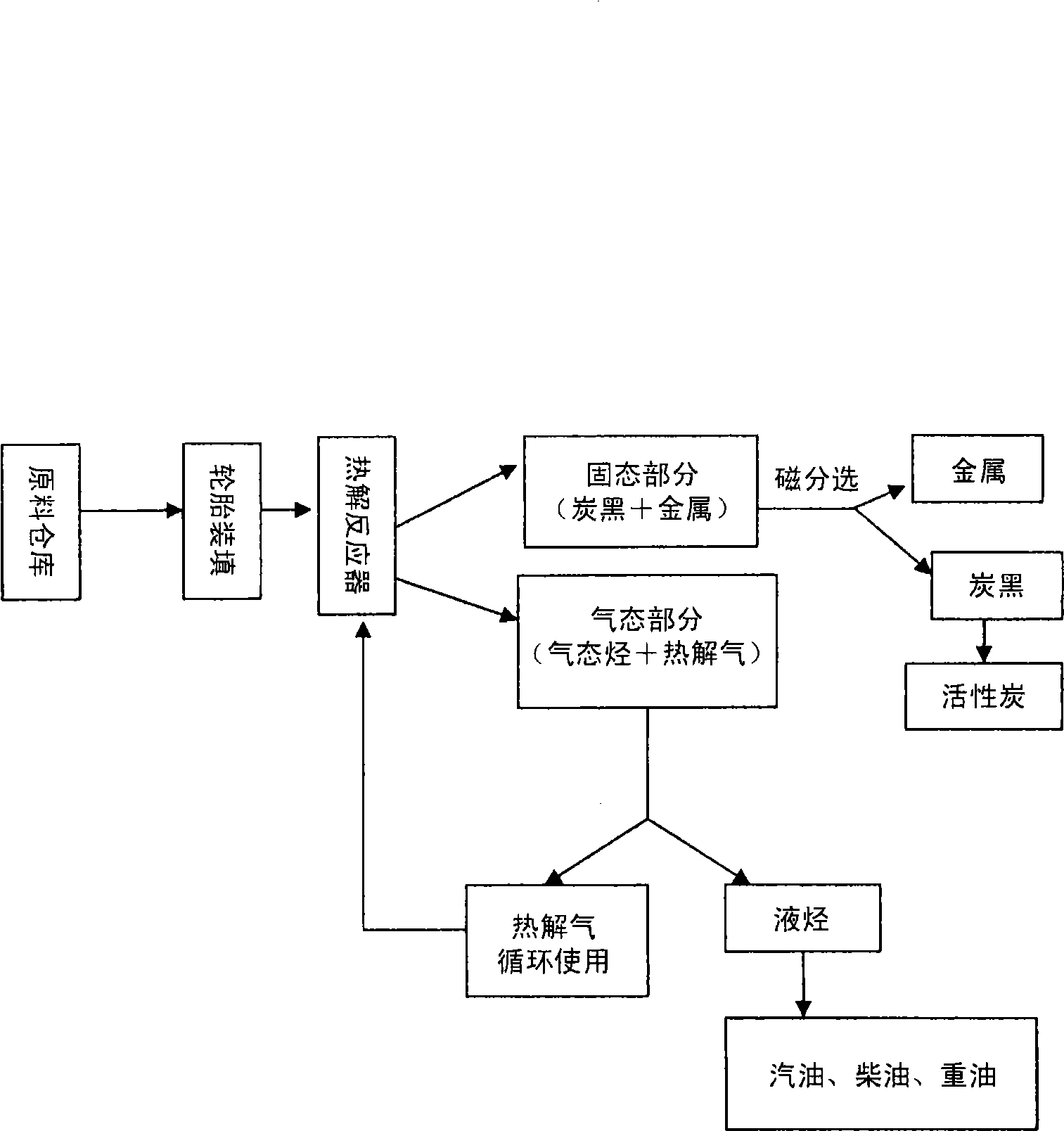

Method for treating waste tire

InactiveCN101544781AFully lysedAdd processing programPigmenting treatmentPlastic recyclingLiquid hydrocarbonsEngineering

The invention relates to a method for treating waste tires, which comprises the following steps: the thermal decomposition of a waste tire is carried out at the airproof state and under the oxygen-free condition; the thermal decomposition temperature is divided into three sections, wherein the first section is close to a feeding end with the thermal decomposition temperature of 700-800 DEG C; the third section is close to a discharging end with the thermal decomposition temperature of 900-1000 DEG C, and the second section is arranged between the feeding end and the discharging end with the thermal decomposition temperature of 800-900 DEG C; mixed steams generated during the thermal decomposition of the tire are condensed to form liquid hydrocarbon and thermal decomposition gas, and the thermal decomposition gas circularly returns to a reactor and is used as fuel; and the solid products are separated to obtain metals and carbon black.

Owner:BEIJING TIANHAIYUAN TECH +1

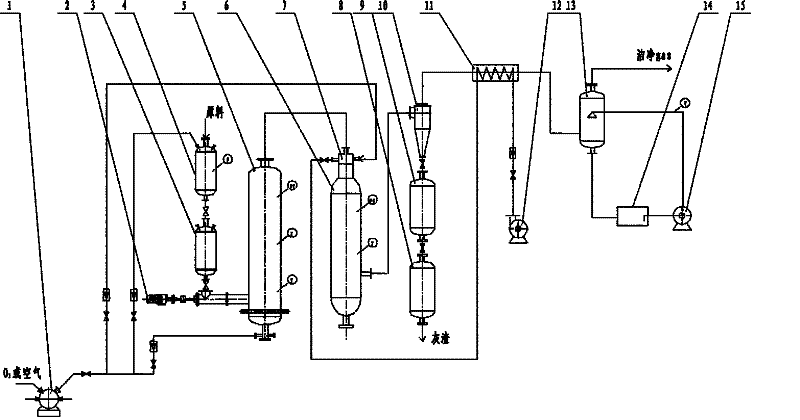

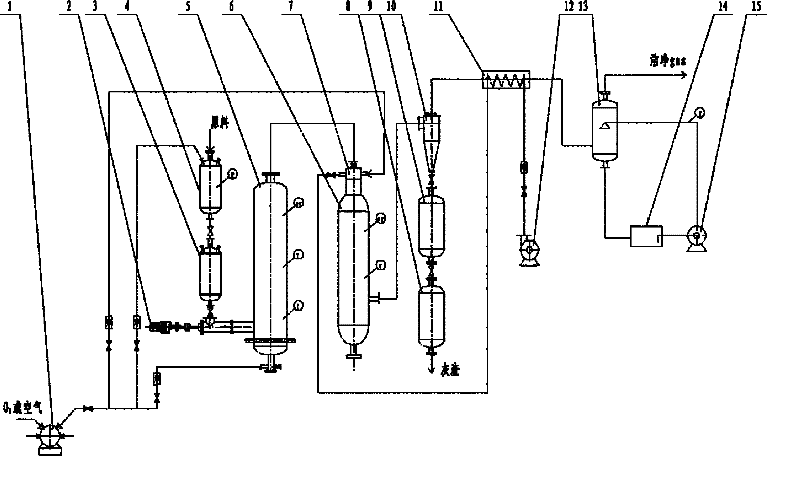

Technology and equipment for preparation of synthetic gas by two-stage high temperature biomass gasification

InactiveCN102226107AImprove equipment production capacityHigh calorific valueProductsReagentsTarCoal tar

The invention relates to a technology and equipment for preparation of synthetic gas by two-stage high temperature biomass gasification. Gasification in the technology is carried out in two stages, namely, primary gasification and high temperature gasification; biomass combustion gas, unreacted solids, tar and the like obtained in the primary gasification are directly delivered into a high temperature vapourizing furnace at high temperature and steam and air are also delivered into the vapourizing furnace so as to carry out high temperature gasification, thereby enhancing thermal efficiency, conversion rate of carbon and cracking rate of tar. In the process of the preparation, heat energy is self supplied, and heat is recovered to improve thermal efficiency; a thermal value of prepared synthetic gas can reach 7 to 8 MJ / m<3>. Equipment for realizing the technology comprises a biomass feed unit, gasification reactors, a dust collector, a heat reclaim unit, a washing unit, an air compressor, etc. The technology and equipment provided in the invention can be used to convert biomass raw materials like agricultural waste into synthetic gas with a high thermal value and low content of tar and are applicable to heat supply by biomass combustion gas, power generation by combustion gas or synthesis of liquid fuels.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

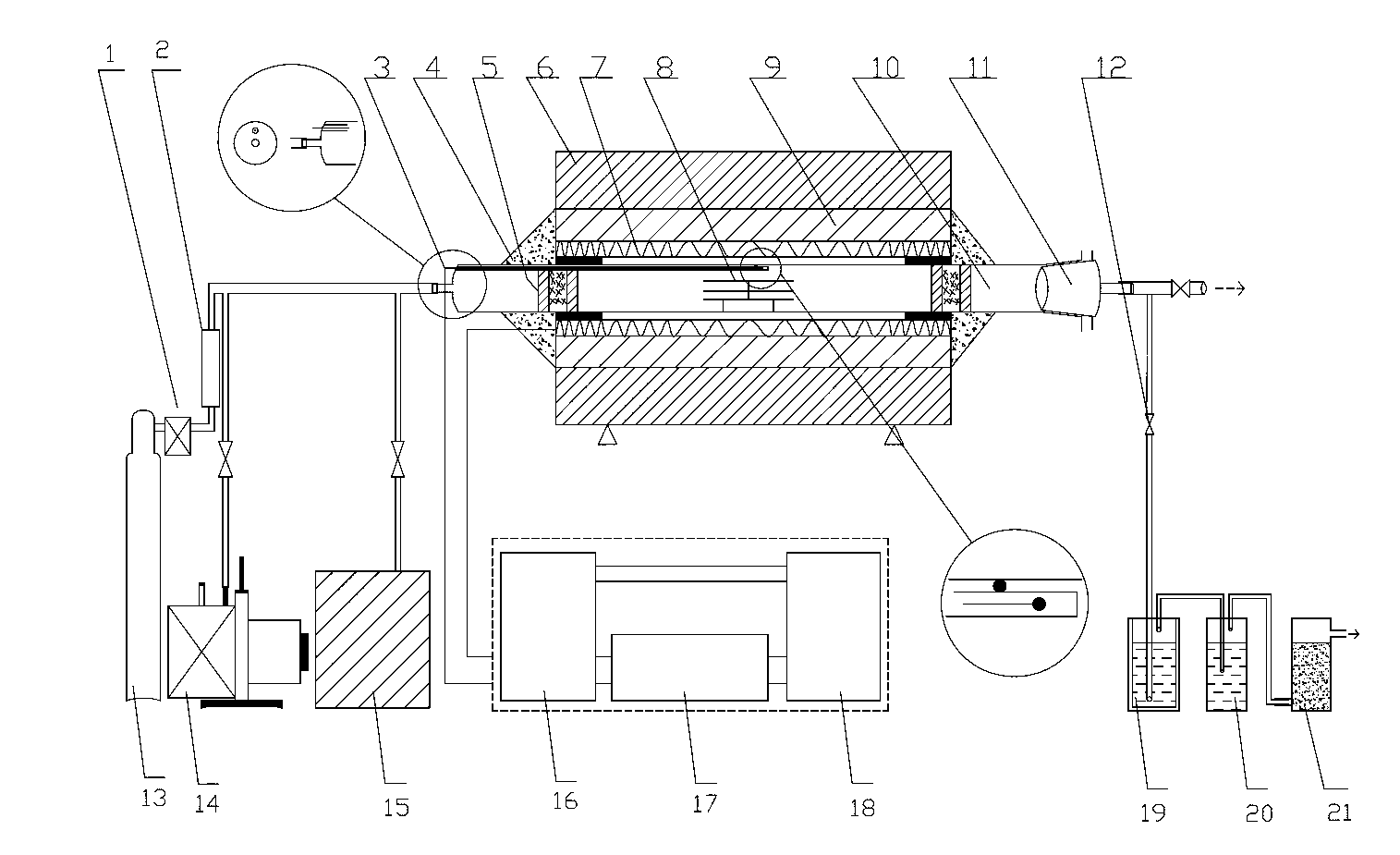

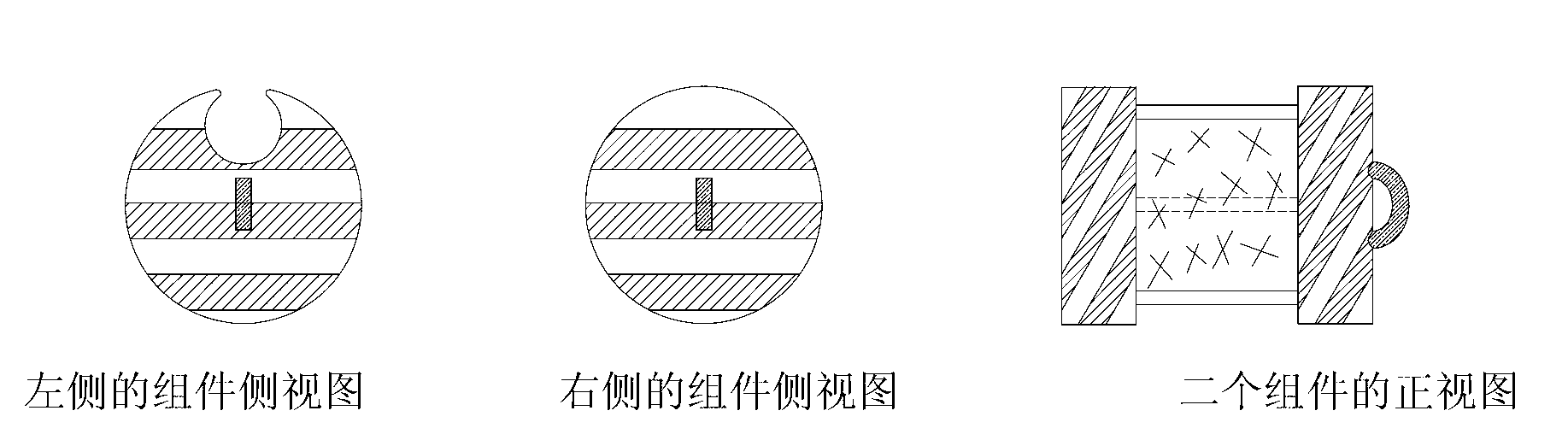

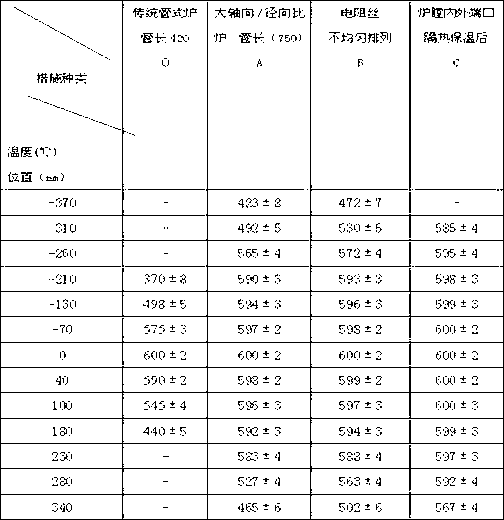

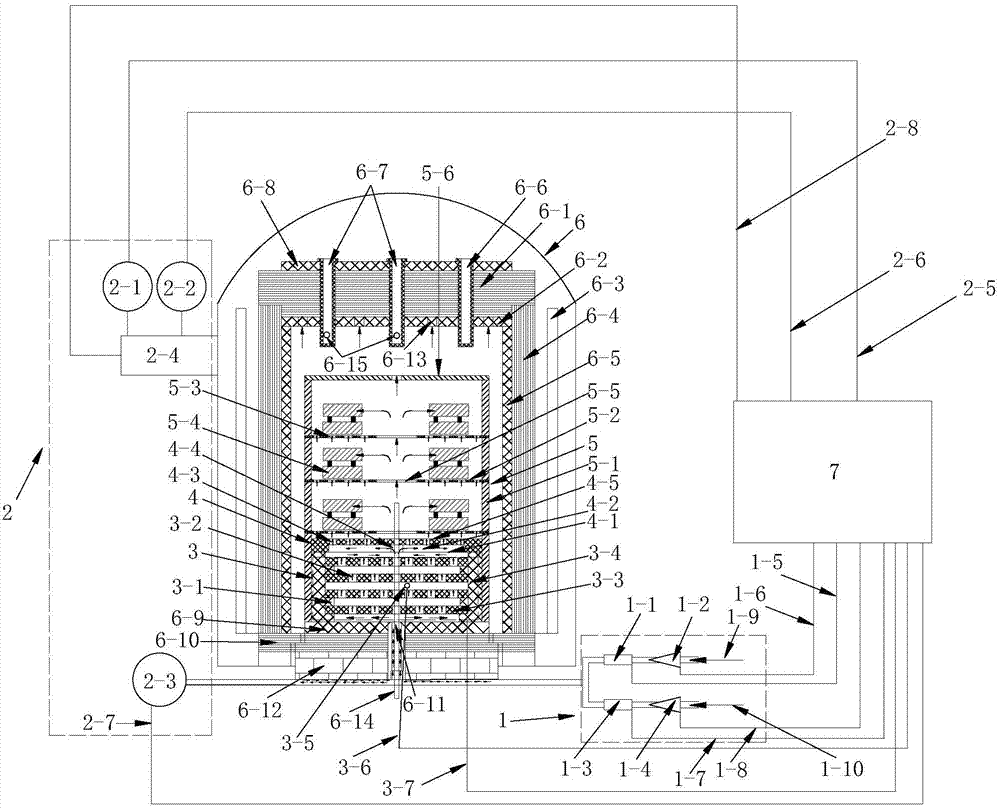

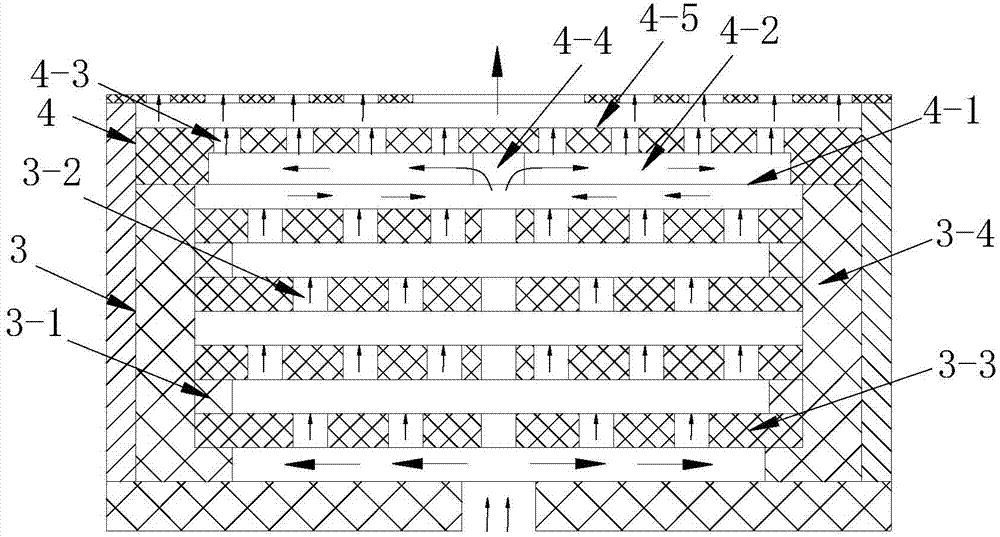

Environment-friendly automatic-temperature-control quartz tube furnace device for pyrolysis of high polymer

InactiveCN103017524AImprove insulation effectUniform temperature distributionHeat treatmentsFurnace typesTube furnaceEngineering

Tube furnaces for pyrolyzing or sintering are large in axial heat radiation, nonuniform in hearth temperature and low in machining amount. The invention discloses an environment-friendly automatic-temperature-control quartz tube furnace device for pyrolysis of high polymer, wherein the environment-friendly automatic-temperature-control quartz tube furnace device comprises a quartz glass tube furnace, a sample stand, a heat-isolation ventilation assembly, a fireproof heat-insulation furnace body, an automatic-heating temperature control device, a safety protection device and a tail gas treatment device. Different from other tube furnaces, the quartz tube furnace device is characterized in that a furnace body structure is improved by taking heat insulation measures additionally for inner and outer ports of a hearth, the axial-radial ratio of the tube furnace is high up to 12.5, resistance wires are arranged in a nonuniform winding manner and are arranged densely at the ports and sparsely in the middle, in addition, a safety protection bag and a tail gas purification column are arranged, and the furnace is internally vacuumized and is introduced with nitrogen. The environment-friendly automatic-temperature-control quartz tube furnace device disclosed by the invention is simple in equipment, low in investment, good in gas tightness, high in vacuum degree, convenient for heating as well as temperature measuring and controlling, and good in heat insulation effect, and is safe, energy-saving and environment-friendly, and an intra-furnace pyrolysis region is long and uniform in temperature, so that pyrolysis and doping reaction effects are good, and the processing amount is large. The environment-friendly automatic-temperature-control quartz tube furnace device can also be applied to other high-temperature reaction processes.

Owner:HARBIN UNIV OF COMMERCE

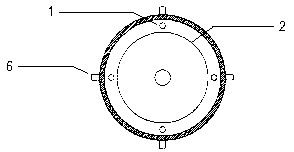

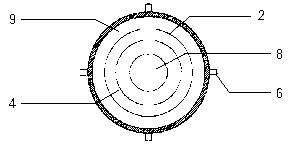

Carbon/carbon composite component chemical vapor infiltration device

ActiveCN104498891AWell mixedIncrease profitChemical vapor deposition coatingPressure controllerCarbon composites

The invention brings forward a carbon / carbon composite component chemical vapor infiltration device and aims to provide a device for solving problems of low reactant gas utilization rate and low infiltration efficiency existing by chemical vapor infiltration in the prior art. The invention is realized by the following technical scheme: a gas mixing and preheating device for primary control of reactant gas diversion direction and a temperature sensor for monitoring preheating temperature of reactant gas are arranged below a deep gas-mixing and outgassing device connected with a sealed infiltration chamber; the regulated and controlled reactant gas enters a gas mixing and preheating device from the bottom of a chemical vapor deposition furnace body through a gas supply device, and a controller automatically regulates electric power on a heater to obtain required preheating temperature; and the preheated reactant gas enters the sealed infiltration chamber and passes through a porous graphite liner plate to infiltrate through a composite preform placed inside the sealed infiltration chamber, and chemical vapor infiltration is performed under constant values by pressure control of a furnace pressure controller and temperature control of a temperature control sensor.

Owner:PLA NO 5719 FACTORY

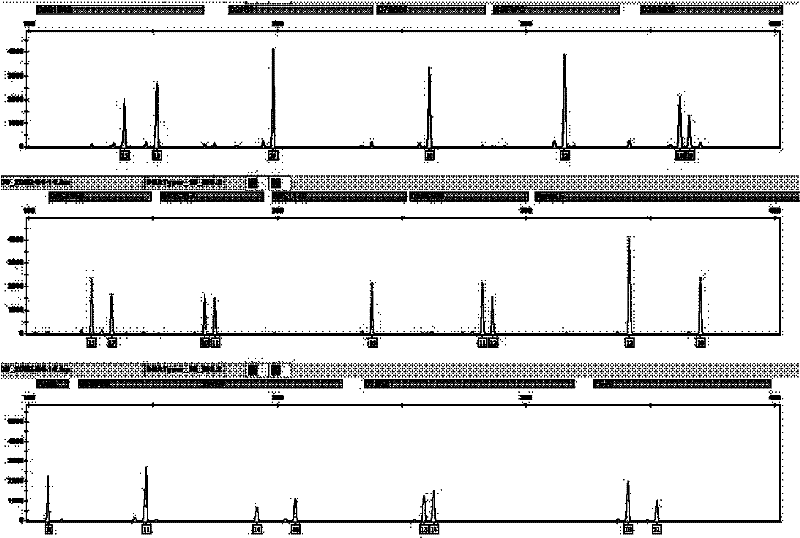

Alcohol-free virus nucleic acid extraction kit based on magnetic bead method

PendingCN109722431AReduce the adsorption of impuritiesImprove stabilityMicroorganism lysisDNA preparationProtein proteinIon

The present invention provides an alcohol-free virus nucleic acid extraction kit based on a magnetic bead method. The alcohol-free virus nucleic acid extraction kit comprises a lysate, a magnetic beadsolution, proteinase K, a polyA solution, a deproteinized solution, a washing solution and a buffer solution. The present invention also provides a method for extracting nucleic acid by using the above kit. Firstly, a sample, the lysate and magnetic beads are mixed evenly, then nucleic acid molecules are captured while pyrolysis is conducted, and finally the special alcohol-free deproteinized solution and the washing solution are respectively used to remove impurities of proteins, salt ions and other impurities on surfaces of the magnetic beads. Compared with a conventional virus nucleic acidextraction method, the method is simple in operation steps, does not need single addition of binding liquid, realizes the simultaneous pyrolysis and binding, and co-extracts DNA and RNA; the whole operation process is free of alcohol or isopropyl alcohol, inhibitory substance residues are less, the experimental procedure is simple, and the whole process only takes about 40 minutes; and the method is safe and pollution-free, and free of toxic reagents of chloroform, phenol, etc., and can be operated manually or on an automation platform.

Owner:SHANGHAI KEHUA BIO ENG

Erythrocyte lysis buffer and application thereof

InactiveCN103789298AHigh purityReduce manufacturing costDNA preparationWhite blood cellWhite blood cell number

The invention provides an erythrocyte lysis buffer. The erythrocyte lysis buffer comprises the following components: 4.5-5.5 mmol / L of sodium chloride, 0.8-1.3% (v / v) of triton 100, 300-340mmol / L of glucose and 0.008-0.012 mol / L of trishydroxymethyl aminomethane. The erythrocyte lysis buffer can effectively lyse the erythrocyte in a whole blood sample, separate and enrich leucocyte in the blood, and facilitate the subsequent nucleic acid extraction operation of the leucocyte, so as to obtain the leucocyte DNA in the whole blood sample and the DNA of virus in the leucocyte.

Owner:SANSURE BIOTECH INC

Lysate, nucleic acid extraction kit, and nucleic acid extraction method for nucleic acid extraction

ActiveCN110684764AReasonable ratioFully lysedMicrobiological testing/measurementDNA preparationLysisActive agent

The invention discloses a lysate, nucleic acid extraction kit, and nucleic acid extraction method for nucleic acid extraction. The lysate for the nucleic acid extraction is prepared from 0.5 to 2M ofsodium salt, 2 to 5M of guanidine salt, 1 to 5mM of a metal ion complexing agent, 0.25% to 1% of a nonionic surfactant, and 1% to 3% of PEG, and the molecular weight of the PEG is 6000 to 10000 Da, preferably 8000 Da. The lysate has a reasonable ratio, cells can be fully and effectively lysed, the lysis efficiency is high, so that the nucleic acids in the cells can be fully released, and the nucleic acids with higher concentration and purity can be obtained, and the quality and extraction efficiency of the nucleic acids are improved advantageously; and according to the lysate and the kit, digestion and removal of protein can be conducted without the aid of proteinase K during the entire nucleic acid extraction process, alcohols are not usedfor precipitate the nucleic acids,the obtained nucleic acids have high purity, and fragments are complete.

Owner:HANGZHOU BIGGER FISH BIOTECHNOLOGY CO LTD

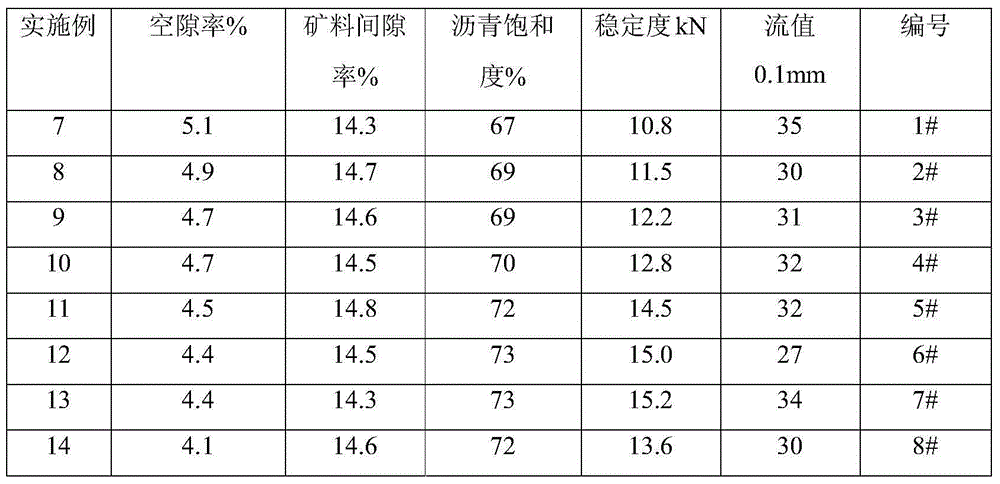

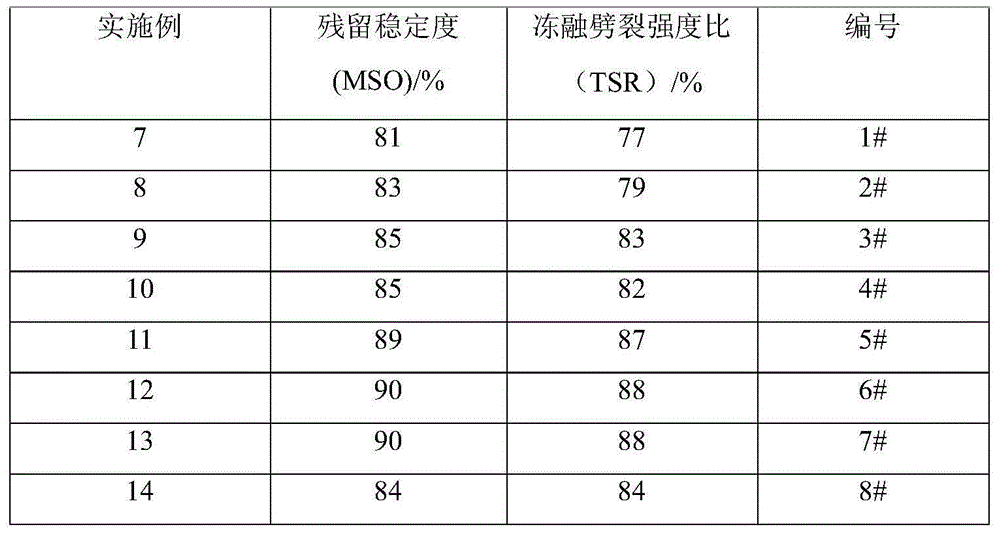

Bituminous mixture using DVS (direct vat set) high-adhesion modifier and preparation method thereof

ActiveCN104693821AControl "Secondary Pollution"Low costBuilding insulationsBulk chemical productionCrack resistancePolymer science

The invention relates to a bituminous mixture using a DVS (direct vat set) high-adhesion modifier and a preparation method thereof. The bituminous mixture is prepared from aggregates, a DVS high-adhesion bituminous mixture modifier and matrix asphalt by mixing, wherein the modifier is prepared from high-desulfurization-degree reclaimed rubber, modified high-temperature coal tar pitch and a skeleton proppant by stirring and extruding. Waste rubber is deeply activated under the high temperature and high shearing action of a twin screw extruder, so that the high-desulfurization-degree reclaimed rubber is obtained; then, the mixture of the modified high-temperature coal tar pitch modified by rubber pyrolysis oil, the high-desulfurization-degree reclaimed rubber and the skeleton proppant is fully mixed by using a screw, and then extruded and granulated so as to obtain the DVS high-adhesion bituminous mixture modifier; and finally, the modifier, the aggregates and the matrix asphalt are mixed so as to obtain a DVS high-adhesion bituminous mixture. The bituminous mixture disclosed by the invention has excellent water damage resistance, good high-temperature rutting resistance and low-temperature crack resistance.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Resource recycling process and system for high-temperature plasma of chlorine-containing waste

InactiveCN109539272AFully harmless treatmentEfficient recyclingDispersed particle filtrationEmission preventionCombustion chamberDecomposition

The invention belongs to the technical field of industrial waste treatment, and particularly relates to a resource recycling process and system for high-temperature plasma of chlorine-containing waste. The method comprises the steps that (1) the chlorine-containing waste is conveyed into a plasma gasifier through a feeding system; (2) synthesis gas produced through splitting decomposition is cooled by a first-stage waste heat exchanger; (3) after entering an acid absorption system to absorb acid, the synthesis gas enters an alkaline tower to be further deacidified; (4) the deacidified synthesis gas enters a secondary combustion chamber to be combusted, and generated high-temperature flue gas is cooled by a second-stage waste heat exchanger; (5) after the cooled flue gas enters a quench cooler to be subjected to quenching, the flue gas enters a bag-type dust remover for dust removal; (6) the flue gas with dust removed enters a flue heater to be warmed; (7) the flue gas enters an SCR catalytic tower to remove nitric oxide in the flue gas; and (8) after the flue gas subjected to SCR treatment enters the heat exchanger for heat exchange, the flue gas is drawn out by an induced draft fan, and the flue gas is discharged into the atmosphere through a chimney. By means of the resource recycling process and system, resource, harmless, reducing and stabilizing treatment of the chlorine-containing waste is achieved, and the system operation cost is low.

Owner:SHANDONG BO RUN IND TECH

Liquid fuel and preparation method thereof

InactiveCN101886001AEasy to prepareHigh yieldLiquid carbonaceous fuelsHazardous substanceLiquid fuel

The invention relates to a liquid fuel and a preparation method thereof. The liquid fuel is prepared by completely stirring the complex of alkylamine and alkyl borane, which serves as a main raw material, and hydrogenated light distillate and aluminum ethyl, which serve as auxiliary materials, under the normal temperature and the normal pressure. The liquid fuel has the characteristics of high heat sink, more pyrolysis products, high eneyne hydrocarbon product selectivity, low coking rate, particular suitability for heat transfer under the supercritical condition of 500 to 1,100 DEG C, simple preparation method and the like. The combustion product of the preparation method does not contain any toxic and harmful substance and meets the environmental requirement.

Owner:BEIJING POWER MACHINERY INST

Biomass and coal fluidized bed co-gasification method

InactiveCN102786990ALow costIncrease profitGranular/pulverulent flues gasificationSyngasCombustion chamber

Owner:TAIYUAN UNIV OF TECH

Method for extracting and purifying semen DNA

ActiveCN102199594AMeet the extraction requirementsEasy to operateDNA preparationSolution systemChemistry

The invention discloses a method for extracting and purifying semen DNA. The method comprises the following steps of: (1) pretreatment: keeping semen in contact with a pretreatment lysis solution and removing solid substances adhered to biological cells to obtain a crude lysis solution; (2) nucleic acid adsorption: mixing the crude lysis solution obtained in the step (1) with a lysis binding solution and a magnetic bead suspension solution to form a solution system containing a magnetic nano microsphere-DNA compound, and collecting the magnetic nano microsphere-DNA compound in the solution system; and (3) washing: washing the magnetic nano microsphere-DNA compound obtained in the step (2) by sequentially using a washing solution I and a washing solution II, and dissolving DNA out with eluent. According to the method provided by the invention, the DNA extraction efficiency can reach 90 percent, and the extracted DNA can be applied to STR (Short Tandem Repeat) composite amplification, DNA sequencing, DNA quantification and other downstream analysis operations.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

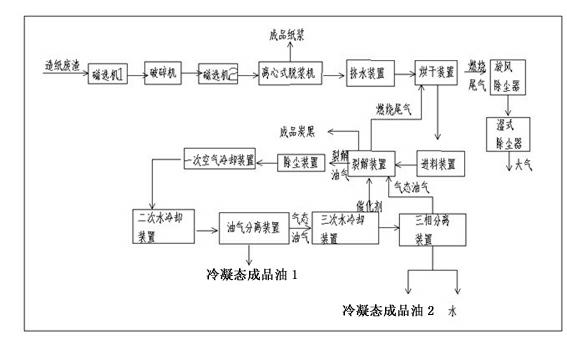

Method for recycling papermaking waste residues

InactiveCN102366756ASmall sizeAvoid destructionSolid waste disposalPaper recyclingPulp and paper industryCracking reaction

The invention discloses a method for recycling papermaking waste residues, belonging to the technical field of papermaking waste residue treatment. The method comprises the following steps: magnetic separation, stave processing, centrifugal deslurrying, squeezing water, drying, cracking and cracking oil-gas separation. The method fully utilized various ingredients of waste residues, can achieve the purpose of recycling the papermaking waste residues, and can eliminate the damage of papermaking waste residue to the environment.

Owner:仁精科技(昆山)有限公司

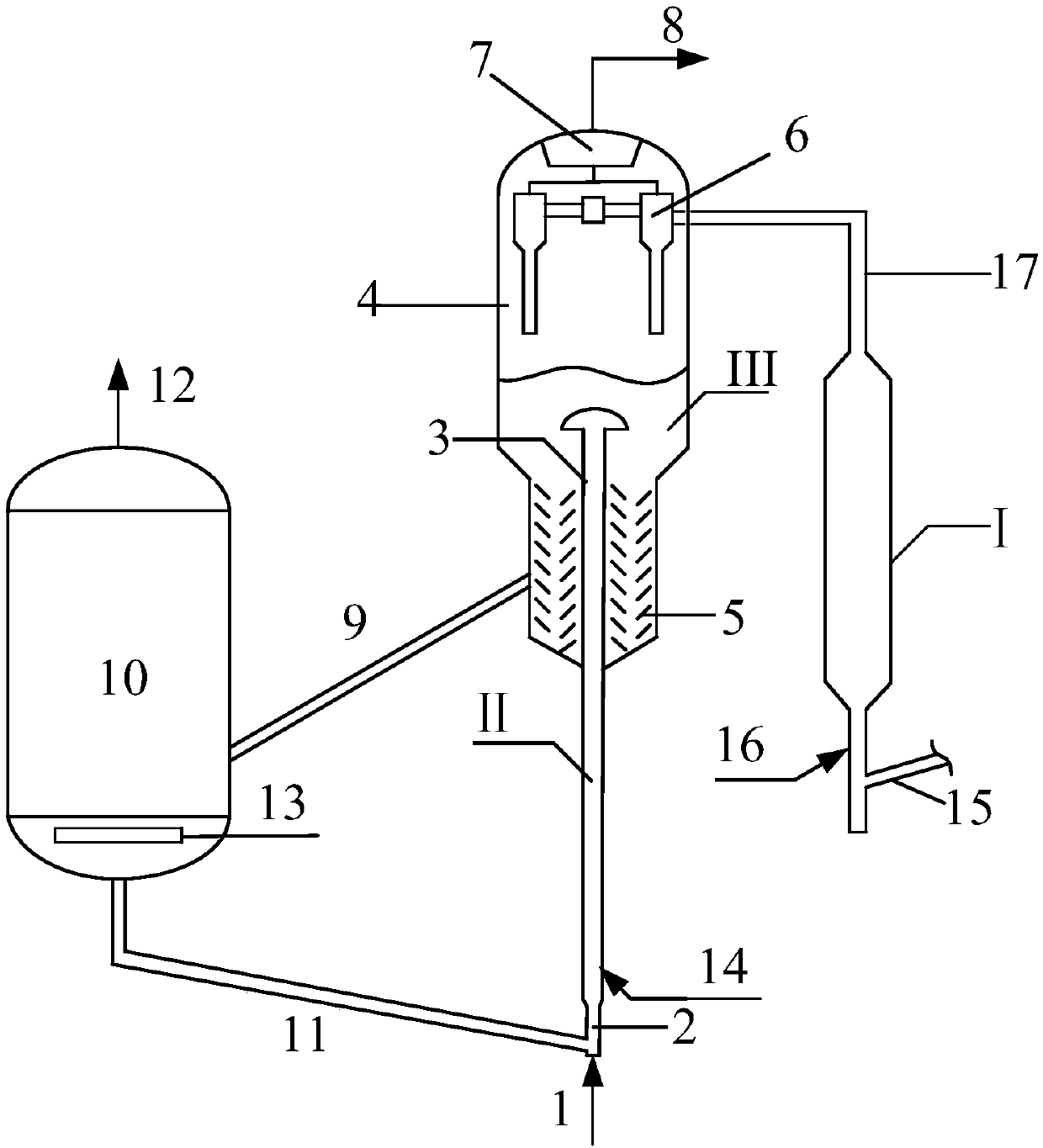

Catalytic cracking method and system for producing propylene and high-octane gasoline

ActiveCN110724558AHigh densityHigh yieldTreatment with plural serial cracking stages onlyCatalytic crackingPtru catalystFluidized bed

The invention relates to a catalytic cracking method and system for producing propylene and high-octane gasoline. The method includes the following steps: introducing preheated high-quality heavy oilfrom the lower part of a dilute-phase conveying bed into the dilute-phase conveying bed to be in contact with a first catalytic cracking catalyst, and performing a primary catalytic cracking reactionfrom the bottom to the top to obtain a primary reaction product and a semi-spent catalyst; sending the obtained primary reaction product and the semi-spent catalyst to a dense-phase fluidized bed, andcontinuing a secondary catalytic cracking reaction to obtain a secondary reaction product and a first spent catalyst; and introducing preheated inferior heavy oil from the lower part of a rapid fluidized bed into the rapid fluidized bed to be in contact with a second catalytic cracking catalyst, and performing a tertiary catalytic cracking reaction from the bottom to the top to obtain a tertiaryreaction product and a second spent catalyst. The method and system provided by the invention have a low yield of coke and dry gas, and a high yield of the low-carbon olefin and the high-octane gasoline during catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

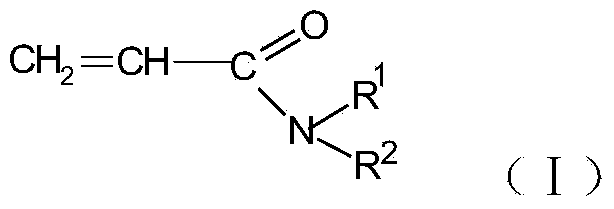

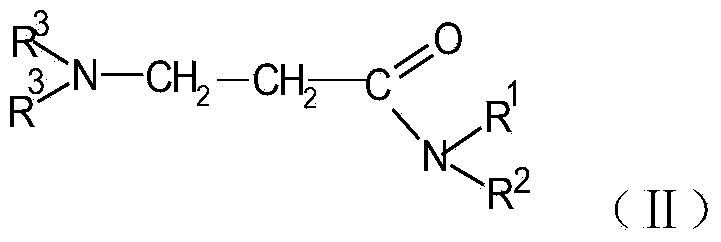

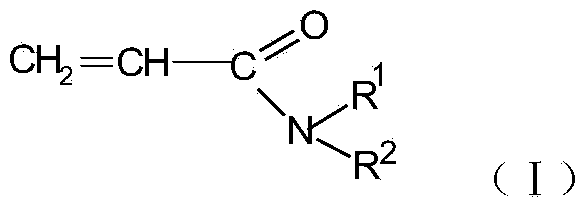

N-substituted acrylic amide synthesized through amine oxide cracking elimination method and method

InactiveCN103420864AReduced thermal stabilityLow yieldOrganic compound preparationCarboxylic acid amides preparationReaction temperatureAmine oxidase

The invention relates to N-substituted acrylic amide synthesized through an amine oxide cracking elimination method and a method. The method is that the N-substituted acrylic amide is synthesized by beta-dialkyl amine-N-substituted acrylic amide (II) through the amine oxide cracking elimination method. The method includes the steps that (1), in water media, hydrogen peroxide performs oxidation on the beta-dialkyl amine-N-substituted acrylic amide (II), and then an amine oxide (III) solution is prepared; (2), a vacuum cracking elimination reaction is performed on the amide oxide in an aprotic solvent, so that N-mono-substituted acrylic amide or N, N-disubstituted acrylic amide is prepared. Beta-dialkyl amine-N-substituted acrylic amide (II) can be prepared with secondary amine R32NH as a protective agent and acrylic ester and alkylamine HNR1R2 as raw materials. According to the process route, the method has the advantages of being low in racking reaction temperature, high in yield and capable of preparing the mono-substituted acrylic amide and the disubstituted acrylic amide, and product monomers are not prone to self-polymerization.

Owner:TIANJIN UNIV

Method for preparing seasonal influenza virus split vaccine

InactiveCN102406930ALess impuritiesHigh content of HAAntiviralsAntibody medical ingredientsEmbryoTGE VACCINE

The invention provides a method for preparing a seasonal influenza virus split vaccine and a vaccine prepared by using the method, belonging to the technical field of vaccine preparation processes. The preparation method comprises the following steps of: preparing an original liquid from influenza A1, A3 and B virus strain verified as WHO (World Health Organization) recommended virus strain or similar strain through the procedures of working seed bank creation through subculture, chick embryo inoculation, virus liquid culture and harvesting, virus inactivation, ultrafilter concentration, gradient centrifugation, ultrafilter sugar removal, column chromatography, virus splitting, secondary purification and filtration sterilization; and carrying out semi-finished product configuration and finished product packaging to obtain the seasonal influenza virus split vaccine. Because gradient centrifugation purification and molecular sieve chromatography column purification are combined and secondary purification including gradient centrifugation purification after virus splitting is carried out, the method provided by the invention has the advantages of good concentration efficiency and recovery rate, low cost, high efficiency and easiness for operation. The finally prepared product has low impurity content and high HA content, and the standards of endotoxin and ovalbumin are far better than the requirements of Chinese Pharmacopoeia 2010 and European Pharmacopoeia. Moreover, the product provided by the invention does not contain thiomersal, inoculation is safer, and inoculated population is larger.

Owner:CHENGDU KANGHUA BIOLOGICAL PROD

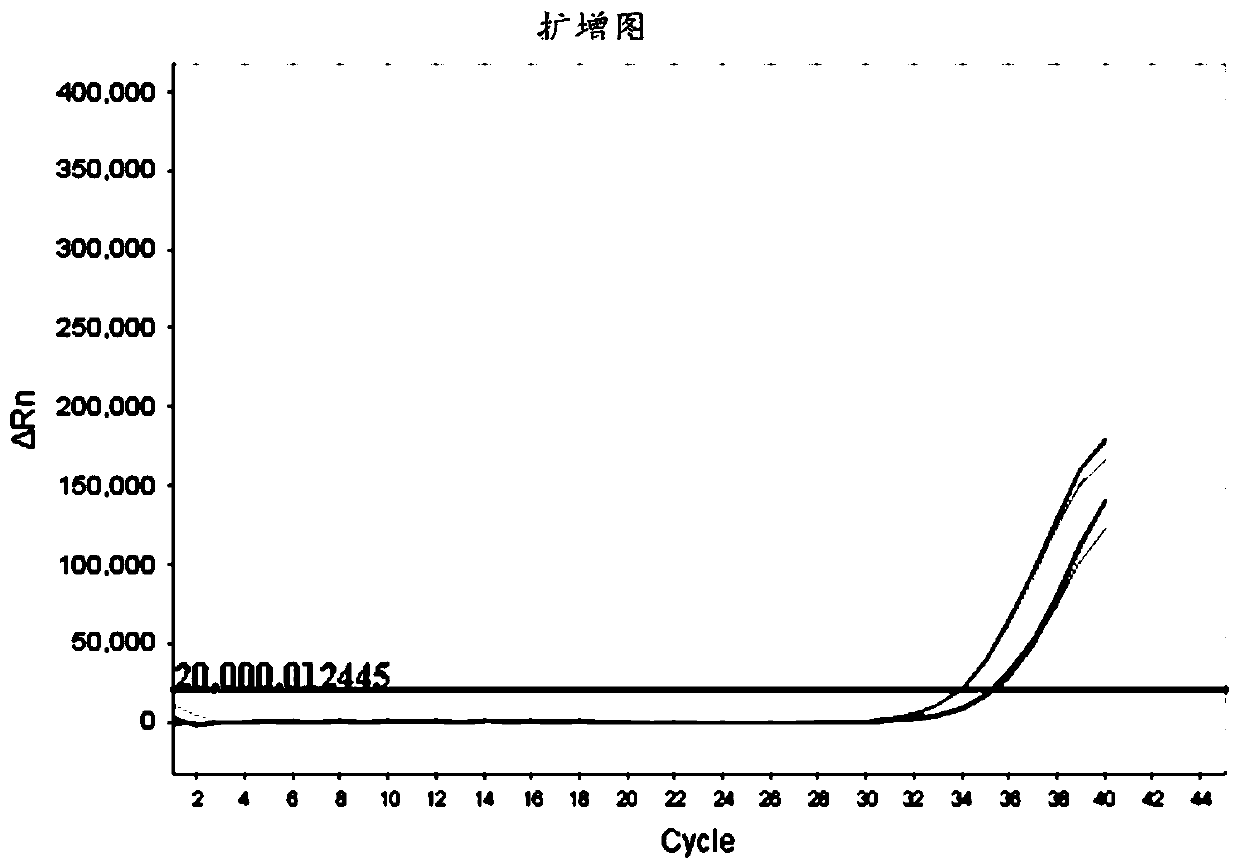

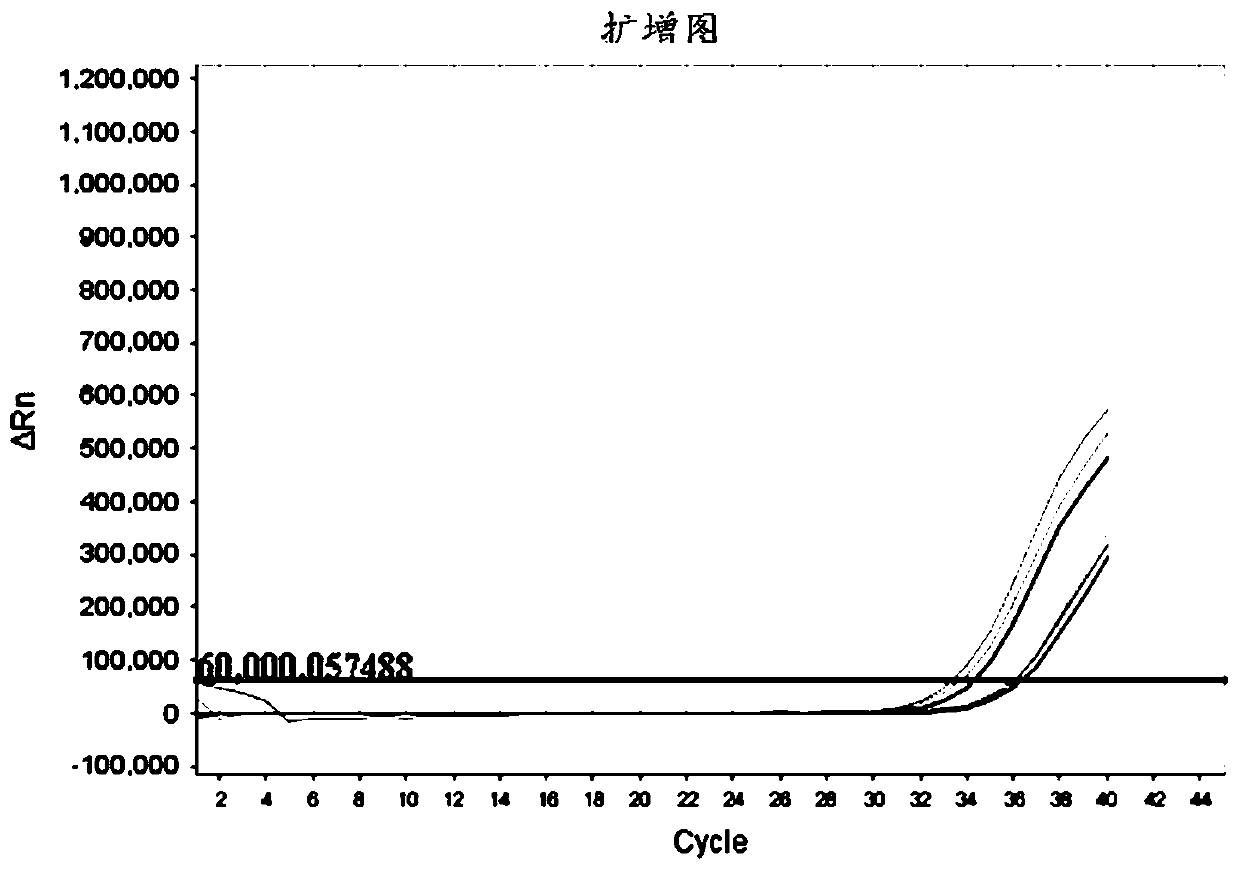

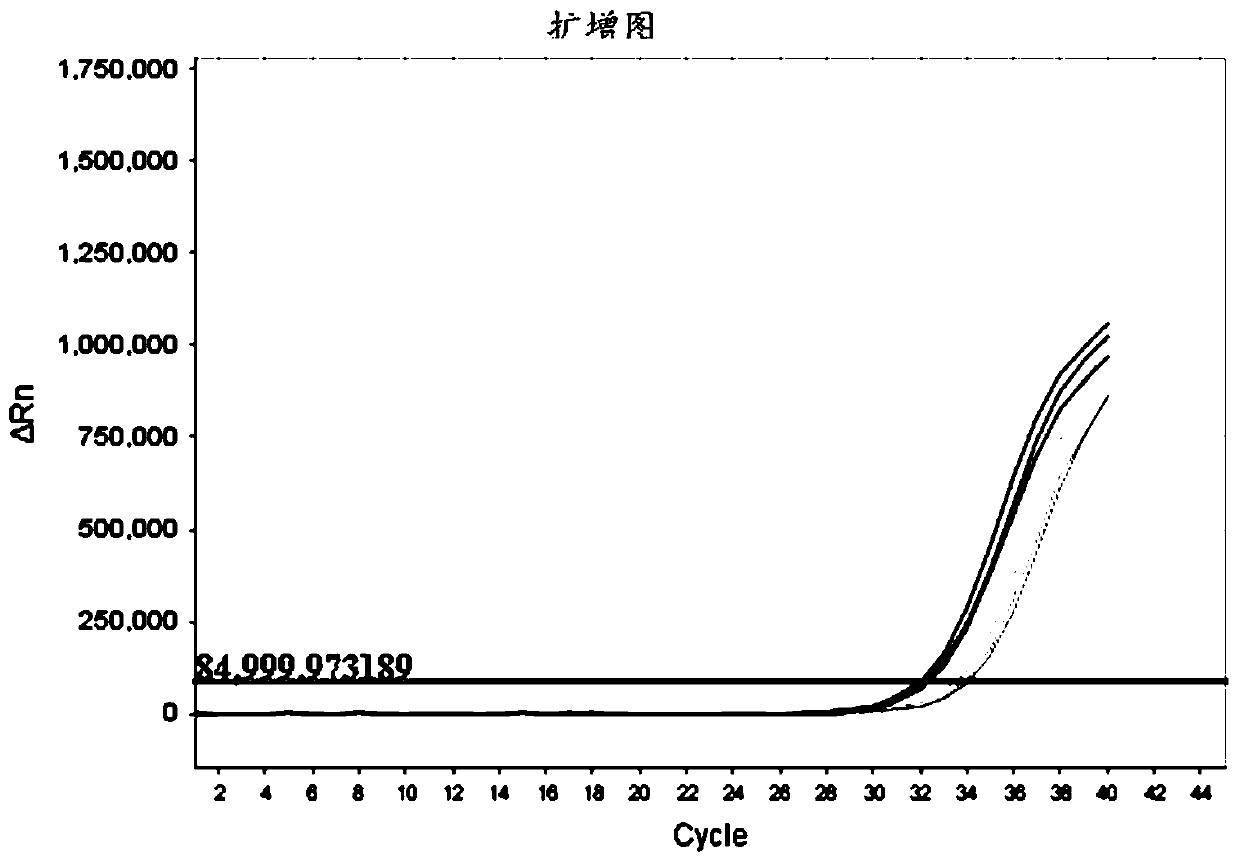

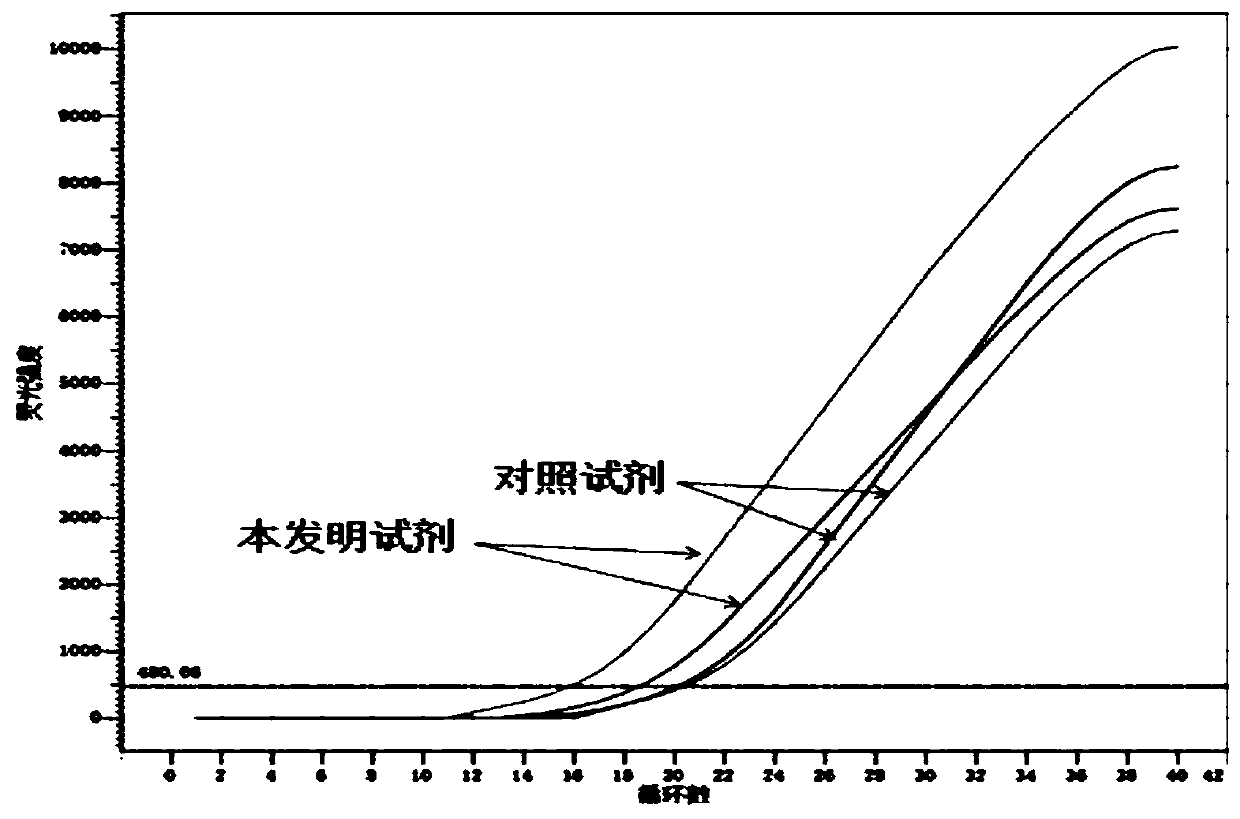

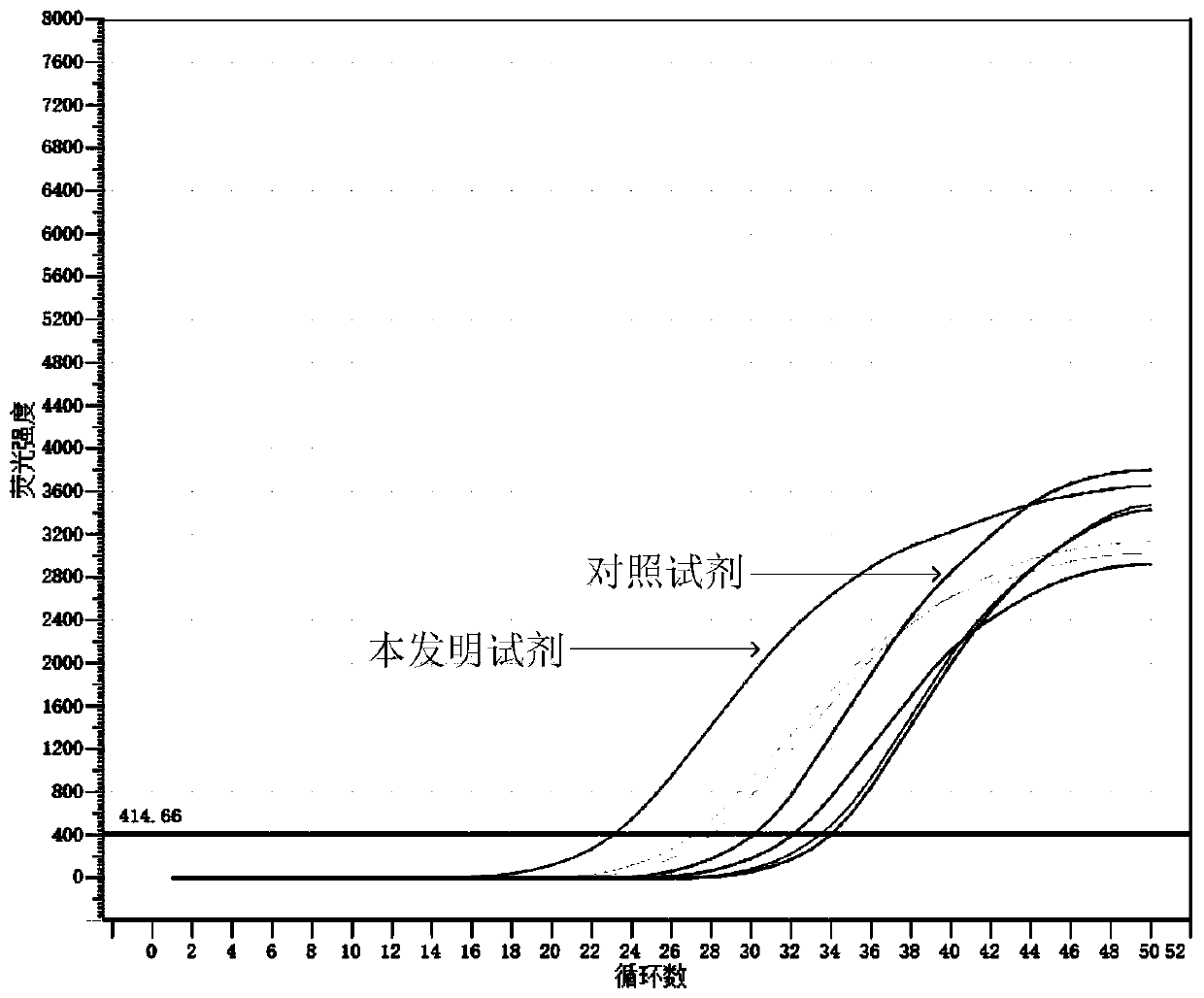

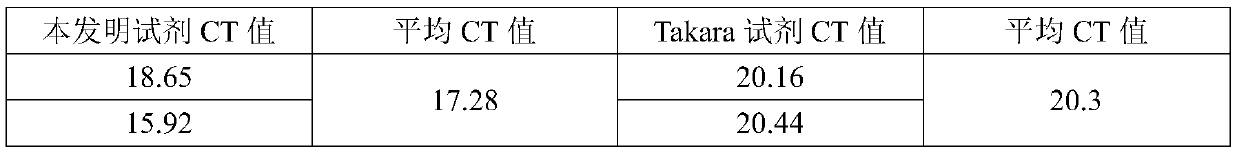

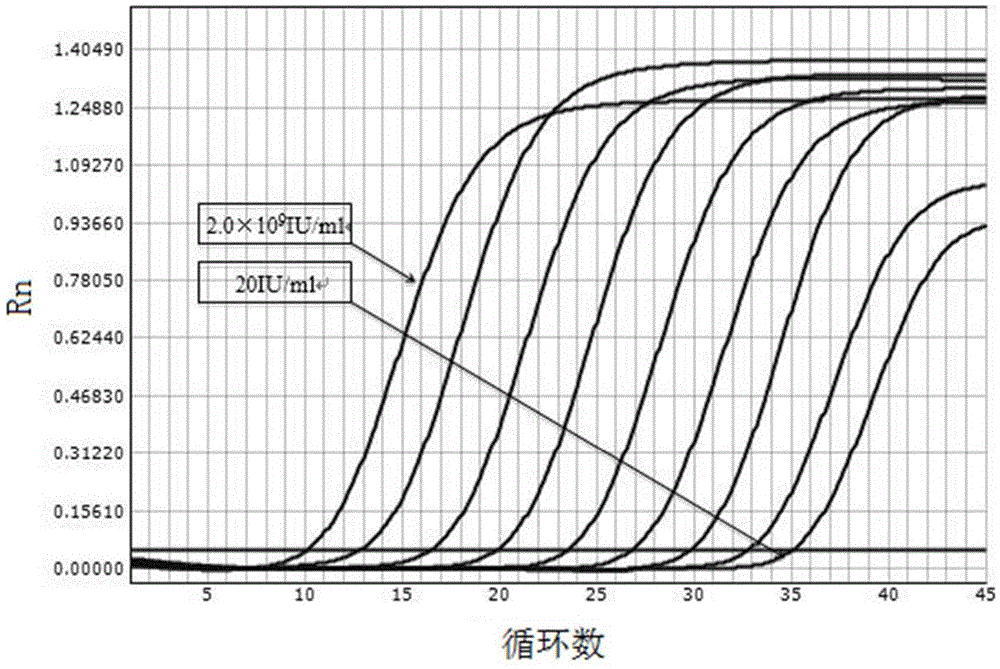

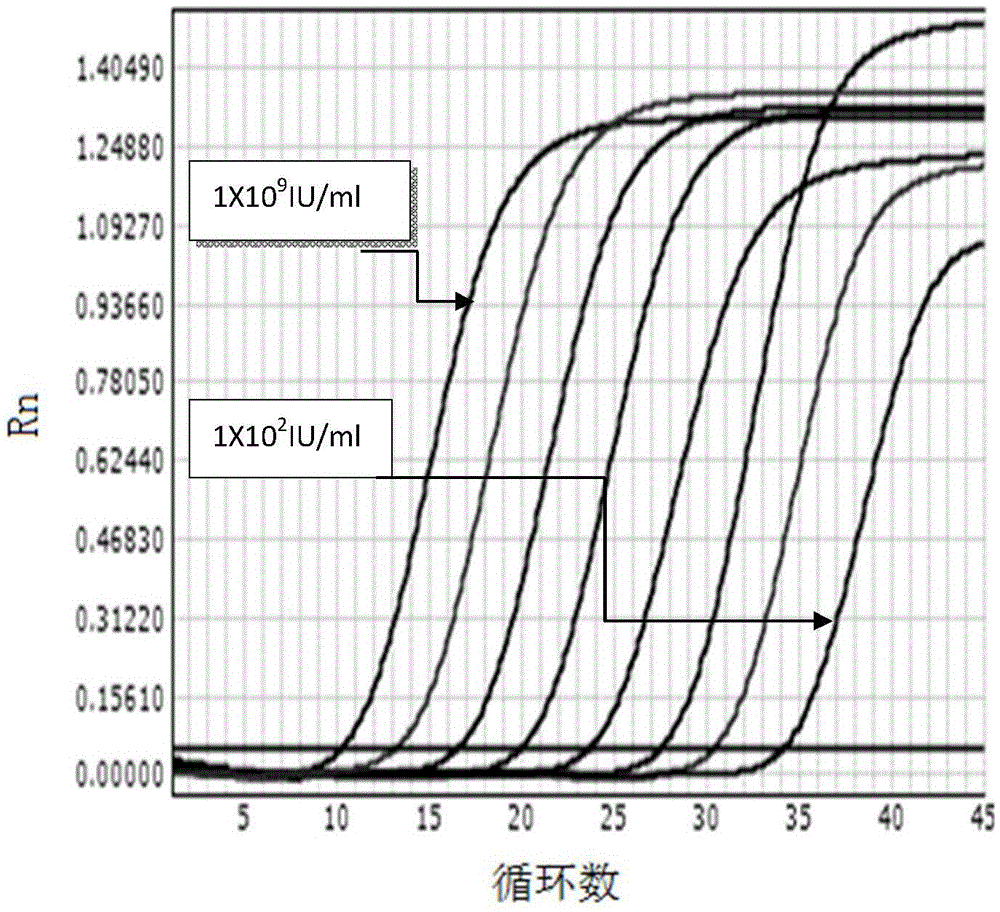

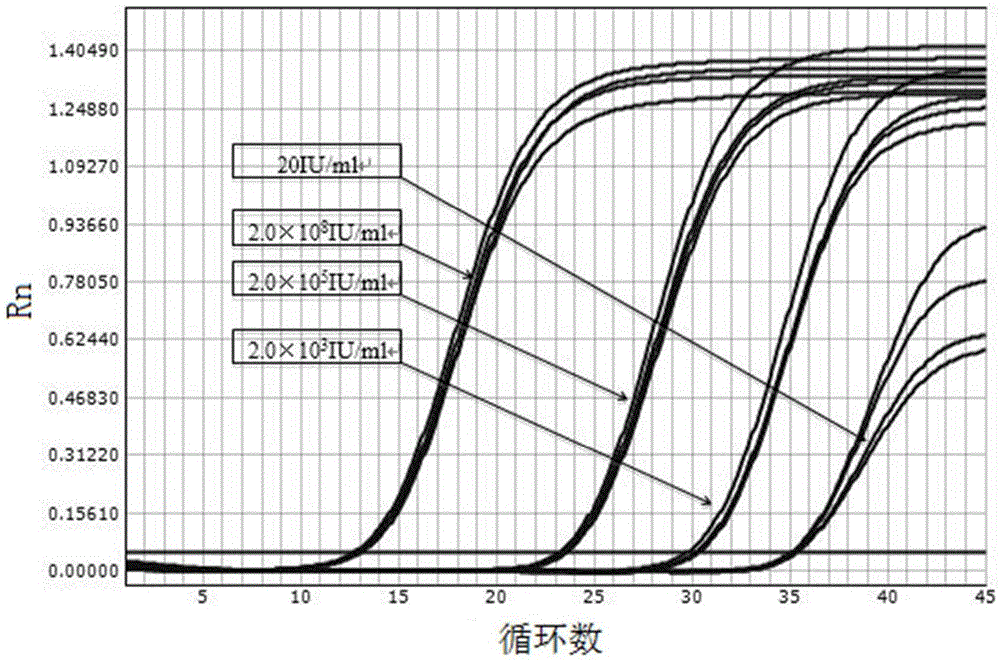

Direct real-time quantitative fluorescent PCR method of layered packaging tape indicator

ActiveCN105420416AKeep aliveRelease fullyMicrobiological testing/measurementMicroorganism based processesLysisFluorescence

The invention provides a direct real-time quantitative fluorescent PCR method of a layered packaging tape indicator. Hot-start DNA polymerase and PCR amplification reaction liquid are both packaged in a PCR amplification tube in layers. Nucleic acid lysis liquid and a sample to be detected are added when the method is used so that real-time quantitative fluorescent PCR can be carried out. By means of the method, the virus quantity lower to 20IU / ml can be detected, and the preferential detection range is 30-2*10<9>IU / ml. Detection results are not limited by the professional level of operators and experiment conditions in a laboratory, and the method has the advantages of being easy, convenient and quick to operate.

Owner:BEIJING NAGENE DIAGNOSTIC REAGENT CO LTD

Method for composting by utilizing straw

InactiveCN105753526ARealize rational useSave resourcesBio-organic fraction processingExcrement fertilisersBiotechnologyPre treatment

The invention relates to the field of plant straw reutilization, in particular to a method for compositing by utilizing straw. The method comprises the following steps: (1) crushing straw into straw particles; (2) mixing the straw particles, soil, animal manure and human excreta to obtain pre-treated straw particles; (3) mixing the pre-treated straw particles, solid inoculants and brewer grains to obtain compost raw materials; (4) stacking the compost raw materials into a fermenting stack. According to the method for composting by utilizing the straw, resources can be fully saved, reasonable utilization of the resources is realized, and the cost is relatively low; during a composting process, a certain amount of ammonium bicarbonate is added, so that the composting time of the straw can be effectively shortened. The bio-fertilizer obtained by the method has high content of N, P and K, and is beneficial to the growth of crops.

Owner:ANHUI DADI ENERGY SAVING SCI & TECH

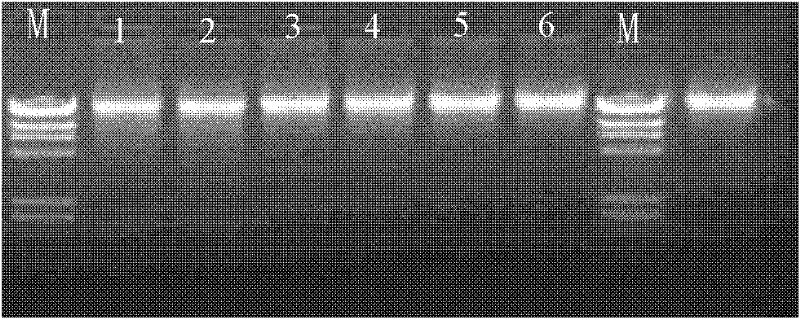

Method for rapidly extracting DNA from whole blood

ActiveCN107058295AIncrease sample sizeIntegrity guaranteedMicrobiological testing/measurementDNA preparationWater bathsWhite blood cell

The invention provides a method for rapidly extracting DNA from whole blood. The method comprises the following steps: S1, centrifuging a blood sample at a high speed, removing a supernatant, keeping precipitate, adding a lysate, uniformly mixing till a clear state, keeping for 40-60min in a water bath with the temperature of 50-60 DEG C, cooling, performing suction extraction by using an organic solvent, centrifuging, and taking a supernatant; S2, adding isopropanol and NaAc into the supernatant, uniformly mixing, collecting the precipitate, cleaning the precipitate and airing; S3, adding a TEN buffer solution and ribonuclease into the precipitate, uniformly mixing, incubating for 30min, then adding a proteinase K containing TEN buffer solution, uniformly mixing, performing water bath for 30min, cooling, centrifuging, taking a supernatant, and purifying to obtain the pure DNA. By the method, the sample treating amount is large; most of red blood cells in the supernatant are removed through high-speed centrifugation first and then blood cells (white blood cells) in the precipitation are lysed by using the self-prepared whole cell lysate by one step so as to rapidly obtain a large number of DNAs applicable to three generations of sequencing from blood.

Owner:武汉希望组生物科技有限公司

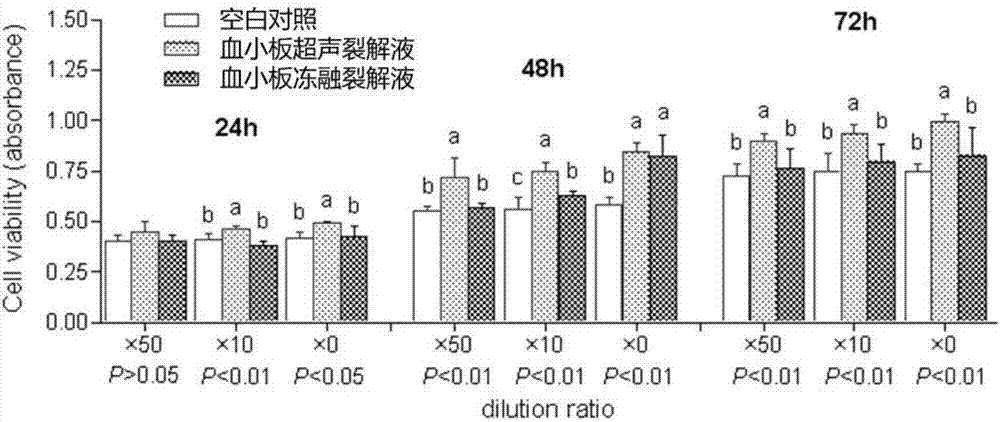

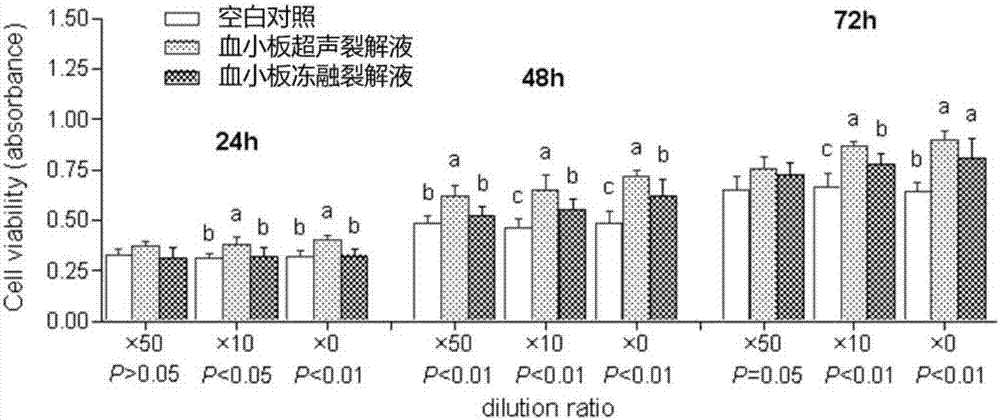

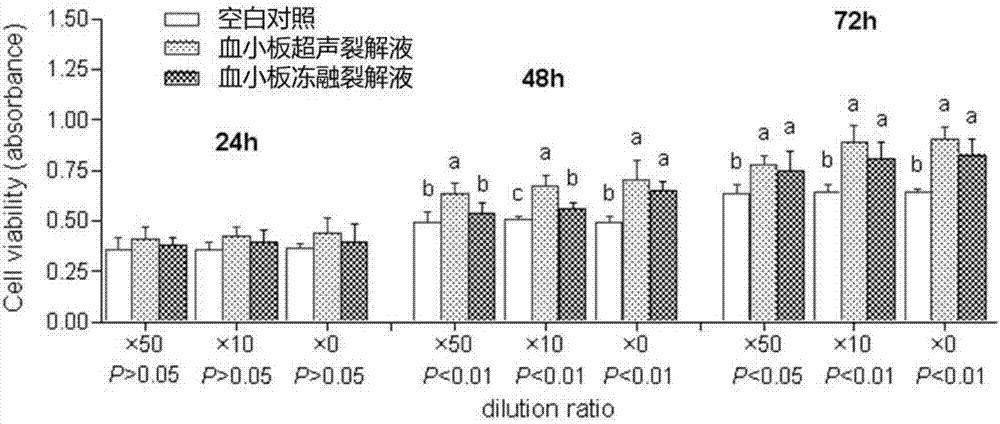

Enrichment method of platelet cell factor concentrates

PendingCN107446036AIncrease contentImprove extraction efficiencyMicroorganism lysisPeptide preparation methodsEnrichment methodsBone tissue

The invention discloses an enrichment method of platelet cell factor concentrates. The method comprises the steps as follows: whole blood is taken, platelets are collected, a cell suspension is prepared with normal saline, subjected to ultrasonic crushing multiple times under the ultrasonic power of 100-200 W and crushed for 1-60 s each time, a crushed mixed solution is filtered, filtrate is taken, and the platelet cell factor concentrates are obtained. The obtained platelet ultrasonic lysates (cell factor concentrates) comprise TGF-beta, PDGF, IGFs, FGFs, EGF, VEGF and the like, have multiple bioactivities, can increase cartilage cell activity of organisms and promote stem cells to proliferate and differentiate and contributes to regeneration and repair of cartilages and bone tissue. The composition can be prepared in the form of injection, powder and the like and has excellent application prospects in the medical bone tissue engineering field.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com